Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Facilitate serial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

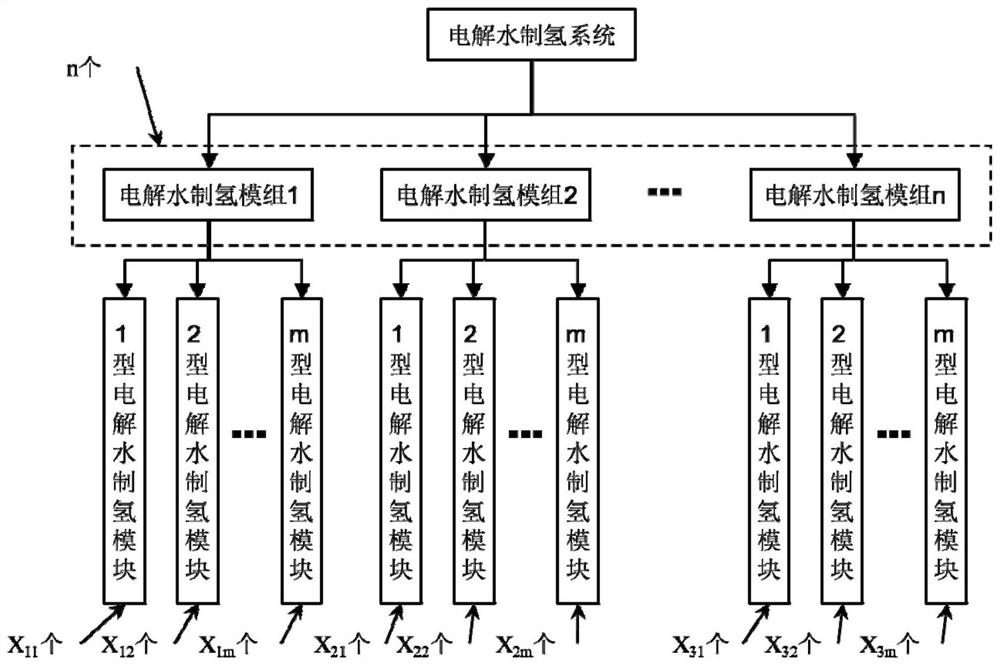

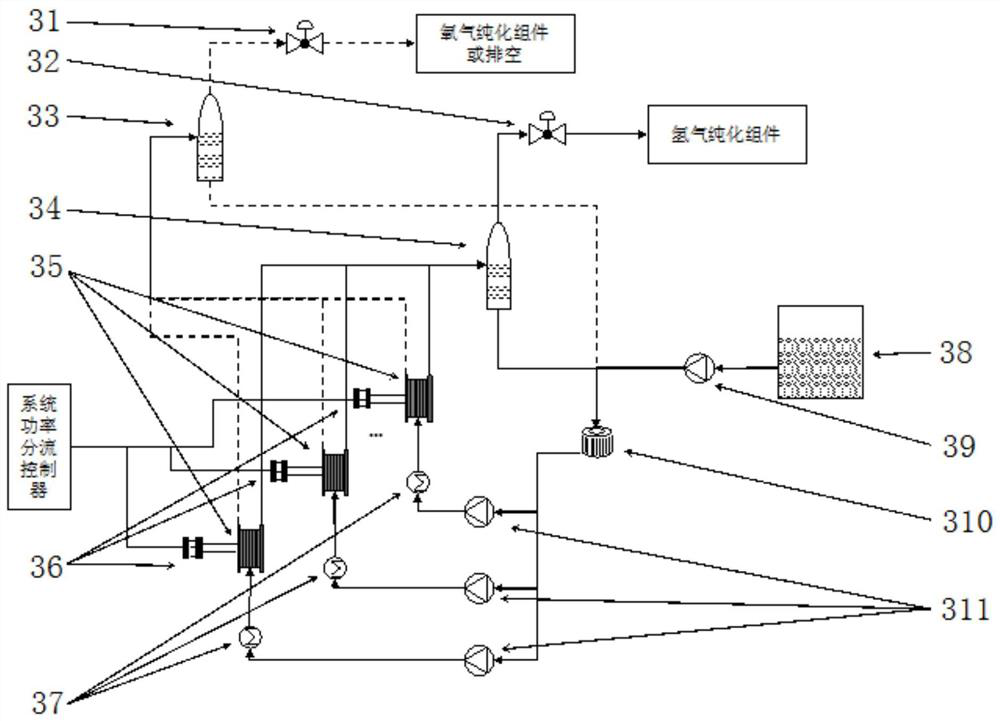

Large water electrolysis hydrogen production system with wide power fluctuation adaptability and control method

PendingCN111826669AImprove the energy consumption efficiency of hydrogen productionImprove the adaptability to wide power fluctuationsCellsThermodynamicsElectrolysed water

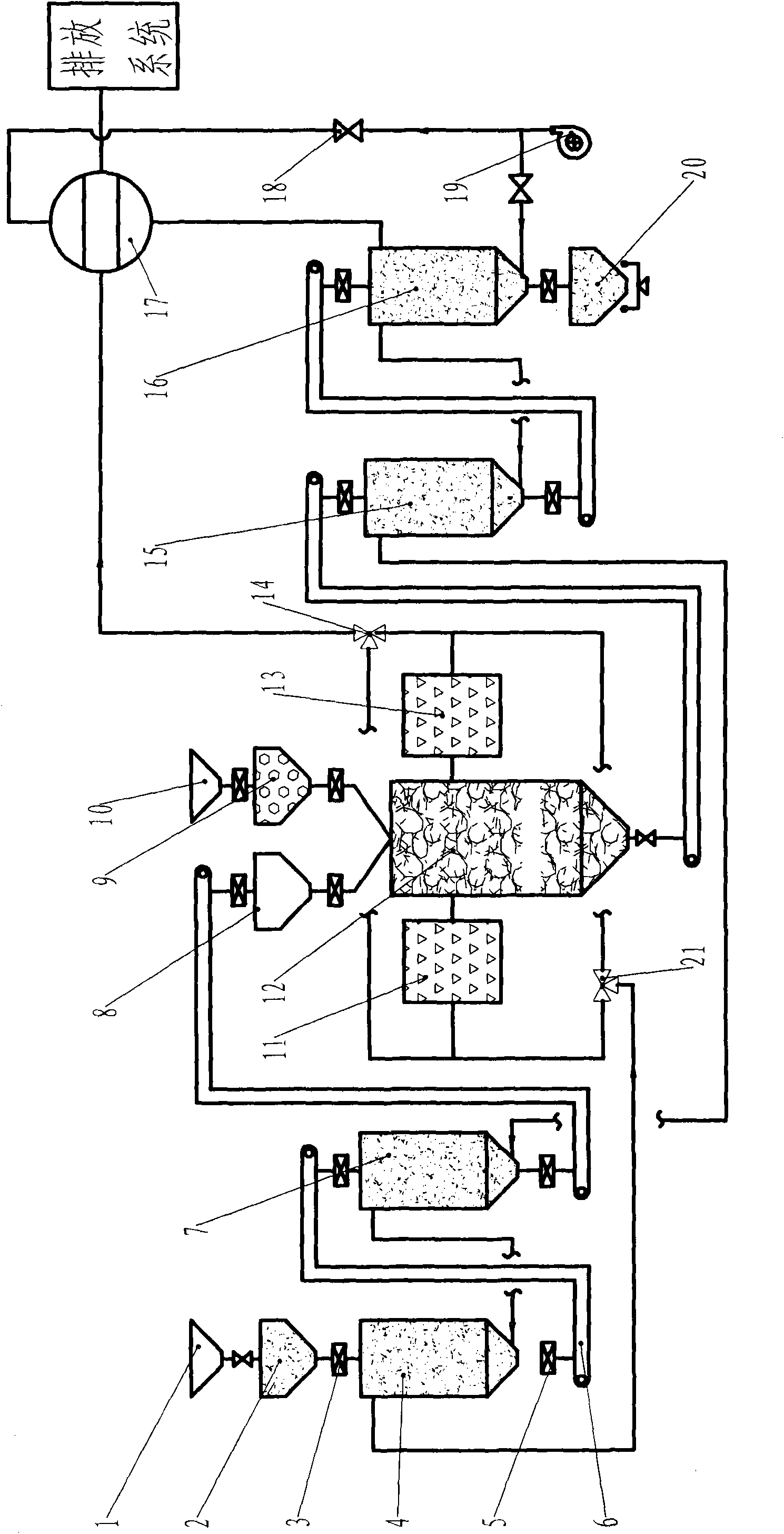

The invention relates to a large water electrolysis hydrogen production system with wide power fluctuation adaptability and a control method. The system comprises: a plurality of water electrolysis hydrogen production module groups which are arranged in parallel; a system power division controller, which is configured to be used for power distribution and control of the water electrolysis hydrogenproduction module groups in the water electrolysis hydrogen production system; each water electrolysis hydrogen production module group comprises a plurality of water electrolysis hydrogen productionmodules with different power levels and a module power division controller, the module power division controller is configured to be used for power diversion control of a water electrolysis hydrogenproduction module in the module group. The module power division controller is connected to the system power division controller, and the water electrolysis hydrogen production modules in the water electrolysis hydrogen production module groups share one module manager used for temperature, alkali liquor circulation and gas-liquid separation control and a hydrogen purification assembly used for hydrogen purification. Compared with the prior art, the hydrogen production energy consumption efficiency and wide power fluctuation adaptability can be improved, the instantaneous response speed is increased, and the power loading cost is reduced.

Owner:TONGJI UNIV

Biodegradation plastics with high-content of starch for producing tableware and method of producing the same

The invention discloses biodegradable plastics which is rich in starch and used to produce dining tools and a preparation method thereof; first, the starch is refined, dried and added in silane coupling agent to be mixed evenly at high speed; and then talc and calcium carbonate are respectively added in to be stirred at medium speed; polypropylene is added in to be stirred at medium speed; and processing aid PE wax, plasticizer EVA and antioxidant DLTP are added in to be stirred at low speed; the materials are mixed and stirred in a cold mixing boiler at low speed, and then added into a three-roll sheet machine to produce sheets. The invention solves the problems of the poor interfacial compatibility and the thermo-plastic performance in the prior art, and is characterized in high content of starch, full biodegradation, sanitation and environmental protection.

Owner:ANHUI DELIN ENVIRONMENTAL PROTECTION DEV GRP

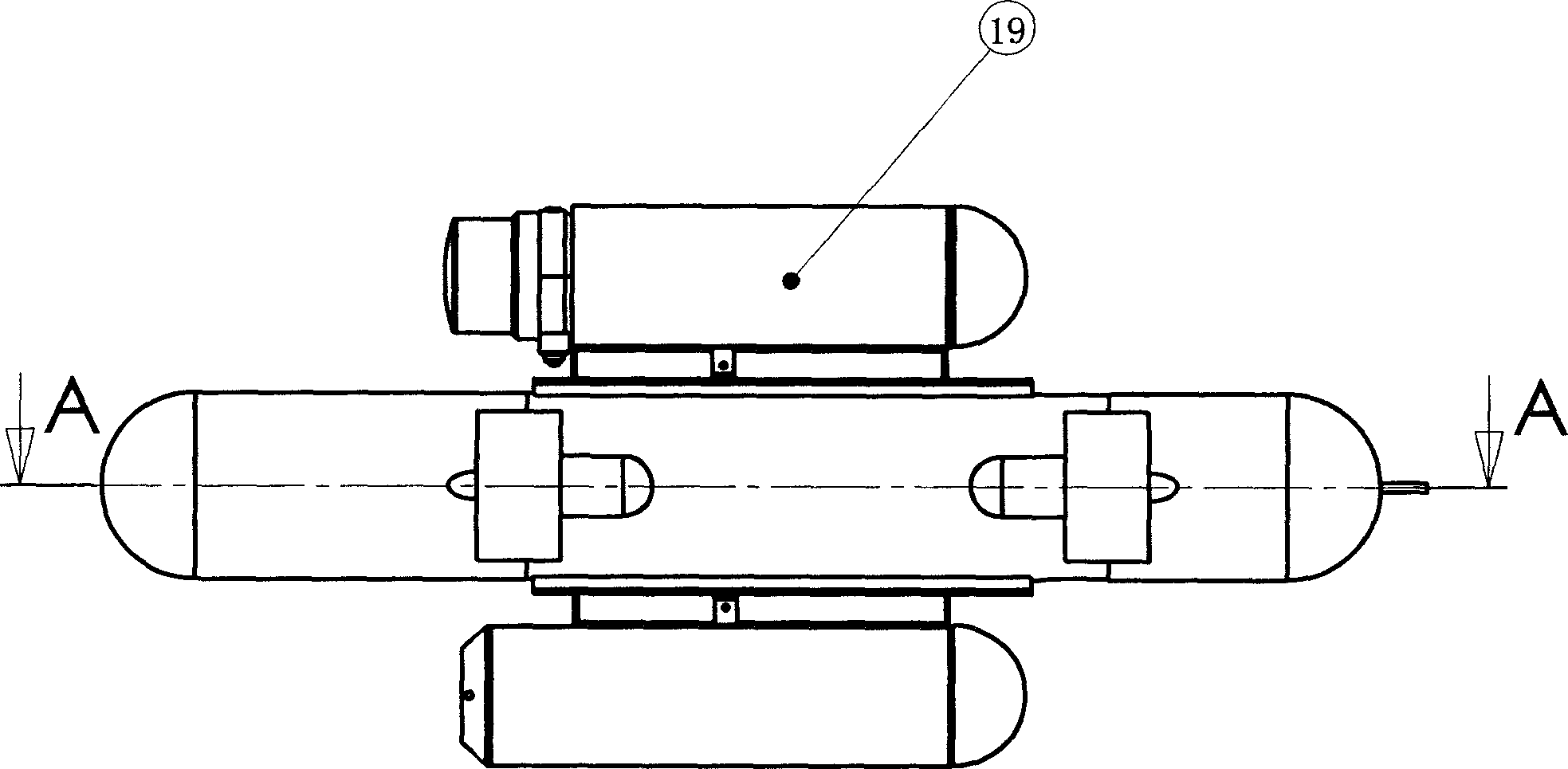

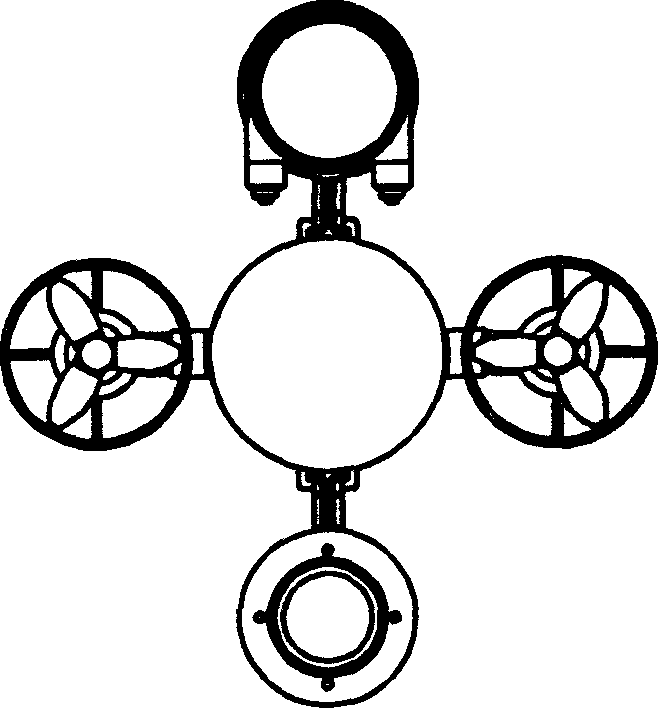

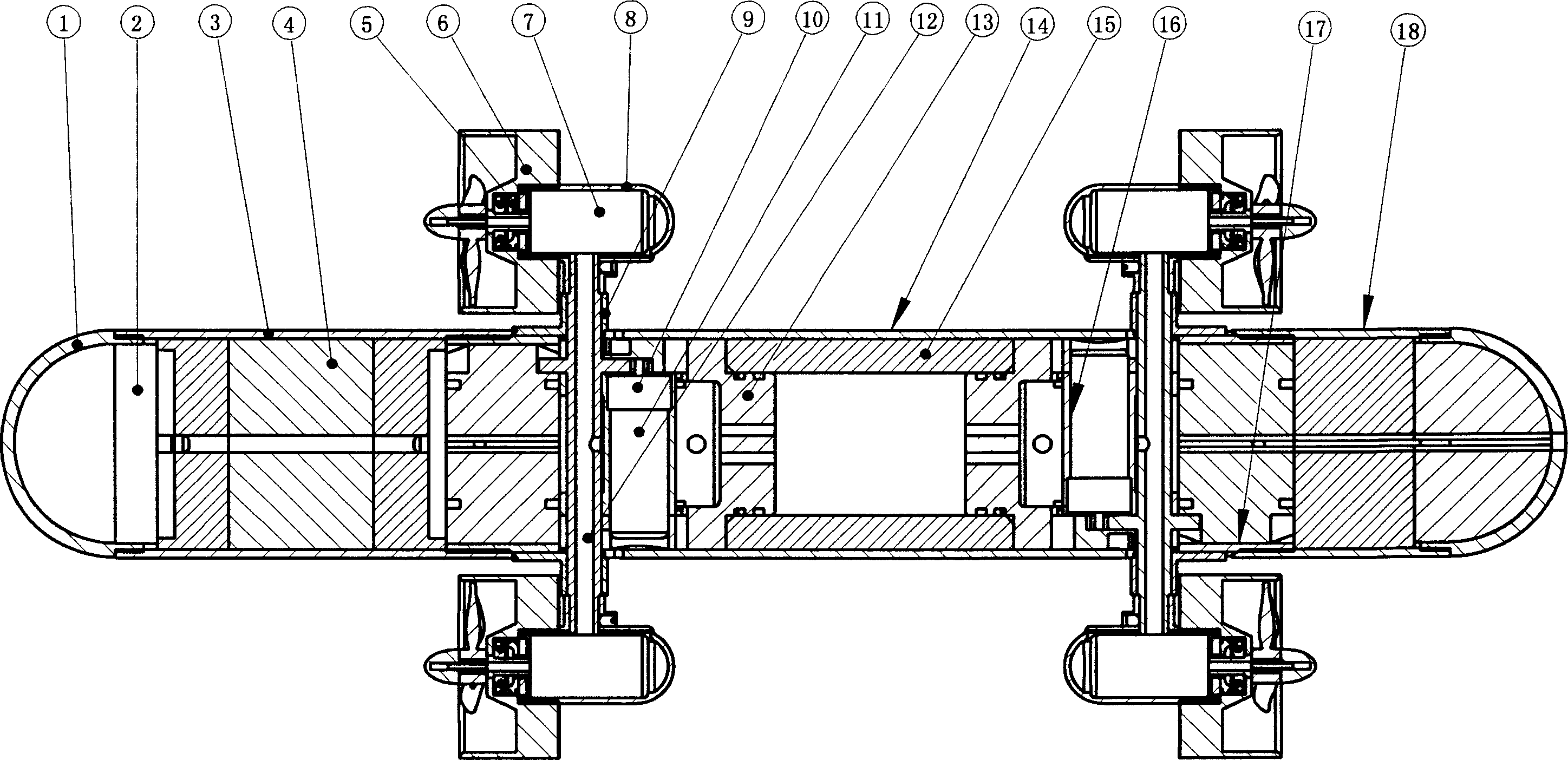

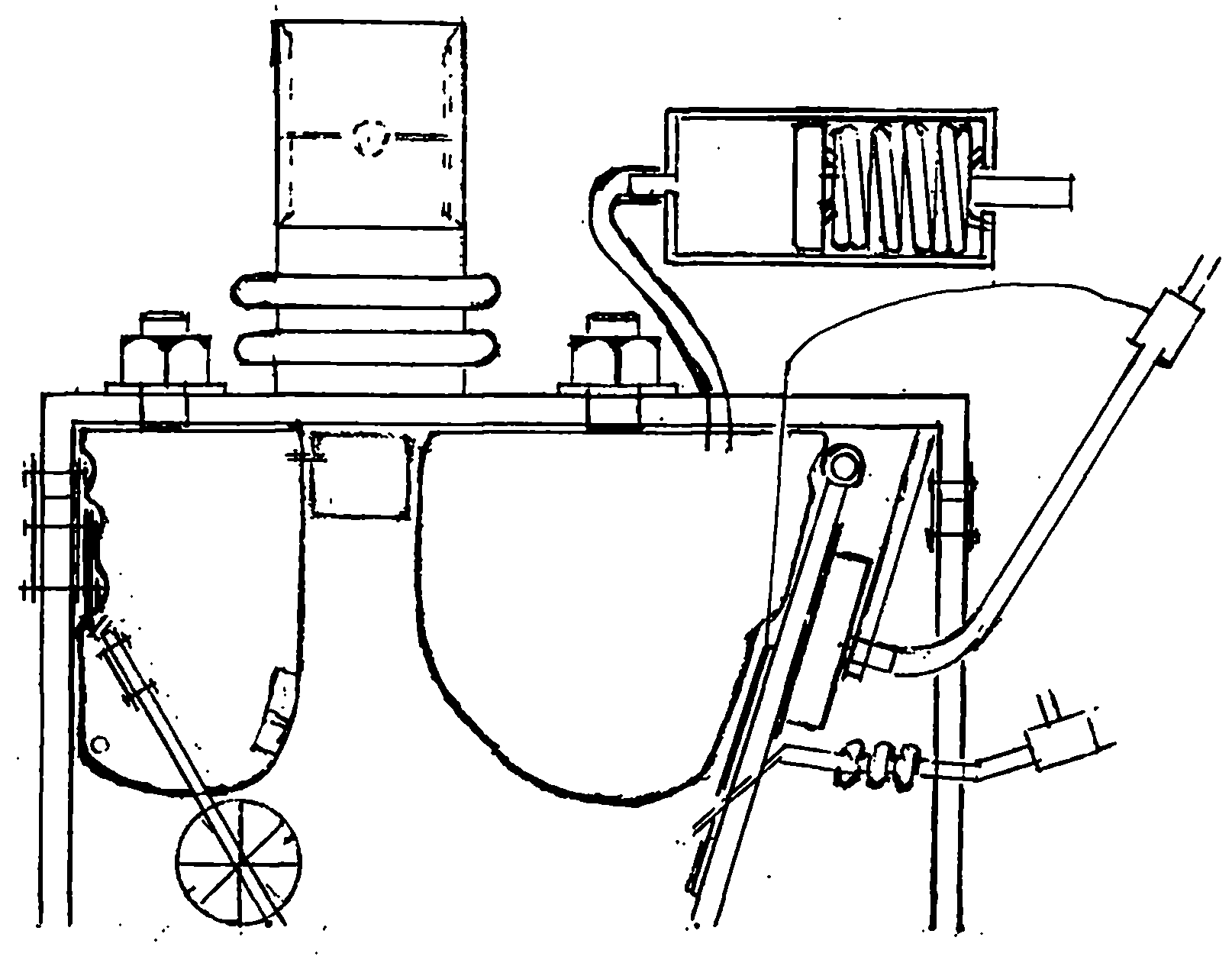

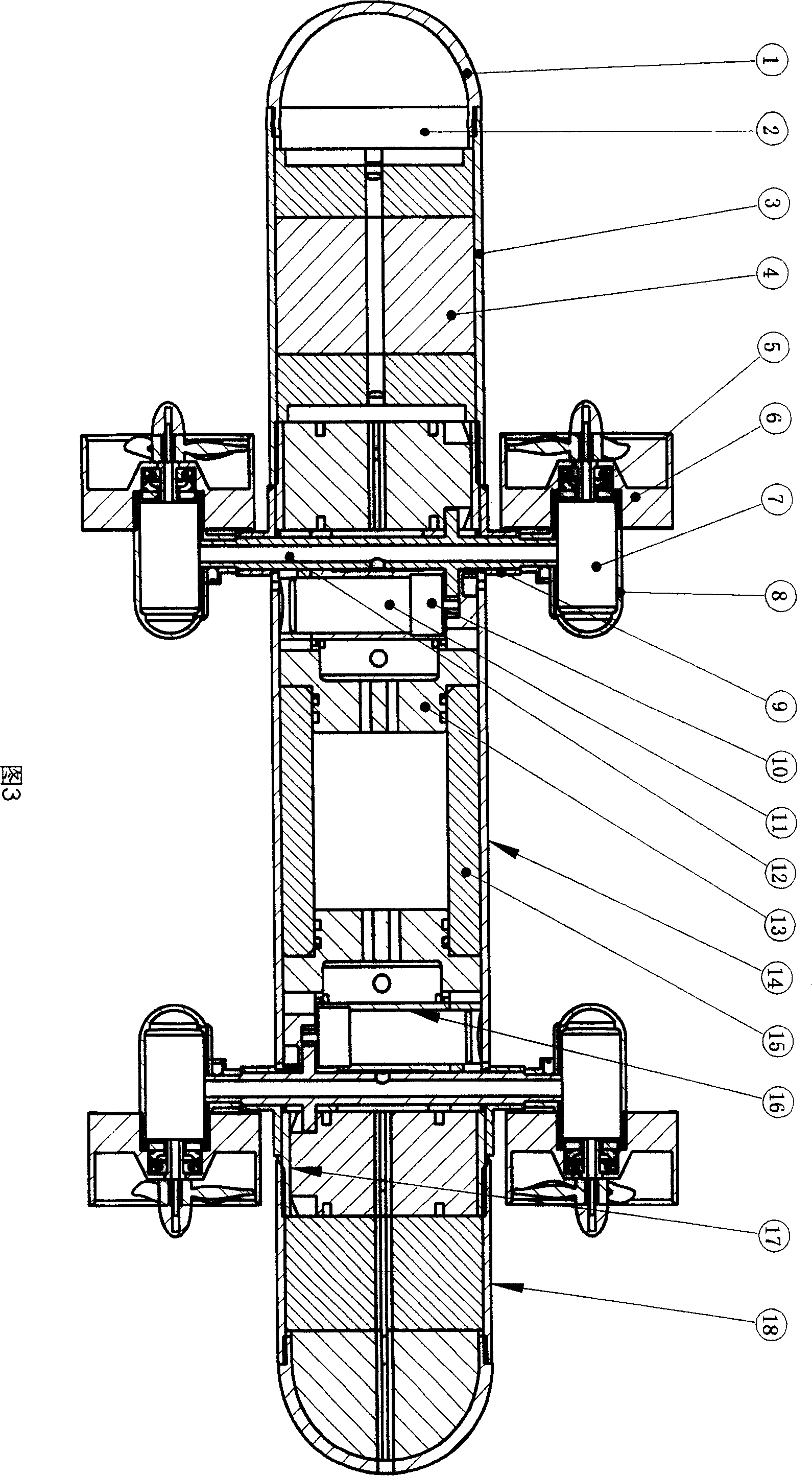

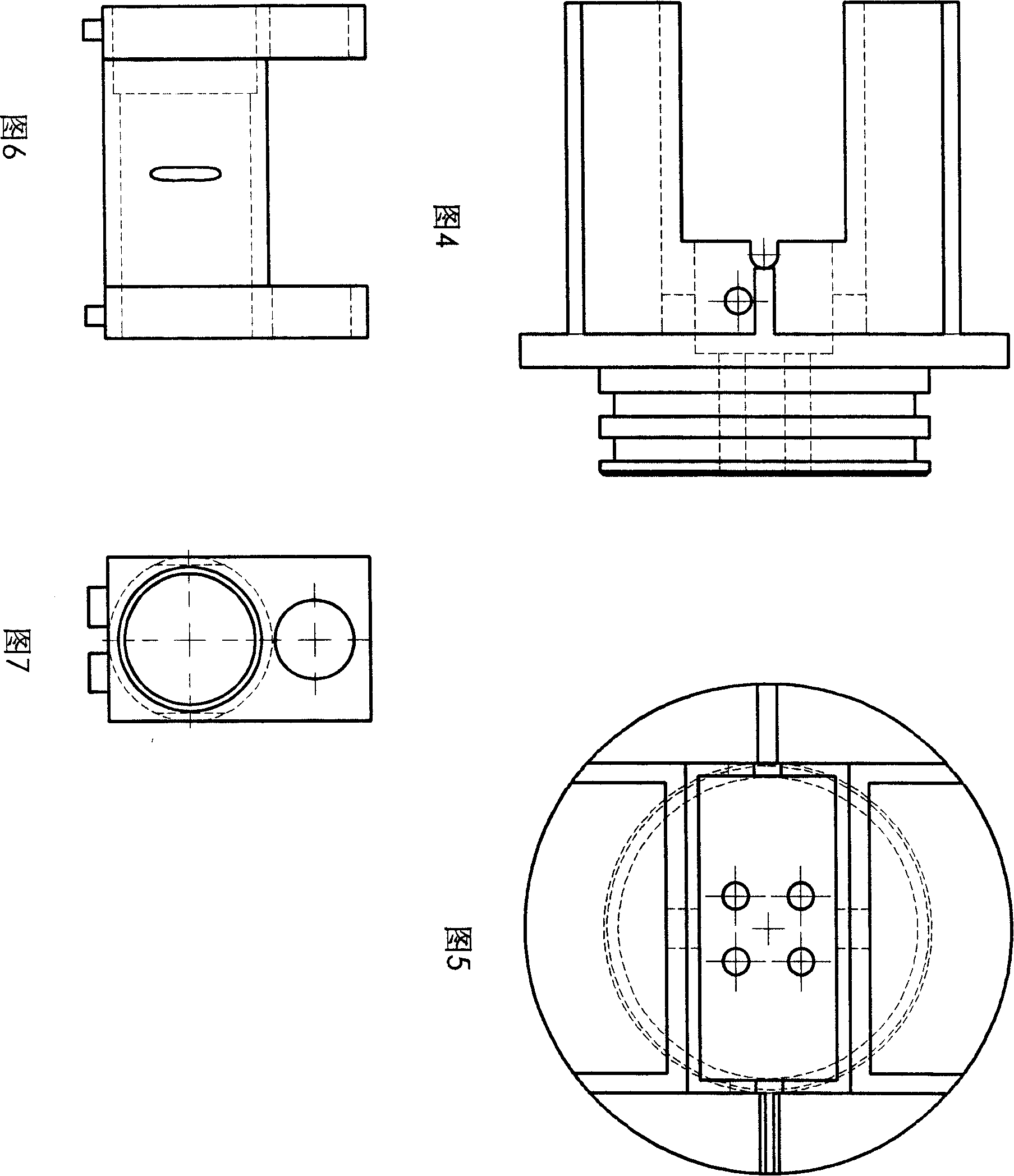

Small underwater robot

InactiveCN1895960AImprove versatilityEasy to assembleUnderwater vesselsUnderwater equipmentPropellerAttitude control

An underwater miniature robot is composed of a segmental shell made of plastic sections and with plastic supporting frames for each segment, sealed cabins, external electric propellers, electric posture controller driven by gears, and the floating body made of foam material.

Owner:李烨

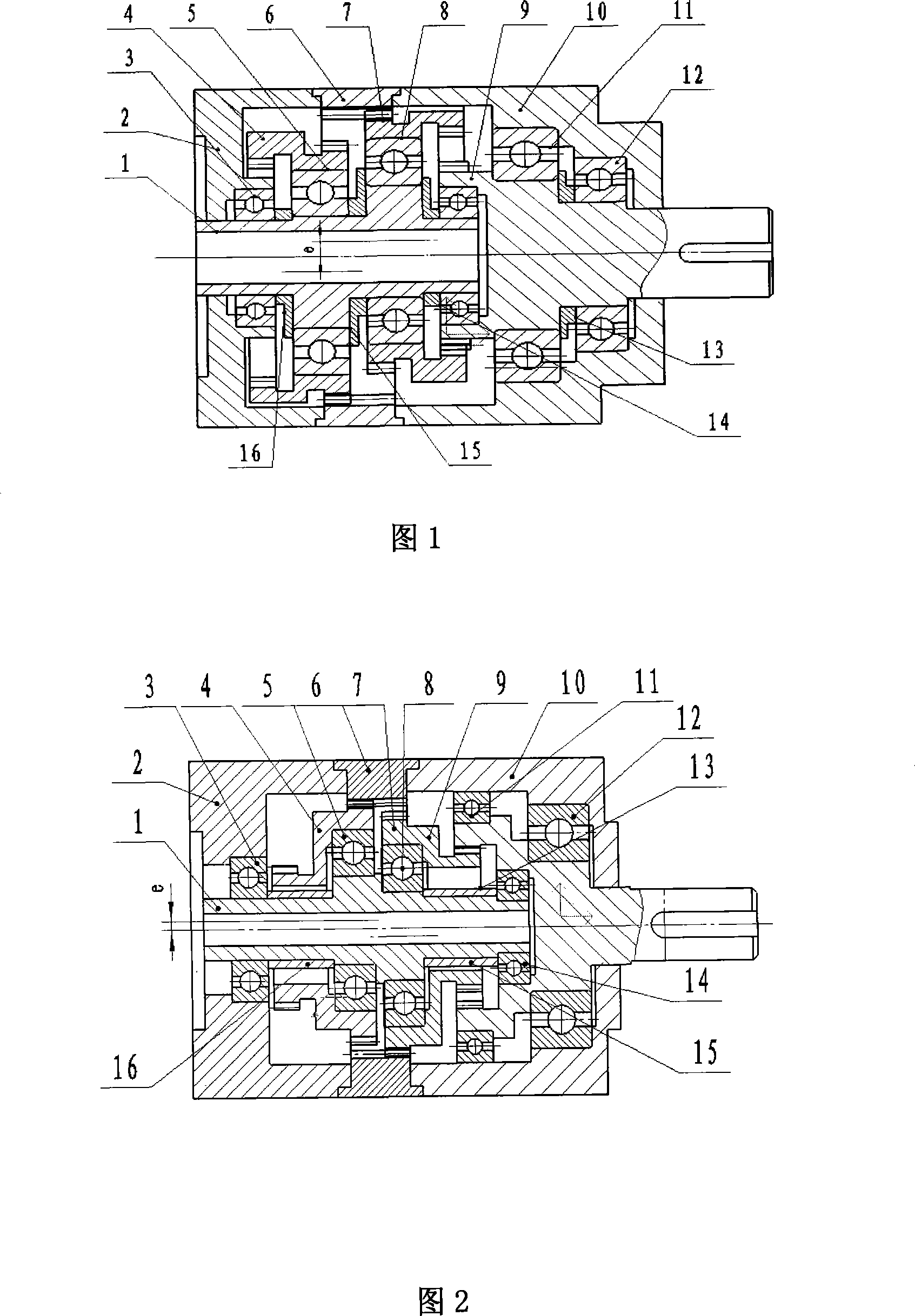

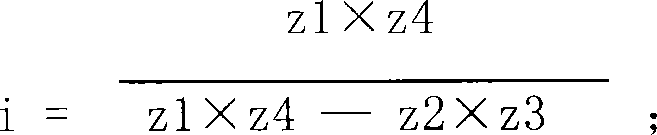

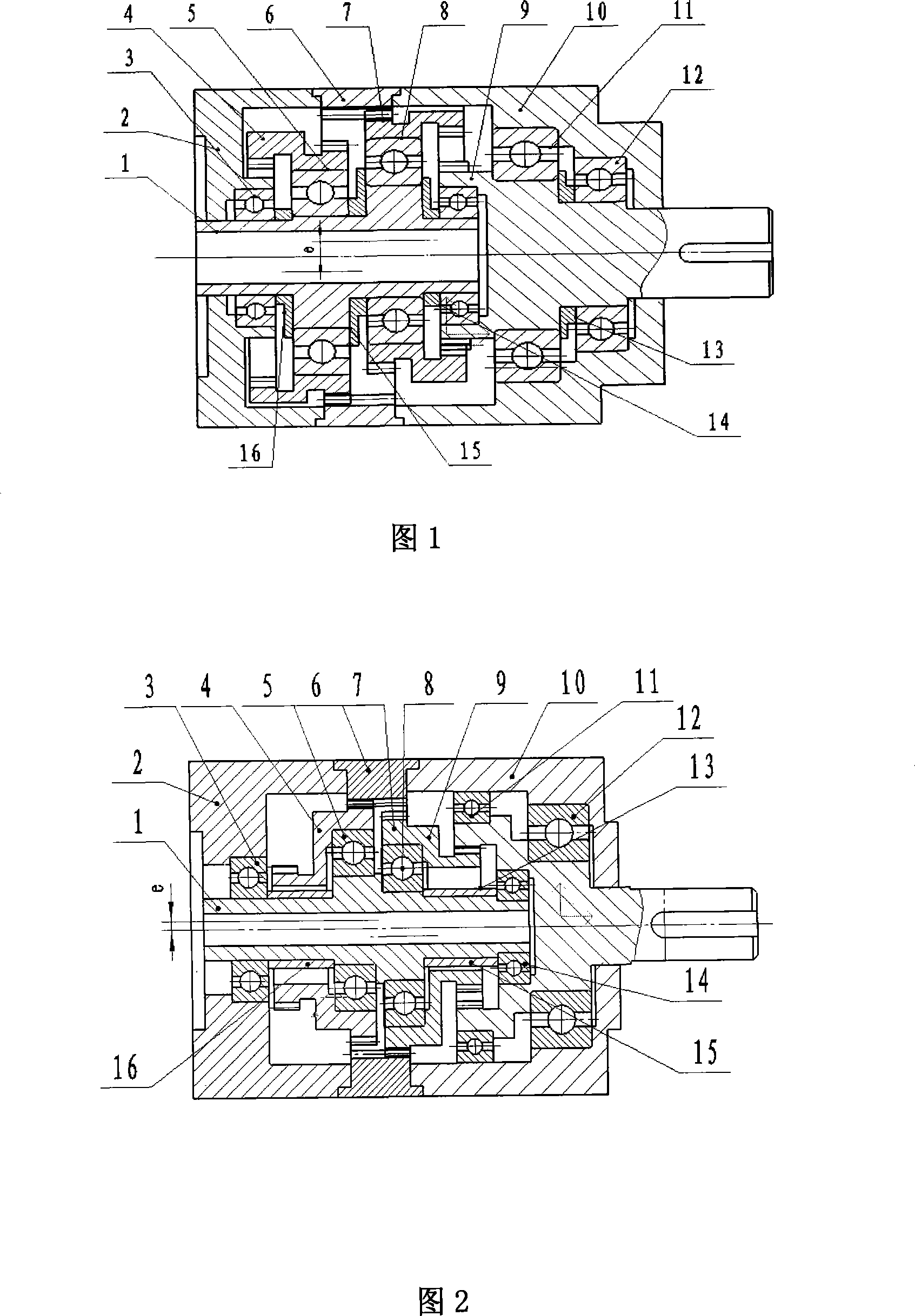

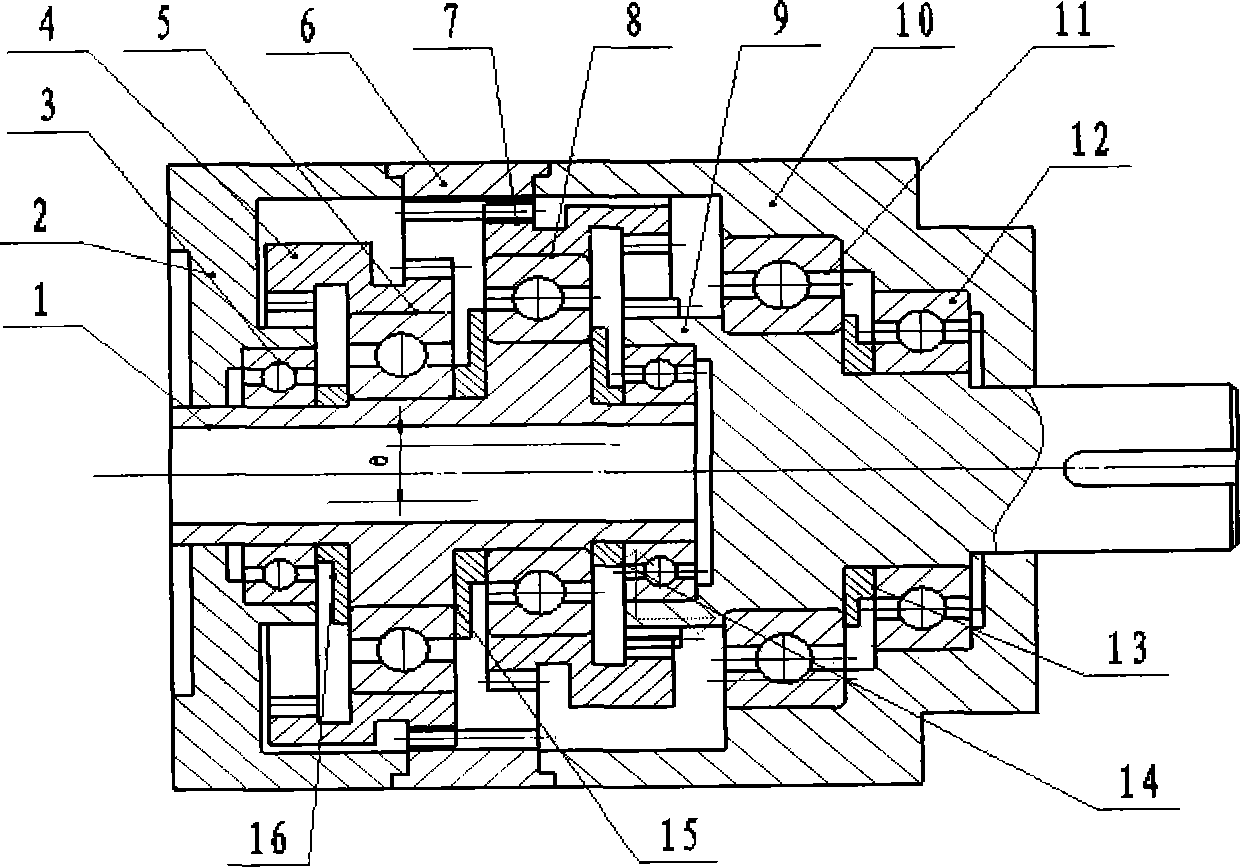

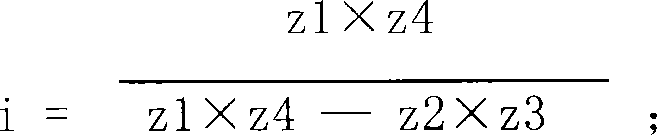

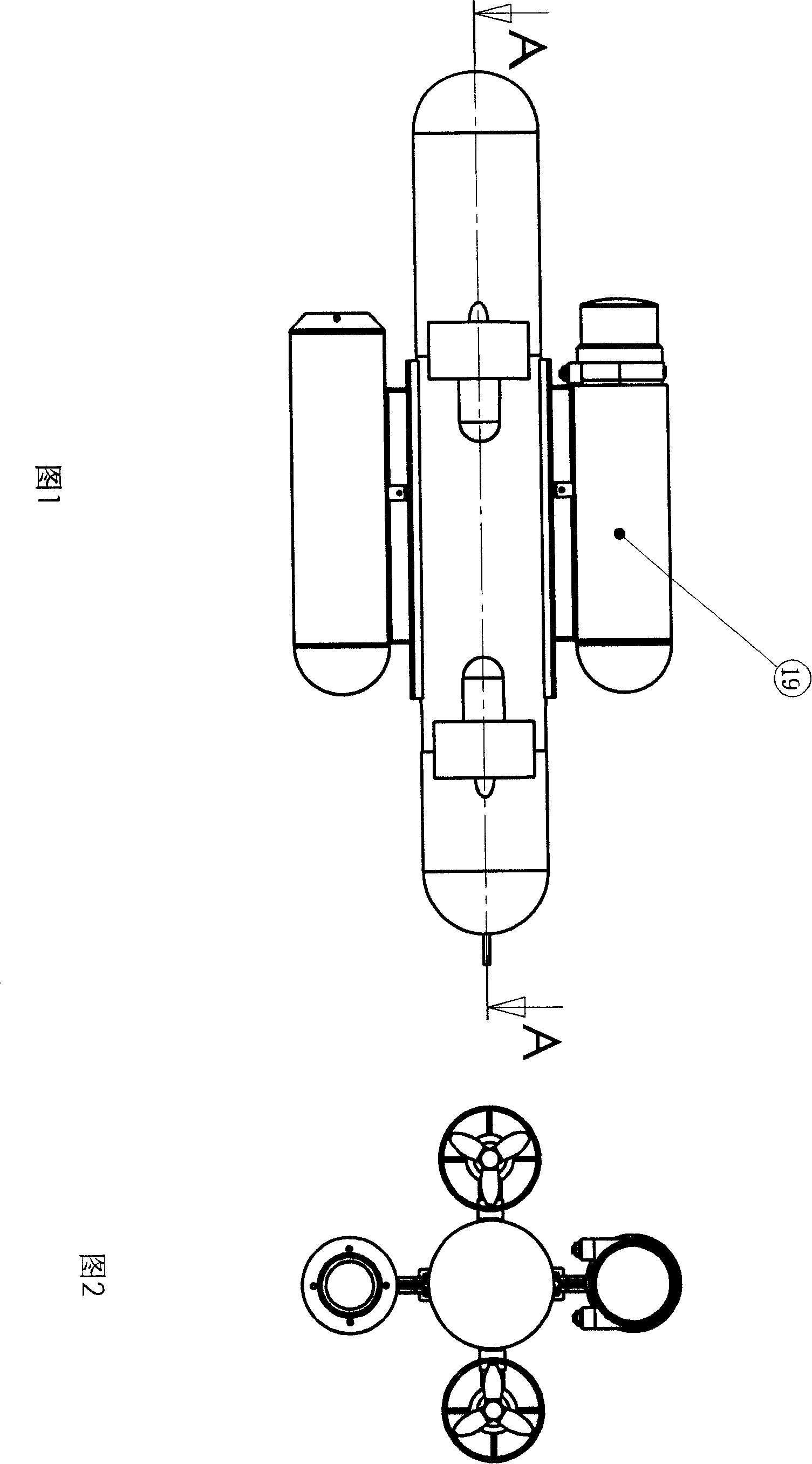

Decelerator for control motor

The invention relates to a speed reducer used for controlling a motor, which comprises an input shaft, a step planetary gear, an internal gear, an output shaft, a right housing, a left housing and a plurality of support bearings. The invention has the advantages that: a high rotational speed meshing is arranged for the gear of the speed reducer, so the processing of the gear is simple with low noise and little heat generating, which is especially obvious with the reducing speed ratio increasing; rolling bearing matching is adopted for the gear and the bearing with high efficiency and convenient installation of the output and the input shafts; 4 to 7 gears participate in meshing work when the gear is meshed with good equal load property, little heat generating, low noise and long service life due to low speed meshing of the gear; four gears can form a speed reducer with less than 100 of drive ratio, thereby adapting to requirement of each sequence reduction ratio and facilitating serial production; reasonable addendum coefficient, modification coefficient and serrated angle of pressure are adopted, thereby achieving a higher transmission efficiency.

Owner:重庆创坤科技发展股份有限公司

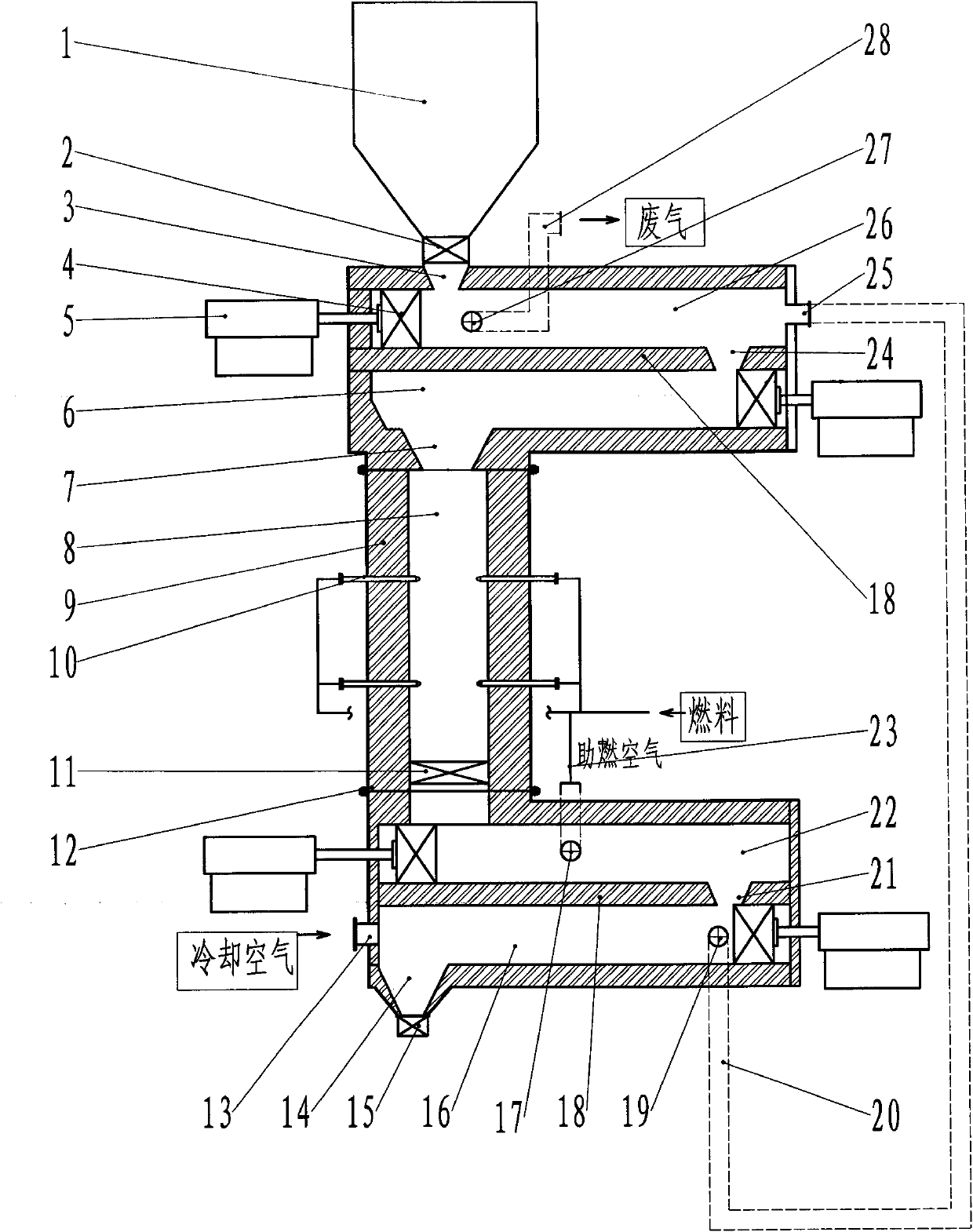

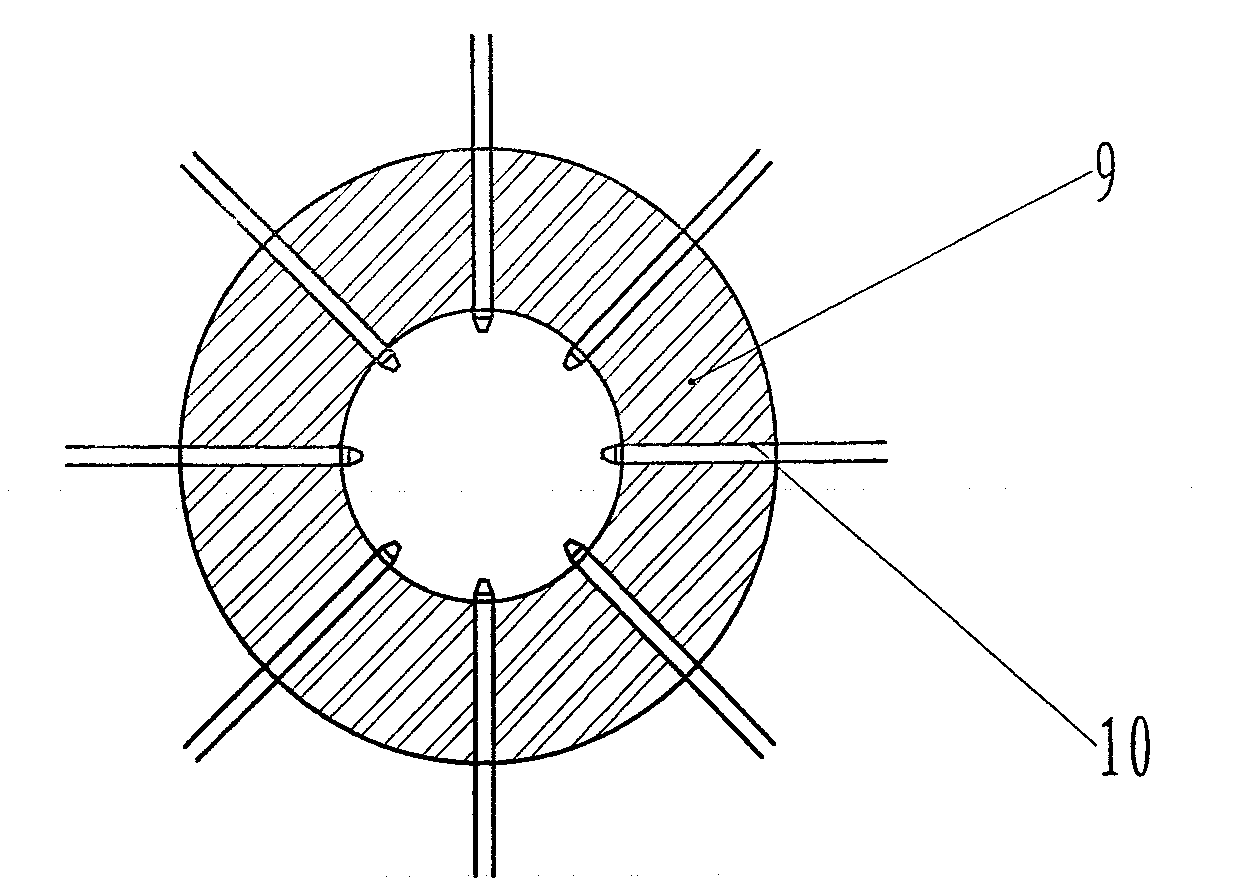

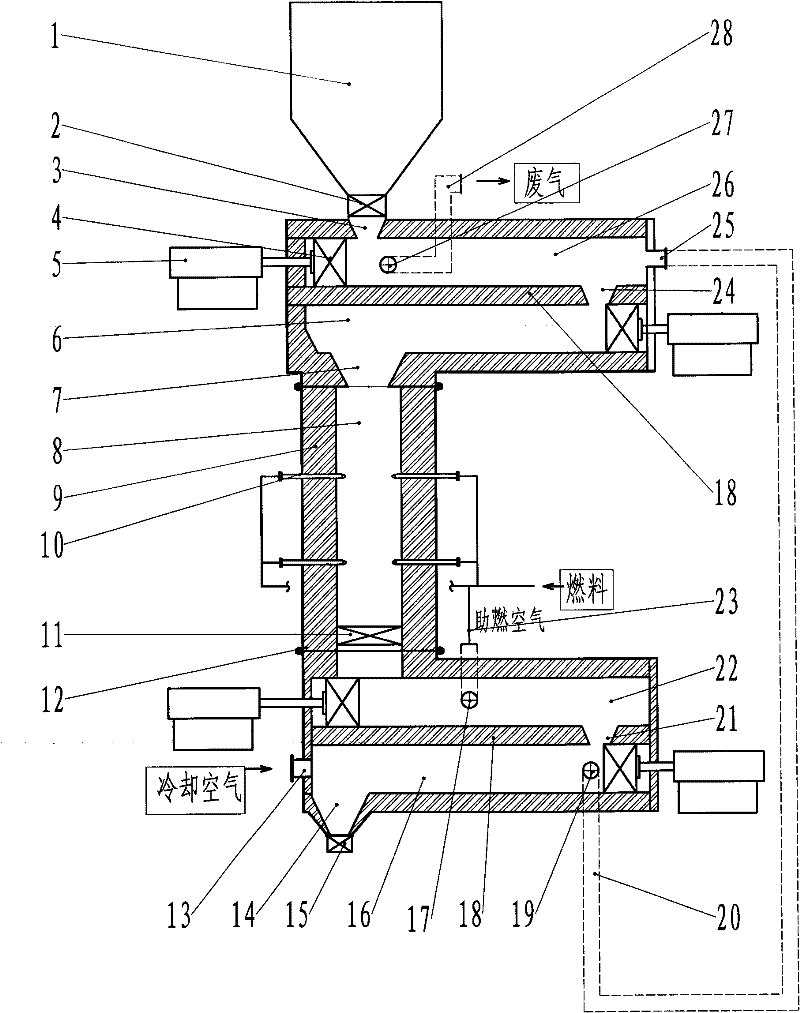

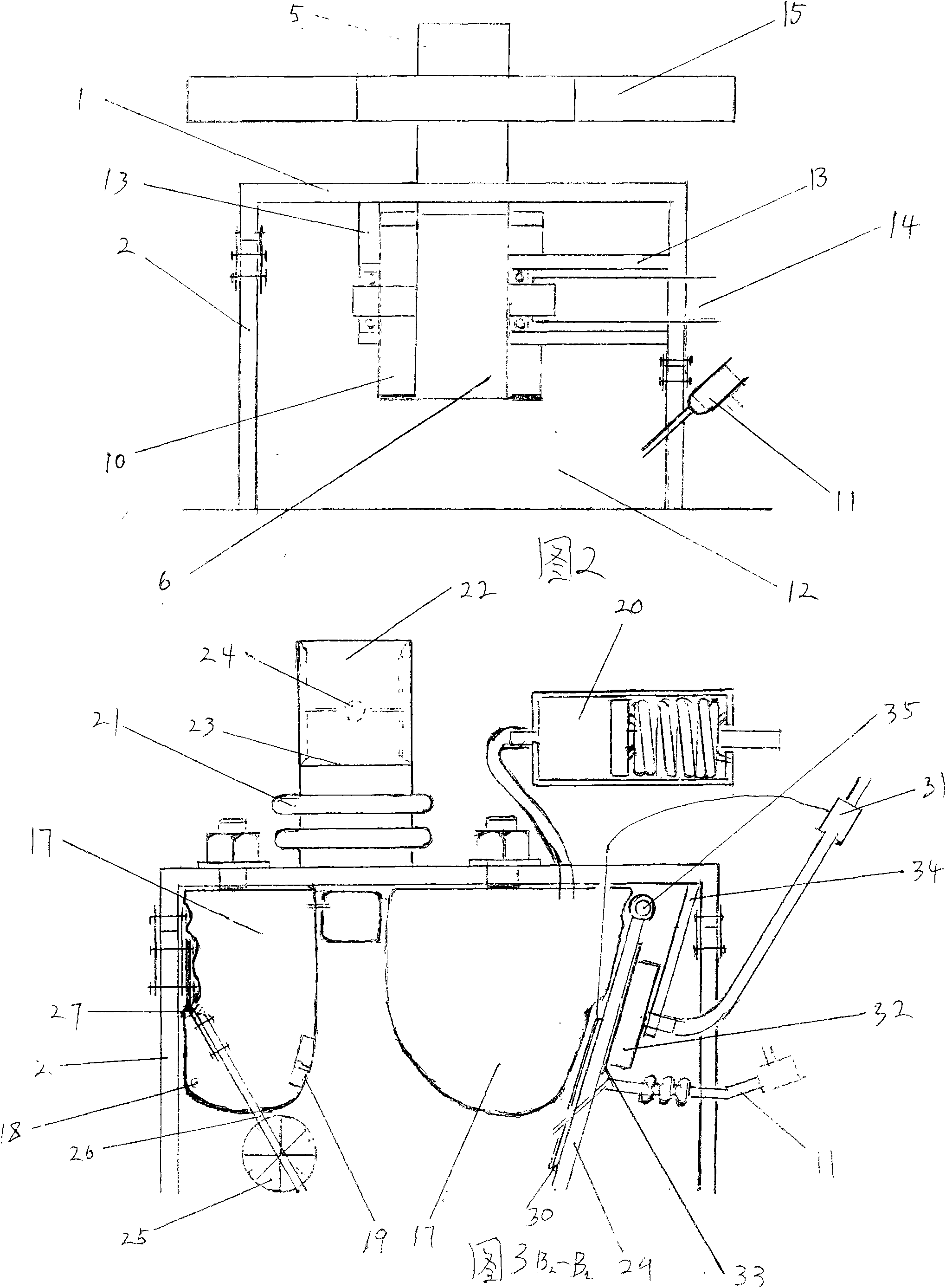

Method and equipment for calculating materials

ActiveCN101817649AImprove product qualityIncrease profitLime productionCombustionNuclear engineering

The invention provides a method and equipment for calculating materials. A preheating chamber, a calculating chamber and a cooling chamber of the equipment are in split structures; and the calculated materials are delivered by a bucket-type hoister among feeding equipment, the preheating chamber, the calculating chamber and the cooling chamber. The calculated materials are preheated, calculated and cooled in the split preheating chamber, calculating chamber and cooling chamber to obtain calculating products. High-temperature gas generated during cooling products in the cooling chamber is delivered to the preheating chamber by a gas pipeline for preheating the calculated materials and enters the calculating chamber to be used as combustion-supporting air after being preheated by a heat accumulator. The invention fully utilizes heat energy, reduces the consumption of fresh air and the emission of room temperature gas and is beneficial to environmental protection. Various units of the equipment are independent assemblies, can be separately produced and assembled on site and are beneficial to serially producing and calculating the equipment. The materials are delivered among various chambers by using the bucket-type hoister, so that the invention realizes split operations and improves the flexibility of operations.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

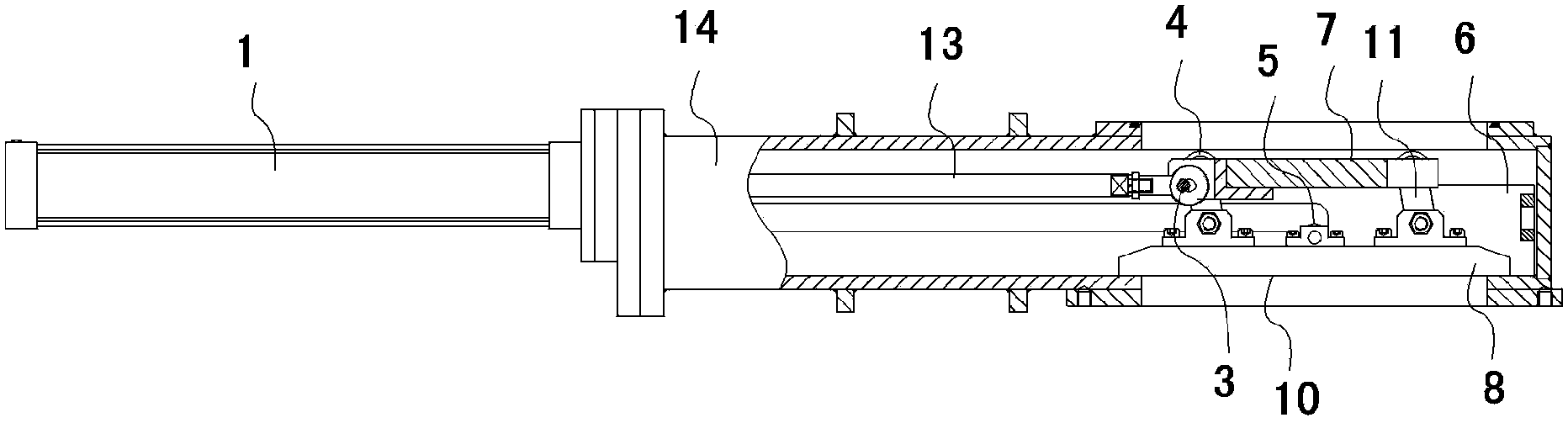

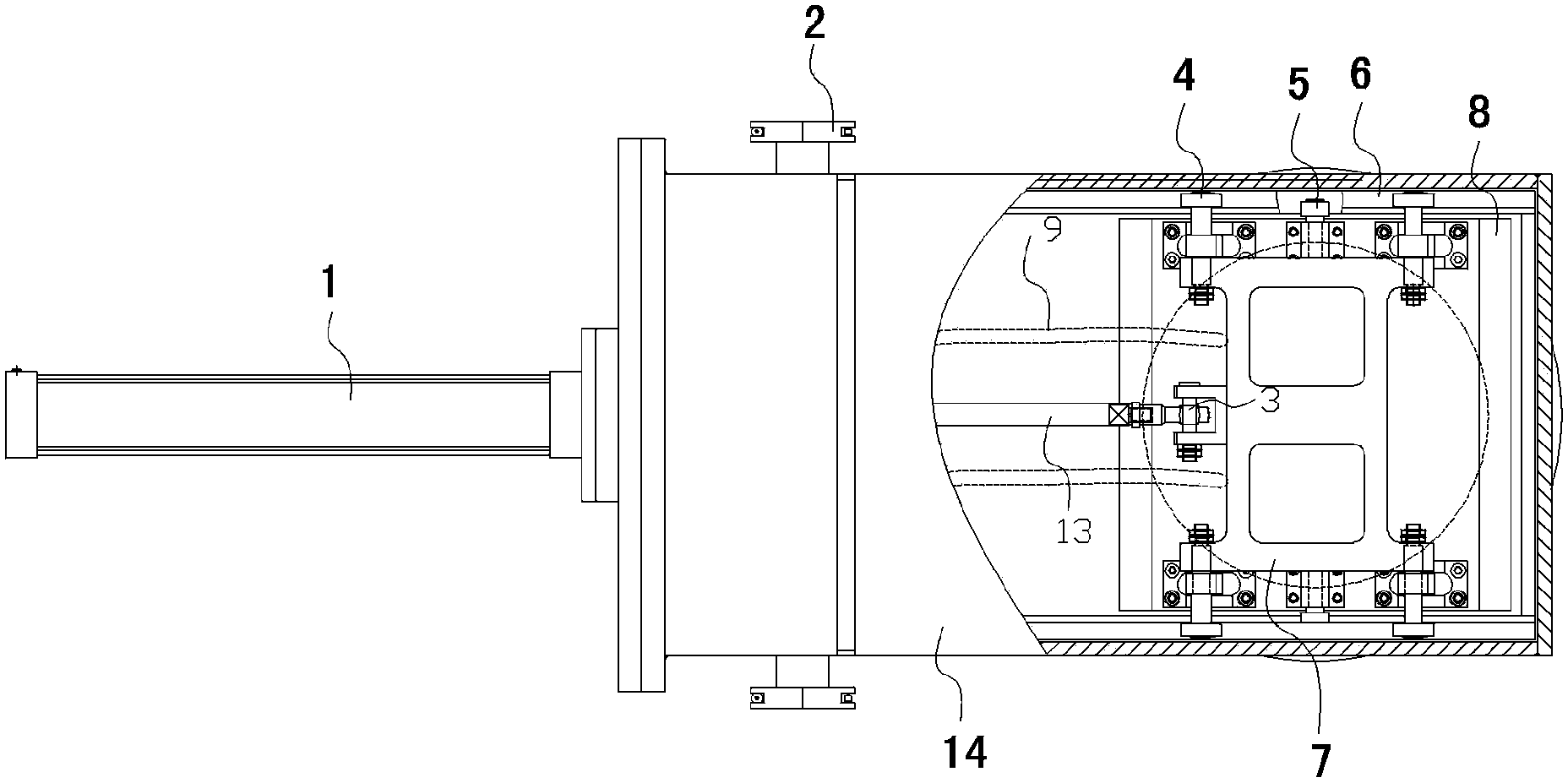

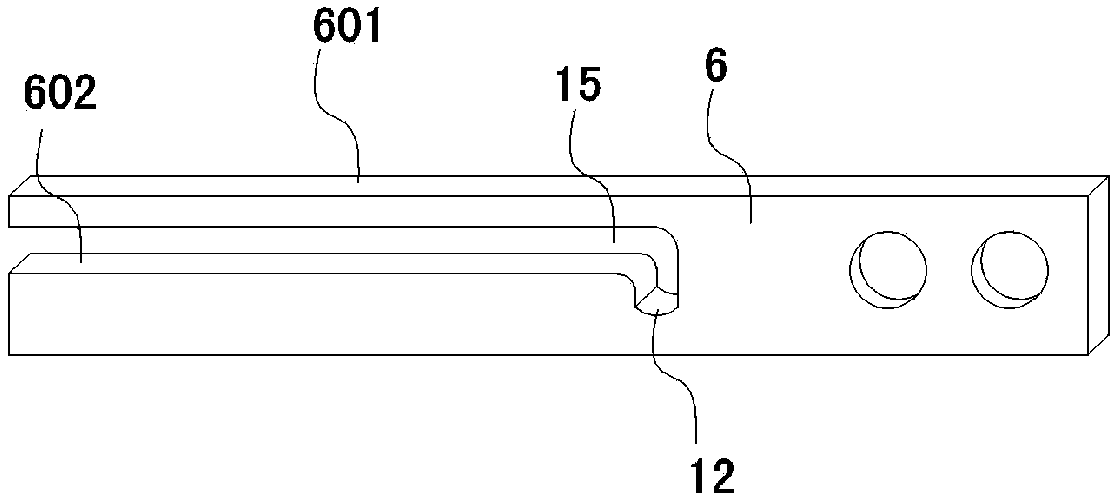

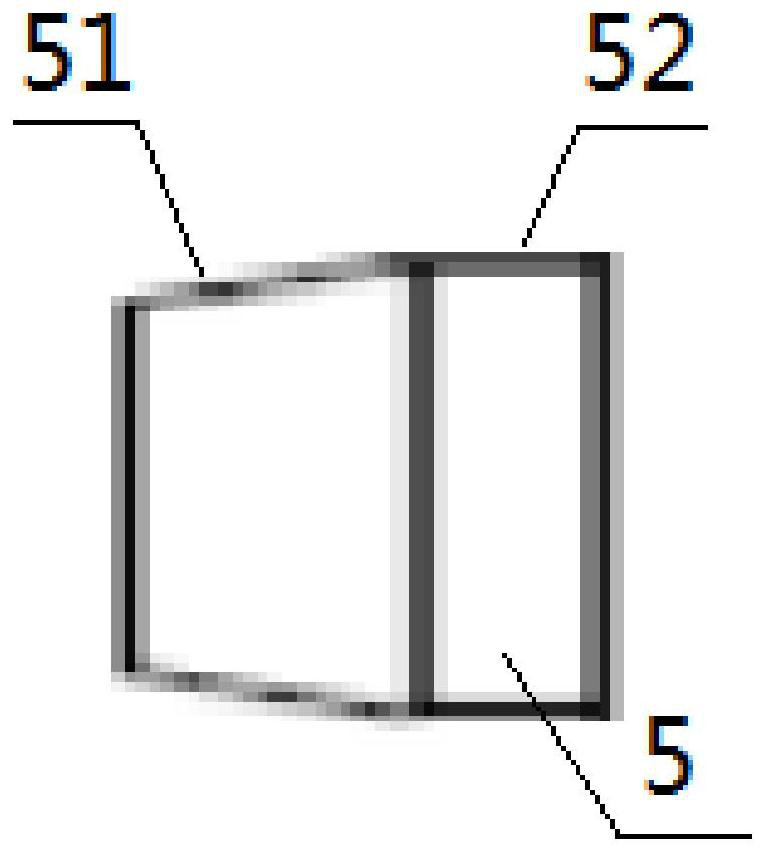

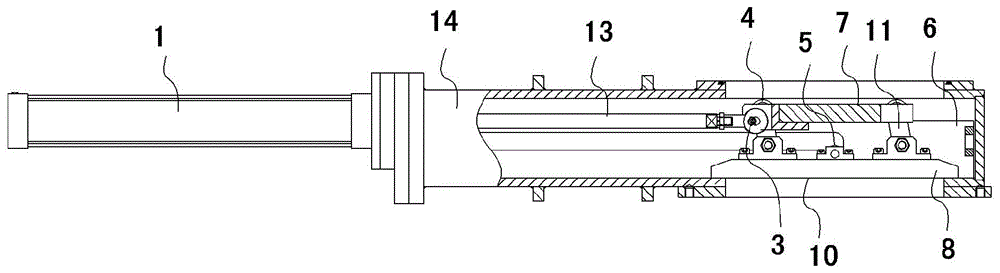

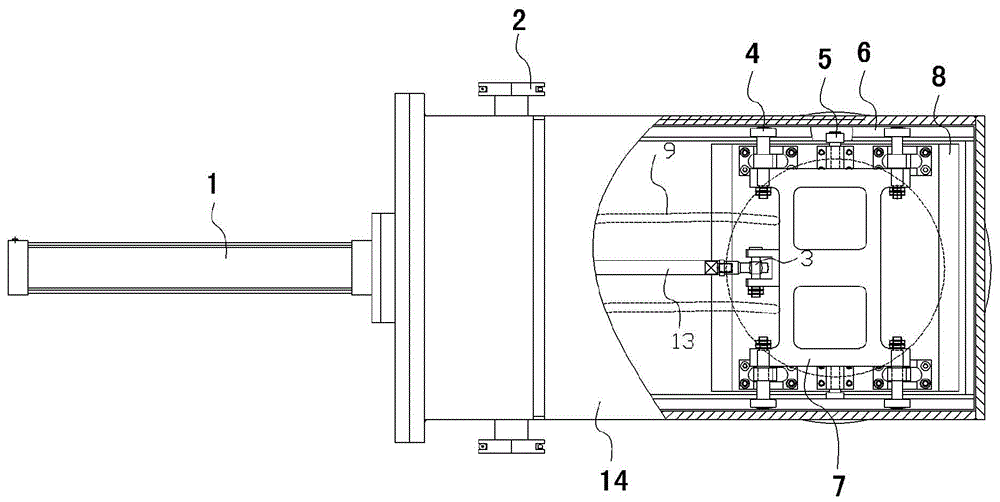

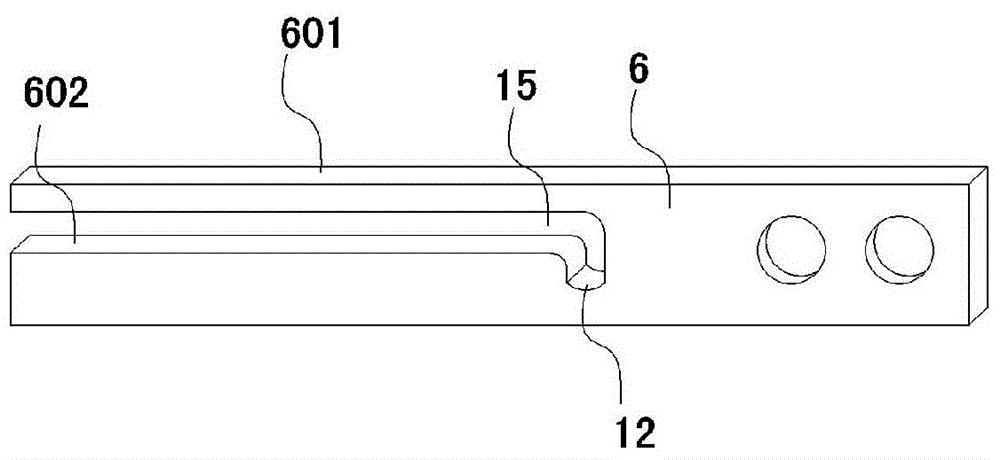

Guide rail vacuum connection rod gate valve

ActiveCN103867737AEasy to disassembleEasy to assembleValve members for heating/coolingSlide valveEngineeringSystem element

The invention belongs to the field of vacuum system elements, and particularly relates to a guide rail vacuum connection rod gate valve. The guide rail vacuum connection rod gate valve comprises a valve body (2) of which a work cavity is internally provided with a transmission mechanism; the transmission mechanism comprises two symmetrical parallel guide rails (6); the guide rails (6) comprise an upper layer rail work surface (601) and a lower layer rail work surface (602) of which one end part is provided with a sunk slot (12); the upper layer rail work surface (601) is provided with a valve frame (7) and is in slide connection with a guide wheel mechanism I (4); the lower layer rail work surface (602) is provided with a valve holder (8); a guide wheel mechanism II (5) is in slide connection with the lower layer rail (602); a connection rod (11) is arranged between the valve frame (7) and the valve plate (8). The guide rail vacuum connection rod gate valve is simple in structure, easy to disassemble, good in sealing property, high in reliability and suitable for high-temperature radiation work conditions.

Owner:SHENYANG VACUUM TECH INST

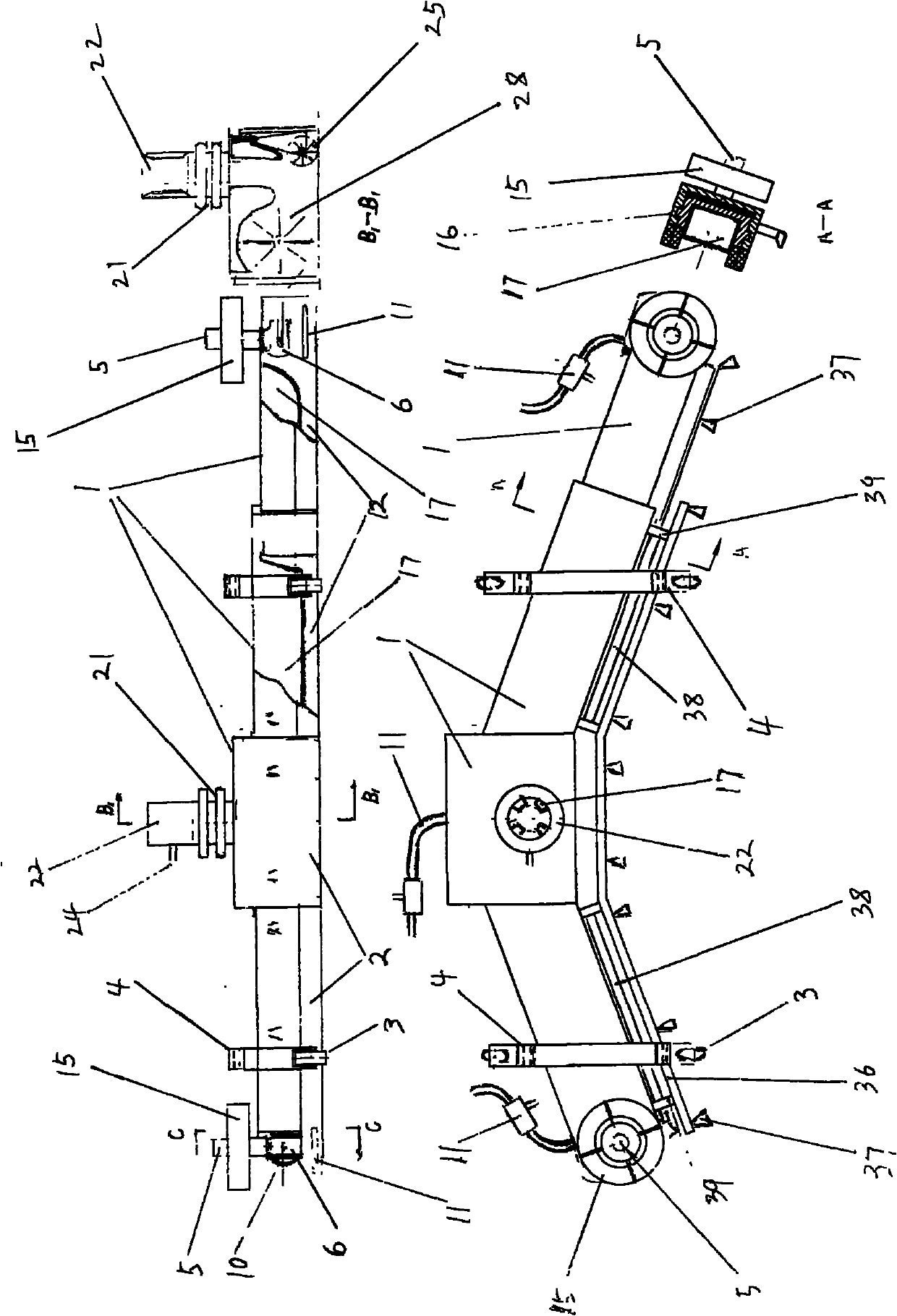

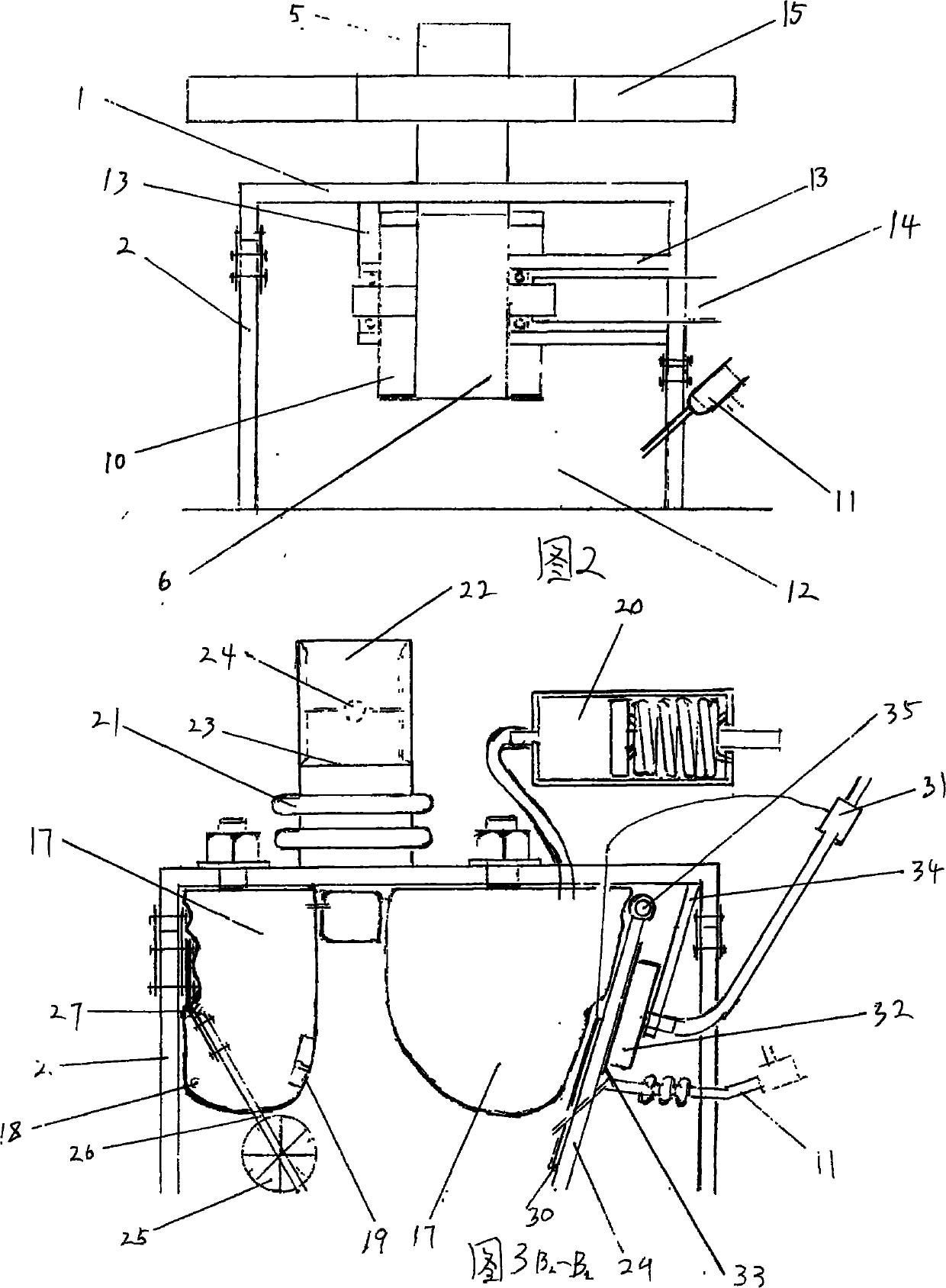

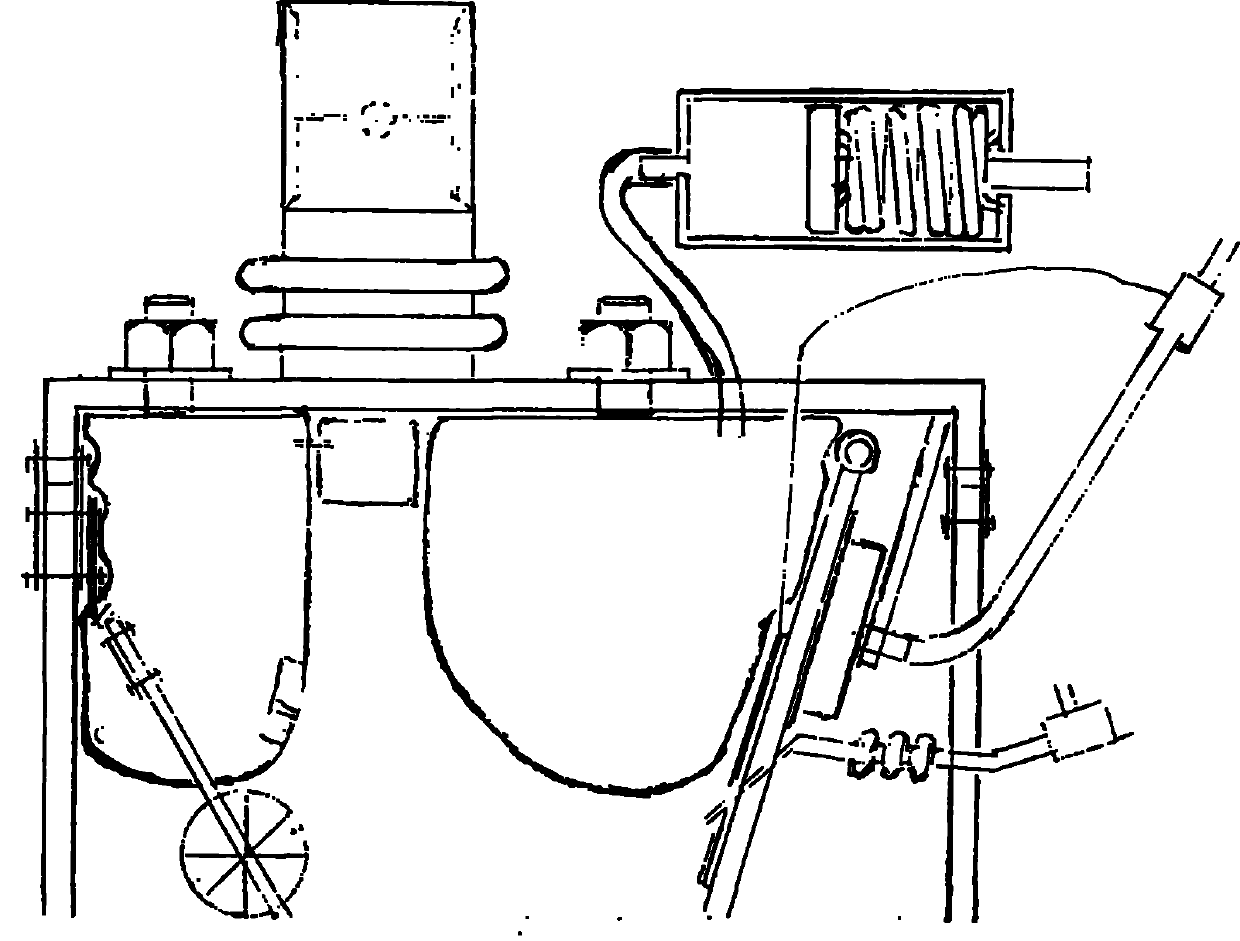

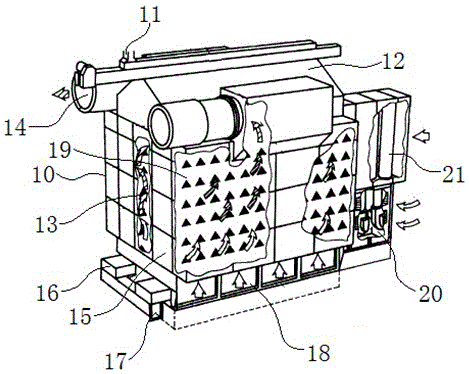

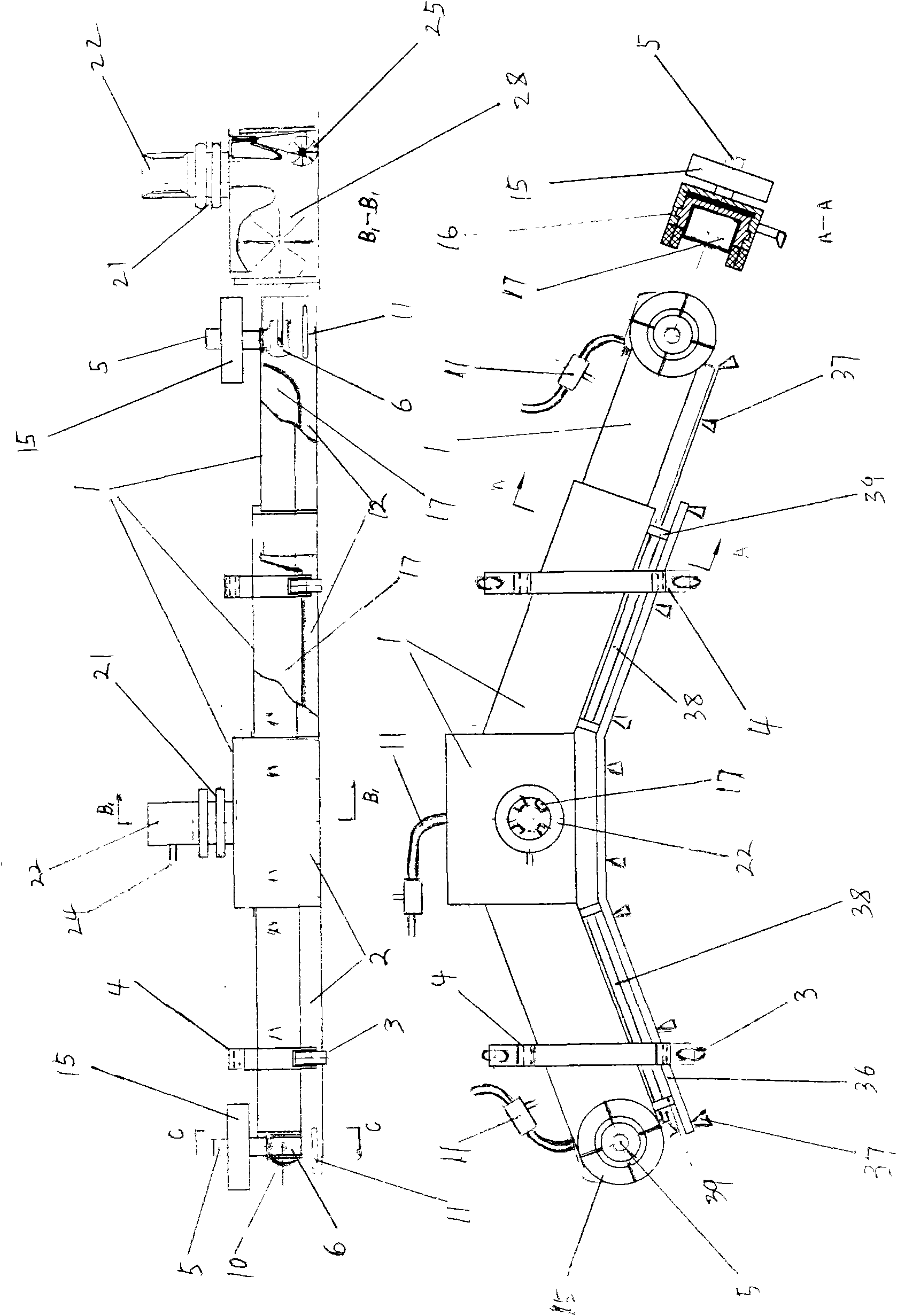

Suction nozzle with soft cavity throttling bodies inside

The invention provides a suction nozzle for cleaning the road surface, which relates to the field of a road sweeper component. The suction nozzle mainly solves the following problem: under the condition that the air quantity of a blower of a road sweeper is not changed, more than one closed cavity bodies made of soft materials are additionally arranged between an upper cover in the suction nozzle and the road surface so as to exert the function of throttling and press air flow of an air flow channel in the suction nozzle to cling to the road surface for rapid flowing, thereby sucking garbage into a garbage can. Each independently closed soft cavity throttling body is provided with a vent pipe which is connected to a space with the pressure intensity being equal to or higher than that of the air flow at the lower part or is connected with a pressure balancer. The suction nozzle further comprises the upper cover, a peripheral sealant skirt, a framework, supporting road wheels, a traction mechanism, a left air suction pipe orifice, a middle air suction pipe orifice and a right air suction pipe orifice, wherein the left and right air suction pipe orifices move along with a left suction nozzle or a right suction nozzle to extend out of a sweeper body for operation, and can retract to the left and right sides in a middle suction nozzle; each air suction pipe orifice is provided with a large-caliber air flow amplifier, an air back-blowing knife connected with a small-caliber air flow amplifier is respectively arranged at the lower rear part of each air suction pipe orifice, and each air back-blowing knife is matched with the blowing and sucking air flow of the blower on the road sweeper to blow and suck the garbage into the garbage can of the road sweeper.

Owner:徐国栋

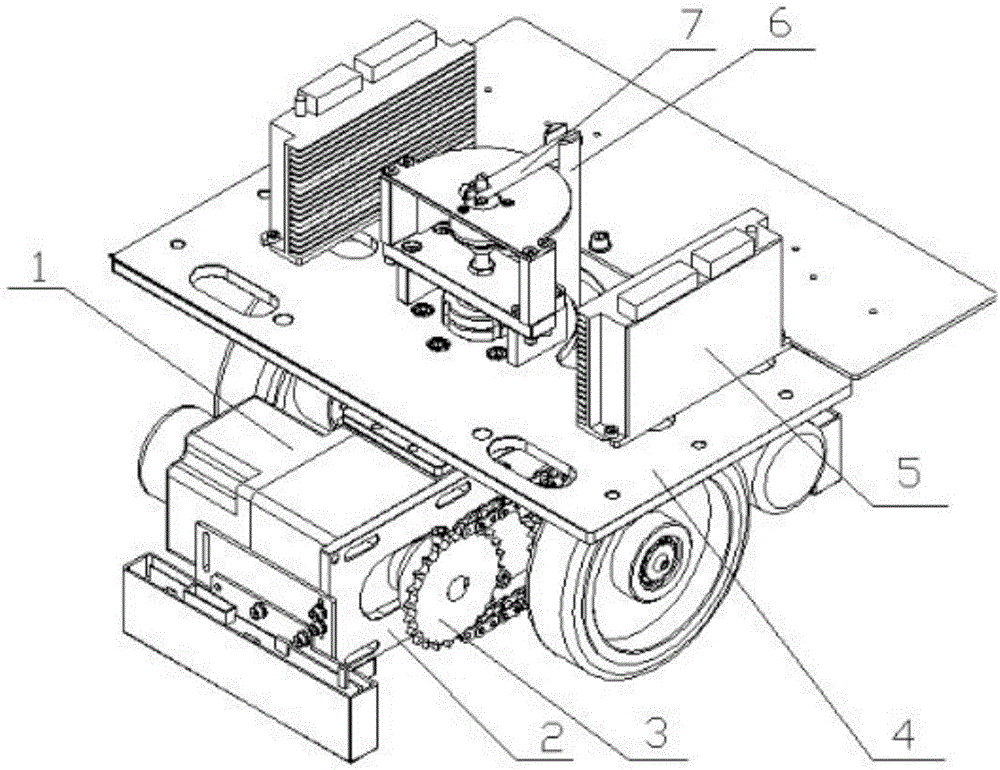

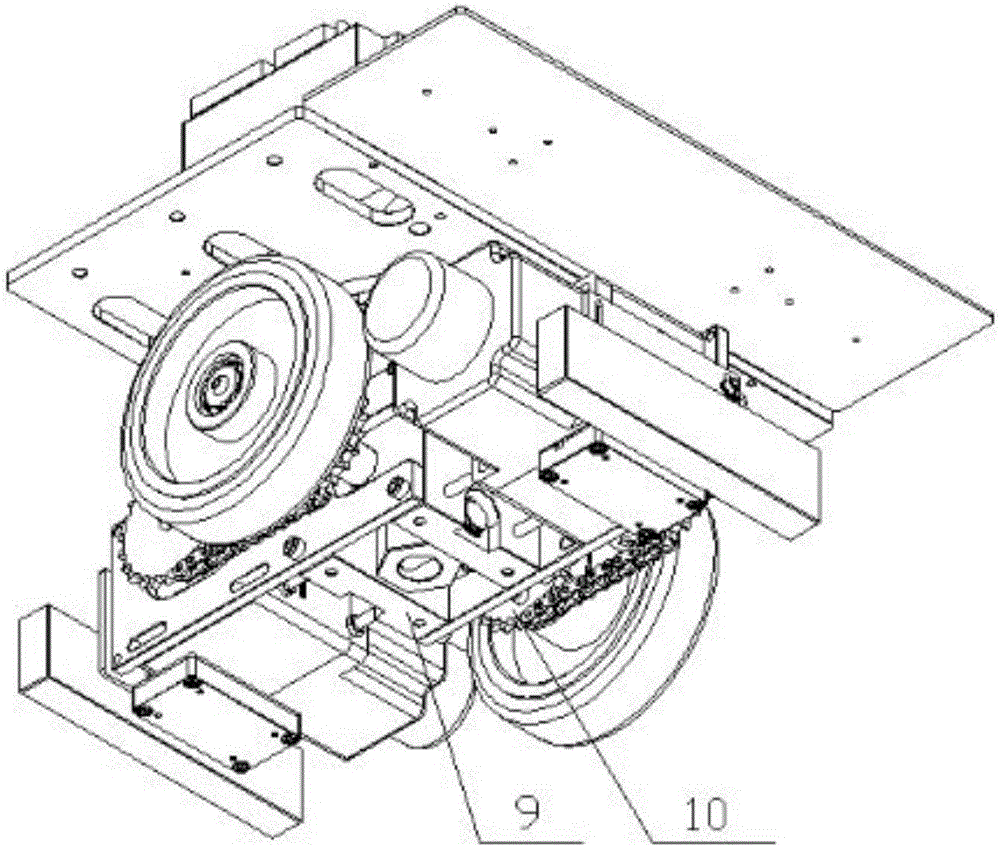

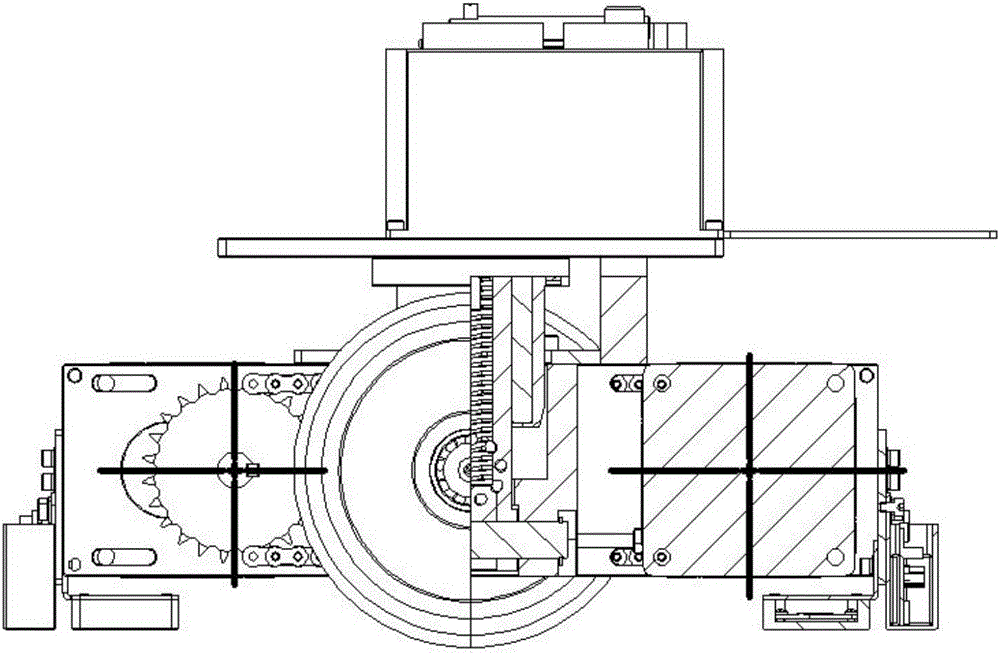

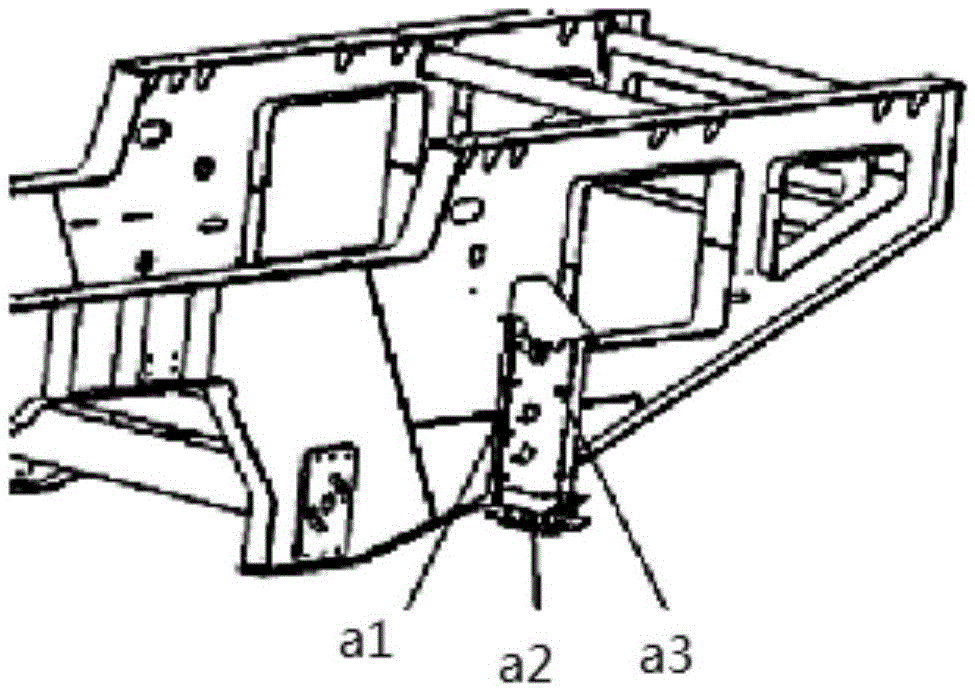

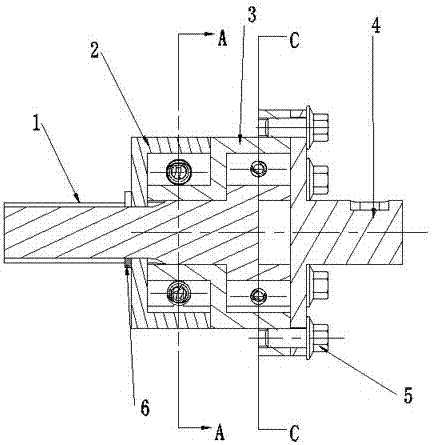

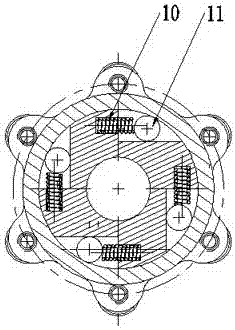

Adjustable-pressure AGV driving mechanism

InactiveCN106005101AImprove standardizationFacilitate serial productionElectric propulsion mountingResilient suspensionsMechanical engineeringEngineering

The invention belongs to the technical field of AGVs and relates to an adjustable-pressure driving mechanism suitable for an AGV. The driving mechanism comprises a pressure adjusting device and a driving device. The pressure adjusting device comprises a linear bearing, a barrel rod, a clamping spring pillar, a bolt, nuts and a support plate frame. The linear bearing is provided with a shaft sleeve fixed under the support plate frame. The clamping spring pillar is sleeved with a spring, and a spring cushion block is arranged at the bottom of the clamping spring pillar. One end of the bolt is connected with a spring adjusting pressing plate and achieves looseness prevention through one nut. The other end of the bolt and the other two nuts press one end of the spring in screwing and combining modes, and deformation quantity of the spring is set. Screwing and combining of the barrel rod and the two round nuts make the spring cushion block fix the other end of the spring. The barrel rod is fixedly connected with a support base in the support plate frame through the clamping spring pillar. The driving mechanism is installed on the AGV so that the bearing limit of the AGV can be changed by adjusting pressure, the bearing range of the AGV is extended, and cost is reduced.

Owner:芜湖智久机器人有限公司

All-metal mixed-flow grain dryer

InactiveCN105053185AReduce harmImprove applicabilitySeed preservation by freezing/coolingSeed preservation by dryingCold airMixed flow

The present invention discloses an all-metal mixed-flow grain dryer which comprises a shell which is made of alloy steel. The middle of the shell is provided with a hot air chamber connected to a hot air inlet, the top of the shell is provided with a storage barn, both sides of the storage barn are provided with exhaust gas discharge outlets, the hot air chamber is connected to a drying zone of a hollow cavity, retractable laminates are arranged inside the drying zone, a cooling zone is arranged below the drying zone, the bottom of the cooling zone is provided with evenly distributed cold air inlets, the hot air inlet is connected to an oil furnace which provides heat source. The all-metal mixed-flow food dryer is convenient to conduct series production, has series combined segments with equal lengths and heights, not only can generate down-flow, but also can generate counterflow and crossflow, has little damage to grains, and strong applicability for materials, can dry small granules of seeds, such as rapeseed, millet, sesame, etc., ensures the drying mass of grains, and can immediately realize cooling after drying is completed, and achieve the storage requirements.

Owner:WUXI HAI CHANG MACHINERY

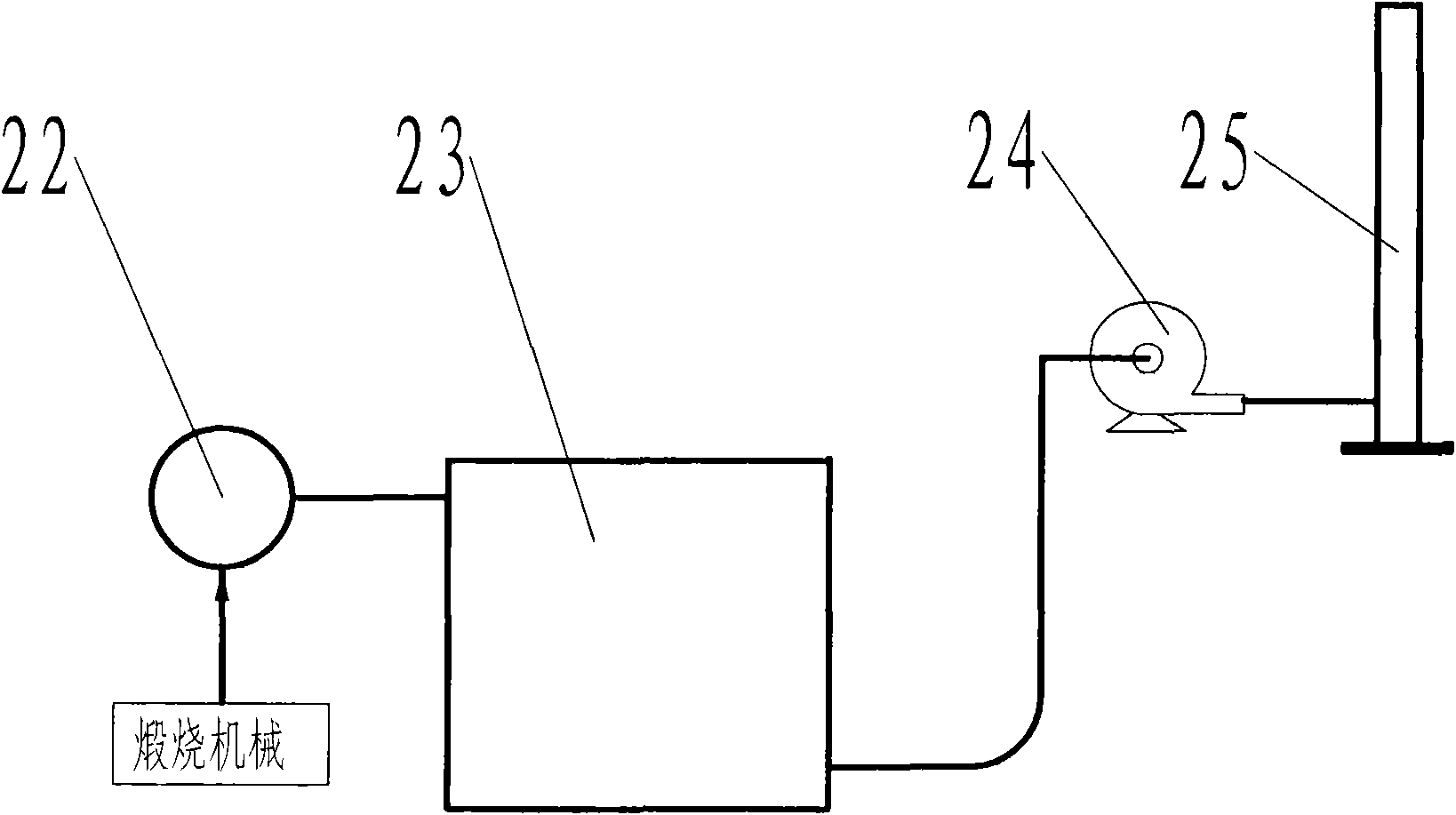

Method and machine for calcining materials

ActiveCN101792273AReduce heat exchange equipmentReduce equipment investment and operating costsEngineeringCombustion

The invention provides a method and a machine for calcining materials, comprising feeding equipment, a preheating chamber, a calcining chamber, a cooling chamber, discharging equipment and an exhaust emission system, wherein the calcining chamber is provided with 1-10 rows of peripheral burners, and the preheating chamber and the cooling chamber are transversely arranged. The preheating chamber and the cooling chamber are respectively divided into a high-temperature preheating chamber and a low-temperature preheating chamber as well as a high-temperature cooling chamber and a low-temperature cooling chamber by partition walls. The materials of the preheating chamber and the cooling chamber transversely move under the push of a pusher; higher-temperature air after the high-temperature cooling chamber cools products is used as combustion air; higher-temperature air after the low-temperature cooling chamber cools the products is used for preheating limestone materials in the preheating chamber. In the invention, heat energy is well utilized to save heat-exchange equipment and reduce equipment investments and operating costs, which reduces the discharge of greenhouse gases and is beneficial to environmental protection. The machinery is a detachable assembly, and all component equipment is manufactured separately and is assembled on site, thereby facilitating transportation, installation, overhauling and replacement and being beneficial to serialized production of calcining machinery.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

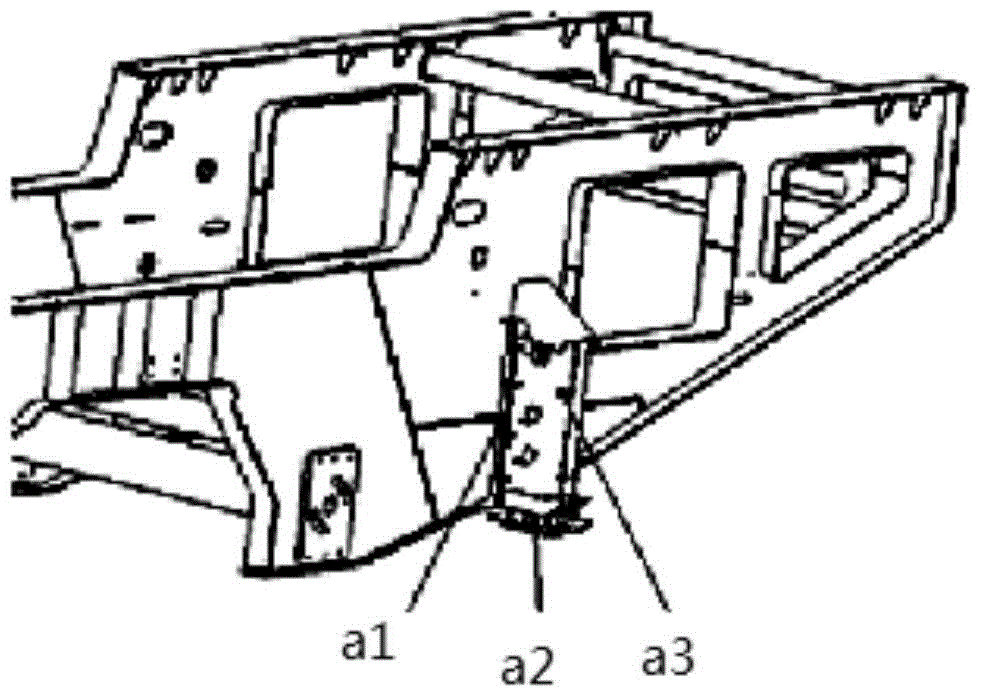

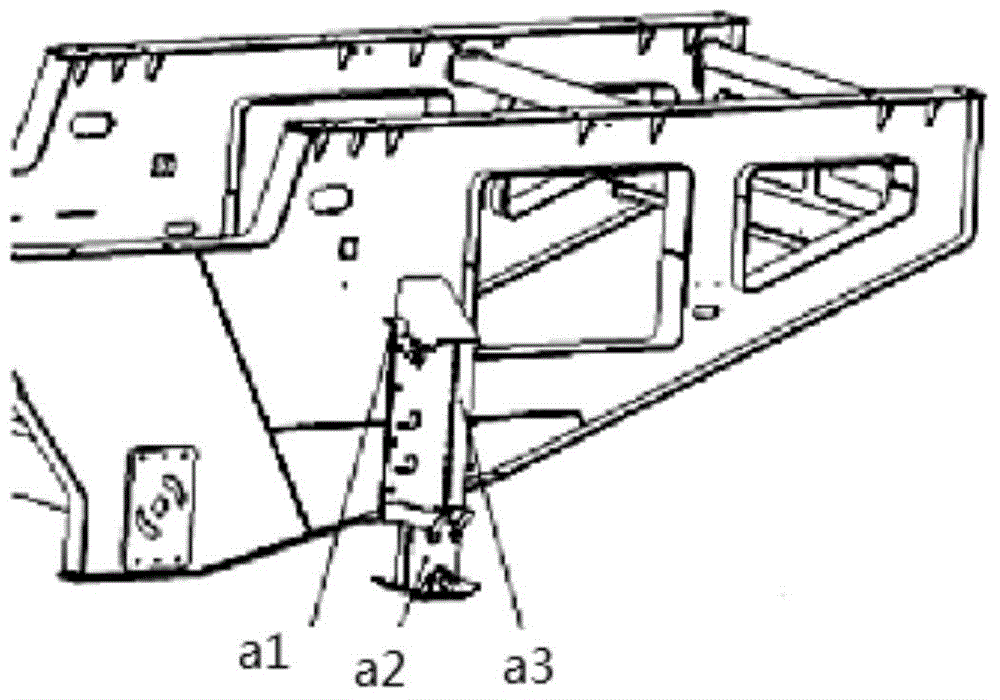

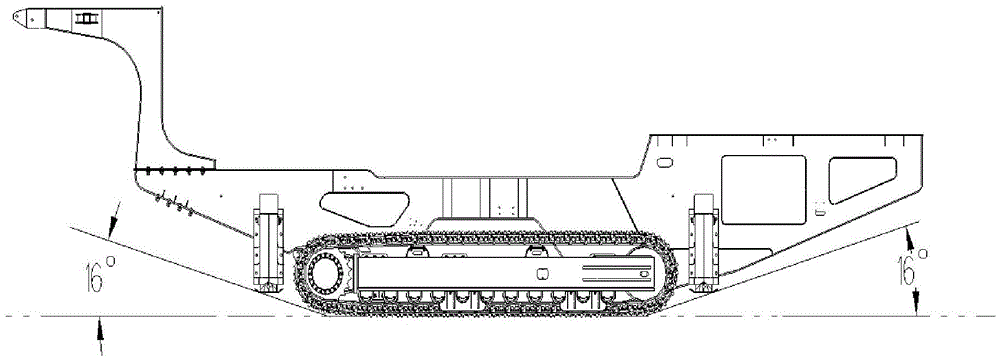

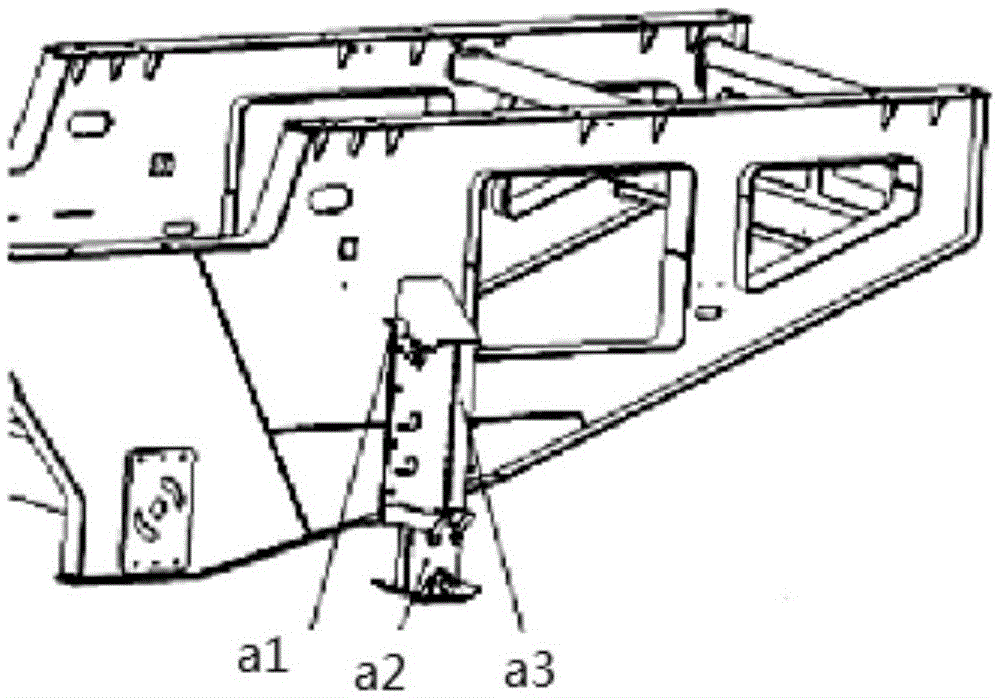

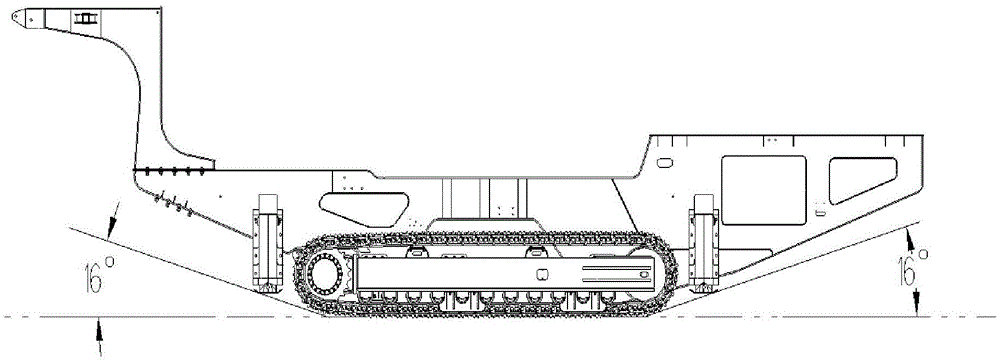

Hydraulic supporting leg structure and movable type crusher

ActiveCN104057927AEasy maintenanceImprove interchangeabilityVehicle fittings for liftingMovable typeEngineering

The invention relates to a hydraulic supporting leg structure and a movable type crusher. The hydraulic supporting leg structure comprises a supporting leg base assembly, a hydraulic supporting leg assembly, a hanging structure and a jacking structure, wherein the supporting leg base assembly is fixedly connected to a frame body of a to-be-supported device; the hydraulic supporting leg assembly can be hung onto the supporting leg base assembly through the hanging structure and can be used for jacking the supporting leg base assembly through the jacking structure. The hydraulic supporting leg structure provided by the invention is convenient to assemble and disassemble, the off-road capability and the passing capacity of the overall movable type crusher can be improved, the overall weight is reduced during movement, the movable type crusher is convenient to transport and maintain, and serialization and immediate replacement are facilitated.

Owner:XUZHOU XCMG MINING MACHINERY CO LTD

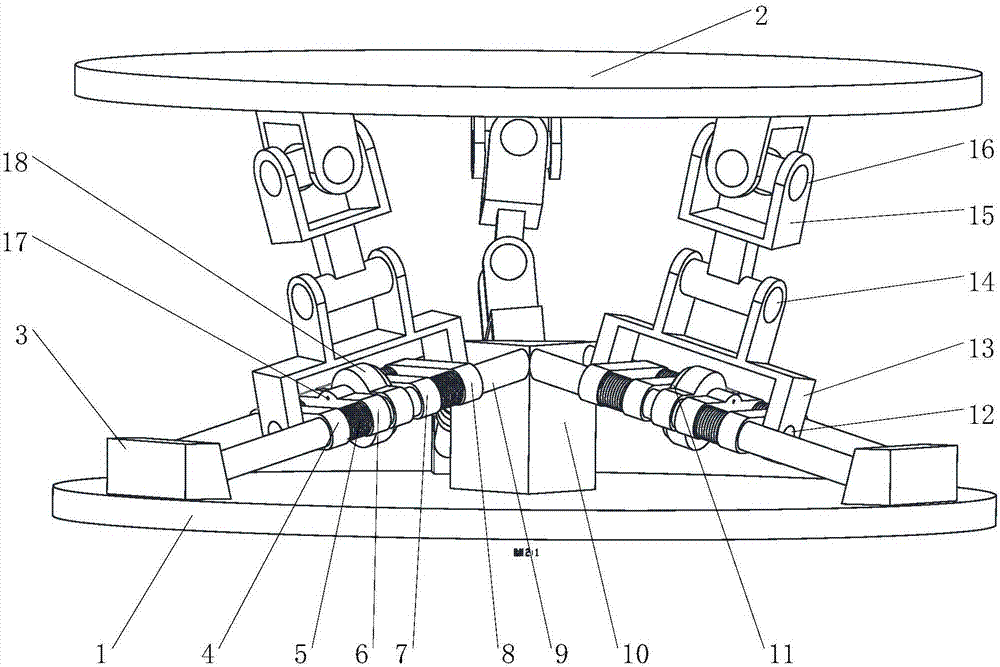

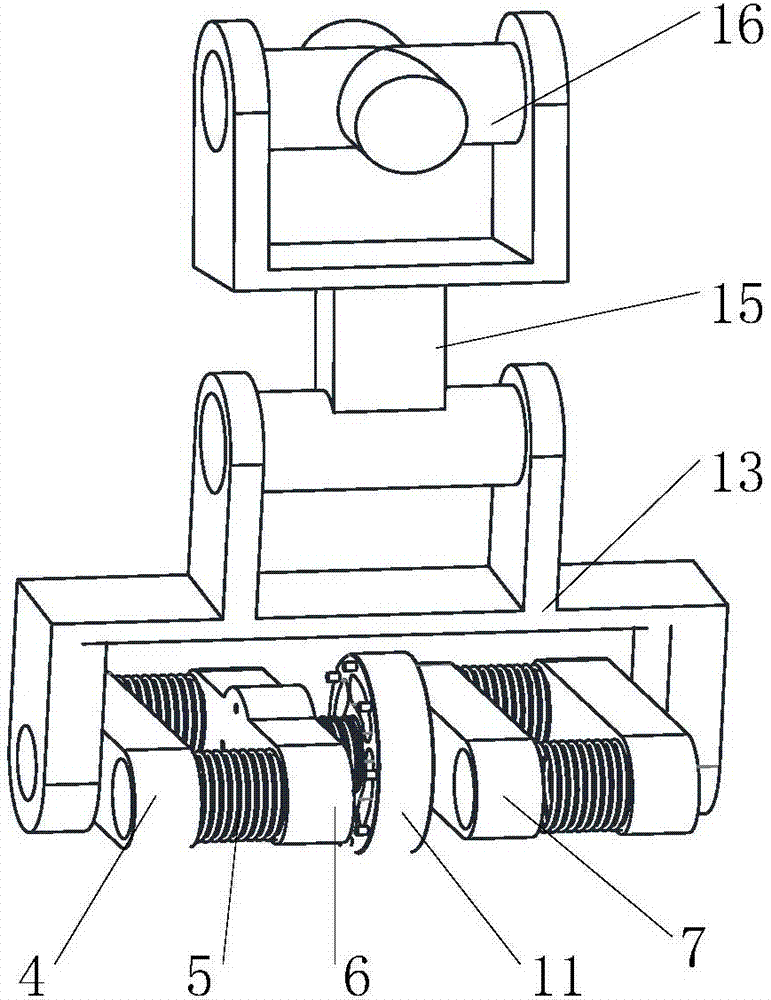

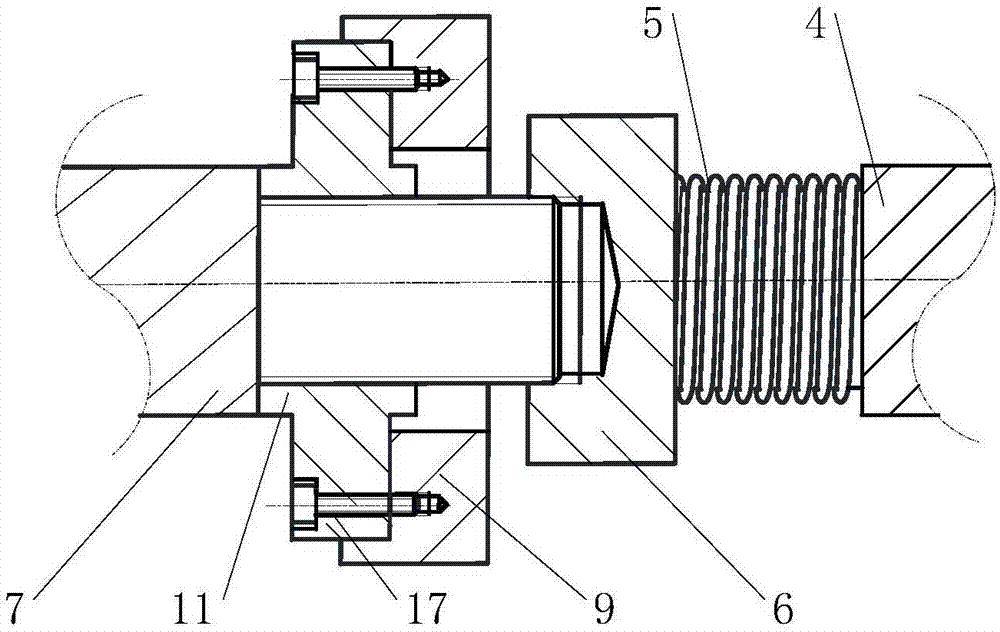

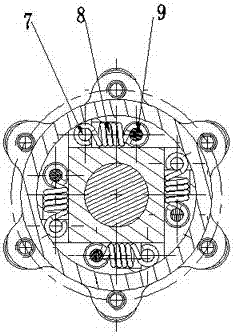

Rigid-flexible mixed three-dimensional force perception mechanism

ActiveCN107314853AImprove perceptionEasy to measureMeasurement of force componentsIsoetes triquetraUniversal joint

The invention provides a rigid-flexible mixed three-dimensional force perception mechanism. The mechanism mainly comprises an upper platform, a lower platform and three deformable force measuring branches connecting the upper and lower platforms. Three edge support columns with the same height which are distributed in an equilateral triangle manner are arranged on the lower platform. A center support column is arranged in the center of the platform. Three pairs of parallel guide rails are arranged between the three edge support columns and the center support column and are connected to each other through the deformable force measuring branches respectively. Each force measuring branch consists of a sensor assembly, a first moving pair, a first revolute pair, a second revolute pair and a first universal joint. A sensor assembly is arranged between two parallel guide rails and mainly comprises a sensor, a sensor connection piece, a sensor fixing connection frame, a sensor fixing support frame, a guide rail connection frame and a spring. According to the invention, deformation can be generated in a three-dimensional force perception measurement process; space three-dimensional force information in a dynamic deformation condition is easily perceived and measured in the deformation process; and the mechanism is advantageous in that the mechanism is simple and symmetrical in structure, and easy to manufacture and serially produce.

Owner:YANSHAN UNIV

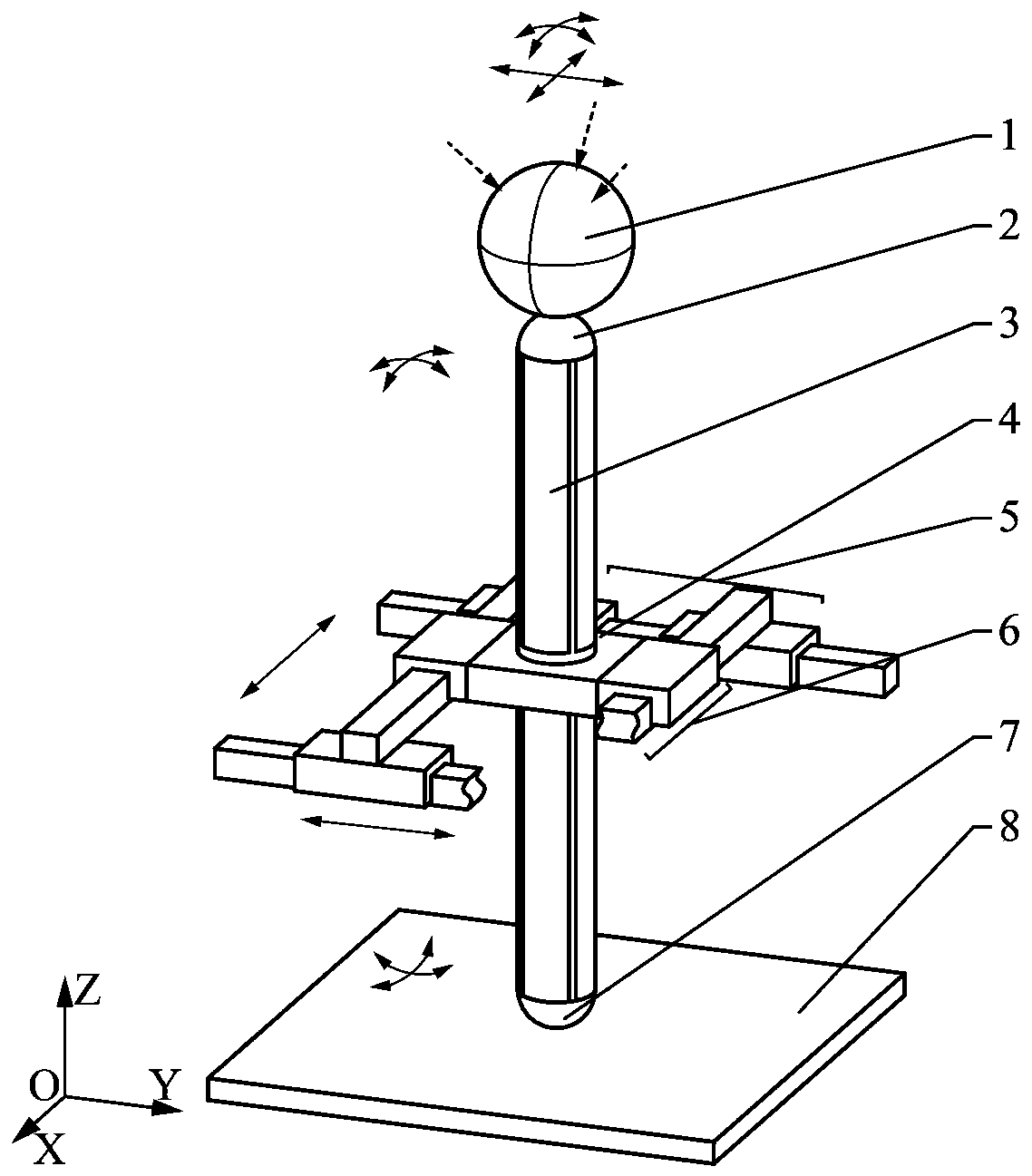

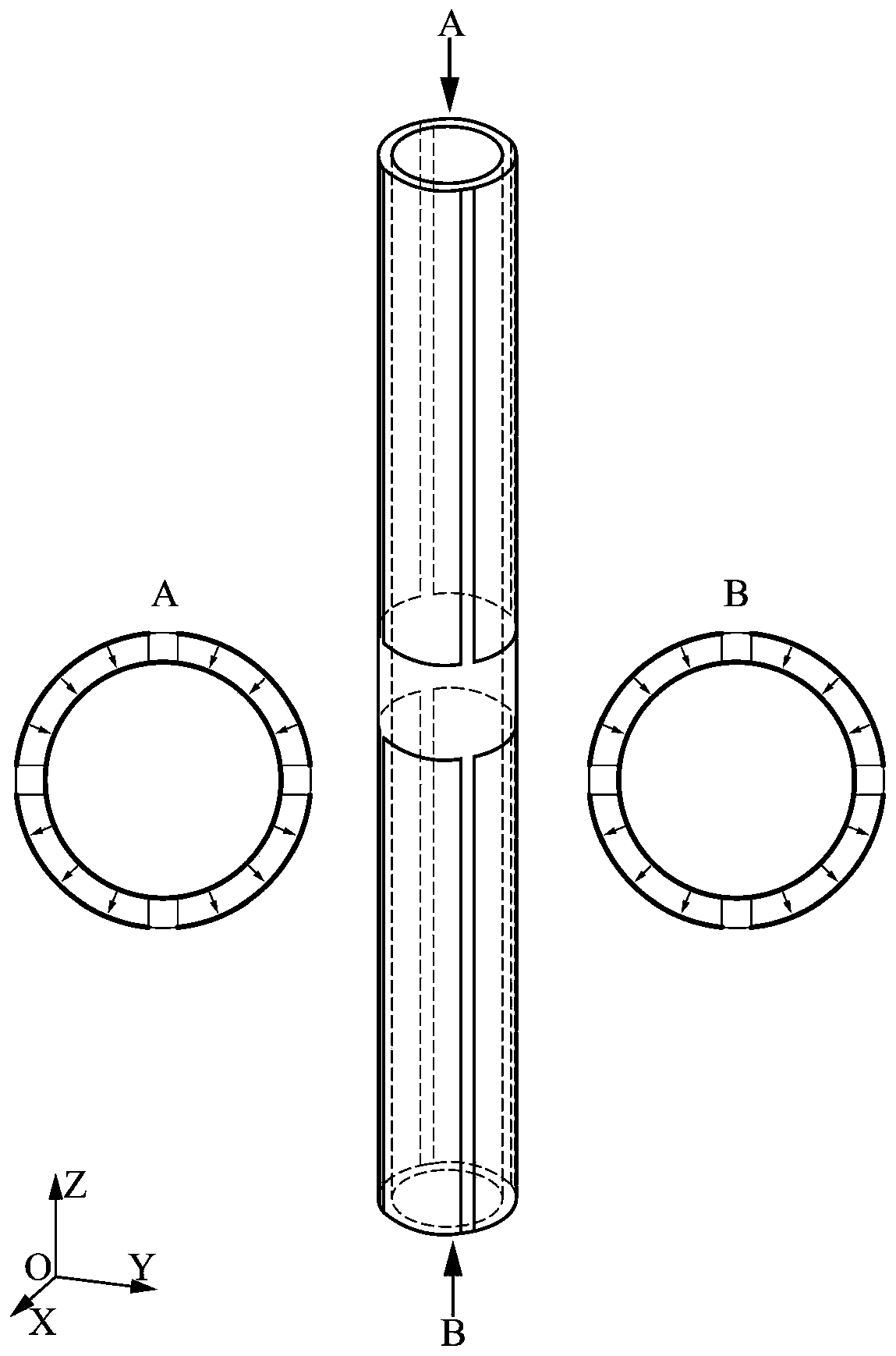

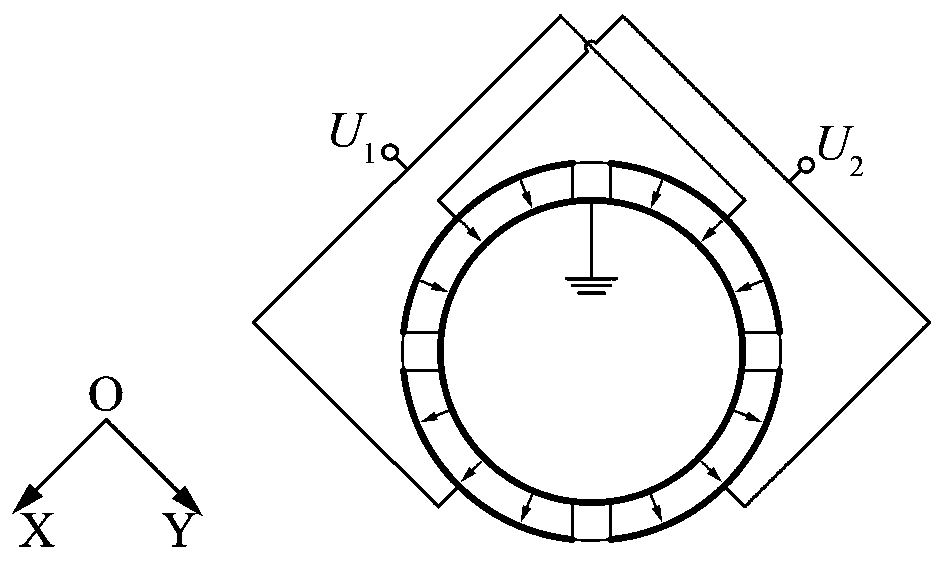

Piezoelectric driving ultra-precision four-degree-of-freedom positioning and attitude adjusting mechanism and excitation method thereof

ActiveCN109951101AMeeting Precision Motion NeedsCompact structurePiezoelectric/electrostriction/magnetostriction machinesLinear motionEngineering

The invention is a piezoelectric driving ultra-precision four-degree-of-freedom positioning and attitude adjusting mechanism and an excitation method thereof. The technical problem that an existing piezoelectric positioning and attitude adjusting mechanism has a single structure, a large size and a high cost of a driving component is solved. The positioning and attitude adjusting mechanism is formed by a mover (1), an upper driving foot (2), a piezoelectric ceramic tube (3), a fixed clamp (4), a lateral guide rail (5), a longitudinal guide rail (6), a lower driving foot (7) and a base (8), wherein the piezoelectric ceramic tube (3) is a main driving element and is used for generating bending deformation to drive the two-degree-of-freedom linear motion and the two-degree-of-freedom rotational motion of the mover (1). Based on the excitation method in the present invention, the positioning and attitude adjusting mechanism can realize large-scale ultra-precision motion. The positioning and attitude adjusting mechanism in the invention has a simple and compact structure, the excitation method is simple and feasible, and the positioning and attitude adjusting mechanism and the excitation method are convenient to apply in the technical field requiring precise positioning and attitude adjustment of an operation object.

Owner:HARBIN INST OF TECH

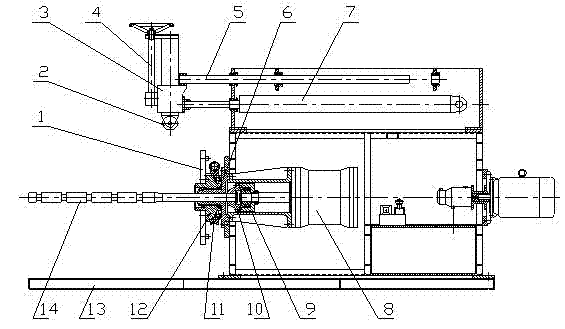

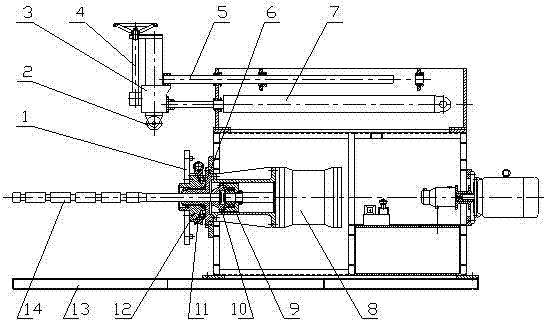

Horizontal cramp machine for laminating motor stator iron cores

InactiveCN102545489ANeatly stackedGuarantee processing qualityManufacturing stator/rotor bodiesHydraulic cylinderControl theory

The invention discloses a horizontal cramp machine for laminating motor stator iron cores, relates to a special cramp machine for laminating motor stator iron cores and particularly relates to a horizontal cramp machine for laminating motor stator iron cores with diameter and height of more than 300mm-1000mm. The horizontal cramp machine is mainly used for solving the problems that the lamination uniformity is poor, the diameter range of processed motor stator iron cores is small, the iron core is difficult to rotate when cramping is performed and the installation is complex in the existing cramp machine for motor stator iron cores. In horizontal cramp machine provided by the invention, a main hydraulic cylinder is horizontally fixed on a machine body, a secondary hydraulic cylinder is horizontally fixed above the main hydraulic cylinder, a piston rod of the main hydraulic cylinder is connected with a piston rod tension transmission mechanism, a laminating tyre connecting disc is connected to the main hydraulic cylinder through a support moving sleeve, a piston rod of the secondary hydraulic cylinder is provided with a pressure head lifting mechanism. The lifting range of a sleeve in the invention is large, the motor stator iron core rotates freely along with a fixture when being laminated and cramped, a tension rod rotates along with the motor stator iron core but the piston rods of the hydraulic cylinders do not rotate, and the installation of the machine is convenient.

Owner:襄阳中车电机技术有限公司

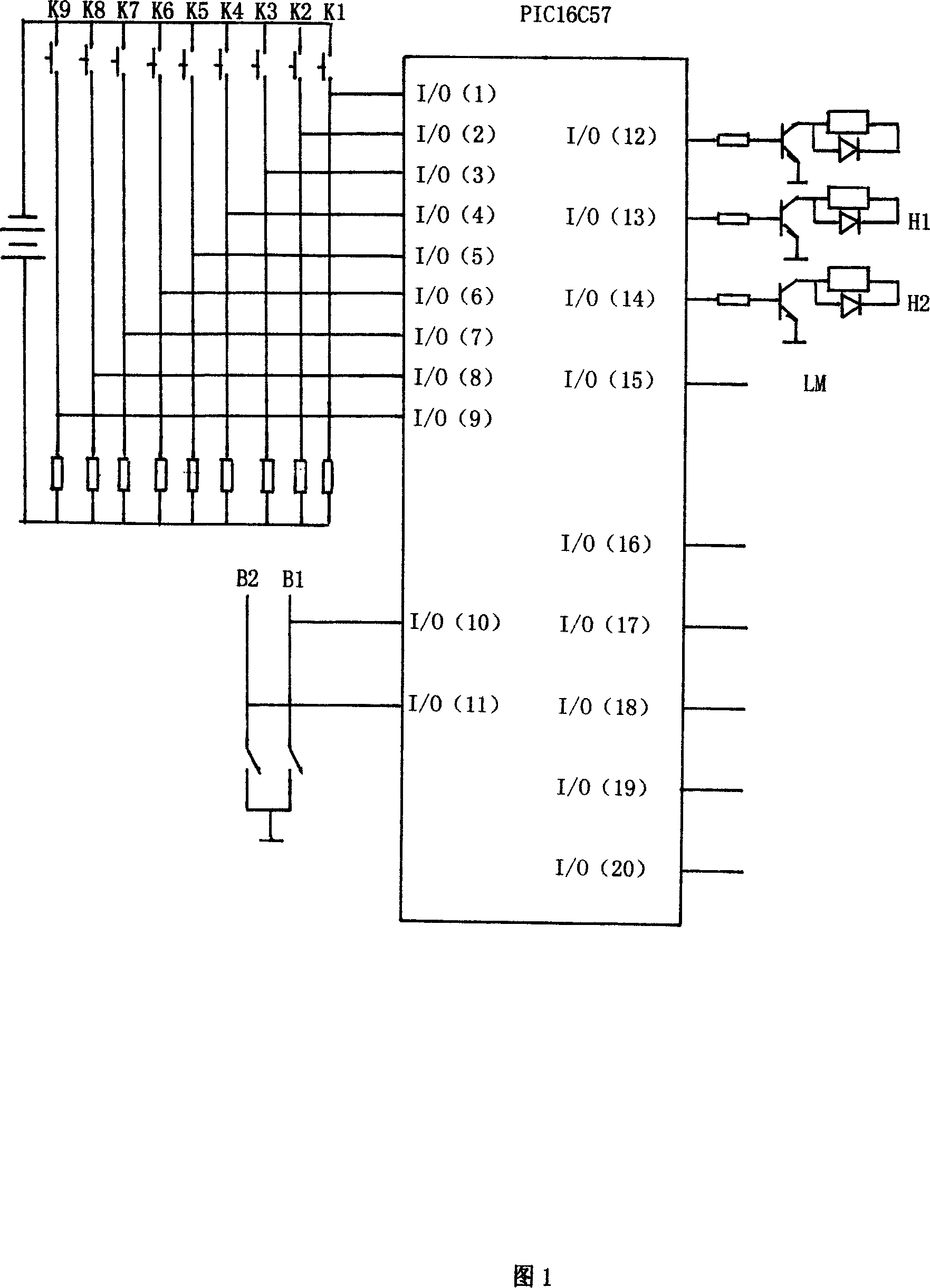

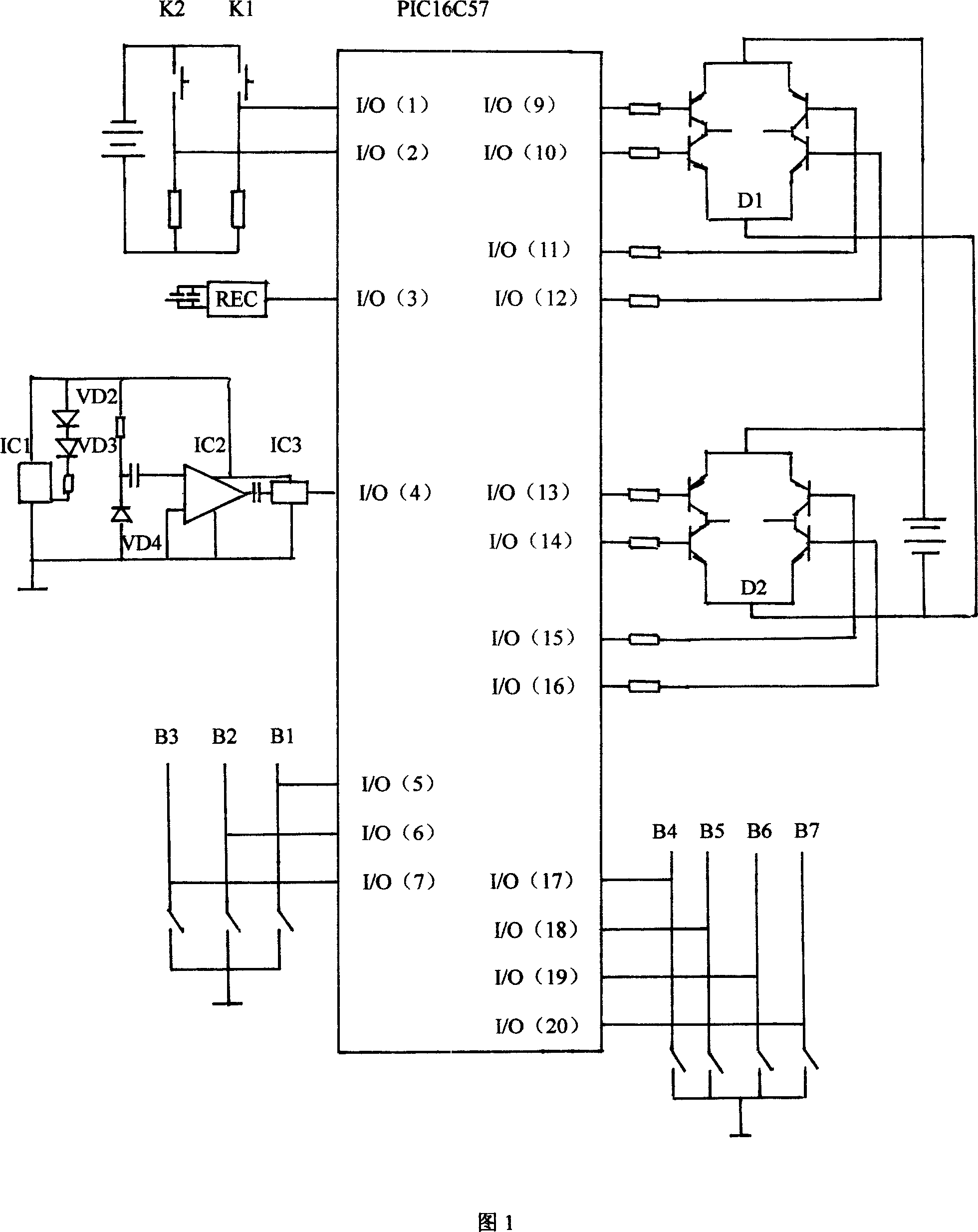

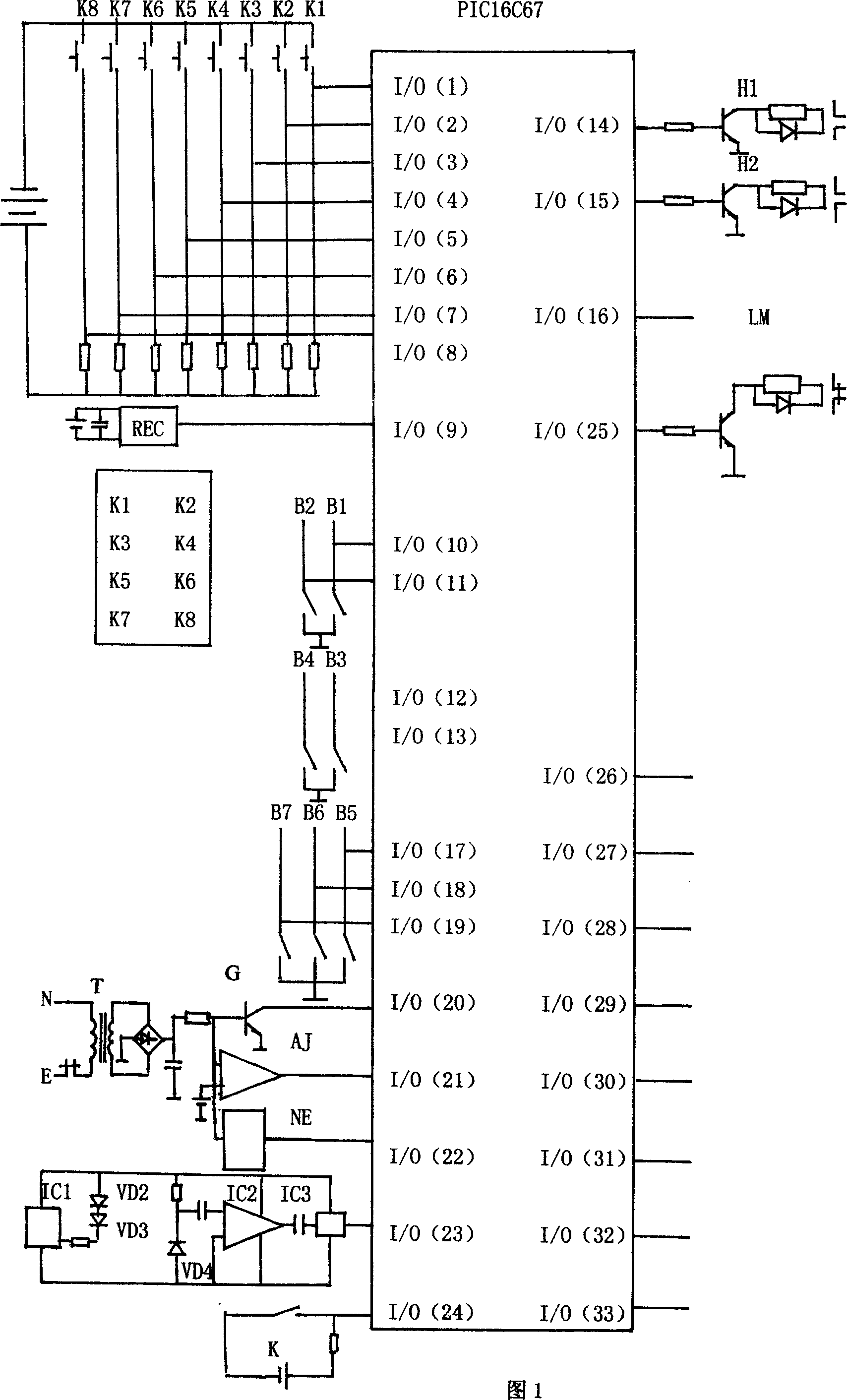

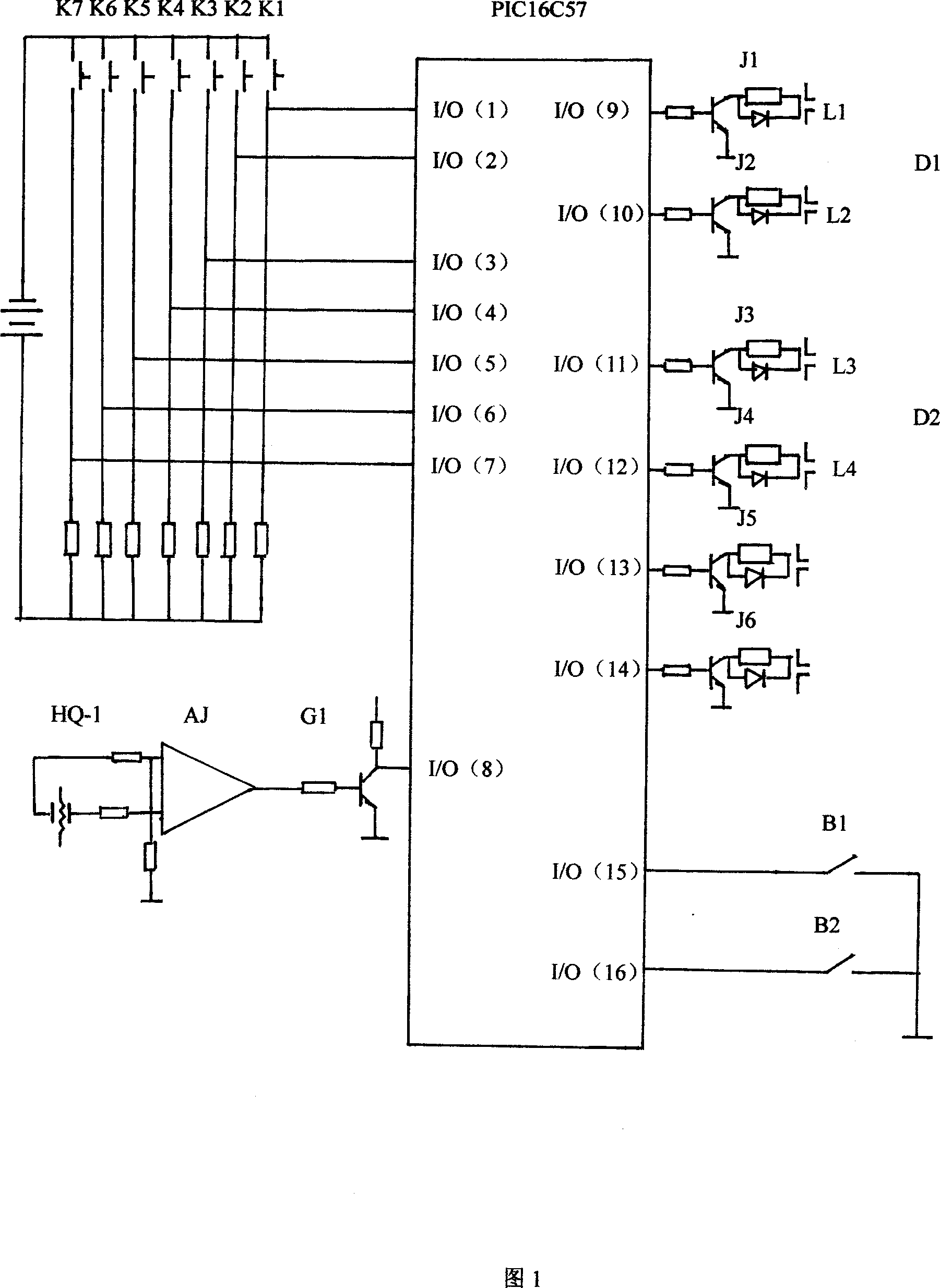

Design of one chip machine shared chip interface and peripheral circuit for embedded type sterilizing cabinet

InactiveCN1949109AEasy to manufactureImprove standardizationComputer controlStatic indicating devicesMicrocontrollerEmbedded software

The invention relates to flush type decontaminate cabinet SCM share chip interface and periphery circuit. Its features are that it has the aggregate of zone bit and flush type software; using to distinguish and select input output type of the periphery circuit that electric heating pipe circuit, temperature display circuit etc by identifying the different combination of zone bit grounding and hanging, flush type software and zone bit; controlling the working of the decontaminate cabinet with different functions. The invention is good for various decontaminate cabinets SCM control chip flush type software making and standardization, serialization production, reducing control chip production cost.

Owner:谭启仁

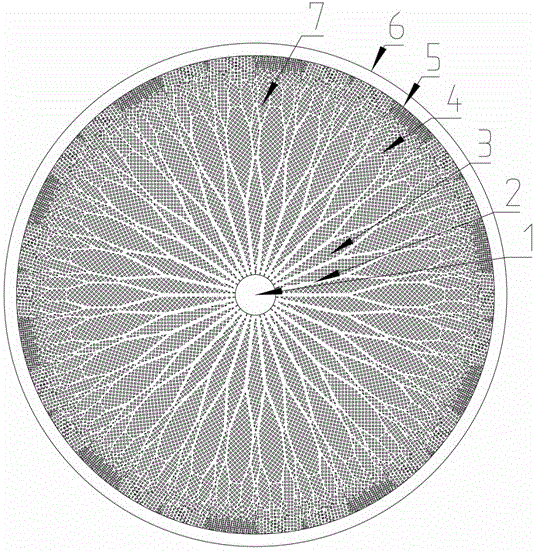

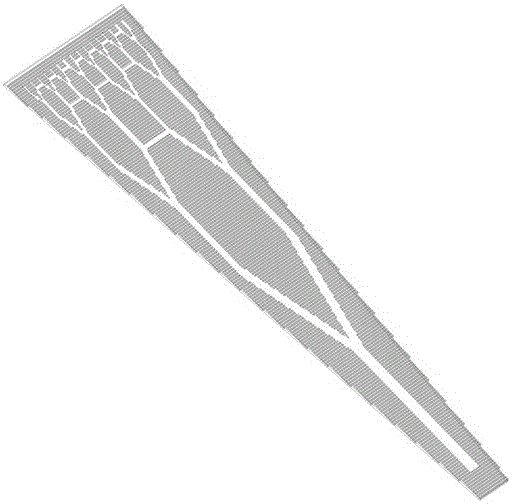

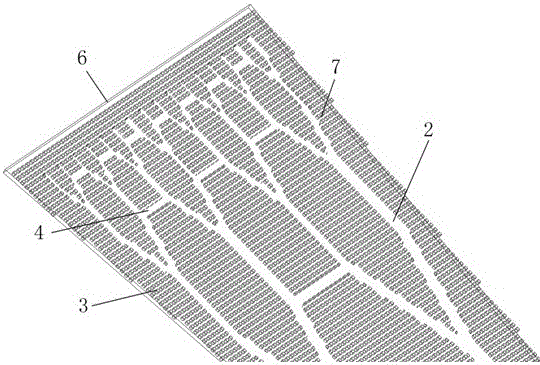

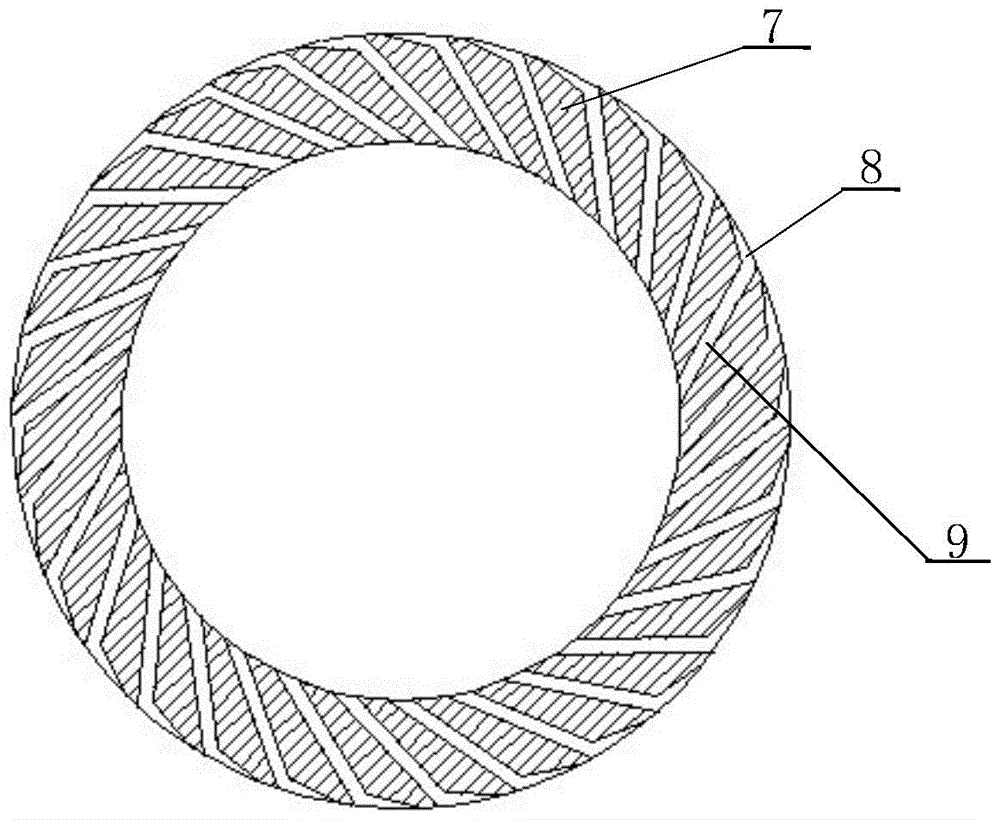

A bionic vapor chamber liquid-absorbing core

ActiveCN103542749BReduce transmission resistanceAvoid local dry-outSemiconductor/solid-state device detailsIndirect heat exchangersCapillary pressureLiquid state

The invention discloses a bionic vapor chamber liquid-absorbing core. The structure of the liquid-absorbing core is based on the efficient transport structure of plant leaves, and is designed according to the transport principle of plant leaves from point to surface and the principle of the shortest path of transport. A novel vapor chamber imitating the transport structure of plant blades. The soaking plate can be integrated with the liquid-absorbing core, so that the working fluid can quickly enter the fractal channel under the action of capillary pressure, and the working fluid transported through the fractal channel can quickly enter the polygonal microstructure surrounded by the fractal channel. And quickly reach the entire condensation surface of the soaking plate, quickly condense into a liquid state, and then return to the evaporation end under the action of capillary pressure. After completing a cycle, it is ready for the next evaporation. At the same time, the polygonal micro-channel structure imitating the leaf vein structure promotes the liquid working fluid to quickly flow to the periphery of the condensation end along the network channel of the liquid-absorbing core, which speeds up the circulation of the working fluid transmission circuit and improves the heat transfer efficiency. The overall size is small and suitable for in sophisticated electronic equipment.

Owner:SOUTH CHINA UNIV OF TECH

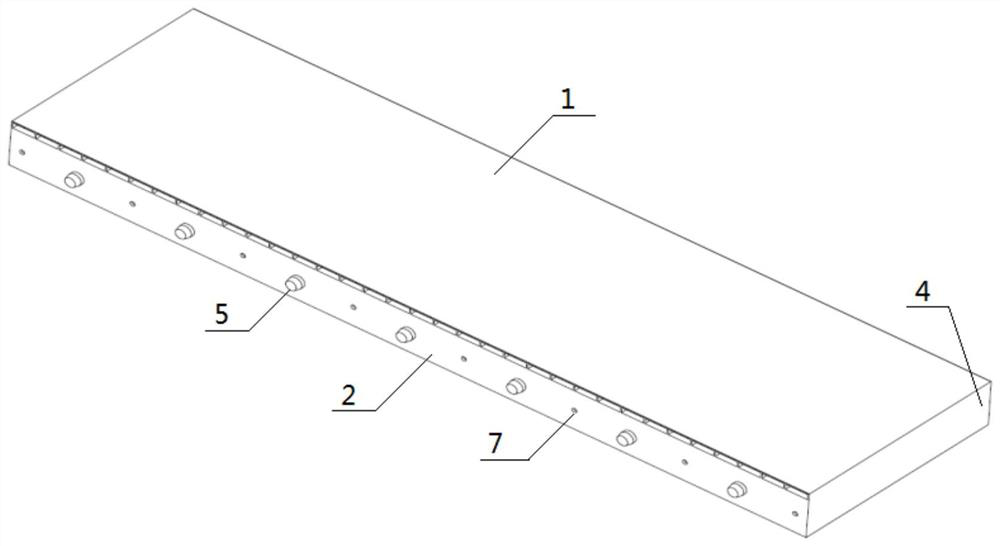

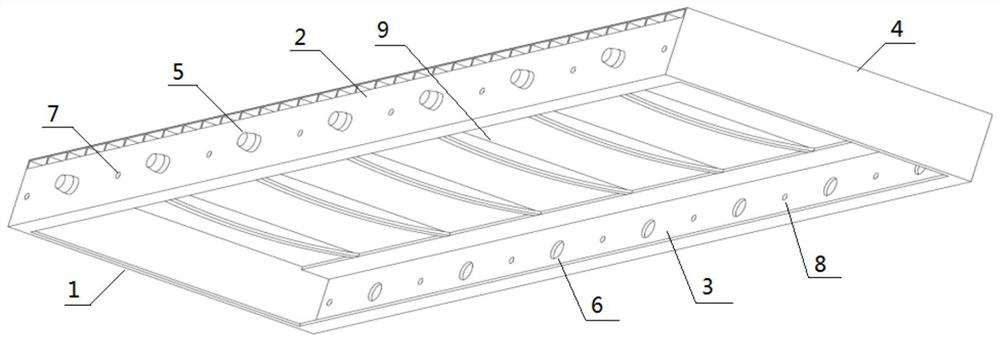

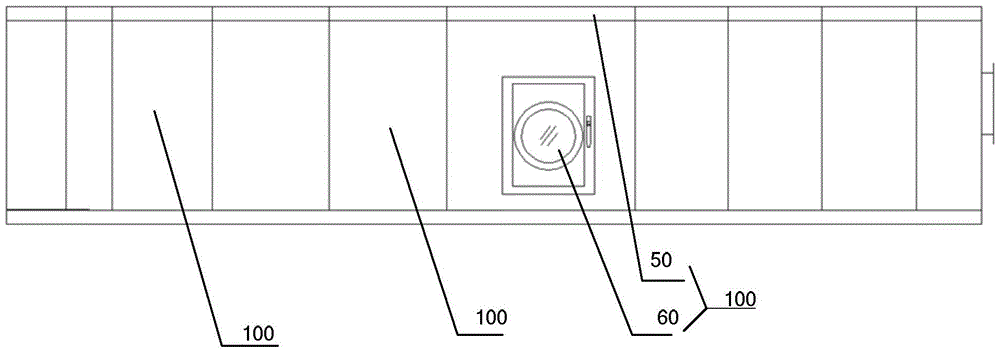

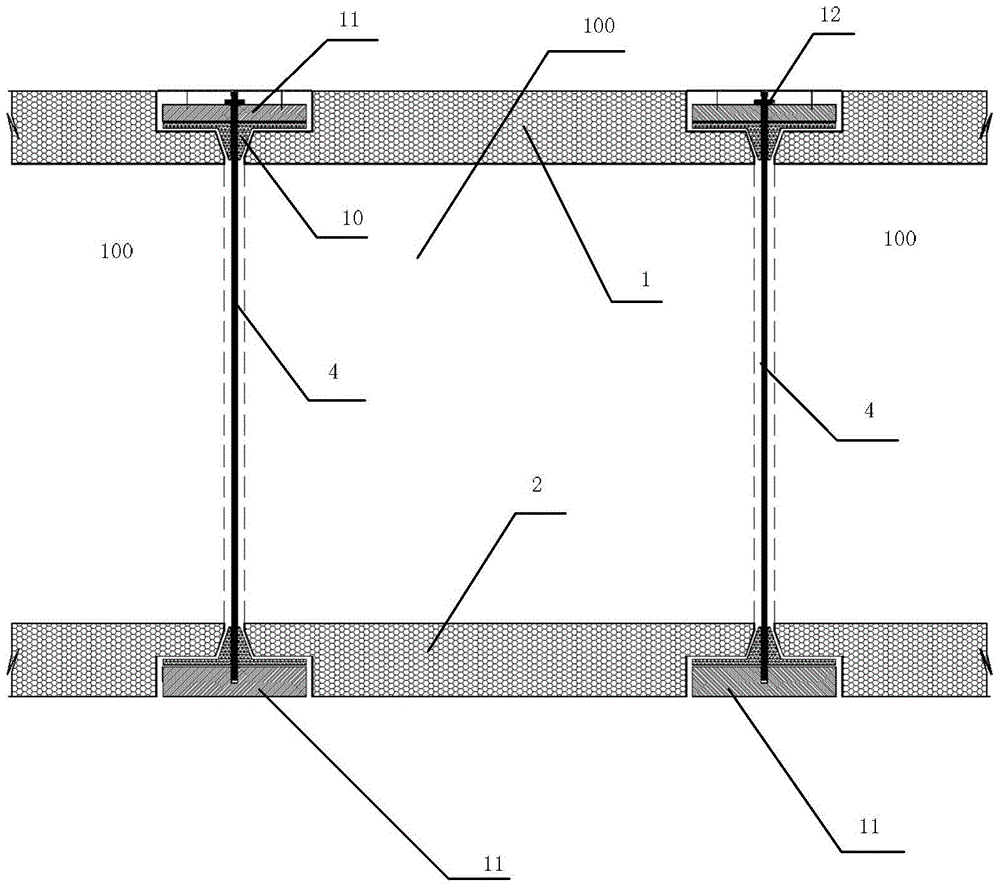

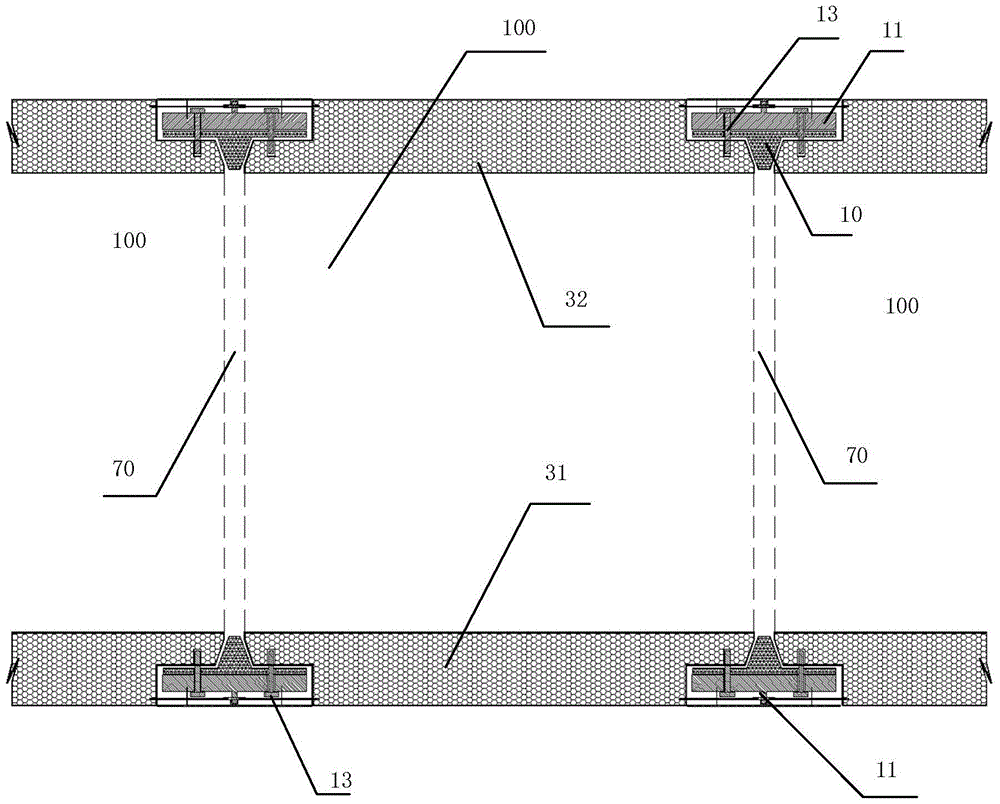

Modular construction and assembly method of boxcar bottom plate

PendingCN112660251AFacilitate serial productionReduce typesLoading-carrying vehicle superstructuresStructural engineeringTruck

The invention discloses a modular construction and assembly method of a boxcar bottom plate. The boxcar bottom plate comprises a floor, a front cross beam, a rear cross beam and side plates. Wherein the two ends of the front cross beam are connected with the two ends of the rear cross beam through side plates respectively, and the tops of the front cross beam, the rear cross beam and the two frames are fixedly connected with the bottom edge of the floor respectively. According to the method, the to-be-produced boxcar bottom plate is formed by combining the pre-produced modules with different sizes, so that the serialization production of the boxcar bottom plates with different sizes is conveniently realized, the mounting process can be simplified, and the production cost is reduced.

Owner:DONGFENG AUTOMOBILE COMPANY

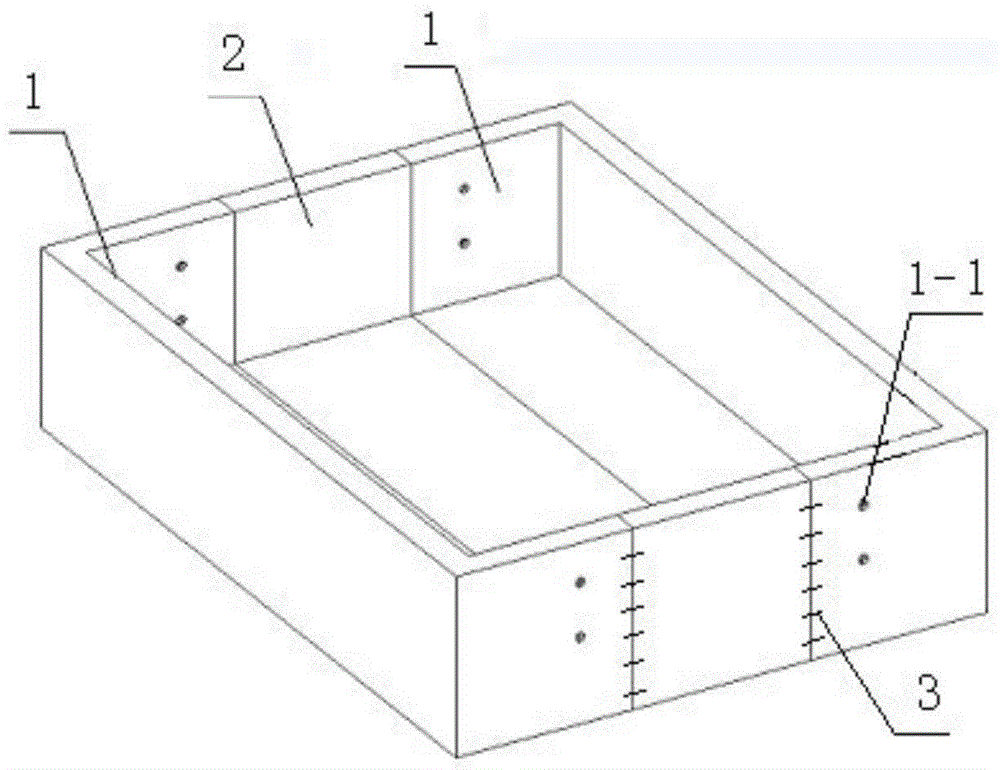

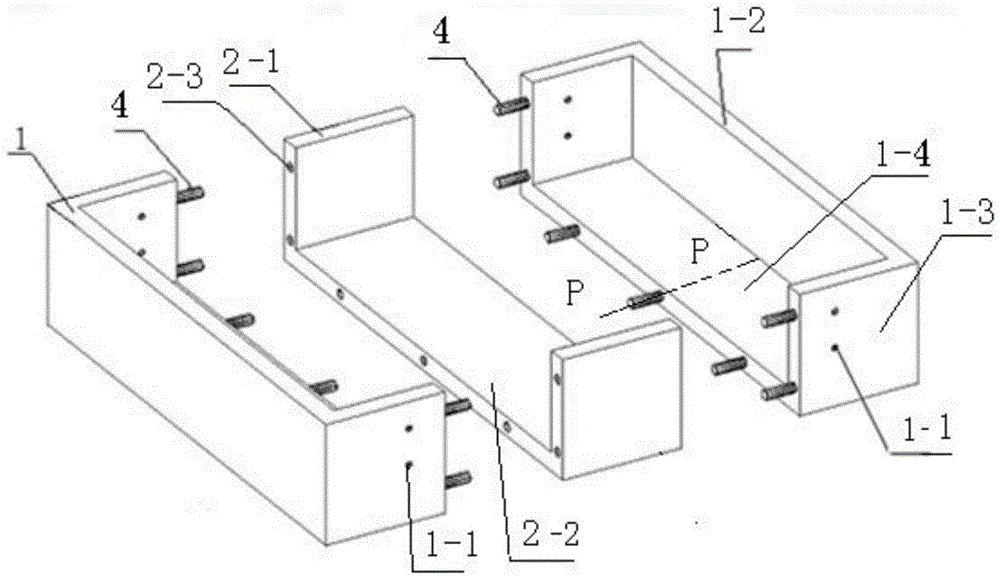

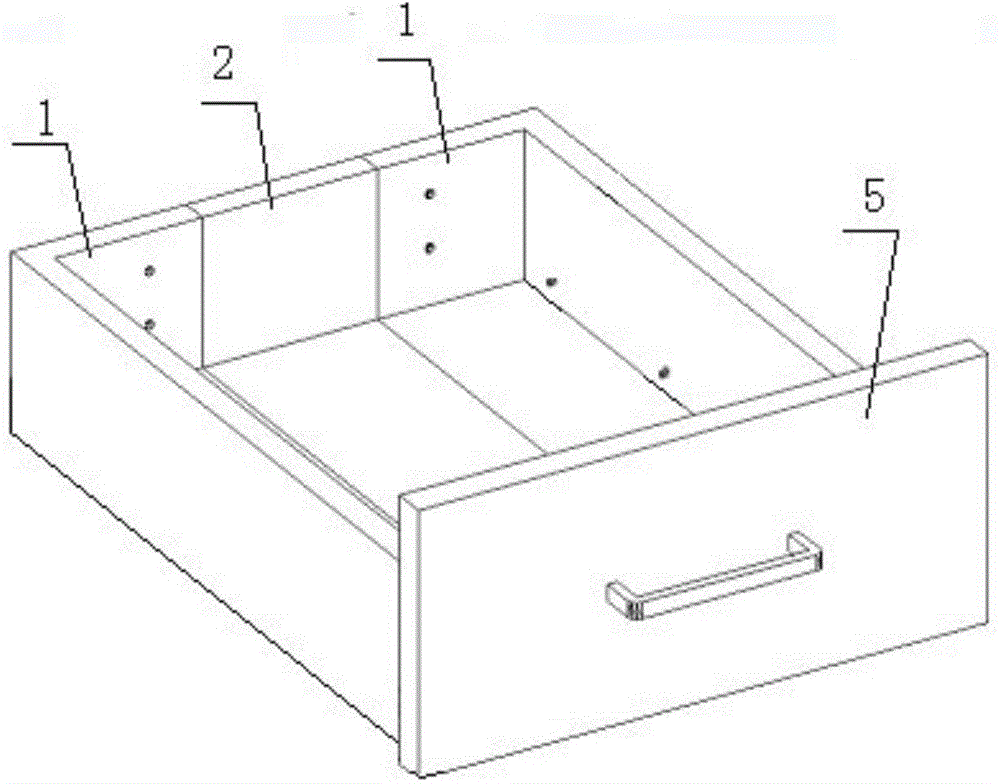

Box-type main body of drawer formed through jointing of members

The invention discloses a box-type main body of a drawer formed through the jointing of members, and the main body comprises first members which are formed through the molding of wood-plastic composite materials, a second member which is formed through extrusion molding. Each first member consists of a box side plate, symmetric box local end plates, and a box local bottom plate. The second member consists of a central bottom plate and symmetric box central end plates. A joint side of each first member is provided with blind holes which are symmetric with blind holes at two sides of a radial axis of the box local bottom plate. The second member is provided with through holes which are corresponding to the blind holes of the first member. The second member is connected with the first members at two sides through connecting wood pins. The main body just needs a compression mold and an extrusion mode under the condition that a depth is determined, thereby meeting the machining and production of box-type main bodies of drawers with different requirements for width. The main body is high in production efficiency, facilitates the standardization of furniture, and also facilitates the series production.

Owner:TIANJIN MINGPIN TECH

Design for common chip interface and peripheral circuit of embedded single-chip microcomputer in water-saving sanitary ware

InactiveCN1966876AEasy to manufactureImprove standardizationComputer controlFlushing devicesMicrocontrollerWater saving

It relates to the design of a single chip shared chip interface and peripheral circuit of embedded water saving sanitary equipment. It has marking positions and embedded software, having the ability of differentiating and selecting touch switches, pressure switches, infrared remote control and receiving circuit, infrared sensing and receiving circuit, electromagnetic valve circuit and other peripheral input and output methods to control different functions of the water saving sanitary equipment. It is beneficial for the standardization and systematic production for the embedded software for control chips of the single chip, saving the resources of single chips with lower cost in production.

Owner:谭启仁

Design of one-chip machine shared chip interface and peripheral circuit for embedded type electric water heater

InactiveCN1949111AEasy to manufactureImprove standardizationWater heatersProgramme control in sequence/logic controllersMicrocontrollerRemote control

The invention relates to flush type electric water heater SCM share chip interface and periphery circuit. Its features are that it has the aggregate of zone bit and flush type software; using to distinguish and select input output type of the periphery circuit that infrared remote control receiving circuit, display circuit etc by identifying the different combination of zone bit grounding and hanging, flush type software and zone bit; controlling the working of the electric water heater with different functions. The invention is good for various electric water heaters SCM control chip flush type software making and standardization, serialization production, reducing control chip production cost.

Owner:谭启仁

Guide rail vacuum connecting rod plug valve

ActiveCN103867737BEasy to disassembleEasy to assembleValve members for heating/coolingSlide valveEngineeringSystem element

The invention belongs to the field of vacuum system elements, and particularly relates to a guide rail vacuum connection rod gate valve. The guide rail vacuum connection rod gate valve comprises a valve body (2) of which a work cavity is internally provided with a transmission mechanism; the transmission mechanism comprises two symmetrical parallel guide rails (6); the guide rails (6) comprise an upper layer rail work surface (601) and a lower layer rail work surface (602) of which one end part is provided with a sunk slot (12); the upper layer rail work surface (601) is provided with a valve frame (7) and is in slide connection with a guide wheel mechanism I (4); the lower layer rail work surface (602) is provided with a valve holder (8); a guide wheel mechanism II (5) is in slide connection with the lower layer rail (602); a connection rod (11) is arranged between the valve frame (7) and the valve plate (8). The guide rail vacuum connection rod gate valve is simple in structure, easy to disassemble, good in sealing property, high in reliability and suitable for high-temperature radiation work conditions.

Owner:SHENYANG VACUUM TECH INST

Modular air conditioning box

ActiveCN104154610BEasy to replaceImprove good performanceLighting and heating apparatusAir conditioning systemsComputer moduleSerialization

The embodiment of the invention provides a modular air handling unit. The modular air handling unit is used for a central air conditioning system and comprises a plurality of functional sections, each functional section in the multiple functional sections is an independent functional section module, and the multiple functional section modules are combined to form the modular air handling unit. Because functional units of the modular air handling unit are manufactured to be the corresponding functional sections, the functions of the modular air handling unit can be divided, produced and assembled in a modular mode, then serialization of modular air conditioner products is facilitated, the functional modules of the modular air handling unit can be arranged compactly, and connection matching and changes in addition and deletion between the corresponding modules can be adjusted freely.

Owner:上海亚冠环境科技有限公司

A hydraulic outrigger structure and a mobile crusher

ActiveCN104057927BEasy maintenanceImprove interchangeabilityVehicle fittings for liftingMovable typeEngineering

The invention relates to a hydraulic supporting leg structure and a movable type crusher. The hydraulic supporting leg structure comprises a supporting leg base assembly, a hydraulic supporting leg assembly, a hanging structure and a jacking structure, wherein the supporting leg base assembly is fixedly connected to a frame body of a to-be-supported device; the hydraulic supporting leg assembly can be hung onto the supporting leg base assembly through the hanging structure and can be used for jacking the supporting leg base assembly through the jacking structure. The hydraulic supporting leg structure provided by the invention is convenient to assemble and disassemble, the off-road capability and the passing capacity of the overall movable type crusher can be improved, the overall weight is reduced during movement, the movable type crusher is convenient to transport and maintain, and serialization and immediate replacement are facilitated.

Owner:XUZHOU XCMG MINING MACHINERY CO LTD

Design of mono-chip machine sheared chip interface and peripheral circuit of inlaid kitchen hood

InactiveCN1936742AEasy to manufactureImprove standardizationProgramme controlDomestic stoves or rangesMicrocontrollerEffect light

It is a new kind of design that is about the chip shared slug interface and peripheral circuit that is from the recessed lampblack shedder. The design involves the peripheral contracture of the chip shared slug, the chip shared slug interface and peripheral circuit that is from the recessed lampblack shedder. The characteristic of the design is to gather the home position soft and the slug soft. It is to distinguish and choose the input an output way that is from the peripheral circuit concluding feather-touch switch, lighting circuit, automatic opening circuit, power circuit and so on in order to control the working of the lampblack shedders which are with different functions. The invention is useful for different lampblack shedders to produce in the standardization, intensivism and series. It is also useful to reduce the product cost of the control slug of lampblack shedders and get over the waste of the chip resources.

Owner:谭启仁

Methods and machinery for calcining materials

The invention provides a method and machine for calcining materials, including: feeding equipment, a preheating chamber, a calcining chamber, a cooling chamber, a discharging device and an exhaust gas discharge system. The calcining chamber is provided with 1 to 10 rows of peripheral burners for preheating The chamber and the cooling chamber are arranged horizontally. The preheating chamber and the cooling chamber are respectively divided into a high temperature preheating chamber and a low temperature preheating chamber, a high temperature cooling chamber and a low temperature cooling chamber by partition walls. The materials in the preheating chamber and cooling chamber move laterally under the push of the pusher mechanism, the higher temperature air after cooling the product in the high temperature cooling chamber is used as combustion air, and the high temperature air after cooling the product in the low temperature cooling chamber preheats the air in the preheating chamber limestone material. The invention makes full use of heat energy, saves heat exchange equipment, and reduces equipment investment and operating costs. Reducing greenhouse gas emissions is conducive to environmental protection. The machine is a detachable component, and each component equipment is manufactured separately and assembled on site, which is convenient for transportation, installation, maintenance and replacement, and is conducive to serial production of calcining machines.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

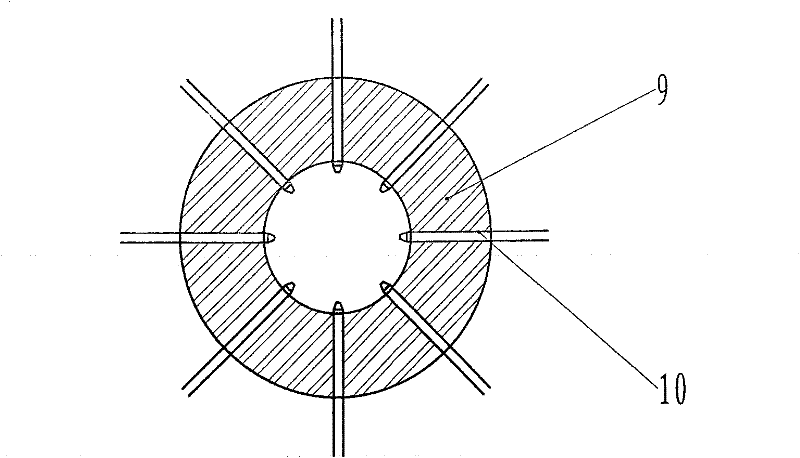

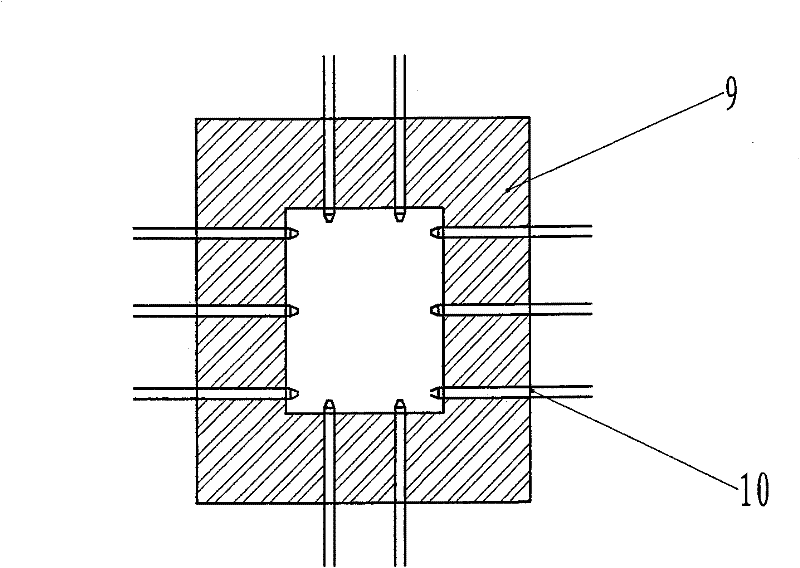

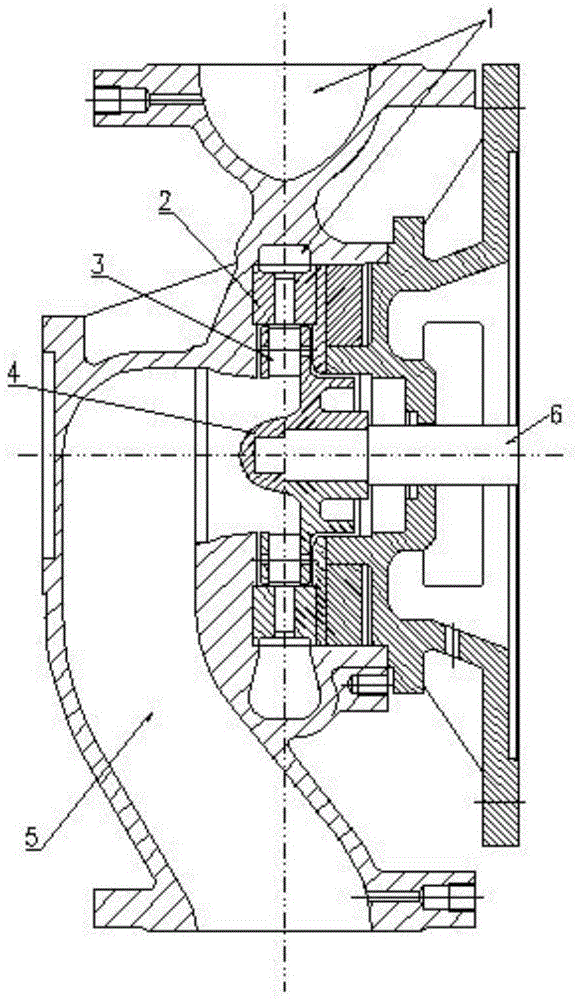

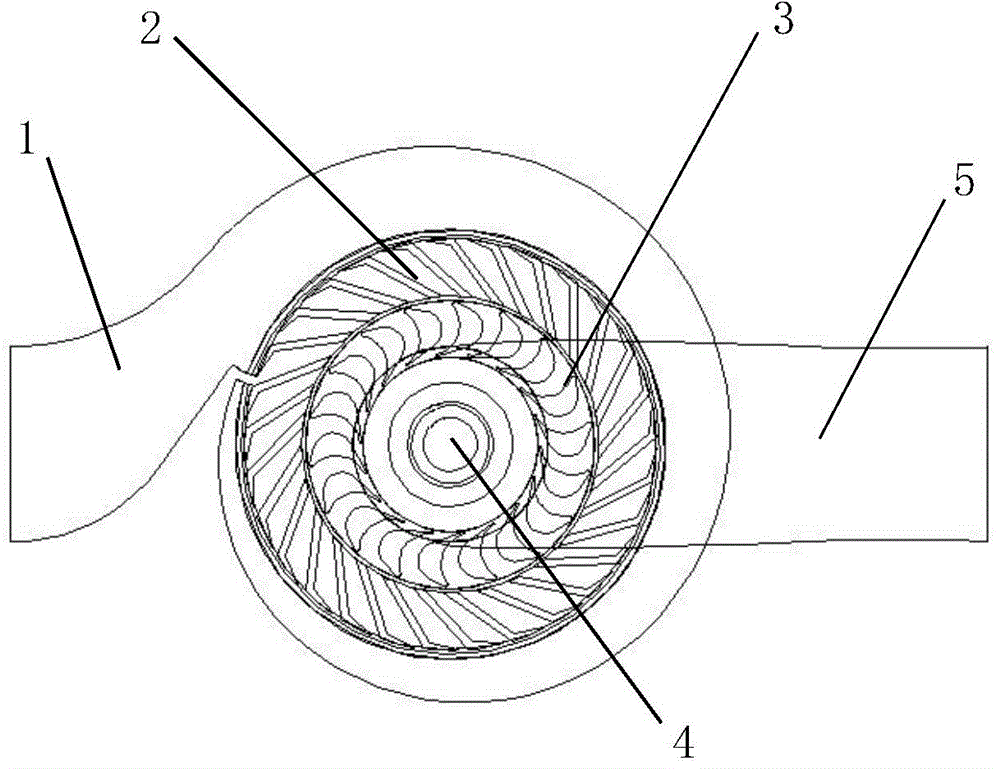

A pipeline water energy recovery device

ActiveCN104500312BEvenly distributedReduce pressure energyReaction enginesEngine componentsPipe waterEnergy recovery

The invention relates to a device for recovering pipeline liquid pressure energy. It includes a volute chamber and a drainage chamber. The drainage chamber is fixed on the volute of the volute chamber, and a rotating shaft is installed on the casing. One end of the rotating shaft is connected to the runner, and the other end drives the generator. Several drainage chambers are evenly distributed along the circumference of the drainage chamber. The drainage cavity is the channel through which the fluid flows. The channel is divided into a front channel and a rear channel. The area of the front channel is tapered and communicates with the volute chamber. connected; the water outlet of the runner is connected to the drain pipe. The beneficial effect of the present invention is: the decompression device is equipped with a volute chamber and a drainage chamber, while effectively reducing the pipeline pressure, it can efficiently recover the pressure energy of the fluid in the pipeline, and the energy recovery efficiency is ≥ 65%.

Owner:XIHUA UNIV

Decelerator for control motor

The invention relates to a speed reducer used for controlling a motor, which comprises an input shaft, a step planetary gear, an internal gear, an output shaft, a right housing, a left housing and a plurality of support bearings. The invention has the advantages that: a high rotational speed meshing is arranged for the gear of the speed reducer, so the processing of the gear is simple with low noise and little heat generating, which is especially obvious with the reducing speed ratio increasing; rolling bearing matching is adopted for the gear and the bearing with high efficiency and convenient installation of the output and the input shafts; 4 to 7 gears participate in meshing work when the gear is meshed with good equal load property, little heat generating, low noise and long service life due to low speed meshing of the gear; four gears can form a speed reducer with less than 100 of drive ratio, thereby adapting to requirement of each sequence reduction ratio and facilitating serial production; reasonable addendum coefficient, modification coefficient and serrated angle of pressure are adopted, thereby achieving a higher transmission efficiency.

Owner:重庆创坤科技发展股份有限公司

Suction nozzle with soft cavity throttling bodies inside

InactiveCN101768934BReduce energy consumptionReduce noiseRoad cleaningAudio power amplifierRoad sweeper

The invention provides a suction nozzle for cleaning the road surface, which relates to the field of a road sweeper component. The suction nozzle mainly solves the following problem: under the condition that the air quantity of a blower of a road sweeper is not changed, more than one closed cavity bodies made of soft materials are additionally arranged between an upper cover in the suction nozzleand the road surface so as to exert the function of throttling and press air flow of an air flow channel in the suction nozzle to cling to the road surface for rapid flowing, thereby sucking garbage into a garbage can. Each independently closed soft cavity throttling body is provided with a vent pipe which is connected to a space with the pressure intensity being equal to or higher than that of the air flow at the lower part or is connected with a pressure balancer. The suction nozzle further comprises the upper cover, a peripheral sealant skirt, a framework, supporting road wheels, a traction mechanism, a left air suction pipe orifice, a middle air suction pipe orifice and a right air suction pipe orifice, wherein the left and right air suction pipe orifices move along with a left suction nozzle or a right suction nozzle to extend out of a sweeper body for operation, and can retract to the left and right sides in a middle suction nozzle; each air suction pipe orifice is provided witha large-caliber air flow amplifier, an air back-blowing knife connected with a small-caliber air flow amplifier is respectively arranged at the lower rear part of each air suction pipe orifice, and each air back-blowing knife is matched with the blowing and sucking air flow of the blower on the road sweeper to blow and suck the garbage into the garbage can of the road sweeper.

Owner:徐国栋

Small underwater robot

InactiveCN100383020CImprove versatilityEasy to assembleUnderwater vesselsUnderwater equipmentGear driveAttitude control

An underwater miniature robot is composed of a segmental shell made of plastic sections and with plastic supporting frames for each segment, sealed cabins, external electric propellers, electric posture controller driven by gears, and the floating body made of foam material.

Owner:李烨

A kind of overrunning clutch with speed control power master-slave commutation

The invention provides an overrun clutch achieving rotating speed control drive and driven power reversing. The overrun clutch is formed by combining two sets of pin roller overrun clutch bodies. An inner ring base and an outer ring base of the first set of pin roller overrun clutch body are fixedly combined with an outer ring base and an inner ring base of the second set of pin roller overrun clutch body respectively. In the initial stage, pin rollers of the two sets of pin roller overrun clutch bodies make contact with and separate from the inner walls of the outer ring bases through springs respectively. The clutch works in a low-speed state, a middle-speed state and a high-speed state. At the low speed, a drive mechanism drives a driven mechanism to rotate through the first set of pin roller overrun clutch body. At the middle speed, the speed of the driven mechanism is increased to exceed the speed of the drive mechanism, and the pin roller overrun clutch bodies are in a separation state. At the high speed, the speed of the driven mechanism is higher than that of the drive mechanism, the second set of clutch body works and reversely drags an original drive mechanism, and power reversing is achieved. The clutch can be applied to the aspects such as electric cars and engine turbine supercharging systems, the performance of a car is improved under driving of a motor at the low speed, the motor is reversely dragged for power generation to achieve energy saving at the high speed, and it is guaranteed that the mechanisms run within the appropriate speed range.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com