Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Free from external pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

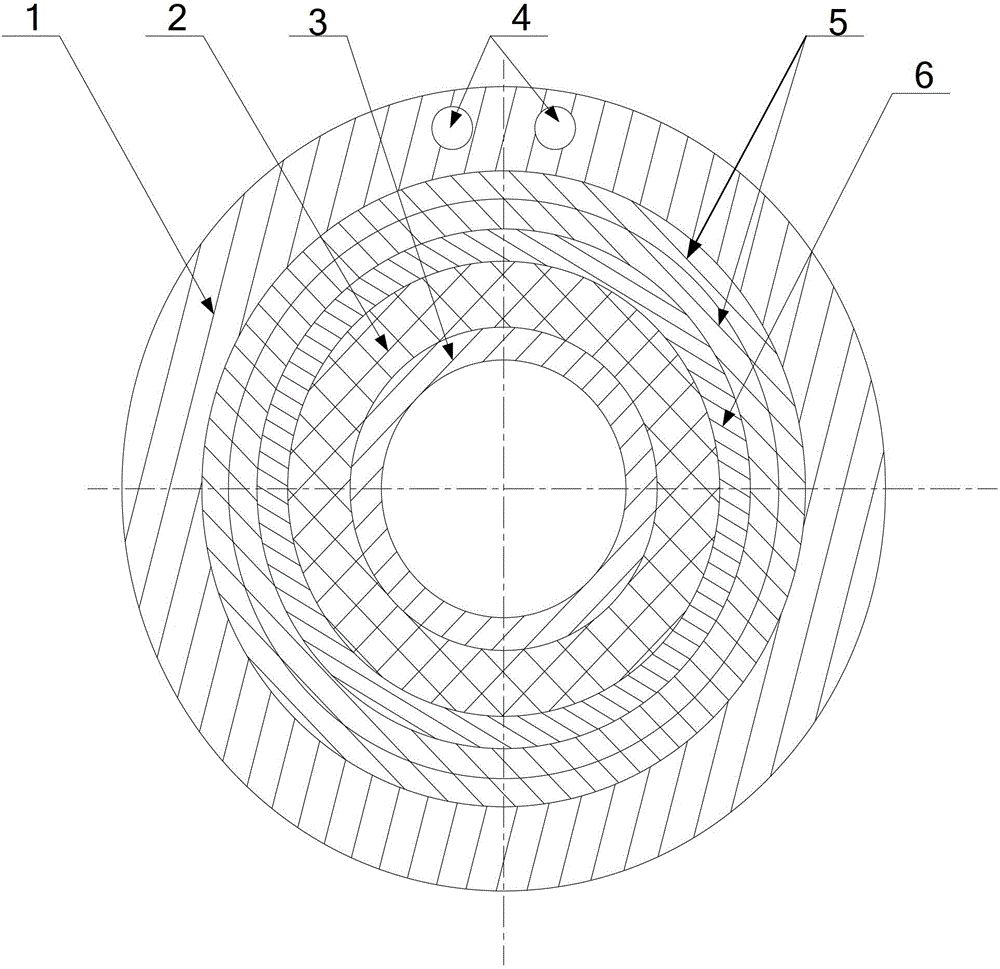

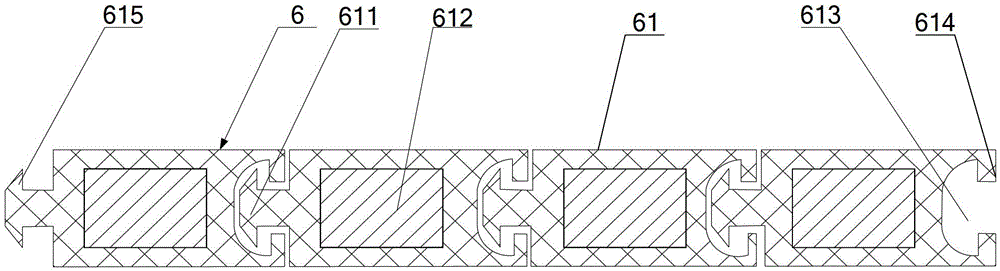

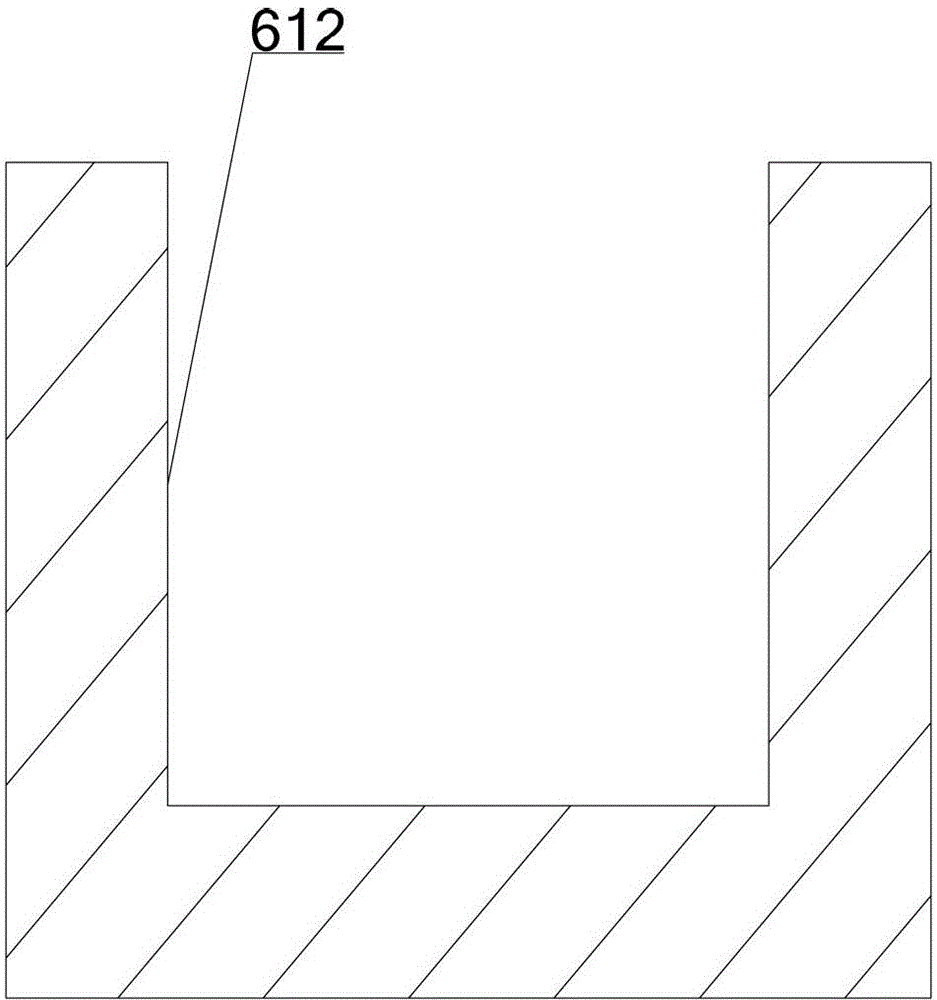

Cooling structure for motor winding end part

InactiveCN102624121AImprove cooling effectLower operating temperatureWindings conductor shape/form/constructionEngineeringMechanical engineering

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

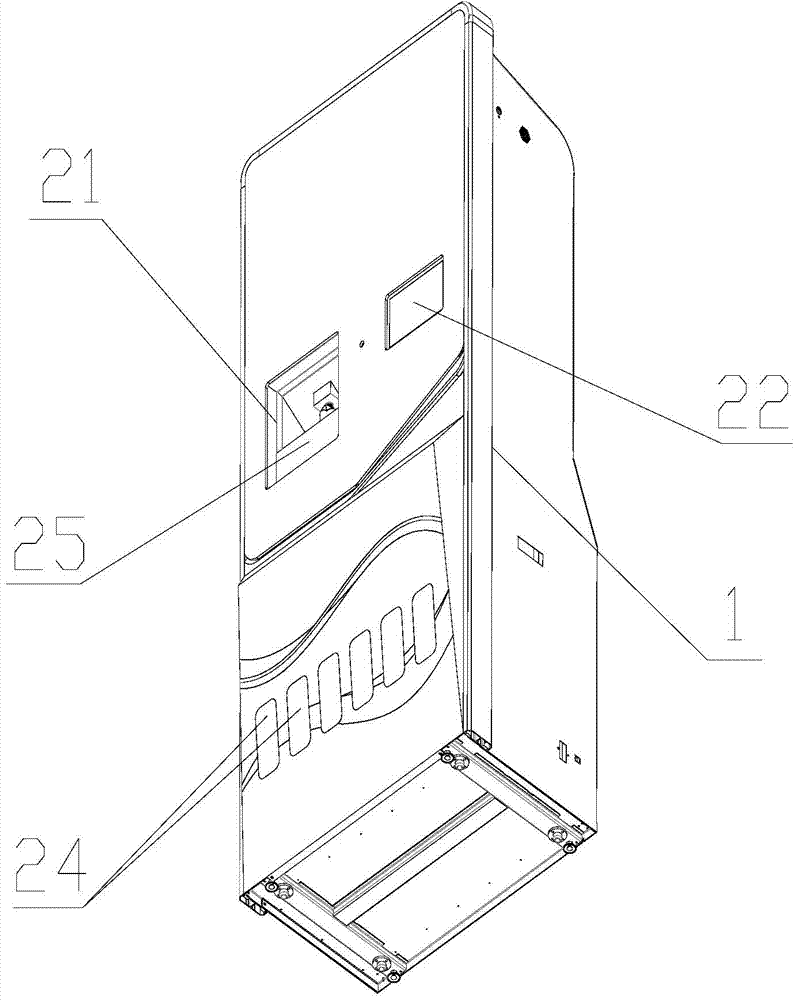

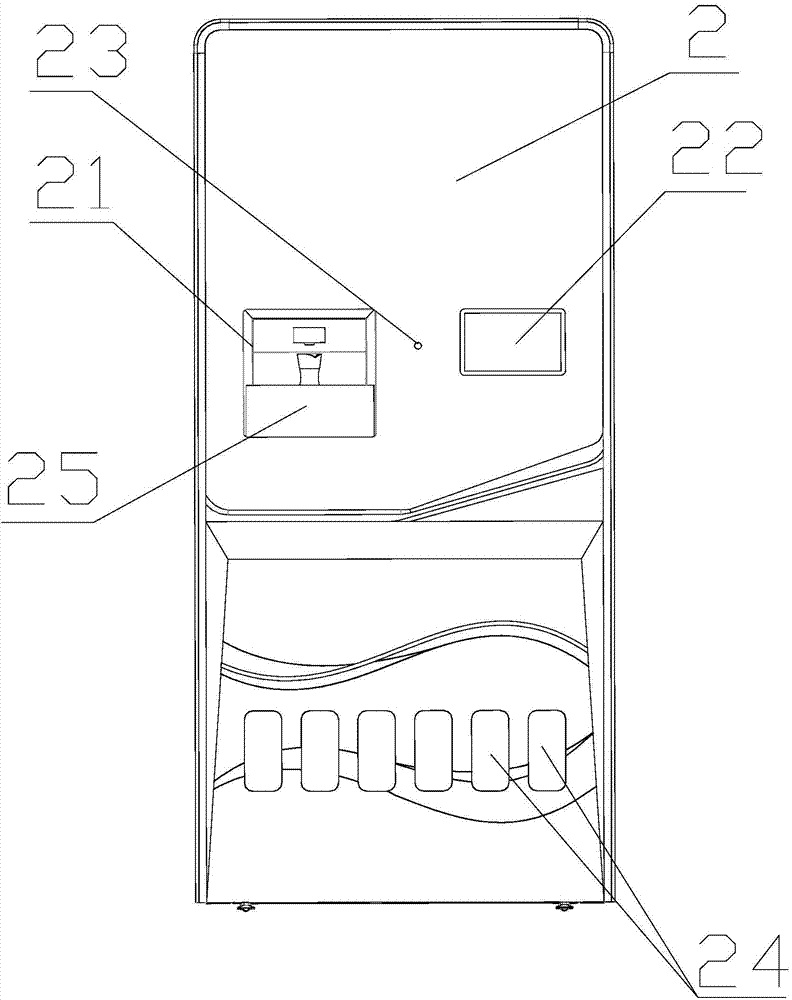

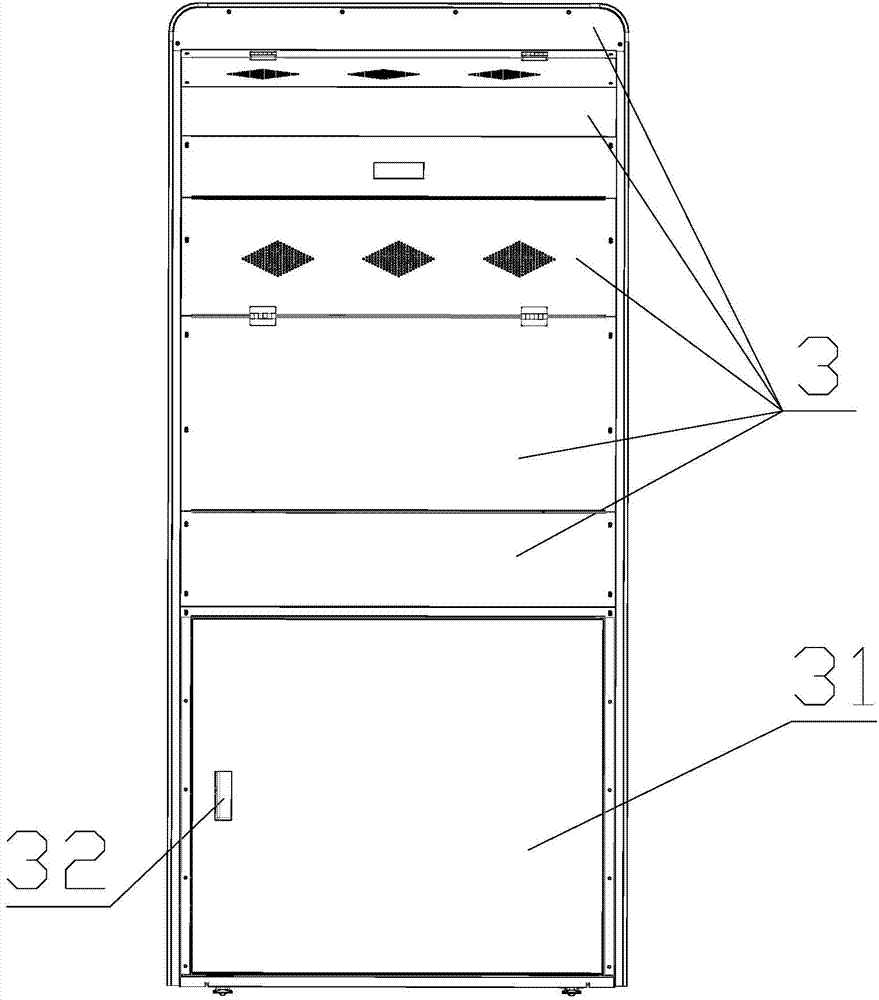

Alcohol sales machine

The invention discloses an alcohol sales machine, which comprises a shell, wherein the shell forms a box body by a front shell, a back shell and side shells; an alcohol receiving window, an operating screen and an alcohol discharging button are arranged on the upper end of the front shell; an alcohol barrel observing window is arranged on the lower end of the front shell; a glass lifting door is arranged on the window part of the alcohol receiving window; an alcohol barrel is arranged on the lower end in the shell; a puncturing and alcohol pumping system corresponding to the alcohol barrel is arranged in the shell; an alcohol discharging box body is arranged in the alcohol receiving window of the shell; an alcohol discharging pipe is arranged in the alcohol discharging box body; an alcohol pumping pipe communicated with the alcohol barrel and the alcohol discharging pipe is arranged in the puncturing and alcohol pumping system; a lifting door lifting system for driving the glass lifting door to lift up and down to open and close is arranged on the glass lifting door. Through the alcohol sales machine, an alcohol dealer can automatically sell retailed alcohol capacity, and an alcohol buyer can take alcohol by himself / herself according to the obtained alcohol capacity, so that convenience is brought to retailed alcohol capacity bargaining transaction.

Owner:SICHUAN DEMIN INVESTMENT CO LTD

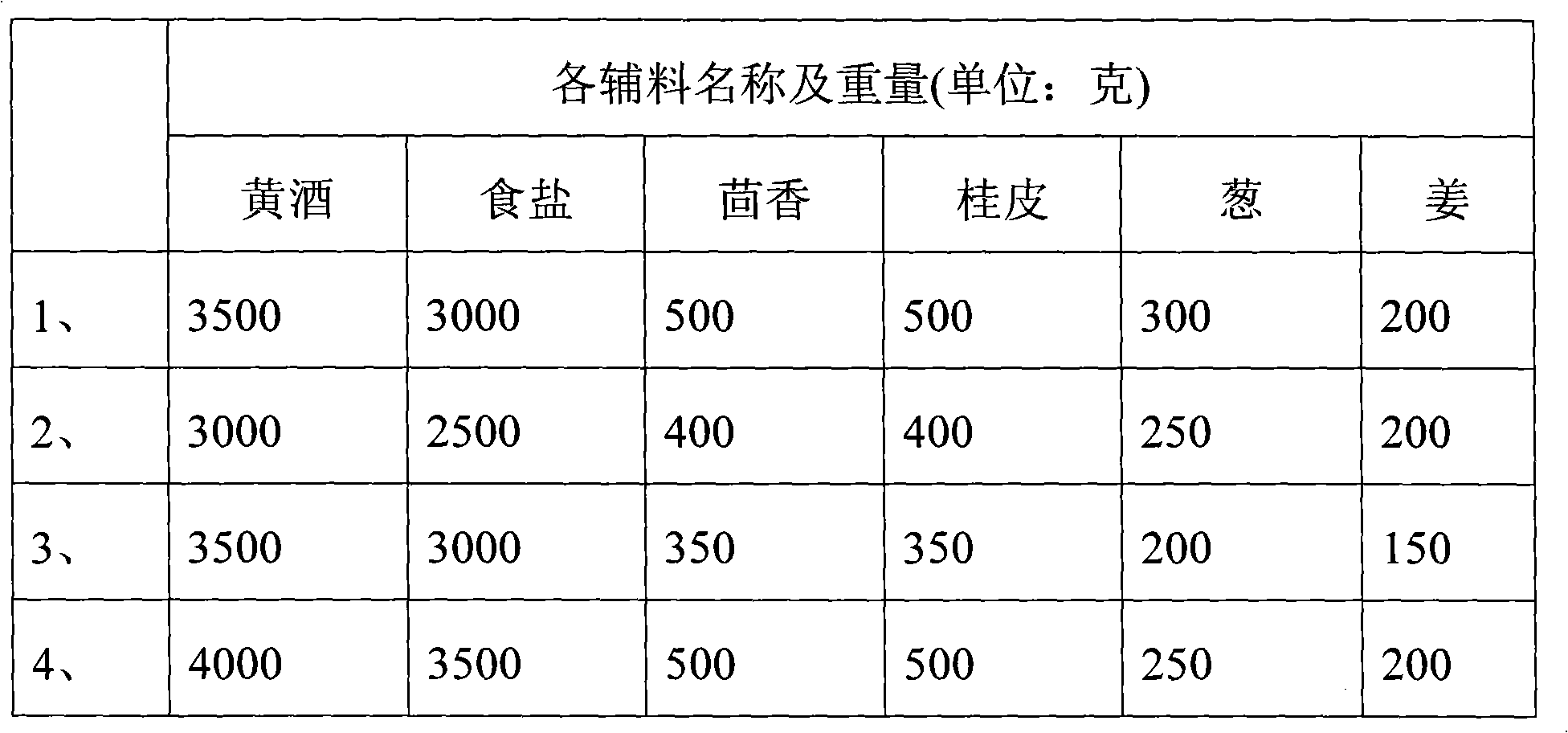

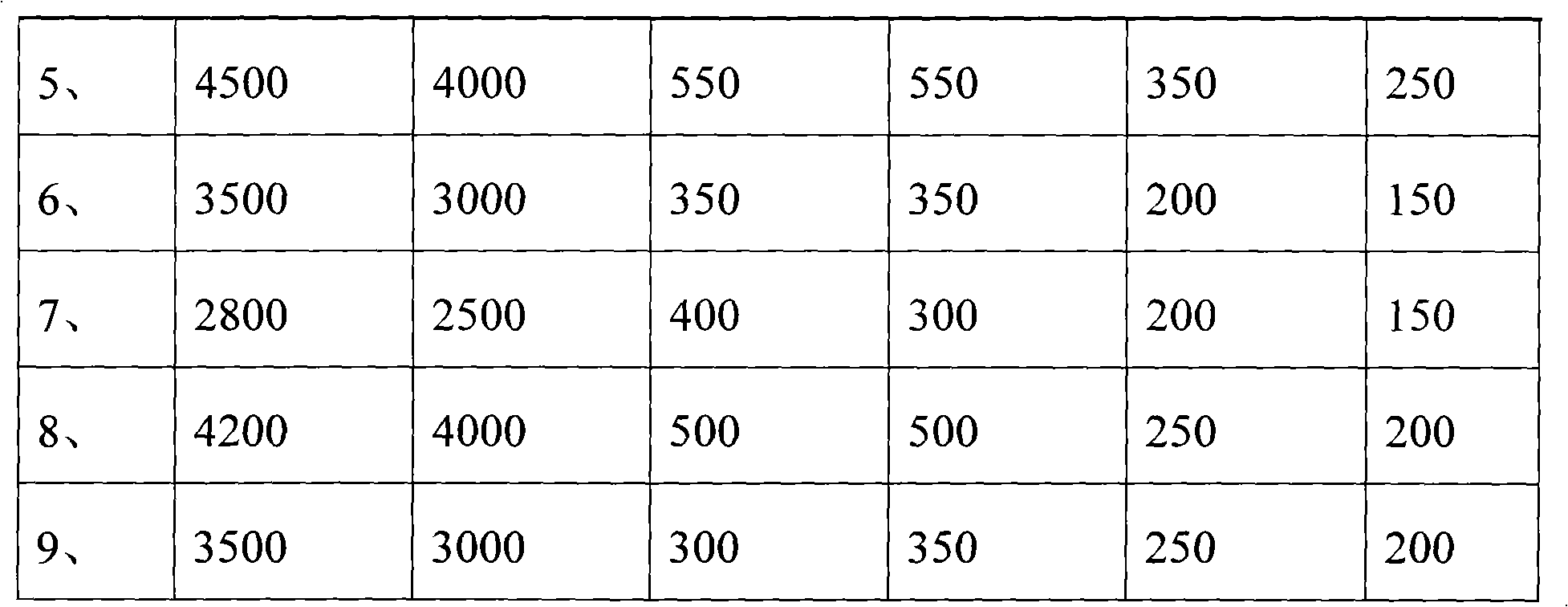

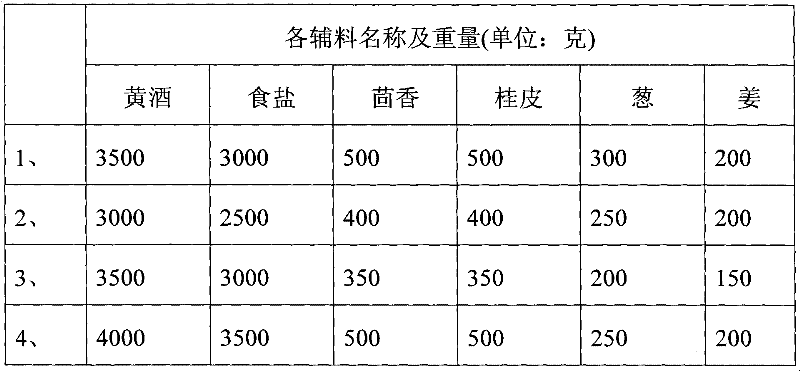

Nutritive chick embryo food

InactiveCN101513263AIntegrity guaranteedAvoid churnFood preparationPlastic packagingAdditive ingredient

The invention discloses a nutritive chick embryo food, wherein the chick embryo is prepared from the following steps: (1) selecting eggs, (2) washing eggs, (3) preparing the stock solution and immersing eggs, namely the clean eggs are immersed in the prepared stock solution, (4) hatching into chick embryo, (5) vacuum plastic packaging, (6) sterilizing by heating, (7) cooling and packaging. Firstly the stock solution is prepared, then the eggs is placed into the stock solution, after the eggs are dialyzed by the stock solution, the eggs are taken out and air-dried, the chick embryo is in the vacuum plastic packaging and in the high temperature sterilizing, the chick embryo is cooked in the high temperature sterilizing process, thus retaining the full nutrition of the chick embryo and preventing the loss of the nutrition. The inventive chick embryo is in the vacuum plastic packaging and in the high temperature sterilizing, thus the chick embryo is free from the pollution, the storage life is longer and the selling is more convenient.

Owner:郑毛毛

Heat-insulation heat-preservation stone-imitating paint for external wall and preparing method thereof

InactiveCN106147478AEfficient reflectionAvoid the limitations of not being rich in colorCoatingsCelluloseCrack resistance

The invention discloses a heat-insulation imitation stone paint for exterior walls, which comprises the following components by weight: 5-9 parts of deionized water, 0.1-0.2 parts of cellulose thickener, and mineral oil defoamer 0.05-0.15 parts, 0.05-0.15 parts of wetting agent, 0.05-0.15 parts of propylene glycol, 0.1-0.5 parts of nano-silver antibacterial agent, 0.3-0.7 parts of silicone water repellent, 0.05-0.15 parts of lauryl alcohol ester, nano-TiO2 photocatalyst 2-6 parts of colloid, 1-3 parts of nano-zirconia dispersion, 10-14 parts of silicone acrylic emulsion, 2-5 parts of polyurethane modified elastic emulsion, 1-5 parts of inorganic potassium silicate, 2-2 parts of PU thickener 5 parts, 45-55 parts of reflective sintered colored quartz sand, 10-20 parts of reflective sintered colored ceramic hollow microspheres. The invention has the effect of realistic imitation of natural stone, efficient near-infrared reflection performance, good heat insulation, rich colors, good self-cleaning performance, long-lasting heat insulation, good water resistance, good crack resistance, light weight and long coating life Long, wide applicability, with excellent economy.

Owner:黄作鹏

Compound plant oil liniment for treating burns and scalds and preparation method of compound plant oil liniment

InactiveCN105168361AProtect the woundPromotes epithelial cell growthHydroxy compound active ingredientsDermatological disorderPsoriasisAnti-inflammatory

The invention relates to a plant oil type compound biological medicine composition for treating burns and scalds and a preparation method of the plant oil type compound biological medicine composition and belongs to externally applied agents. The compound biological medicine composition is prepared from major ingredients including clove oil, lavender essential oil, tea tree oil, argy wormwood leaf oil, star anise oil and cassia oil as well as the balance medically acceptable solvents or minor ingredients. The compound biological medicine composition has the advantages that the compound biological medicine composition has definite treatment effect for local burns and scalds, can alleviate symptoms of dermatoses such as psoriasis, dermatitis and eczema, is capable of promoting cell regeneration, speeding up wound healing, removing scars, burns and sunburns effectively and has the pharmacological activity such as antiviral action, bactericidal action, pain relief and anti-inflammatory action.

Owner:JILIN UNIV

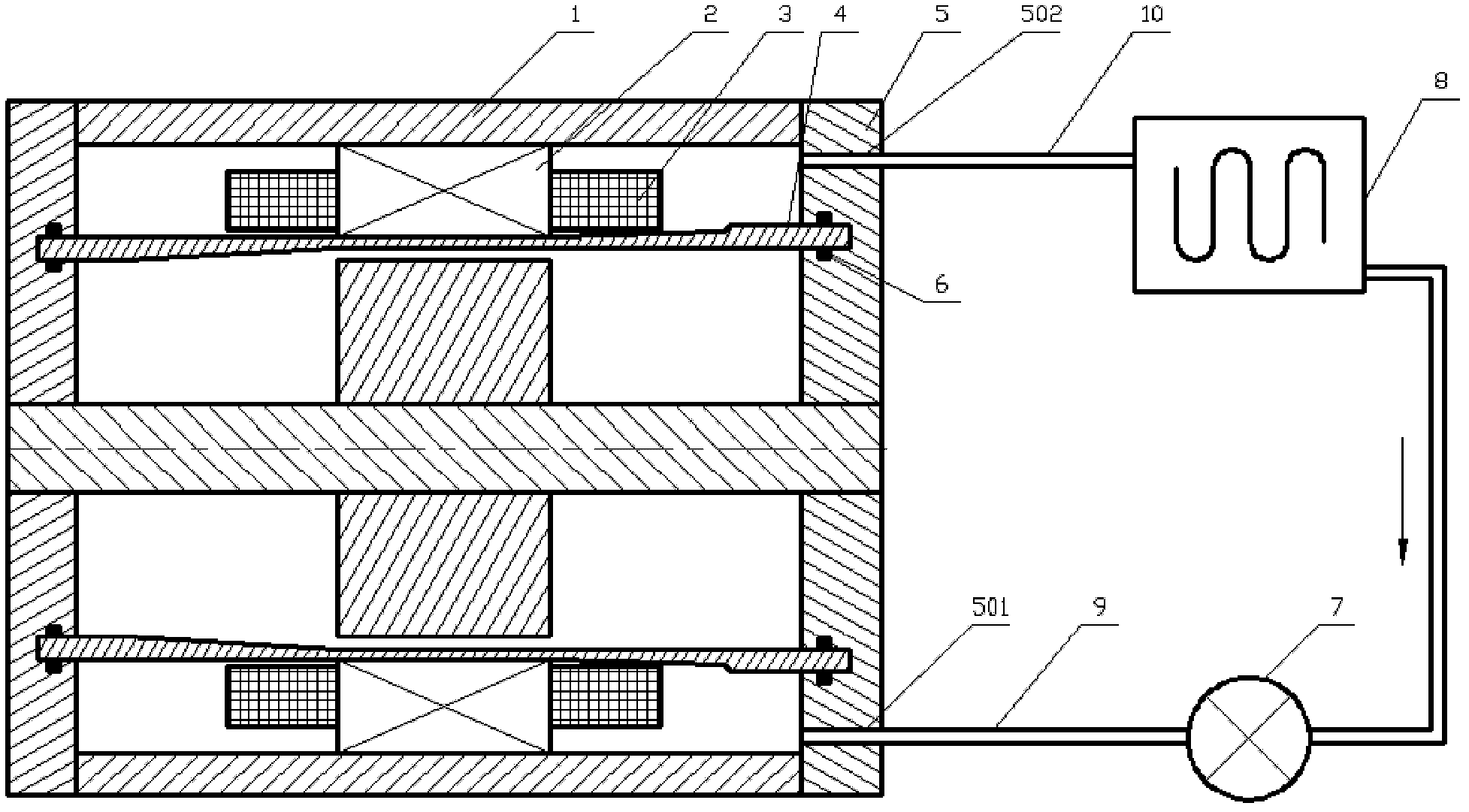

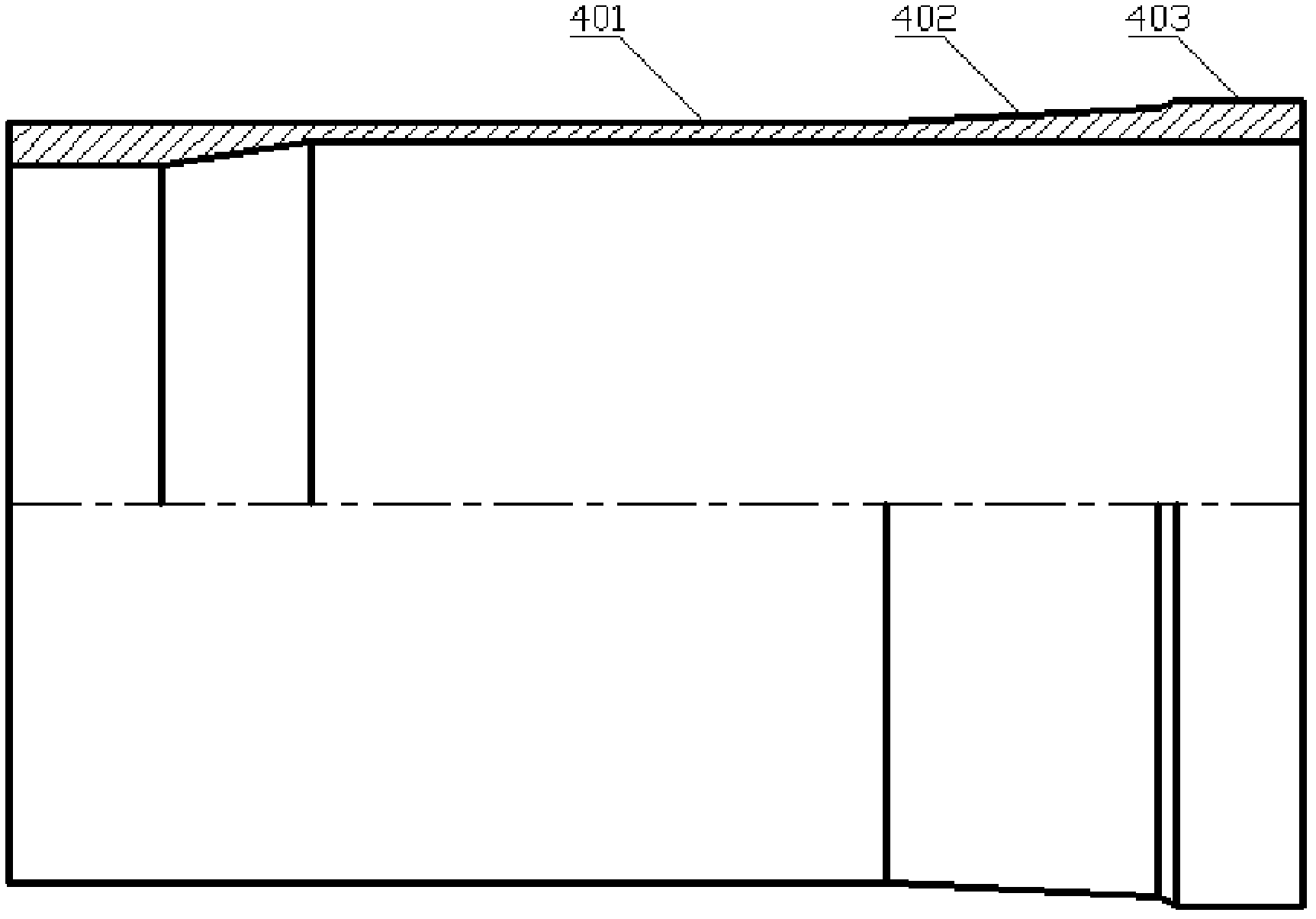

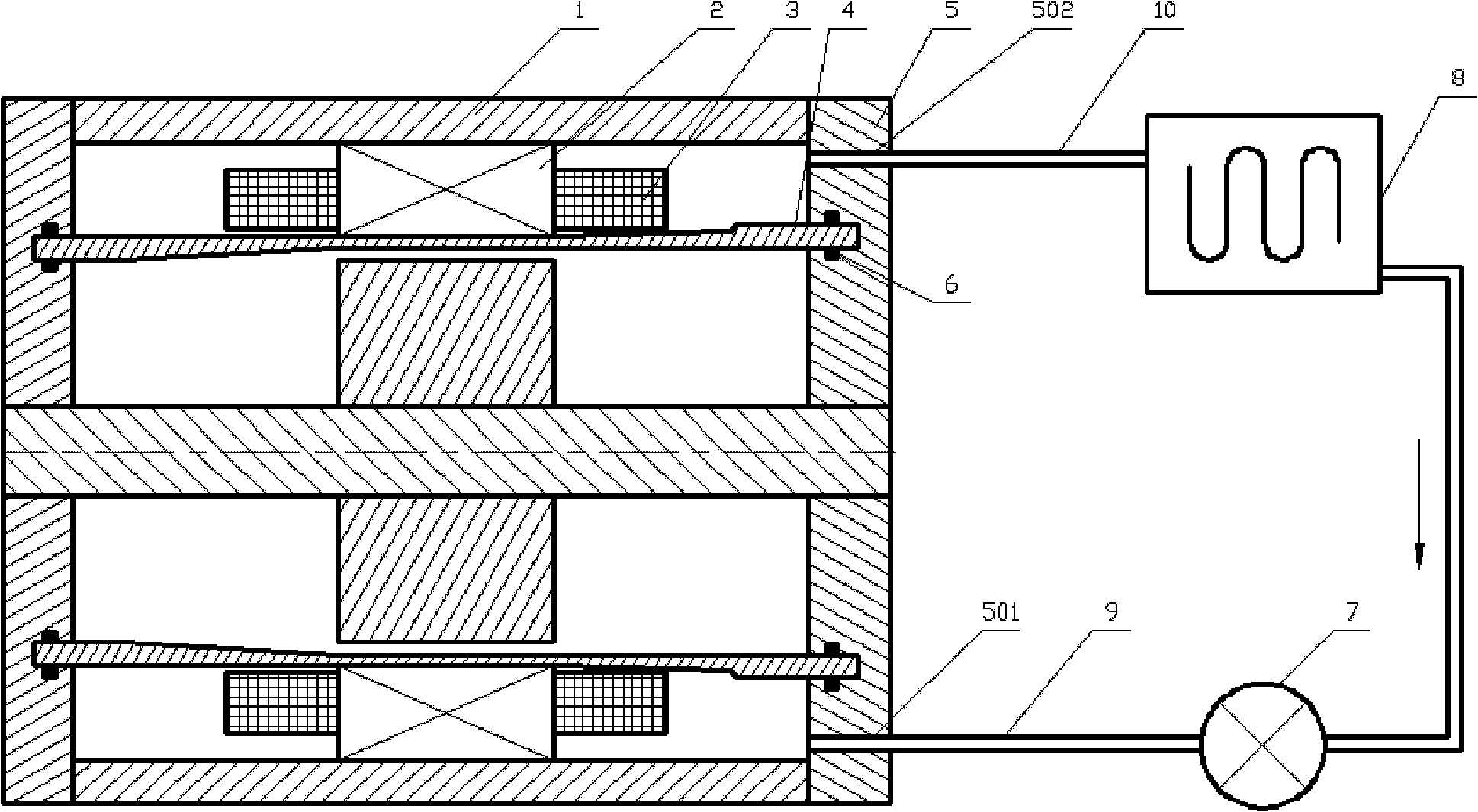

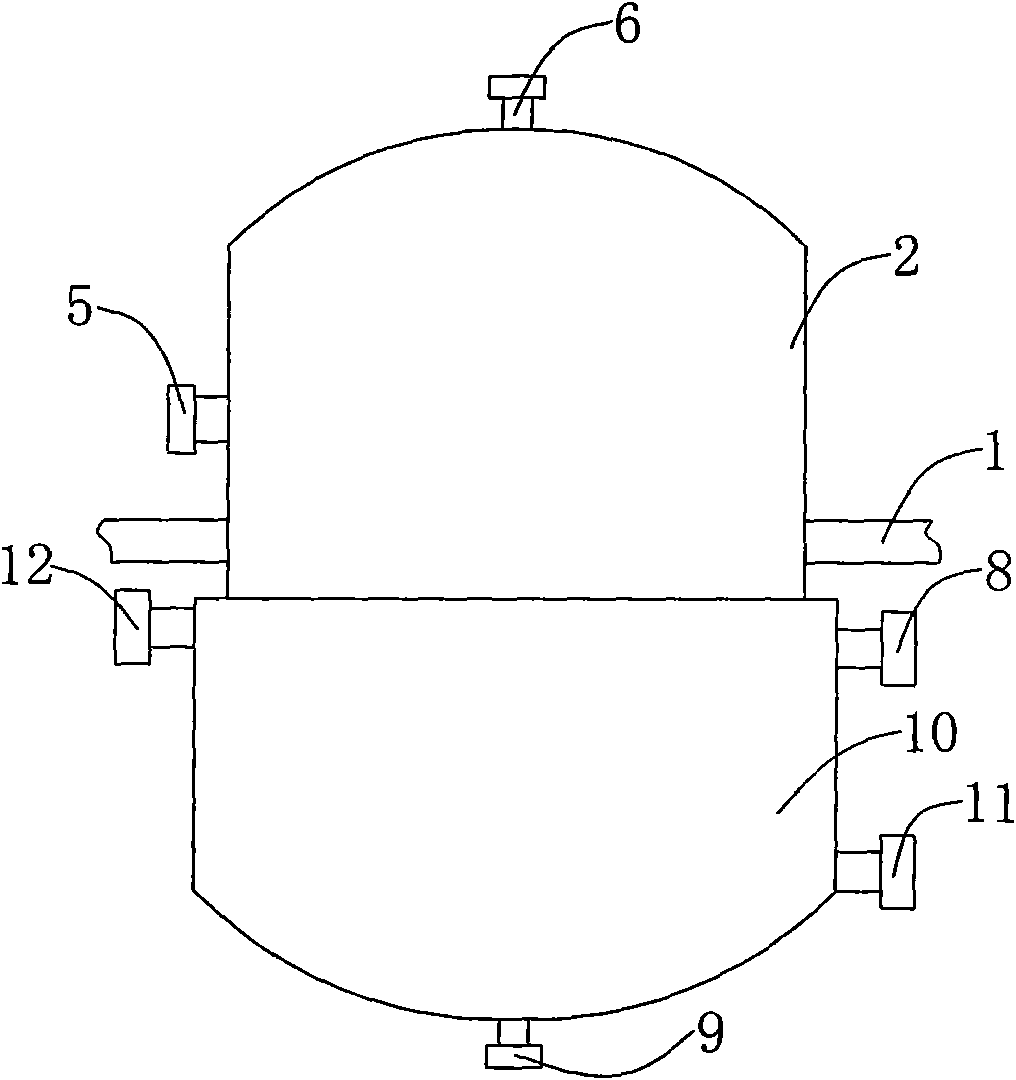

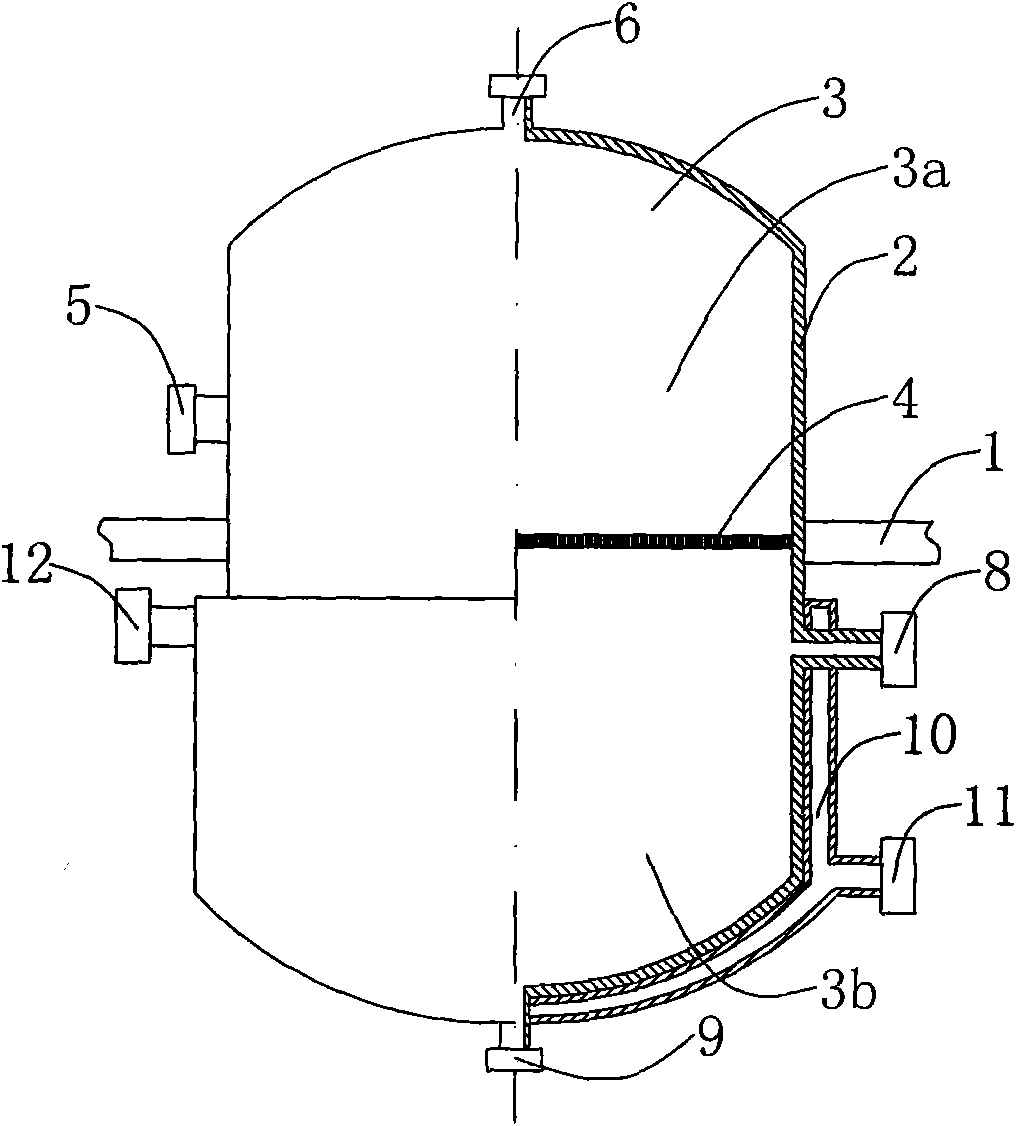

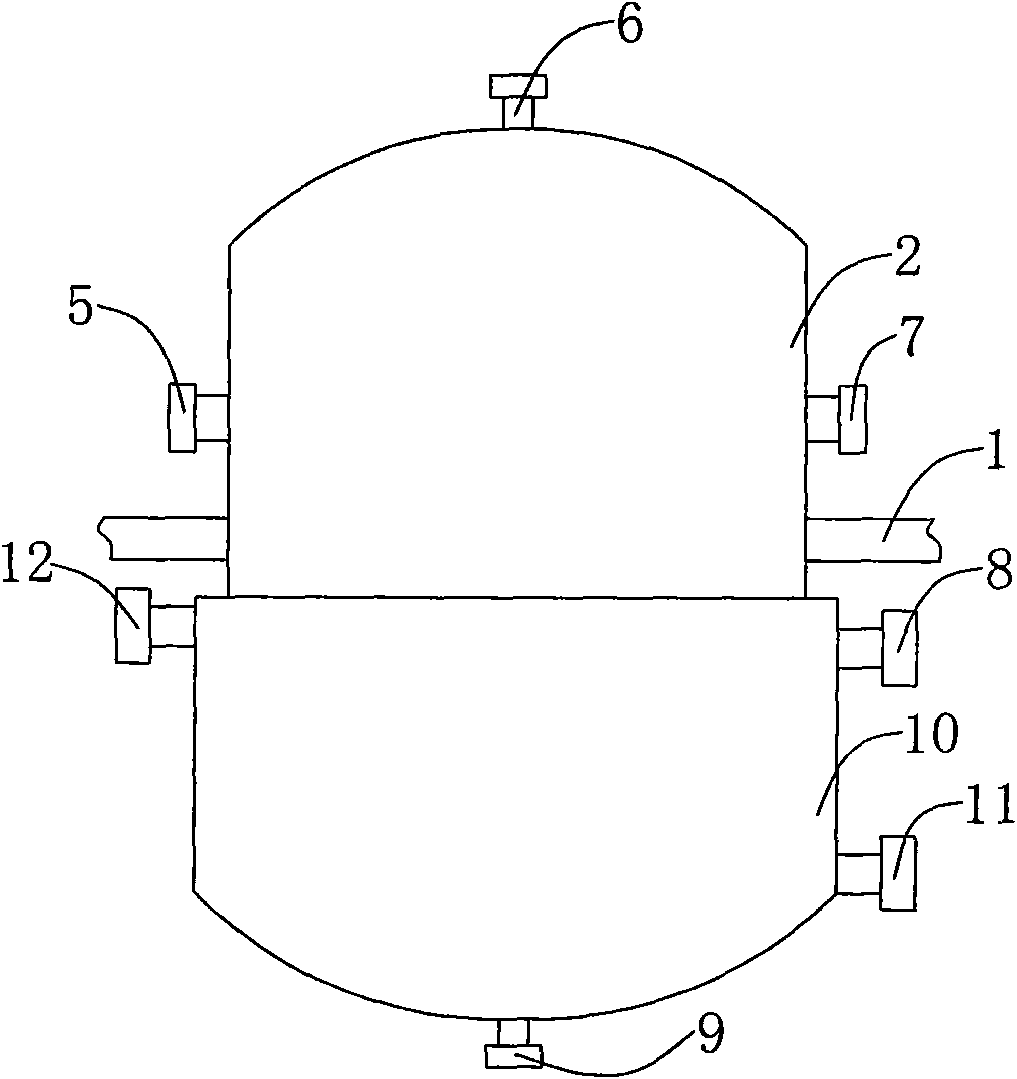

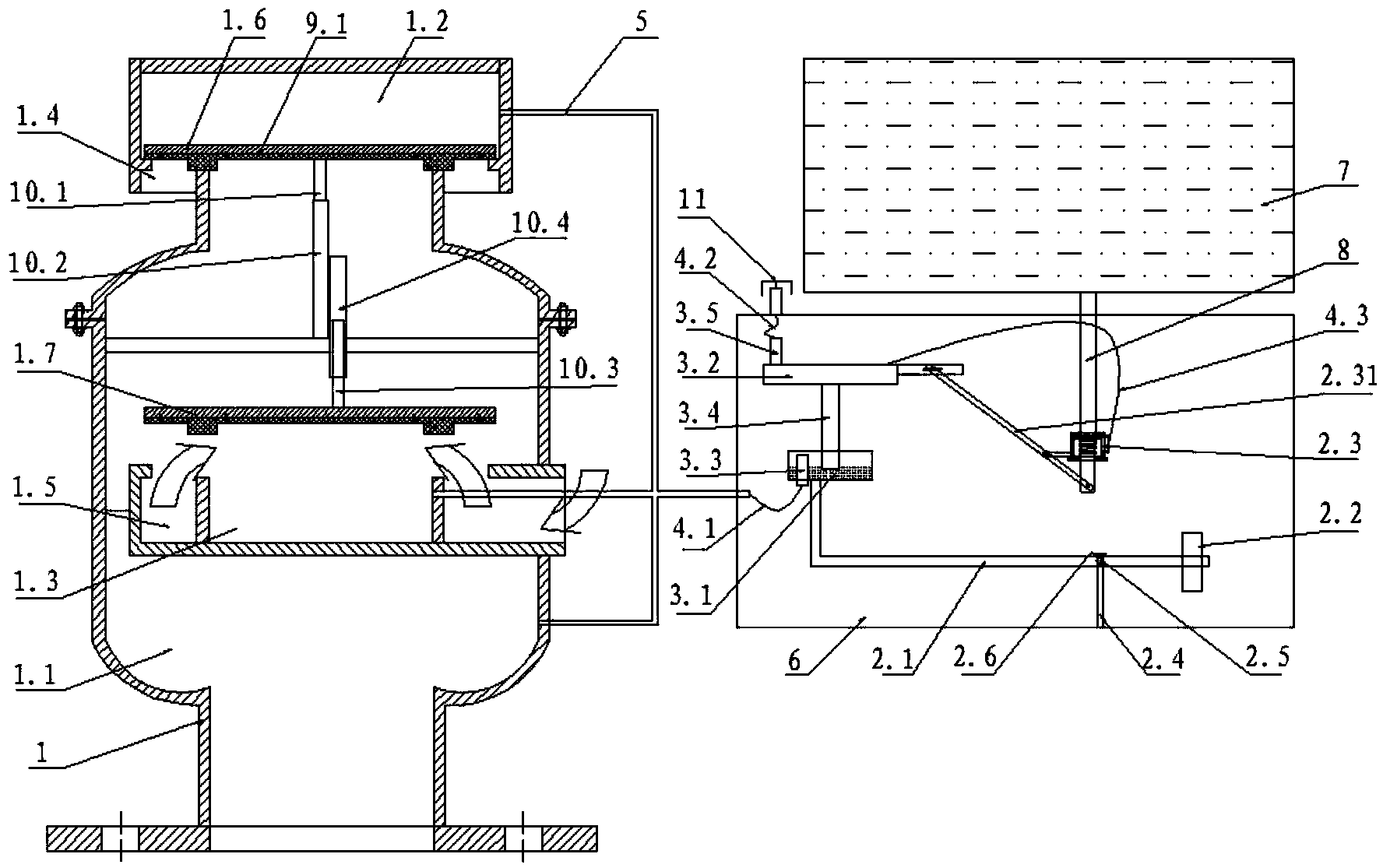

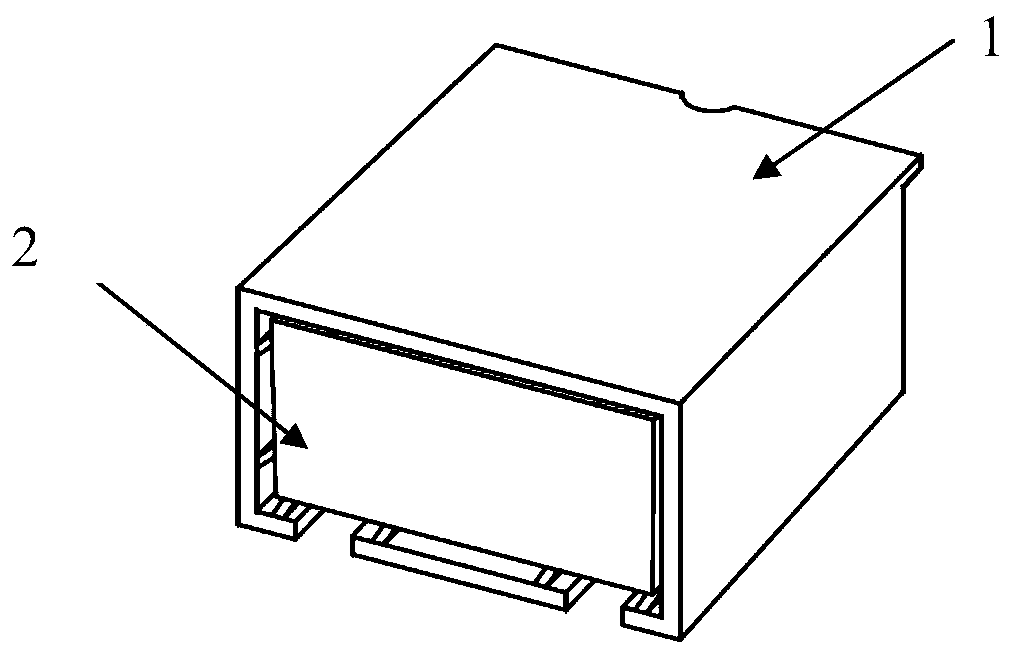

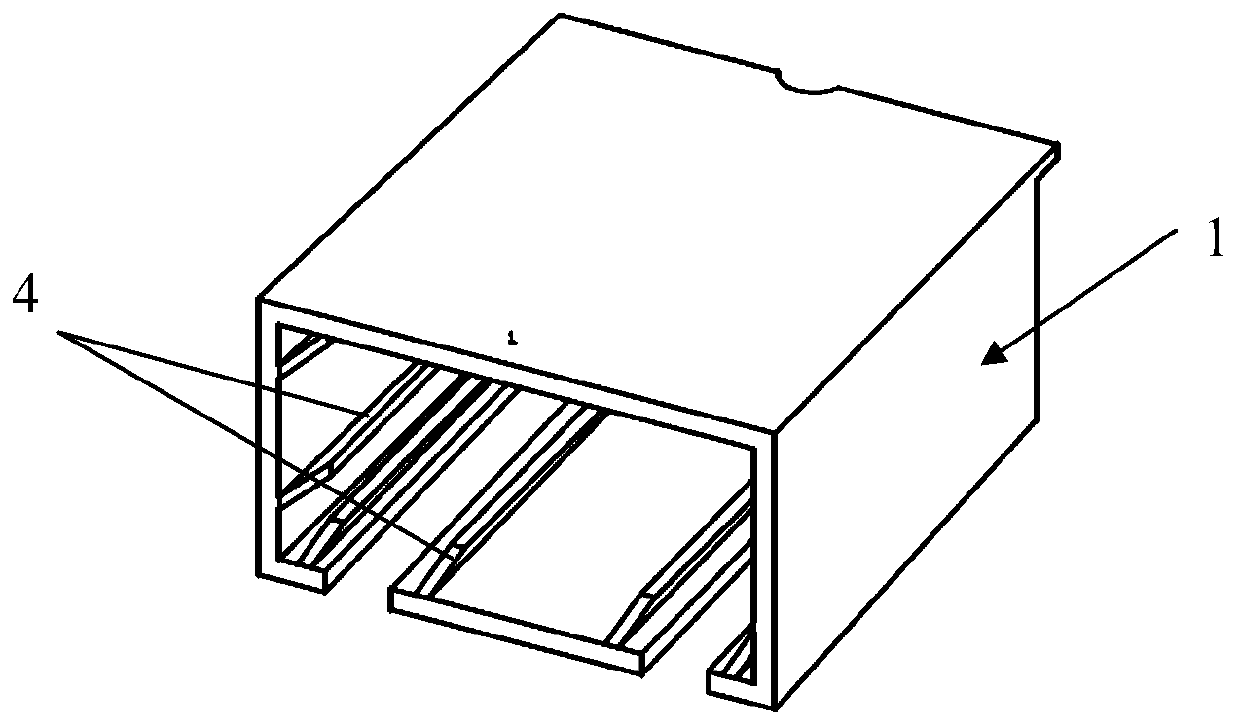

Recrystallization purifying device for lactide

InactiveCN101648938AFree from external pollutionHigh crystal purityOrganic chemistrySolution crystallizationLactideEngineering

The invention provides a recrystallization purifying device for lactide, which has the advantages of seal operation, high recrystallization purity, economic and efficient running, and the like and mainly comprises a tank body, wherein the tank body is supported by a rotating shaft and can rotate along the rotating shaft; an inner cavity of the tank body is formed a recrystallization chamber; the inner wall of the tank body is provided with a filter plate for dividing the recrystallization chamber into an upper recrystallization chamber and a lower recrystallization chamber; the upper recrystallization chamber is provided with a recrystallization solvent inlet and a drawing outlet; the lower recrystallization chamber is provided with a lactide inlet and a lactide outlet; a heat preservationsleeve filled with cooling and heating media is fixed on the outer wall of the tank body at the outer side of the lower recrystallization chamber and provided with a cooling and heating media inlet and a cooling and heating media outlet. The whole pumping filter process is carried out in a seal or vacuum environment and has no stirring and mechanical power in running, the recrystallized liquid isuniformly mixed fully in a cavity body without residual undissolved lactide crystals, and the recrystallization purification is more complete.

Owner:ZHEJIANG BOSHUOBEI BIOLOGICAL TECH

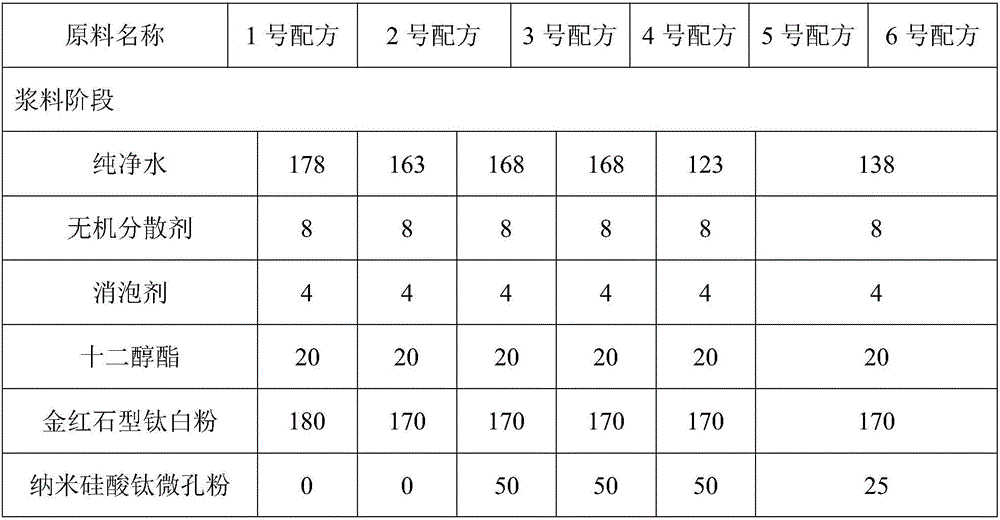

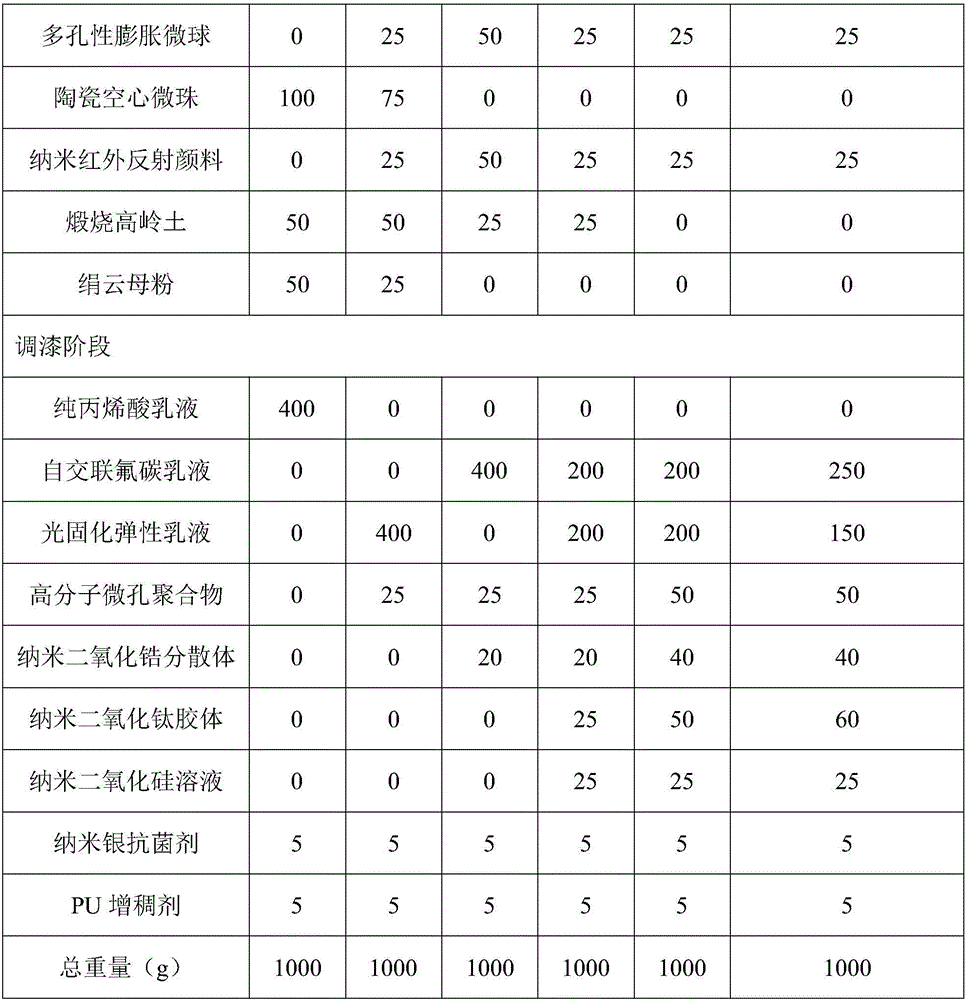

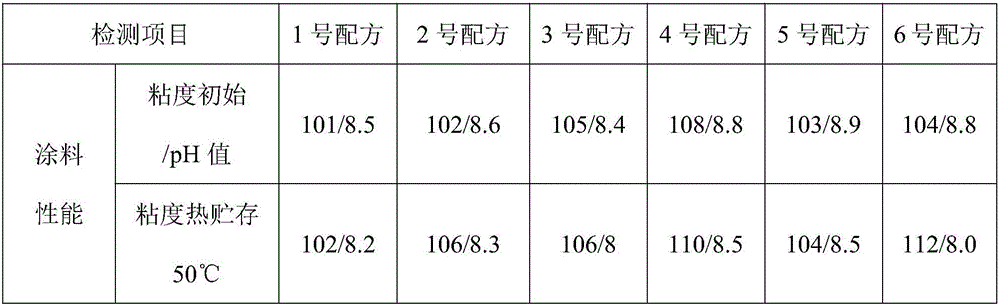

Composite heat-insulating paint for exterior walls and preparation method of composite heat-insulating paint

PendingCN106009967AImprove reflectivityEfficient reflectionAntifouling/underwater paintsPaints with biocidesMicrosphereAntibacterial agent

The invention discloses composite heat-insulating paint for exterior walls and a preparation method of the composite heat-insulating paint. The composite heat-insulating paint is prepared from purified water, an inorganic dispersing agent, a defoaming agent, texanol ester alcohol, rutile titanium dioxide, nano-titanium silicate microporous powder, porous expansible microspheres, infrared reflection nano-pigment, a self-crosslinking fluorocarbon emulsion, a photocured elastic emulsion, a macromolecular porous polymer, a nano-zirconium dioxide dispersing agent, a nano-titania colloid, a nano-silica solution, a nano-silver antibacterial agent and a PU thickening agent. The heat-insulating paint has efficient heat radiation reflection performance, good heat insulation and self-cleanness, lasting heat, good decorative performance, wide applicability and great environment friendliness, and a coating is long in service life.

Owner:黄作鹏

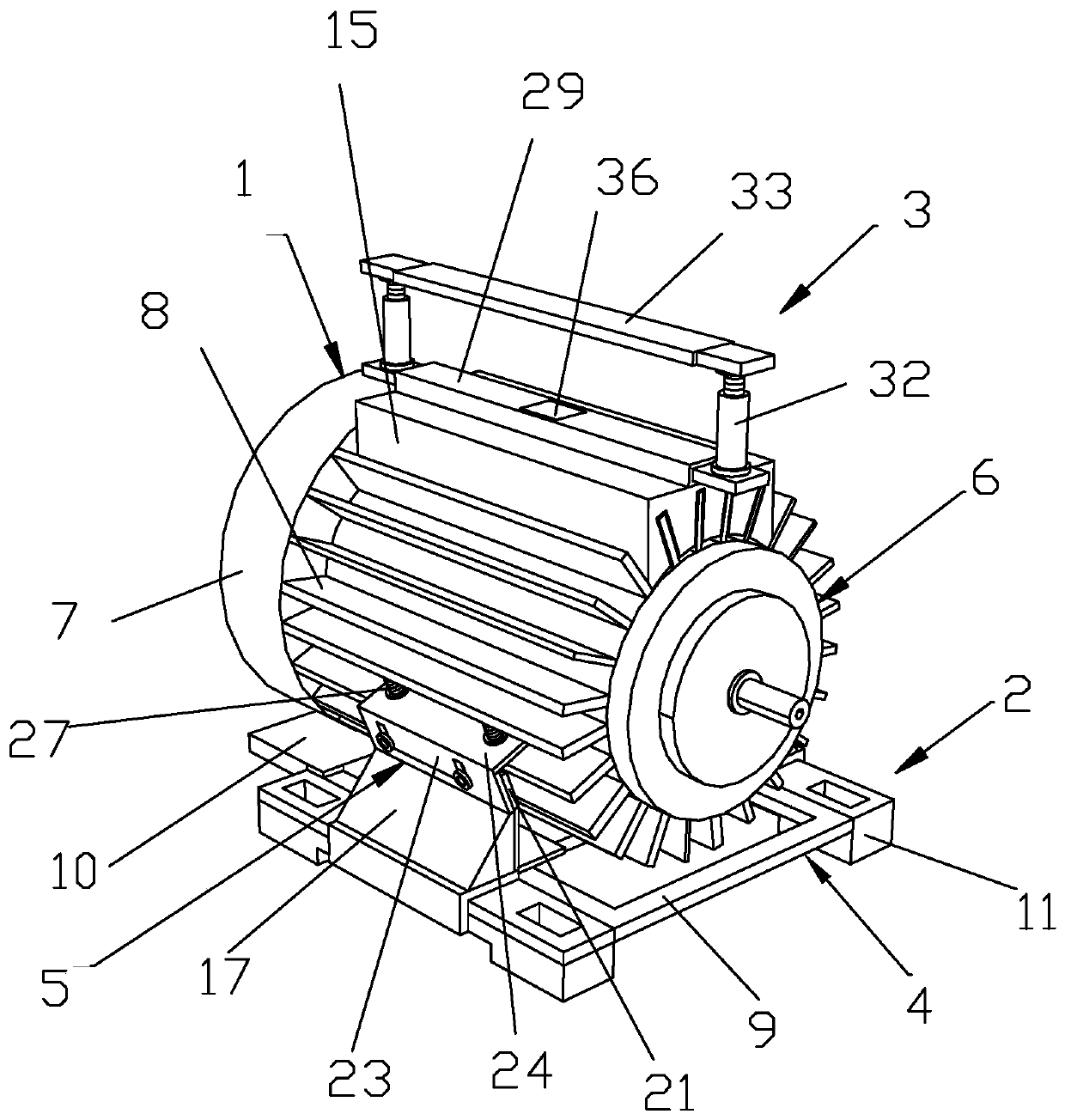

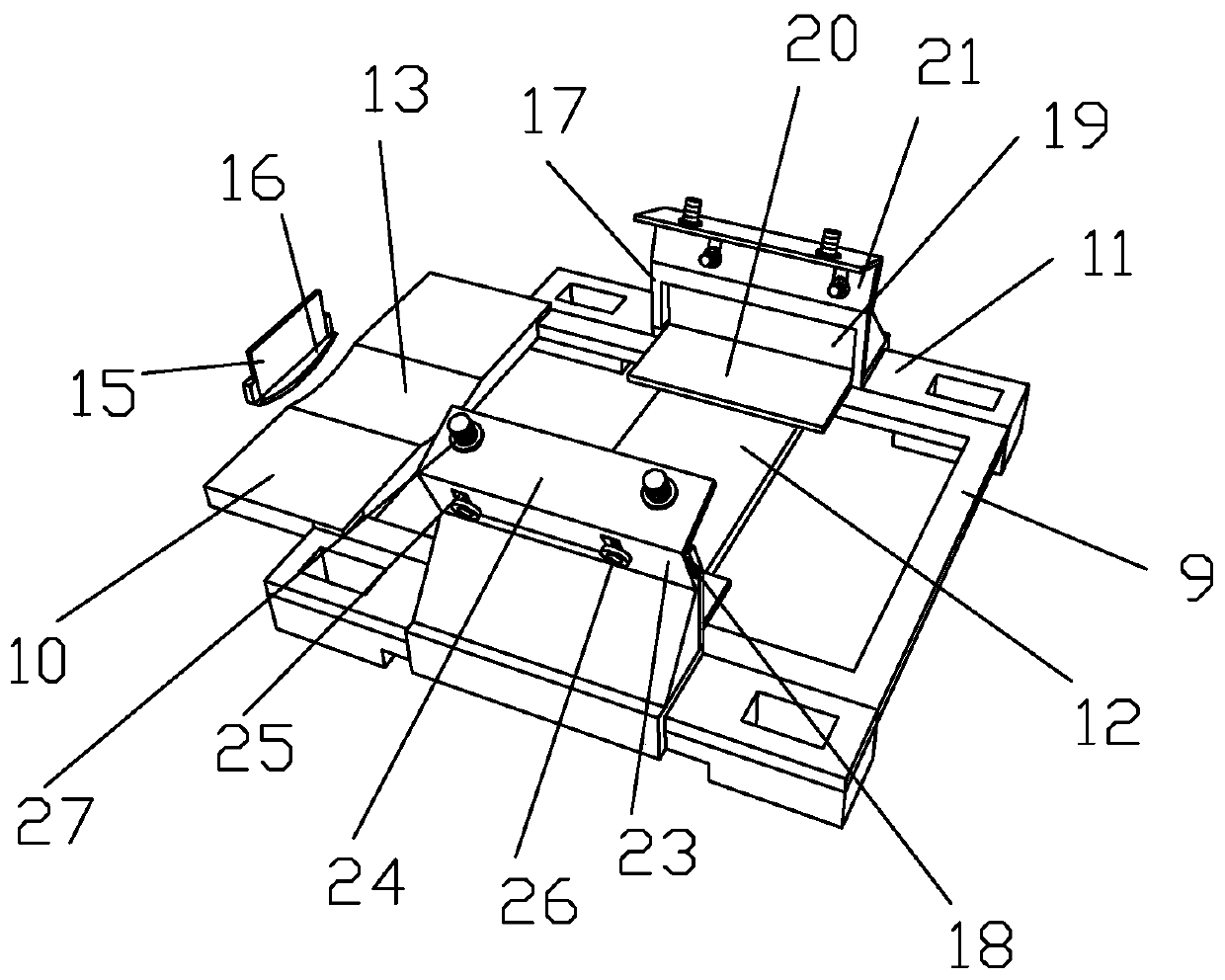

AC variable-frequency asynchronous motor with high stability and installation method thereof

PendingCN110086309AStable structureAchieve installationAsynchronous induction motorsManufacturing dynamo-electric machinesElectric machineEngineering

The invention discloses an AC variable-frequency asynchronous motor with high stability, which comprises a body and a casing, wherein the casing is installed outside the body. The AC variable-frequency asynchronous motor with high stability further comprises an adjustment base and a suspension, wherein the adjustment base includes a supporting frame and a locking assembly, the casing is installedabove the supporting frame, and the casing is fixedly connected with the locking assembly. The installation method of the AC variable-frequency asynchronous motor with high stability comprises the steps of 1) the installation of the adjustment base; 2) the installation of the casing and the adjustment base; and 3) the installation of the casing and the suspension. The invention not only can provide the stable adjustment base for the installation and fixation of the motor and an installation point below, but also can provide the suspension to fix the motor and an installation point above, thereby enabling the motor to be installed and fixed in both the upper and lower directions. Meanwhile, the installation carried out according to the invention can ensure the balanced installation of the motor, and the installation steps are simple.

Owner:嵊州市恒润电机制造有限公司

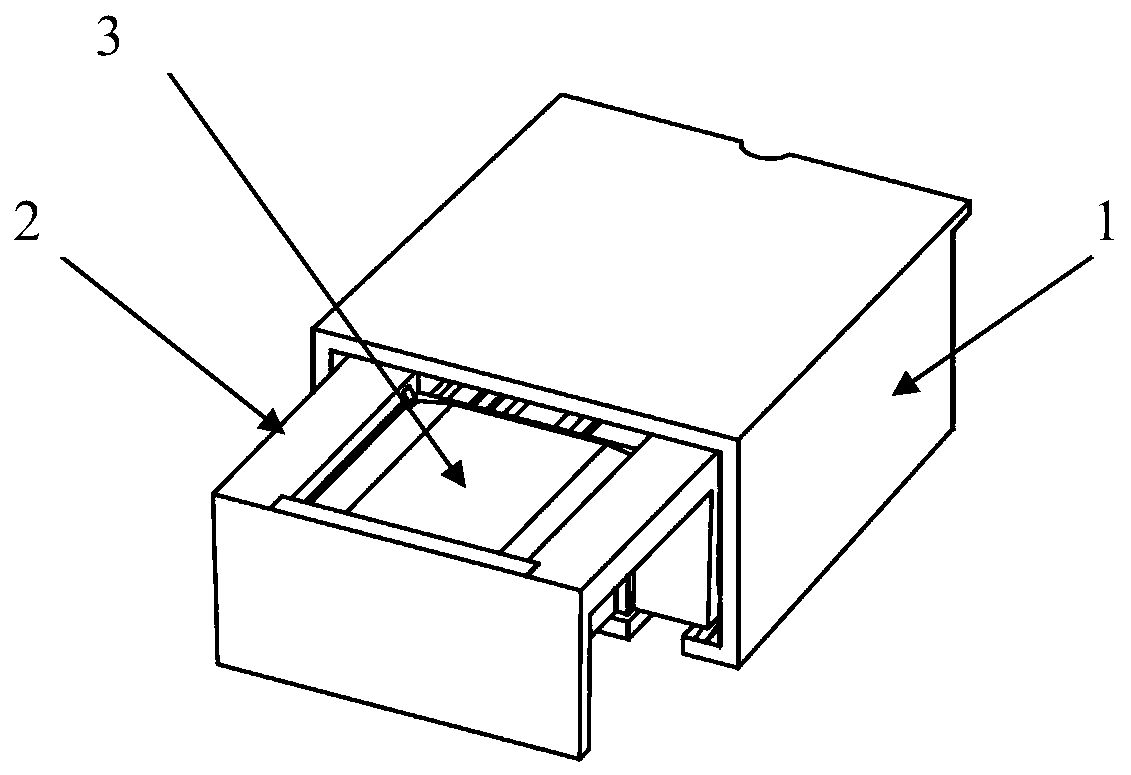

Tool kit frame for electromechanical device

The invention discloses a tool kit frame for an electromechanical device. The tool kit frame comprises a fixing frame body and a tool kit. The tool kit is correspondingly arranged on the top of the fixing frame body. The tool kit is arranged in an L-shaped structure, and a longitudinal baffle is arranged on the front side, the tool kit is correspondingly arranged on the fixing frame body through a fixing cover shell, the fixing cover shell is arranged in a hollow structure, the two ends of the fixing cover shell are correspondingly fixed to the fixing frame body, the two ends of the tool kit and the fixing frame body are correspondingly arranged through rotating shafts, and springs are correspondingly arranged on the rotating shafts on the two sides of the tool kit, so that the tool kit turns around the rotating shafts under the effect of the springs. The tool kit frame is simple in structure, convenient to use, capable of effectively protecting tools against external contamination and convenient to take.

Owner:苏州英得福机电科技有限公司

Puffball compound coating agent and preparation method thereof

The invention relates to a puffball compound coating agent. Each 1000 g of the coating agent is mainly prepared from the following raw materials: 180 to 220 g of puffball, 90 to 110 g of coptis, 90 to 110 g of fructus forsythiae, 45 to 55 g of borneol, 18 to 22 g of bletilla rhizome adhesive pulp, 110 to 140 g of glycerin, 15 to 20 g of PVA-124 and 8 to 10 g of Tween-80, with the balance being ethanol. The coating agent has the efficacy of detumescence, detoxification, itching relieving and haemostasis, is used for treatment of ulcerative carbuncle, edema pains, traumatic bleeding and the like, can effectively isolate the surface of a wound and prevents contamination of the surface of the wound and local infection.

Owner:HENAN SOAR VETERINARY PHARMA

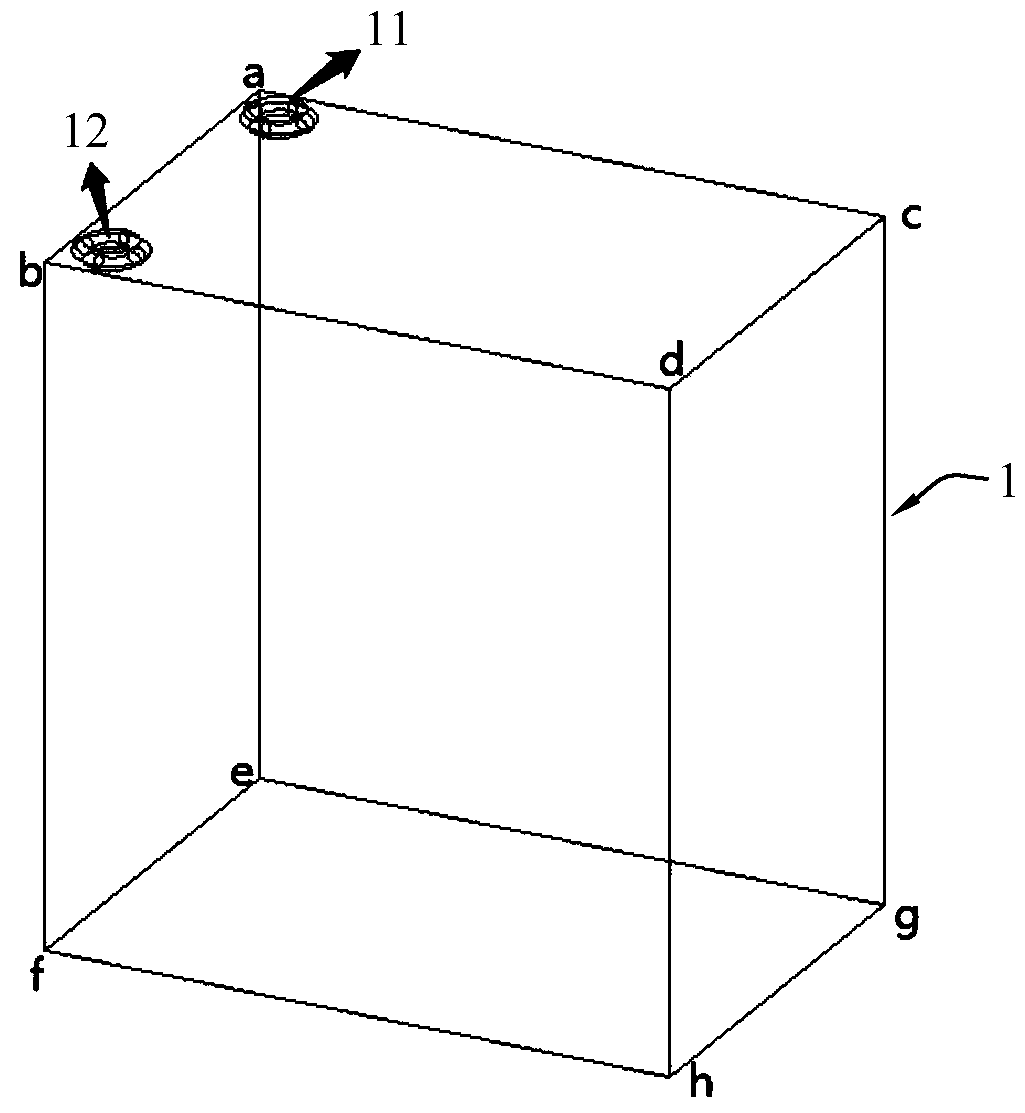

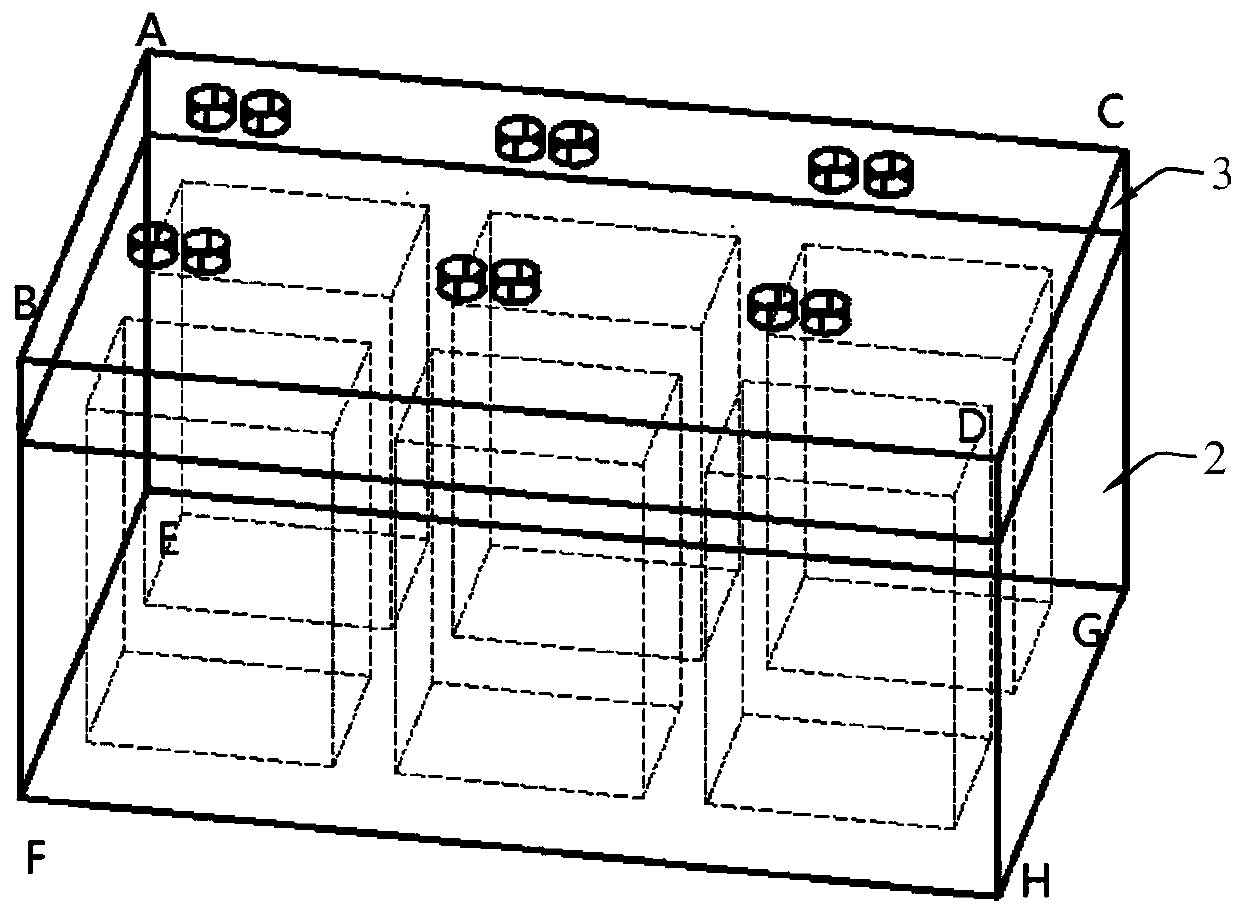

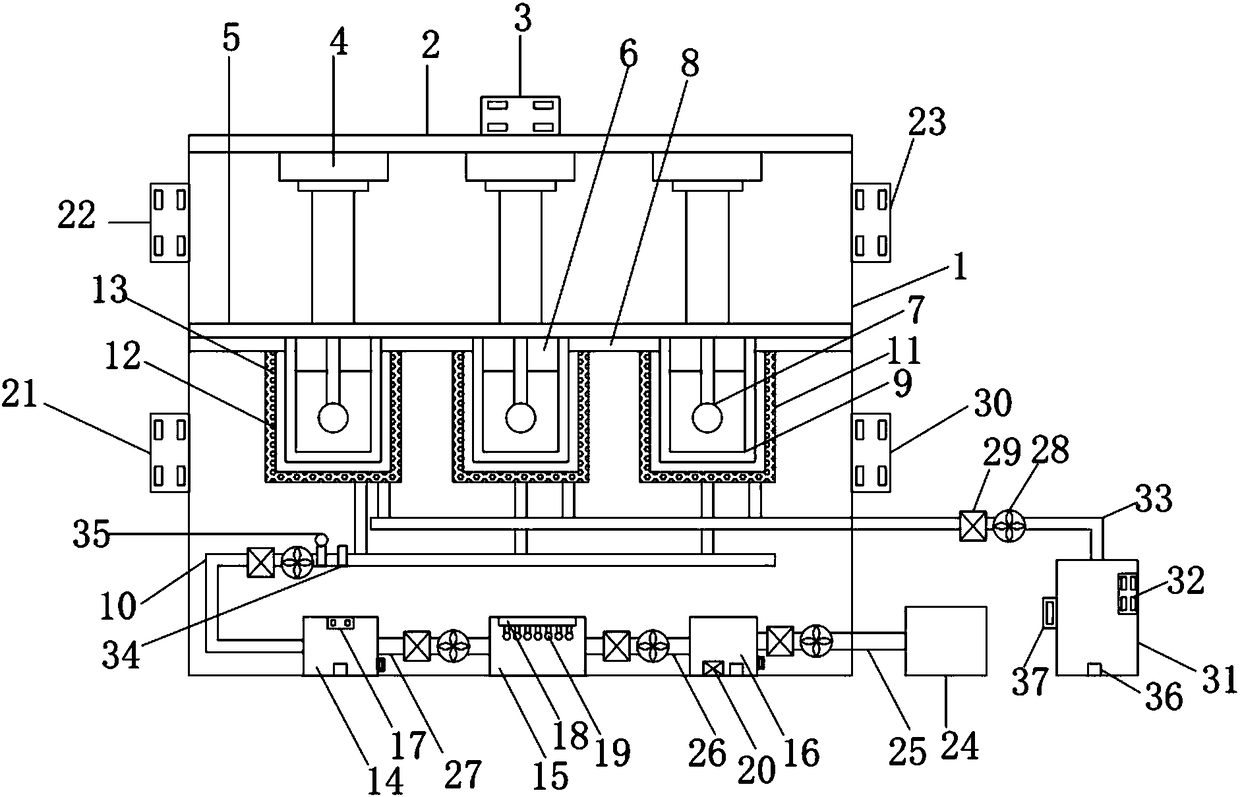

Cell culture method and system

ActiveCN109593703AGuaranteed aseptic operationFree from external pollutionBioreactor/fermenter combinationsBiological substance pretreatmentsCell factoryEngineering

The invention discloses a cell culture method and system. The method comprises the following steps: S10. a liquid interface expansion step: expanding one liquid interface of a cell factory into a plurality of liquid expansion interfaces; S20. an inoculation step: injecting a first culture solution containing inoculating cells into the cell factory through the first liquid expansion interface; S30.a first liquid expansion interface closing step: after the first culture solution is injected, closing the first liquid expansion interface and no longer opening the first liquid expansion interface;S40. a culture step; S50. a digestion step: identifying an unused liquid expansion interface and completing liquid exchange of the cell factory through the unused liquid expansion interface. The system includes the cell factory having at least one liquid interface, a liquid interface expansion device, and a liquid exchange device capable of being docked with or separated from the liquid expansioninterface to complete the liquid exchange of the cell factory. The cell culture method and system protect the liquid exchange process of the whole cell culture from being polluted by the outside andguarantee aseptic operations.

Owner:广州瑞贝斯药业有限公司

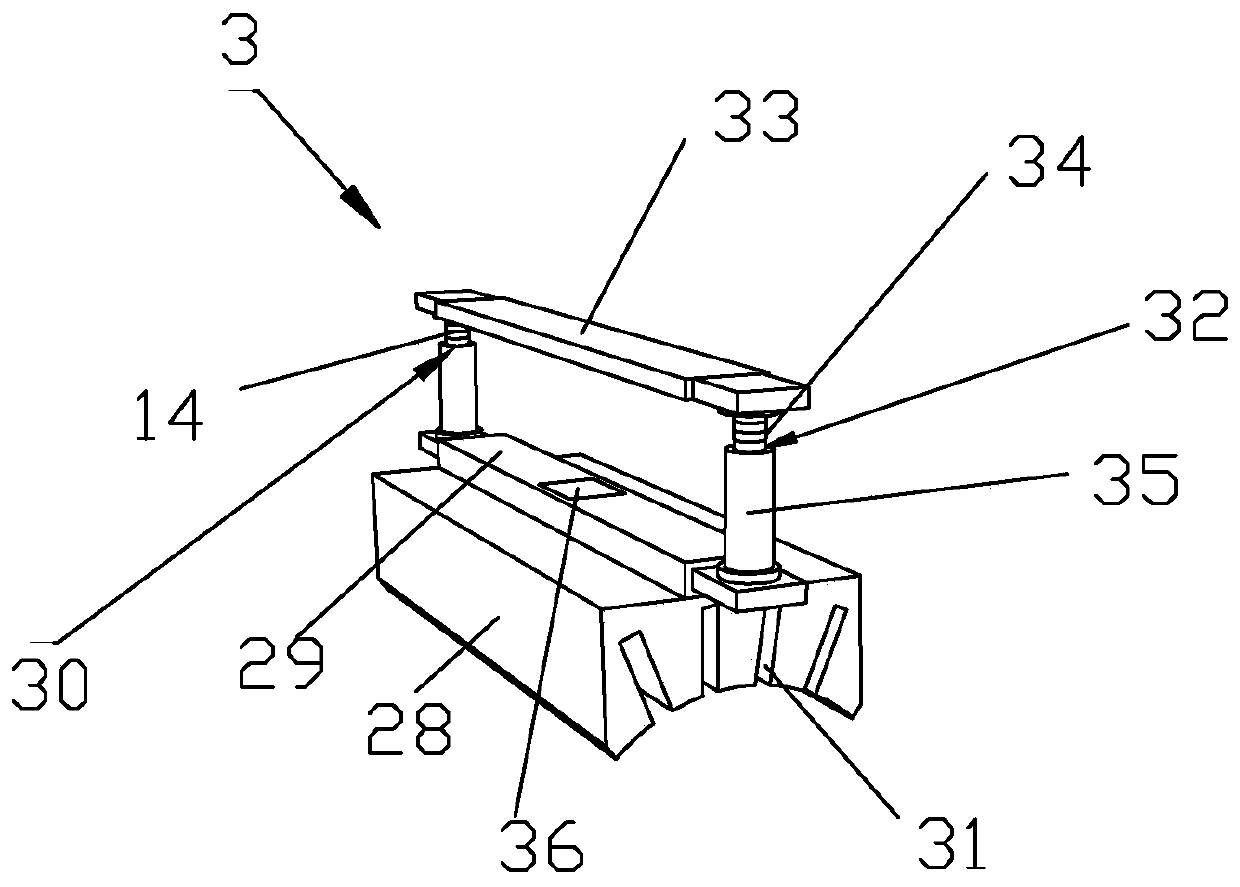

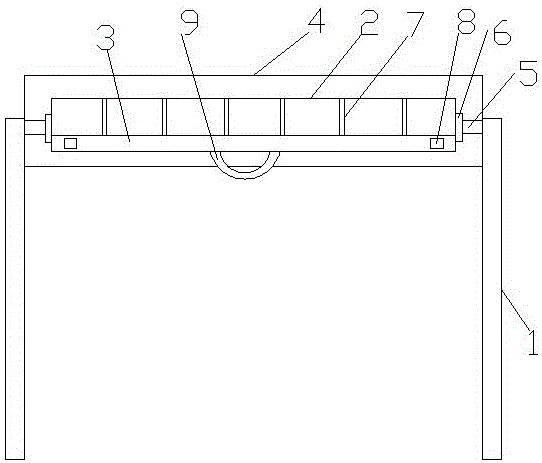

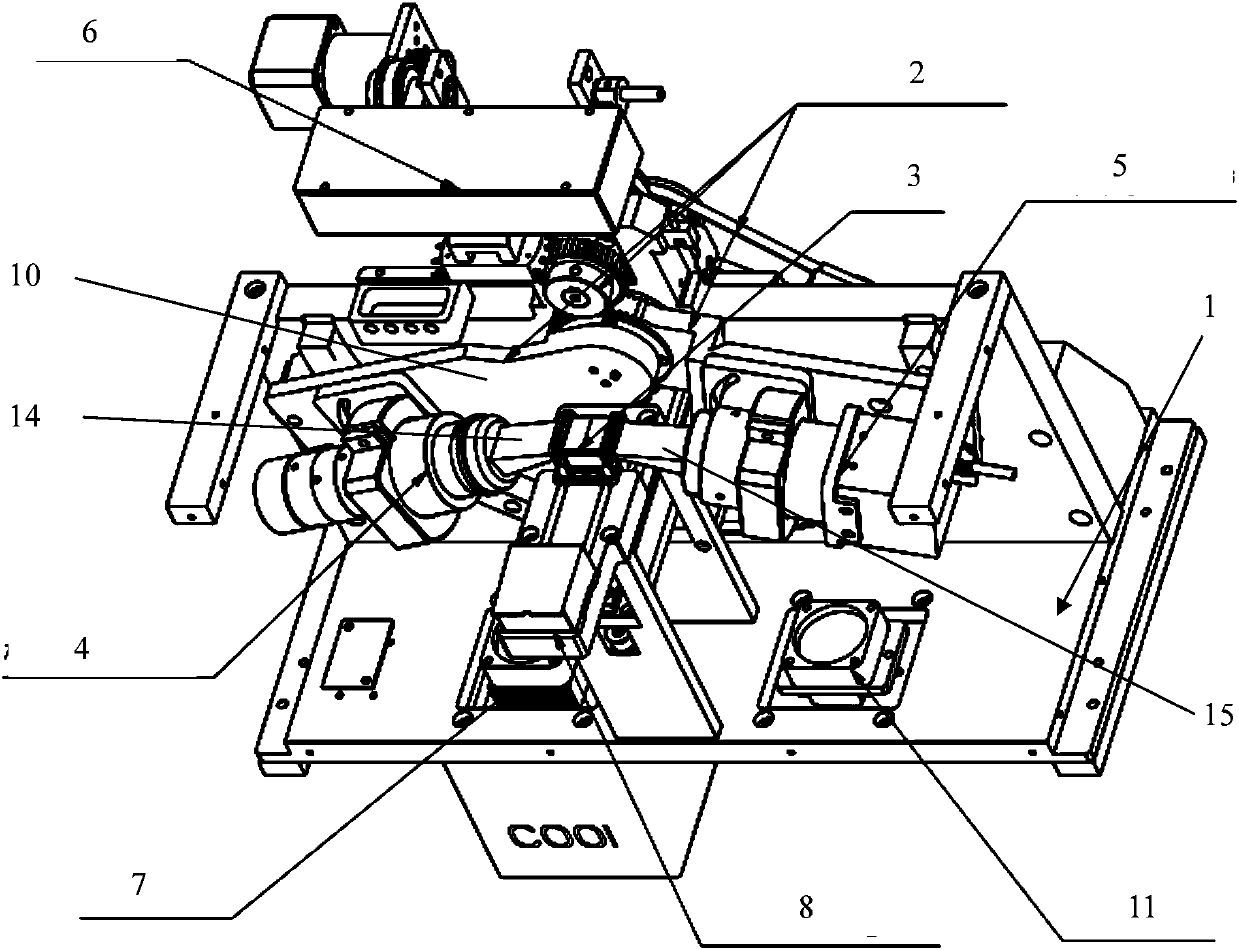

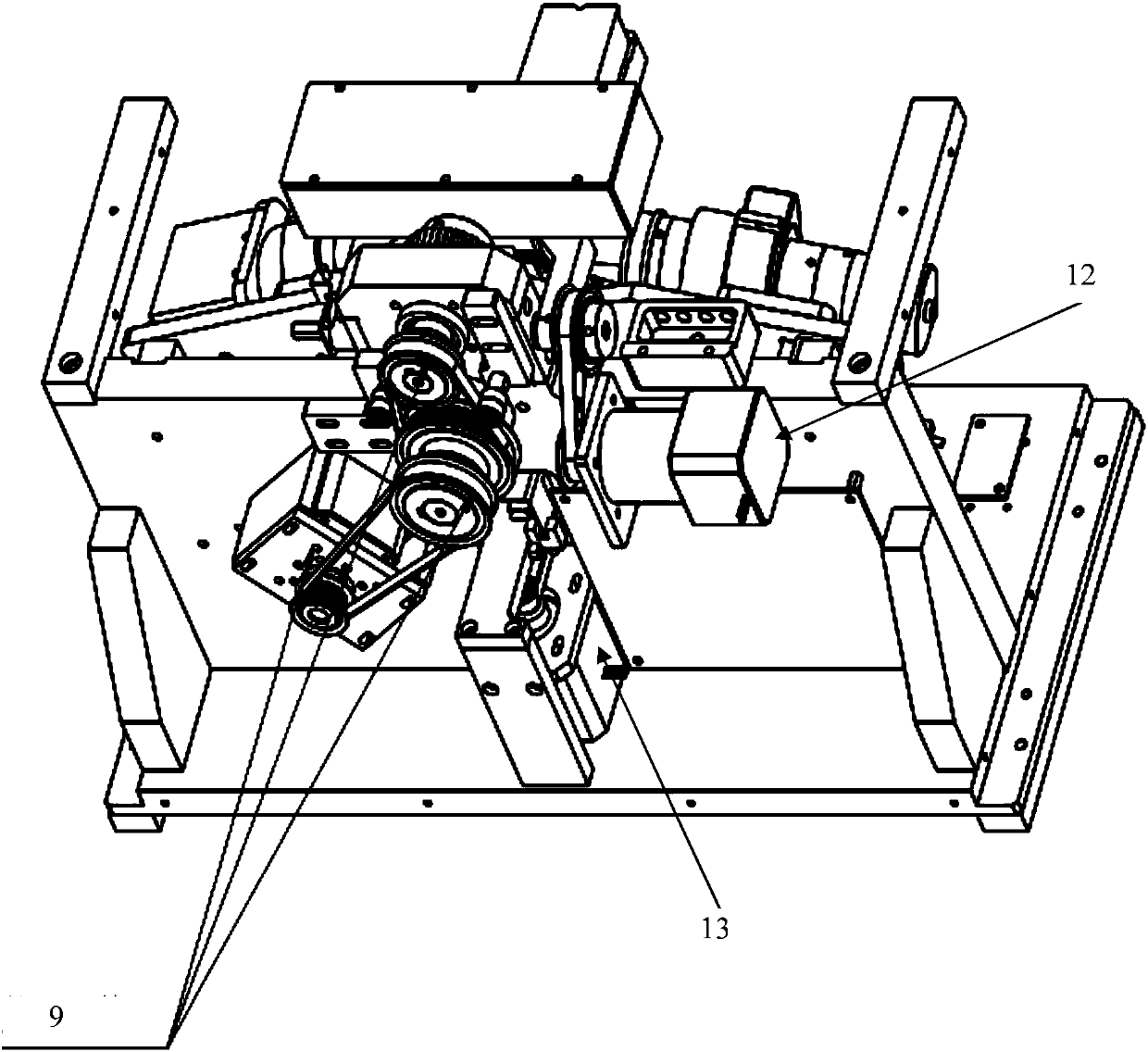

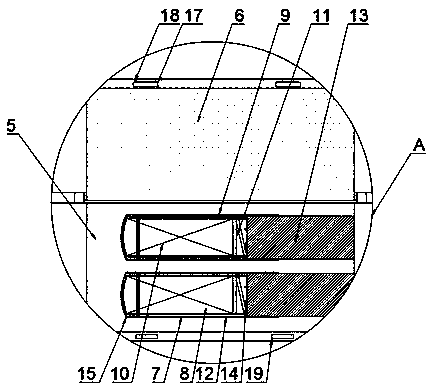

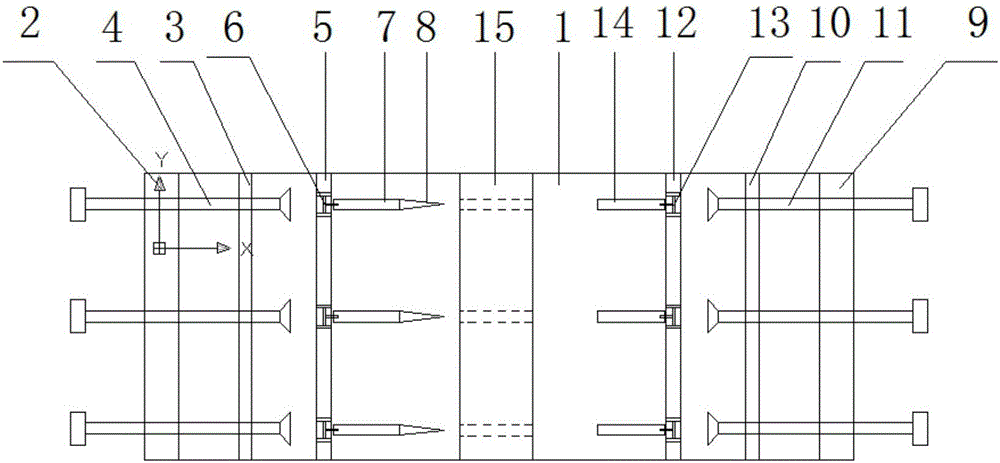

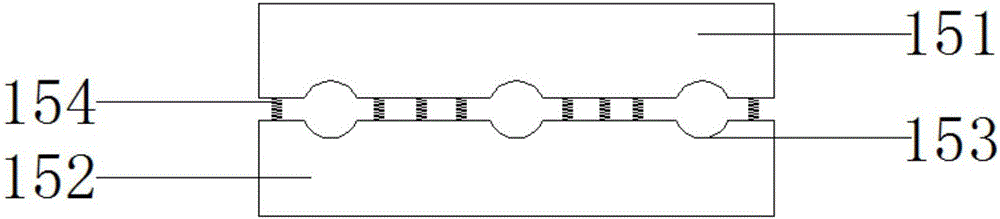

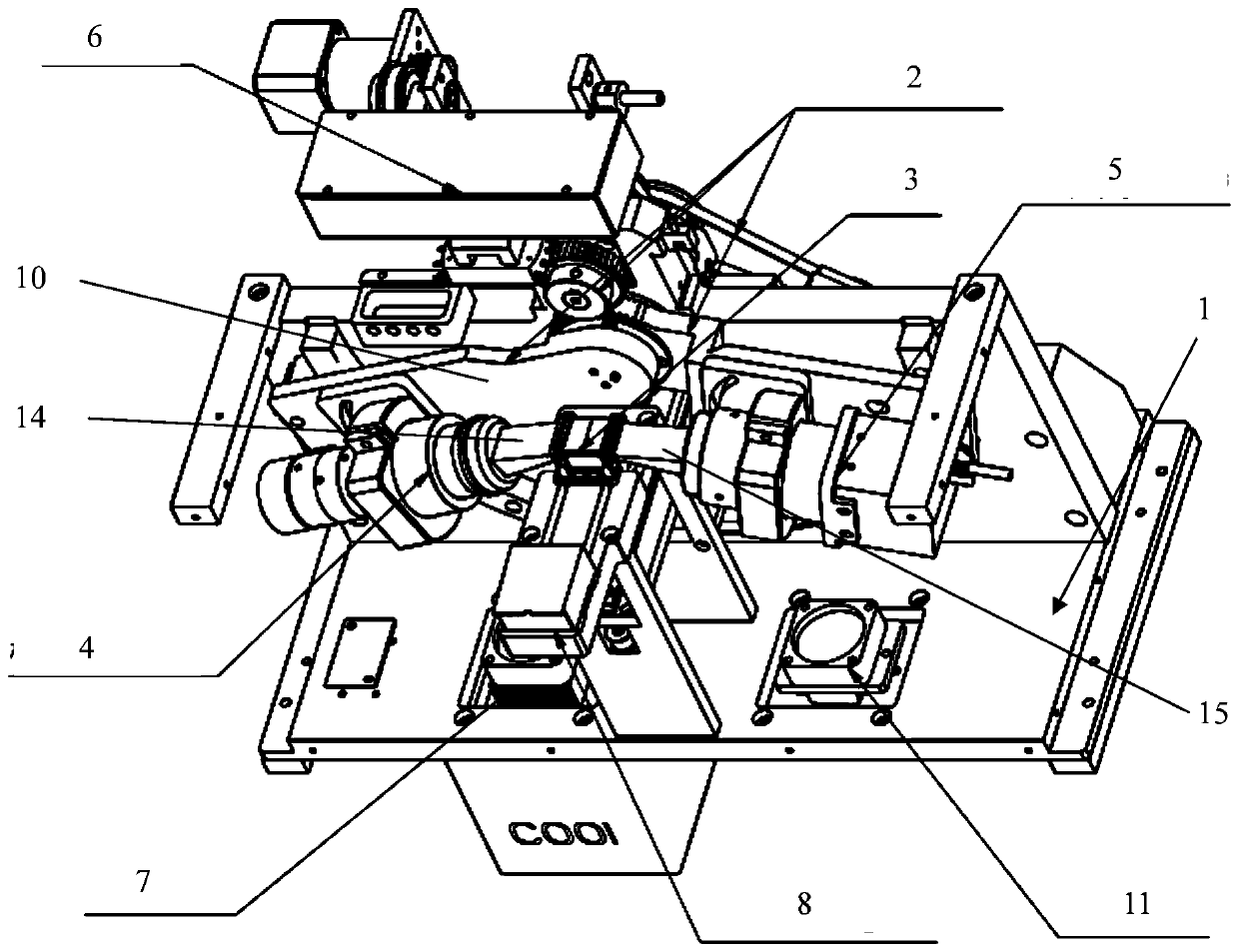

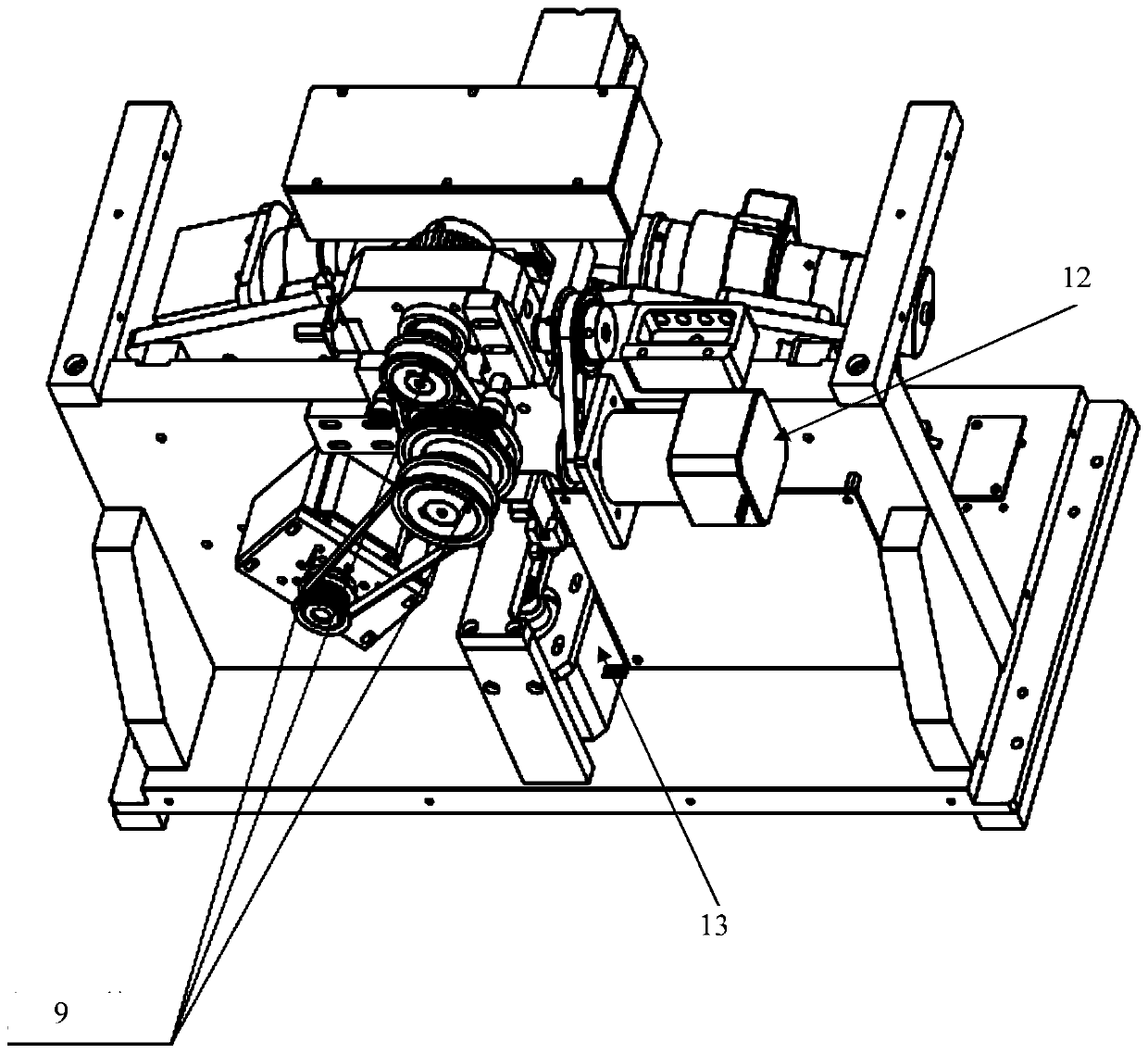

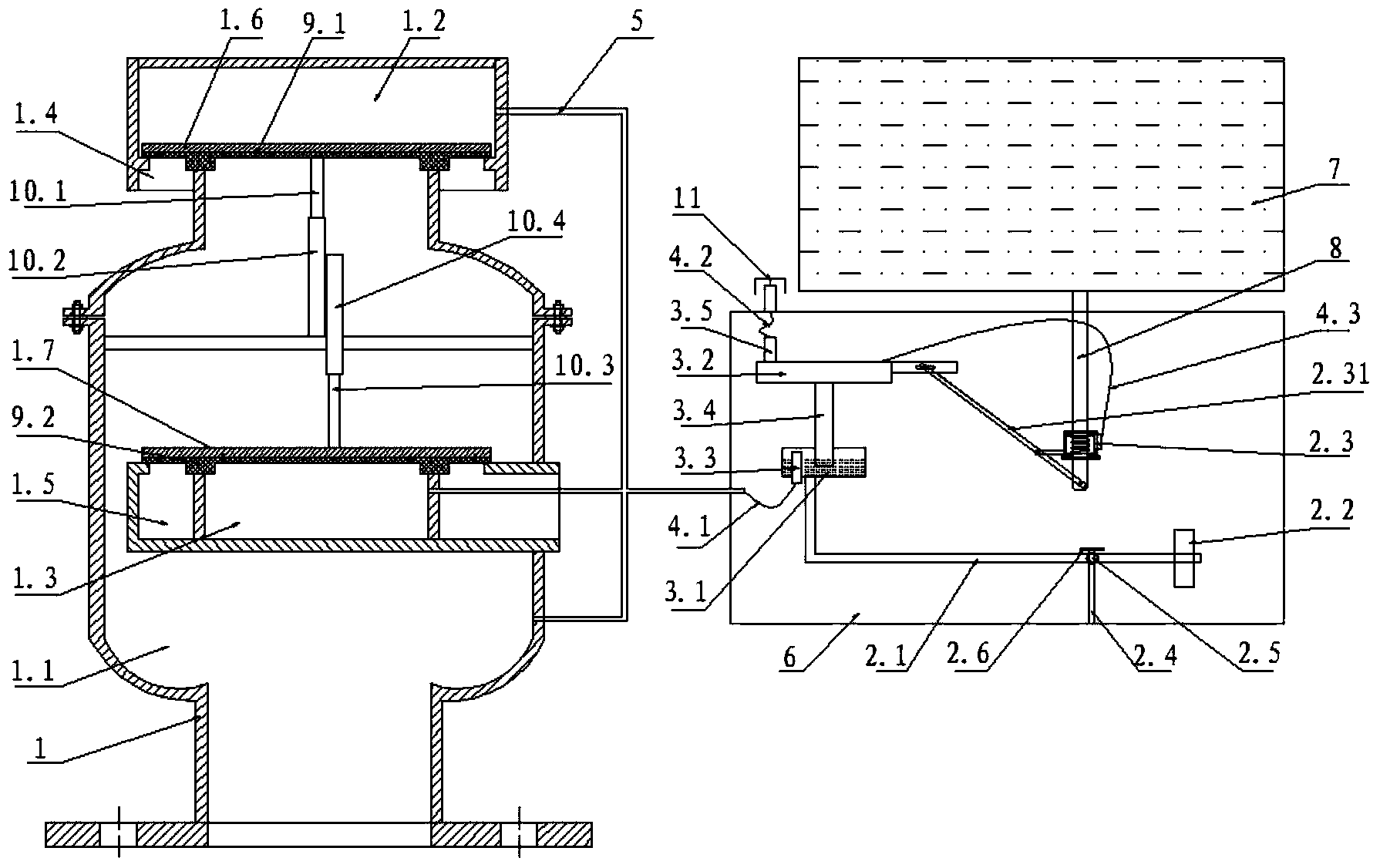

Prism-type surface plasmon resonance spectrometer angle modulation mechanism

ActiveCN107843558APrecise angle adjustmentQuick Angle AdjustmentScattering properties measurementsAngle modulationLight beam

The invention discloses a prism-type surface plasmon resonance spectrometer angle modulation mechanism. The mechanism comprises a fixing frame, a synchronous rotation mechanism installed on the fixingframe, first and second transmission mechanisms, an integrated prism chip, a flow cell, a wedge-shaped light transmitting end, a CCD receiving end, a compressing mechanism and two rotation arms. Thesynchronous rotation mechanism drives the two rotation arms to synchronously rotate under action of the first transmission mechanism. The wedge-shaped light transmitting end and the CCD receiving endare respectively fixed on one rotation arm and can rotate along with the rotation arm. The extension lines of the rotation shafts of the two rotation arms are located in the center of the top surfaceof the integrated prism chip. The wedge-shaped light transmitting end emits a wedge-shaped light beam to the center of the integrated prism chip and the reflected wedge-shaped light beam irradiates CCD of the CCD receiving end. The compressing mechanism can move downward under the action of the second transmission mechanism to compress the chip and the flow cell. The mechanism can accurately and fast adjust an angle and has a large adjustment range.

Owner:丁利 +4

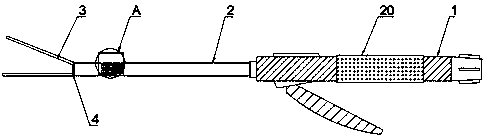

An electric anastomat with intelligent detection

InactiveCN109199492AGood protectionExtended service lifeOrgan movement/changes detectionDiagnostics using spectroscopyDistal anastomosisWound suturing

The invention discloses an electric anastomat with intelligent detection, including an anastomat body. At one end of that anastomat body, a connecting rod is arranged. At one end of that connecting rod is provided with an anastomosis clamp, a pressure sensor is arranged at the center of the anastomosis clamp, a cavity is arranged inside the connecting rod, a cover plate is arranged at the top ofthe cavity, a first storage bin is arranged inside the cavity, an ultrasonic sensor is arranged inside the first storage bin, and a second storage bin is arranged at the top of the first storage bin.As that infrared sensor is arranged, it is convenient to test the anastomosis force of anastomosis forceps by pressure sensor. The ultrasonic sensor and an infrared sensor can detect a wound suture condition, and that first and second storage bin can protect the ultrasonic sensor and the infrared sensor from external contamination, thereby integrally enable the invention to detect the wound suturecondition and playing a very good protective role to the sensor. The ultrasonic sensor and the infrared sensor can detect the wound suture condition.

Owner:TIANJIN ONEHEALTH MEDICAL INSTR CO LTD

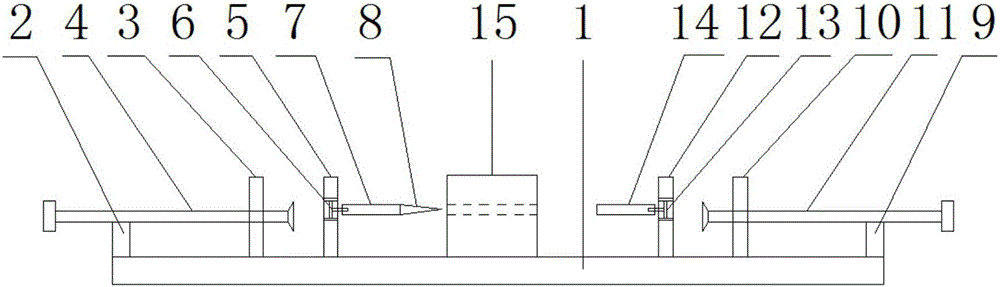

Expanding device for cold-contacted cable accessory

The invention discloses an expanding device for a cold-contacted cable accessory. The expanding device comprises a worktable; a supporting plate I is mounted at the left end of the worktable; a fixed plate I is mounted at the right of the supporting plate I; a hydraulic driving rod I is arranged on the supporting plate I and passes through the fixed plate I; a movable plate I is arranged at the right of the fixed plate I; a fixed base is fixedly mounted on the movable plate I; an expanding mold is fixedly mounted on the fixed base I; a conical head is mounted at the front end of the expanding mold; a supporting plate II is mounted at the right end of the worktable. According to the expanding device for the cold-contacted cable accessory, three groups of expanding devices are arranged in order to expand three products simultaneously, so relatively high work efficiency is realized; by arranging a silicon rubber pressing mold provided with a spring, the products are prevented from damages during an expansion process; sterilized lubricating grease is capable of protecting the products from external pollution, so relatively high product protectiveness is realized.

Owner:七星电气股份有限公司

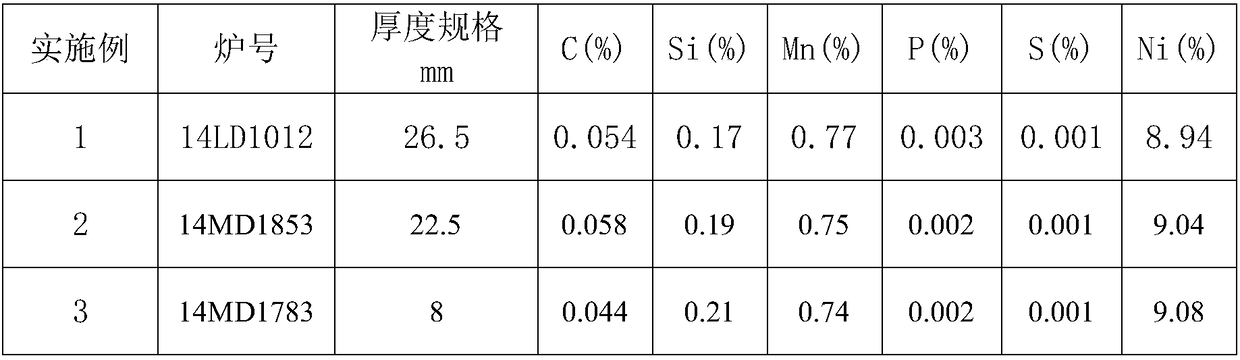

9Ni steel plate residual magnetism control manufacturing method

InactiveCN109022685AGood low magnetic propertiesReduce magnetismFurnace typesHeat treatment process controlSheet steelMode of transport

The invention discloses a 9Ni steel plate residual magnetism control manufacturing method. The method comprises the following steps that (1) the mode of transport of the steel plates of all the processes after quenching all adopts vacuum suction cups for hoisting; (2) quenching treatment is conducted, specifically, according to the characteristic that the steel plates lose magnetism after being heated to the Curie point temperature of 770 DEG C, the steel plate quenching temperature is 800+ / -30 DEG C; (3) tempering treatment is conducted, specifically, the steel plate tempering temperature is630+ / -20 DEG C; (4) steel plate stacking is conducted, specifically, the steel plates after heat treatment are all stacked at the stacking position in the distance of 50 meters away from a heat treatment furnace; (5) residual magnetism measurement is conducted, specifically, all the steel plates are subjected to residual magnetism measurement before delivery; and (6) degaussing treatment is conducted, specifically, when the steel plate residual magnetism is greater than 30 Gauss, the steel plates are subjected to degaussing treatment. By means of the 9Ni steel plate residual magnetism controlmanufacturing method, each process after quenching treatment adopts the vacuum suction cups for hoisting to ensure the lower magnetic properties of the steel plates, the magnetic properties of each process are controlled to be free from external pollution, by measuring the residual magnetism of the key processes, the residual magnetism monitoring of the whole process of the steel plate productionis guaranteed, and the qualified steel plates are provided.

Owner:ANGANG STEEL CO LTD

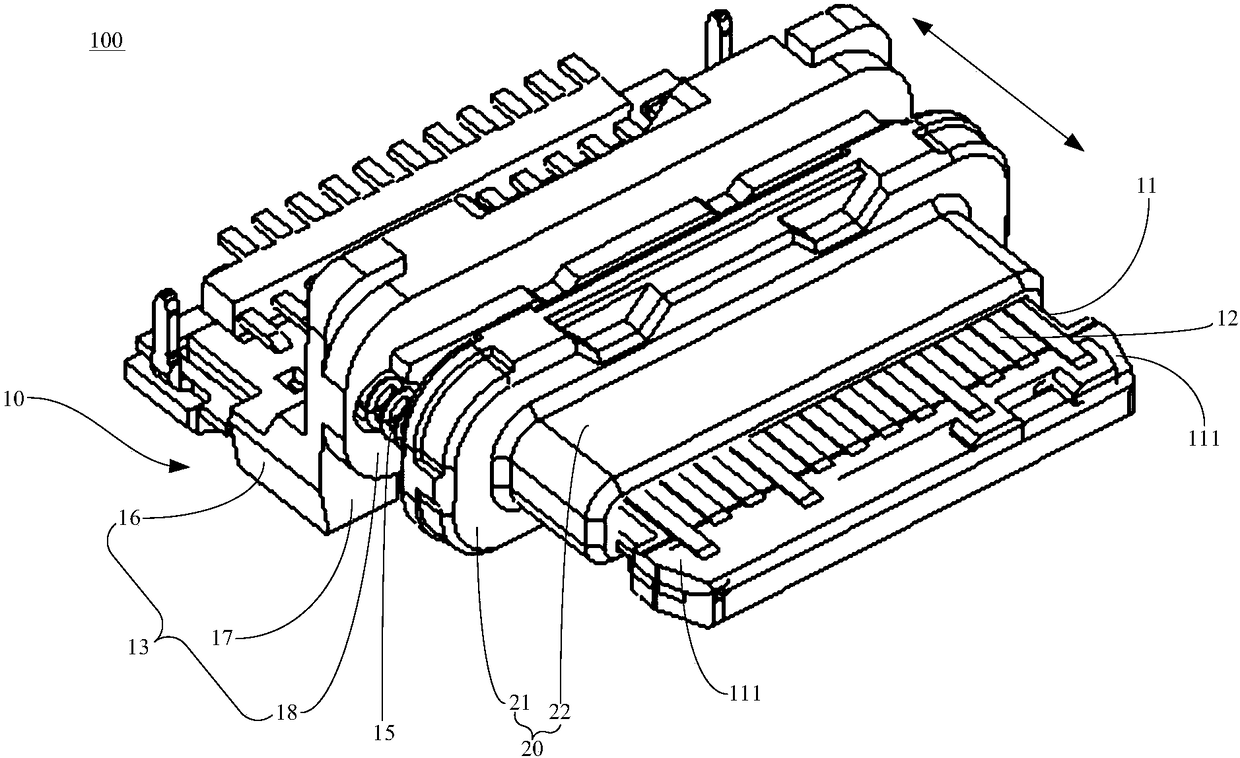

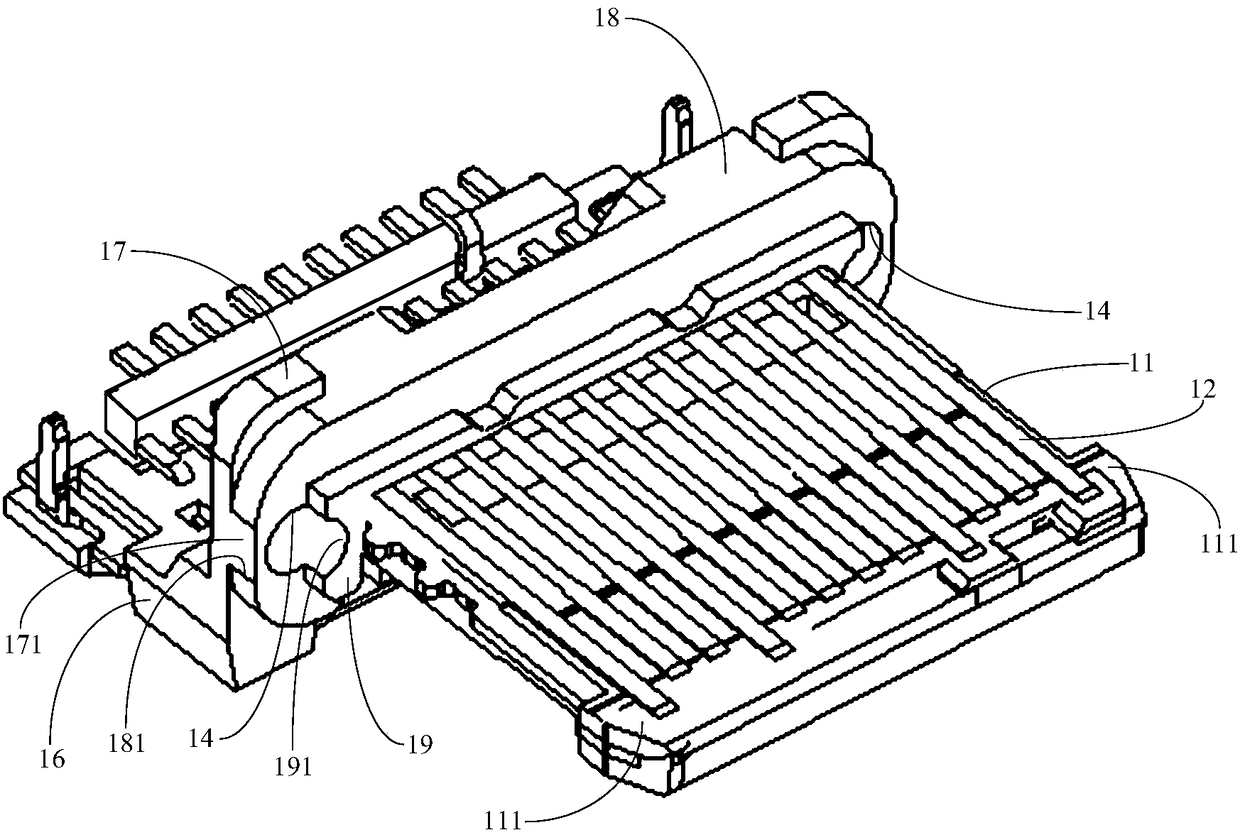

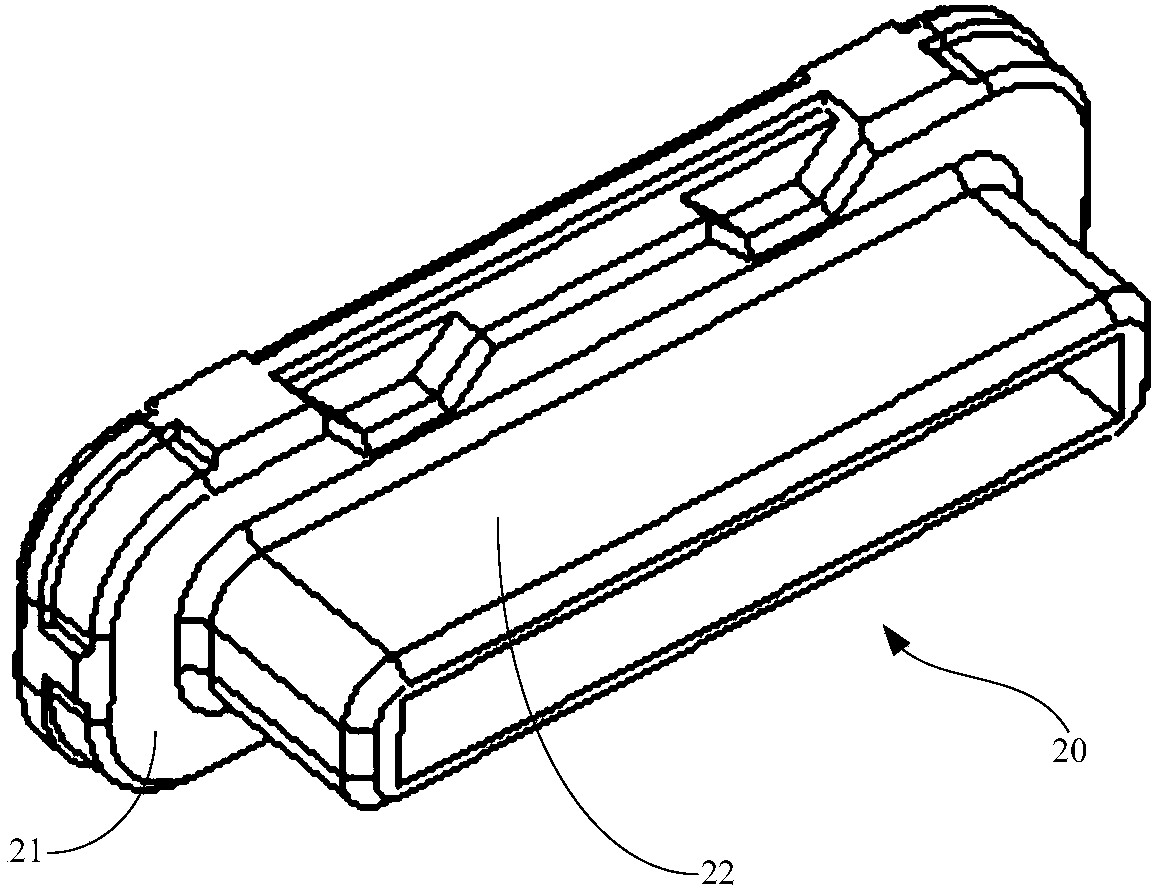

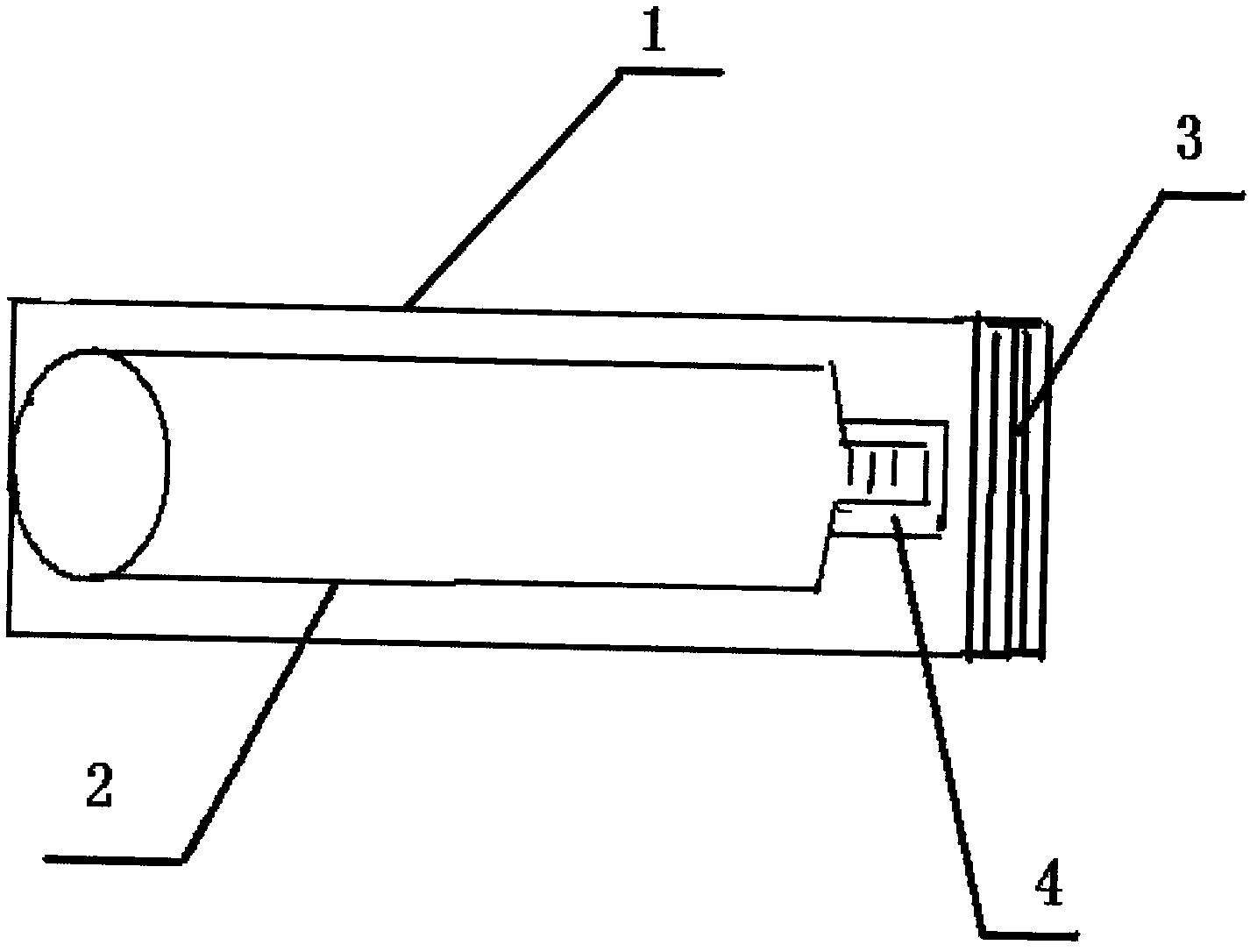

USB female base and mobile terminal

InactiveCN108574175AEasy to useFree from external pollutionCoupling device detailsTelephony connectorsElectricityEngineering

The present disclosure relates to a USB female base and a mobile terminal. The USB female base includes: a female base body including a female base tongue and an electrical contact terminal disposed on the female base tongue; and a cover which covers the female base tongue and is movably connected to the female base body in an extending direction of the electrical contact terminal. When the covermoves to a first position, the electrical contact terminal is covered by the cover; when the cover moves to a second position, the electrical contact terminal is exposed out of the cover; when the USBfemale base is not in use, the cover is moved to the first position and covers the electrical contact terminal so as to ensure that a surface of the electrical contact terminal of the USB female baseis free from external pollution; and when the USB female base needs to be used with a male base, the cover can be pushed to the second position during the insertion of the male base into the female base, so that the electrical contact terminal is exposed out of the cover body and is connected to the male base, thereby ensuring normal use of the USB female base.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

Airing device for gene detection

PendingCN108424846AEasy to fixImprove work efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsBiochemical engineeringDesiccant

The invention provides an airing device for gene detection and belongs to the technical field of gene detection. The airing device comprises an airing box, a sealing cover is arranged on the top faceof the airing box, a first controller is arranged on the top face of the sealing cover, electric extensible cylinders are arranged on the undersurface of the sealing cover and electrically connected with the first controller, a lifting frame in transverse arrangement is arranged in the airing box, the lower end of an extensible rod of each electric extensible cylinder is connected with the liftingframe, fixing rings are arranged on the lifting frame, a sampling rod is connected on each fixing ring in a clamped manner, a mounting plate and an air delivery pipe are arranged on the airing box, adrying barrel and a sample container are arranged on the mounting plate, a faveolate fixing member is arranged on the inner side wall of the drying barrel, a drying agent is arranged in the drying member, the air delivery pipe and the drying barrel are communicated, and a cooling box, a sterilization box and a high-temperature box are arranged on the inner undersurface of the drying box. The airing device has the advantages that the sampling rods can be fixed firmly, humid samples on the sampling rods are less prone to being polluted in the process of airing, and working efficiency is high.

Owner:南京申友生物技术有限公司

Flexible pipe for ocean

ActiveCN103090126BPrevent from being crushedReduce weightLayered productsFlexible pipesEngineeringMaterials processing

The invention discloses a flexible pipe for ocean, wherein the flexible pipe for the ocean comprises a skeleton layer, a lining layer, a compression resistance layer, an anti-pull layer and an outer protective layer from inside to outside. The skeleton layer is a metal skeleton layer with a supporting function, the lining layer and the outer protective layer are both plastic layers, the compression resistance layer comprises a metal support and a plastic substrate which covers the outer portion of the metal support, the anti-pull layer is a spiral fiber reinforced material belt, and the spiral fiber reinforced material belt is coiled on the outer wall of the compression resistance layer. Compared with the prior art, a plastic and metal common processing method is utilized in the flexible pipe for the ocean, and particularly the plastic and metal common processing method is utilized in the compression resistance layer, original flat steel coiling is replaced by the fiber reinforced material processing in the anti-pull layer, and the weight of the flexible pipe for the ocean is reduced correspondingly, and therefore the flexible pipe for the ocean is further convenient to transport and install.

Owner:孟庆义

A prism-type surface plasmon resonance spectrometer angle modulation mechanism

ActiveCN107843558BPrecise angle adjustmentQuick Angle AdjustmentScattering properties measurementsFlow cellLight beam

The invention discloses a prism-type surface plasmon resonance spectrometer angle modulation mechanism. The mechanism comprises a fixing frame, a synchronous rotation mechanism installed on the fixingframe, first and second transmission mechanisms, an integrated prism chip, a flow cell, a wedge-shaped light transmitting end, a CCD receiving end, a compressing mechanism and two rotation arms. Thesynchronous rotation mechanism drives the two rotation arms to synchronously rotate under action of the first transmission mechanism. The wedge-shaped light transmitting end and the CCD receiving endare respectively fixed on one rotation arm and can rotate along with the rotation arm. The extension lines of the rotation shafts of the two rotation arms are located in the center of the top surfaceof the integrated prism chip. The wedge-shaped light transmitting end emits a wedge-shaped light beam to the center of the integrated prism chip and the reflected wedge-shaped light beam irradiates CCD of the CCD receiving end. The compressing mechanism can move downward under the action of the second transmission mechanism to compress the chip and the flow cell. The mechanism can accurately and fast adjust an angle and has a large adjustment range.

Owner:丁利 +4

Nutritive chick embryo food

The invention discloses a nutritive chick embryo food, wherein the chick embryo is prepared from the following steps: (1) selecting eggs, (2) washing eggs, (3) preparing the stock solution and immersing eggs, namely the clean eggs are immersed in the prepared stock solution, (4) hatching into chick embryo, (5) vacuum plastic packaging, (6) sterilizing by heating, (7) cooling and packaging. Firstly the stock solution is prepared, then the eggs is placed into the stock solution, after the eggs are dialyzed by the stock solution, the eggs are taken out and air-dried, the chick embryo is in the vacuum plastic packaging and in the high temperature sterilizing, the chick embryo is cooked in the high temperature sterilizing process, thus retaining the full nutrition of the chick embryo and preventing the loss of the nutrition. The inventive chick embryo is in the vacuum plastic packaging and in the high temperature sterilizing, thus the chick embryo is free from the pollution, the storage life is longer and the selling is more convenient.

Owner:郑毛毛

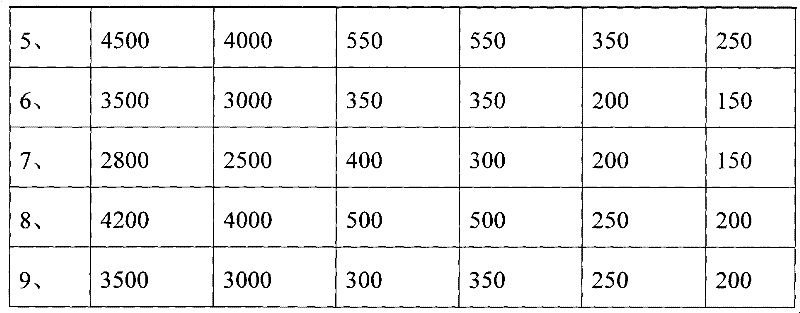

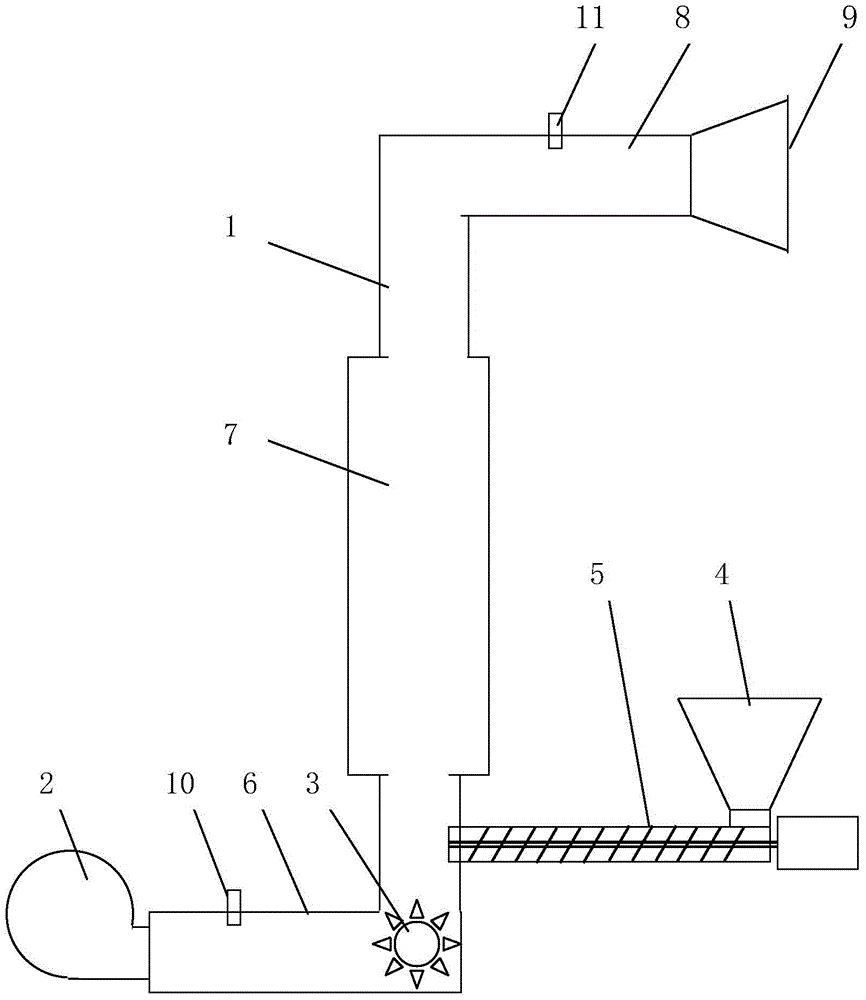

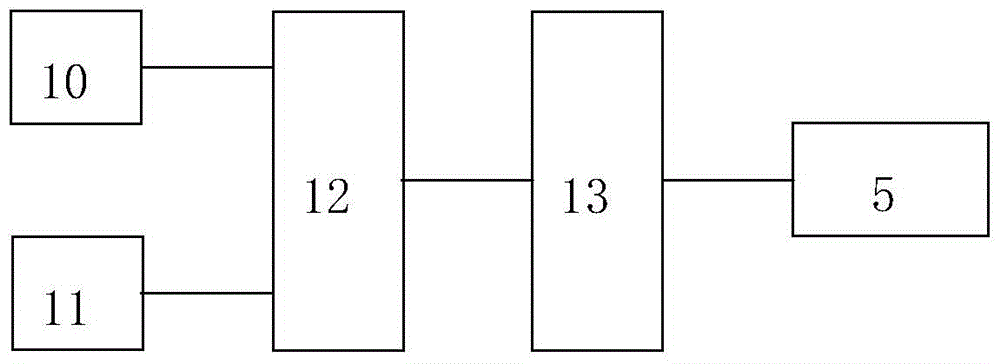

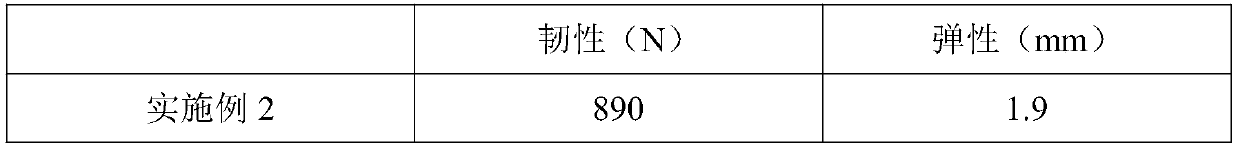

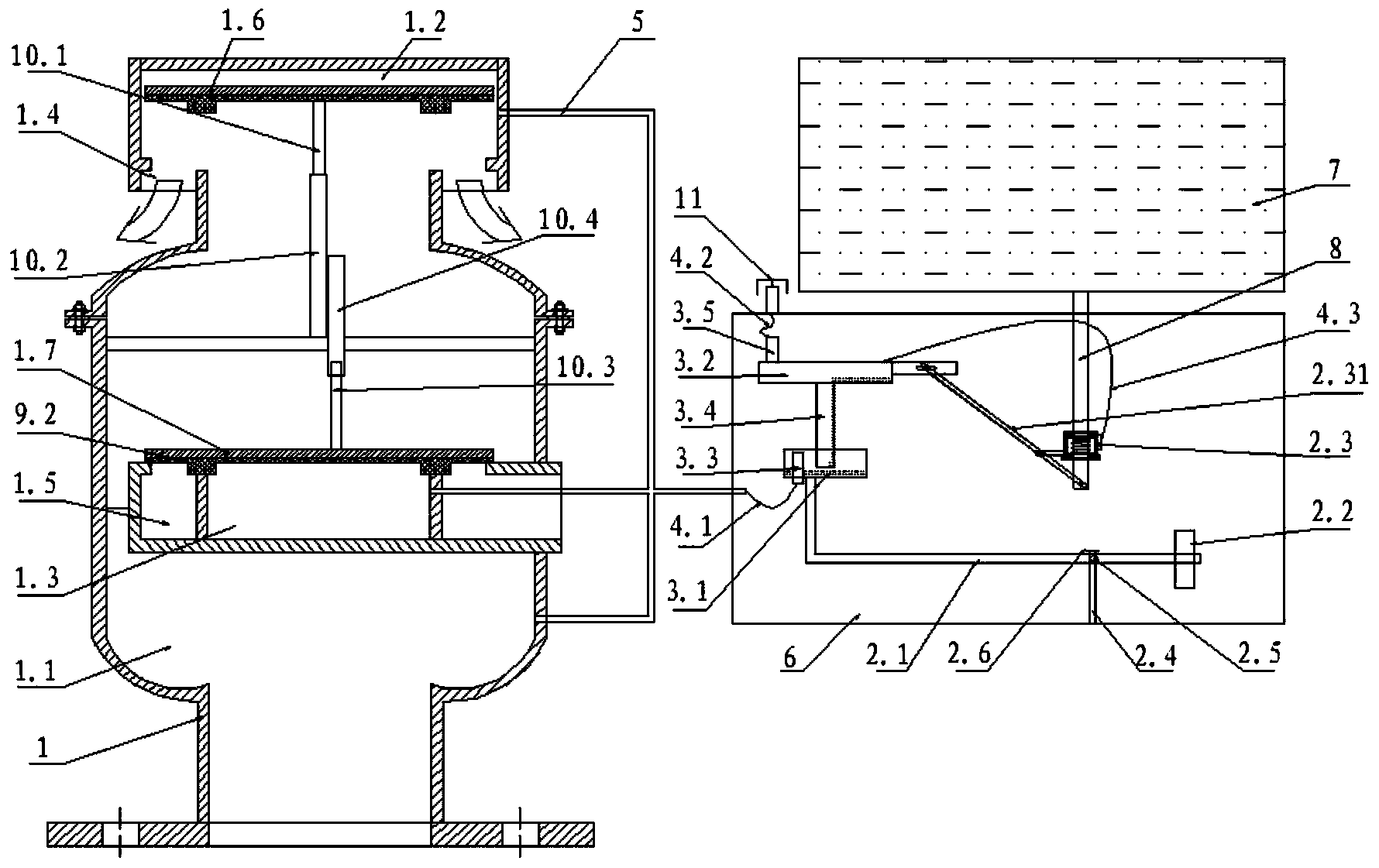

Two-stage airflow powder material drying device

ActiveCN104634086BKeep dryFree from external pollutionDrying solid materialsDrying machinesPulp and paper industryDrying time

The invention relates to a drying device, in particular to a double-level airflow powdery material drying device. The double-level airflow powdery material drying device comprises a vertical drying pipe, a induced draft fan, a pulverizer, a mixer and a spiral feeder; the induced draft fan is connected to the bottom end of the vertical drying pipe through an air inlet pipe, the pulverizer is arranged in the pipe located at the joint, the mixer is arranged on the side face of the vertical drying pipe through the spiral feeder, the center of the vertical drying pipe is an expansion portion, and the top end of the vertical drying pipe is connected with a discharge hole through a discharge pipe; an inlet air temperature sensor is arranged on the air inlet pipe, a discharge temperature sensor is arranged on the discharge pipe, and the inlet air temperature sensor and the discharge temperature sensor are connected through a circuit and the spiral feeder. According to the double-level airflow powdery material drying device, the drying time of material granules is increased, the hot gas around the material granules is increased, secondary smashing of the material granules in the pipe is achieved, therefore, the drying degree of powdery materials is improved, clustering phenomenon is avoided from occurring, the fact that the powdery materials cannot be polluted by the outside world is guaranteed, and the product quality is improved.

Owner:GUANGDONG JIALONG FOOD

Compound radices lithospermi liniment for burns and scalds

InactiveCN105726964AEasy topical applicationNo pollutionHydroxy compound active ingredientsPharmaceutical non-active ingredientsBenzoic acidBletilla striata

The invention discloses a compound radices lithospermi liniment for burns and scalds. The compound radices lithospermi liniment mainly comprises the components in parts by weight: 30-80 g of radices lithospermi, 30-80 g of rheum officinale, 30-80 g of bletilla striata powder, 50-125 g of polyvinyl alcohol, 5-15 g of benzoic acid, 10-24 g of borneol, 30-50 g of glycerin, 5-10 g of Tween-80, 200-600 g of purified water and 500-900 g of ethanol. The liniment disclosed by the invention is a semi-solid preparation; after a solvent dries, a film is formed; the liniment is easy to elute and convenient for local application of skins, does not pollute clothes, enables a wound surface to avoid external pollution as well, is high in stability, can keep good stability in a polarity temperature environment and is wide in application range; the borneol has bacteriostatic and anti-inflammatory effects and has no negative interference on drug properties of radices lithospermi and rheum officinale.

Owner:CHENGDU AIBIKE BIOTECH

Tissue engineered skin containing living cells and its preparation method

The invention belongs to the technical field of tissue engineering and particularly relates to tissue engineering skin containing living cells and a preparation method of the tissue engineering skin. The tissue engineering skin comprises an epidermis layer, an imitated corium layer and a corium layer, wherein the imitated corium layer contains keratinocytes, fibroblasts and a bio-scaffold material, and the density ratio of the keratinocytes to the fibroblasts is (0.1-0.2) to 1; and the bio-scaffold material contains gelatin, chitosan, glutamine and hyaluronic acid in a mass ratio of (6-7) to (1.5-2) to (0.5-1) to 1. The tissue engineering skin prepared by virtue of the preparation method has good biocompatibility, plasticity and mechanical strength and can be used for repairing the surface of a wound with a good effect.

Owner:GUANGZHOU RAINHOME PHARM&TECH CO LTD

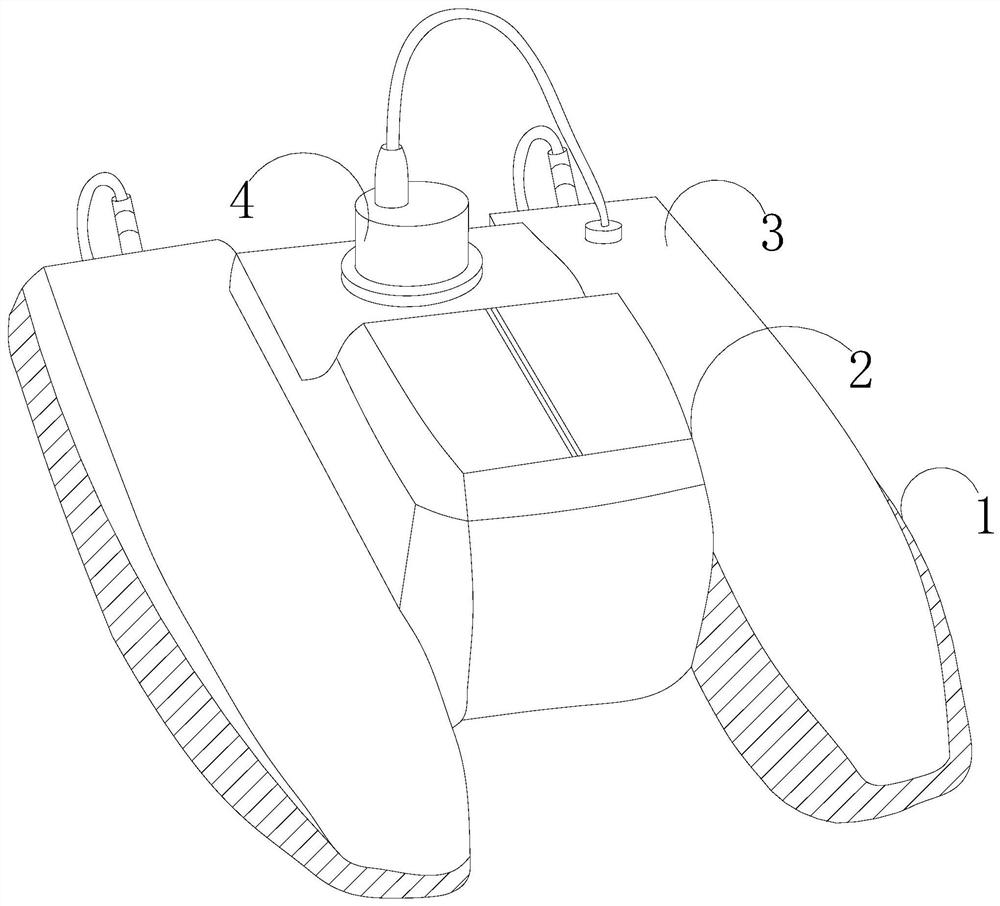

Hydrological monitoring environment-friendly ship

InactiveCN112874702AGuaranteed tightnessDry enoughWithdrawing sample devicesVessel partsElectric machineryEnvironmental geology

The invention discloses a hydrologic monitoring environment-friendly ship. The ship structurally comprises an anti-collision strip, a collecting box, a ship body and a motor, the anti-collision strip is arranged on the edge of the ship body, the collecting box and the motor are arranged on the ship body, the collecting box is provided with a turning cover, a sampling bottle, a containing groove, a fixing base, a sampling device and a partition plate, the turning cover is hinged to the collecting box, the containing groove is formed in the collecting box, and the fixing base is arranged in the containing groove. The sampling bottle is matched with the sampling device, a liquid inlet formed in the sampling bottle is communicated with a water outlet pipe, and the water inlet pipe is matched with a winder and can extend and go deep into a river for sampling; and liquid needing to be collected is pumped into the sampling bottle through a water pump to be stored, so that the defect that in the prior art, a sampling bottle is directly filled with samples to soak the sampling bottle is overcome. The method can guarantee sealing performance of the sampling bottle, and can be guaranteed that the containing groove is dry enough.

Owner:郑培智

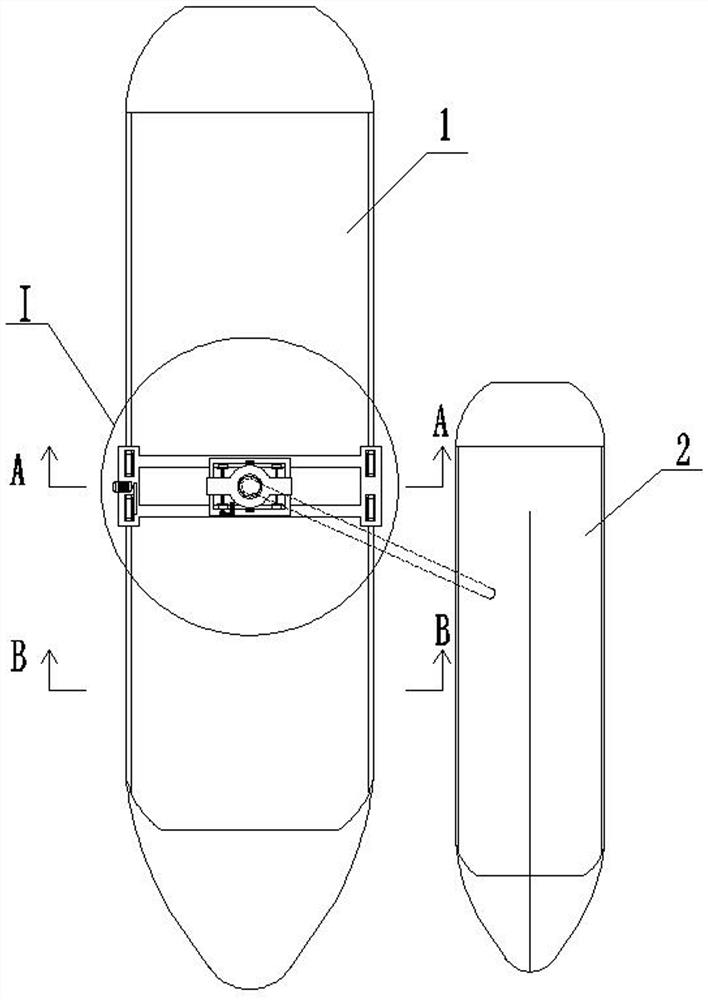

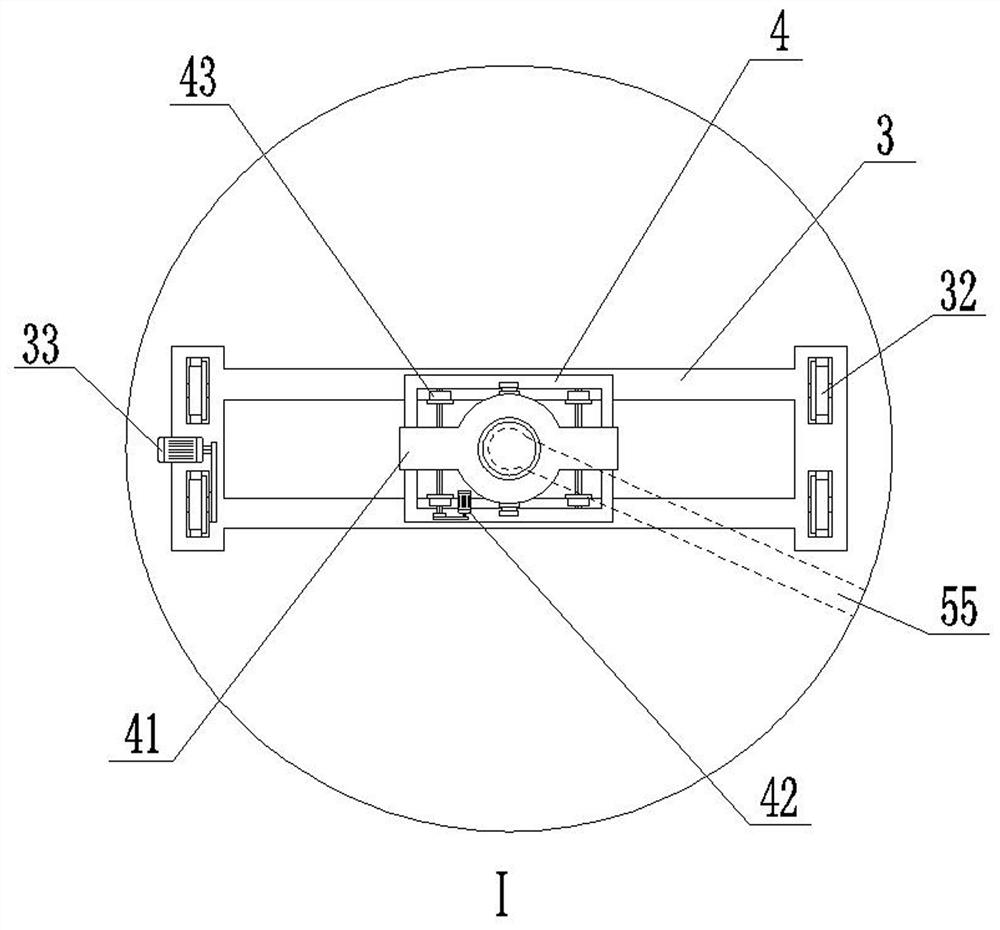

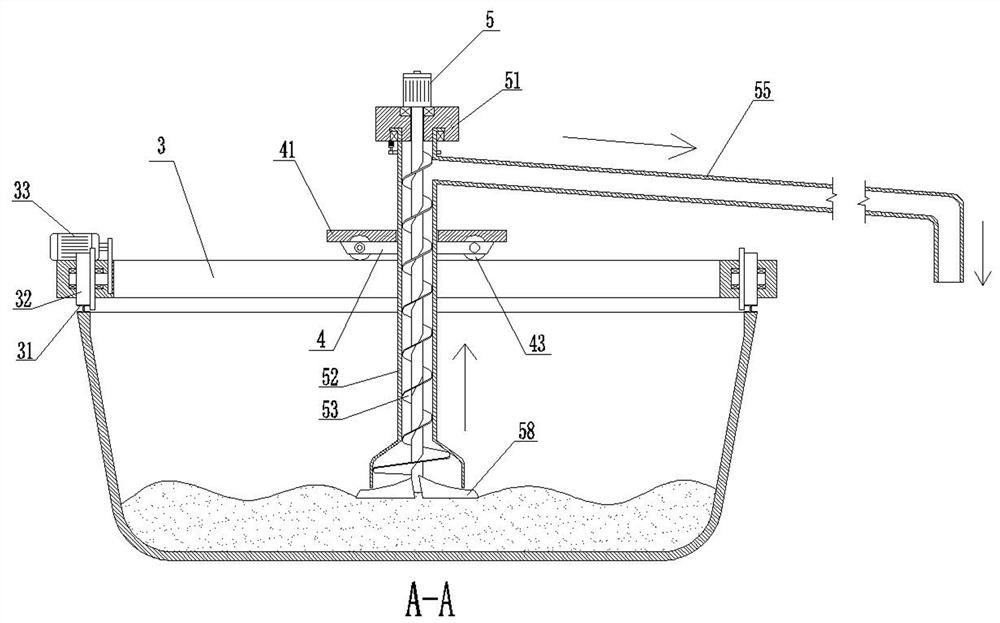

Particle material ship side-by-side lightering method

InactiveCN113386910AFree from external pollutionHigh degree of automationCargo handling apparatusPassenger handling apparatusHydraulic cylinderElectric machinery

The invention discloses a particle material ship side-by-side lightering method. The method comprises the following steps: (1) after a transport ship is anchored, enabling a barge to get close to one side of the transport ship in parallel; (2) starting a particle material ship side-by-side lightering system, starting a rotating motor, rotating out the tail end of a transverse material conveying pipe, and enabling an outlet to be aligned with a cargo bin of the barge; (3) starting a material conveying motor, and enabling a packing auger to continuously convey the particle materials in the cargo bin of the transport ship from the vertical material conveying pipe to the transverse material conveying pipe to the cargo bin of the barge; (4) enabling a longitudinal moving walking vehicle to be matched with a transverse moving trolley, enabling a hydraulic cylinder to perform lifting action, and enabling the vertical material conveying pipe to walk to all positions of a cabin to suck all materials to the barge; and (5) starting the rotating motor to retract the tail end of the transverse material conveying pipe to the position in the transport ship, and completing lightering operation. The method is applied to lightering operation of bulk particle materials, and has the effects of being high in lightering efficiency, convenient to operate and capable of achieving the effect of totally-closed material conveying.

Owner:余勇

Pilot-operated type automatic fluid infusion respiration valve

InactiveCN103953765AControl feasibilityControl reliabilityEqualizing valvesSafety valvesFluid infusionMedicine

The invention relates to a pilot-operated type automatic fluid infusion respiration valve which comprises a valve body, a pilot device and a fluid infusion device, wherein the pilot device is connected with the inner chamber of the valve body, an expiration cavity and an aspiration cavity through a pilot pipe; the fluid infusion device comprises a balance bar, a balance block and a control valve; the pilot device is arranged at one end of the balance bar; the balance block is arranged at the other end of the balance bar; a control handle of the control valve is fixedly connected with one end of the balance bar; a liquid inlet of the control valve is connected with an external fluid infusion source; a liquid outlet of the control valve is connected with the pilot device. The pilot-operated type automatic fluid infusion respiration valve has the benefits that as the lever principle is utilized, the fluid infusion amount is controlled precisely, the expiration pressure and the aspiration pressure are always guaranteed in conformity with requirement for setting pressure; as the pilot pipe technology is adopted, the liquid volatilization is effectively reduced, the feasibility and reliability of liquid pressure control valve body in expiration and aspiration are guaranteed; the technology solves the problem that the traditional physical counter weight respiration valves are easy to leak.

Owner:左萌

Bottle used for eyedrops for contact lenses

A bottle used for eyedrops for contact lenses comprises an outer bottle, wherein an inner bottle is arranged in the outer bottle, and the outer bottle and the inner bottle are respectively provided with a first bottle cap and a second bottle cap. The bottle used for the eyedrops for the contact lenses is good in sealing performance, ensures that the eyedrops are not polluted by the outside environment and ensures hygiene and health.

Owner:江苏博思源防火材料科技有限公司

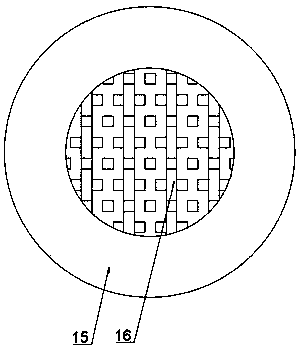

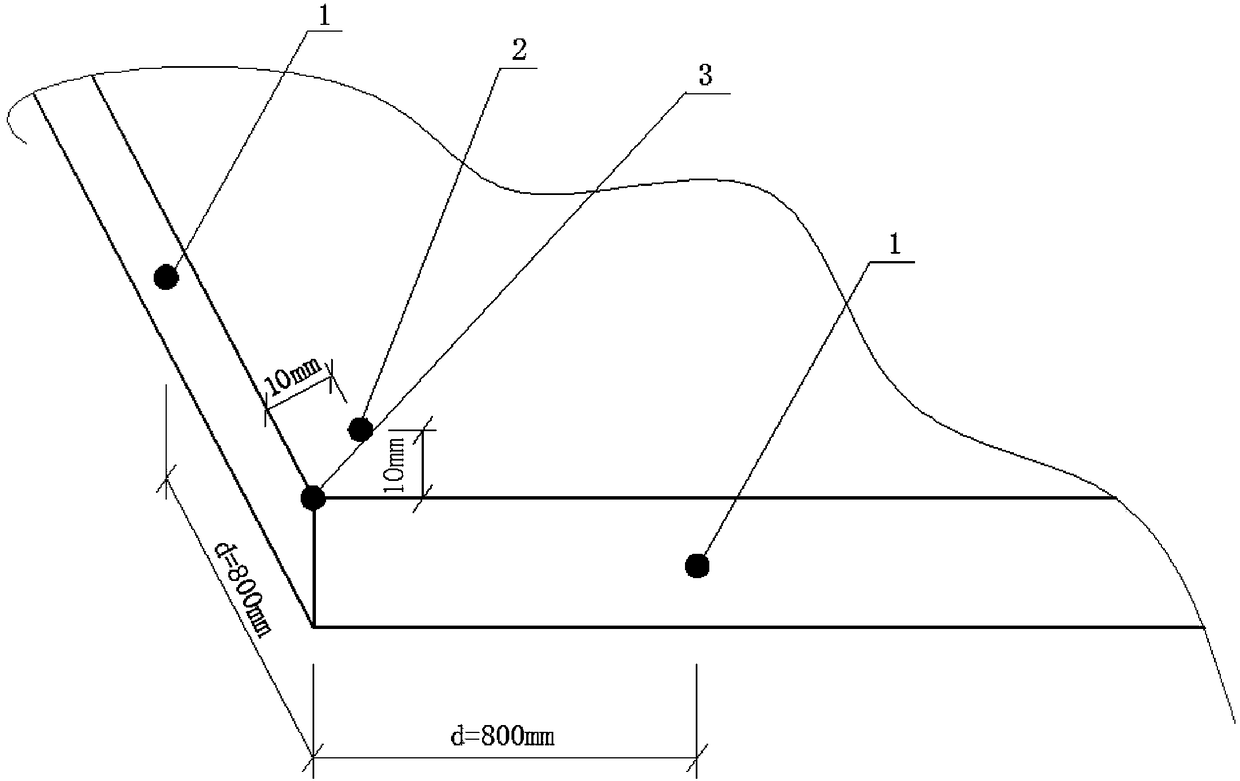

An integrated prism assembly for surface plasmon resonance detection system

ActiveCN107843577BReduce lossesSave time at workMaterial analysis by optical meansSurface plasmonPrism

The invention discloses an integrated prism assembly for a surface plasmon resonance detection system. The integrated prism assembly comprises a chip outer box, a chip clamping box and an integrated prism chip. The chip outer box is a hollow regular hexahedron with front and rear open sides. The top surface of the chip clamping box is provided with an open hole. A cavity for accommodating the integrated prism chip is formed in the chip clamping box. The left and right sides of the chip clamping box are respectively provided with two through holes for allowing incident light and outgoing lightto pass. The front end of the chip clamping box is provided with a jack allowing an insertion pole for a chip ingress and egress mechanism to enter. The integrated prism chip has three optical surfaces, the top surface is a fully reflecting surface and is plated with a metal film and other two optical surfaces are respectively located in two sides of the top surface, are planes or cylindrical surfaces and are respectively used as the light inlet surface and the light outlet surface. The three optical surfaces are corresponding to the hole on the top surface of the chip clamping box and throughholes in two sides. The integrated prism assembly has high detection accuracy and detection efficiency, is easy to operate and realizes a low production cost.

Owner:丁利 +4

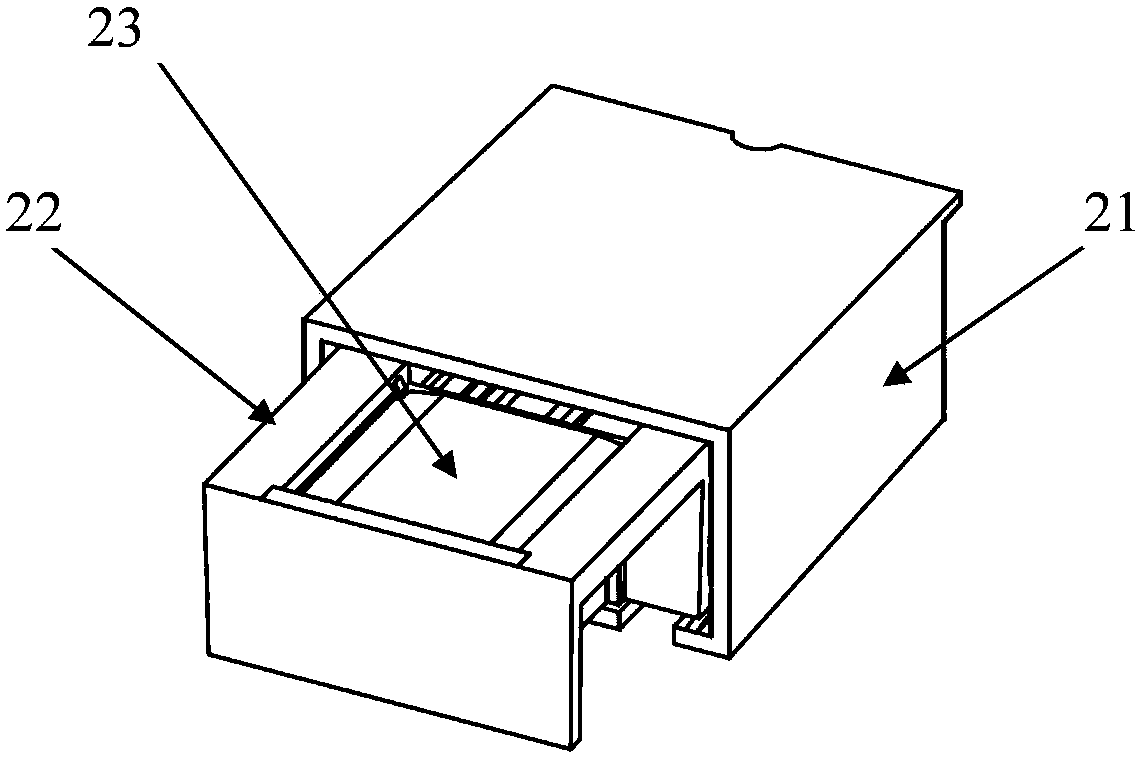

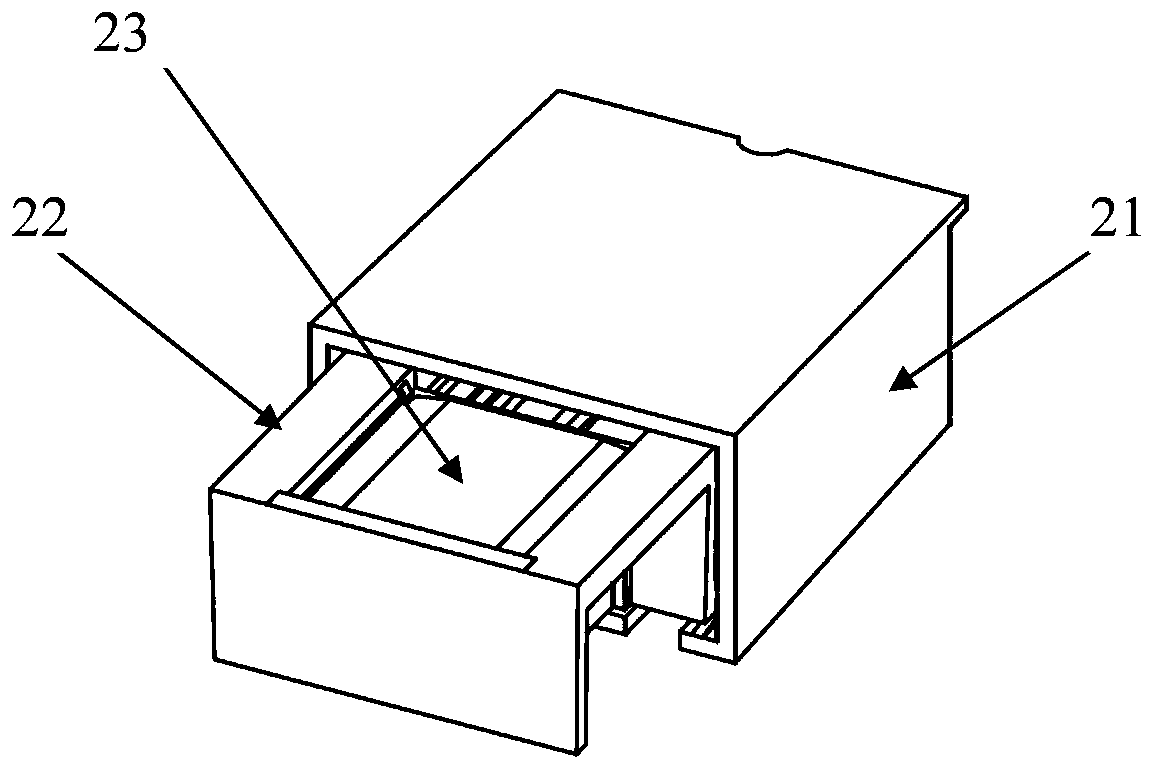

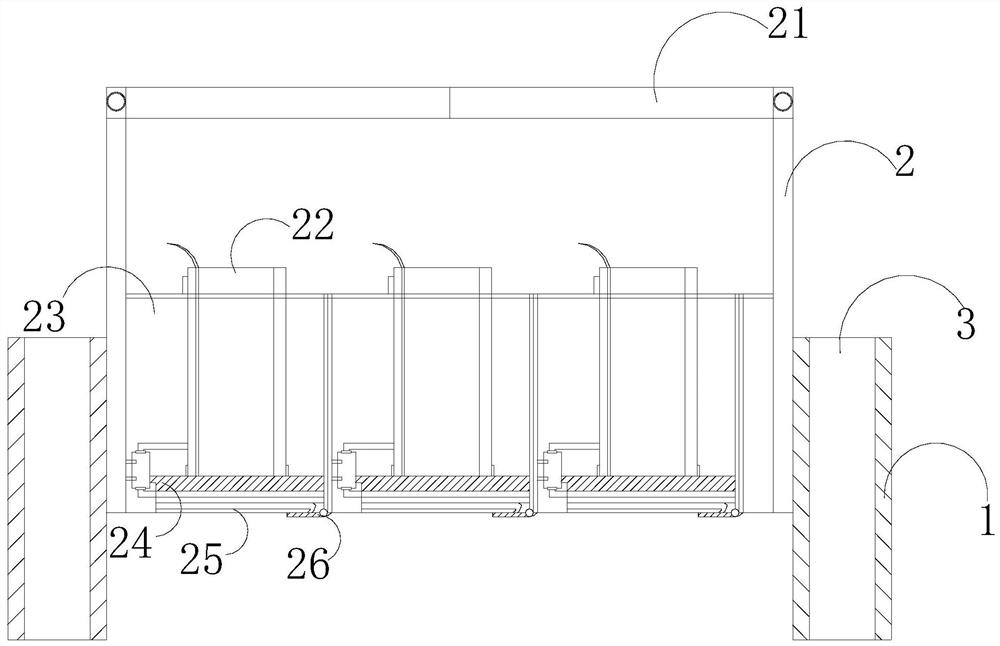

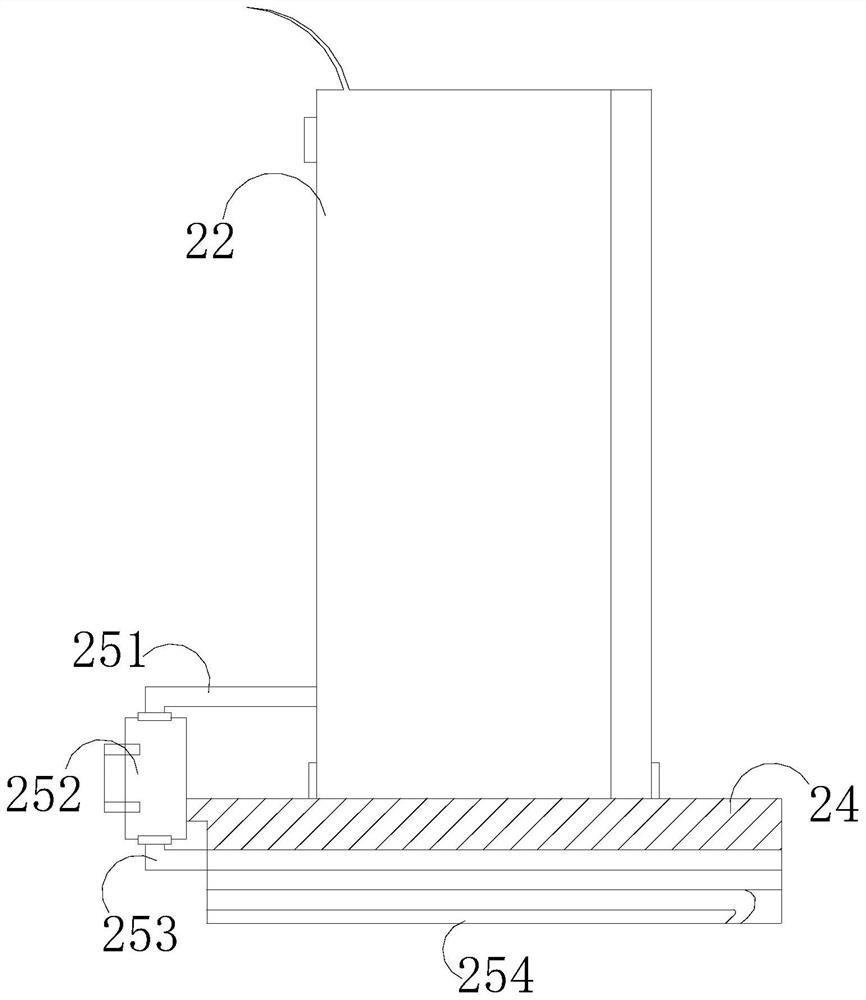

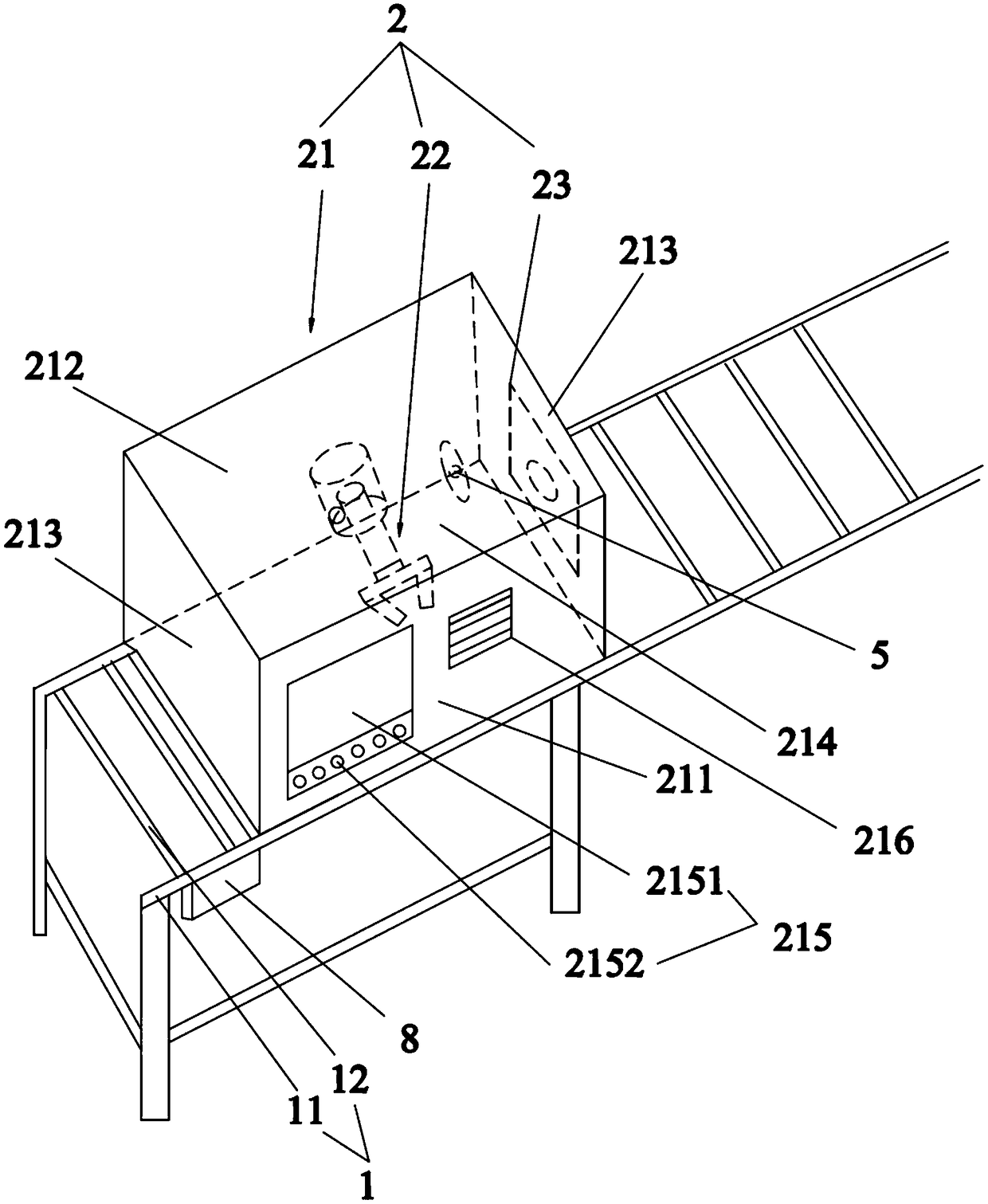

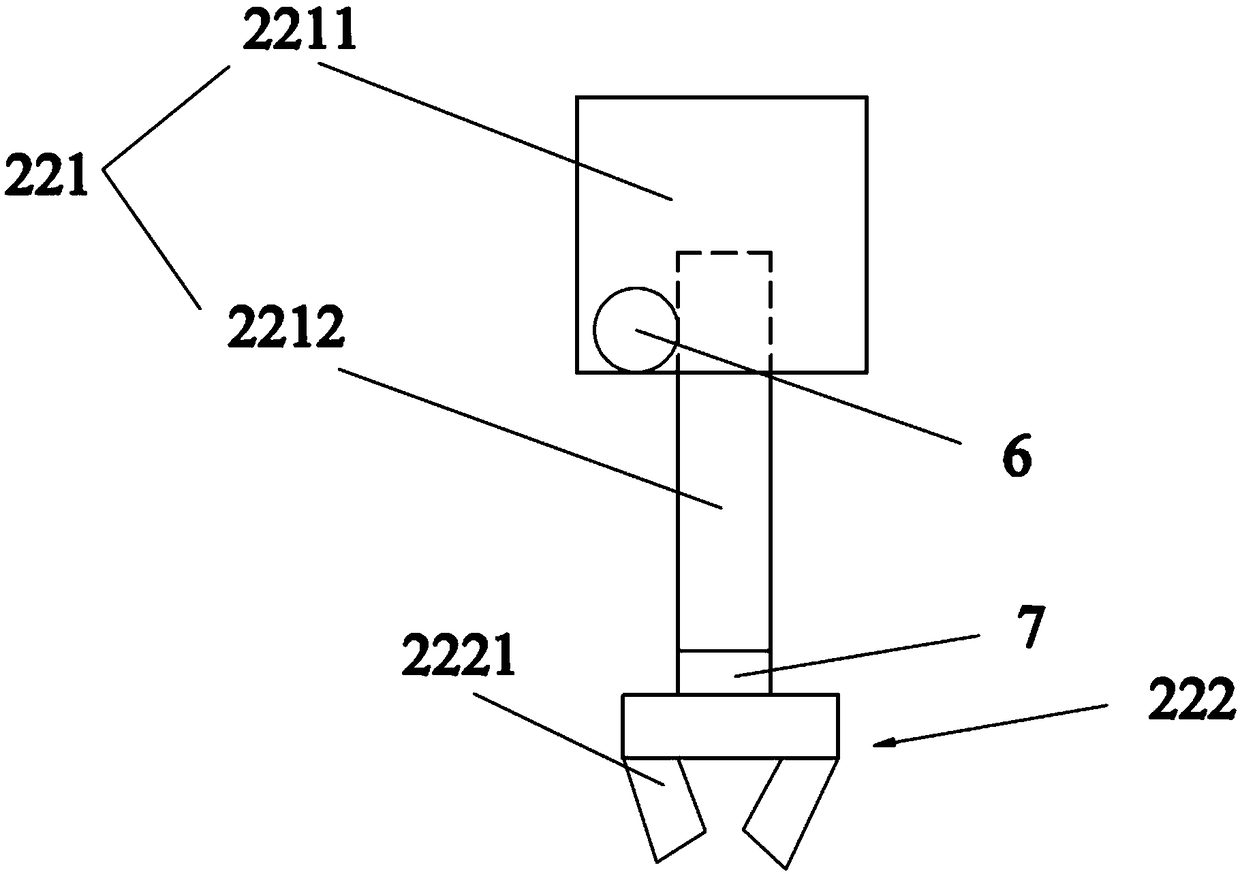

Device for cleaning head cover of battery and method of cleaning head cover of battery

PendingCN108704902AAvoid damageReduce scrap rateCleaning processes and apparatusEngineeringColloidal particle

The invention belongs to the technical field of cleaning devices, and in particular relates to a device for cleaning a head cover of a battery. The device comprises a conveying mechanism (1) and a laser cleaning mechanism (2) for cleaning the head cover of the battery on the conveying mechanism (1), wherein the laser cleaning mechanism (2) comprises a cleaning box (21), a grabbing device (22) connected to the cleaning box (21) and a positioning device (23) arranged in the cleaning box (21). The device provided by the invention can be used for removing colloidal particles and electrostatic particles attached to the edge of the head cover, and meanwhile can prevent the battery from being damaged. The device is relatively small in size, high in cleaning speed and pollution-free. The energy consumption in the production process can be also reduced, the production cost is lowered, and long-term development of an enterprise is facilitated. In addition, the invention also discloses a method of cleaning the head cover of the battery.

Owner:JIANGSU ZENIO NEW ENERGY BATTERY TECH CO LTD

A Welding Process of Stainless Steel Control Box

ActiveCN102922097BGood welding performanceFree from external pollutionArc welding apparatusSlagAlloy

The invention discloses a welding process of a stainless steel control box. The welding process is characterized in that the wall thickness of the control box is 7 millimeters; a V-shaped or U-shaped or X-shaped groove is formed at a welding position; for a welding piece, a filling welding wire is subjected to oil removal and descaling; for welding parameters, welding current is 240 to 260A, arc length is 0.5 to 3 millimeters, arc voltage is 8 to 10V, welding speed is 5 to 10 millimeters / second, and protection airflow is carbon dioxide gas; direct current is adopted for welding, and an electrode serves as an arc carrier and also serves as a welding line filling material; the electrode comprises an alloy or non-alloy metal core wire and a welding rod cover, and the cover is used for protecting a welding line from being damaged due to air and stabilizing arc, gives rise to forming a slag layer, and protects the welding line to be formed; and an electric welding rod is a titanium welding rod or an alkaline welding rod. The welding process is simple to operate and has a good welding effect on a stainless steel plate, the welding line is flat and smooth with good airtightness, and a component in the control box is protected from outside pollution, and is ensured to be reliable in performance.

Owner:STATE GRID CORP OF CHINA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com