Modular construction and assembly method of boxcar bottom plate

A technology for the carriage floor and assembly method, which is applied to the upper structure of the truck, the upper structure, and vehicle parts, etc., can solve the problems of the limited size of the carriage floor, achieve enhanced sound insulation and heat insulation, tight connection, and reduce types and Quantity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

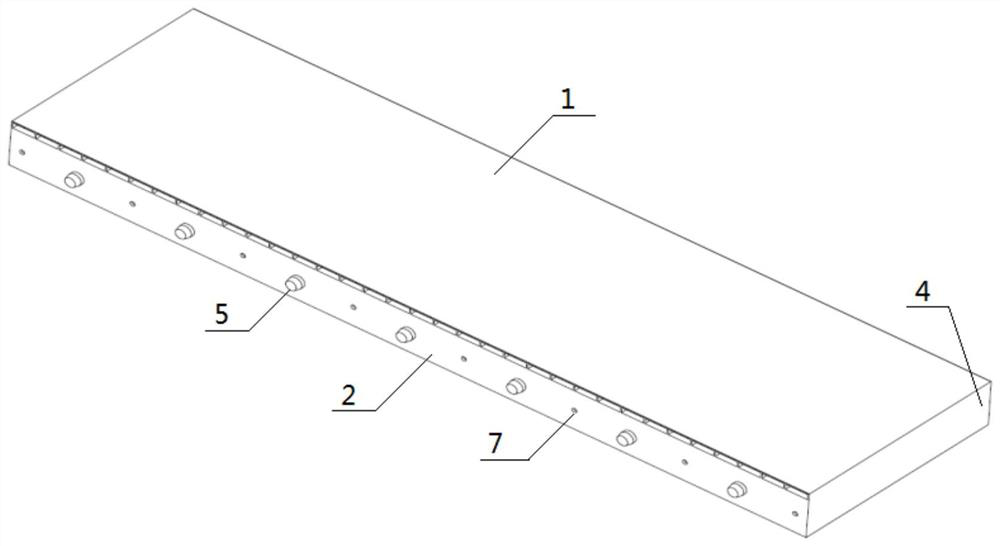

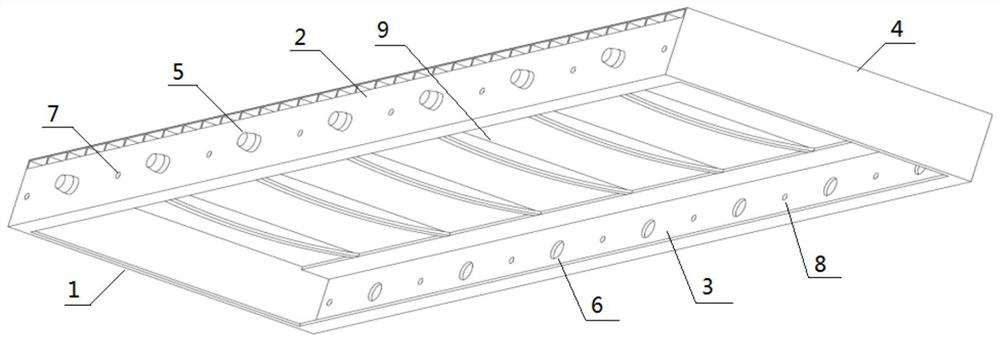

[0056] A truck compartment floor modular construction structure, the truck compartment floor module includes: a floor 1, a front beam 2, a rear beam 3 and a side panel 4; The two ends of 3 are connected, and the tops of the front beam 2, the rear beam 3 and the two frames 4 are respectively fixedly connected with the bottom edge of the floor 1.

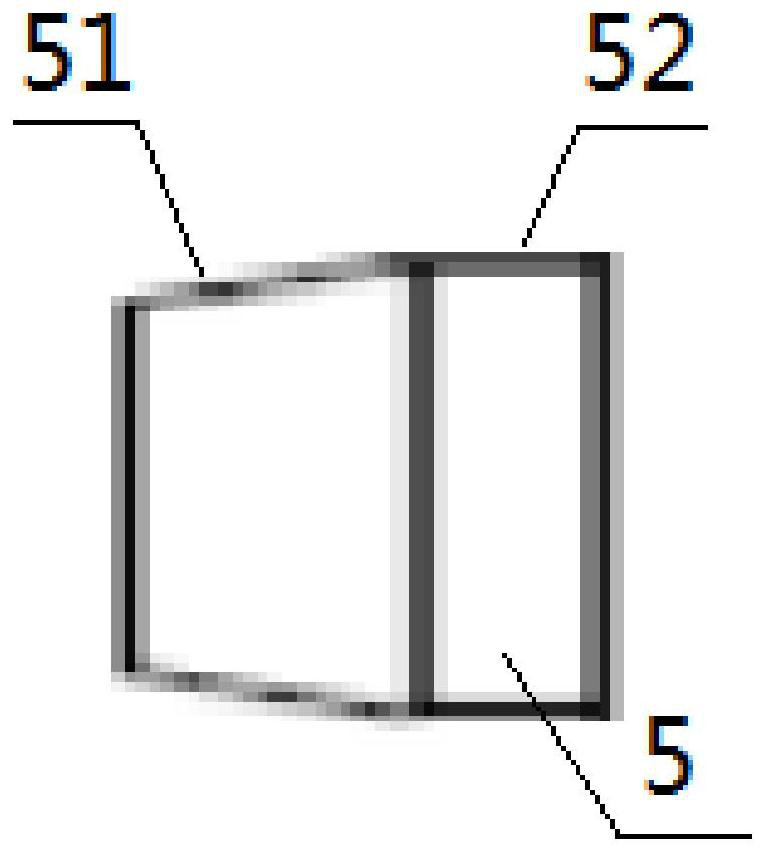

[0057] The front end of the front beam 2 is evenly provided with a plurality of positioning bosses 5, the positioning boss 5 includes a cone 51 and a positioning pin 52 connected with the cone 51, one end of the positioning pin 52 is connected with the cone 51, and the positioning pin 52 is connected to the cone 51. The other end is connected with the front beam, and the diameter of the frustum 51 becomes larger gradually from the far beam end to the near beam end.

[0058] The front beam 2 is provided with a plurality of bolt connection holes 7 , and the bolt connection holes 7 and the positioning bosses 5 are alternately arranged on...

Embodiment 2

[0070] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

[0071] The upper surface of the floor 1 is a smooth surface or a patterned surface, the floor 1 is a hollow floor, and its hollow structure is a square through hole, and the opening direction of the square through hole is parallel to the short side of the floor 1; The lower part of the floor 1 is provided with reinforcing ribs 9, the reinforcing ribs 9 are bow-shaped, the height of the middle part is higher, and the height of both sides is lower, and the section of the reinforcing ribs 9 is an inverted T shape.

Embodiment 3

[0073] Embodiment 3 is basically the same as Embodiment 2, and its difference is:

[0074] The outside of the side plate 4 is provided with a hinge for fixing the side wall panel of the compartment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com