High-performance concrete corrosion-resistant anti-cracking agent and producing method thereof

A high-performance concrete and anti-cracking agent technology, applied in the field of concrete, can solve problems such as insufficient uniformity, inability to exert the comprehensive interactive superposition effect of admixtures, and affect concrete performance indicators and durability effects, so as to achieve sulfate corrosion resistance and Good anti-chloride ion penetration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

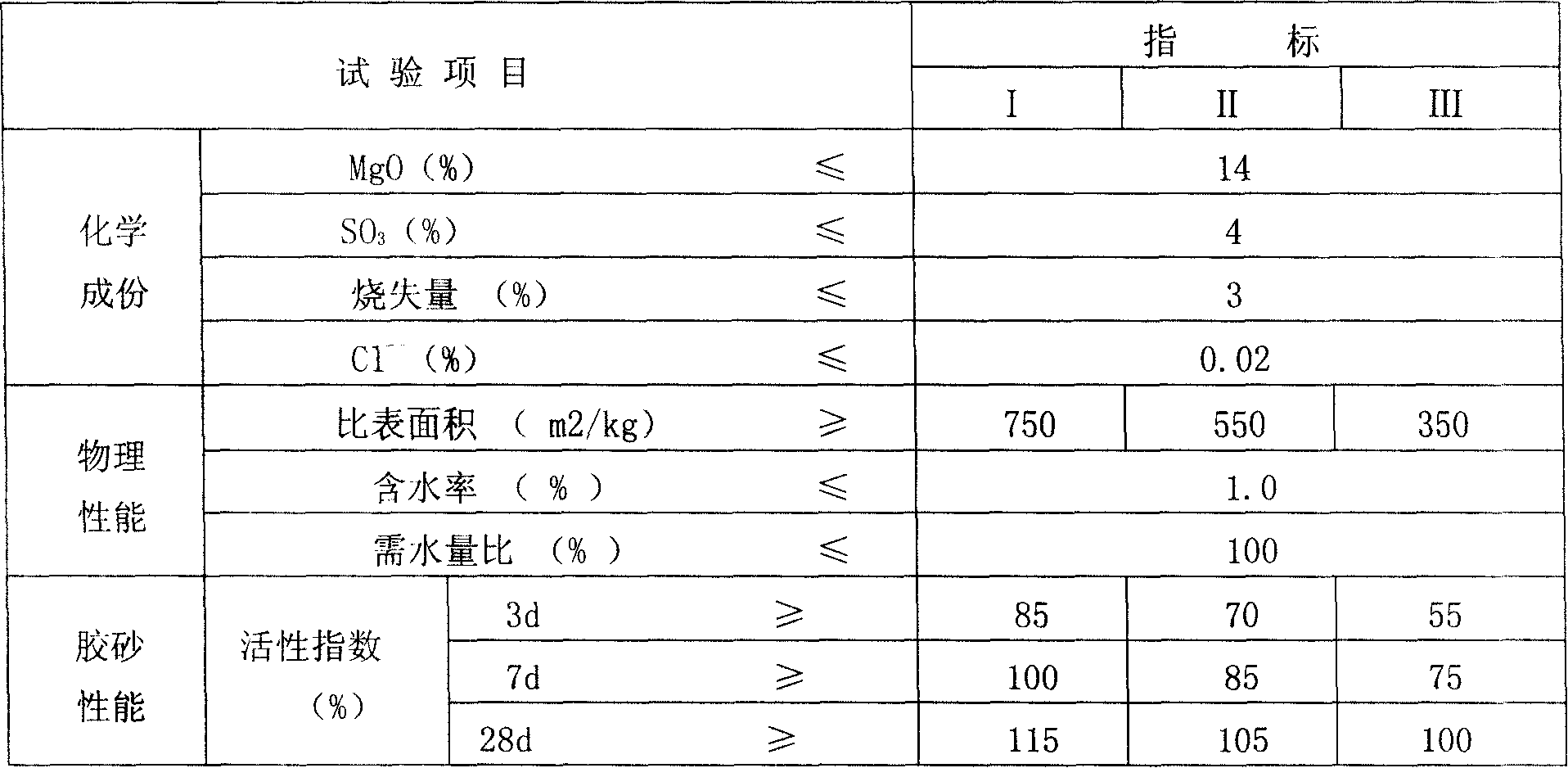

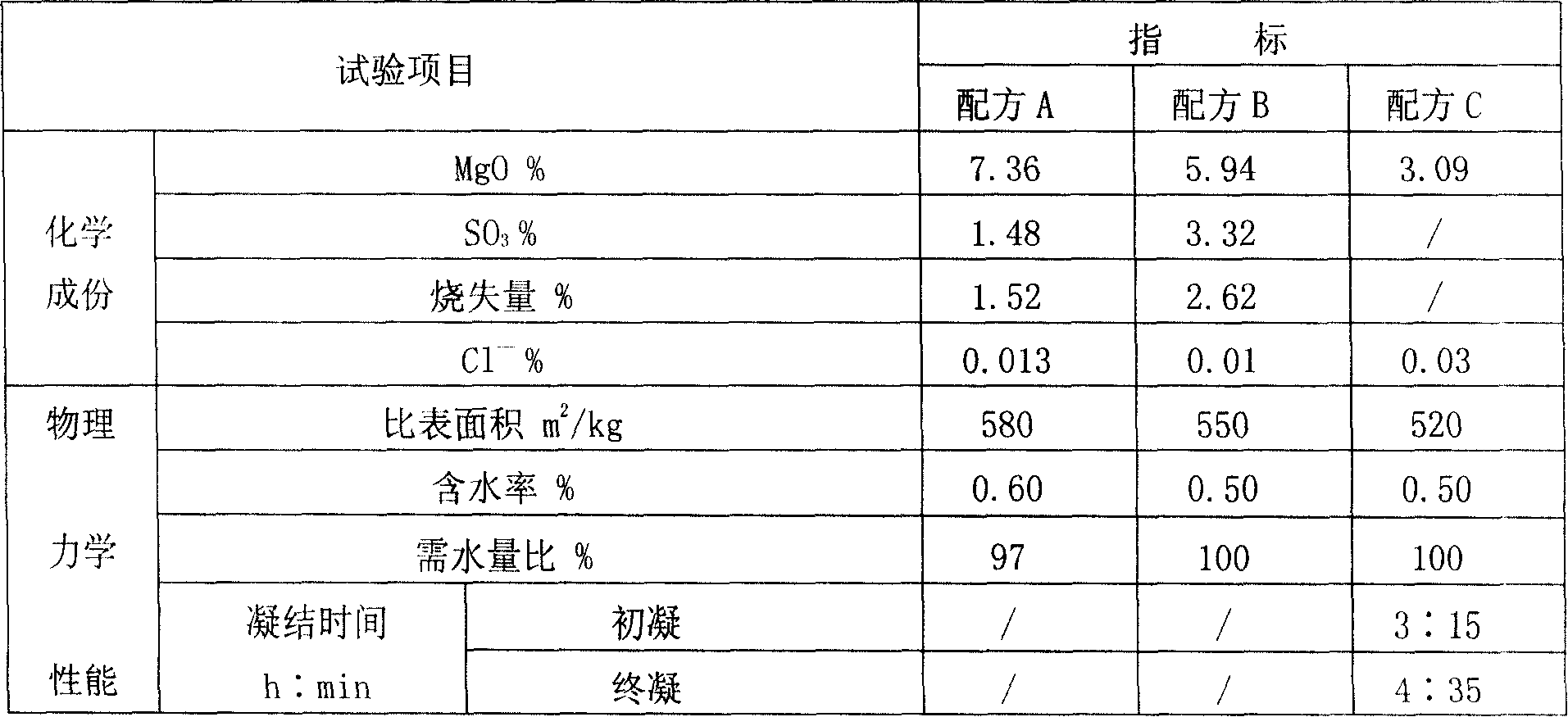

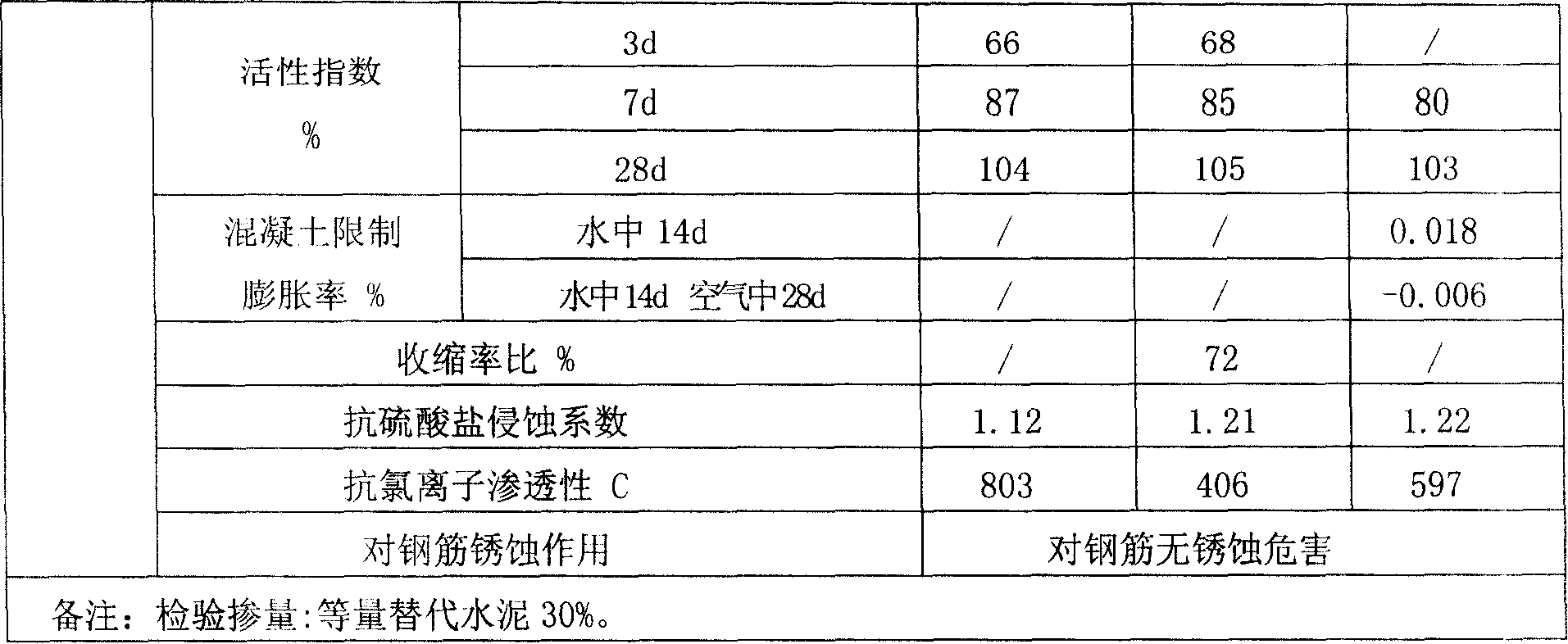

[0080] Example 1: Production of Type A High Performance Concrete Anti-corrosion and Anti-cracking Agent

[0081] The formula is as follows:

[0082] Raw material and grinding aid name

[0083] The blocky slag, zeolite, metakaolin, etc. are mixed according to the formula and electronically weighed at 15t / h, and first enter the vertical mill for drying and grinding to 200m 2 / Kg, and then enter the ball mill, while the fly ash and silica fume are directly mixed with the powder from the vertical mill to 580m 2 / Kg, during the grinding process, atomize triethanolamine and dispersant 0.4t / h through special spray equipment and spray them into the ball mill, so that the various components are evenly mixed, and then discharged into the finished product warehouse, that is, A type high-performance concrete corrosion and crack resistance agent.

example 2

[0084] Example 2: Production of B-type high-performance concrete corrosion and crack resistance agent

[0085] B formula is as follows: example 1 formula 90% adds 10% polyoxyethylene shrinkage reducing agent.

[0086] The blocky slag, zeolite, metakaolin, etc. are mixed according to the formula and electronically weighed at 13.5t / h, and firstly enter the vertical mill for drying and grinding to 200m 2 / Kg, and then enter the ball mill, meanwhile, the fly ash and silica fume are mixed and ground to 590m 2 / Kg, during the grinding process, atomize triethanolamine, dispersant 0.4t / h and polyoxyethylene shrinkage reducer 1.9t / h through special spray equipment and spray them into the ball mill to make the various components evenly mixed Finally, the material is discharged into the finished product warehouse, and the B-type high-performance concrete anti-corrosion and anti-cracking agent is made.

example 3

[0087] Example 3: Production of C-type high-performance concrete anti-corrosion and anti-cracking agent

[0088] C formula is as follows: Example 1 formula 70% plus 18% anhydrite + 12% aluminum clinker.

[0089] The blocky slag, zeolite, metakaolin, anhydrite, aluminum clinker, etc. are mixed according to the formula and electronically weighed at 15t / h, and first enter the vertical mill for drying and grinding to 200m 2 / Kg, and then enter the ball mill. At the same time, the fly ash and silica fume are mixed and ground to 560m2 by electronically weighing 4.4t / h directly into the ball mill and the powder from the vertical mill. 2 / Kg, during the mixing milling process, atomize triethanolamine and dispersant 0.4t / h through special spray equipment and spray them into the ball mill, so that the various components are evenly mixed, and then discharged into the finished product warehouse, that is, C-type high-performance concrete anti-corrosion and anti-cracking agent.

[0090] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com