Guide rail vacuum connection rod gate valve

A technology of guide rail type and plug-in valves, which is applied in the direction of sliding valves, valve details, valve devices, etc., can solve the problems of no heat insulation, inappropriateness, etc., and achieve the effect of easy disassembly, assembly and maintenance, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

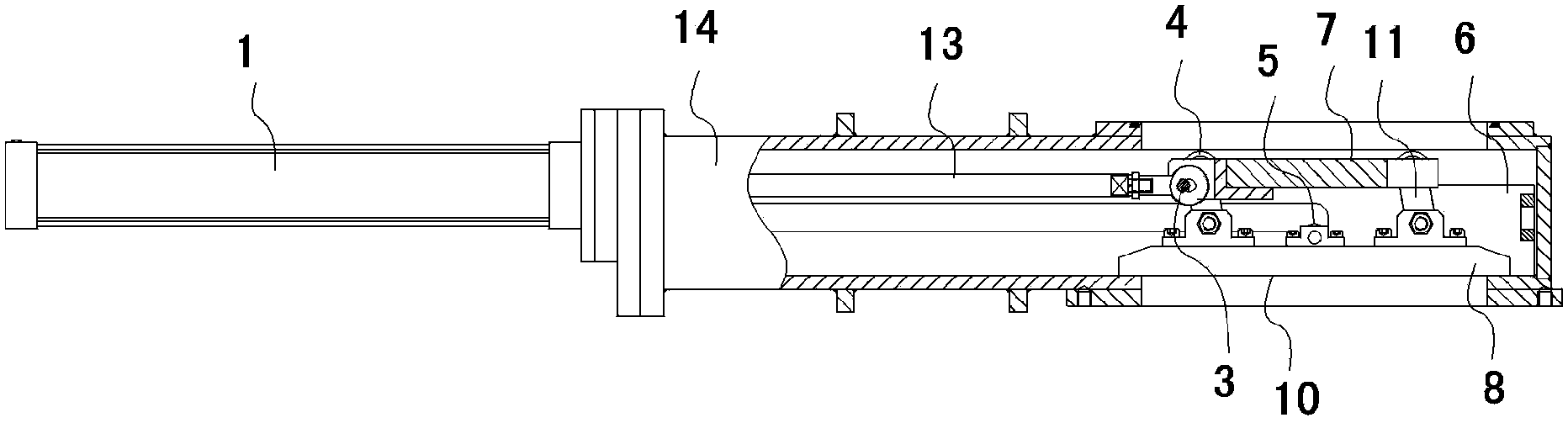

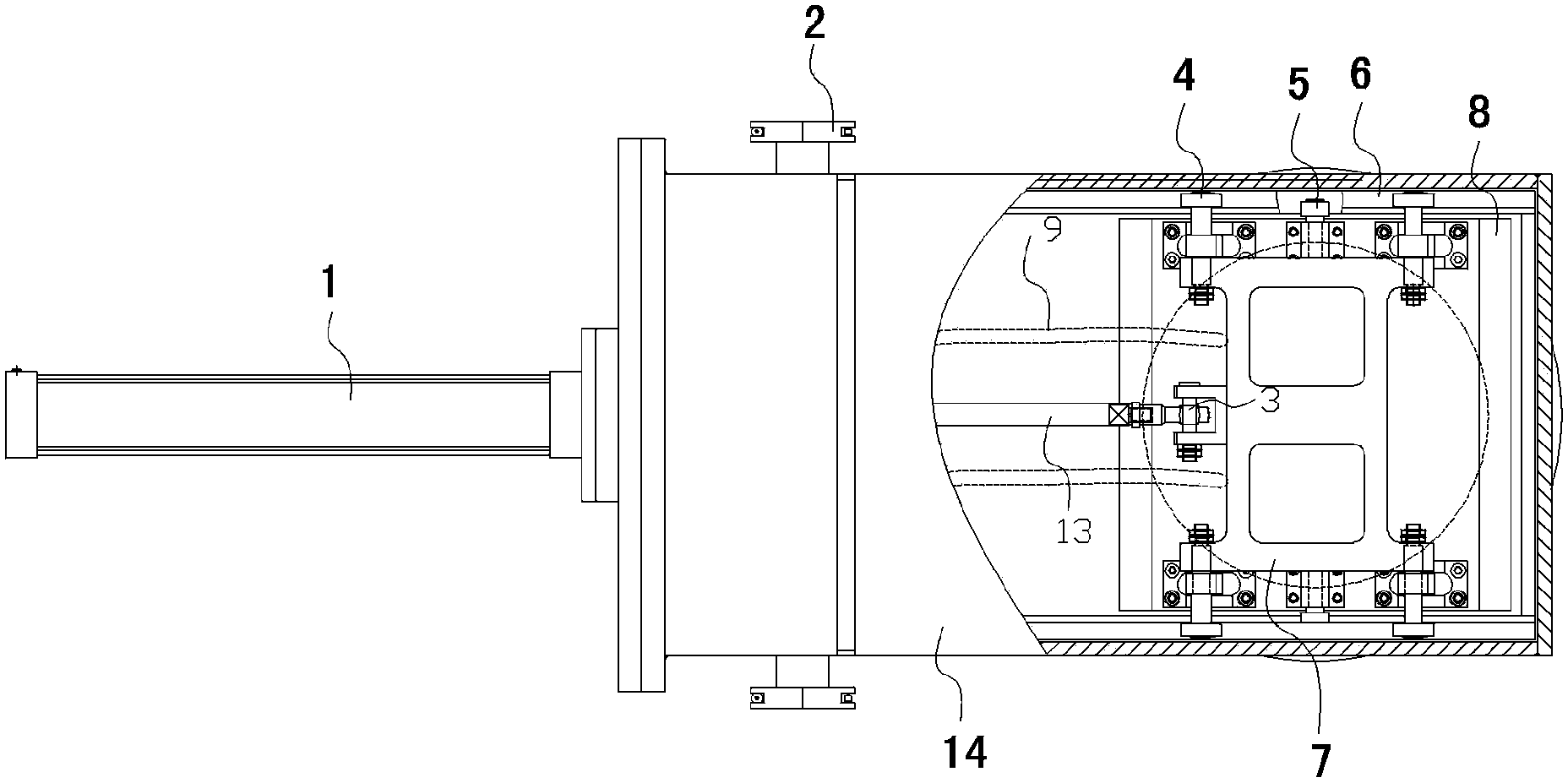

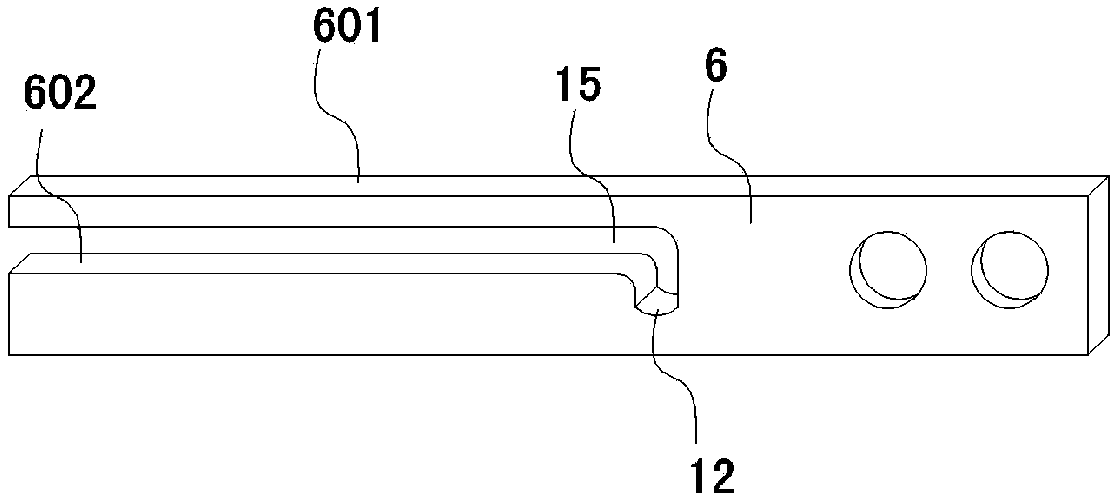

[0019] As shown in the figure, a guide rail type vacuum connecting rod plug-in valve includes a valve body 2; a transmission mechanism is provided in the working cavity of the valve body 2; the transmission mechanism includes two symmetrical parallel guide rails 6; The guide rail 6 includes an upper rail working surface 601 and a lower rail working surface 602; one end of the lower rail working surface 602 is equipped with a sinking groove 12; the upper rail working surface 601 is provided with a fixed matching guide wheel mechanism I4 Valve frame 7; the guide wheel mechanism I4 is in sliding connection with the upper track working surface 601; the lower track working surface 602 is provided with a valve plate 8 fixedly connected to the guide wheel mechanism II5; the guide wheel mechanism II5 is connected to the lower layer The track working surface 602 is slidingly connected; one end of the valve body 2 is fixed with a cylinder 1; the push rod 13 of the cylinder 1 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com