Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63results about How to "Efficiently performed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

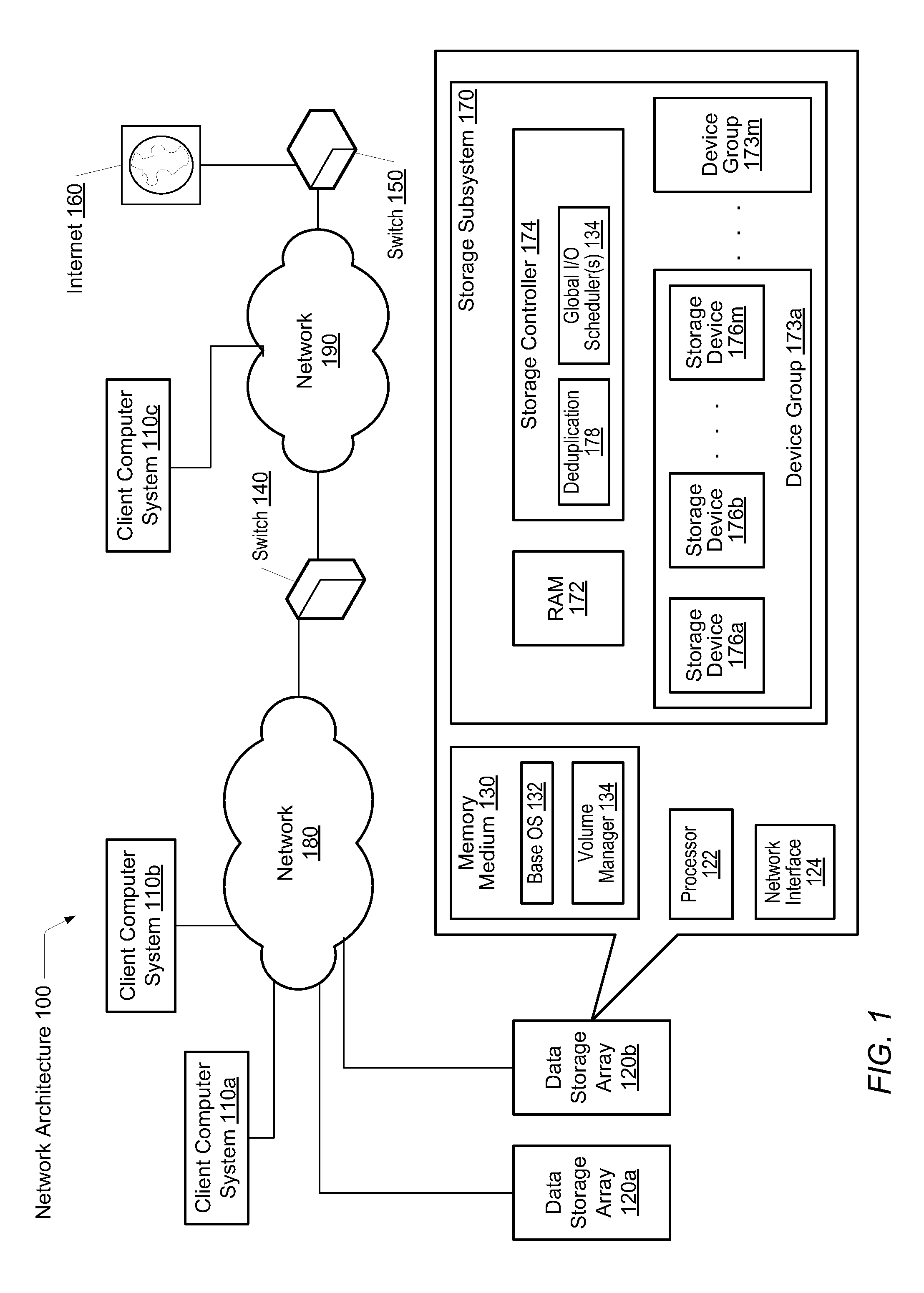

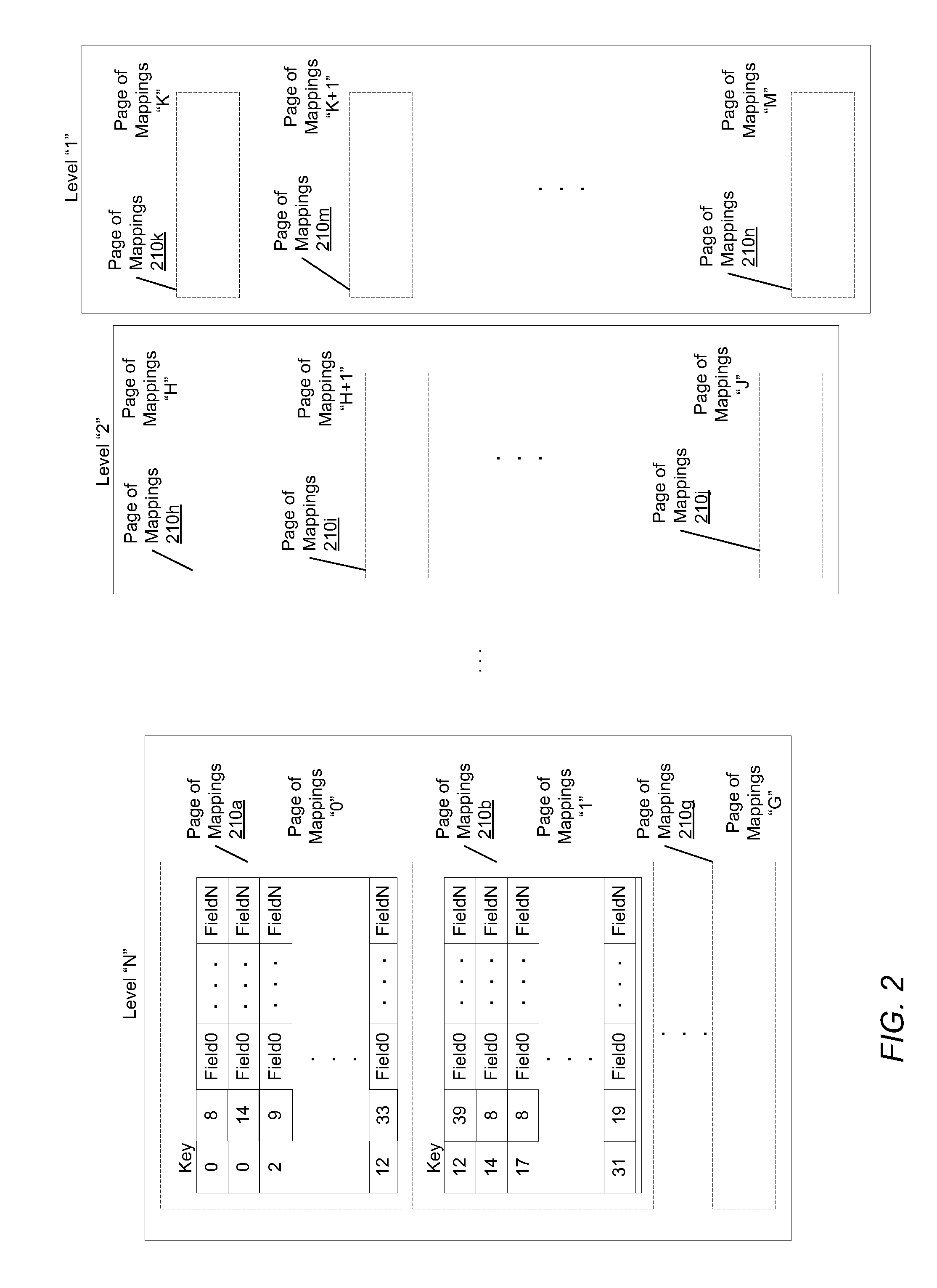

Logical sector mapping in a flash storage array

InactiveUS20130042052A1Efficiently performedMemory architecture accessing/allocationMemory loss protectionSolid-state storageStorage virtualization

A system and method for efficiently performing user storage virtualization for data stored in a storage system including a plurality of solid-state storage devices. A data storage subsystem supports multiple mapping tables. Records within a mapping table are arranged in multiple levels. Each level stores pairs of a key value and a pointer value. The levels are sorted by time. New records are inserted in a created newest (youngest) level. No edits are performed in-place. All levels other than the youngest may be read only. The system may further include an overlay table which identifies those keys within the mapping table that are invalid.

Owner:PURE STORAGE

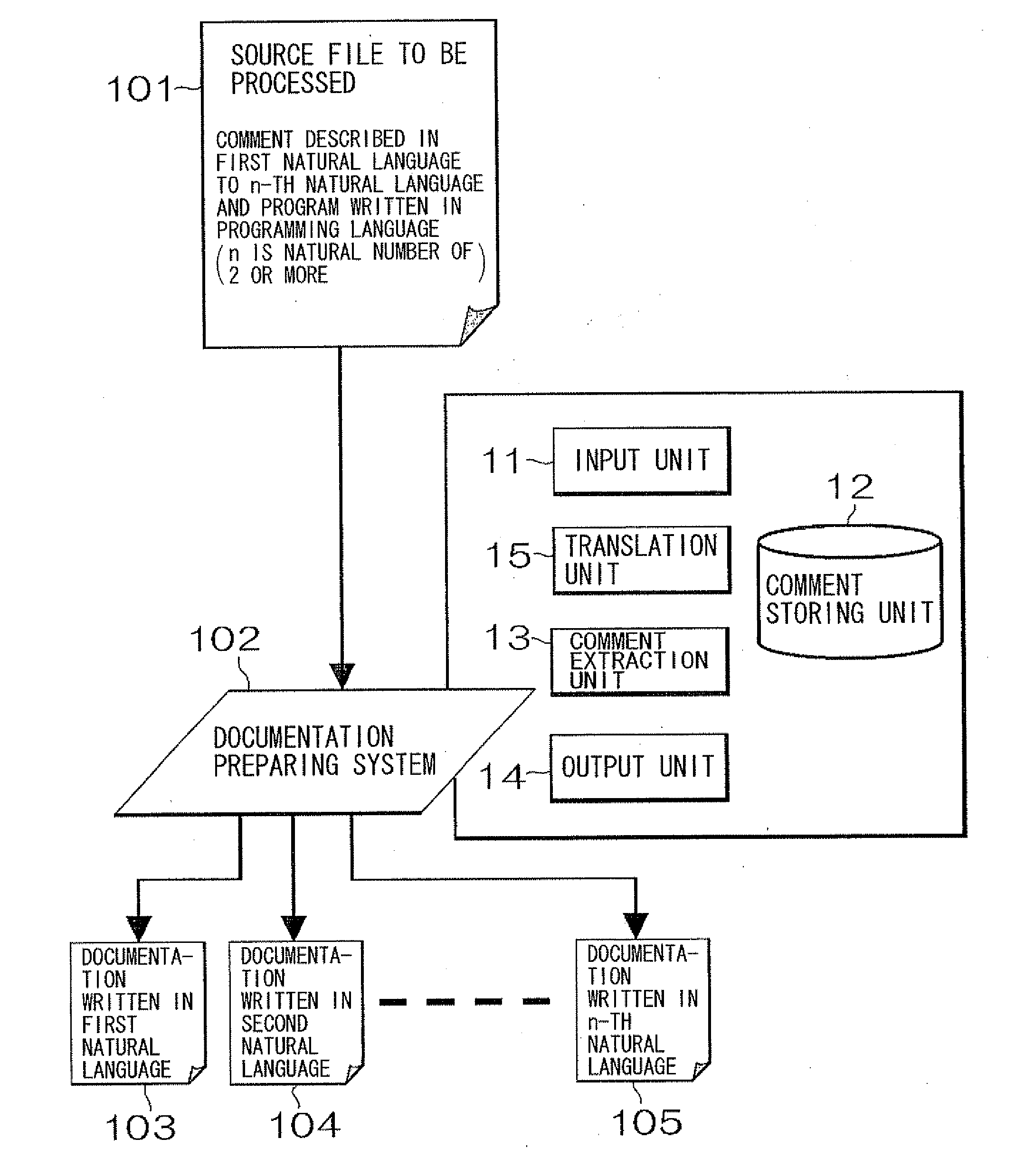

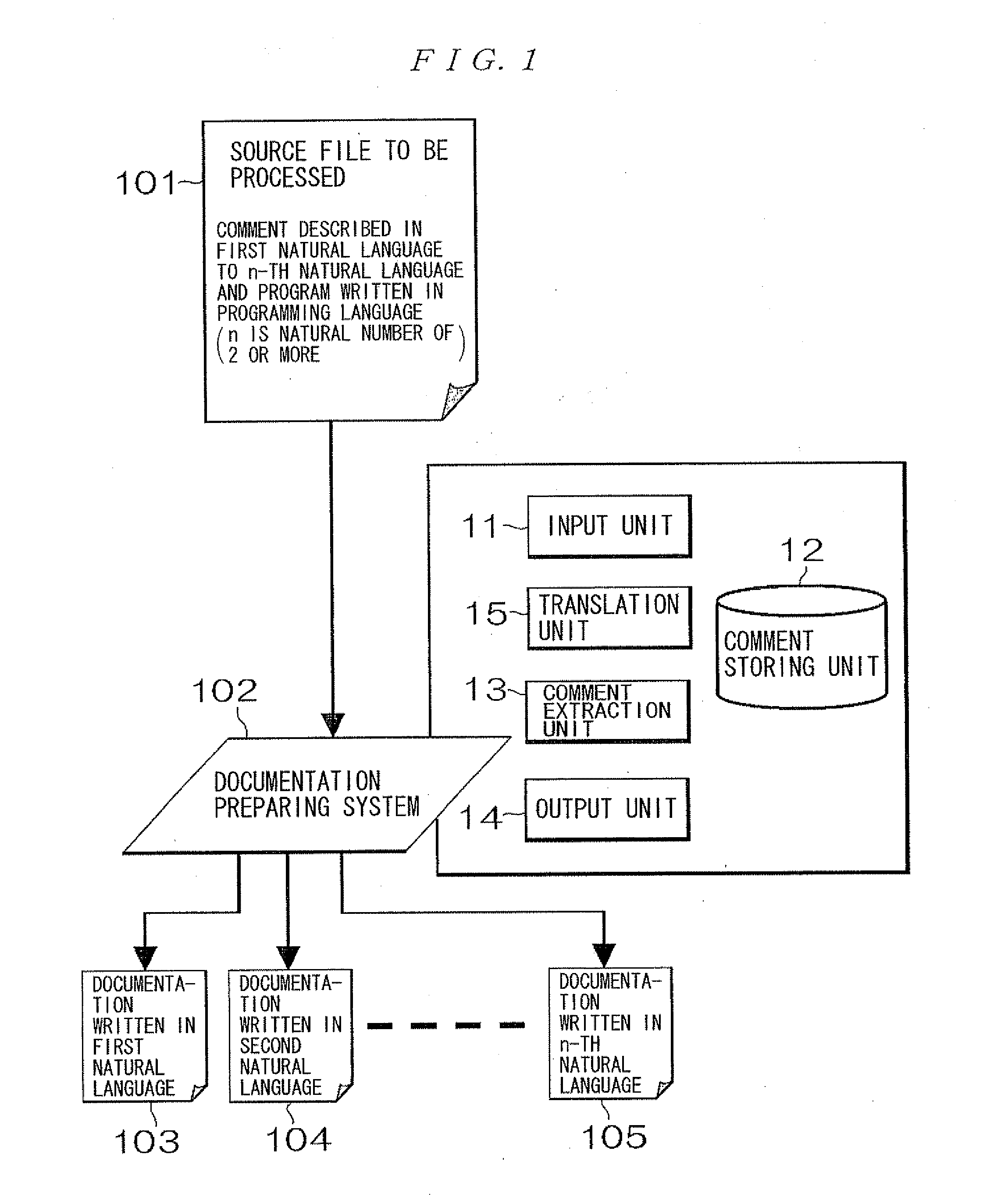

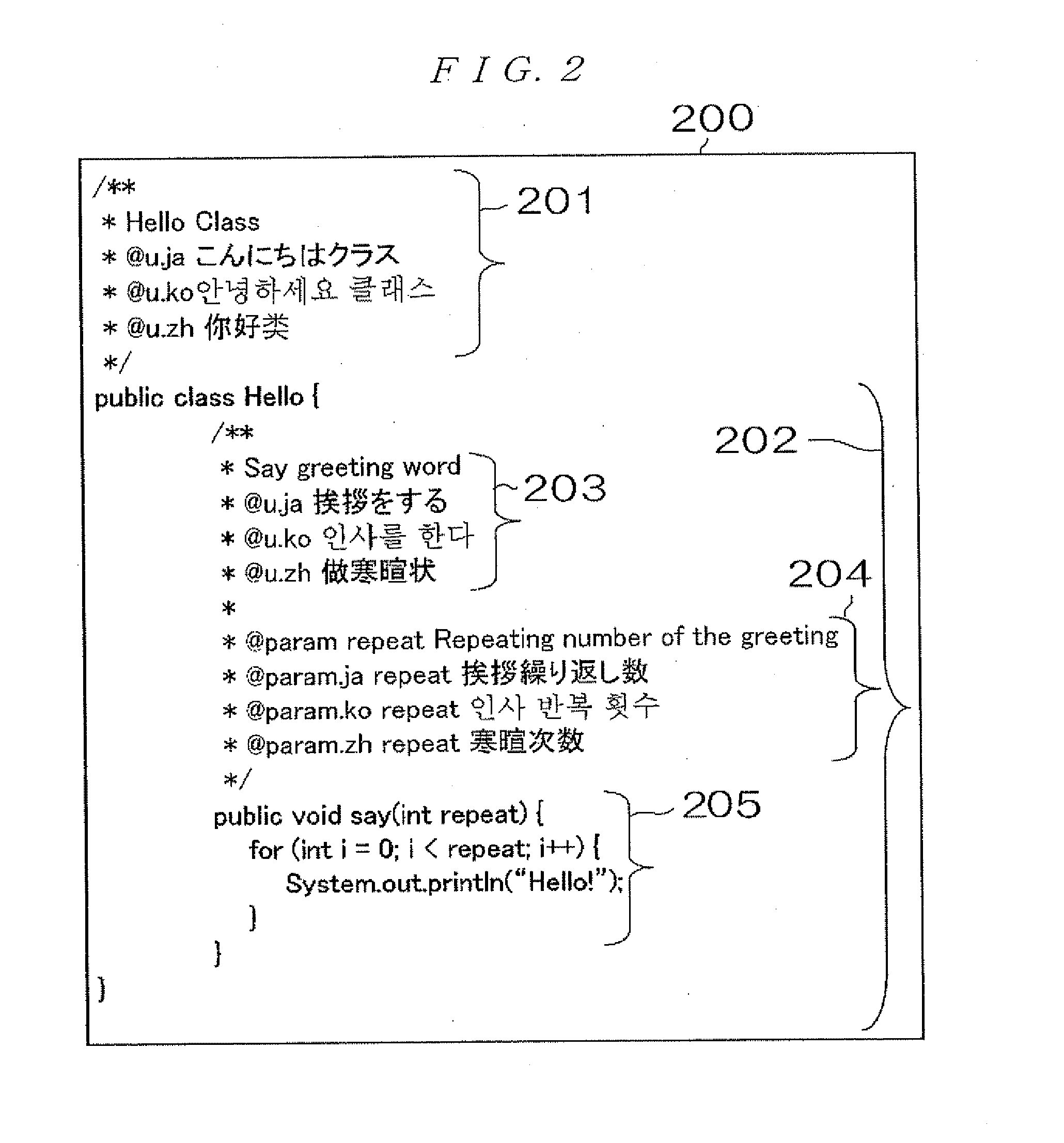

System for Preparing Software Documentation in Natural Languages

InactiveUS20100146491A1Efficiently performedEfficient executionProgram documentationExecution for user interfacesSystem usageSoftware documentation

A software documentation preparing system which can prepare software documentation written in plural natural languages is provided. The software documentation preparing system uses input unit for inputting a source file including a source code statement written in a programming language and a comment assigned to the source code statement, in which source file, the comment describing one of functions in the source code is described in plural natural languages, each of the descriptions in the natural languages provided with a combined sign of a sign indicating the function and a sign indicating a type of natural language; interprets the input source file, identifies the combined sign, associates the sign with a source code statement, and stores a comment on memory; extracts only a comment provided with a sign corresponding to the type of the user-specified natural language to be output; and outputs software documentation in the natural language to be output for the source code statement based on the extracted comment.

Owner:NAT INST OF ADVANCED IND SCI & TECH

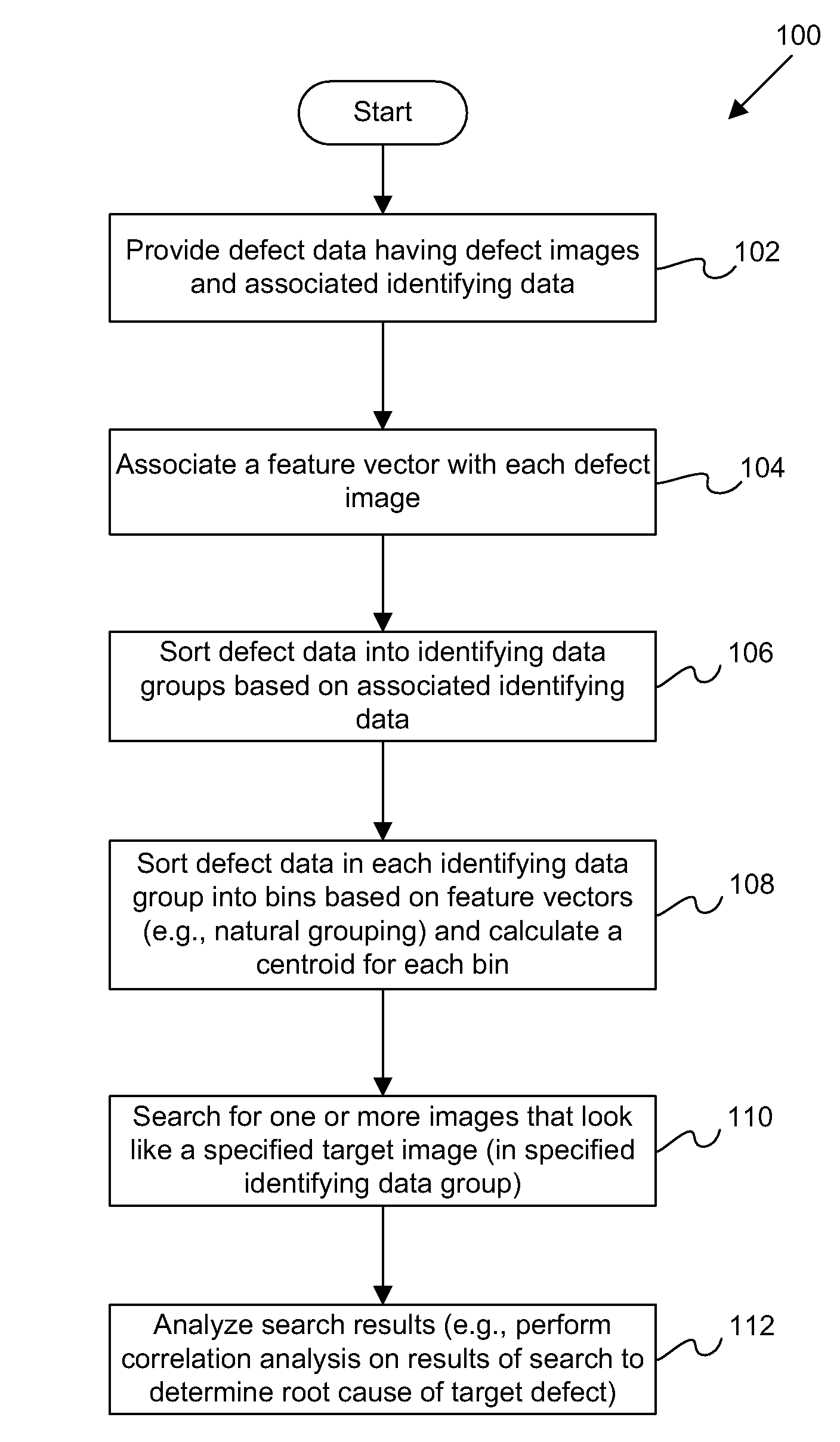

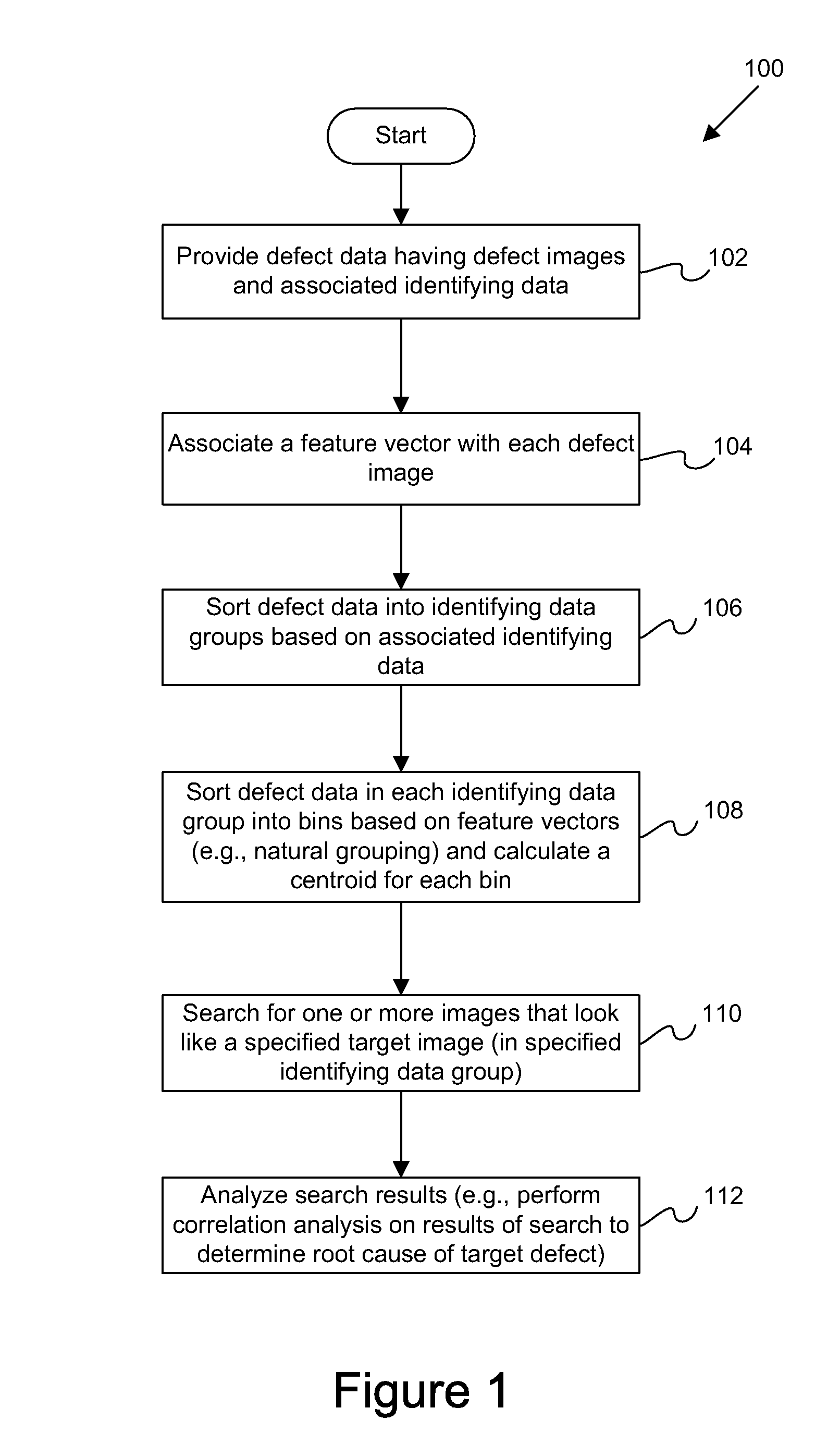

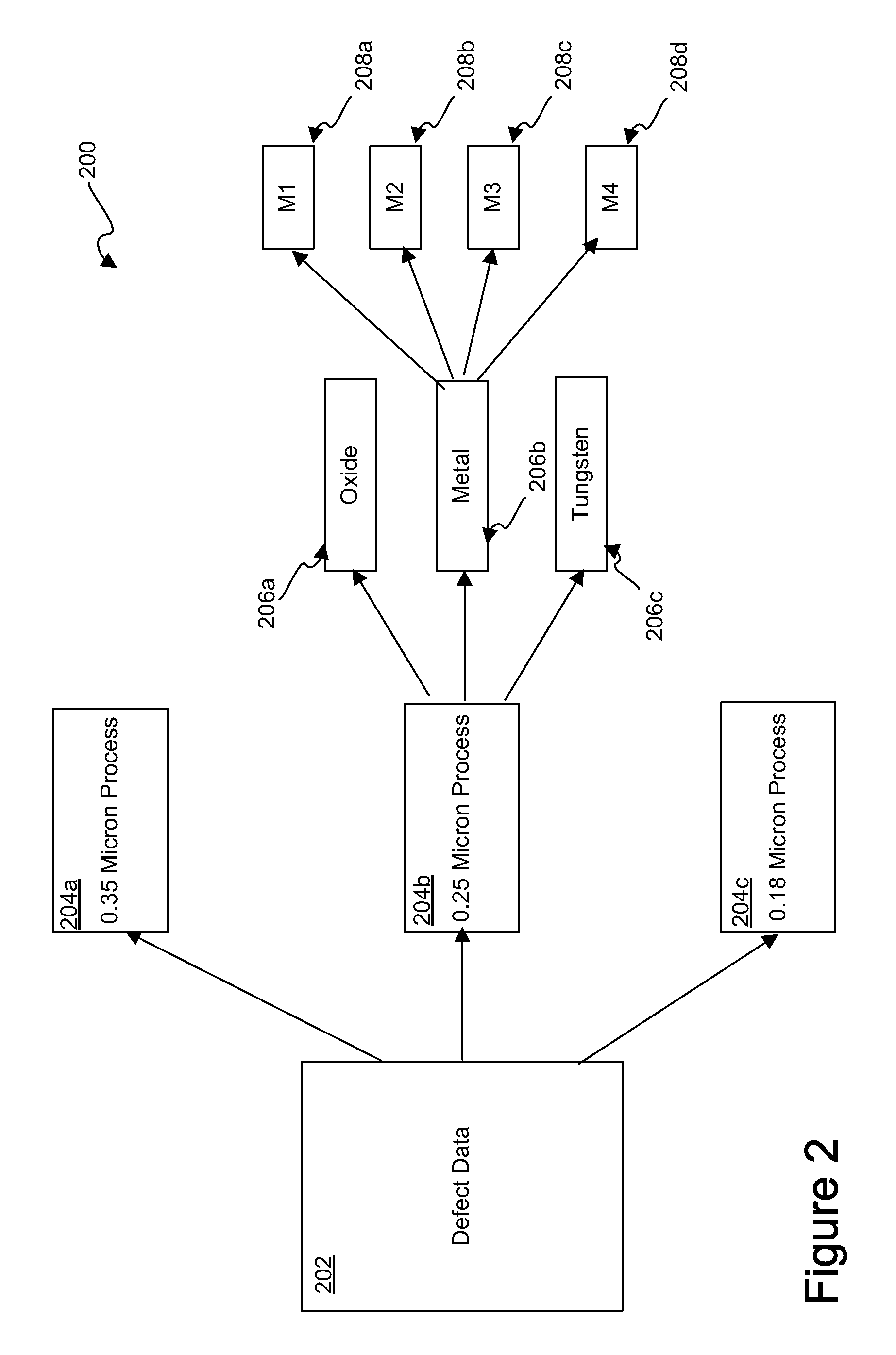

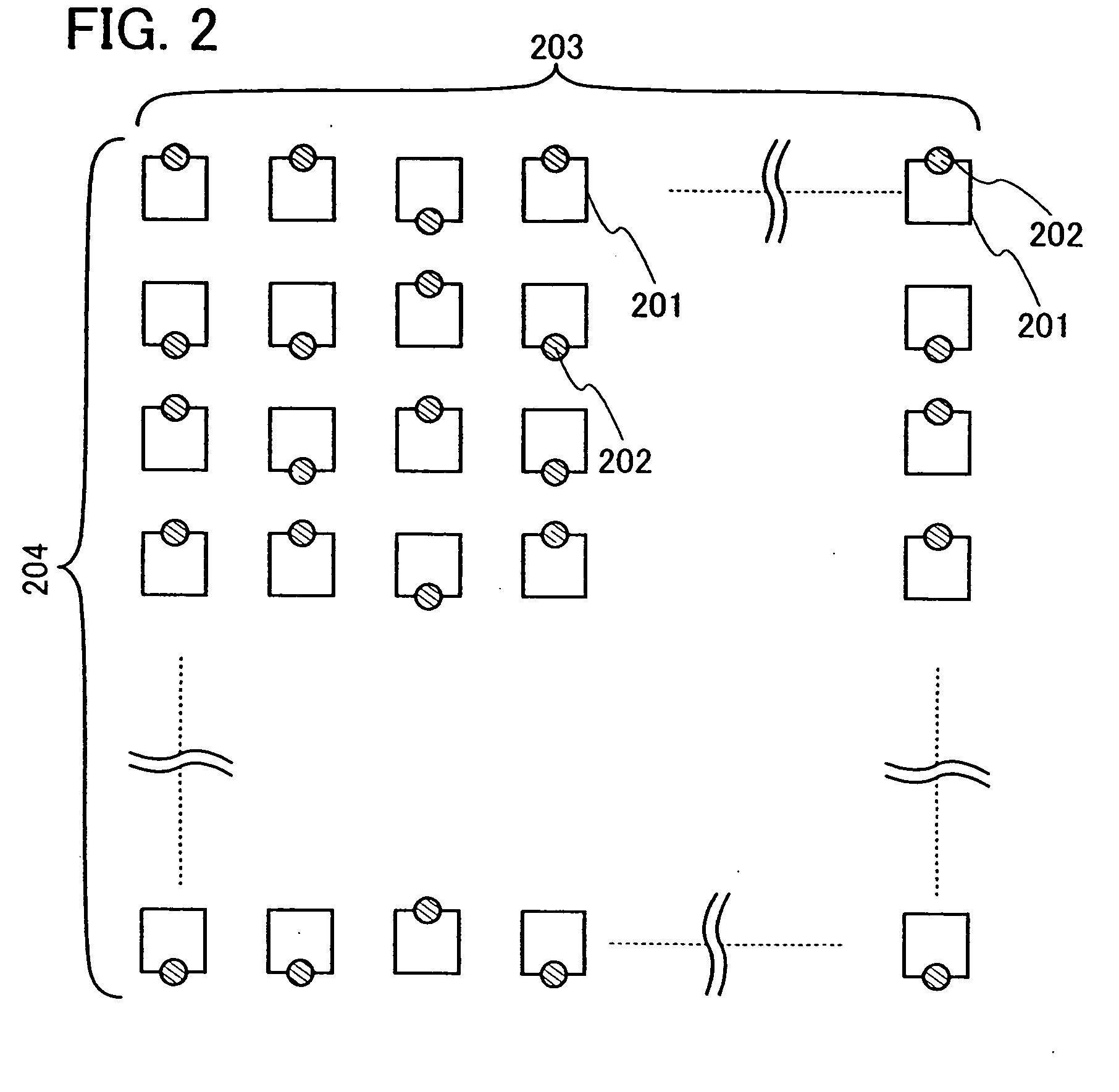

Apparatus and methods for searching through and analyzing defect images and wafer maps

ActiveUS7283659B1Efficiently performedEfficient executionImage enhancementImage analysisGraphical user interfaceTraining set

Disclosed are methods and apparatus for automatically organizing and / or analyzing a plurality of defect images without first providing a predefined set of classified images (herein referred to as a training set). In other words, sorting is not based on a training set or predefined classification codes for such defect images. In one embodiment, the defect images each include associated identifying data, such as a fabrication identifier, lot number, wafer number, and layer identifier. Initially, the defect images are sorted according to at least a portion of the associated identifying data into a plurality of “identifying data groups” or image families. The defect data in each identifying data group is then automatically sorted according to defect appearance. That is, similar defect images are associated with a single bin and similar bins are associated with other similar bins. For example, similar bins are arranged next to each other within a graphical user interface (GUI). A representative feature vector (herein referred to as a “centroid”) is then associated with each bin. The centroid generally represents the images within the particular bin. A search for images that “look like” a specified target image may then be efficiently performed on a particular identifying data group using the centroids of each bin. The target image's feature vector is compared with the centroid of each bin that is within the same identifying data group or image family as the target image. The techniques of the present invention may also be applied to wafer maps, as well as defect images.

Owner:KLA TENCOR CORP

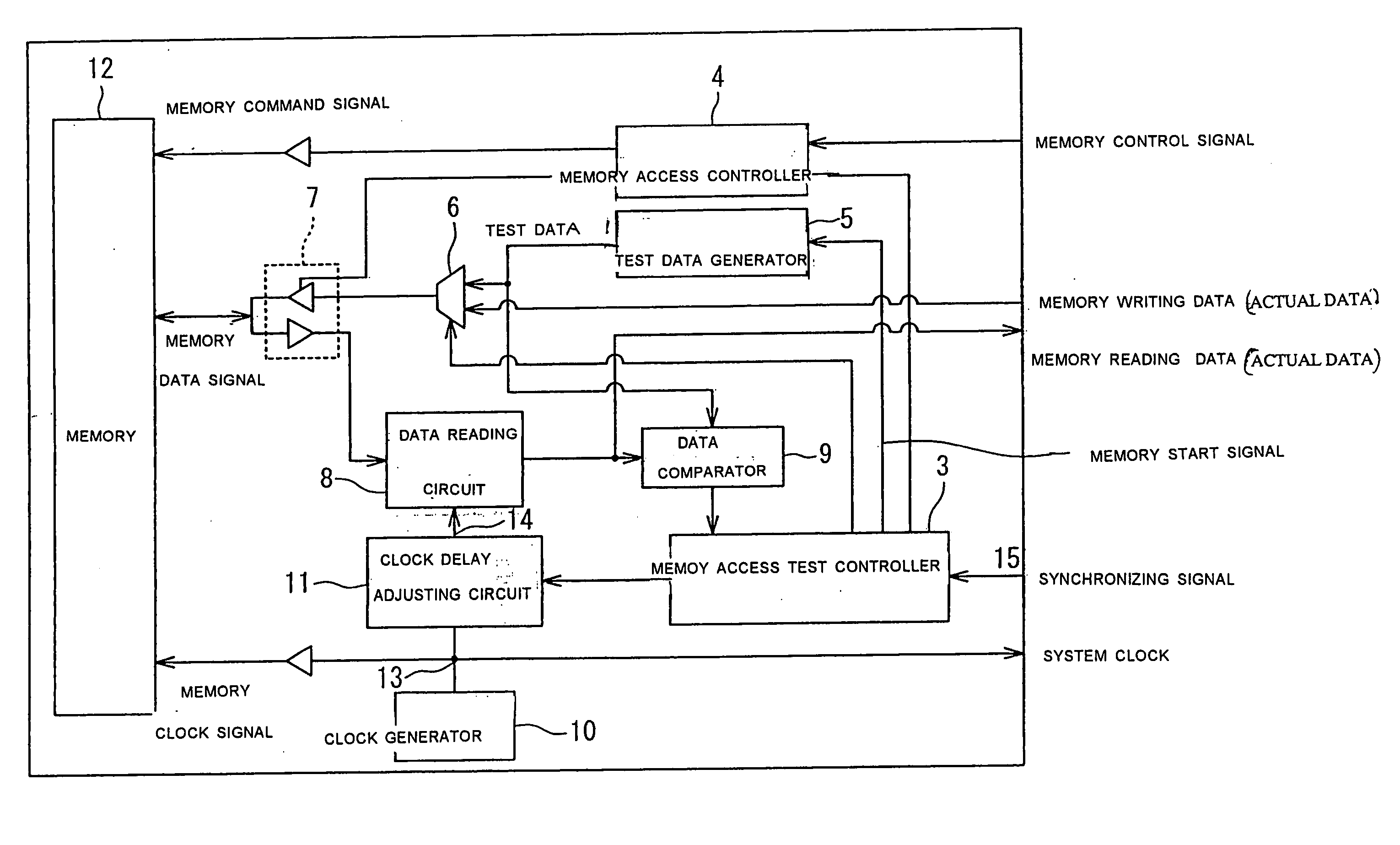

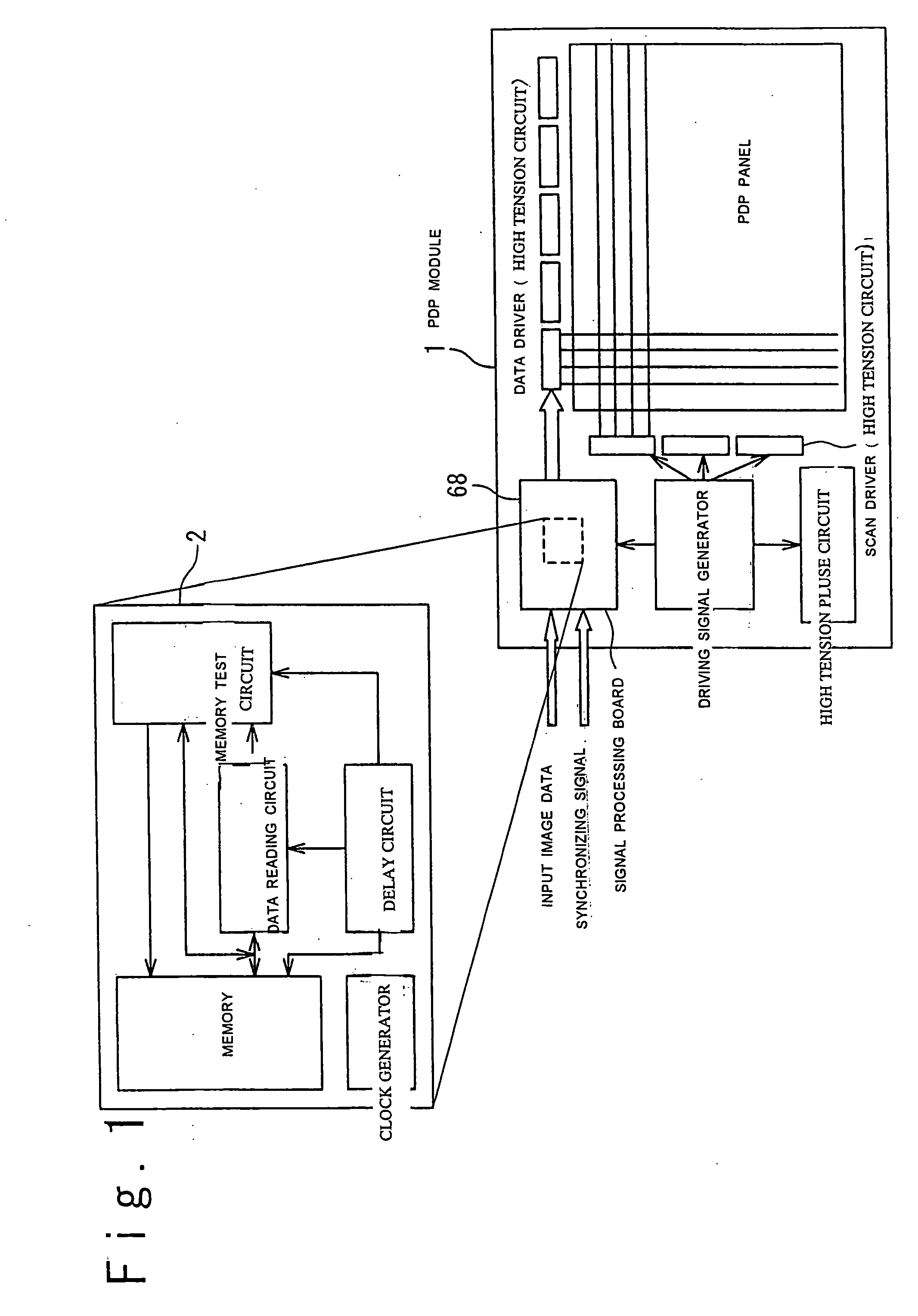

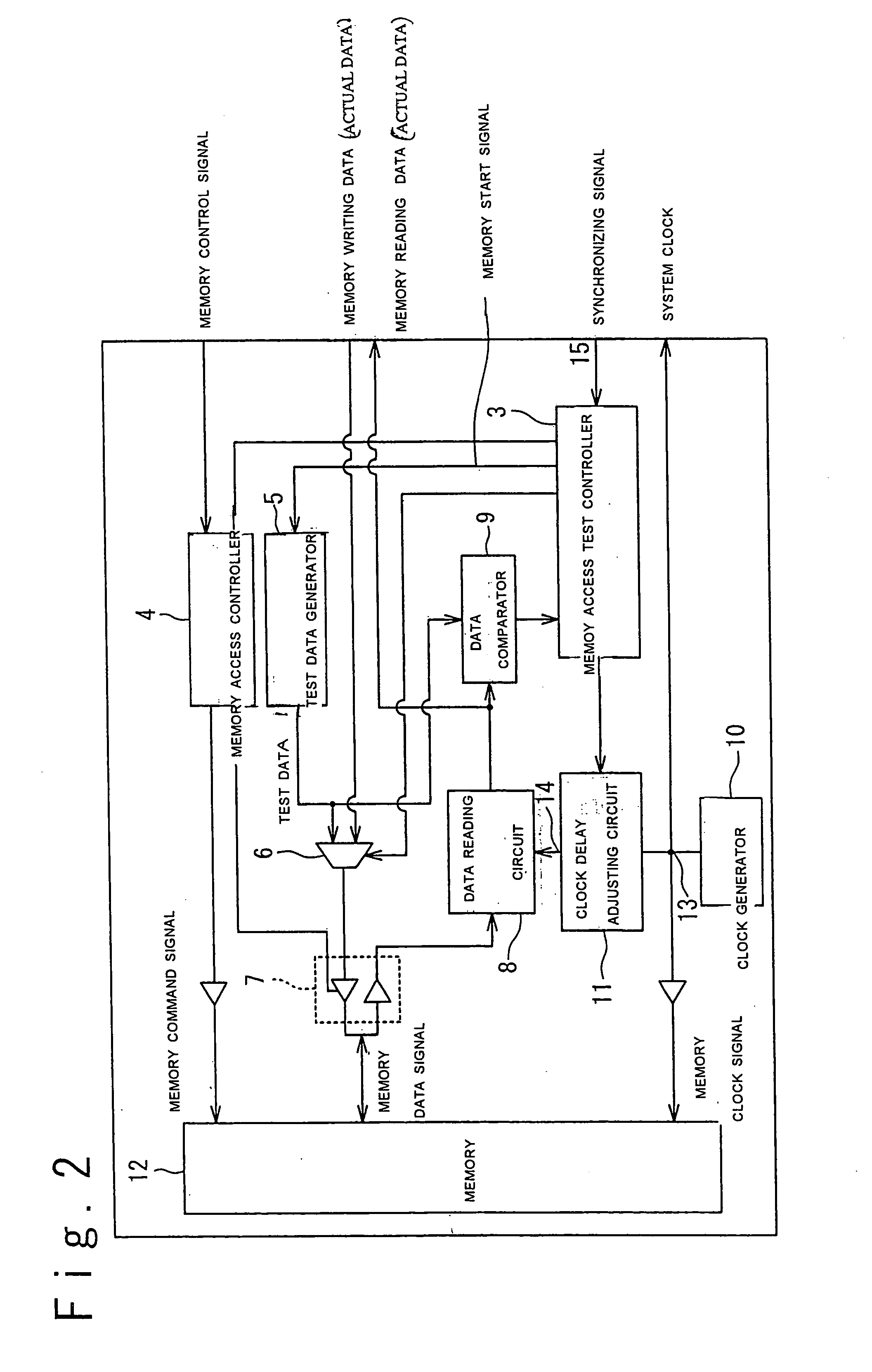

Memory access circuit for adjusting delay of internal clock signal used for memory control

InactiveUS20050135167A1Efficiently performedEasily affectedDigital storageStart signalClock generator

It is to form a memory access circuit comprising a memory, a clock generator for generating a reference clock signal, and a clock delay adjusting circuit for delaying the reference clock signal to create a delay clock signal. The clock delay adjusting circuit is a circuit for generating a plurality of delay clock signals of various delay value. The memory access circuit further comprises a test data generator for generating test data and a memory access test controller for supplying a memory writing test start signal in reply to the external synchronizing signal. The test data generator generates the test data in reply to the memory writing test start signal, writes the test data into the memory in synchronization with the reference clock, and supplies the write data corresponding to the test data in synchronization with the reference clock, and the memory access test controller reads the test data from the memory in synchronization with the delay clock signal, compares the read test data with the write data, and adjusts the memory access timing according to as a result of the comparison.

Owner:PIONEER CORP

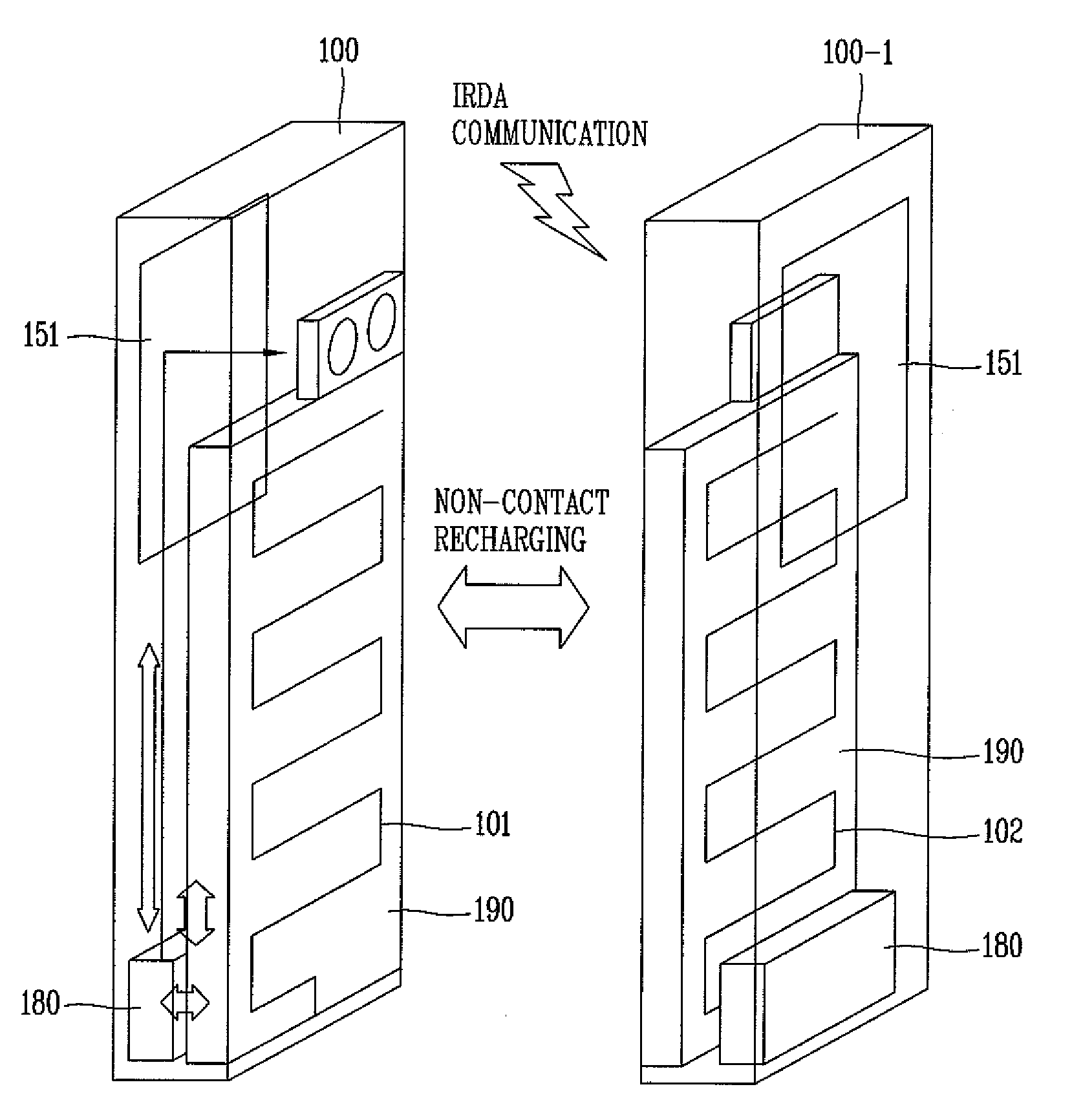

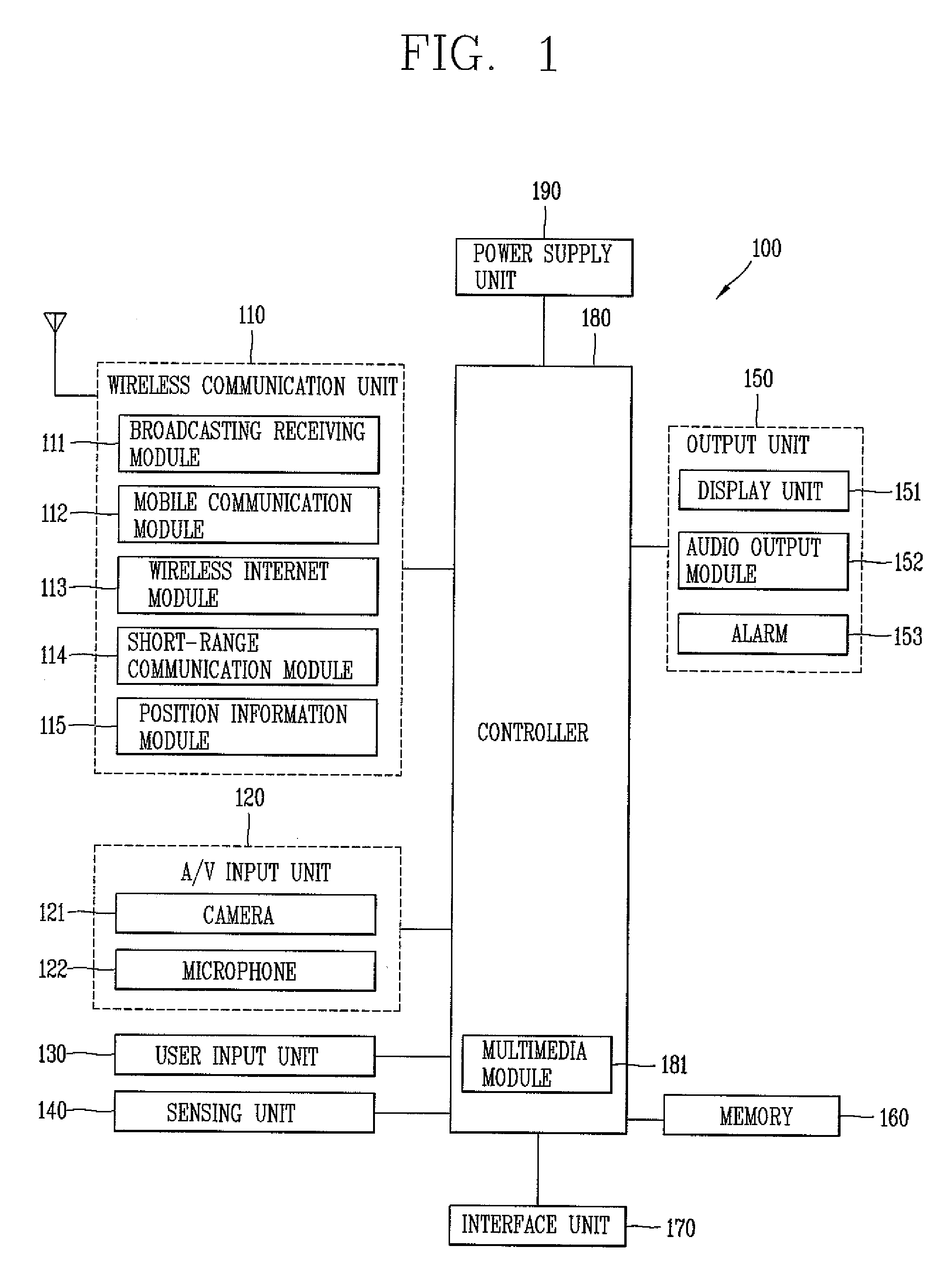

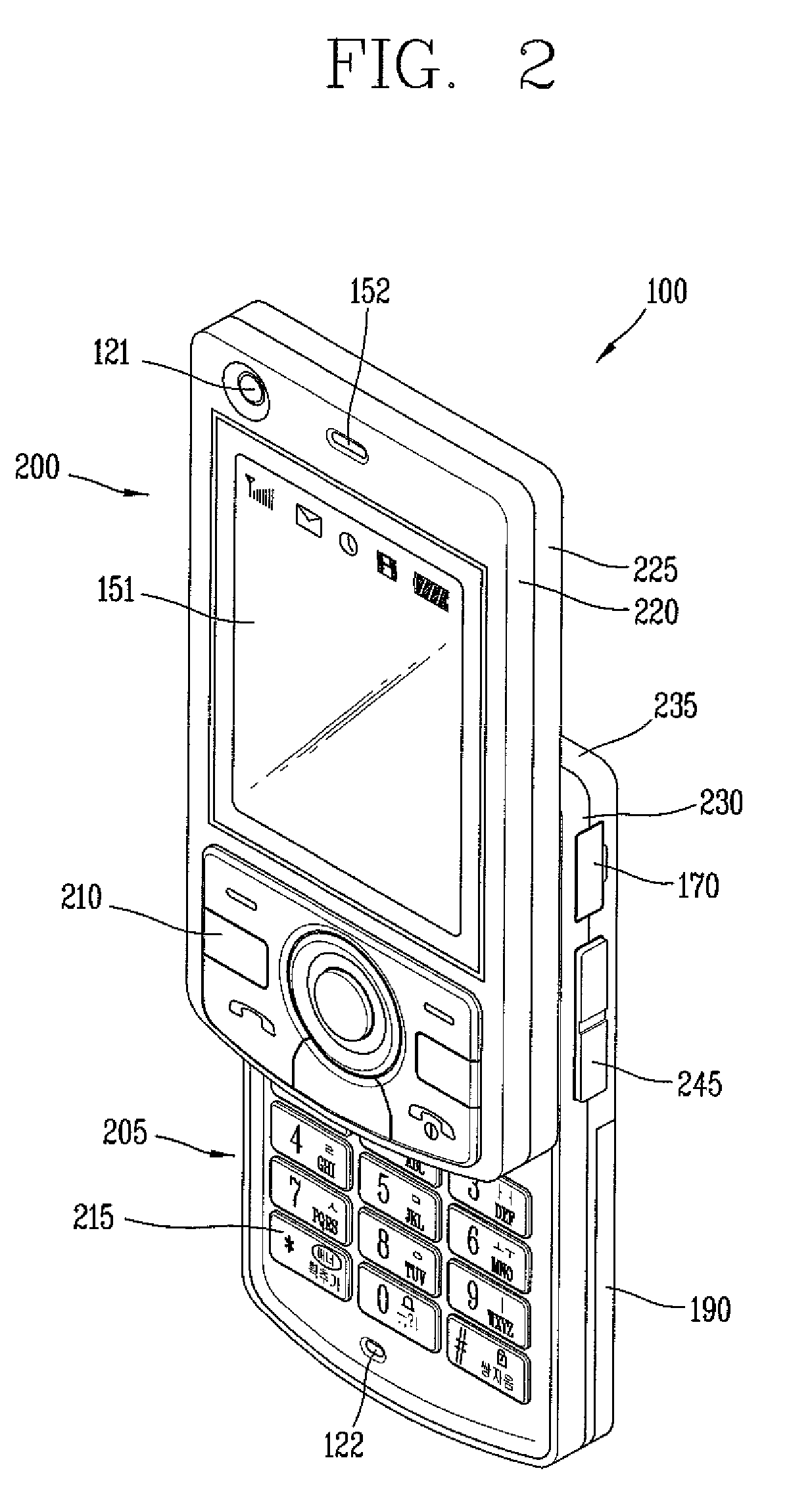

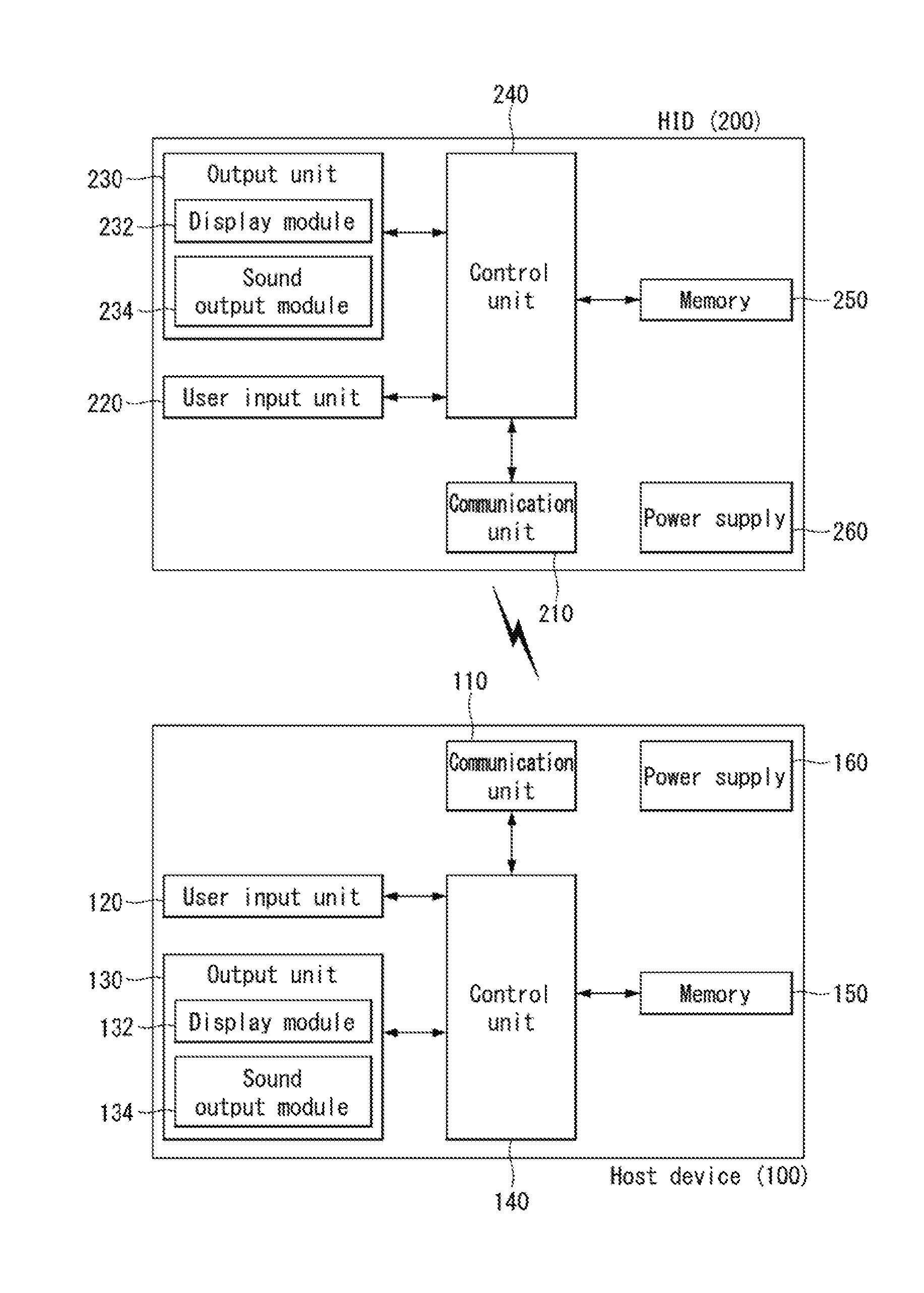

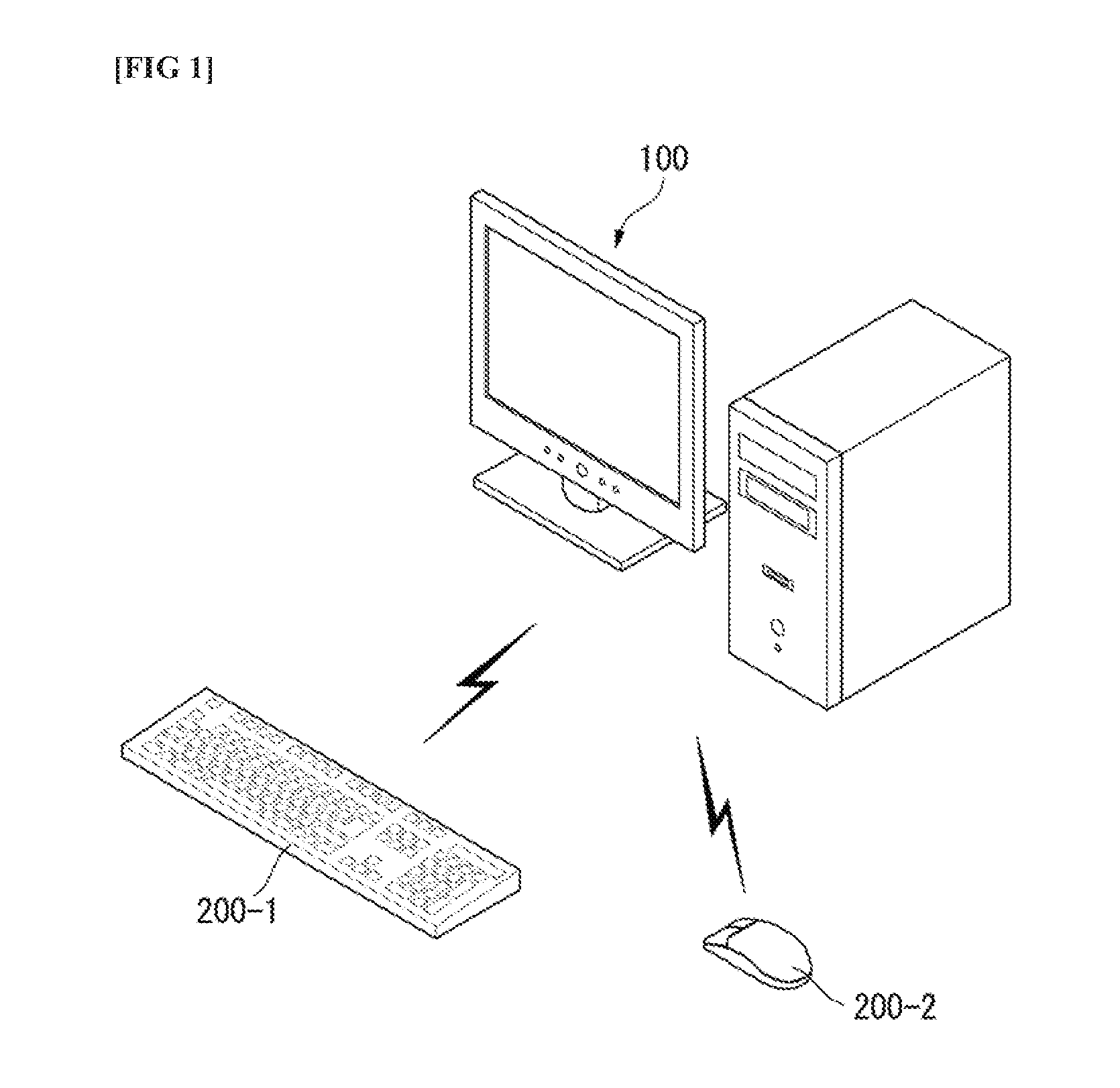

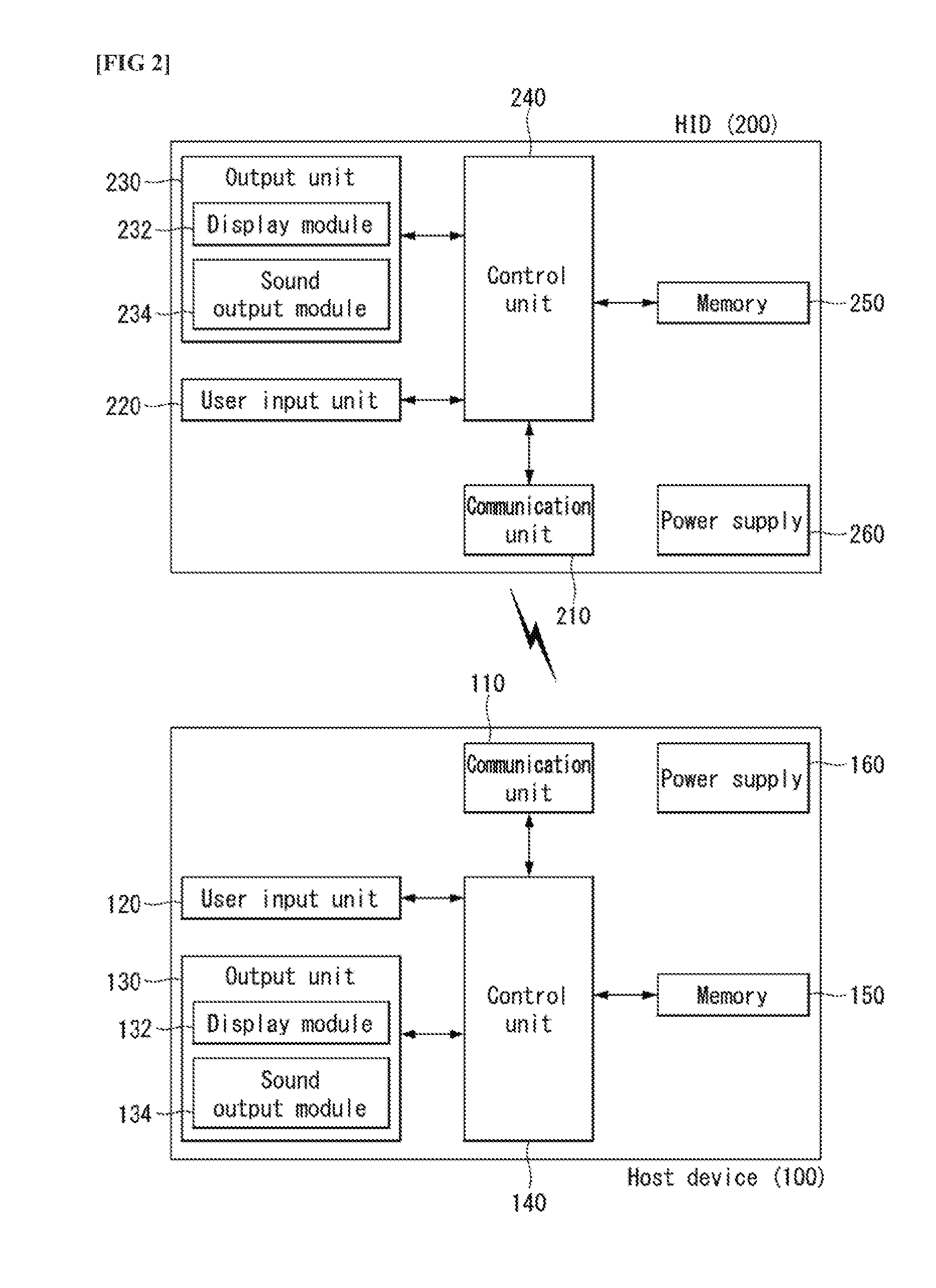

Mobile terminal having recharge menu setting function and inter-recharging method using the same

InactiveUS20090140692A1Efficiently performedEfficient executionTransformersTransmission systemsEmbedded systemInductive coupling

A non-contact recharging apparatus and method provides a recharge menu to a first mobile terminal when performing non-contact recharging using inductive coupling. A user can set and operate a menu for recharging a second mobile terminal according to the recharge menu to perform inter-recharging between the mobile terminals. A recharge menu setting state is displayed in the form of icon, and the mobile terminal performs short-range communication with the counterpart terminal during the recharging to exchange information about the remaining battery capacity and the amount of current. The exchanged information is displayed on a display module such that the user can easily check which one of the mobile terminals is being recharged and can also check the recharge level of the mobile terminal being recharged.

Owner:LG ELECTRONICS INC

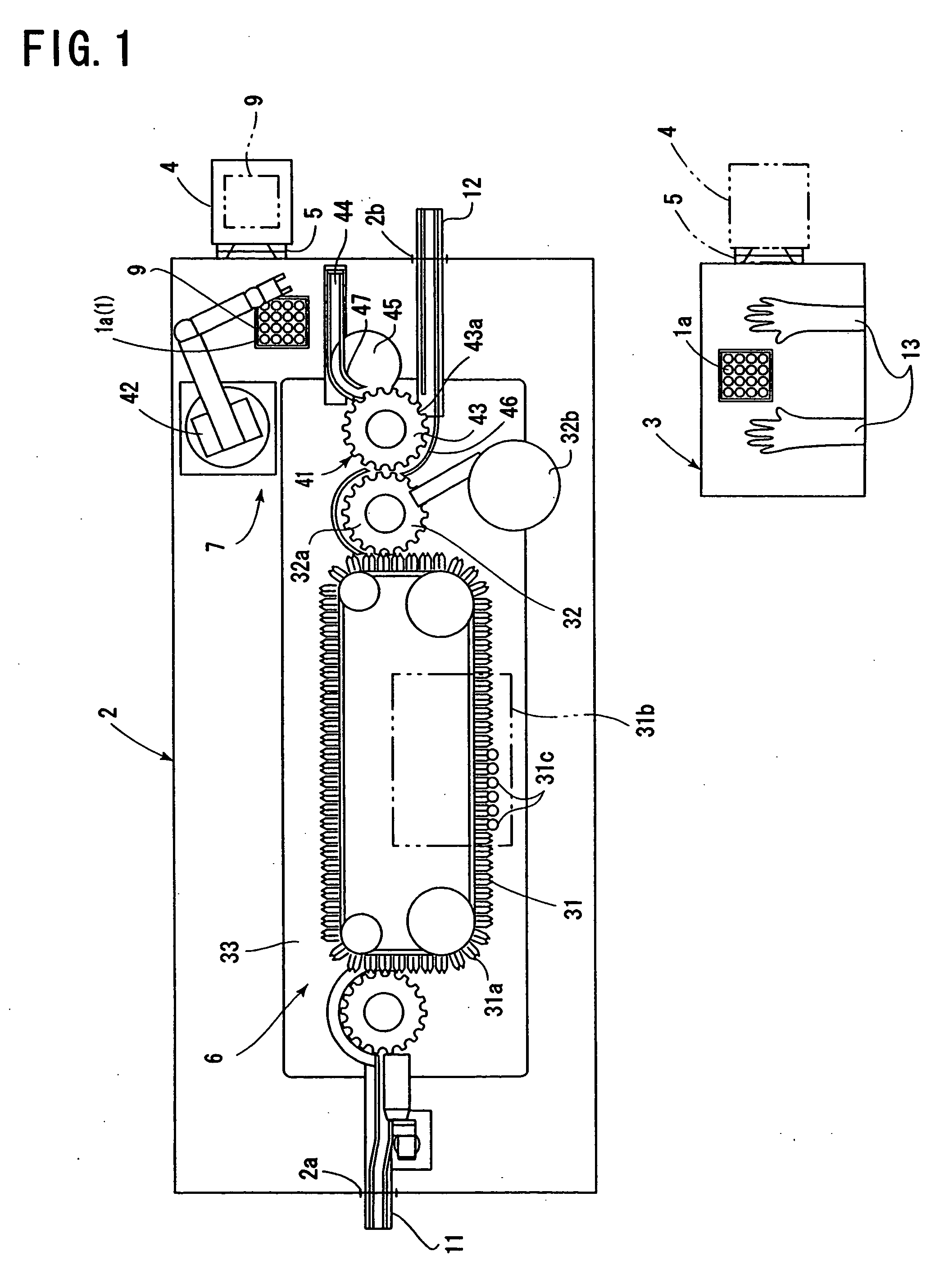

Sterility sampling test method and apparatus

InactiveUS20050042710A1Efficiently performedEfficient executionMicrobiological testing/measurementWithdrawing sample devicesEngineeringPallet

In a work isolator which is a work chamber maintained in a sterile condition, a predetermined sample containers to be subjected to a sterile test are extracted by a rejection device from containers filled with a material and sealed by a filling and sealing line, and a robot places the extracted sample containers on a collection pallet. The sample containers are moved from the work isolator to an accommodation device together with the pallet. The accommodation device is separated from the work isolator while being maintained in a sterile condition and is then connected to a test isolator which is a testing chamber maintained in a sterile condition. The sample containers are moved from the accommodation device into the test isolator while being maintained in a sterile condition. The sample containers are maintained in the sterile condition at all times from the work chamber to the testing chamber. Therefore, the need for sterilization of the outer surfaces of the sample containers at the time of sterility test in the testing chamber is eliminated and the drug sterility test can be immediately started.

Owner:SHIBUYA IND CO LTD

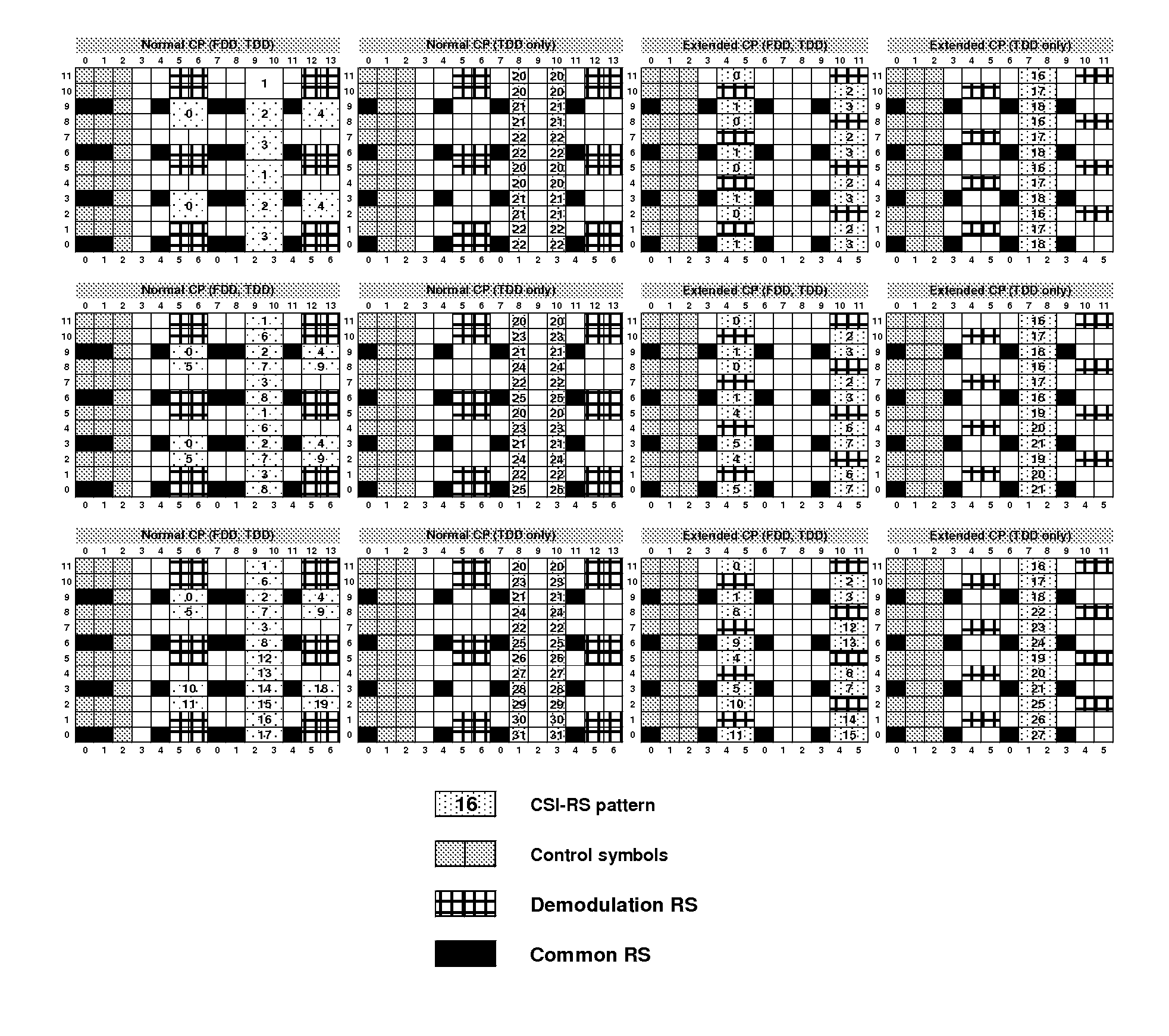

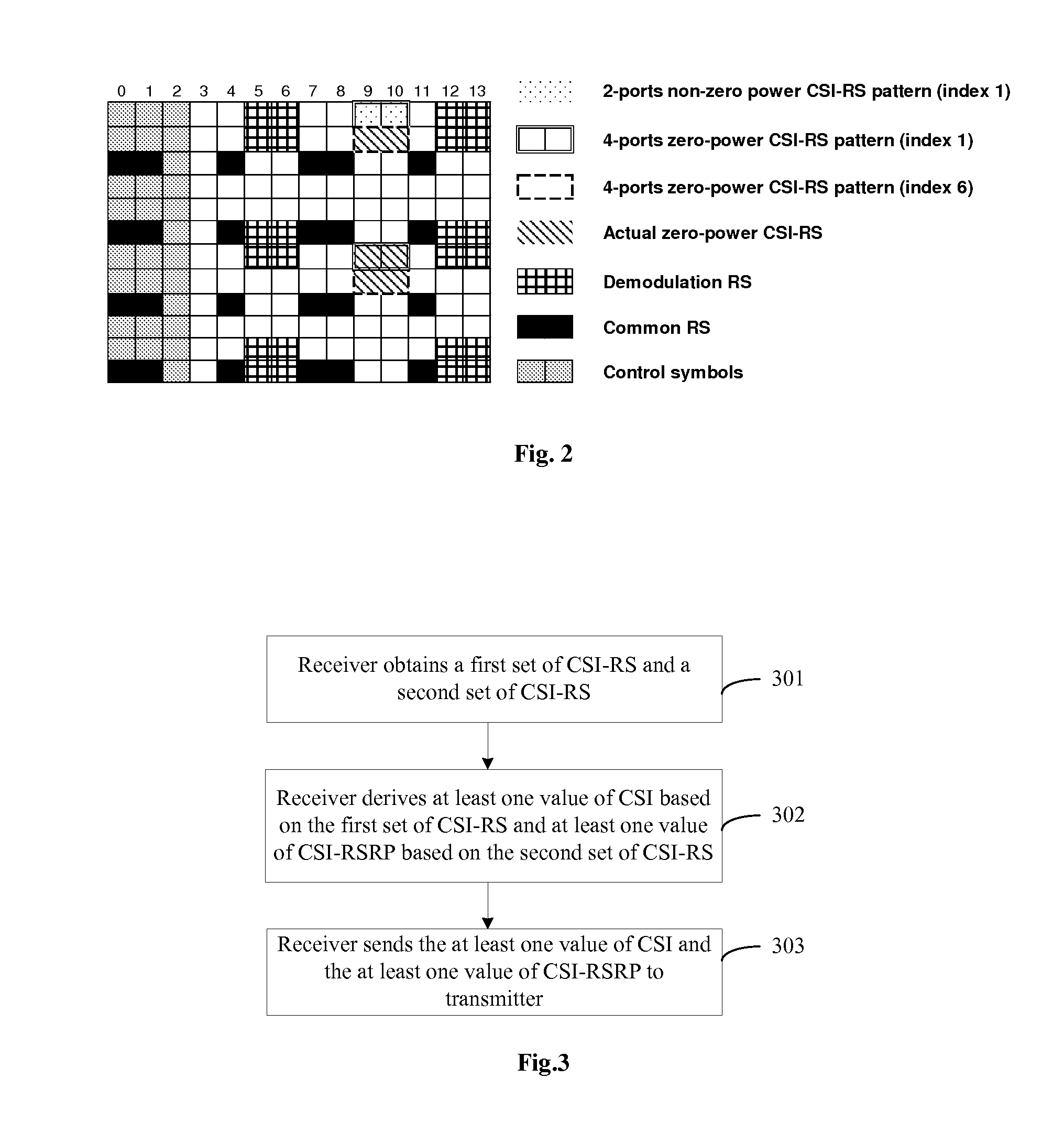

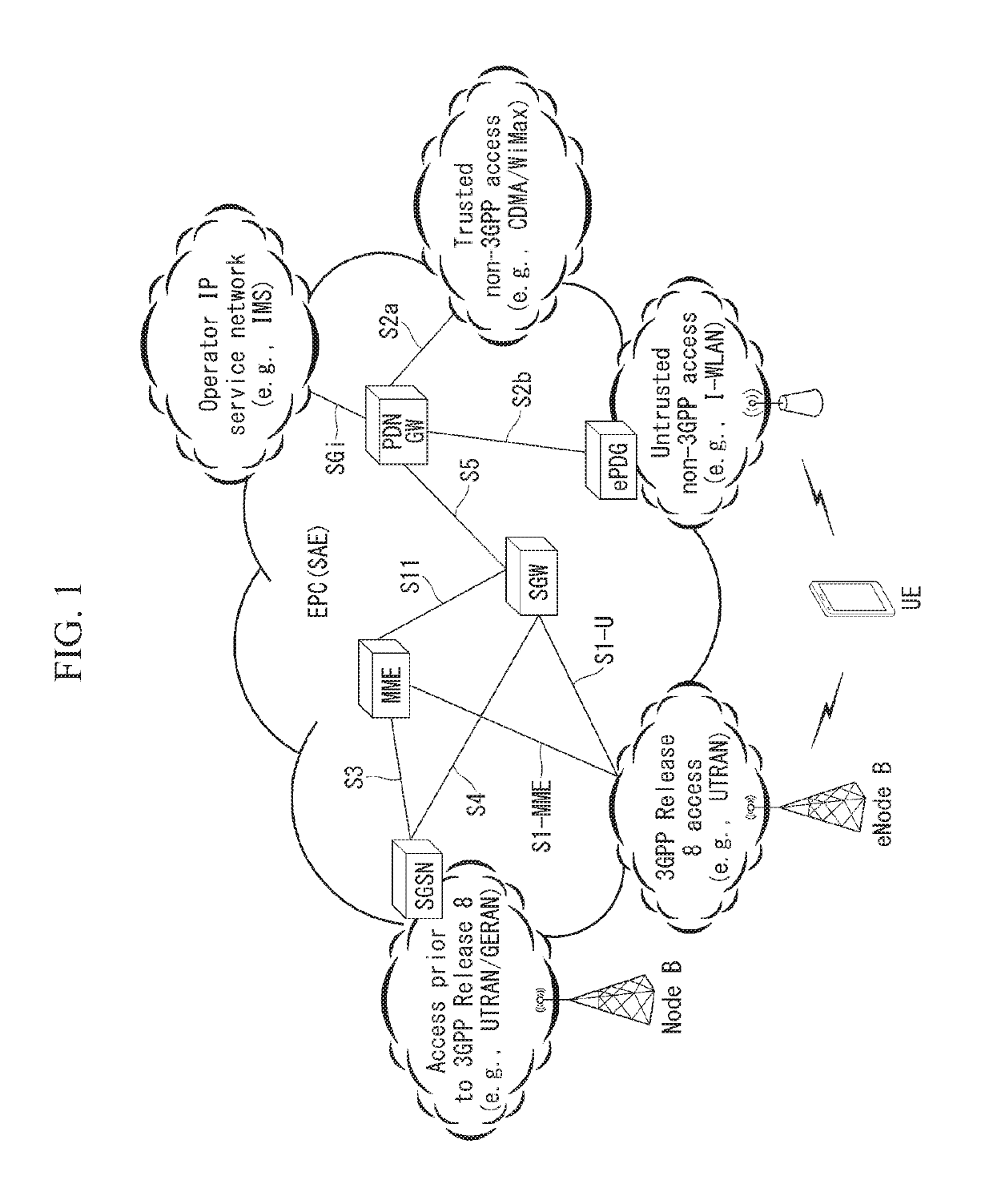

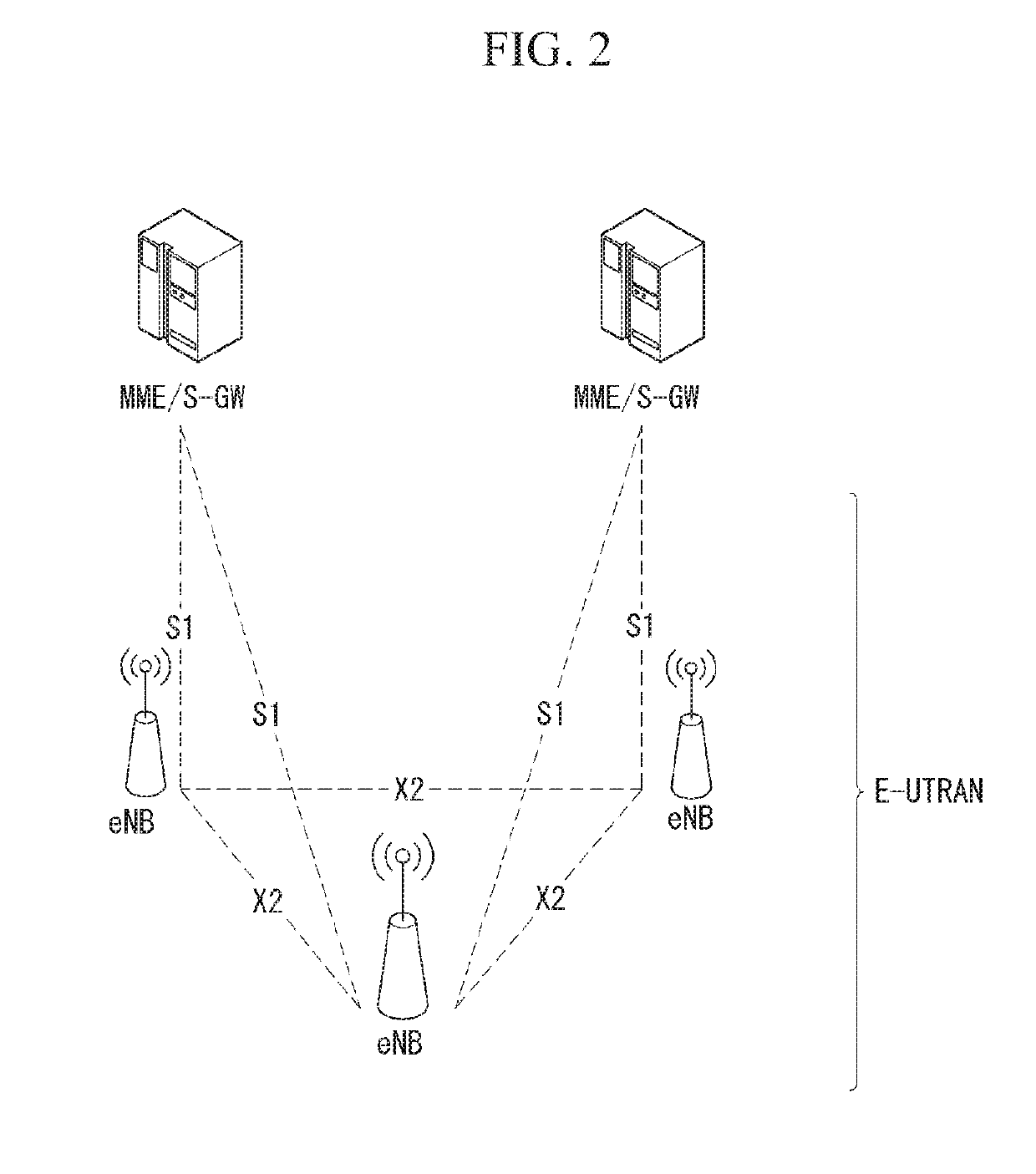

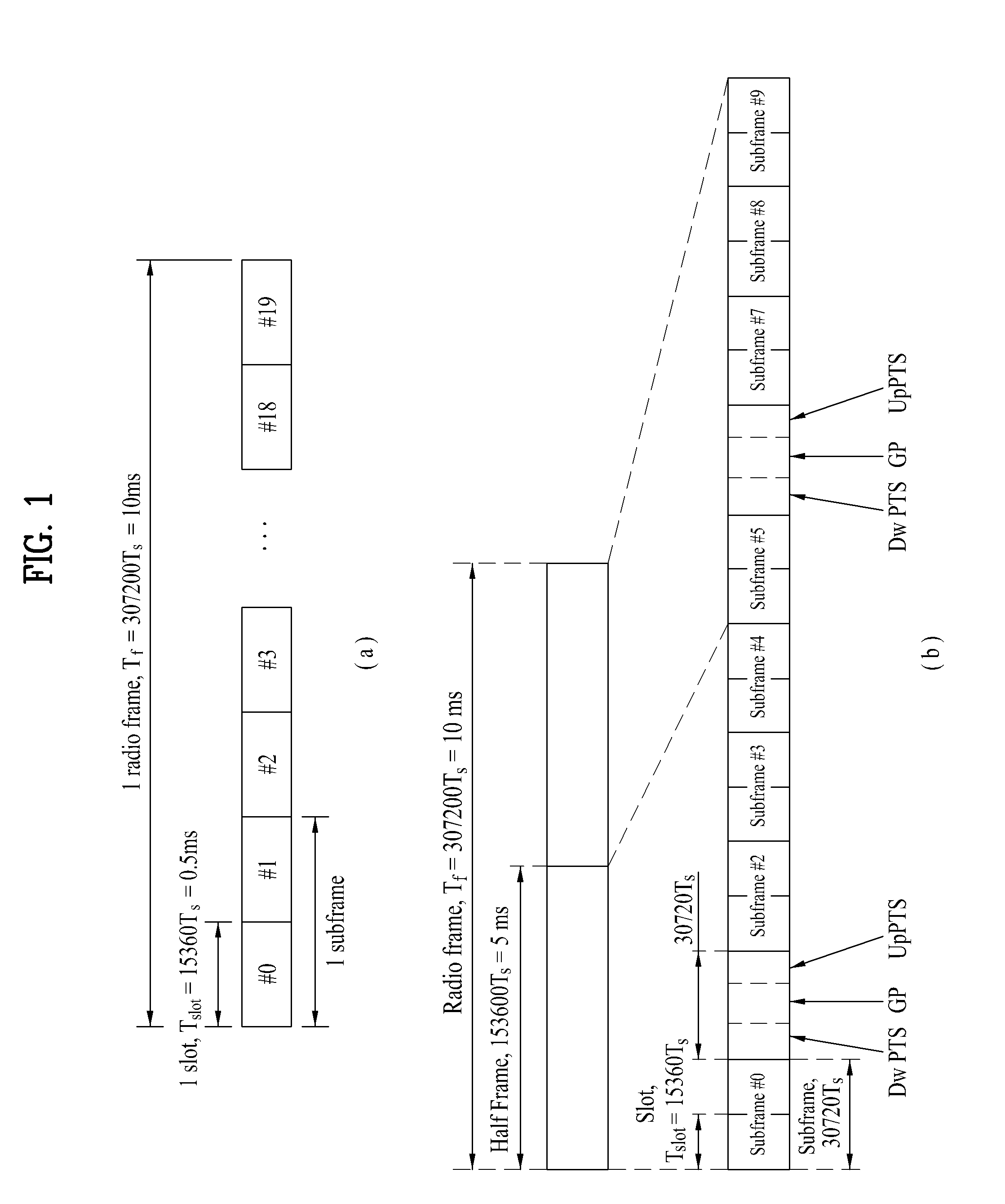

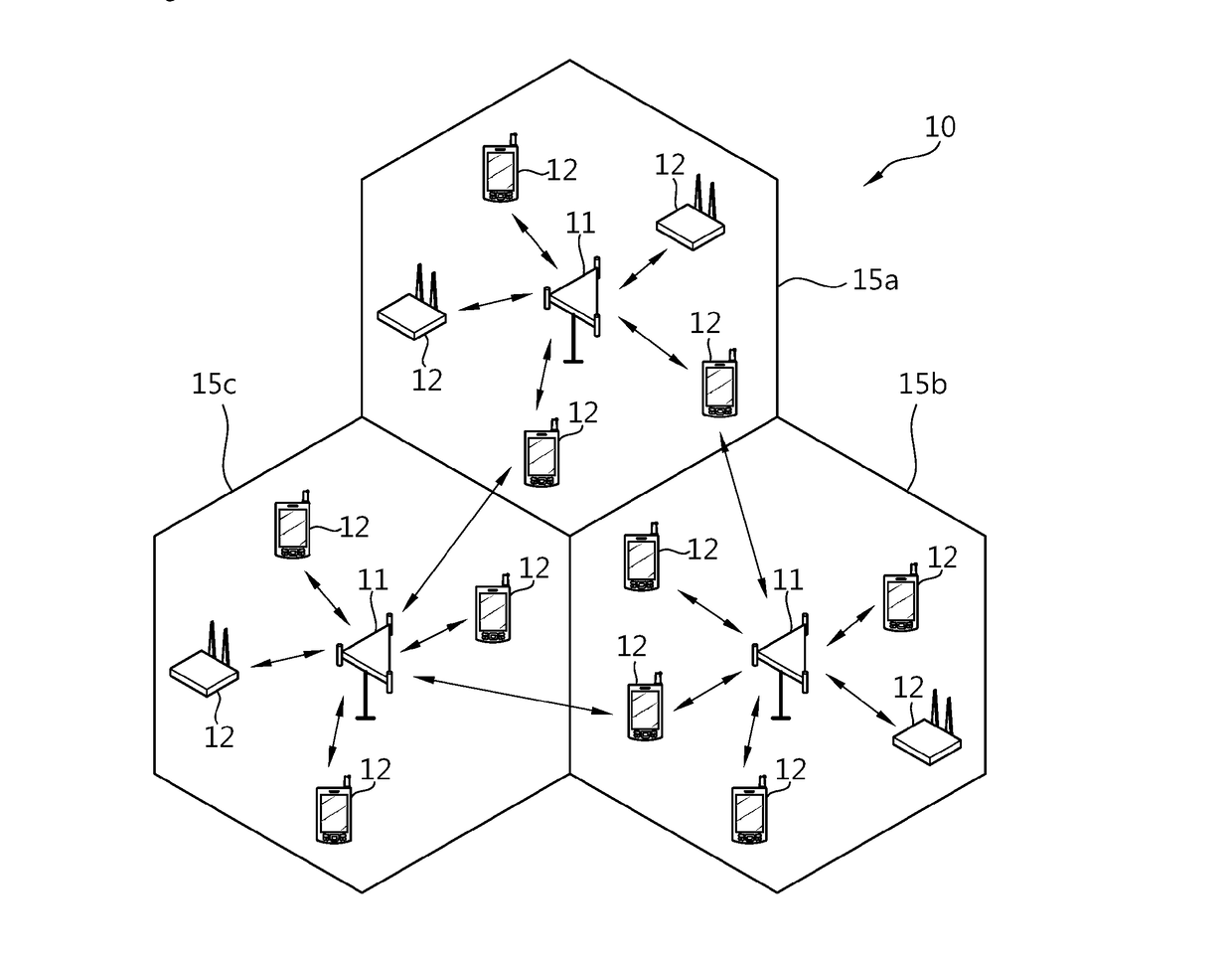

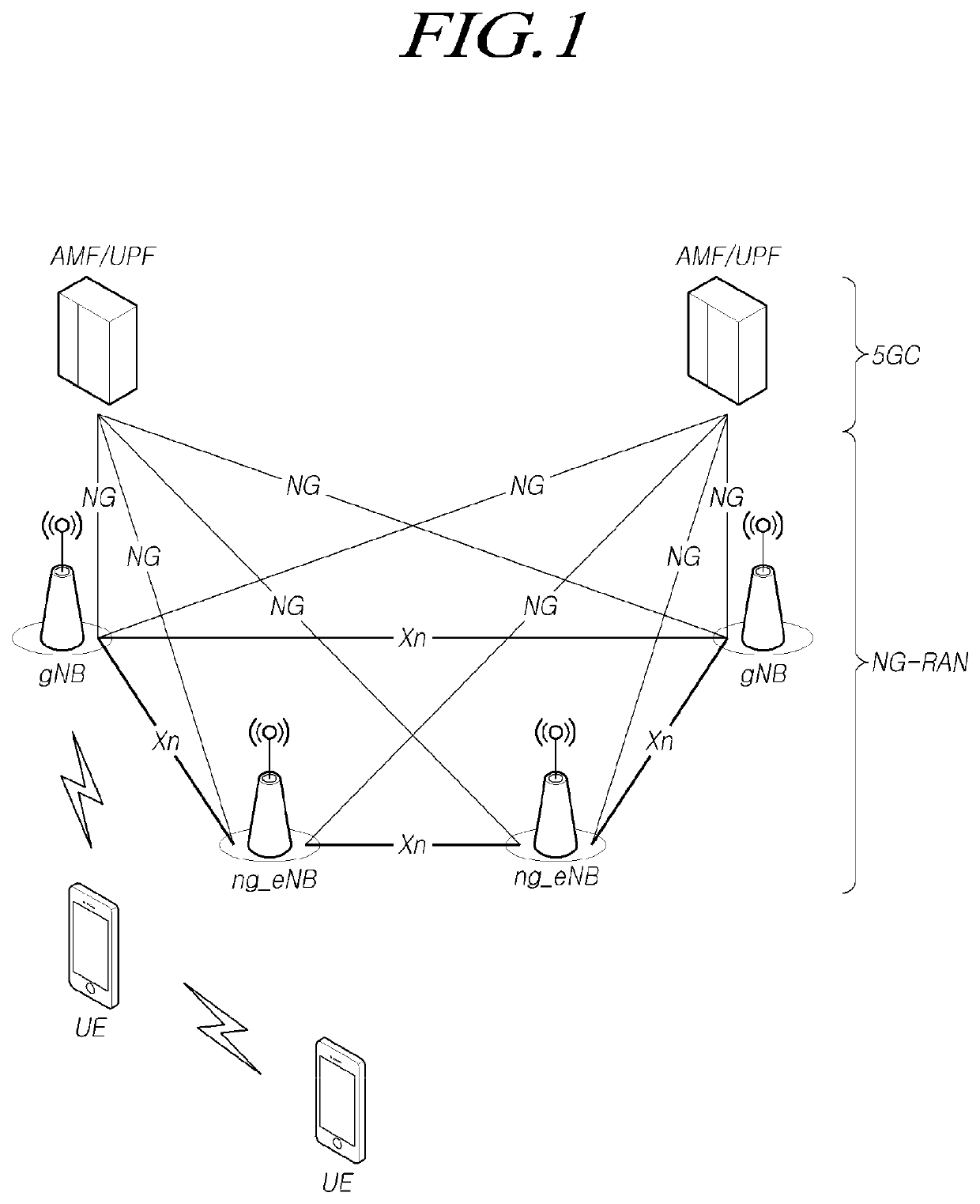

Method and apparatus for channel measurements for coordinated multipoint transmission

InactiveUS20140153526A1Efficiently performedEfficient executionSite diversitySpatial transmit diversityTransmission pointChannel state information

The present invention relates to a method for configuring reference signals and measurement sets to support coordinated multipoint transmission with distributed antennas. A first set of reference signal patterns is used for measuring and reporting received signal power from different transmission points, and a second set of reference signal patterns is used for measuring and reporting channel state information from different transmission points. The method allows to minimize power consumption and feedback overhead, while still being flexible in the configuration and re-configuration of the measurement sets.

Owner:HUAWEI TECH CO LTD

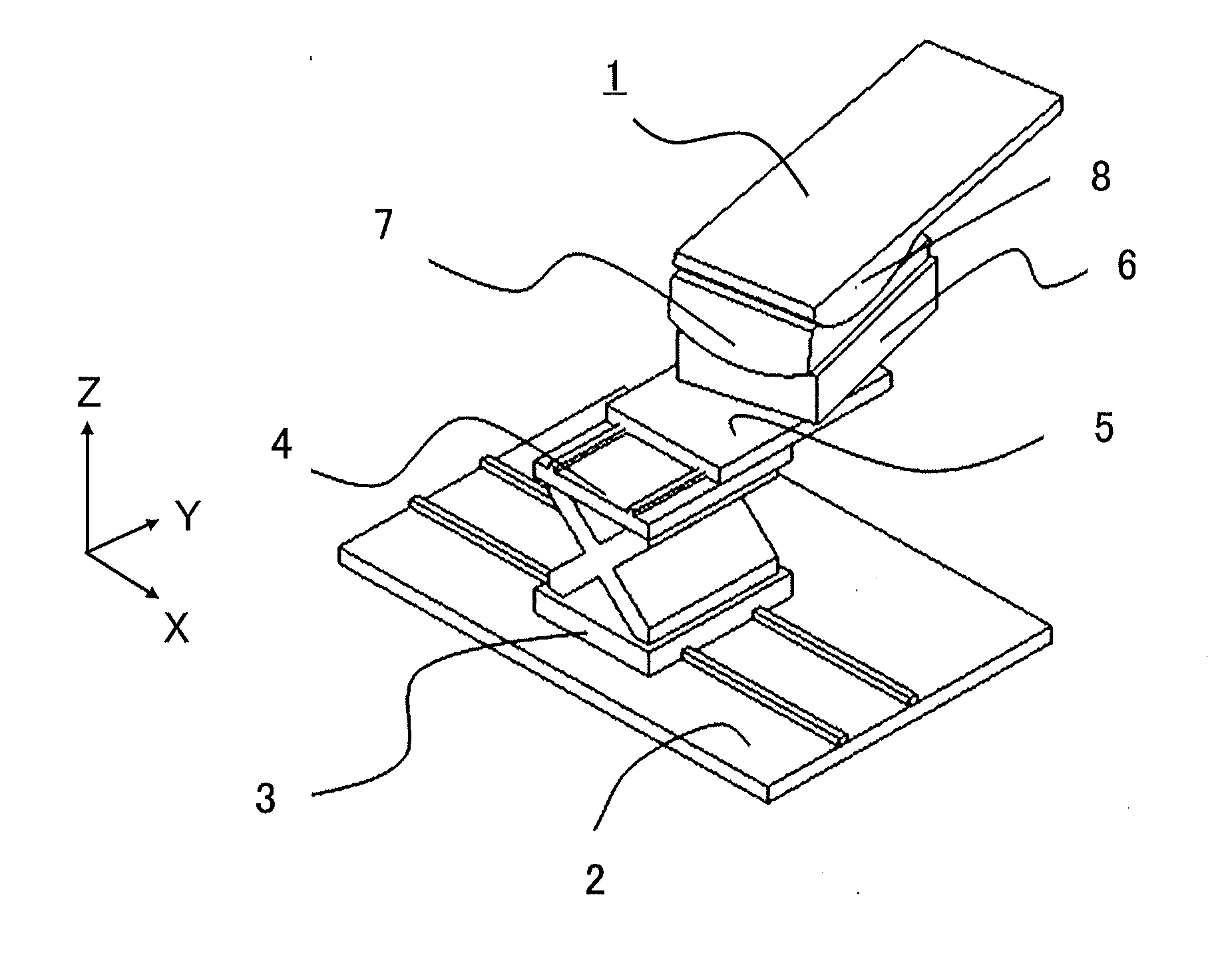

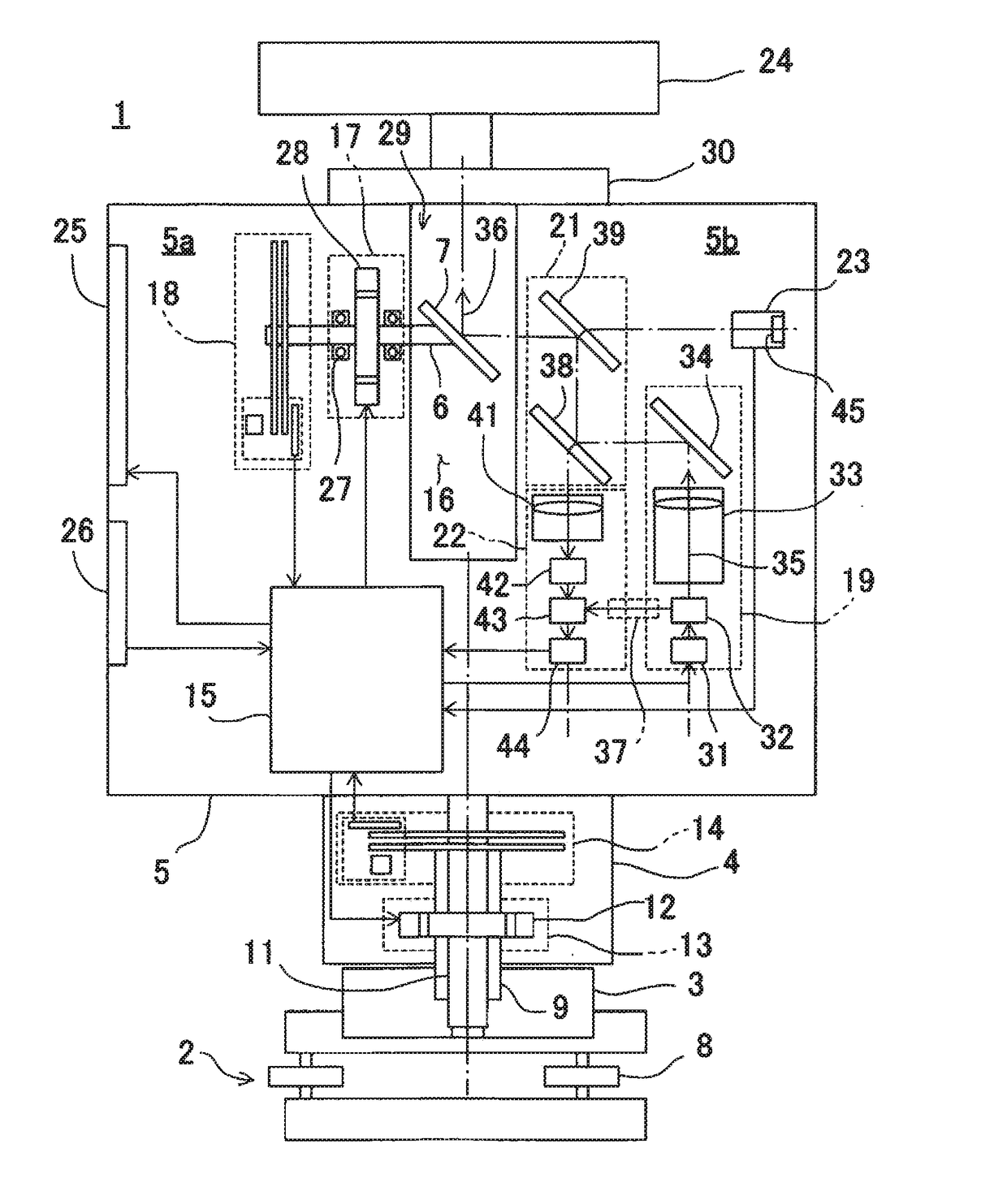

Driving type patient platform, control device for driving type patient platform, control program for driving type patient platform, and particle beam therapy system utilizing these items

ActiveUS20110215259A1Efficiently performedEfficient executionMaterial analysis using wave/particle radiationPhotometryParticle beamEngineering

The objective is to obtain a driving type patient platform that can efficiently perform positioning work for making the position and the posture of a diseased site coincide with those established when a treatment plan is generated. There are provided translation units that translate a top board in the X direction, the Y direction, and the Z direction, respectively, in a fixed coordinate system; rotation units that rotate the top board in the θ direction around the X axis, the φ direction around the Y axis, and the ξ direction around the Z axis, respectively; and a control device that controls the translation units and the rotation units, based on an inputted desired rotation center point and an inputted desired rotation angle. The control device is provided with a rotation drive signal generation unit that generates a rotation drive signal for moving the top board in a rotating manner from the reference state “a” of the translation units and the rotation units to a desired rotation angle; and a translation drive signal generation unit that generates a translation drive signal for translating the translation units in such a way that the amount of translation movement, of the desired rotation center point, that is caused by the rotation movement becomes the same as or smaller than a predetermined value.

Owner:MITSUBISHI ELECTRIC CORP

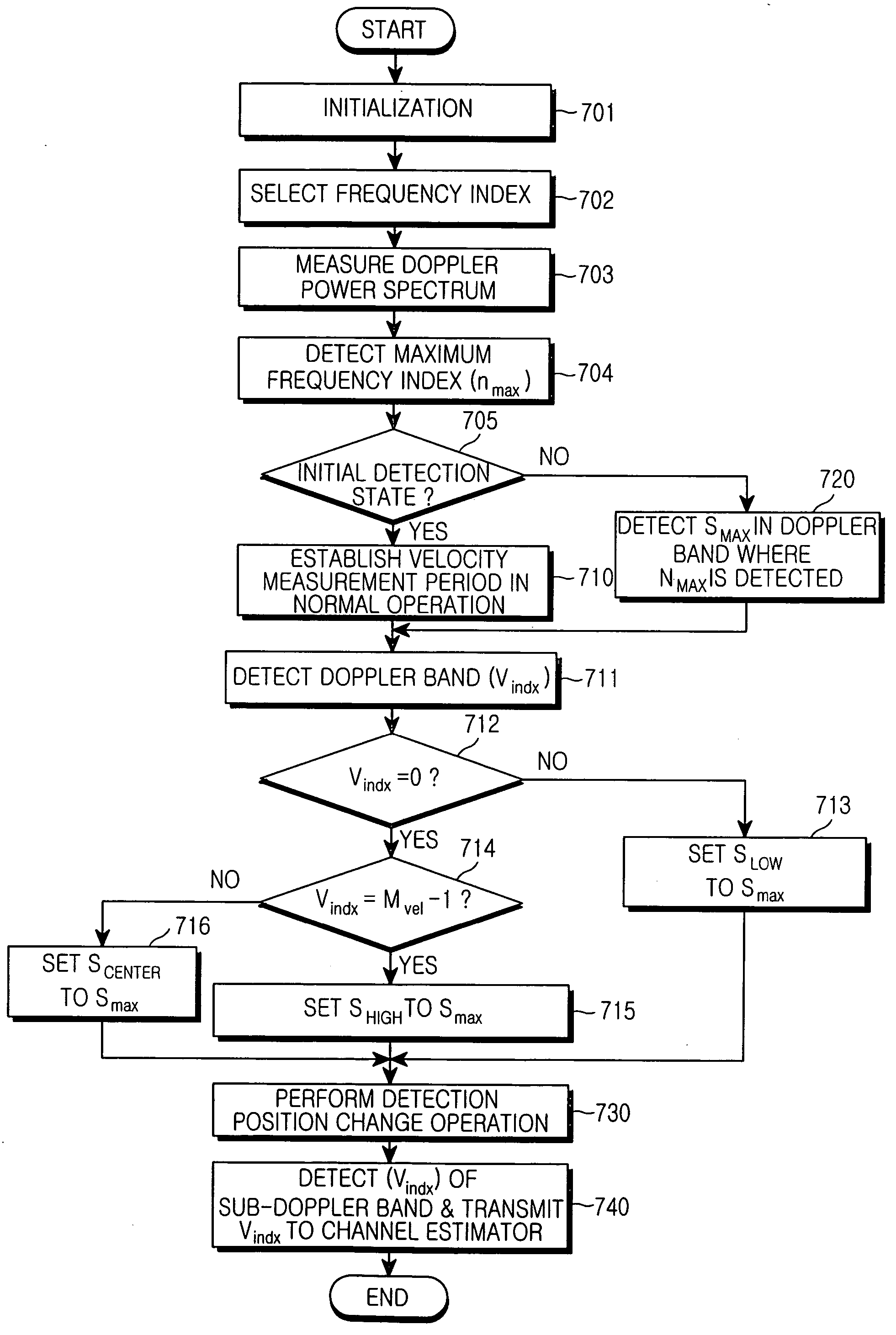

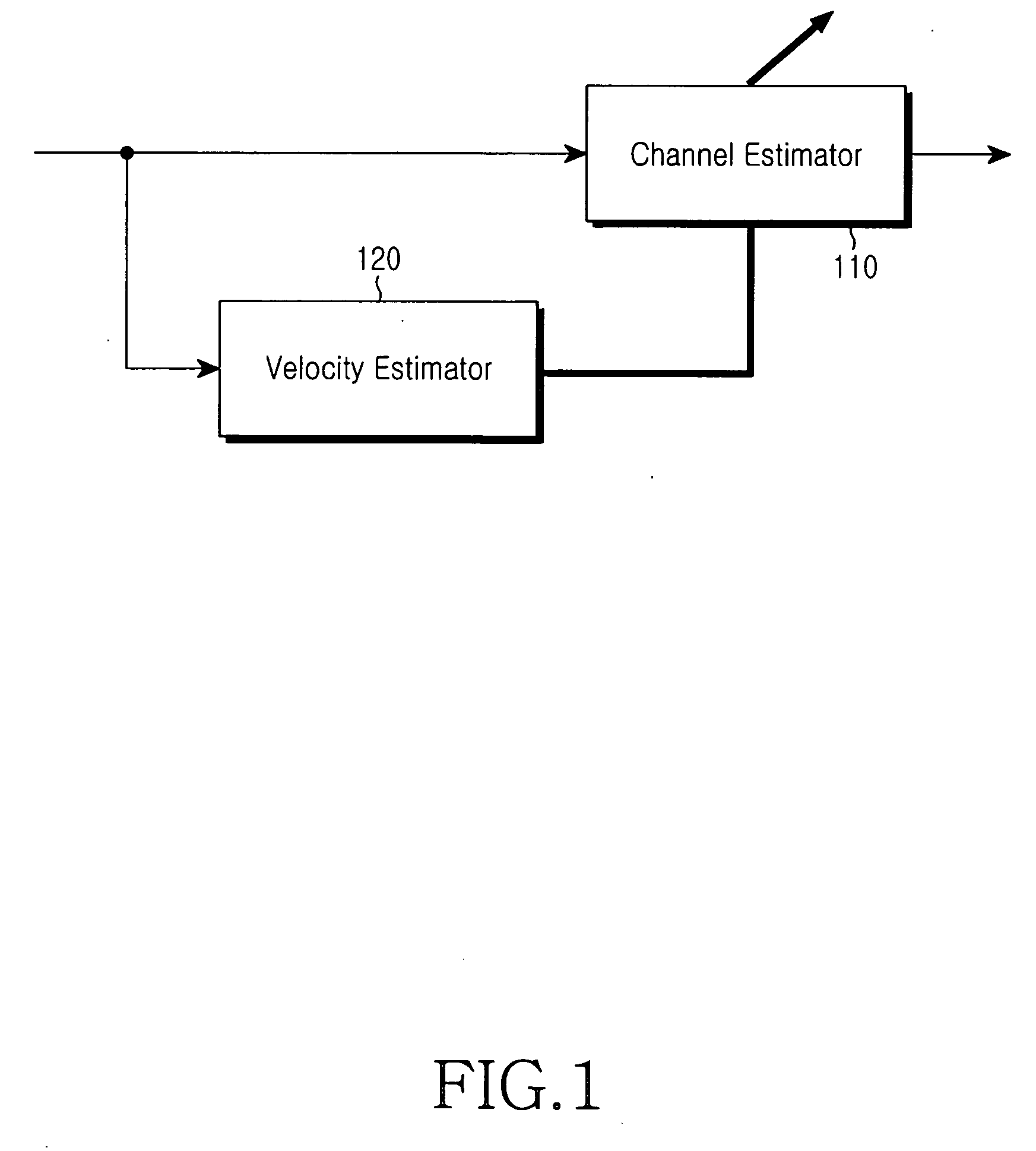

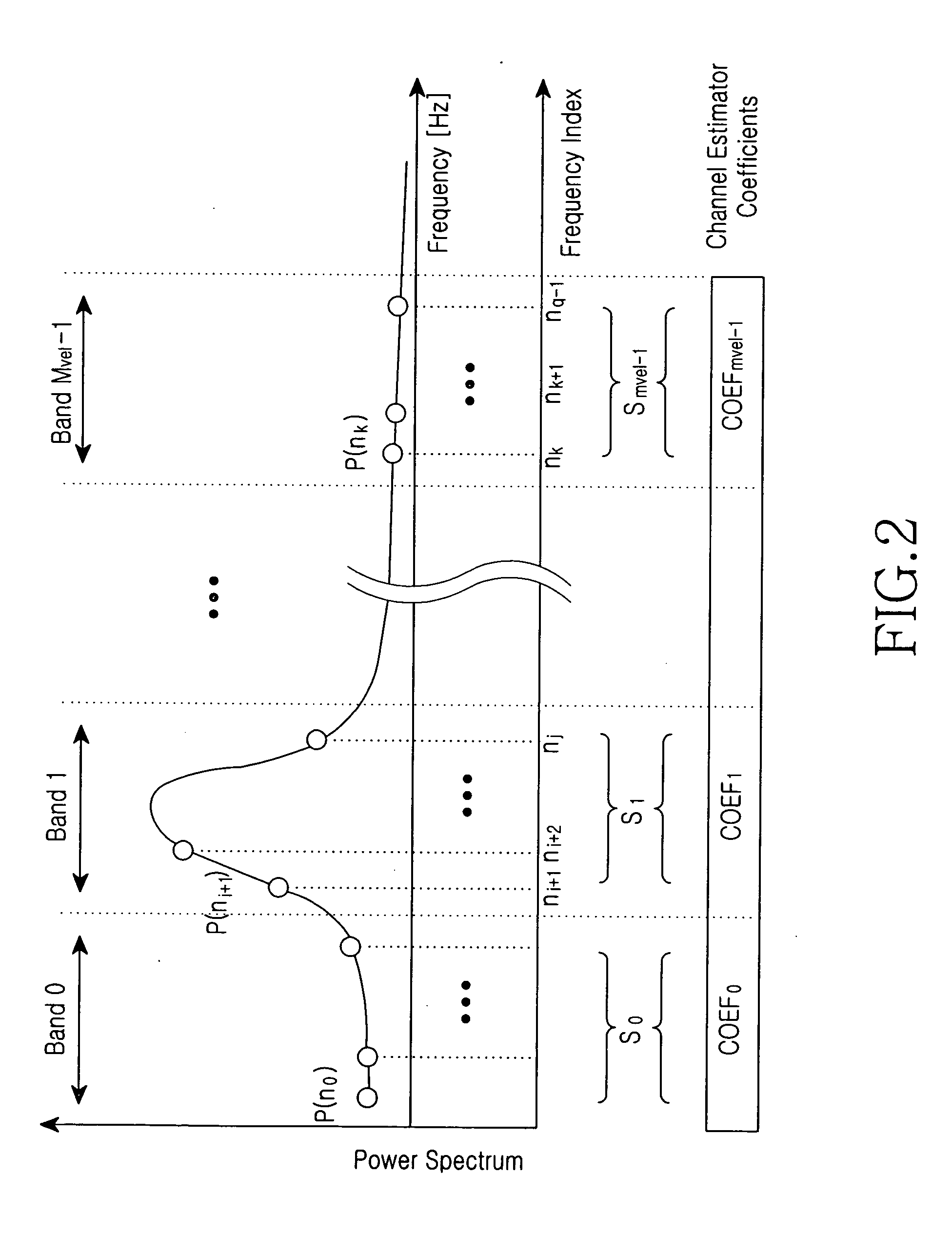

Apparatus and method for estimating a velocity of a mobile terminal in a mobile communication system

InactiveUS20050059356A1Efficiently performedEfficient executionDirection finders using radio wavesActive radio relay systemsFrequency bandEngineering

A Base Station (BS) apparatus for estimating a velocity of a Mobile Station (MS) in a mobile communication system includes a channel estimator for performing channel estimation according to a velocity band, receiving a wireless channel signal from the MS, and performing channel estimation using channel estimation coefficients optimized for individual velocity bands; and a velocity estimator for dividing the velocity band into a plurality of sub-Doppler bands, detecting a sub-Doppler band including a frequency index having a maximum frequency response from among the divided sub-Doppler bands, and transmitting information of the detected sub-Doppler band to the channel estimator such that a channel estimation coefficient corresponding to the information is transmitted.

Owner:SAMSUNG ELECTRONICS CO LTD

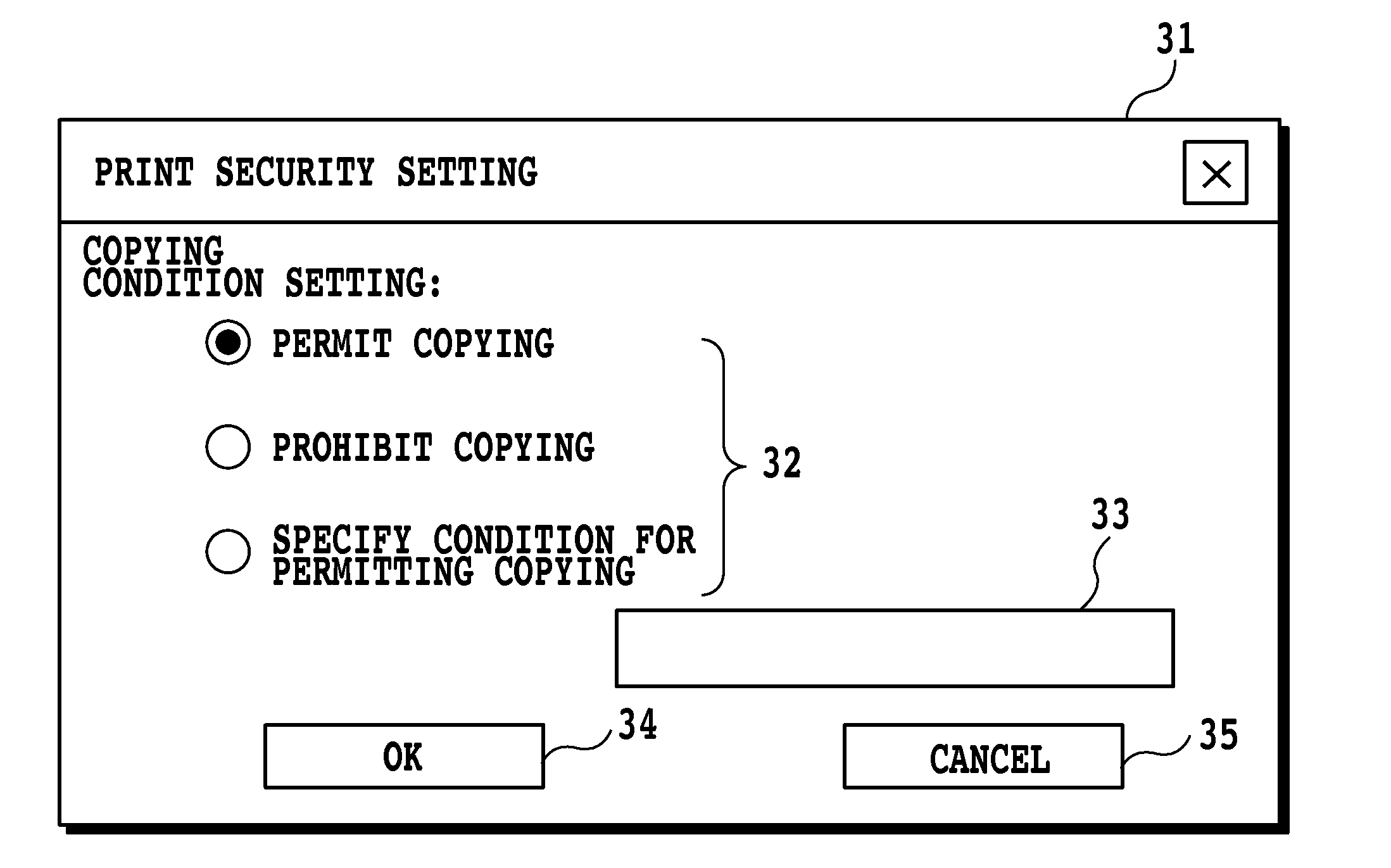

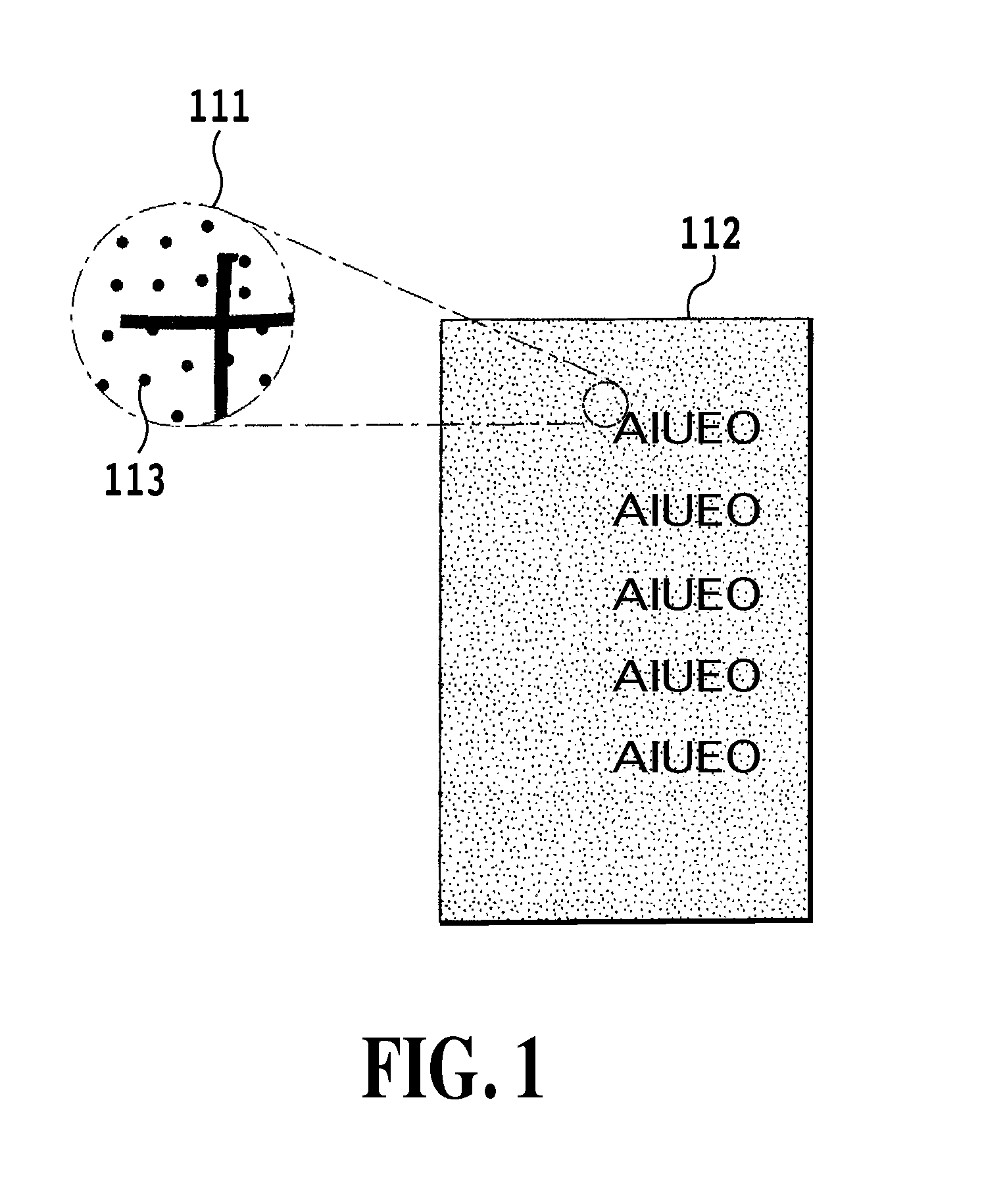

Apparatus, method and program

InactiveUS20100060923A1Efficiently performedEfficient detectionDigital computer detailsVisual presentationImaging processingInformation processing

An object of the present invention is to provide an image processing apparatus which can efficiently perform detection and decode processing carried out in parallel for a plurality of kinds of codes. For achieving the above object, an apparatus according to the present invention is an information processing apparatus capable of causing a printing unit to print a first code that can include both of copy prohibition information and copy permission information and a second cod that can include only the copy prohibition information of the copy prohibition information and the copy permission information, wherein the copy prohibition information is included in the first code, when the first code is printed together with the second code by the printing unit.

Owner:CANON KK

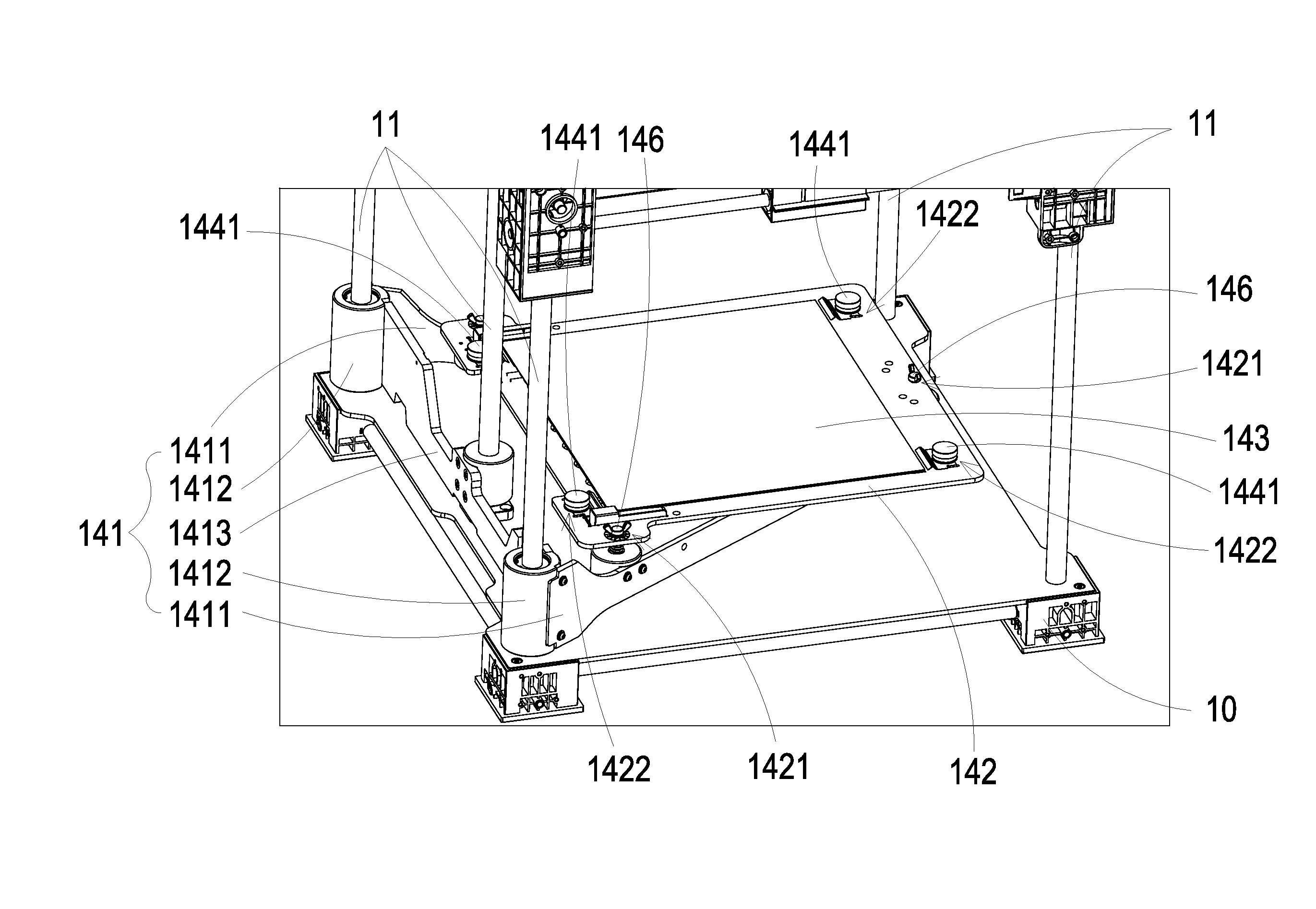

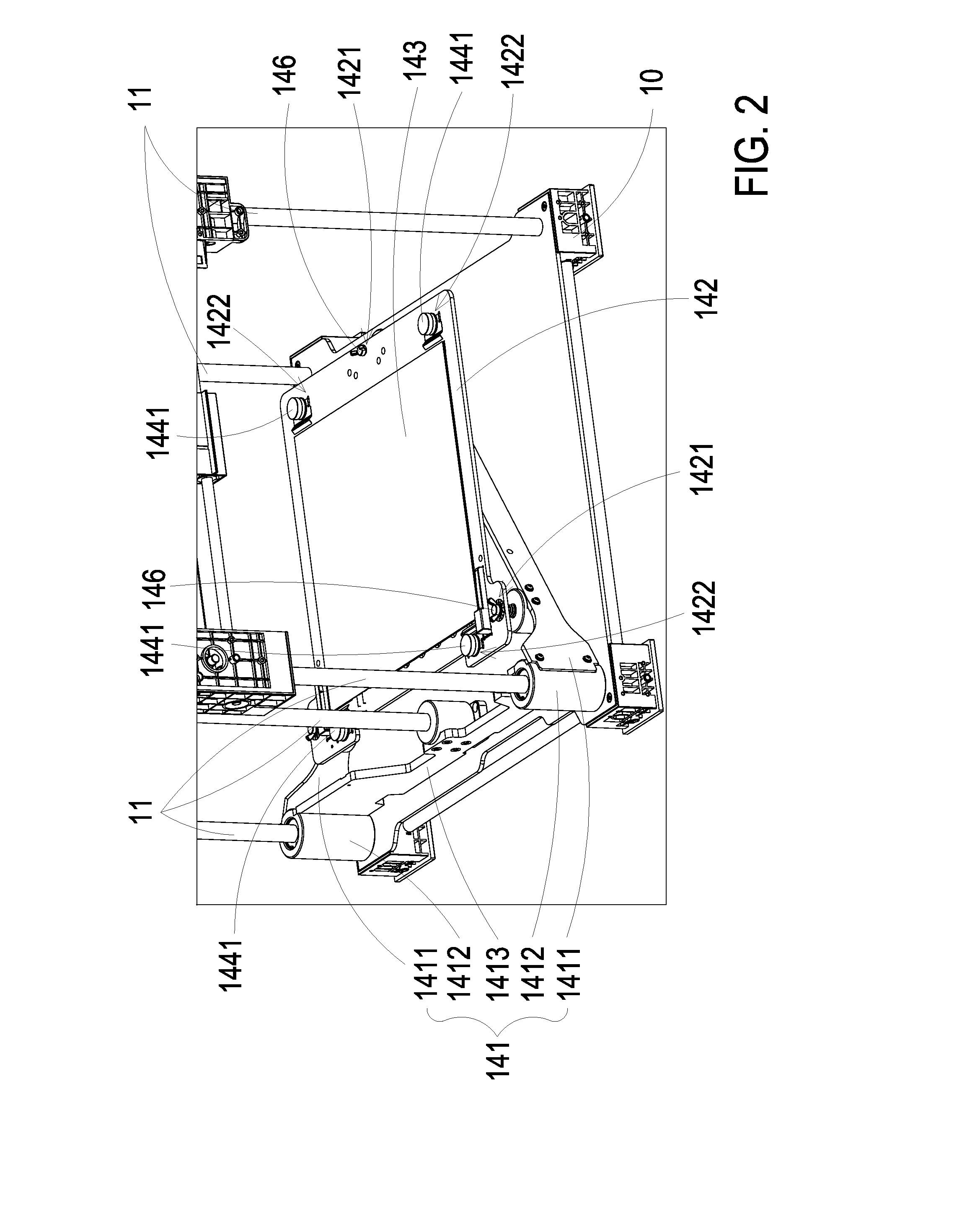

Printing platform supporting module and three-dimensional printer using same

ActiveUS20170043538A1Efficiently performedOvercomes drawbackManufacturing platforms/substratesManufacturing heating elementsEngineering3D printing

The present disclosure relates to a printing platform supporting module and a three-dimensional printer using same. The printing platform supporting module comprises a supporting frame, the printing platform, a heating assembly, an adjusting module, and a printing plate. The heating assembly is disposed on the printing platform. The adjusting module is disposed on the printing platform and comprises a plurality of locking units. The printing plate has a working surface and a mounting surface opposite to the working surface. The mounting surface is urged against the heating assembly. The printing plate is removably disposed on the printing platform by means of a locking action and an unlocking action of the locking units.

Owner:TECO IMAGE SYST

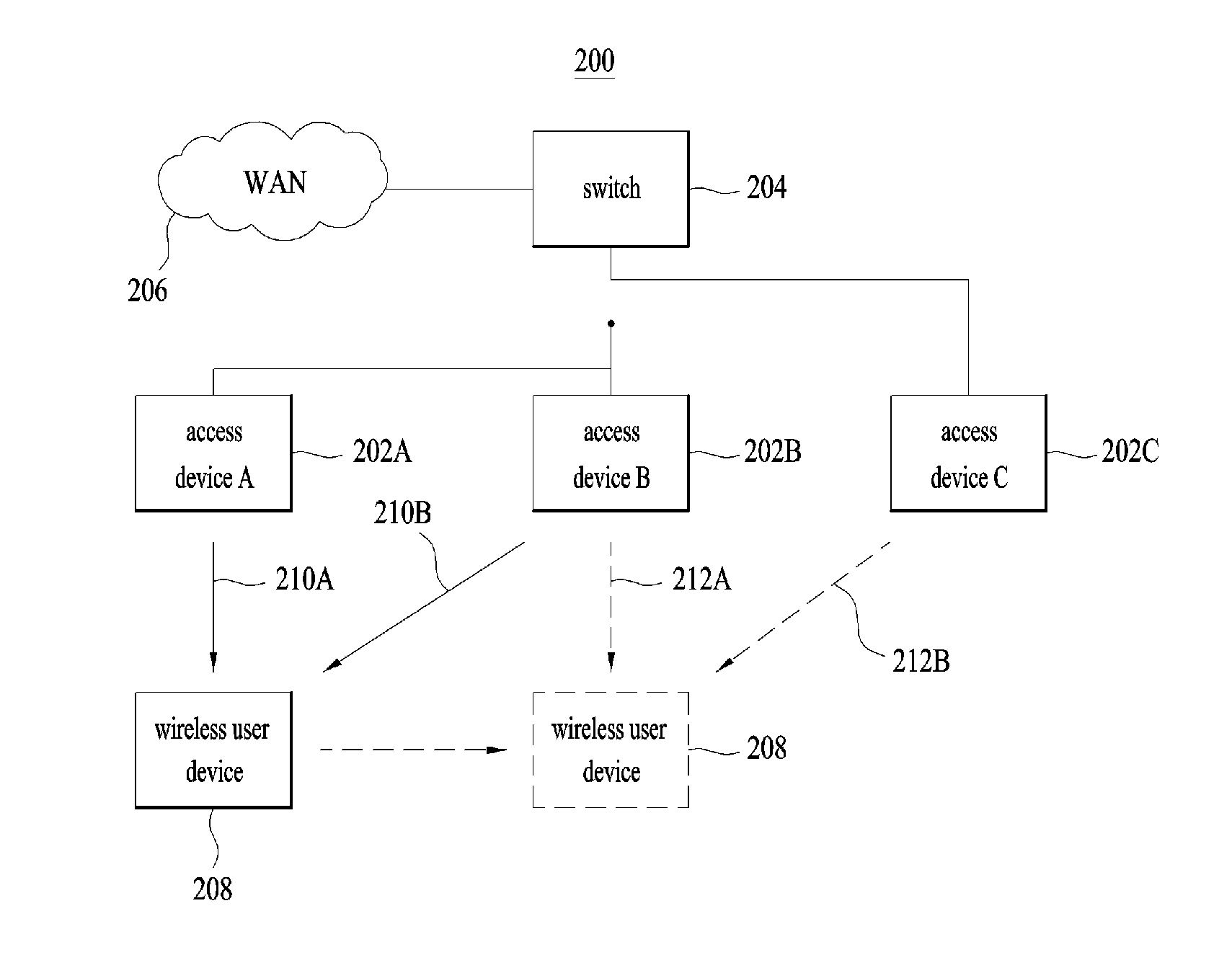

Method for performing service request procedure in wireless communication system and device therefor

InactiveUS20190230723A1Efficiently performedEfficient executionConnection managementInformation storageRadio resource management

Disclosed are a method for performing a service request procedure in a wireless communication system and an apparatus therefore. Specifically, a method for performing, by a base station, a service request procedure triggered by a remote UE when a connection between a relay user equipment (UE) and a remote UE is set up in a wireless communication system may include: receiving, from the relay UE, a radio resource management (RRC) message encapsulated with a service request message for the remote UE, which includes an identifier of the remote UE; transmitting the service request message to a mobile management entity (MME) within an S1 interface message; receiving, from the MME, an S1 initial context setup request message for the remote UE without UE radio capability information of the remote UE; and storing the UE radio capability information of the relay UE as the UE radio capability information of the remote UE.

Owner:LG ELECTRONICS INC

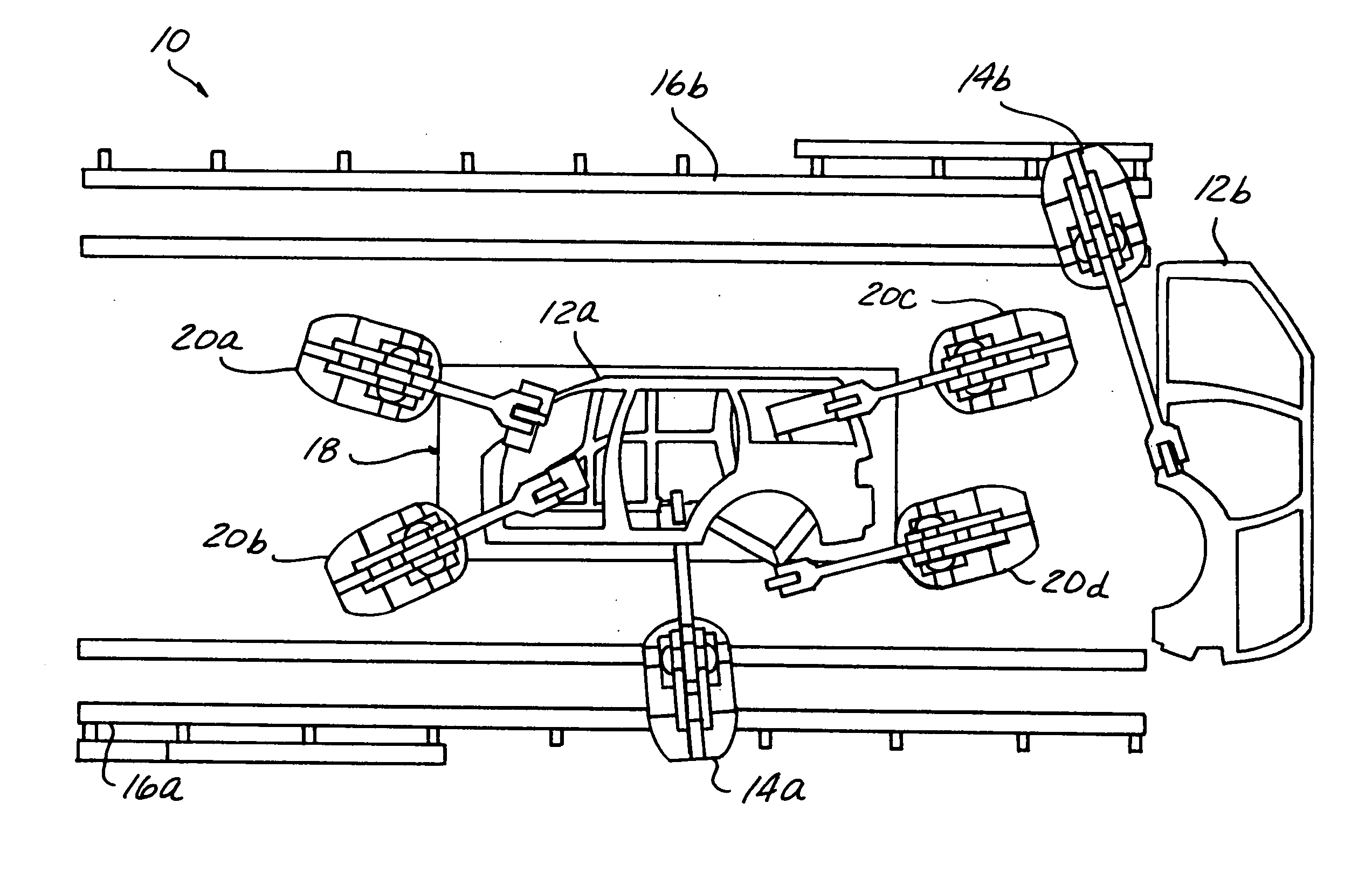

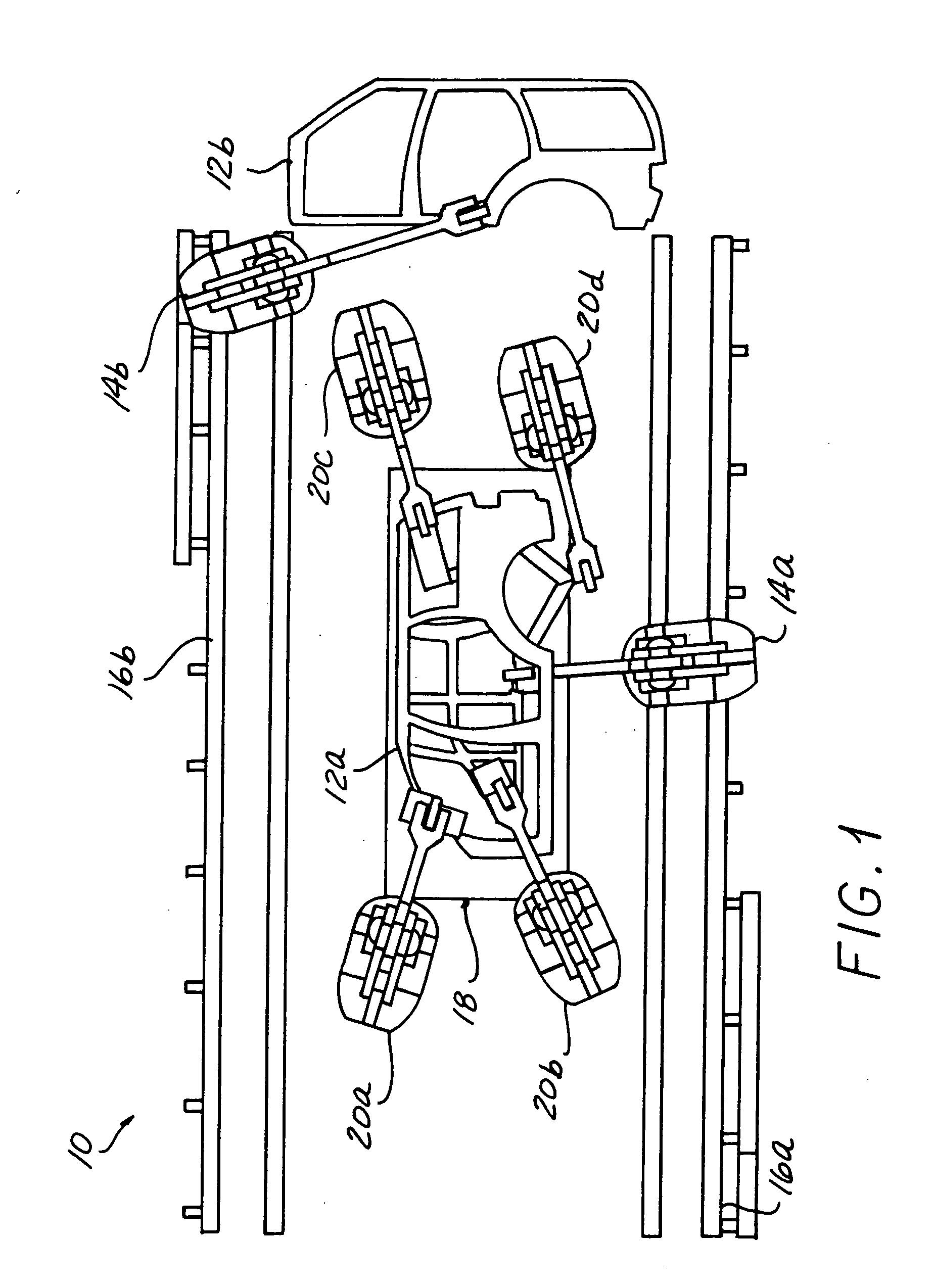

Flexible body workstation for assembling workpieces

InactiveUS20050189399A1Efficiently performedEfficient executionWelding/cutting auxillary devicesAuxillary welding devicesActuatorMaterial handling

A workstation and method for processing a plurality of workpieces includes at least one material handling robot movable along a processing path for supporting a workpiece to be moved along the processing path. At least one station can be defined by at least one processing position adjacent the processing path for receiving workpieces to be processed when delivered and positioned by the at least one material handling robot. Interchangeable end effecters can be connected to the material handling robot for holding and supporting different configurations of workpieces. The material handling robot can disengage from the end effecter at the processing position, to allow engagement with a processing tool for performing additional processing operations on the workpiece. A flexible body workstation for assembling workpieces can use multiple robots and / or multiple fixtures for processing different workpiece configurations in any sequential order along two processing paths.

Owner:COMAU INC (US)

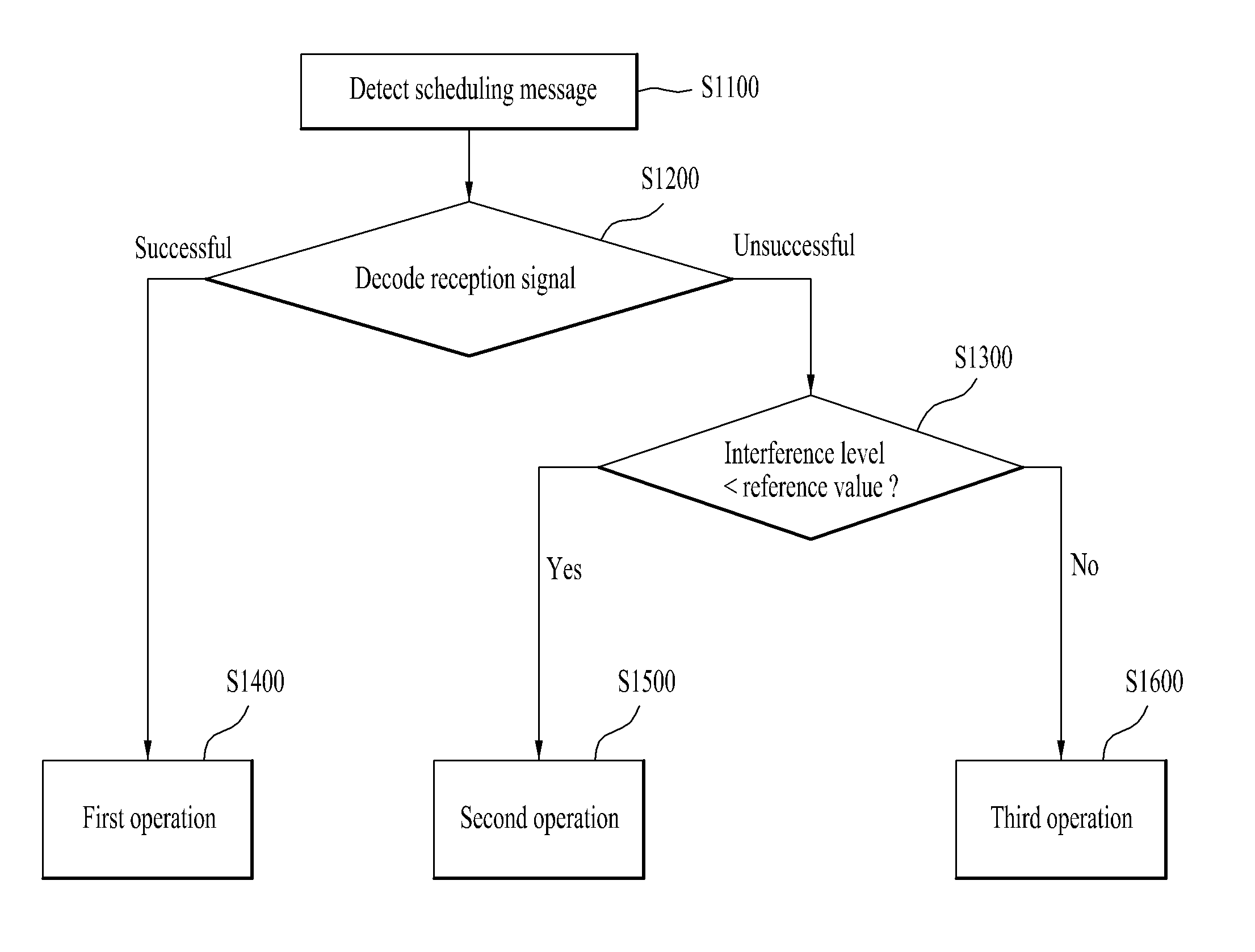

Signal transmission method and user equipment, and signal reception method and base station

InactiveUS20150071193A1Avoid operationEfficiently performedError prevention/detection by using return channelSignal allocationEngineeringElectrical and Electronics engineering

According to the present invention, user equipment performs an HARQ operation for a signal in consideration of the interference experienced by the signal when the signal is received by the user equipment. An apparatus transmitting a signal to the user equipment retransmits the signal in consideration of the interference experienced by the signal when the signal reaches the user equipment on the basis of ACK / NACK information from the user equipment.

Owner:LG ELECTRONICS INC

Method and apparatus for performing d2d operation in non-activated carrier in wireless communication system

ActiveUS20170135074A1Efficiently performedEfficient executionConnection managementNetwork planningCarrier signalWireless communication systems

A method and apparatus for performing device-to-device (D2D) operation in a wireless communication system is provided. A user equipment (UE) receives a signal for D2D operation, and performs the D2D operation in a non-activated carrier.

Owner:LG ELECTRONICS INC

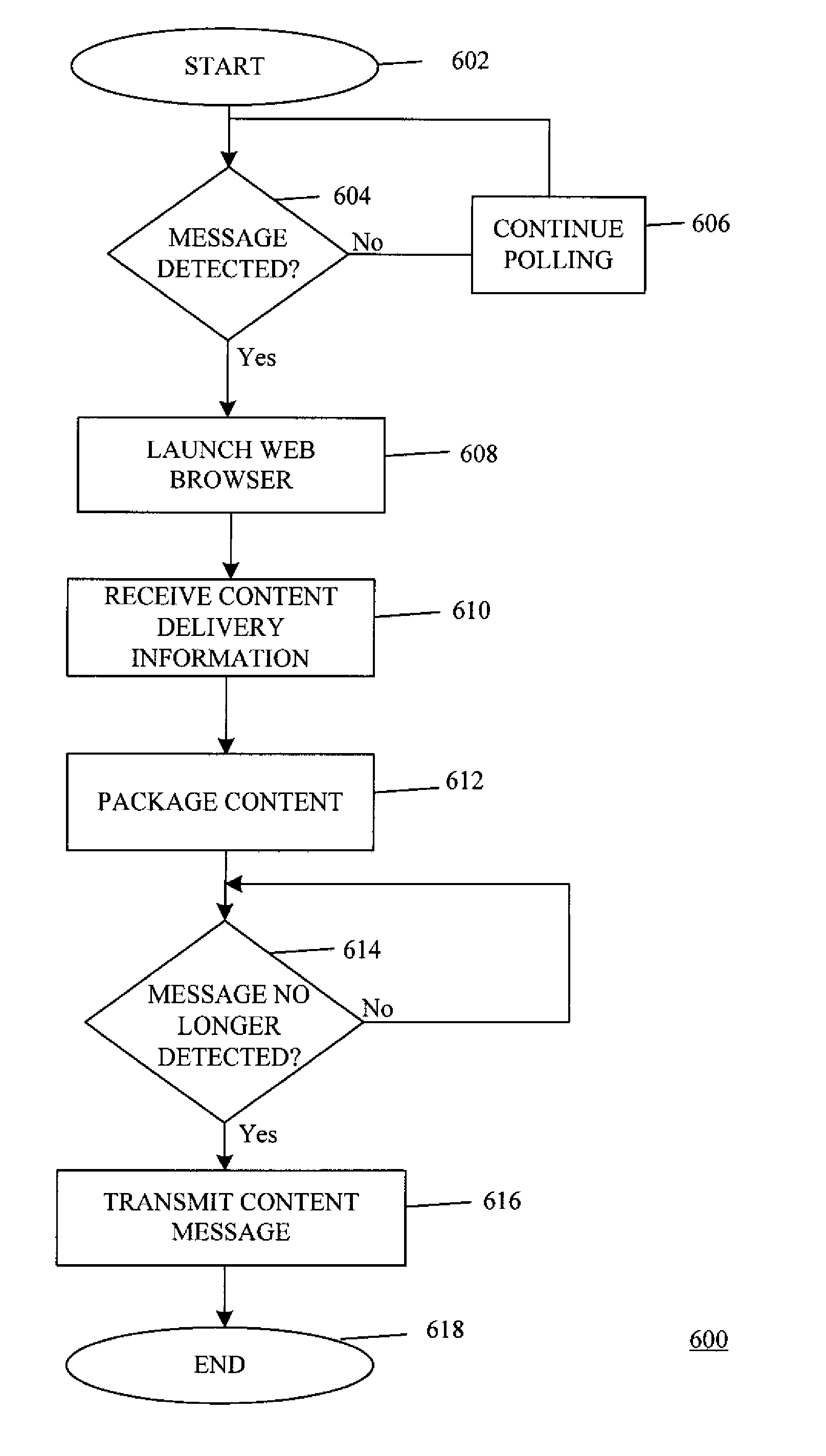

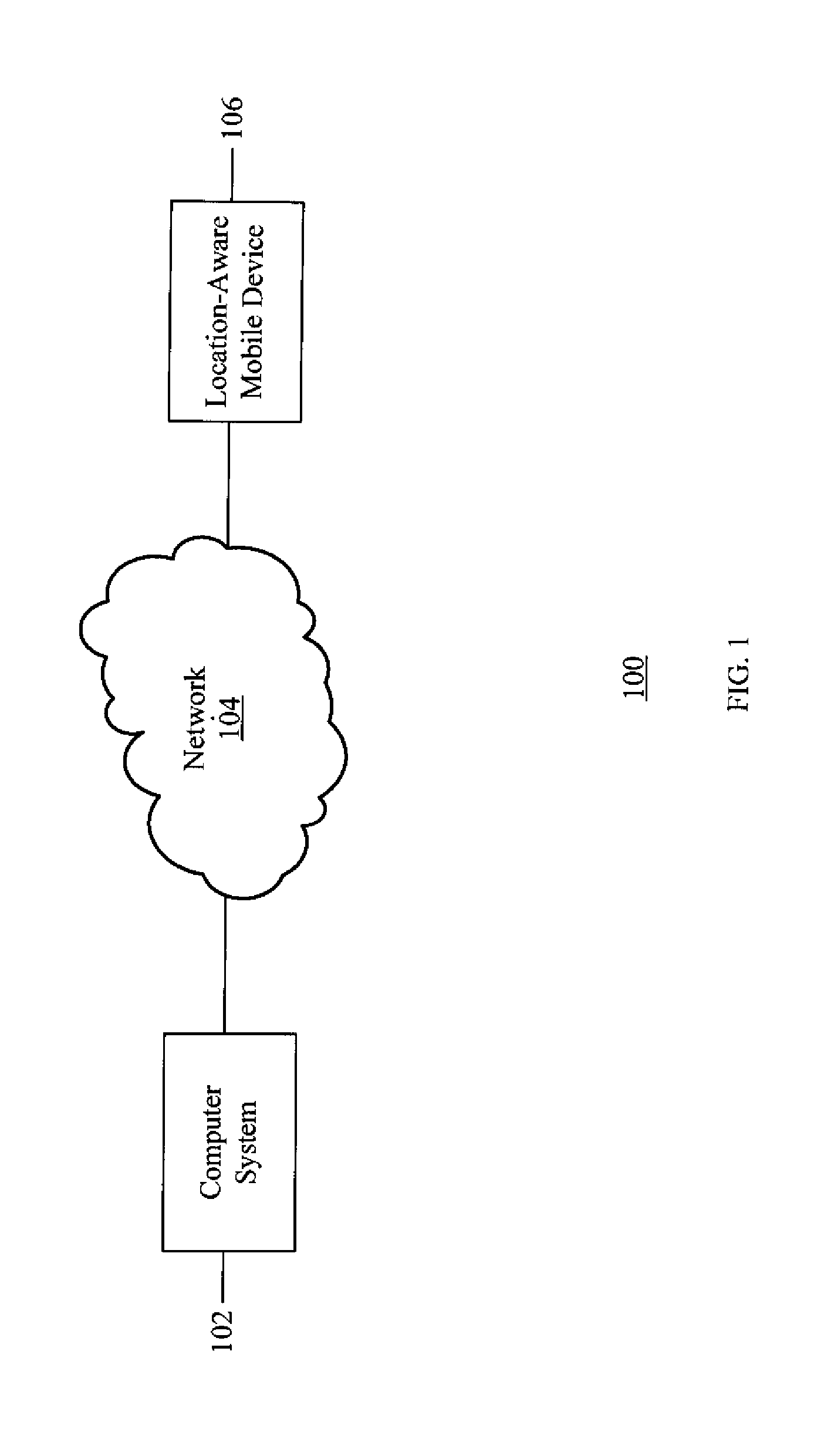

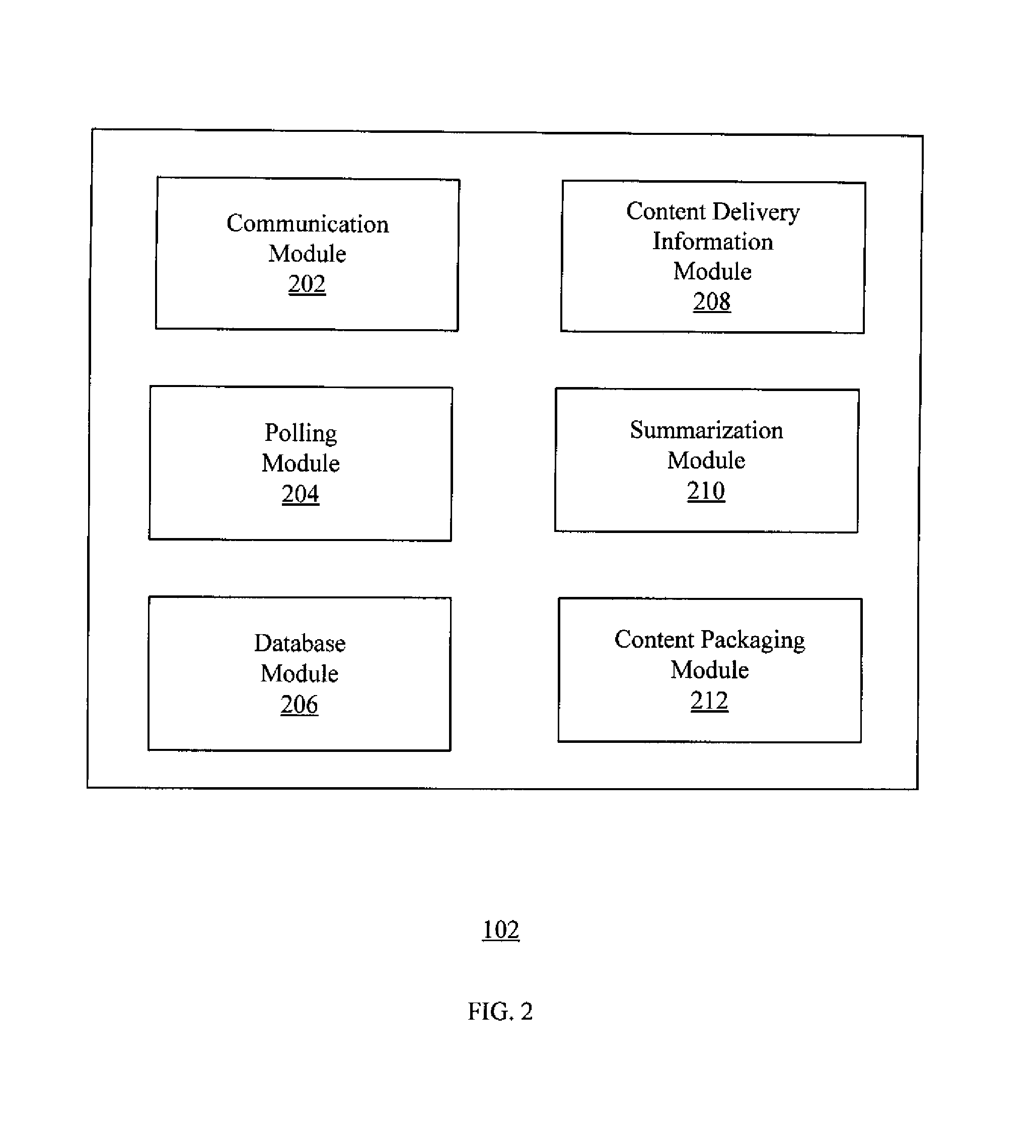

Method and system for providing preference based content to a location aware mobile device

ActiveUS8769008B1Efficiently performedMultiple digital computer combinationsLocation information based serviceLocation awareContent delivery

A system and method in accordance with exemplary embodiments may include receiving a message from a location-aware mobile device associated with a user, receiving content delivery information from the user, formulating a content package at least based on the content delivery information, and sending a content message associated with the content package to the location-aware mobile device via a network.

Owner:THE NEW YORK TIMES COMPANY

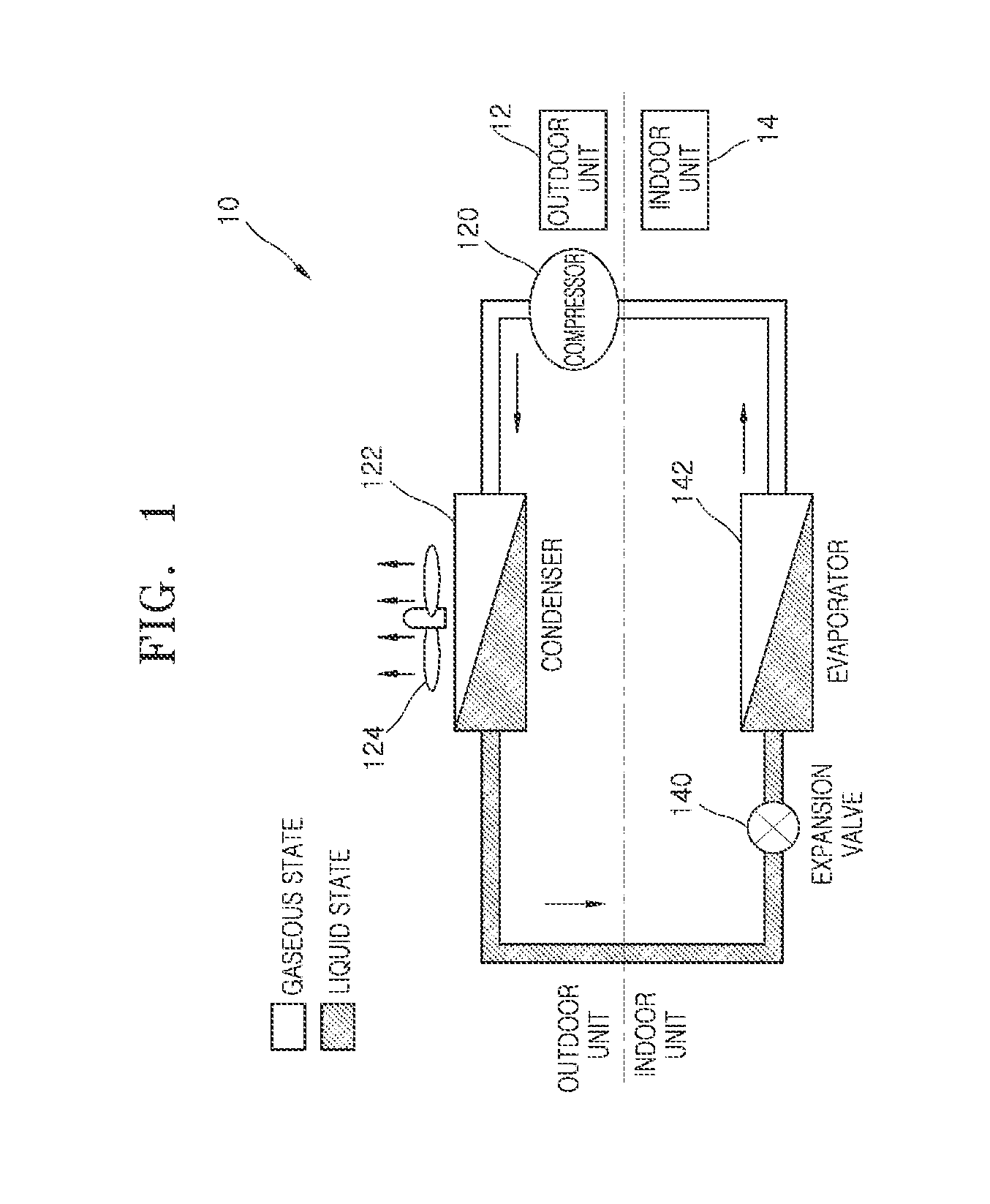

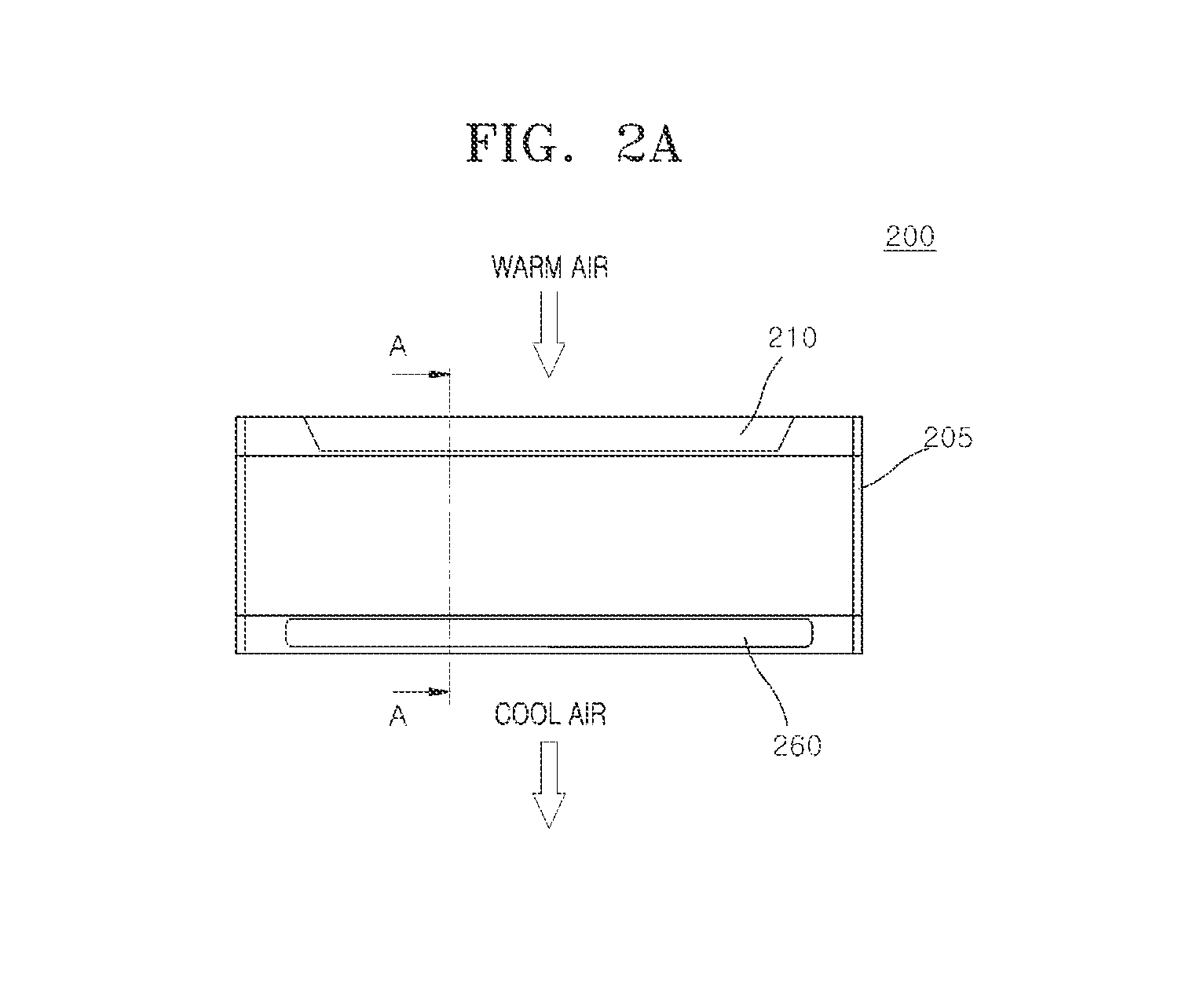

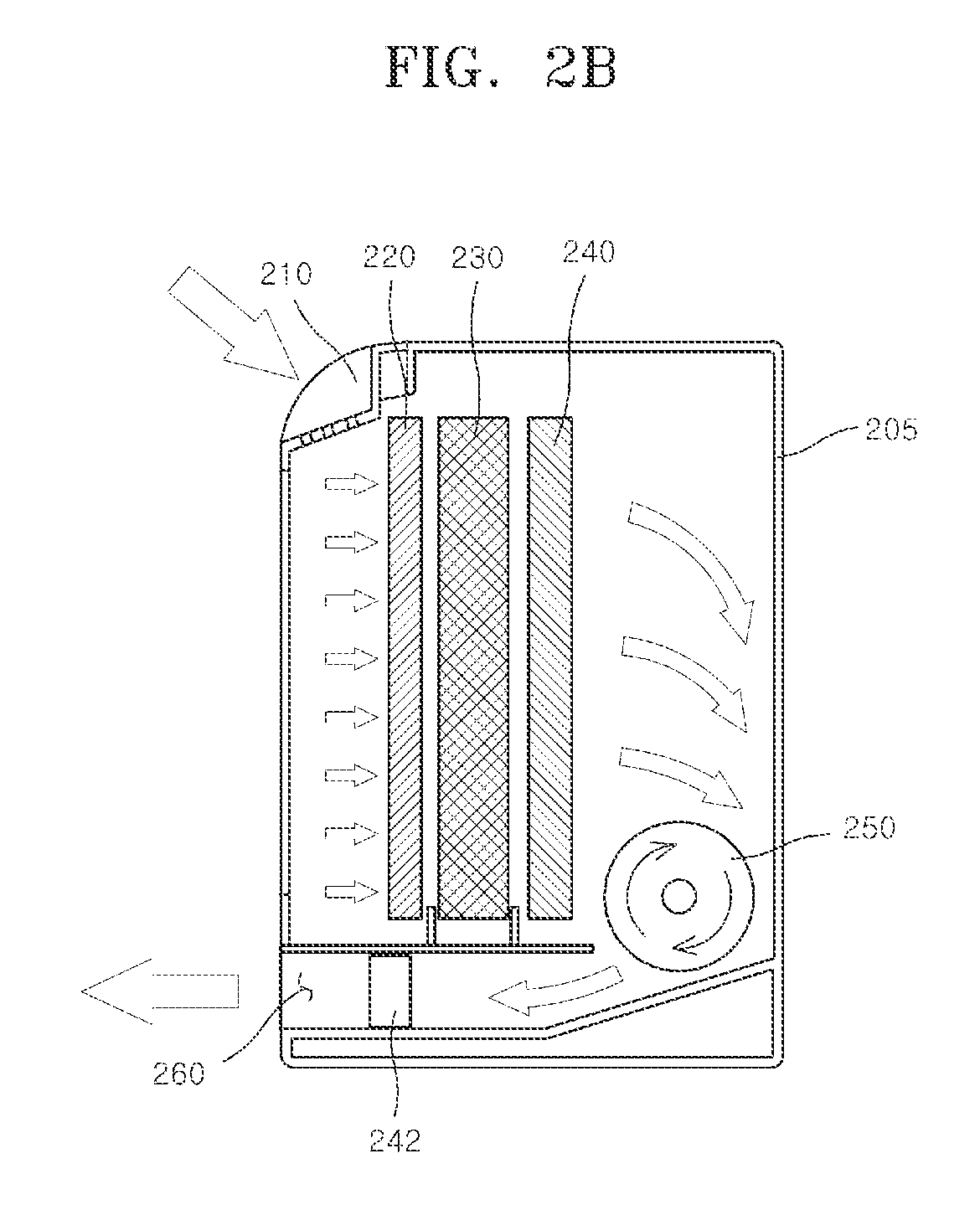

Air Conditioner Having Air Purifying Module

InactiveUS20150037217A1Improve cleanlinessEfficiently performedMechanical apparatusLighting and heating apparatusEvaporatorDiode

An air conditioner including a body having an evaporator for heat-exchanging air flowing in the body, and an air purifying module coupled to the body. The air purifying module may have a light emitting diode part disposed along a flow path of the air to provide ultraviolet rays, and a filter part disposed adjacent to the light emitting diode part.

Owner:SEOUL VIOSYS CO LTD

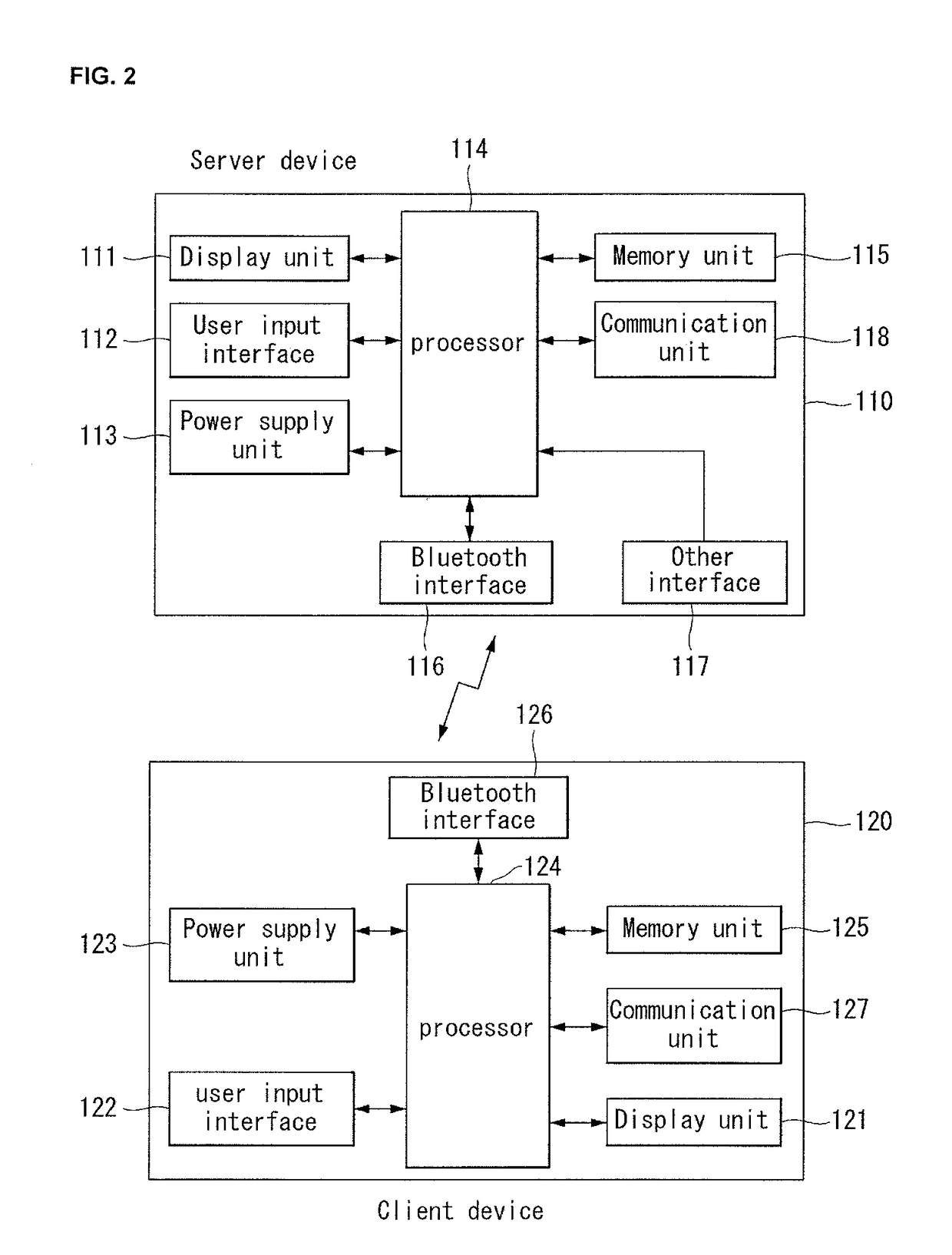

Method and apparatus for bluetooth connection

ActiveUS20160286341A1Reduce reconnection timeEfficiently performedNetwork topologiesConnection managementBluetoothBeacon

The present invention relates to a method and device for performing a Bluetooth reconnection procedure. In accordance with embodiments of the present invention, there are provided a method and device, including sending a first message notifying a second device of the activation of a first device to the second device through a specific channel, receiving a beacon message through the specific channel from the second device as a response to the first message, sending a request message requesting a connection with the second device using Bluetooth to the second device through the specific channel, and receiving a confirm message through the specific channel from the second device as a response to the request message. The first device stores information related to the Bluetooth connection with the second device.

Owner:LG ELECTRONICS INC

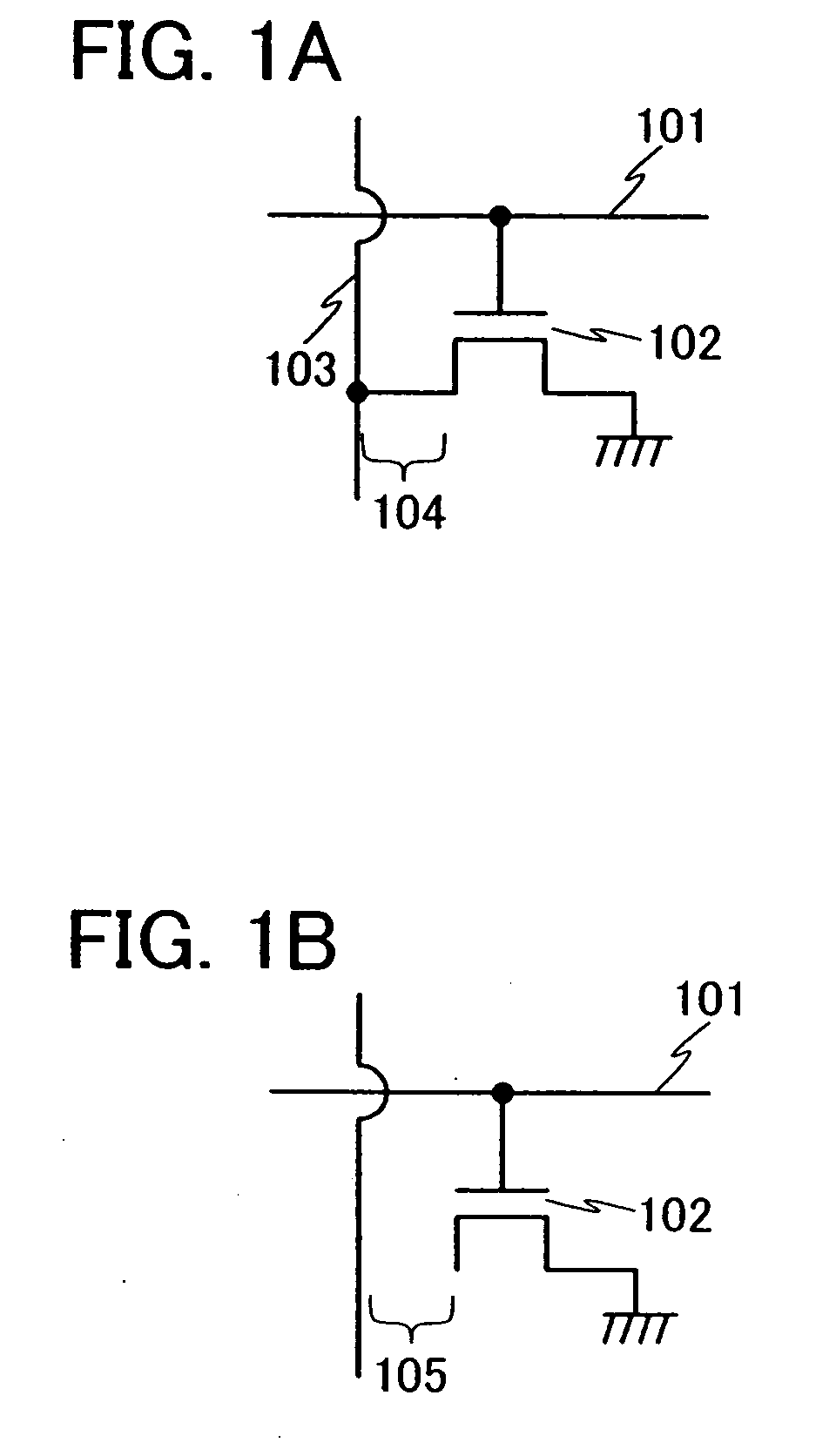

Manufacturing method of memory element, laser irradiation apparatus, and laser irradiation method

ActiveUS20070184639A1Easily storedEfficiently performedSolid-state devicesPhotomechanical apparatusPhotoresistResist

A method for rapidly performing laser irradiation in a desired position as laser irradiation patterns are switched is proposed. A laser beam emitted from a laser oscillator is entered into a deflector, and a laser beam which has passed through the deflector is entered into a diffractive optical element to be diverged into a plurality of laser beams. Then, a photoresist formed over an insulating film is irradiated with the laser beam which is made to diverge into the plurality of laser beams, and the photoresist irradiated with the laser beam is developed so as to selectively etch the insulating film.

Owner:SEMICON ENERGY LAB CO LTD

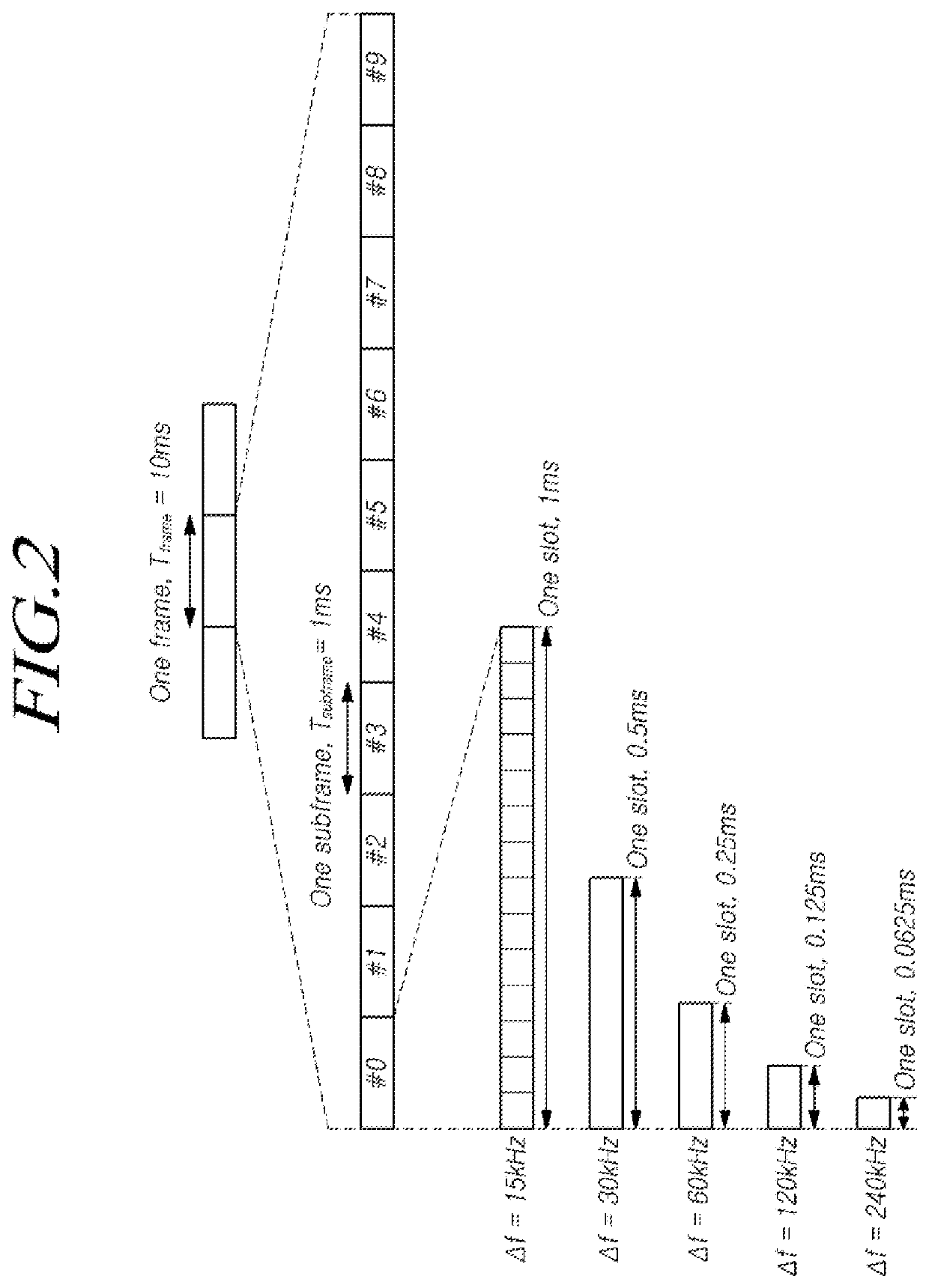

Methods for controlling a paging operation and apparatuses thereof

ActiveUS20200084747A1Reduce power consumptionEfficiently performedPower managementAssess restrictionFrequency bandEngineering

Provided are a method and apparatus for enabling a user equipment to perform a paging operation. The method includes: monitoring whether a paging message is present at a set of PDCCH monitoring occasions included in a paging occasion, detecting whether a base station has accessed to a channel including a frequency band over which the paging message is transmitted at one or more of the PDCCH monitoring occasions, and stopping the monitoring when detecting that the base station has accessed the channel.

Owner:KT CORP

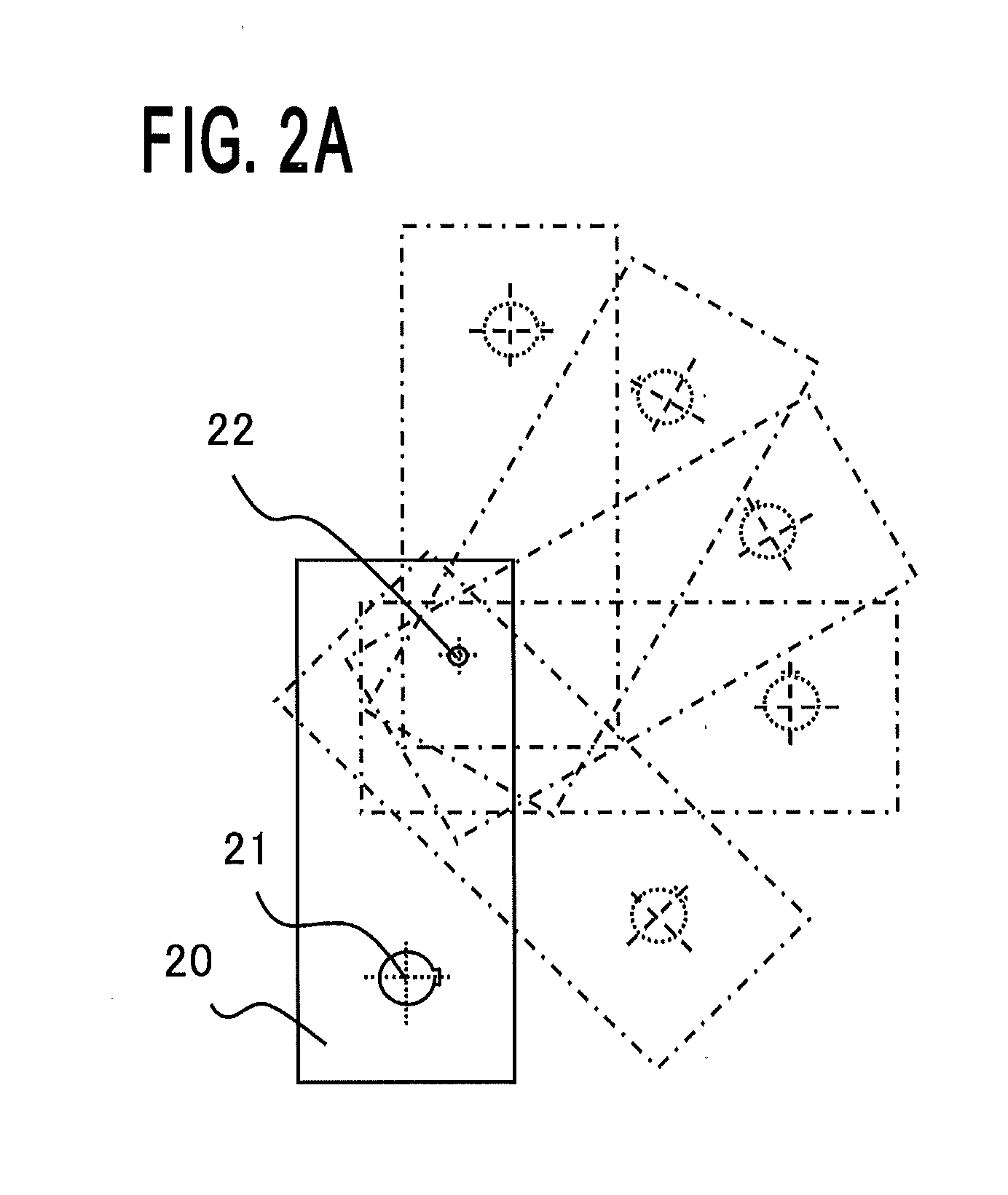

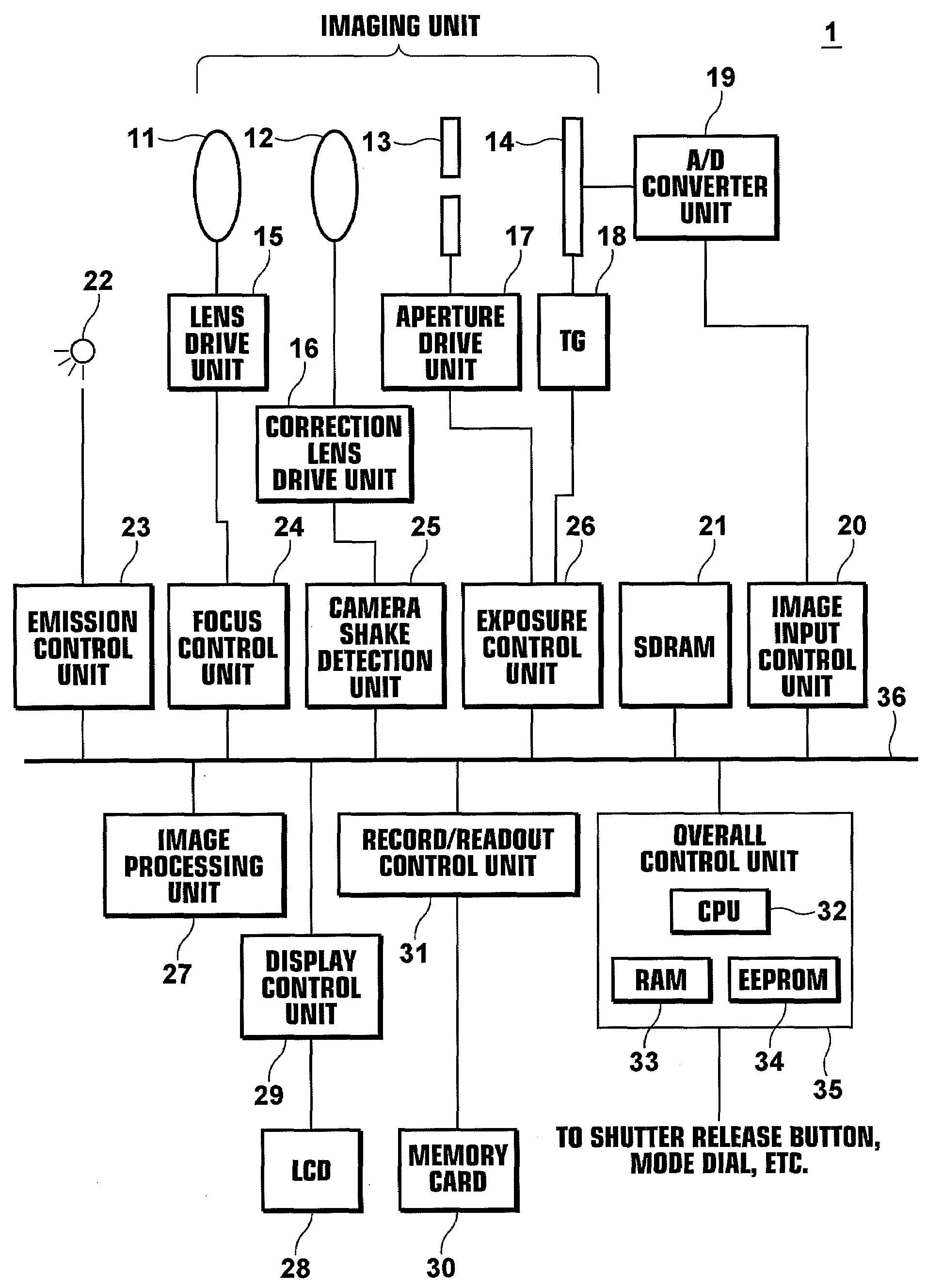

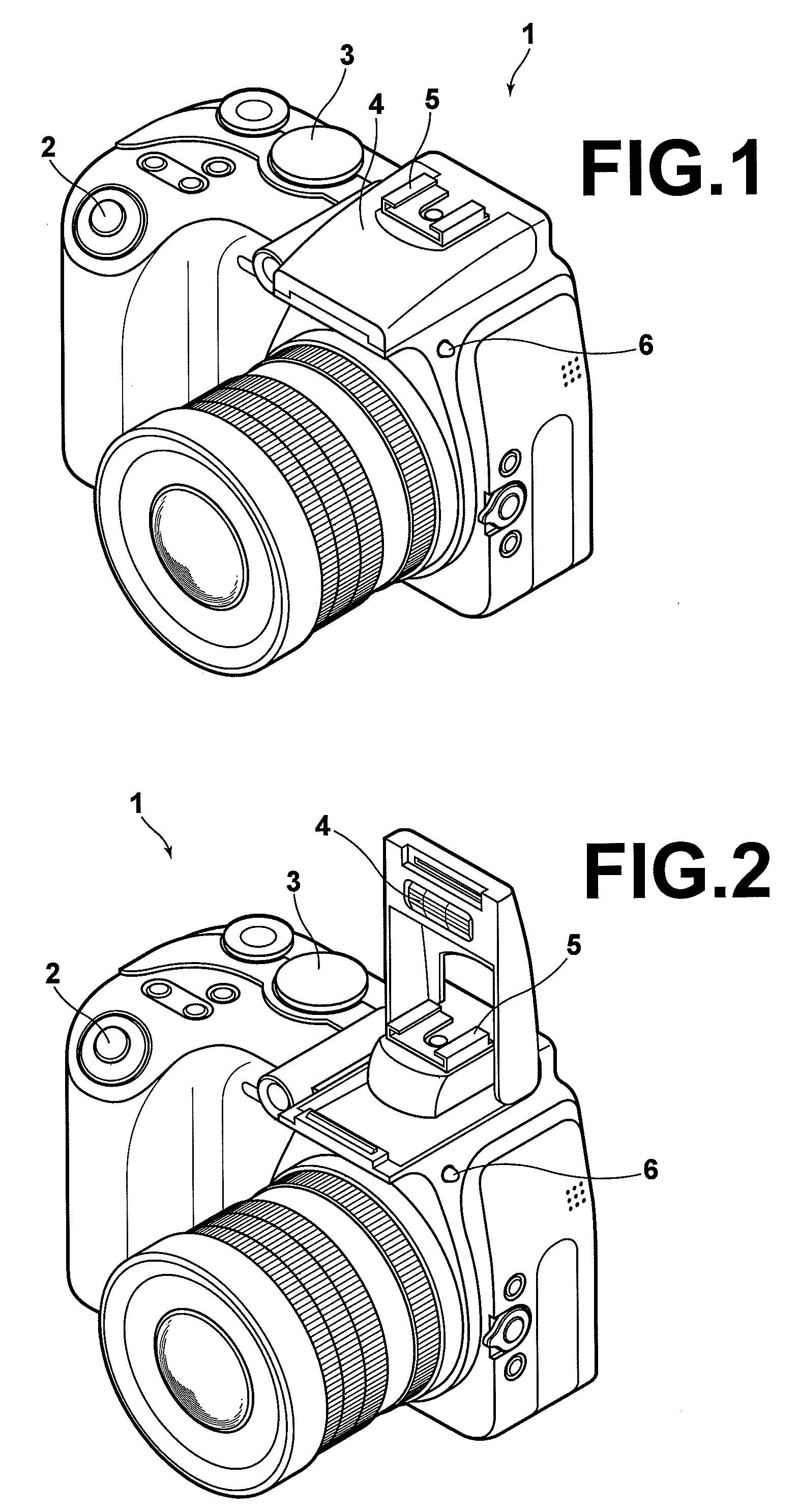

Photographing apparatus, and control method and computer program product for controlling the same

InactiveUS20090028537A1Efficiently performedEfficient executionTelevision system detailsColor television detailsComputer visionOptical axis

A photographing apparatus including: a photographing means that photographs a subject to obtain an image representing the subject by receiving an instruction to perform photographing; a camera shake correction means constructed to be driven in a direction different from the optical axis of the photographing means and corrects a camera shake induced blur of an image to be obtained by the photographing; and a correction system driving means that receives an instruction to perform main photographing and initiates driving of the camera shake correction means from a first predetermined position during a period from the time when the instruction to perform main photographing is given to the time when the subject is photographed, and drives the camera shake correction means to a second predetermined position during a period from the time when the driving is initiated to the time when the main photographing is performed.

Owner:FUJIFILM CORP

Method for finding instrument for wi-fi direct p2p (peer to peer) communication and apparatus therefor

ActiveUS20150382287A1Efficiently perform D2DEfficiently performedAssess restrictionNetwork topologiesTelecommunicationsInstrumentation

Owner:LG ELECTRONICS INC

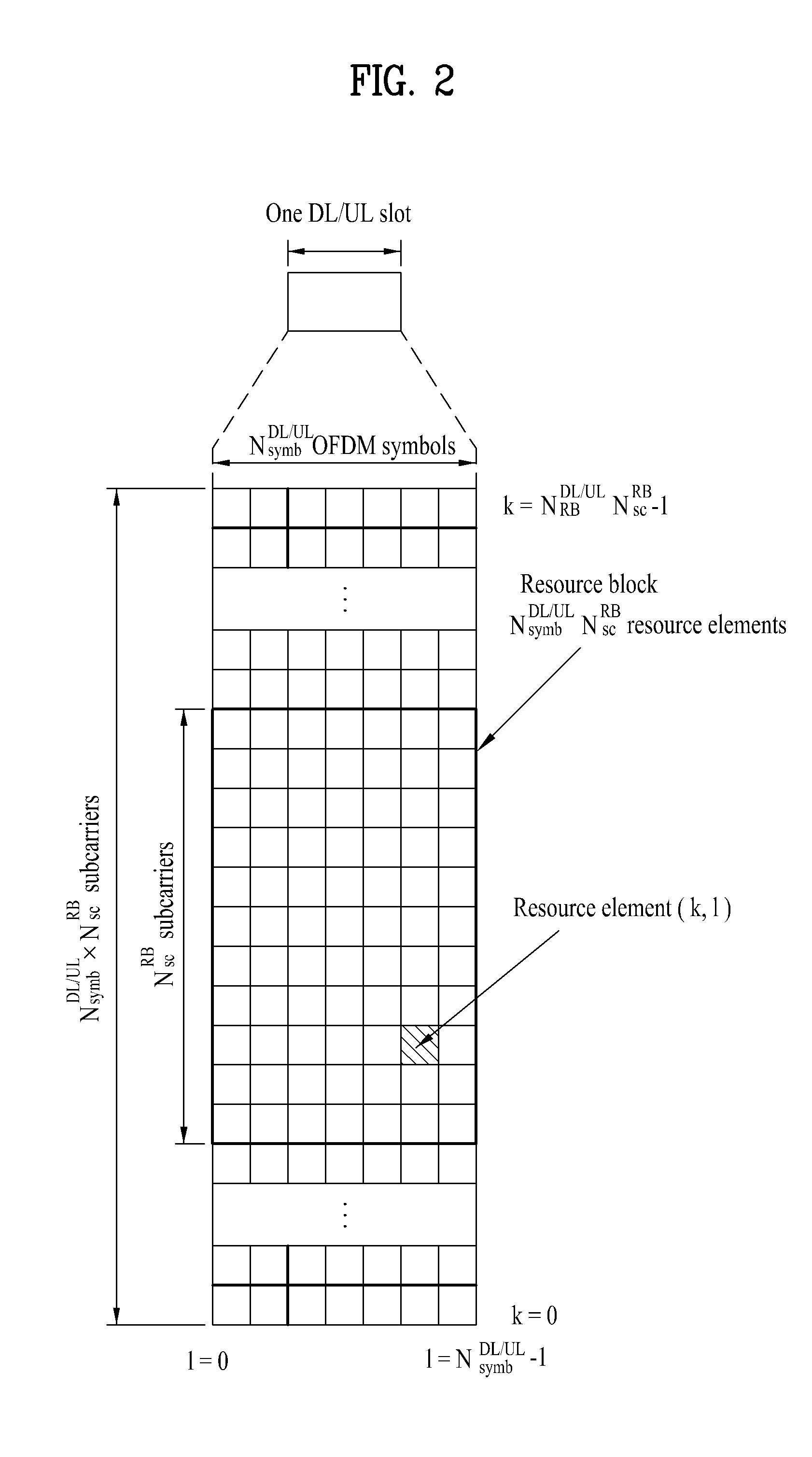

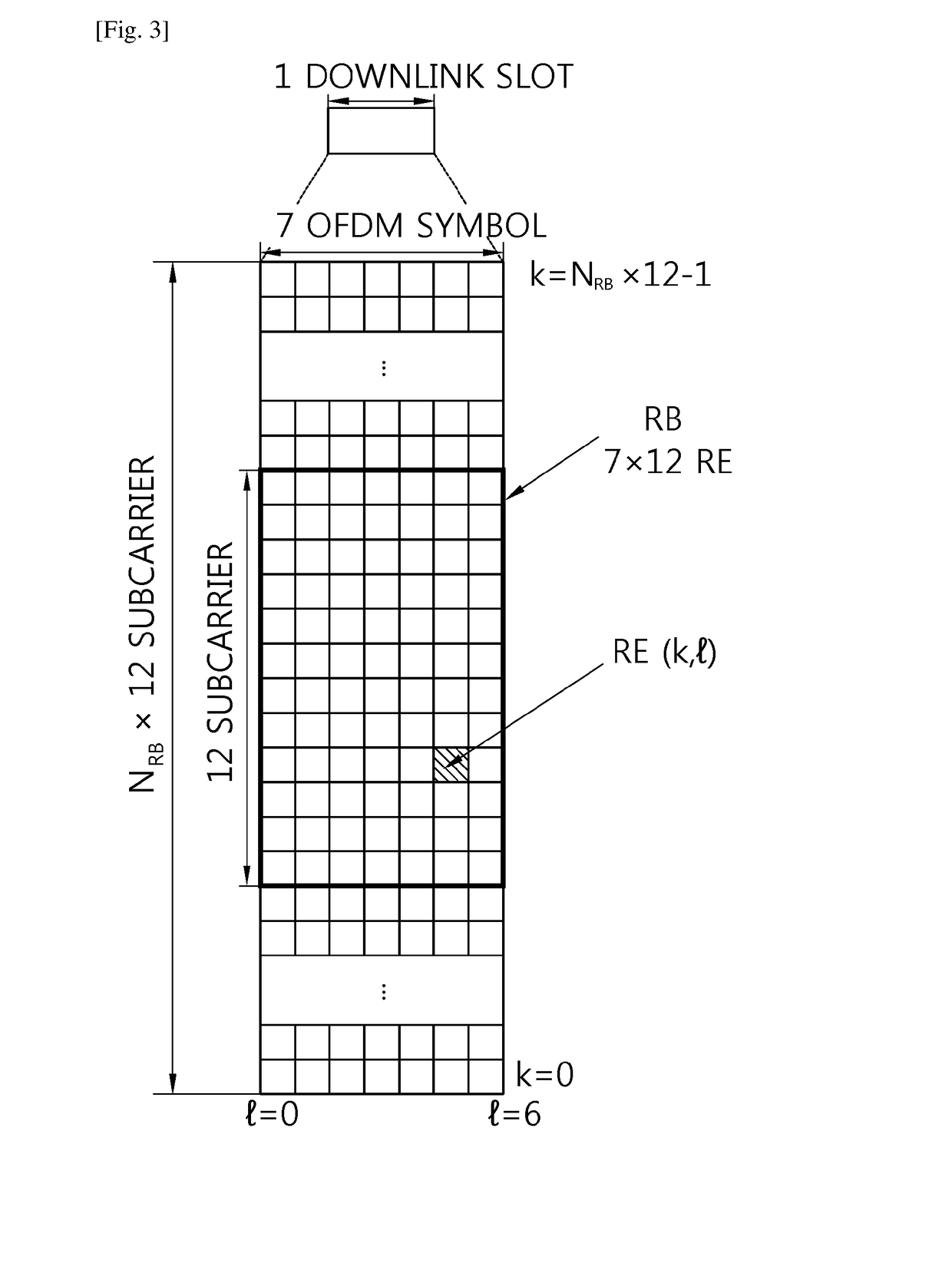

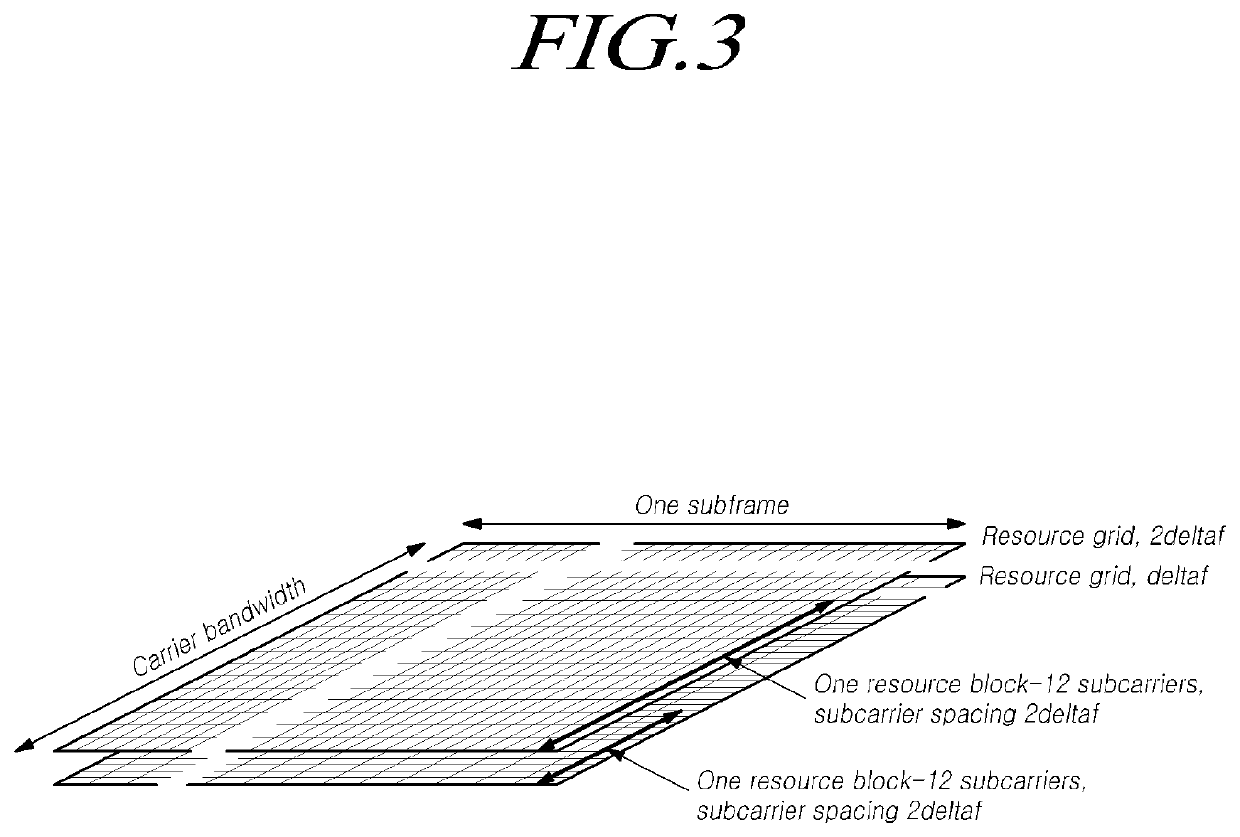

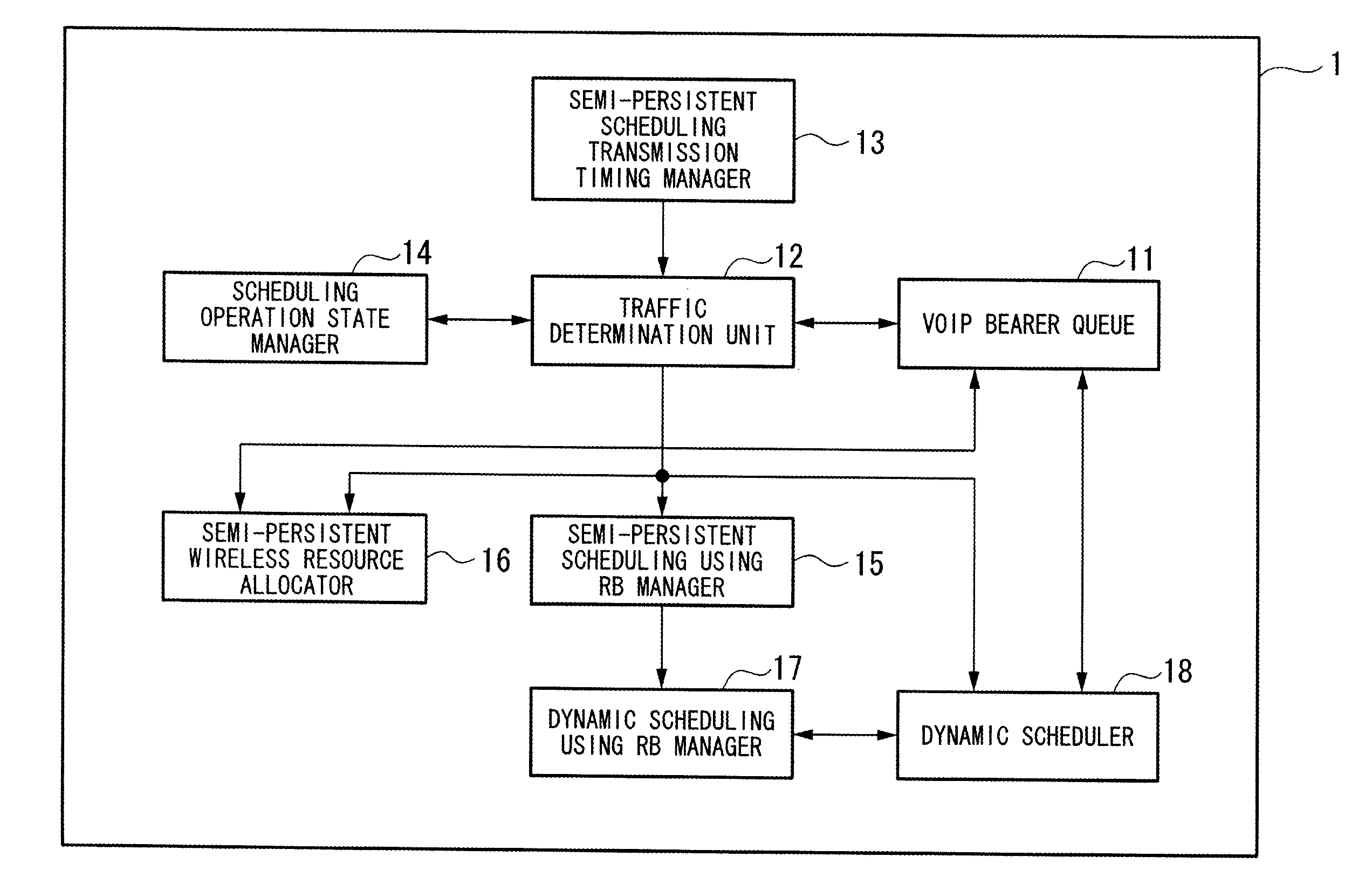

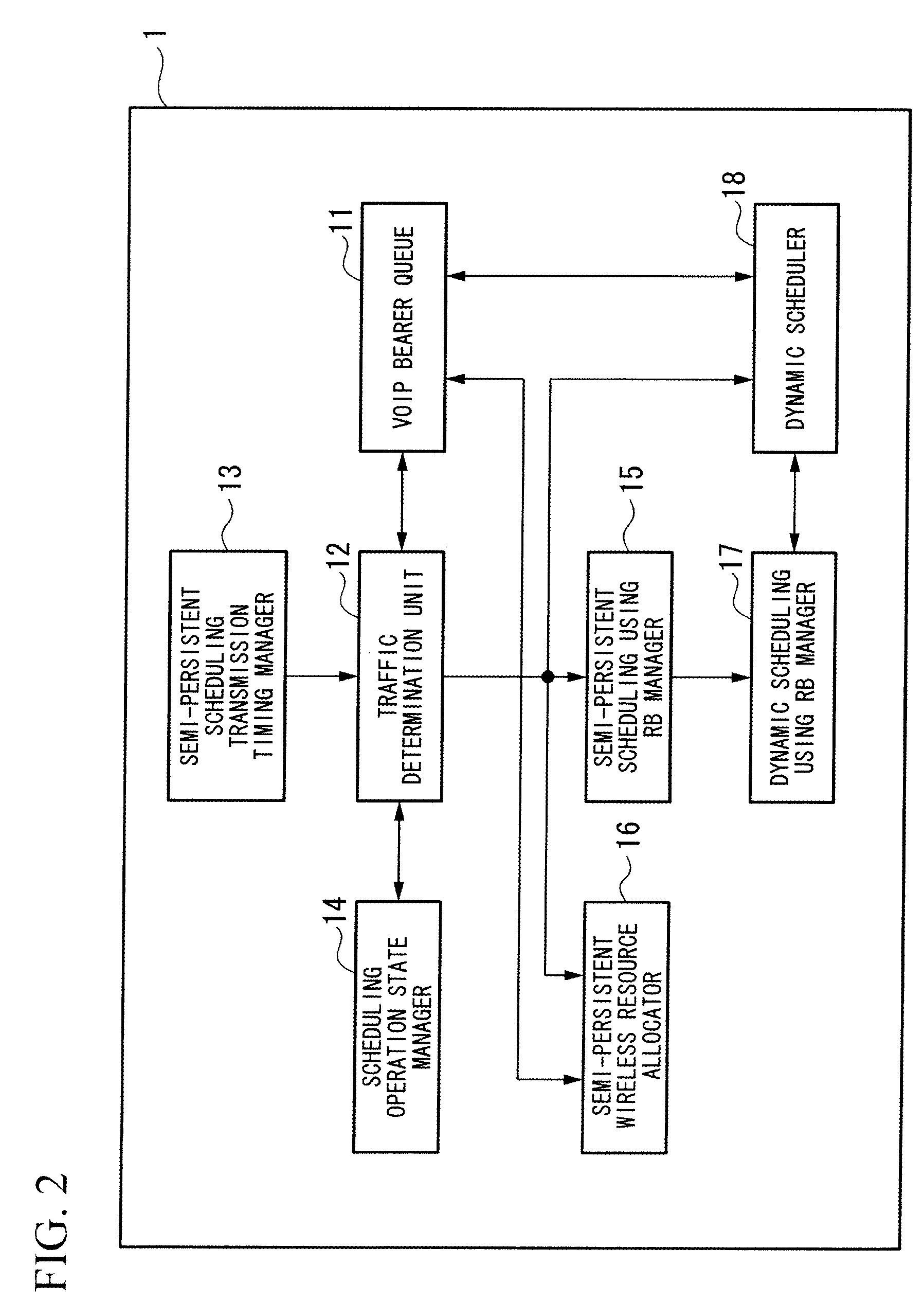

Wireless resource allocation apparatus and method

InactiveUS20110063975A1Efficiently performedEfficient executionError preventionNetwork traffic/resource managementWireless resource allocationResource block

A wireless resource allocation apparatus performs determining an amount of VoIP traffic for each terminal station; determining whether semi-persistent scheduling or dynamic scheduling is used for transmitting each packet of the VoIP traffic, based on a result of the determination for the amount of the VoIP traffic; managing, for each terminal station, a resource block allocated in the semi-persistent scheduling; and managing each resource block which is not managed for the allocation in the semi-persistent scheduling and is allocated in the dynamic scheduling. If it is determined that the dynamic scheduling is used for transmitting each packet of the VoIP traffic to a terminal station, the resource block, which has been managed for the relevant terminal station as a resource block allocated in the semi-persistent scheduling, is released, and the released resource block is managed as a resource block allocated in the dynamic scheduling.

Owner:KDDI CORP

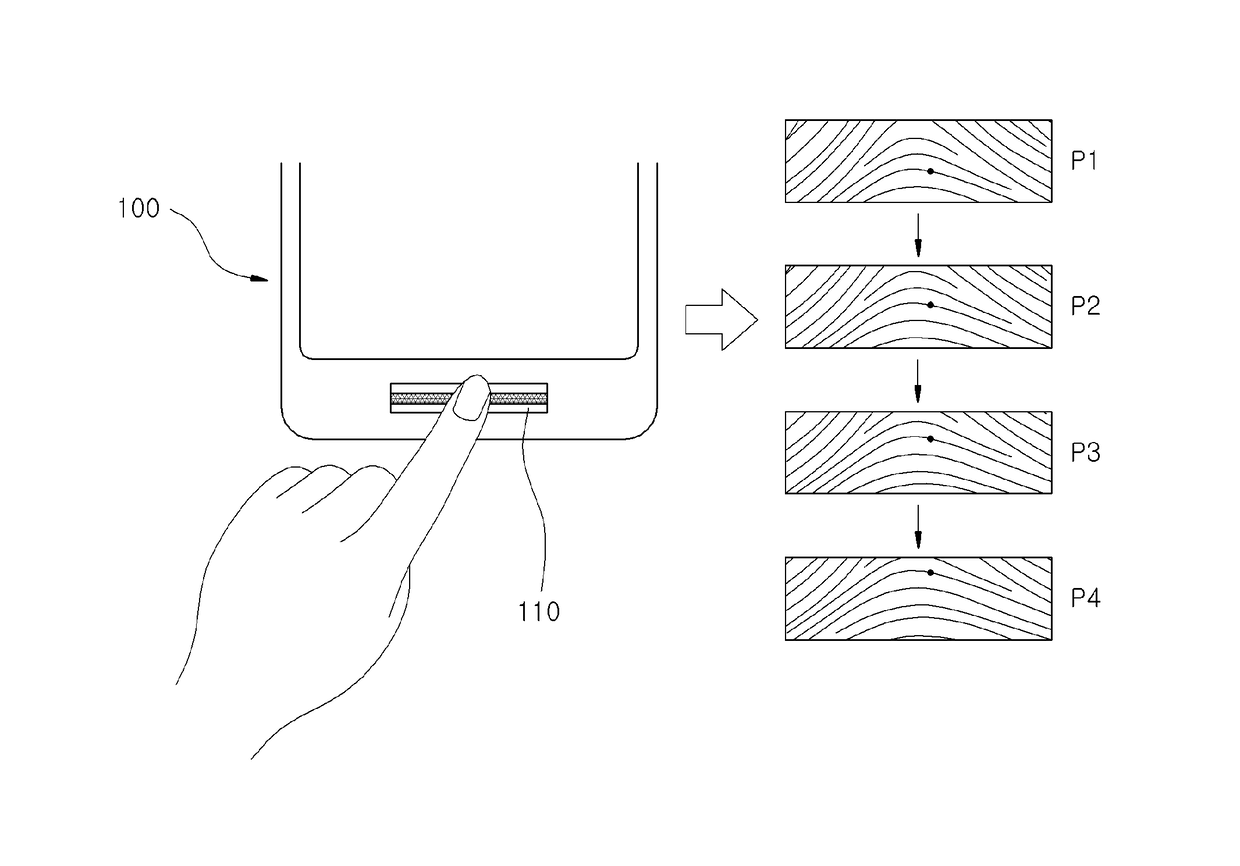

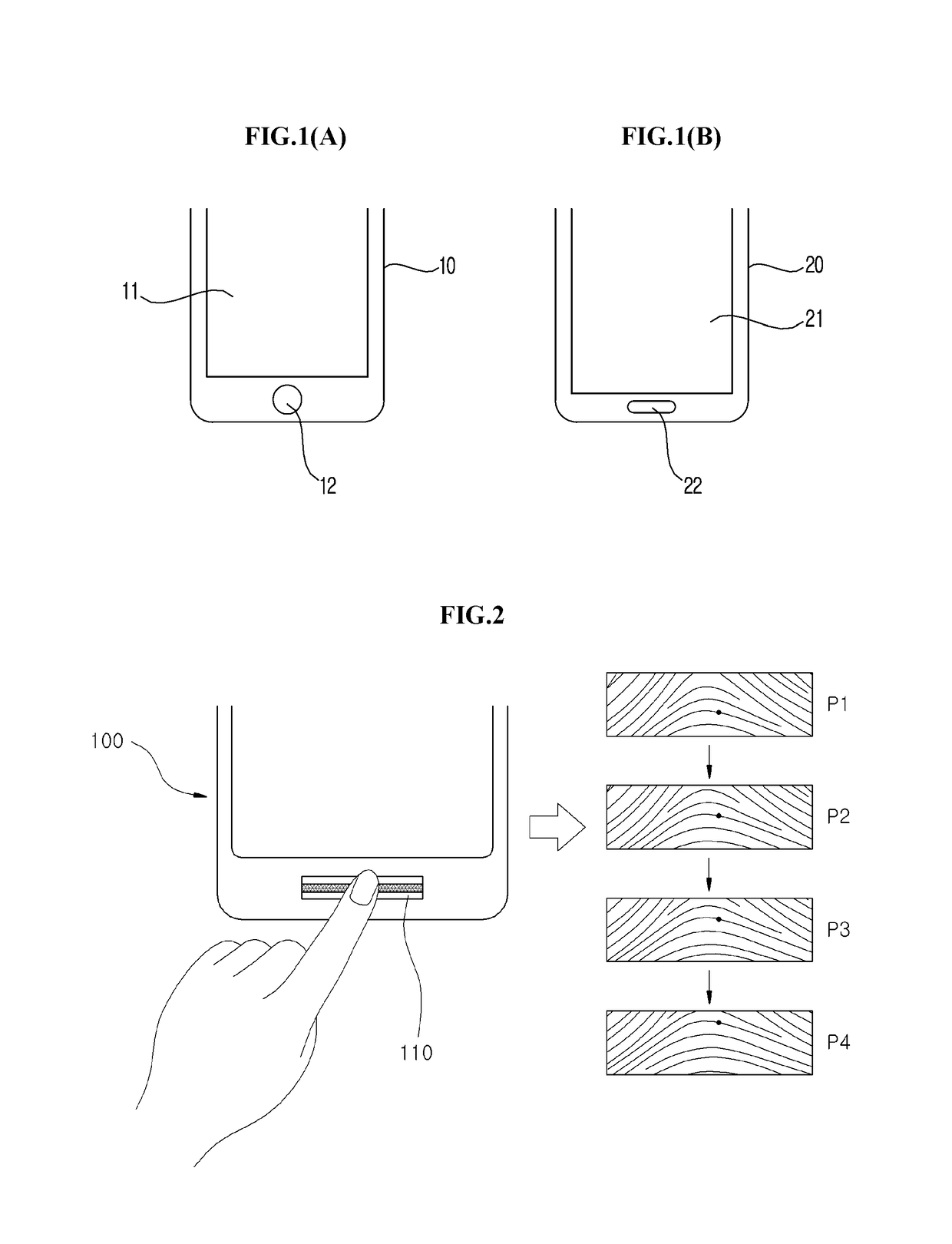

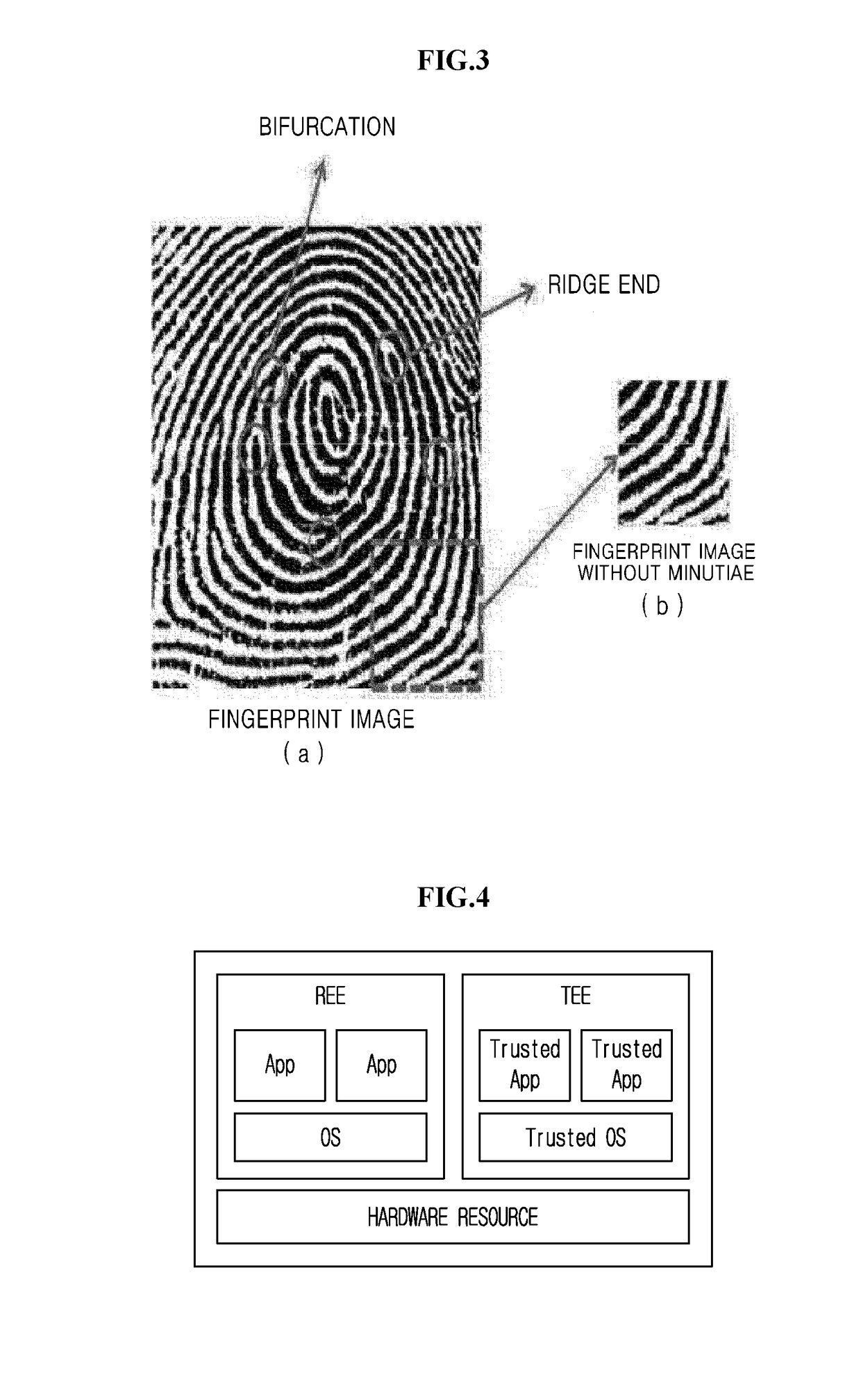

Fingerprint information processing method and apparatus for speed improvement of fingerprint registration and authentication

ActiveUS20170103253A1Efficiently performedImprove accuracyImage enhancementImage analysisFingerprintFingerprint image

A fingerprint information processing method and apparatus in which the method includes: obtaining a fingerprint image; calculating an average value of shading values of pixels in a specific region based on a pixel with respect to each pixel of the fingerprint image, performing a first processing of calculating a sum of average values of shading values of pixels included in an expanded region while gradually expanding the specific region, and generating a first processing image for the fingerprint image using a first processing-performed value for each pixel; and forming a window including a predetermined region in the first processing image, and selecting feature points among pixels in a window region while moving the window.

Owner:CRUCIALTEC +1

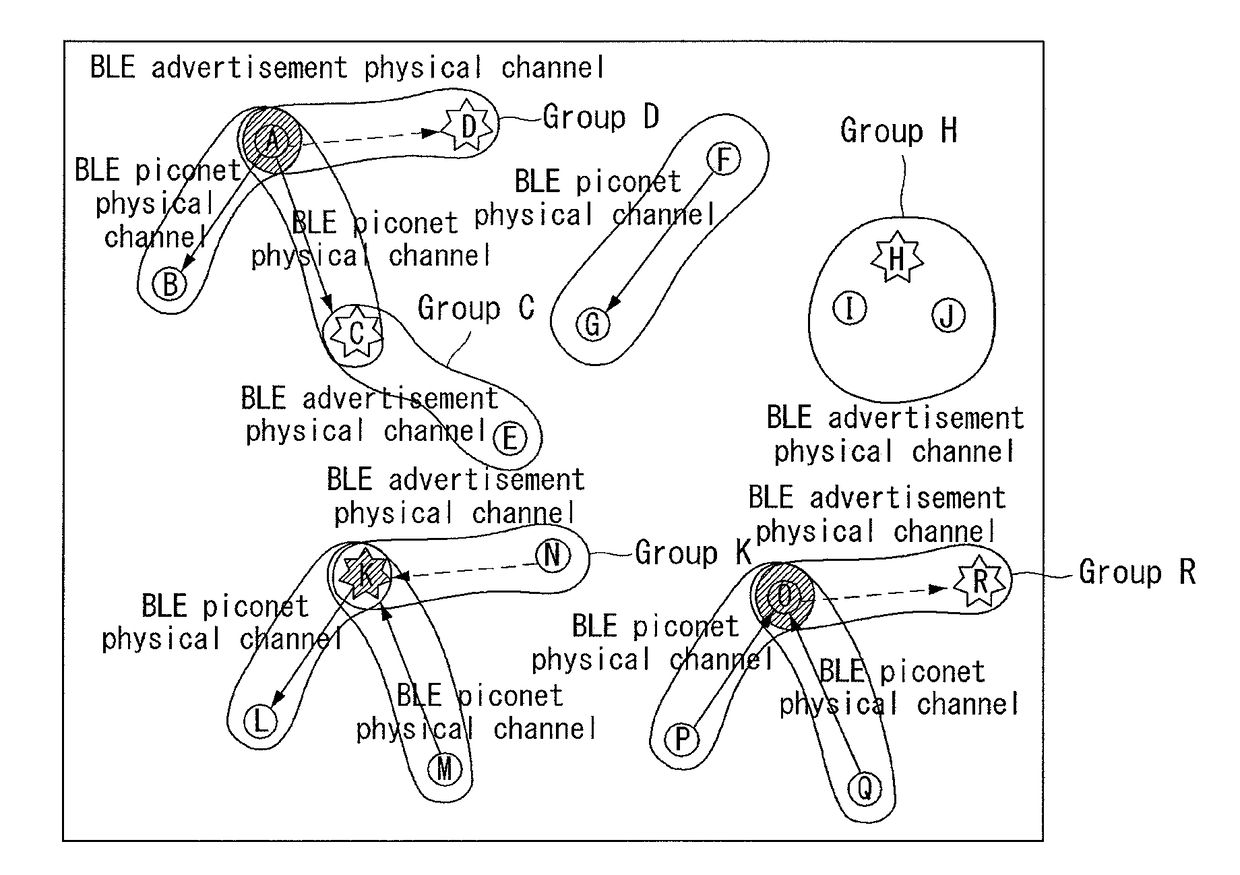

Method and device for controlling device using bluetooth low-power energy technology

InactiveUS20180091932A1Efficiently performedLow power consumptionNetwork topologiesConnection managementBluetooth Low EnergyService information

The present invention relates to a method and a device for controlling, by a control device, pairing of a first device and a second device using a Bluetooth low energy (LE). According to the present invention, the control device receives supportable service information and pairing mode information from the first and second devices, sends, to the first and second devices, a message for instructing a specific operation, and sends a specific value or determines whether to perform direct pairing or not, thereby controlling the pairing of the first and second devices.

Owner:LG ELECTRONICS INC

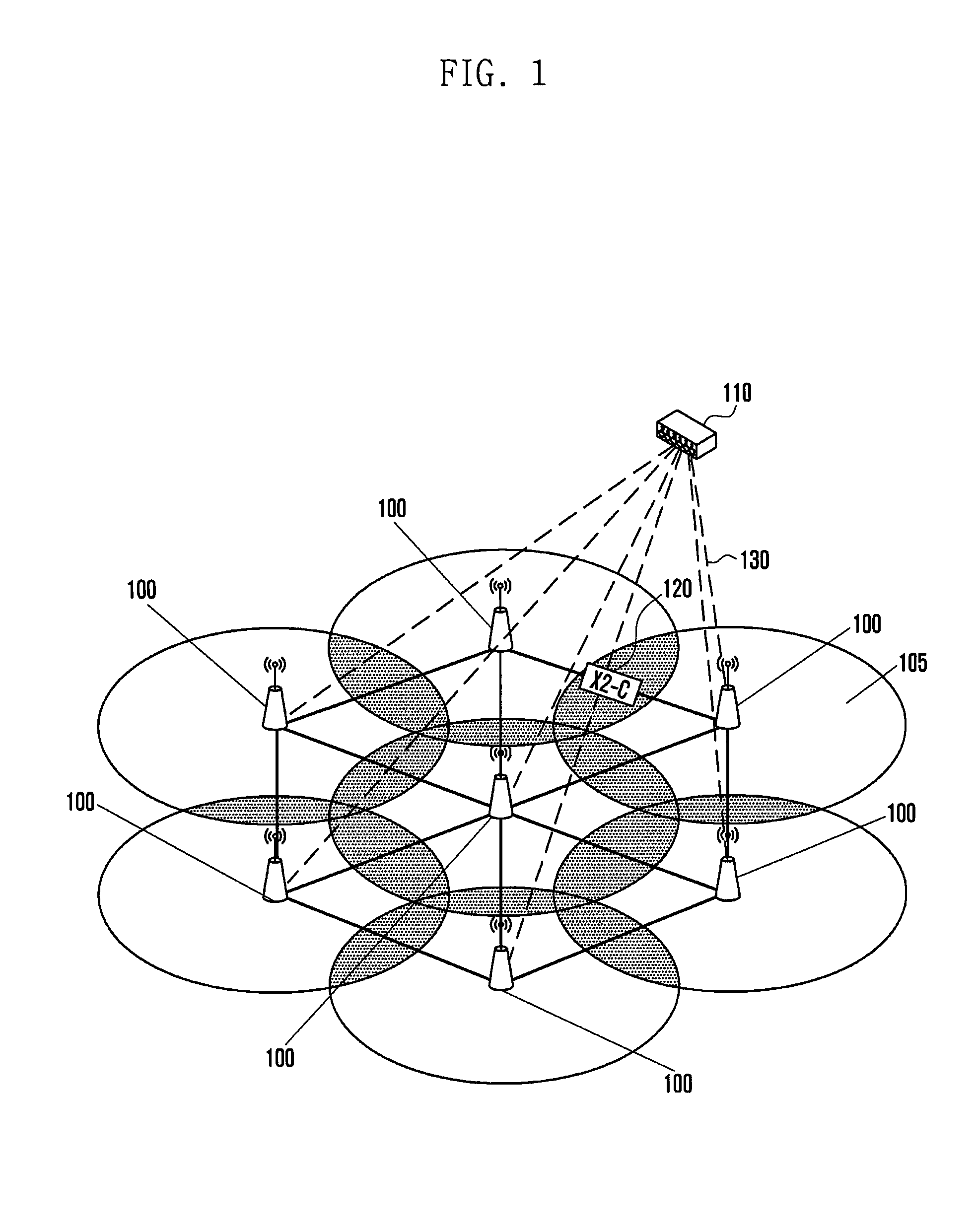

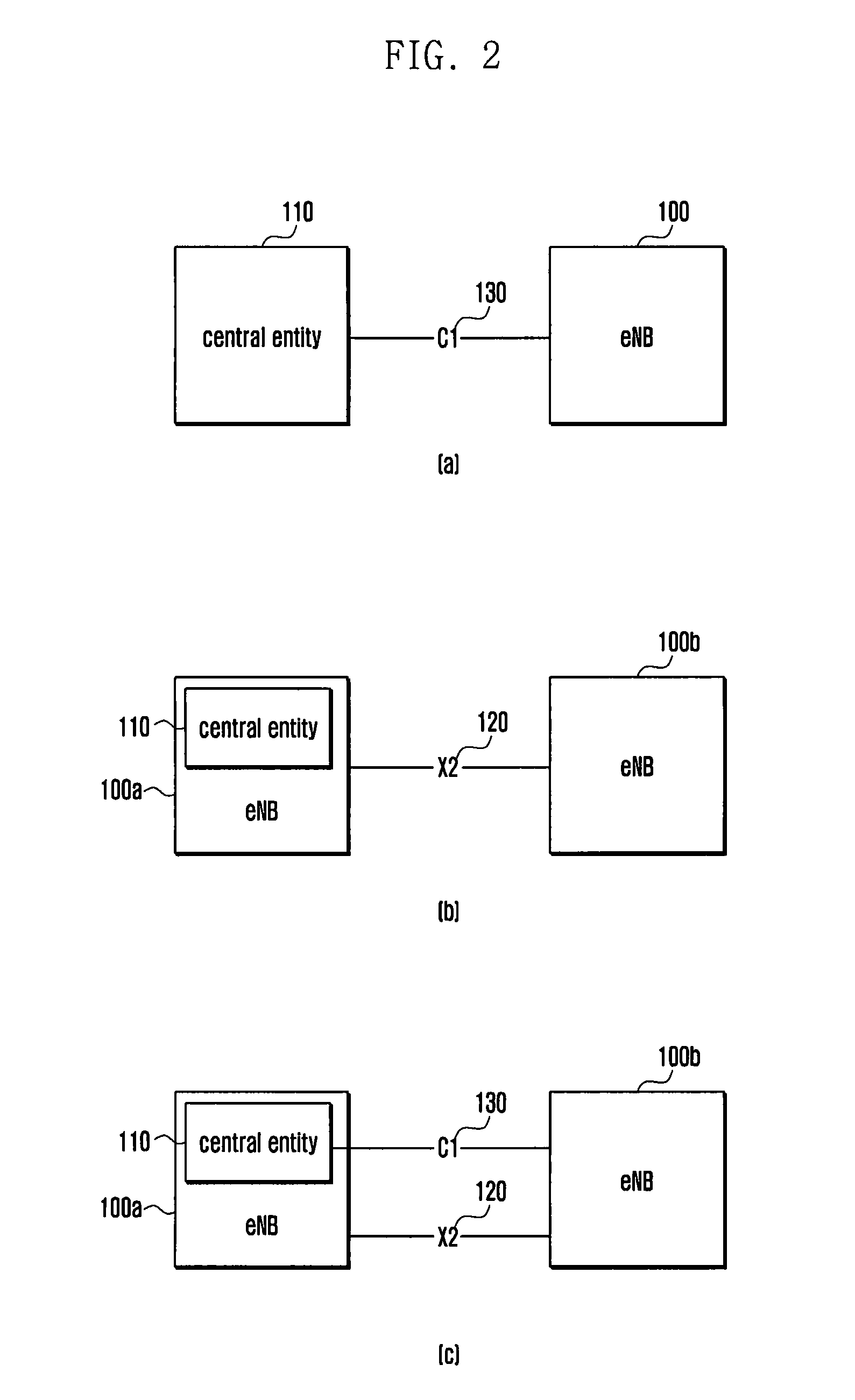

Method and apparatus for cooperation between base stations

The present invention relates to a method and apparatus for eliminating and improving issues that can occur during the execution of the cooperation between base stations in a wireless communication. The method comprises the steps of: identifying whether at least one cell among cells belonging to a counterpart base station is located in the vicinity of a base station; determining, according to a result of the identifying, whether to include information on a neighboring cell in a base station-related message; and transferring the base station-related message to the counterpart base station according to the determination.

Owner:SAMSUNG ELECTRONICS CO LTD

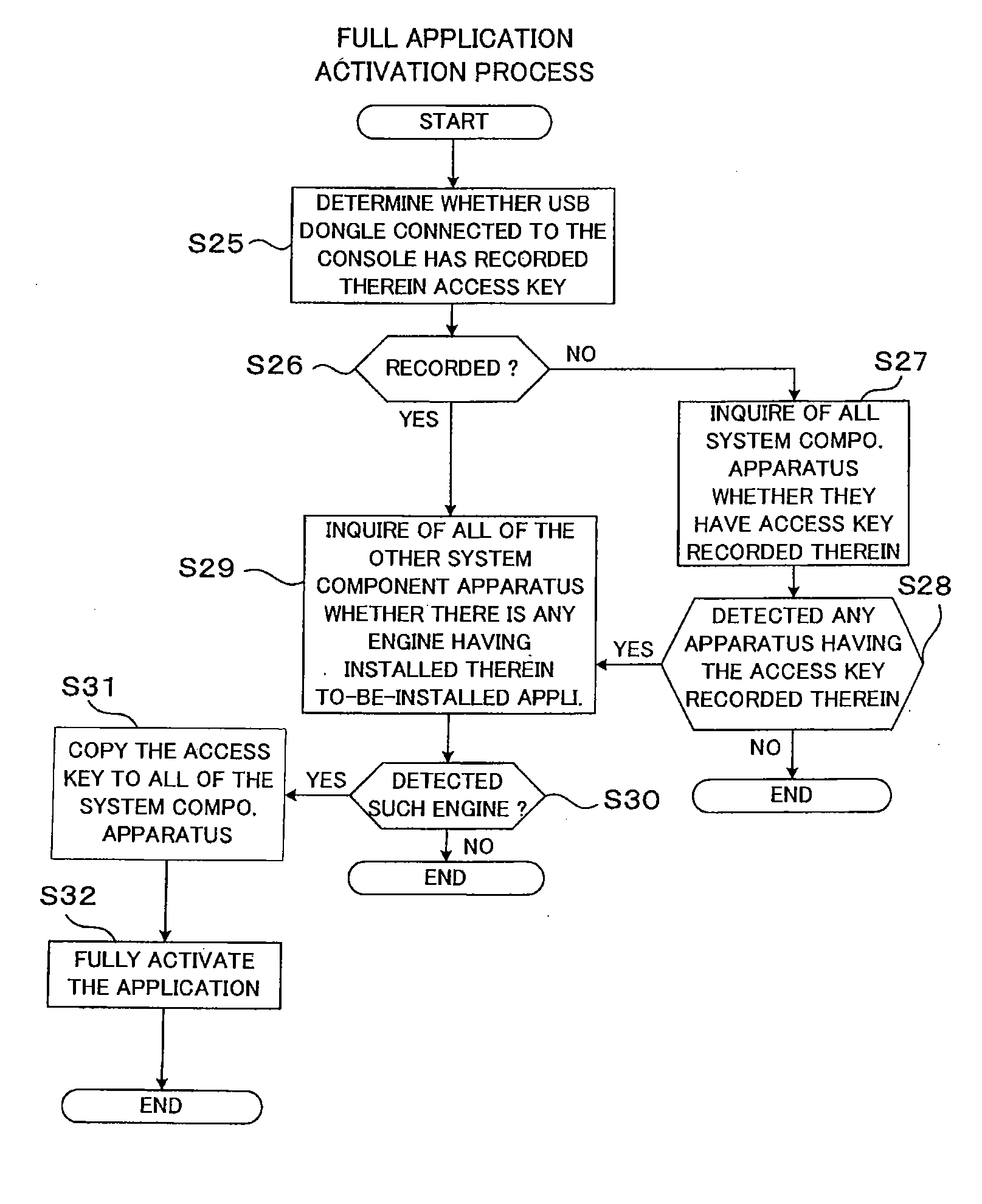

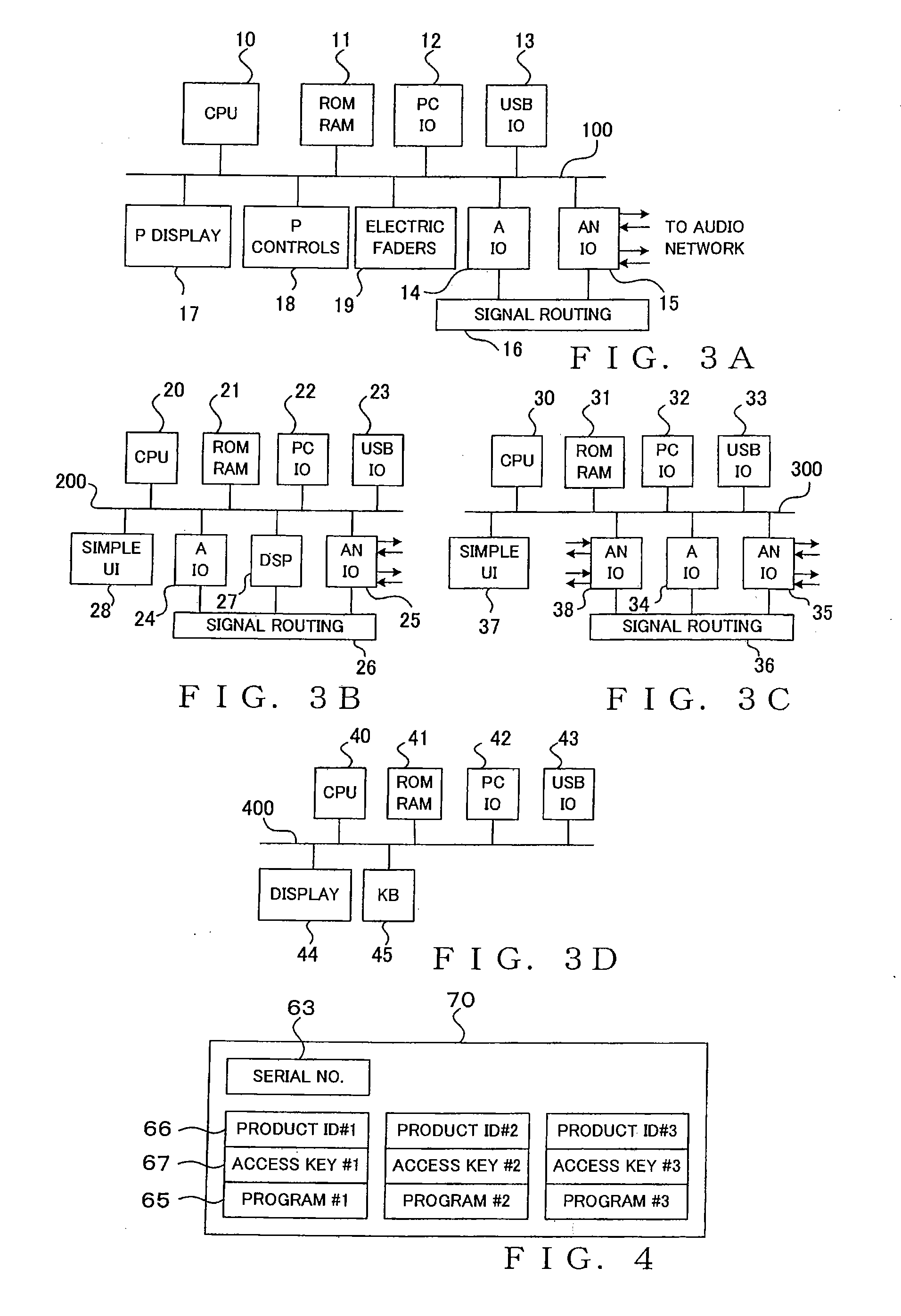

Controlling activation of an application program in an audio signal processing system

InactiveUS20110083178A1Efficiently performedEfficient executionDigital data processing detailsUnauthorized memory use protectionApplication softwareSignal processing

User operates a selection switch to instruct temporary activation of an application. For the application of which the temporary activation has been instructed, a CPU of a console allocates resources necessary for signal processing by a DSP of an engine and for a parameter editing function of the console. In the DSP, a bypass parameter is set to ON. Thus, there is provided a state capable of accepting various parameter setting operation related to the application, but the signal processing based on the application program is prevented from being started in a substantive manner. In response to a full activation instruction of an application via a full activation instruction switch, the bypass parameter is set to OFF, so that audio signal processing based on the application can be started. In this way, preparatory work for setting parameters related to the application can be performed efficiently.

Owner:YAMAHA CORP

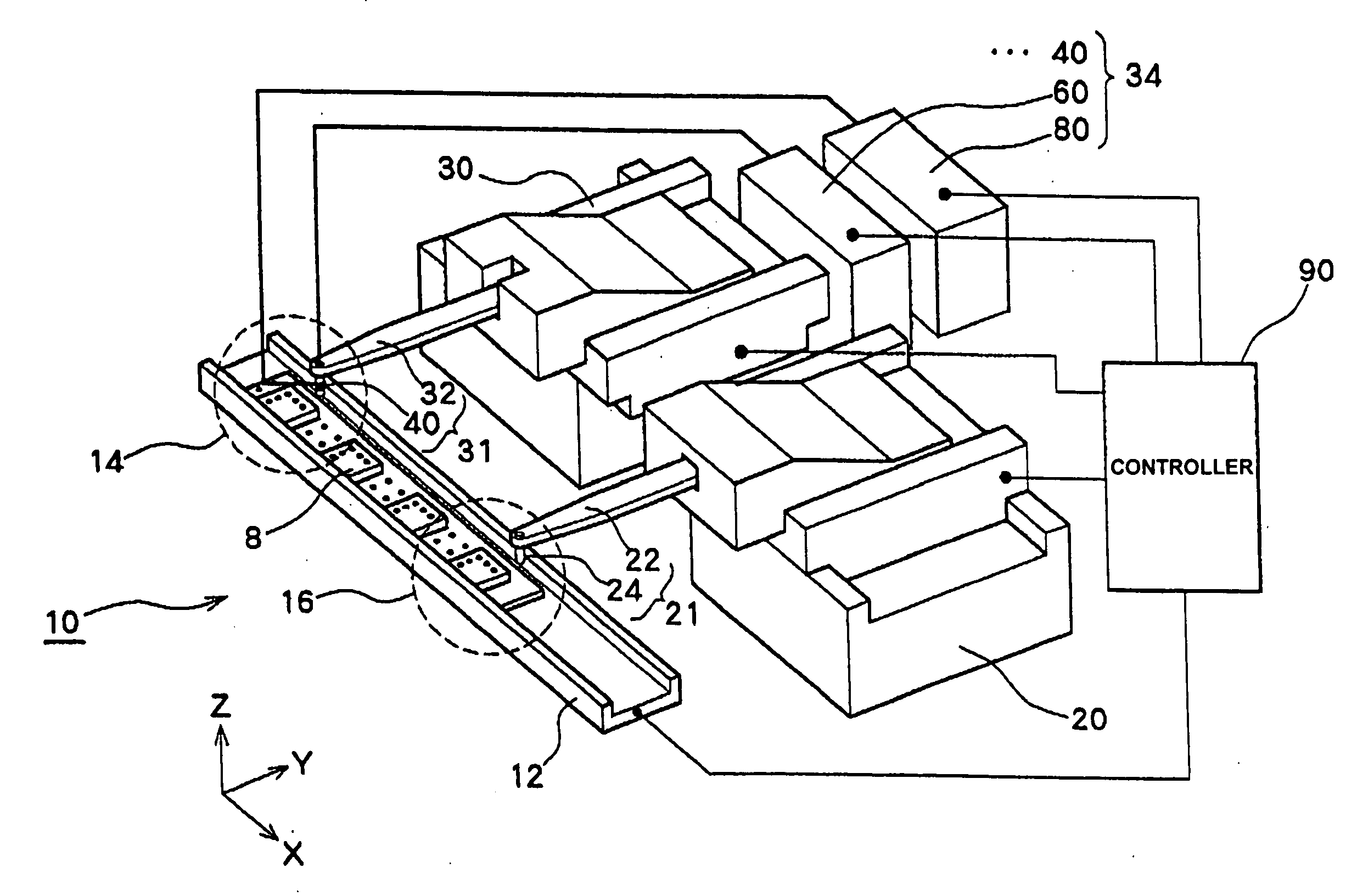

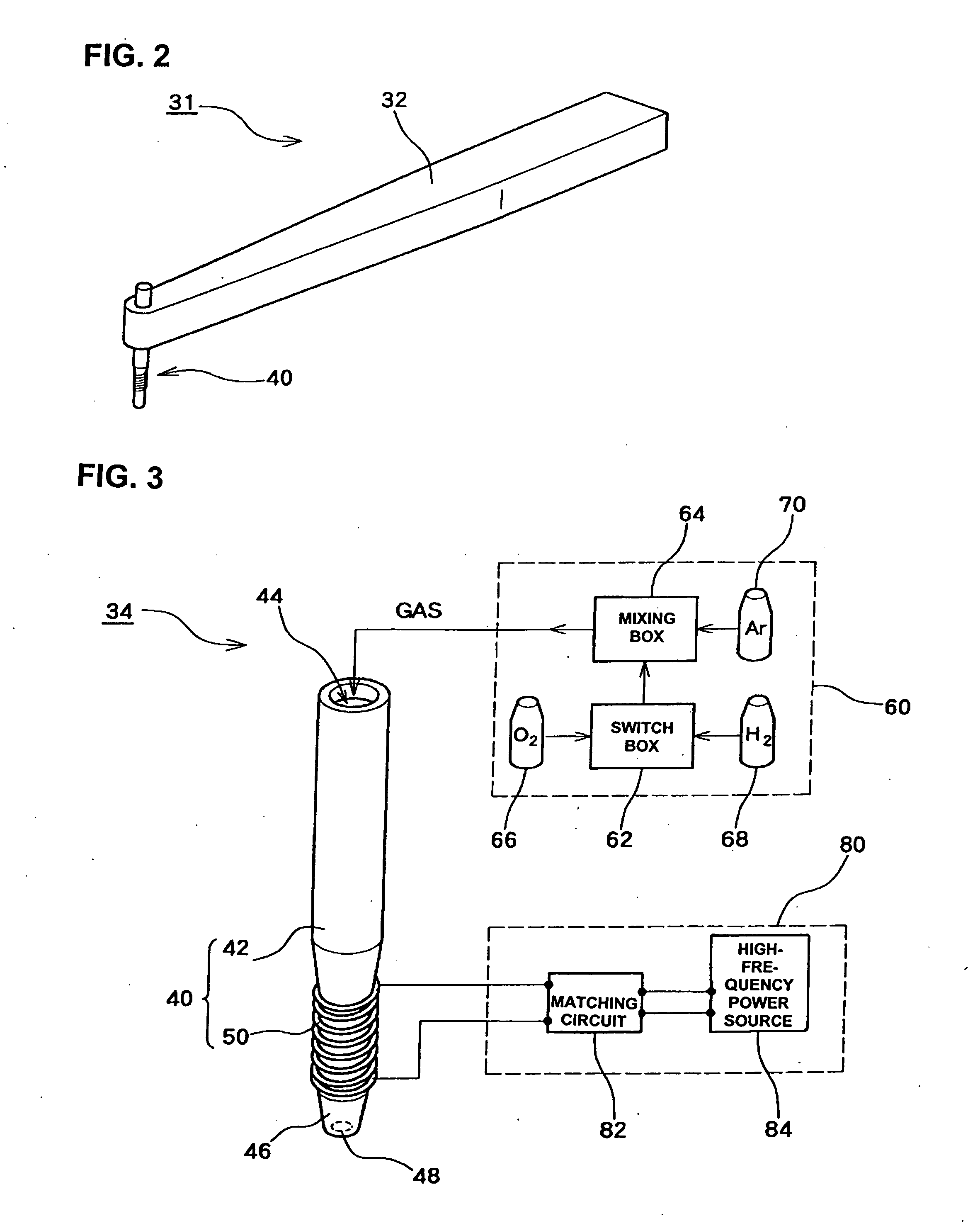

Bonding apparatus and method

InactiveUS20070001320A1Efficiently performedEfficient executionSemiconductor/solid-state device detailsSolid-state devicesEngineeringWire bonding

A wire bonding apparatus 10 including an XYZ drive mechanism 20 for moving a bonding arm 21 that has a bonding capillary 24 at its tip end, an XYZ drive mechanism 30 for driving a plasma arm 31 that has a plasma capillary 40 having a high-frequency coil wound at its tip end portion end, a gas supply unit 60 for supplying gas to the plasma capillary, and a high-frequency power supply unit 80 for supplying high-frequency electric power to the high-frequency coil. With a supply of high-frequency electric power to the high-frequency coil, gas is being a plasma inside the plasma capillary and is ejected from its tip end against a bonding subject 8, thus performing surface treatment on the bonding subject; and using the bonding capillary, bonding is performed interconnectedly with this surface treatment.

Owner:SHINKAWA CO LTD

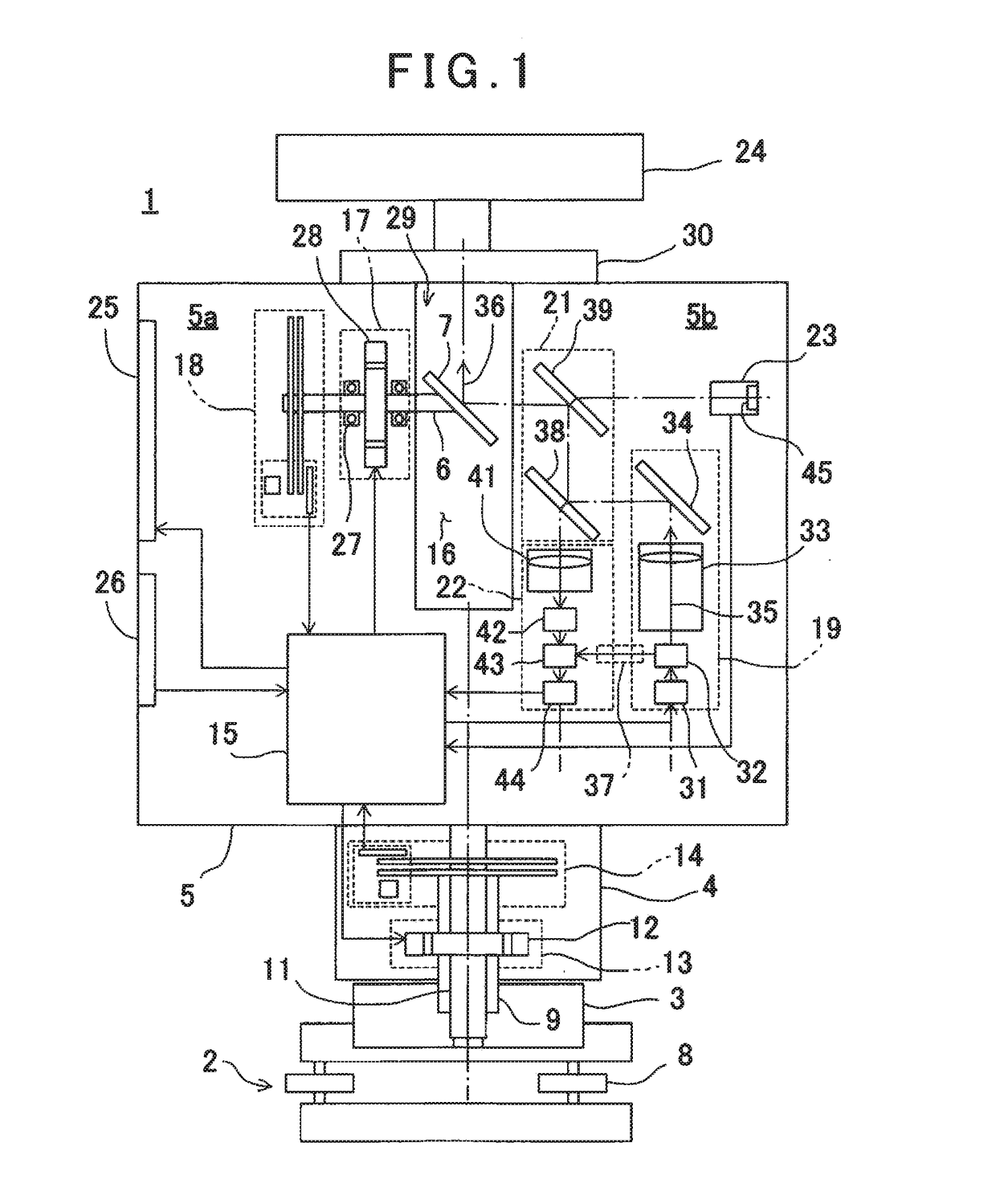

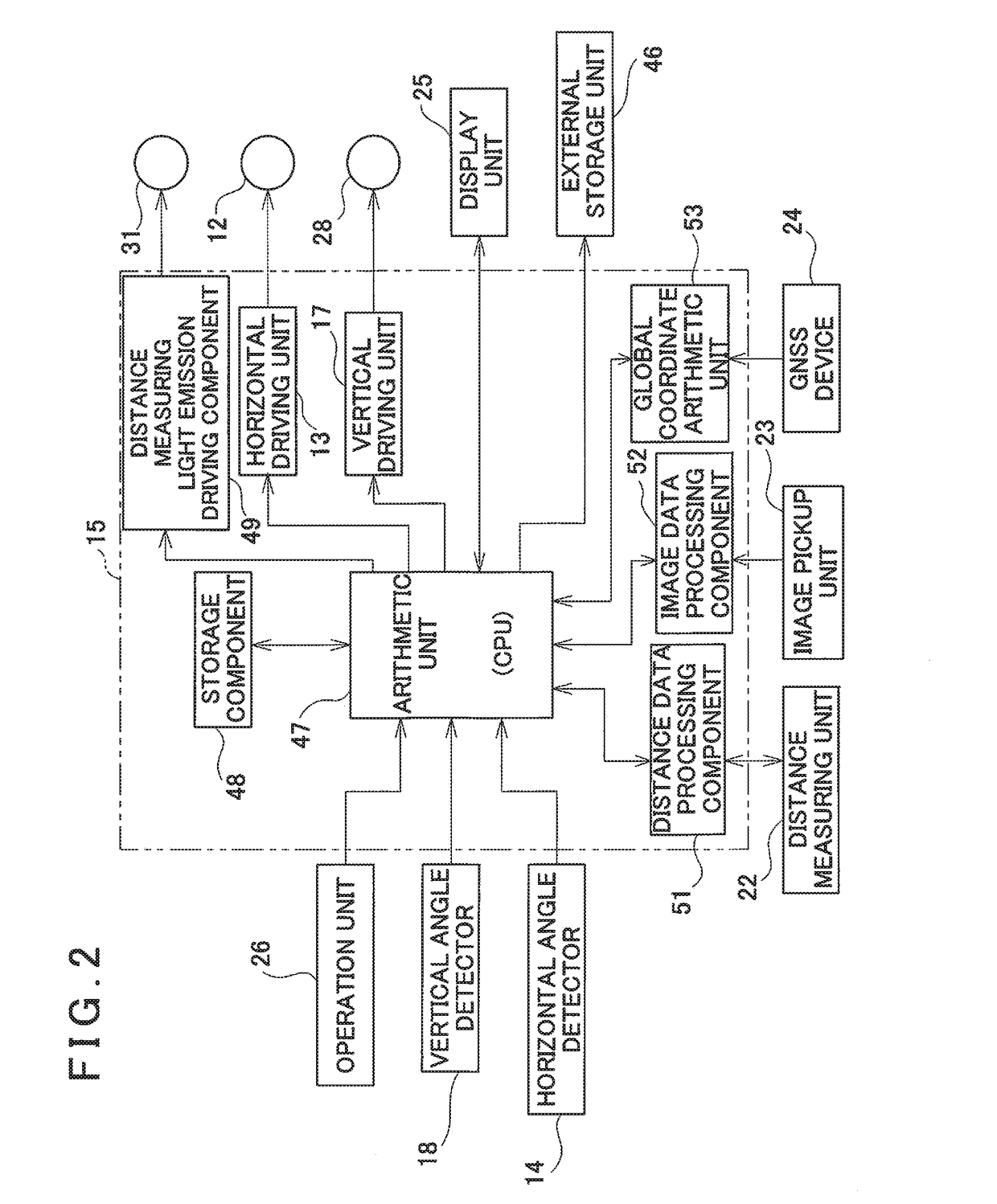

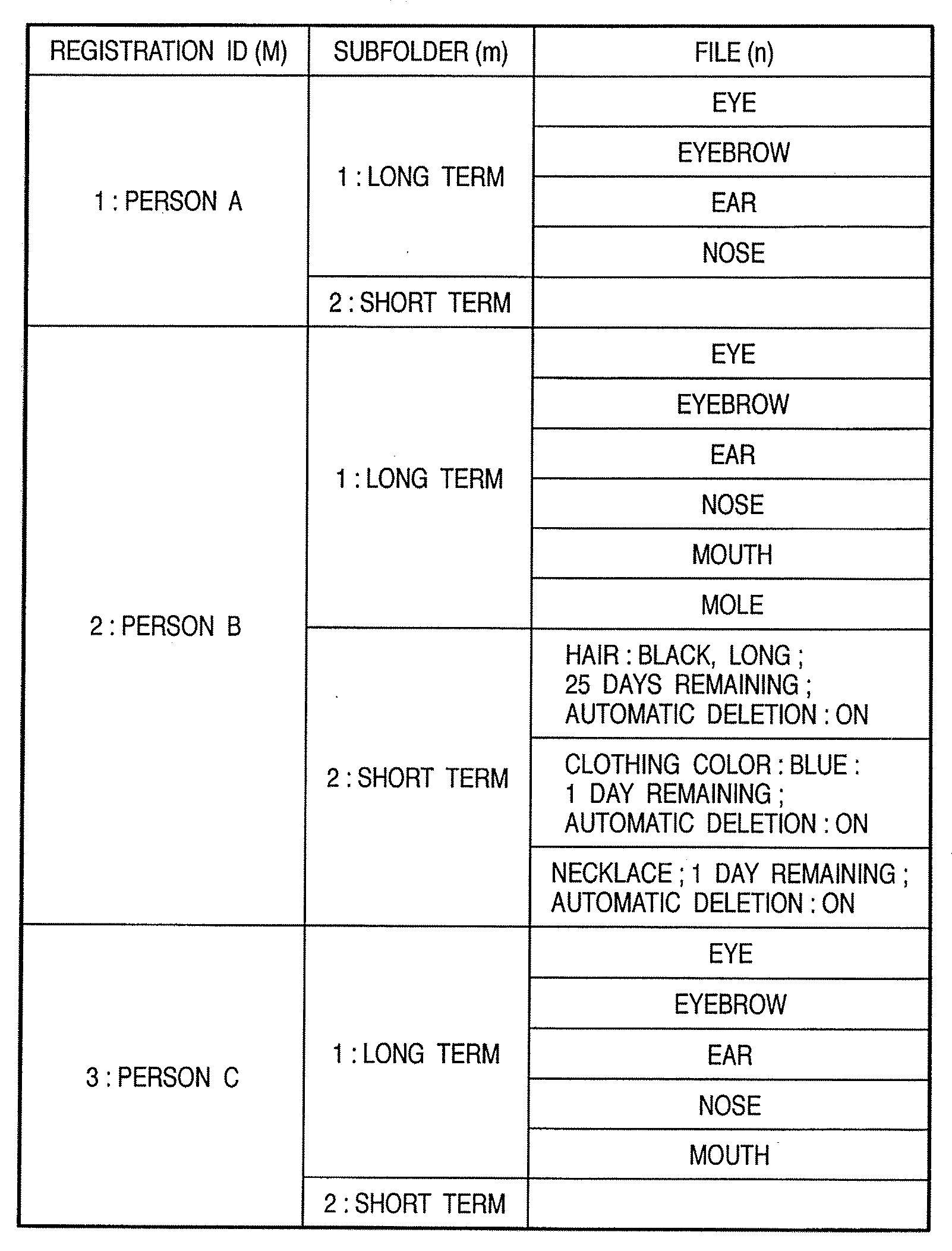

Laser Scanner System And Registration Method Of Point Cloud Data

ActiveUS20180003825A1Efficiently performedEasy to setActive open surveying meansSatellite radio beaconingLaser scanningOptoelectronics

The invention provides a laser scanner system, which comprises a laser scanner which includes a distance measuring unit for emitting a distance measuring light, receiving a reflected light, and performing a distance measurement, a scanning unit for rotatably irradiating the distance measuring light, a directional angle detecting unit for detecting an irradiating direction of the distance measuring light, a GNSS device and a control arithmetic unit, and a target which sets a back sight point, wherein the control arithmetic unit has a target scanning mode and a point cloud data measurement mode, and is configured to calculate point cloud data with a global coordinate value and a global coordinate value of the target based on the global coordinate value obtained by the GNSS device, a measurement result obtained by executing the point cloud data measurement mode and a measurement result obtained by executing the target scanning mode.

Owner:KK TOPCON

Image processing apparatus and method

InactiveUS20070122006A1Improve recognition rateEfficiently performedCharacter and pattern recognitionImaging dataPattern recognition

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com