Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Economic benefit maximization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

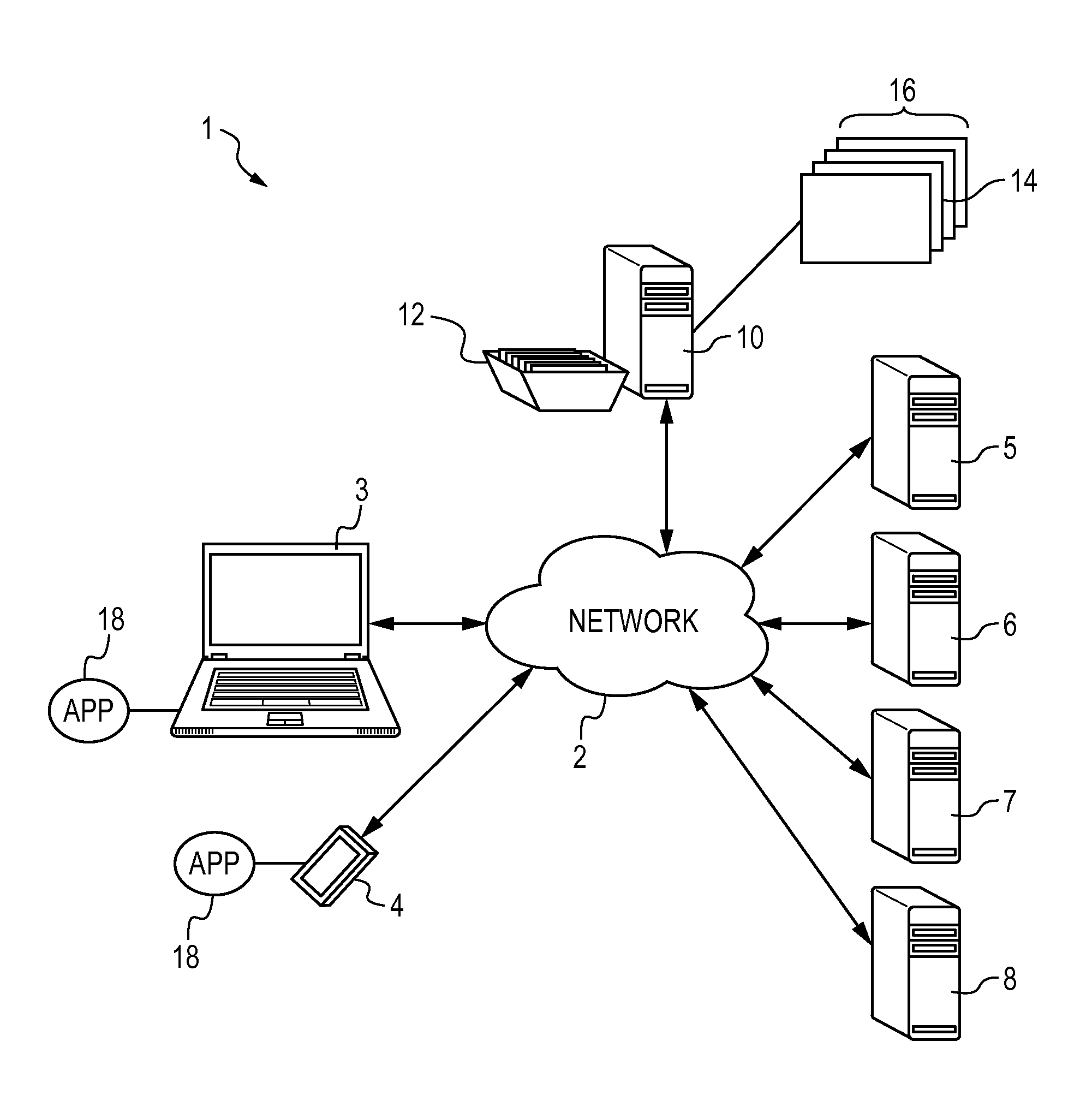

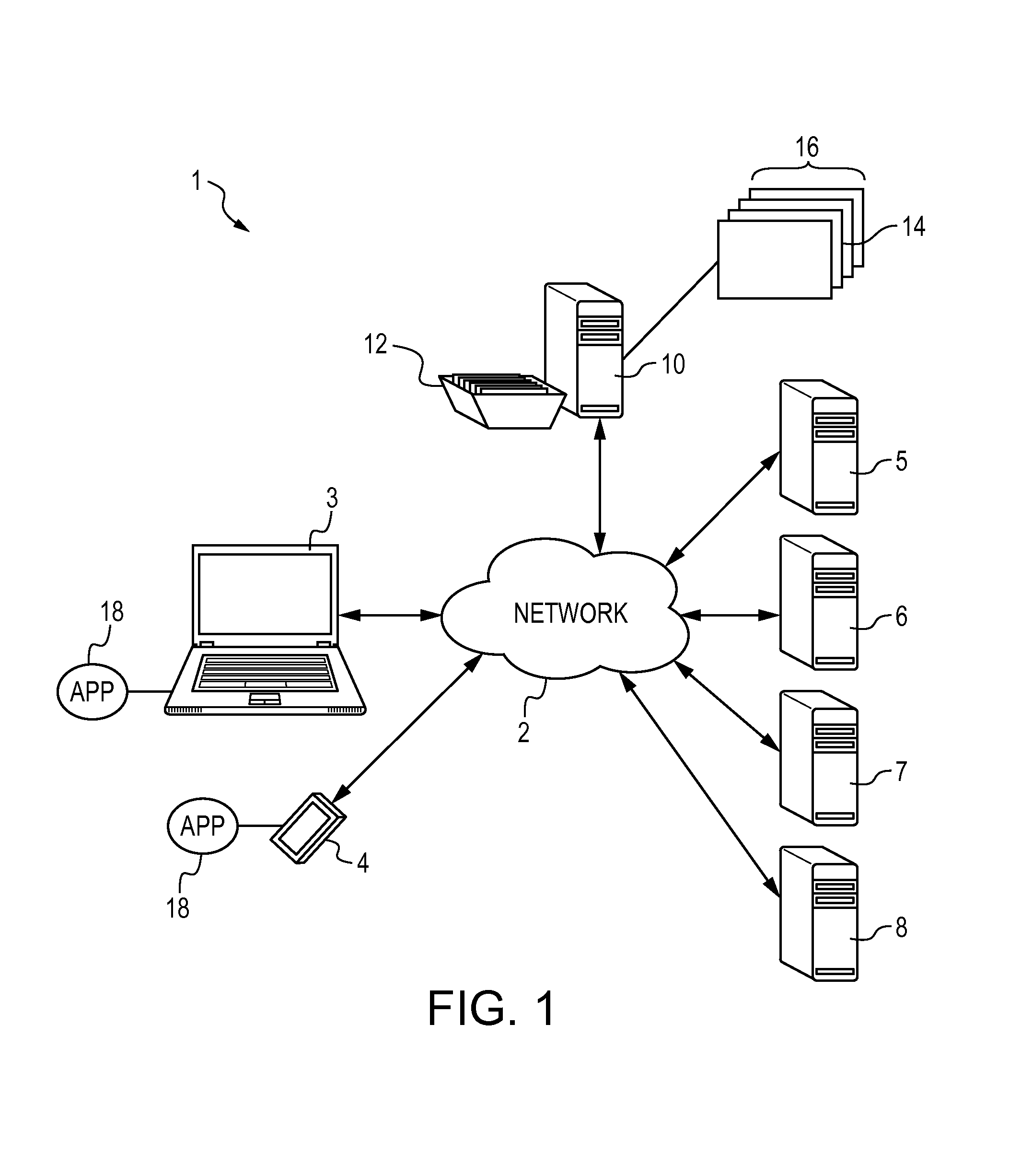

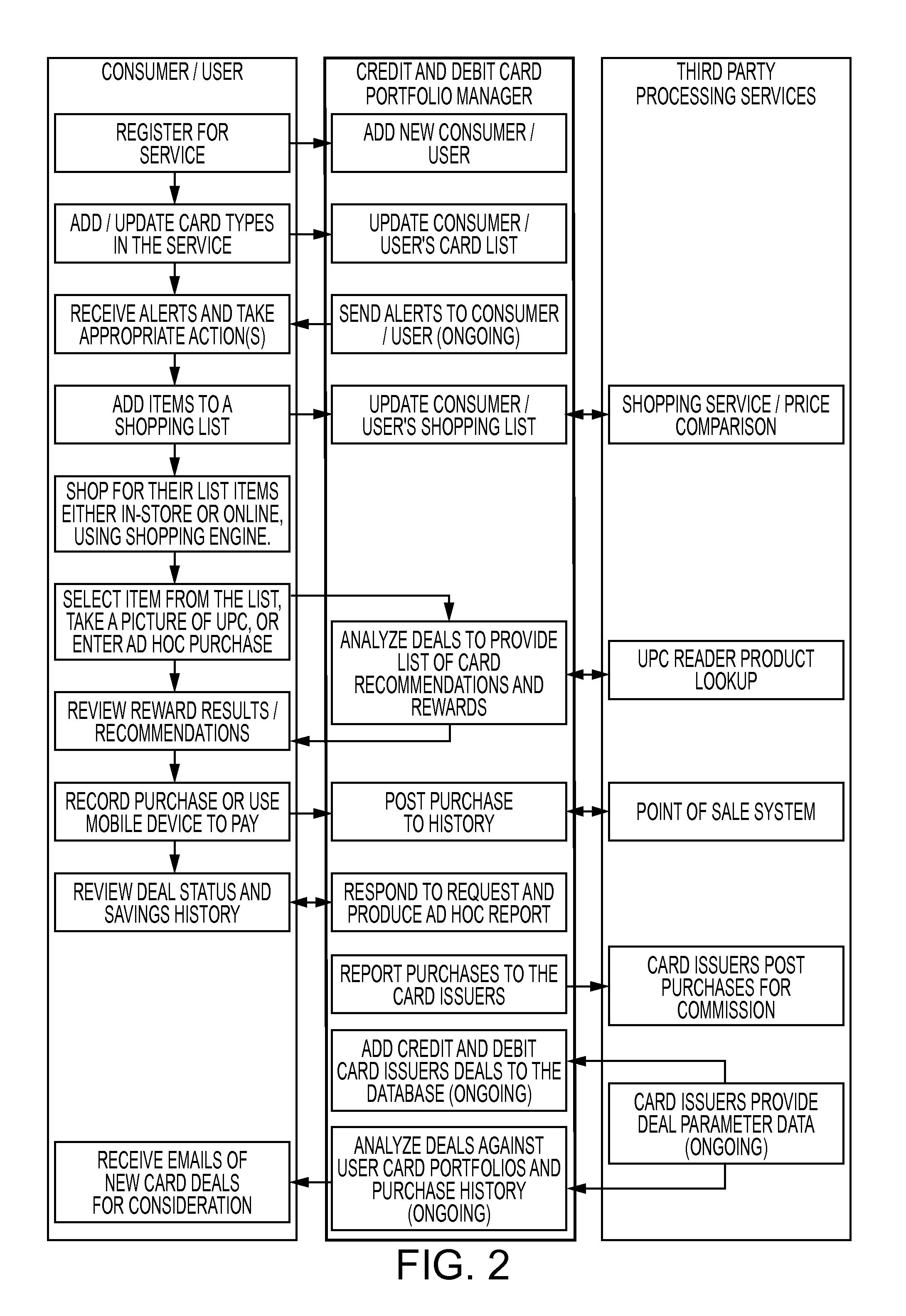

Method and system for optimizing the usefulness of a credit and debit card portfolio

ActiveUS8540151B1MaximizeEconomic benefit maximizationFinanceCredit schemesComputer scienceFinancial interest

A method, for maximizing the financial benefits that accrue to one from optimally taking advantage of the incentives offered by the various providers of credit cards, includes the steps of: (1) collecting card provider information regarding currently offered incentives, (2) collecting one's information regarding past and proposed card purchases, (3) analyzing this information to determine the benefits that would accrue to one from making the proposed purchase with each of one's available cards, (4) communicating the results of this analysis so as to enable it to be used in selecting the card to be used in one's next purchase, (5) presenting the incentives of other cards which are not in the one's card portfolio, and (6) if one is considering adding one of these other cards to one's portfolio in order to take advantage of its incentives, advising of the impact on one's credit rating of applying for a new card.

Owner:OPTIWALLET

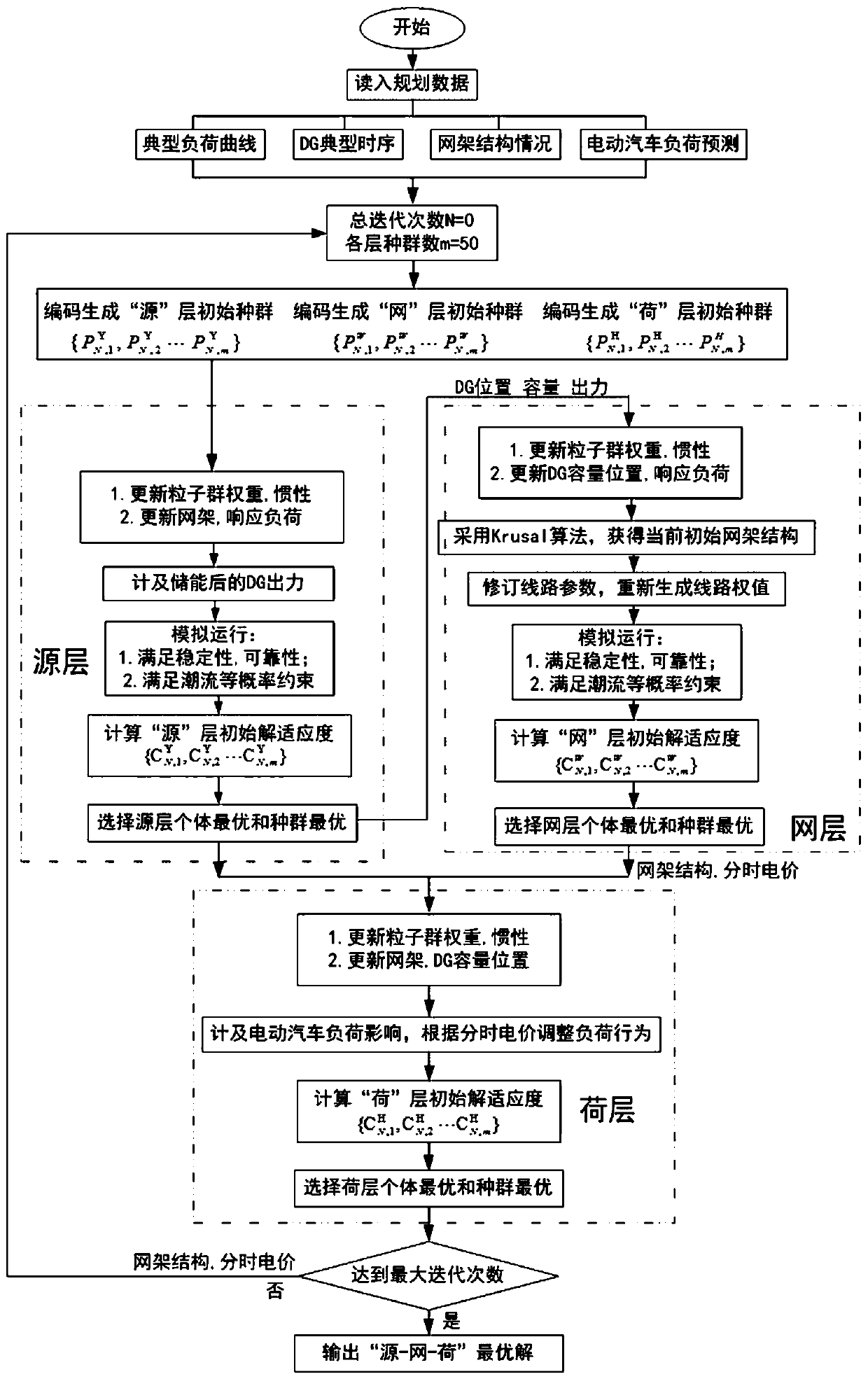

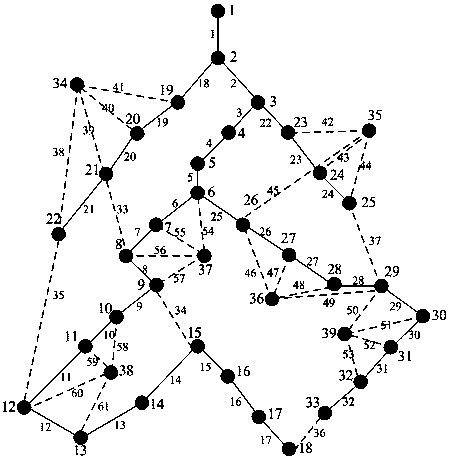

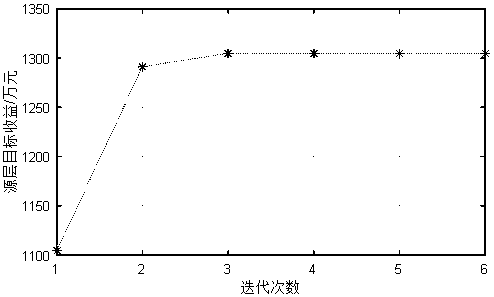

Electric vehicle load demand response-considered network-source-load coordination planning method

InactiveCN108446796ALow investment and operation costEconomic benefit maximizationForecastingCharge layerEngineering

The invention relates to an electric vehicle load demand response-considered network-source-load coordination planning method. According to the method, firstly, during the load forecasting process, the influence of an electric vehicle is considered, and the probability distribution of the first travel time of the electric vehicle is obtained. Meanwhile, the probability distribution calculation iscarried out on the daily running mileage. Through predicting two parameters, the charge load distribution of the electric vehicle for 24 hours of the day is further predicted and the load distributioninformation is improved. After that, under the condition that the interests of three parties, namely the power grid, the power supply and the load, are considered, the network-source-load coordination planning is carried out. According to the invention, the interests of three parties, namely the power grid, the power supply and the load, are coordinated and planned. Meanwhile, the electric vehicle is taken as one of the influence factors of the load response considered in the charge layer planning process, so that the advantages of three parties are complementarily coordinated and developed.The requirement for the planning work of the power distribution network in a new situation is met. The investment and operation cost of a power grid company is saved. Meanwhile, the maximization of economic benefits of operators is guaranteed. The method has important practical value.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +1

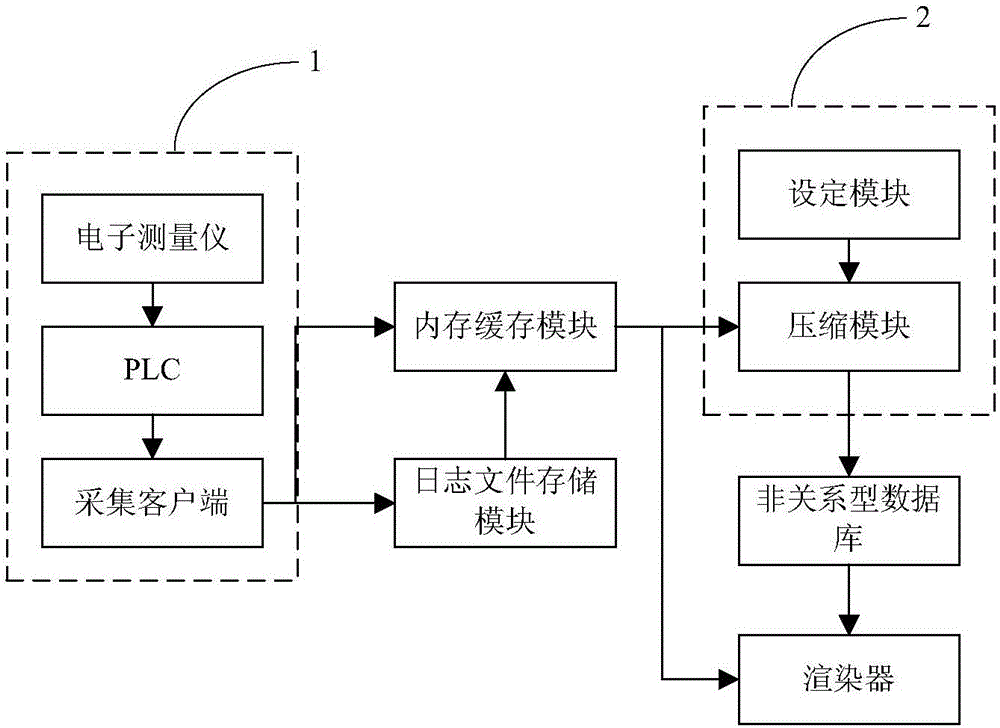

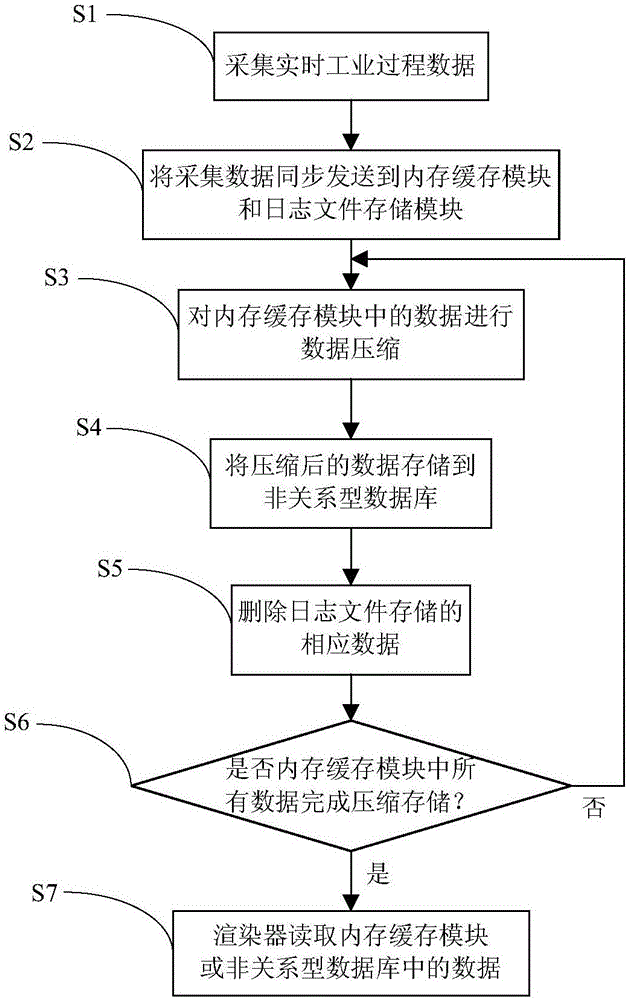

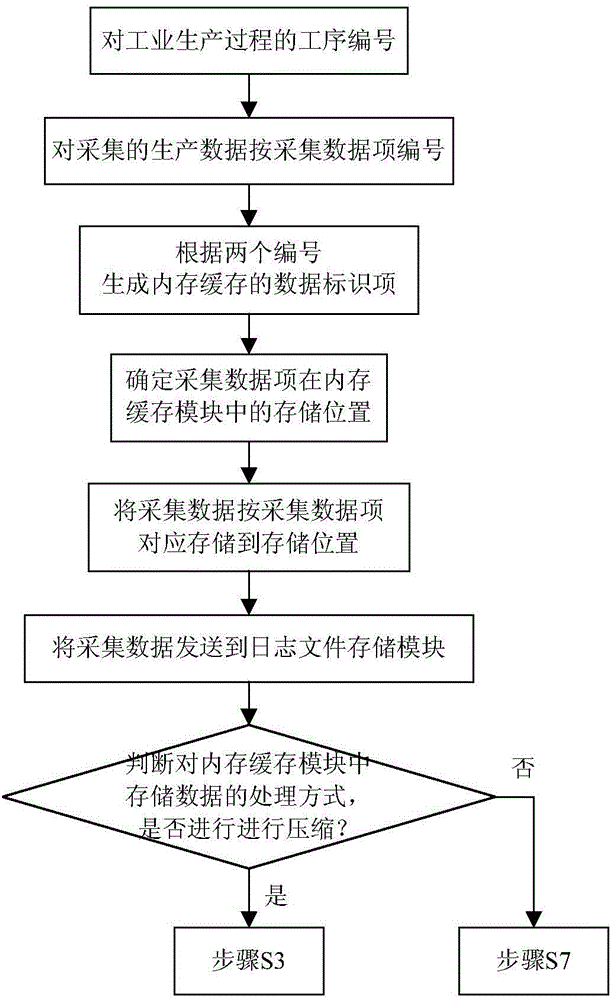

Real-time industrial process big data compression and storage system and method

ActiveCN106354774AAvoid storageSolve storage problemsSpecial data processing applicationsData compressionRelational database

The invention provides a real-time industrial process big data compression and storage system and method and relates to the technical field of big data analysis. The system comprises a data acquisition module, a log file storage module, a memory cache module, a data compression module, a non-relational database and a rendering device. The data acquisition module is used for acquiring real-time industrial process data and synchronously sending the real-time industrial process data to the memory cache module and the log file storage module, data in the memory cache module is compressed, and the compressed data is stored in the non-relational database. By means of the real-time industrial process big data compression and storage system and method, the purpose of storing real-time industrial process big data can be effectively achieved, the real-time industrial process big data is compressed to the maximum and stored with the non-relational database, the real-time industrial process big data is effectively stored, the huge cost generated for storing the real-time industrial process big data can be reduced for enterprises, and online inquiry, calculation and the like of data can be quickly responded to.

Owner:NORTHEASTERN UNIV

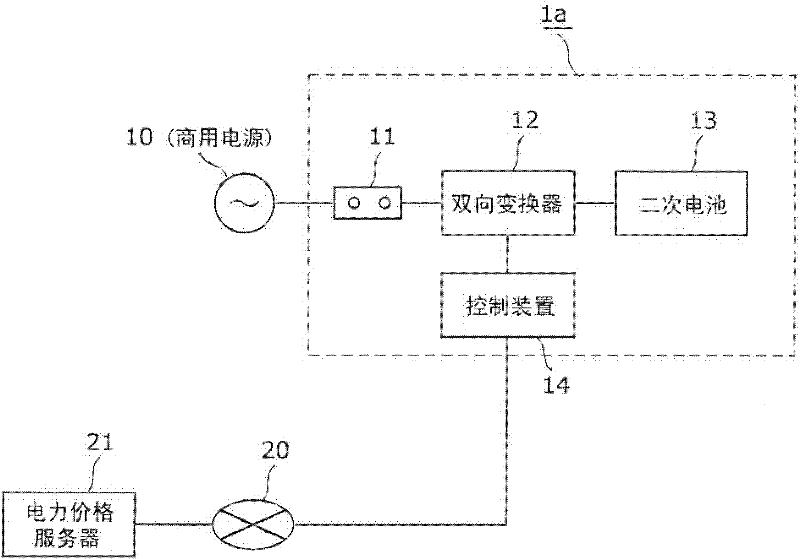

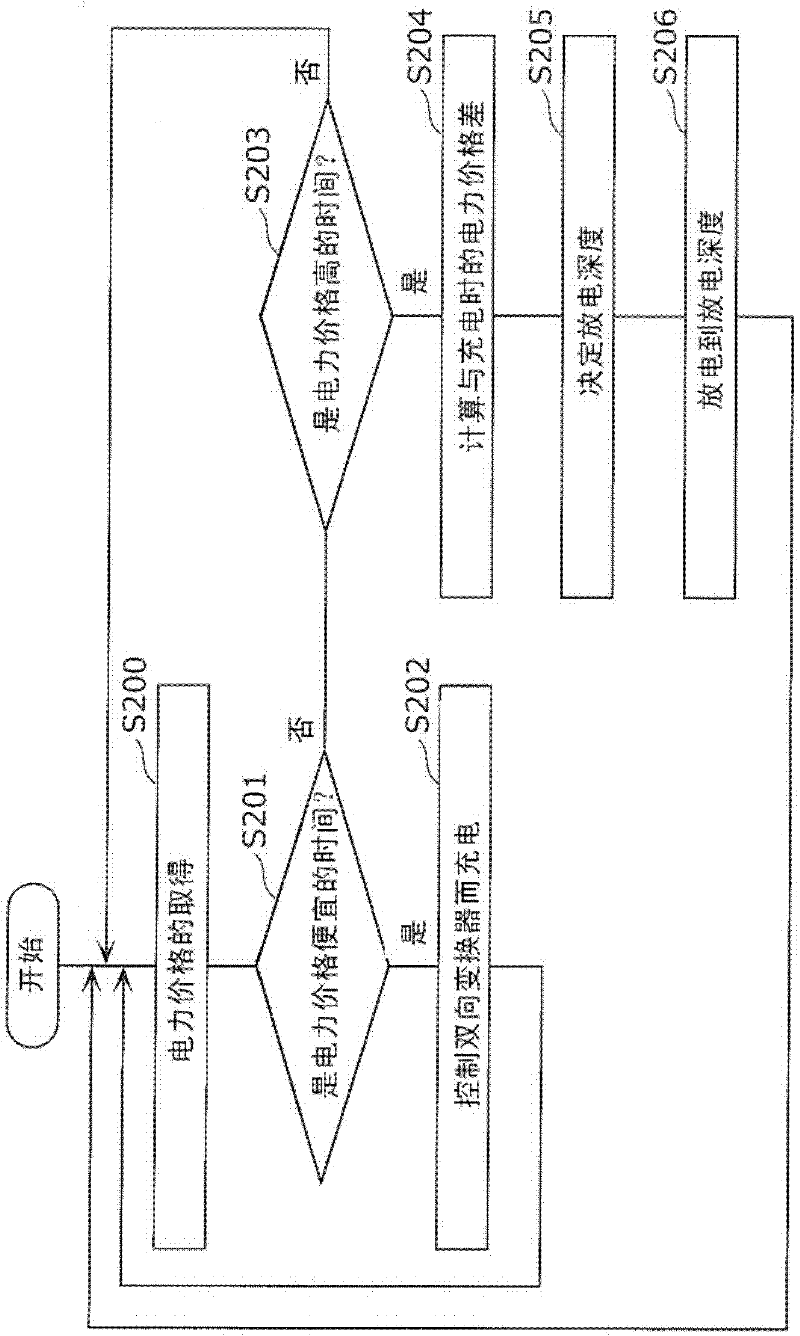

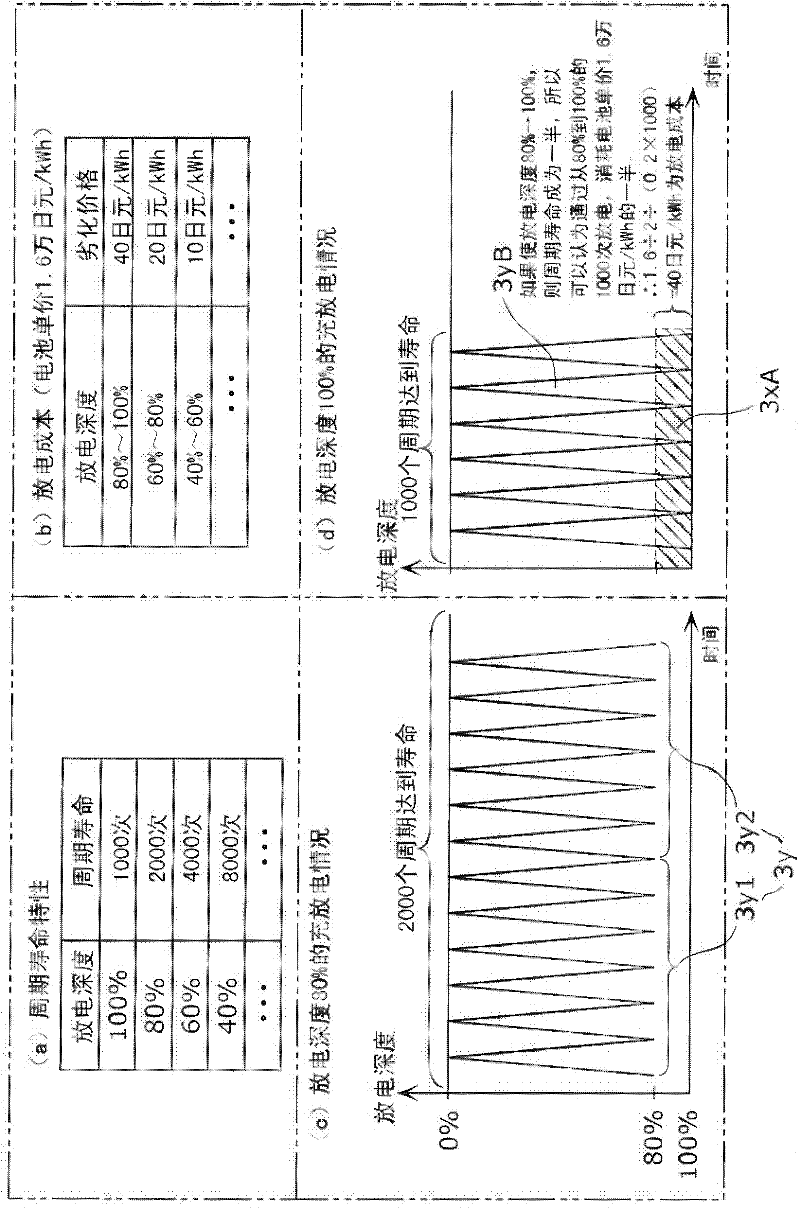

Control device, charge storage system, control method, and computer program

InactiveCN102474115AEconomic benefit maximizationFinanceSecondary cells charging/dischargingElectric power systemPrice difference

A control device (14) in a charge storage system connected to a commercial power system has: a degradation price holding unit (14a) for holding discharge costs in correspondence to the depths of discharge of a secondary battery (13) so as to enable a depth of charge and discharge to be appropriately determined in consideration of the life characteristics of a storage battery and the price difference in dynamic power prices; a price information acquiring unit (14b) for acquiring power prices; and a depth-of-discharge switching unit (14c) for allowing the secondary battery to discharge with a depth of discharge that allows the discharge costs held in correspondence to the depths of discharge not to exceed the price difference.

Owner:PANASONIC CORP

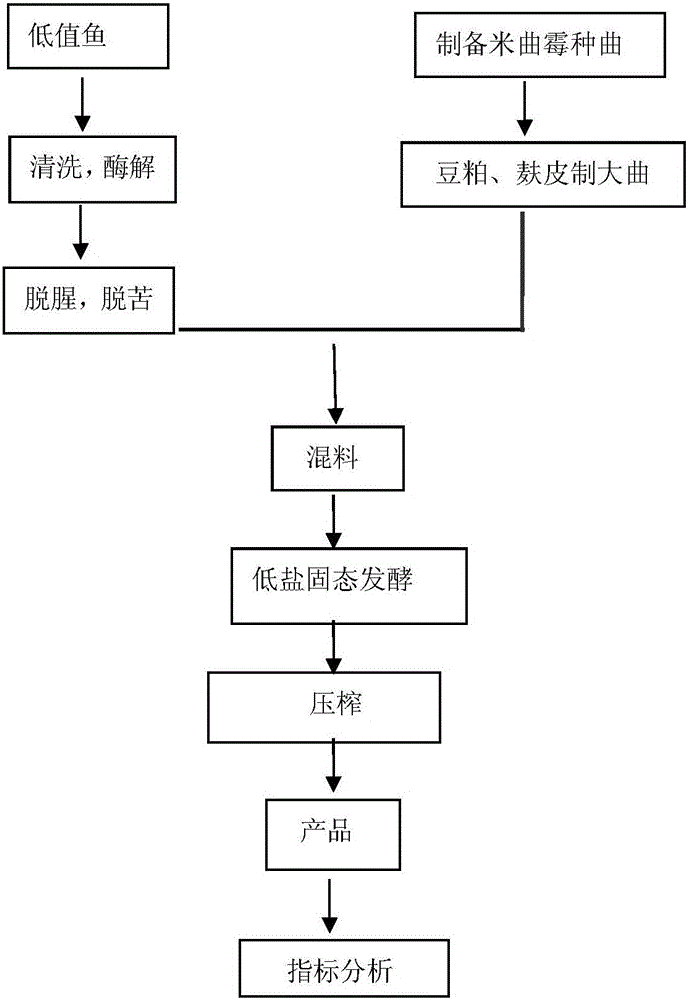

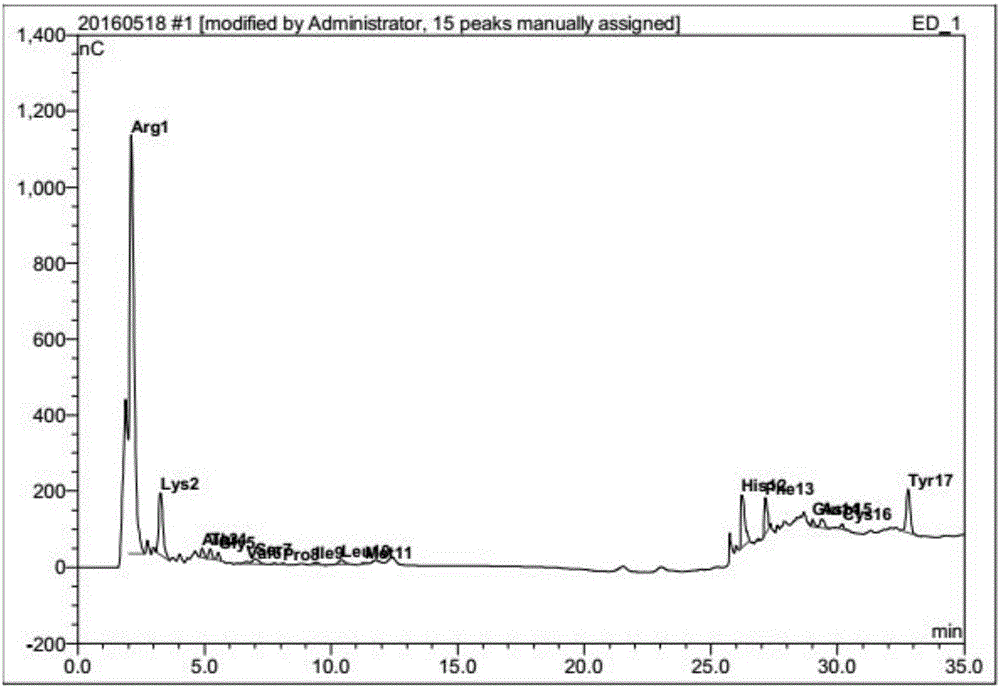

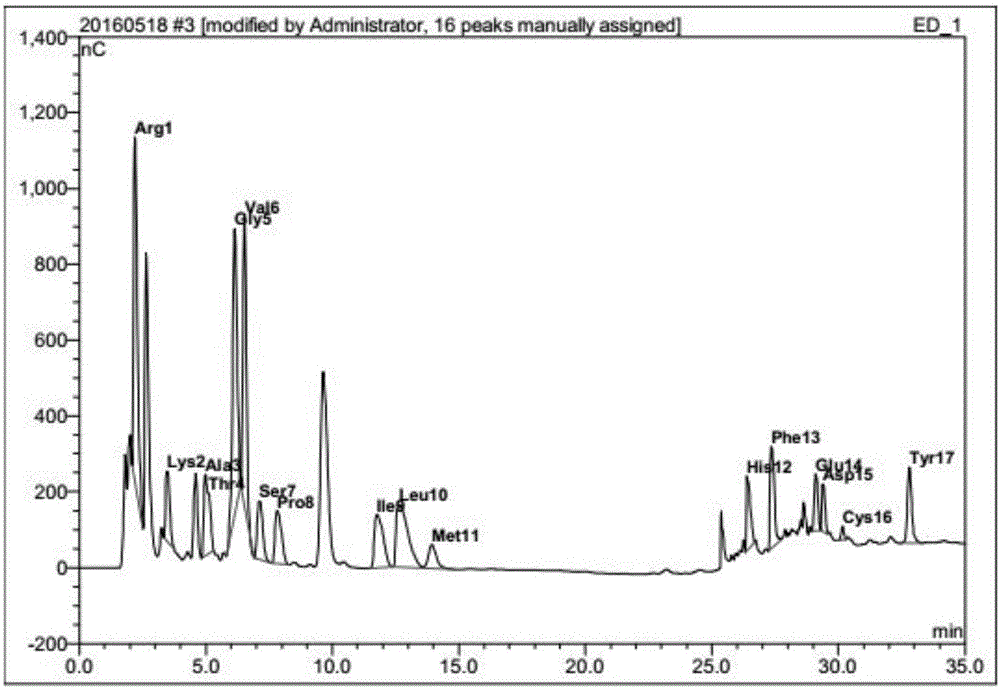

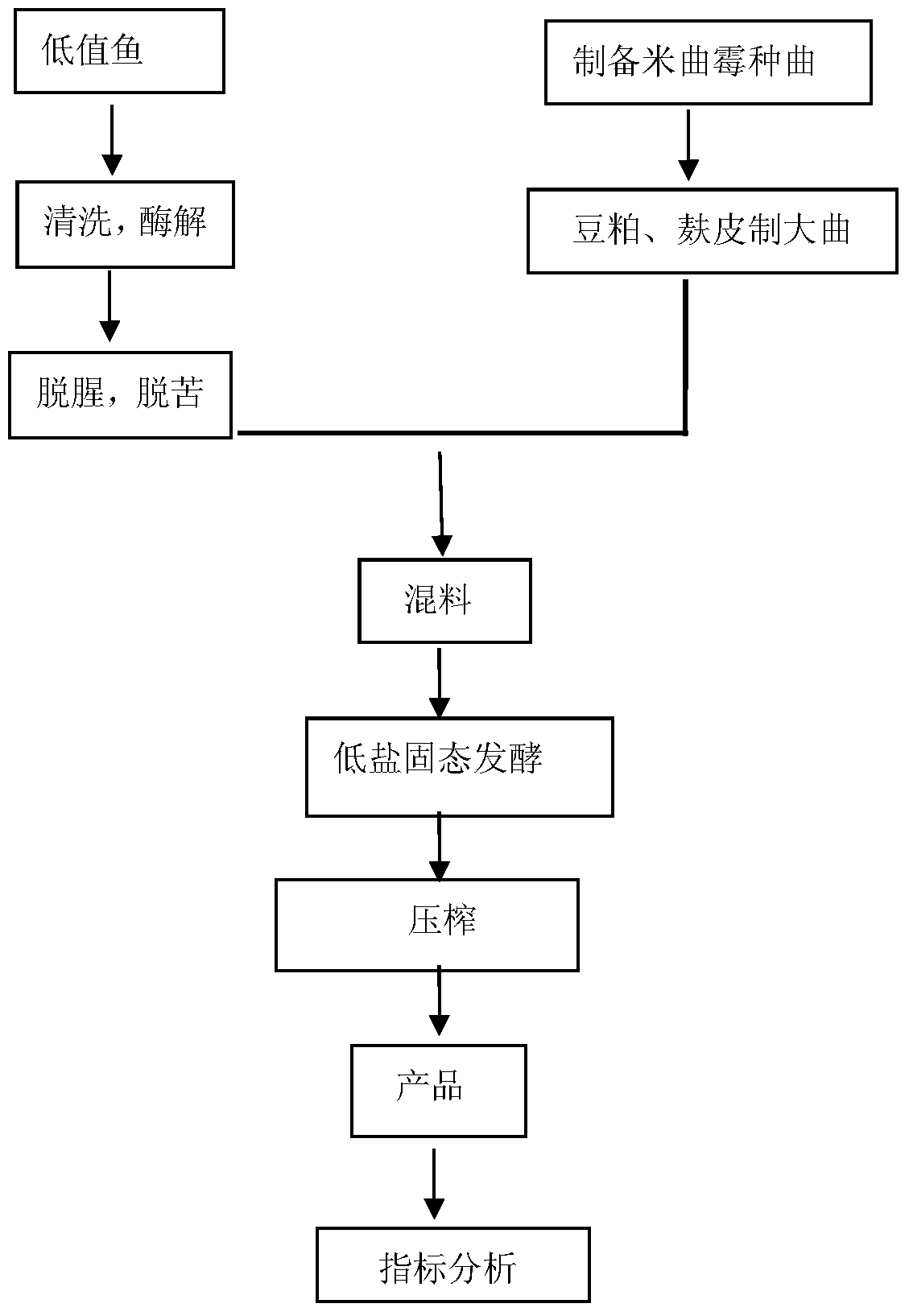

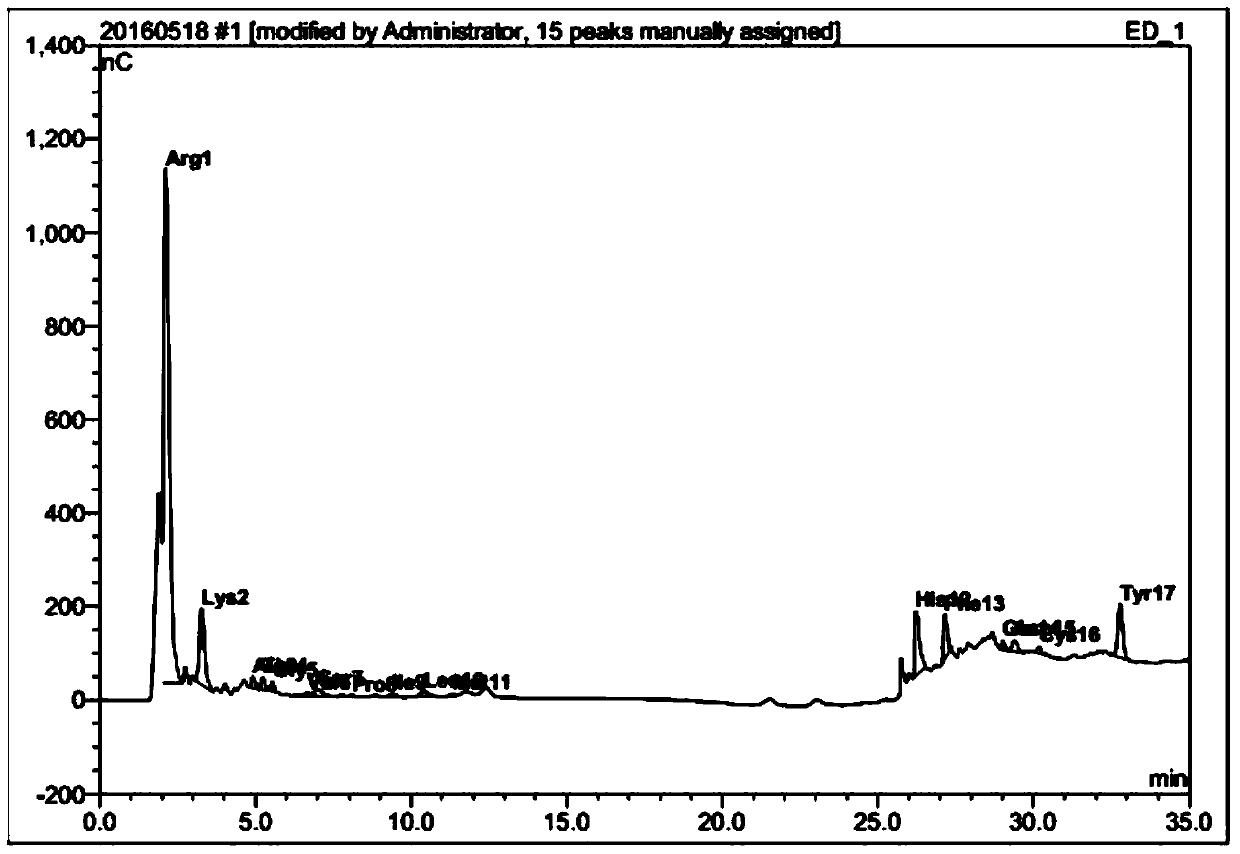

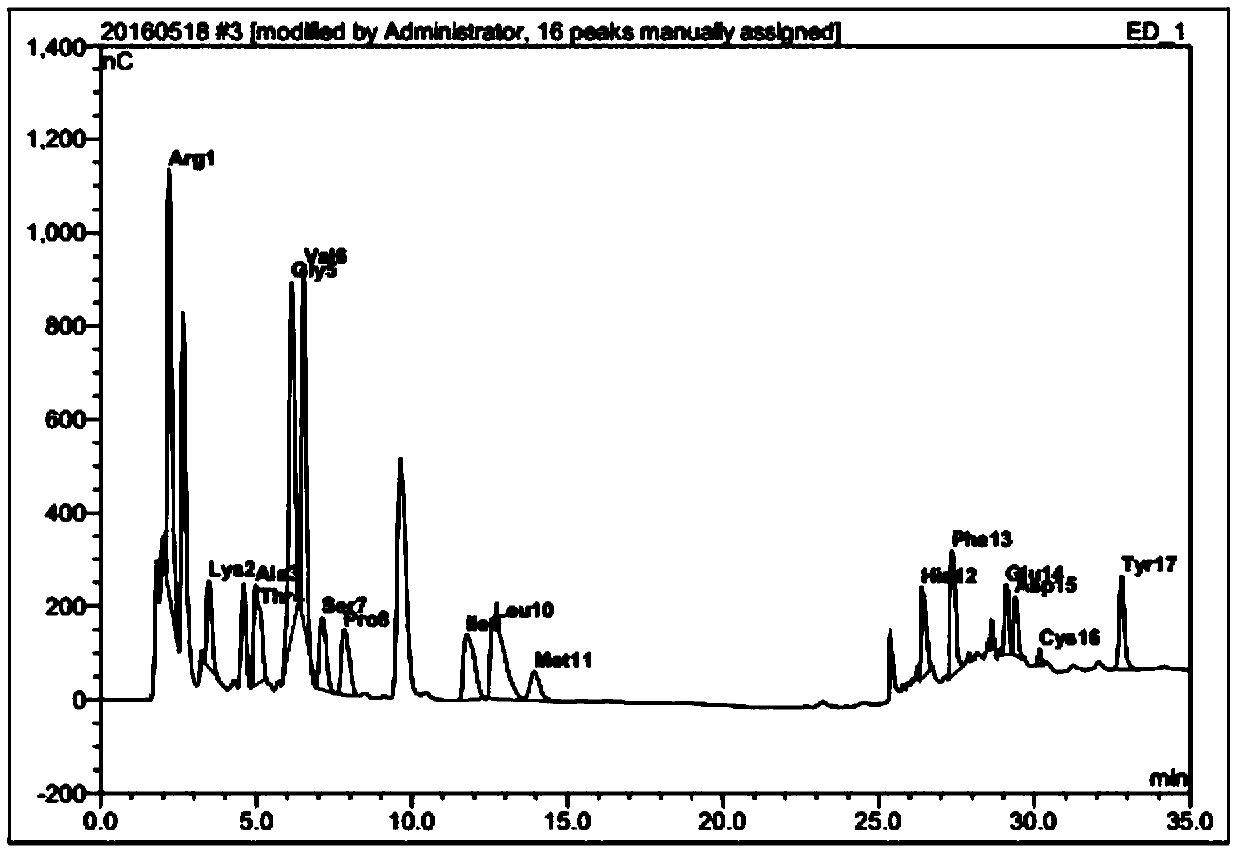

Production method of quickly-fermented high-umami seafood fermented soybean sauce

The invention relates to a production method of quickly-fermented high-umami seafood fermented soybean sauce, including; preparing small-molecular fish protein enzymatic hydrolysate by means of efficient biological enzymatic hydrolysis, and jointly fermenting through the small-molecular fish protein enzymatic hydrolysate with soybean meal and bran to obtain the seafood fermented soybean sauce. The method is low in cost and has a short production cycle, only 30 d, umami of the obtained soybean sauce can be improved, added value of low-value fishes can also be improved, low-value marine animal resources can be comprehensively utilized, and innovation is also made to zero addition of flavorings; meanwhile, the method of the invention is different from common low-salt solid fermented soybean sauces, the addition of the fish protein enzymatic hydrolysate enables the seafood soybean sauce to be healthy, environment-friendly, low in cost, good in property and excellent in umami, and compared with like products, the seafood soybean sauce will be popular with consumers owing to the excellent flavor.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

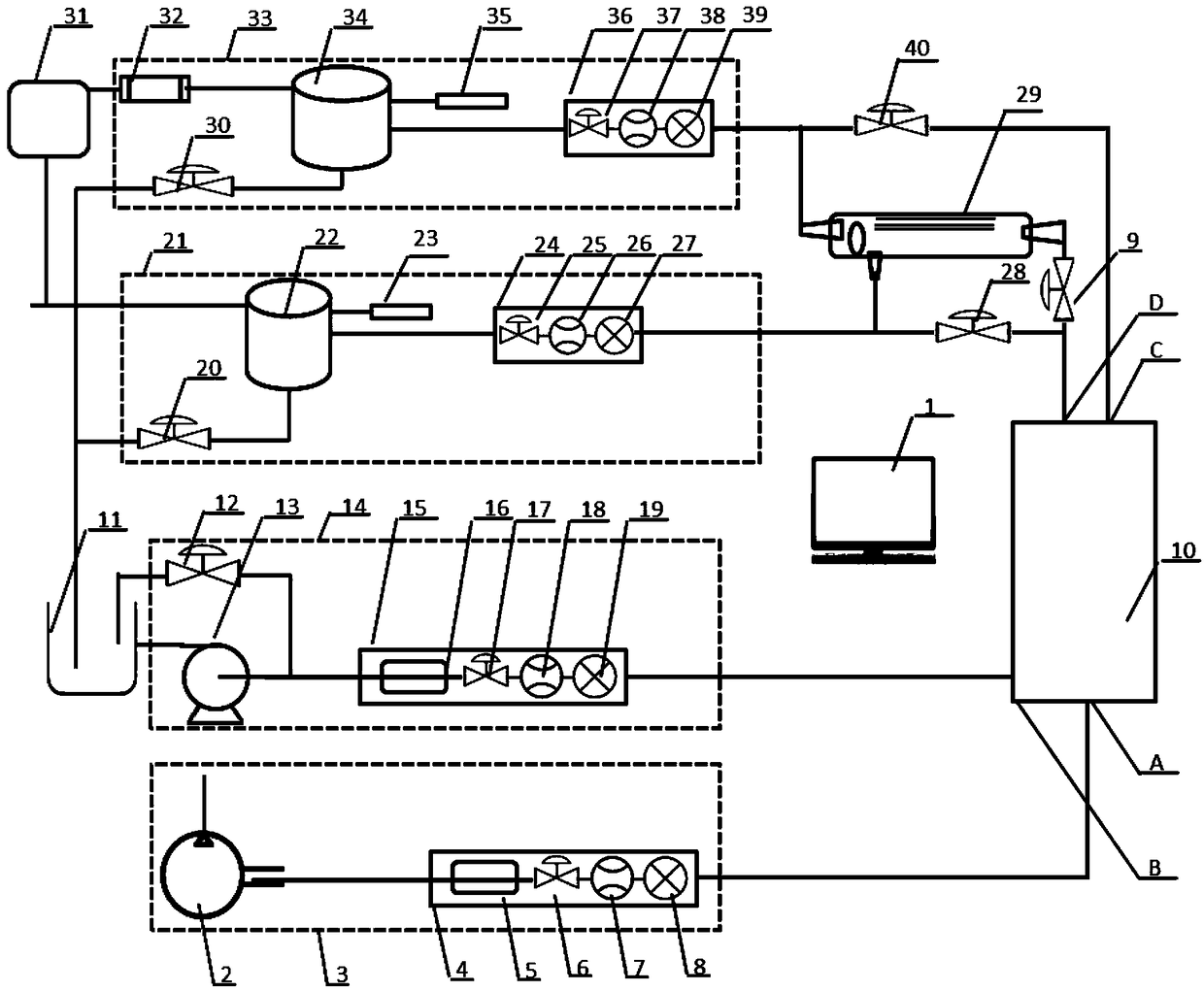

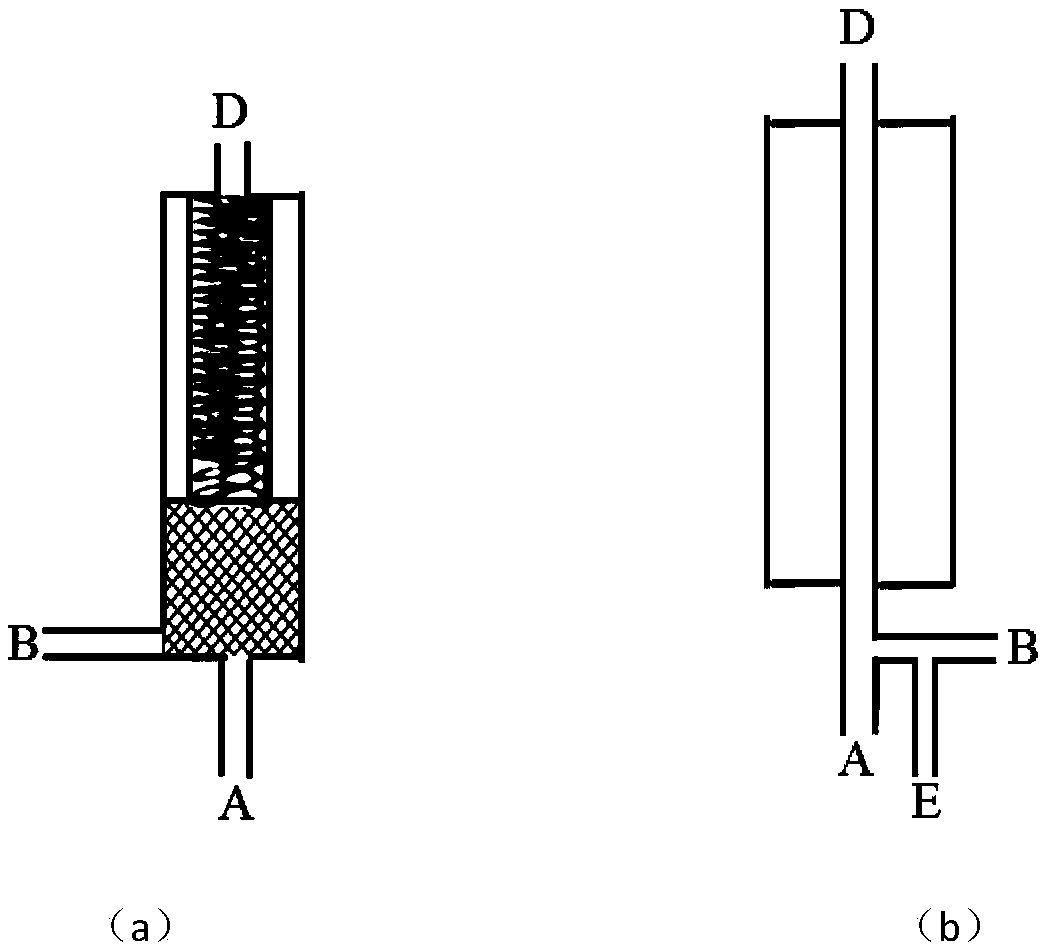

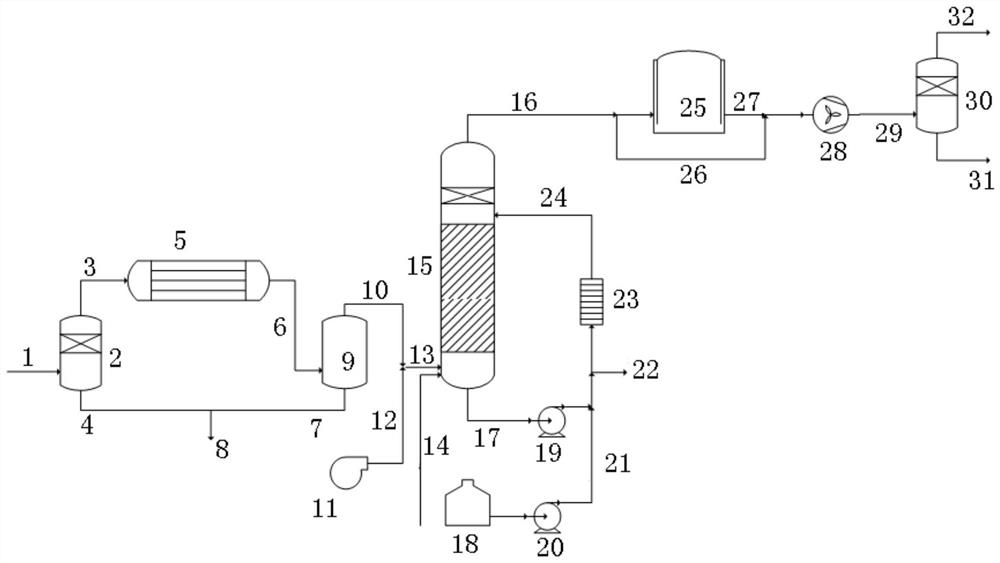

Gas well drainage and production process evaluation system integration and method

InactiveCN109296343AThe unit takes up little spaceSave device configuration costSurveyFluid removalLiquid jetProduct gas

The invention discloses gas well drainage and production process evaluation system integration and method. The gas well drainage and production process evaluation system integration is a set of systemintegrated by five gas well drainage and production process evaluation systems, and comprises a gas supplying device, a liquid supplying device, a drainage and production process evaluation device, agas treating device and a liquid treating device; and the gas well drainage and production process evaluation method is constituted by four gas well drainage and production process evaluation methodsof the cyclone separator gas-liquid separation efficiency, the gas well critical liquid carrying gas volume, the liquid-gas jet pump efficiency and the gas-liquid jet pump efficiency. The investmentcost can be lowered, the success rate of a drainage and production process device applied to a site is increased, and the important effect on gas well stable production is achieved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Waxberry storage and fresh-keeping method

InactiveCN104186642ANo rotSweet and sour tasteFruits/vegetable preservation by freezing/coolingEngineeringRelative air humidity

The invention relates to a waxberry storage and fresh-keeping method which comprises the following steps: (1) postharvest pre-cooling, to be specific, putting harvested waxberries into a pre-cooling room to pre-cool and ensuring that the temperature in the pre-cooling room is 1-5 DEG C, and the relative air humidity is 85-90 percent, so that the temperature of the waxberries is reduced to 5 DEG C; (2) vacuum packaging, to be specific, equivalently sub-packing the waxberries into vacuum fresh-keeping bags, pumping and sealing with a vacuum packaging machine, wherein the pressure of the vacuum packaging machine is 12-15 mmHg; (3) packing and ice block sprinkling, to be specific, correspondingly putting a bag of waxberries in a foam box, capping and sealing, and sprinkling ice blocks which are not lighter than the waxberries around the bottom and the periphery of the vacuum fresh-keeping bag; (4) fresh-keeping at a low temperature, to be specific, piling and storing the foam boxes in a refrigerator, wherein the temperature in the refrigerator is minus 3- minus 5 DEG C, and the relative humidity is 90-95 percent. Though the adoption of the waxberry storage and fresh-keeping method, the waxberries can be subjected to lasting fresh-keeping for 18-20 days, the assistance of a chemical agent and complicated equipment is avoided, the operation is simple, the cost is low, and the popularization is facilitated.

Owner:WENLING WUGEN STRAWBERRY PROFESSIONAL COOP

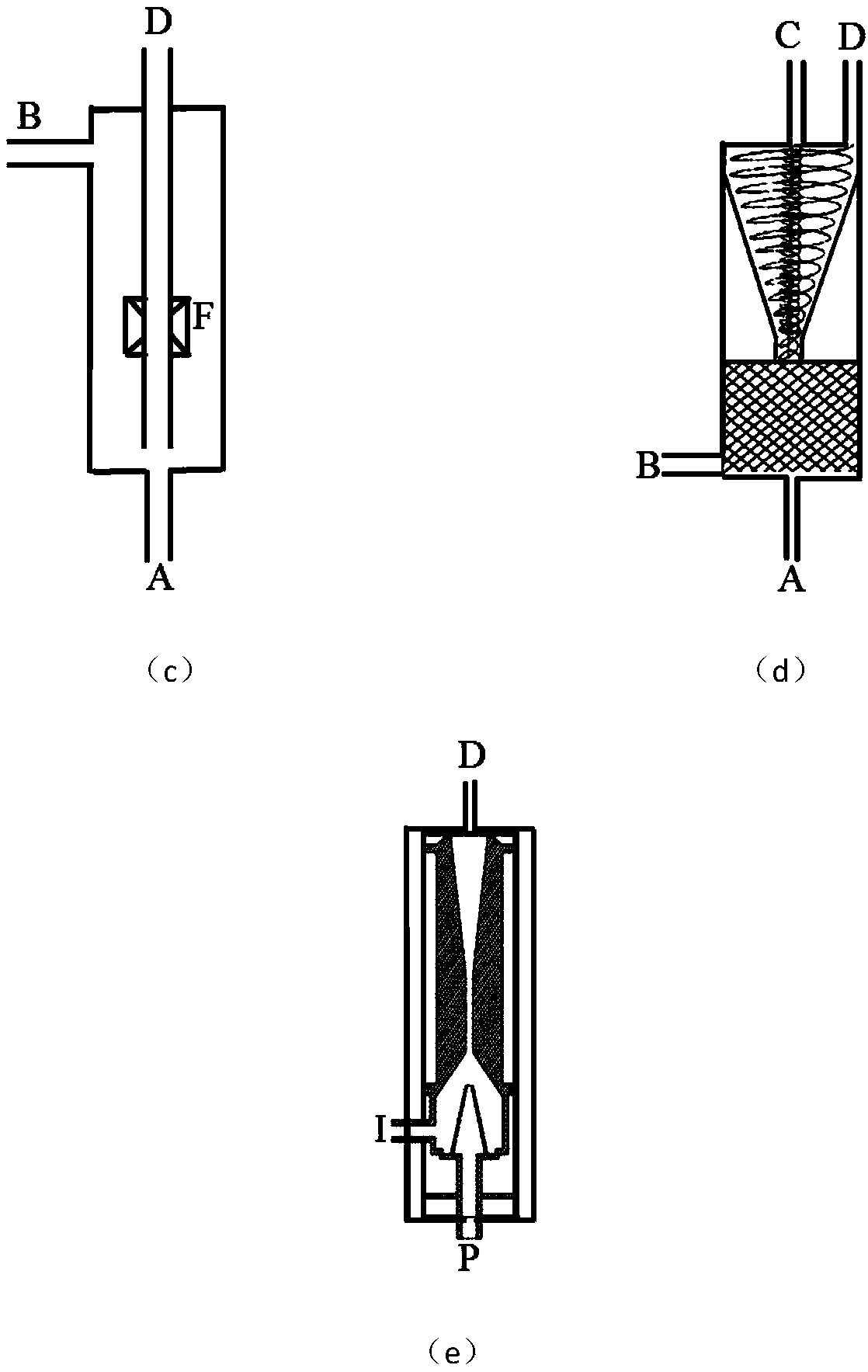

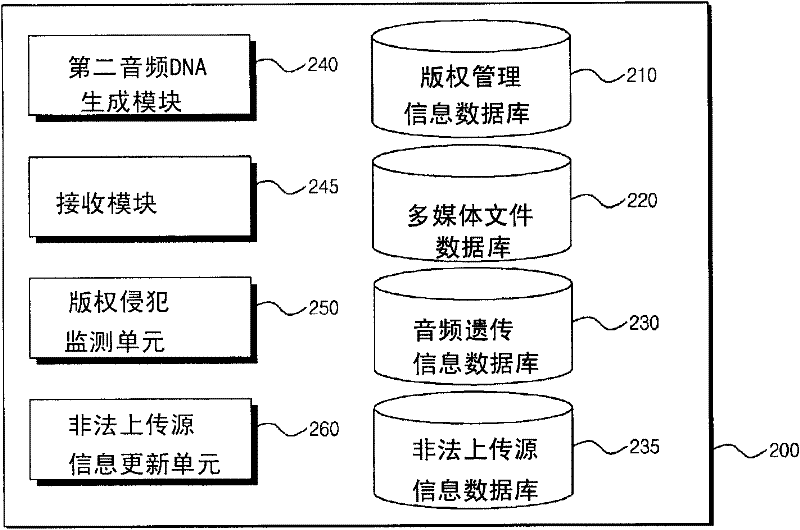

Multimedia content file management system for and method of using genetic information

InactiveCN102449636AEconomic benefit maximizationQuality improvementProgram/content distribution protectionFile sharingManagement system

A multimedia content file management system for and a method of monitoring copyright and watching ratings in real time under the circumstance of the multimedia file sharing service using genetic information are disclosed.

Owner:MUREKA

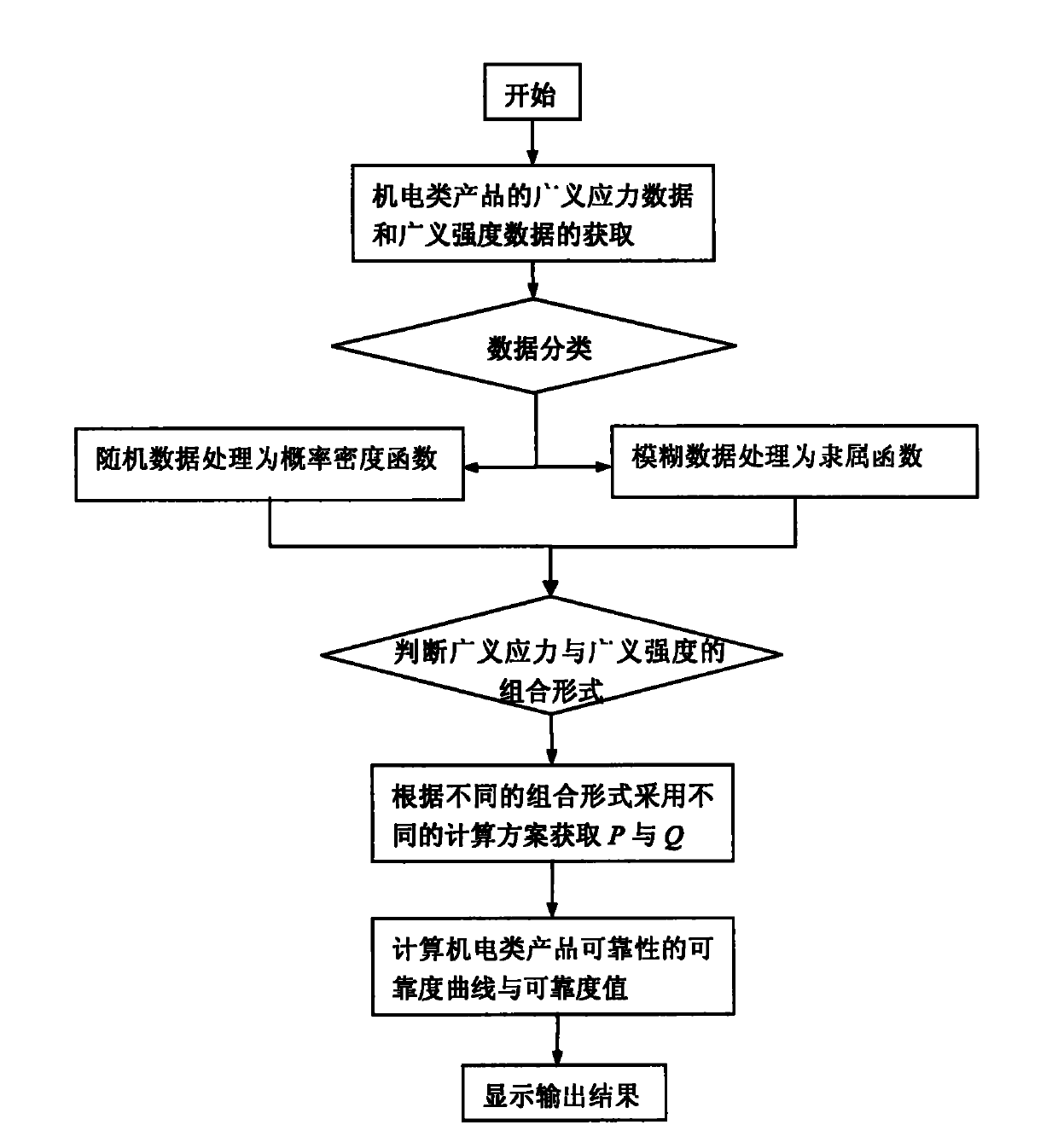

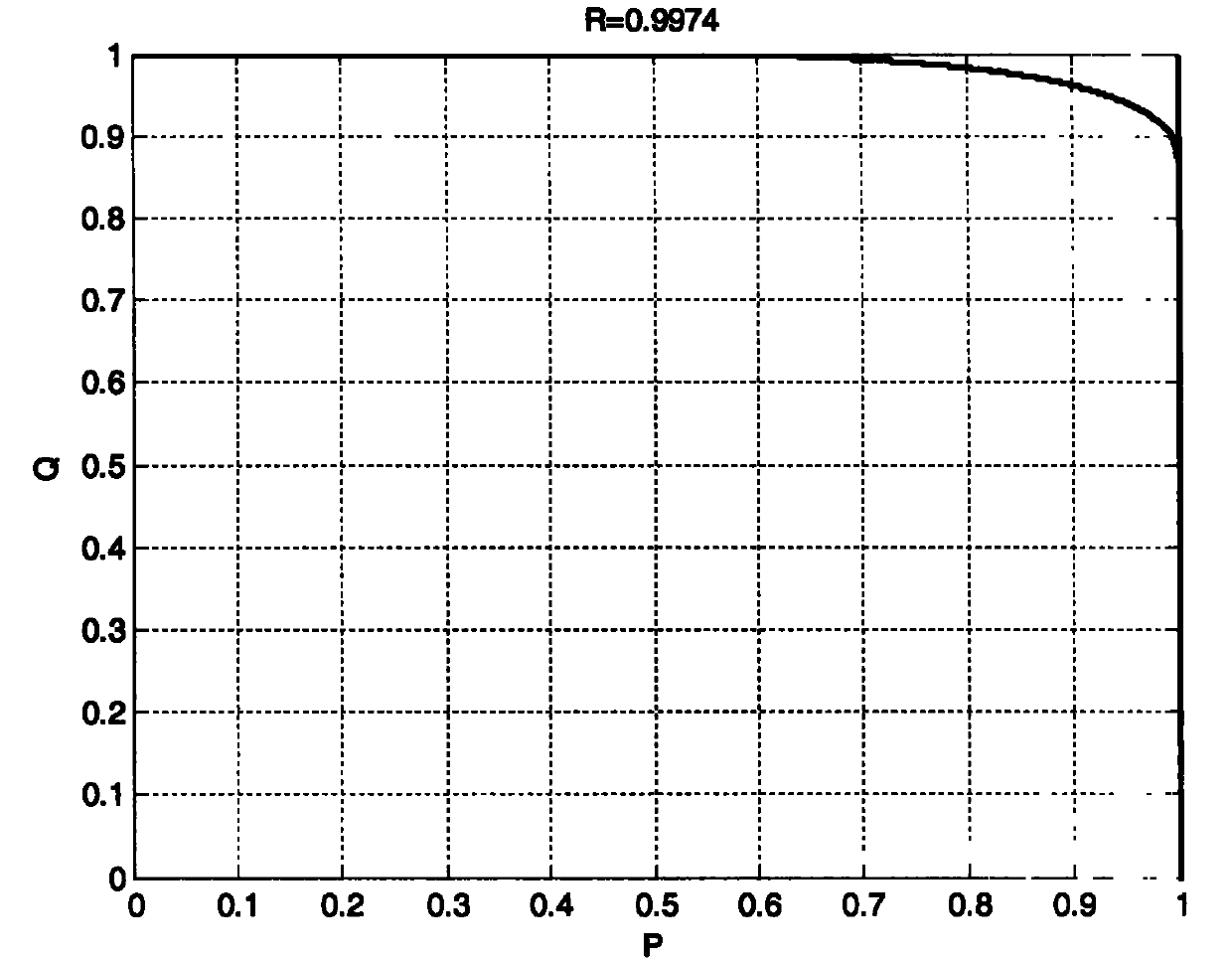

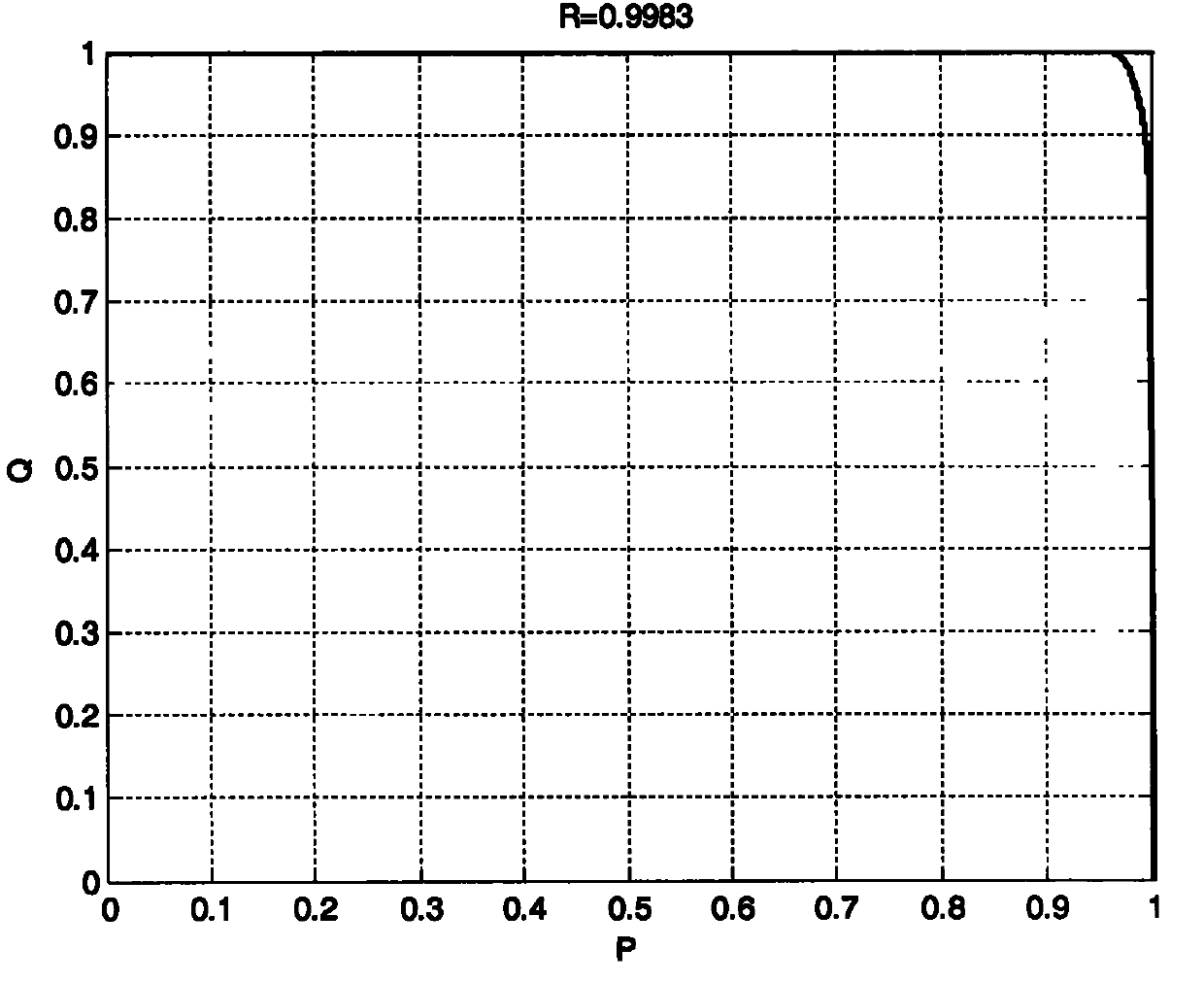

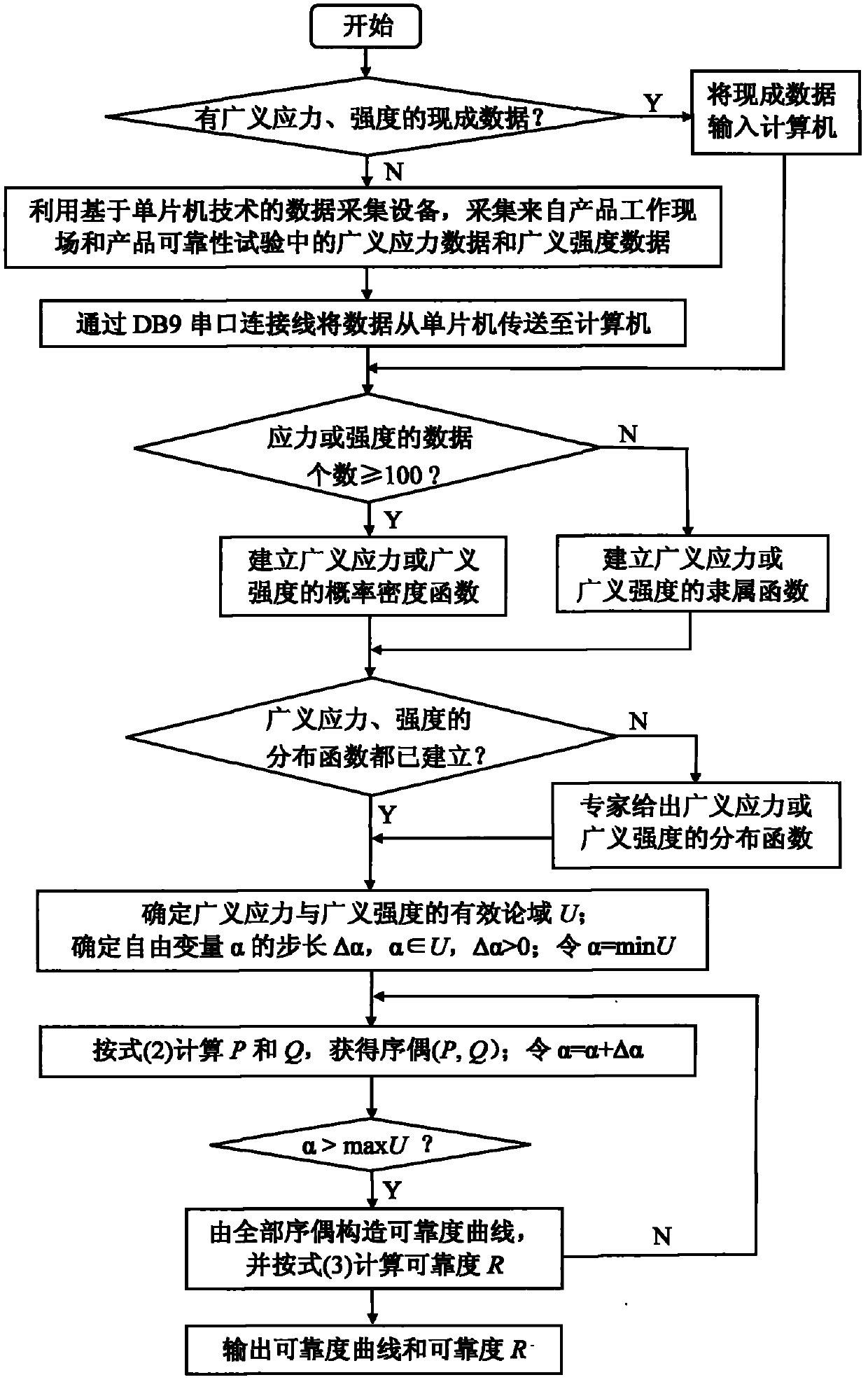

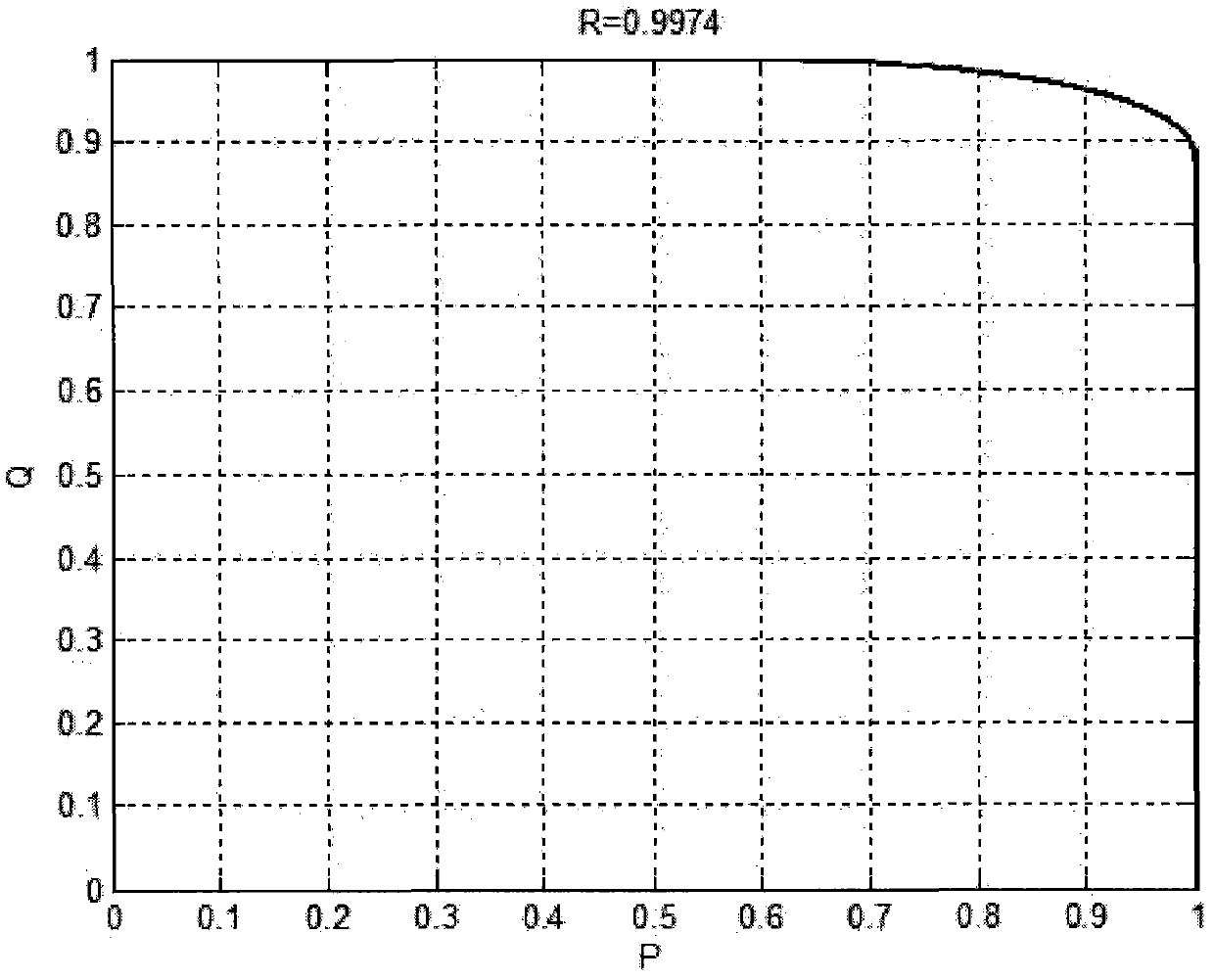

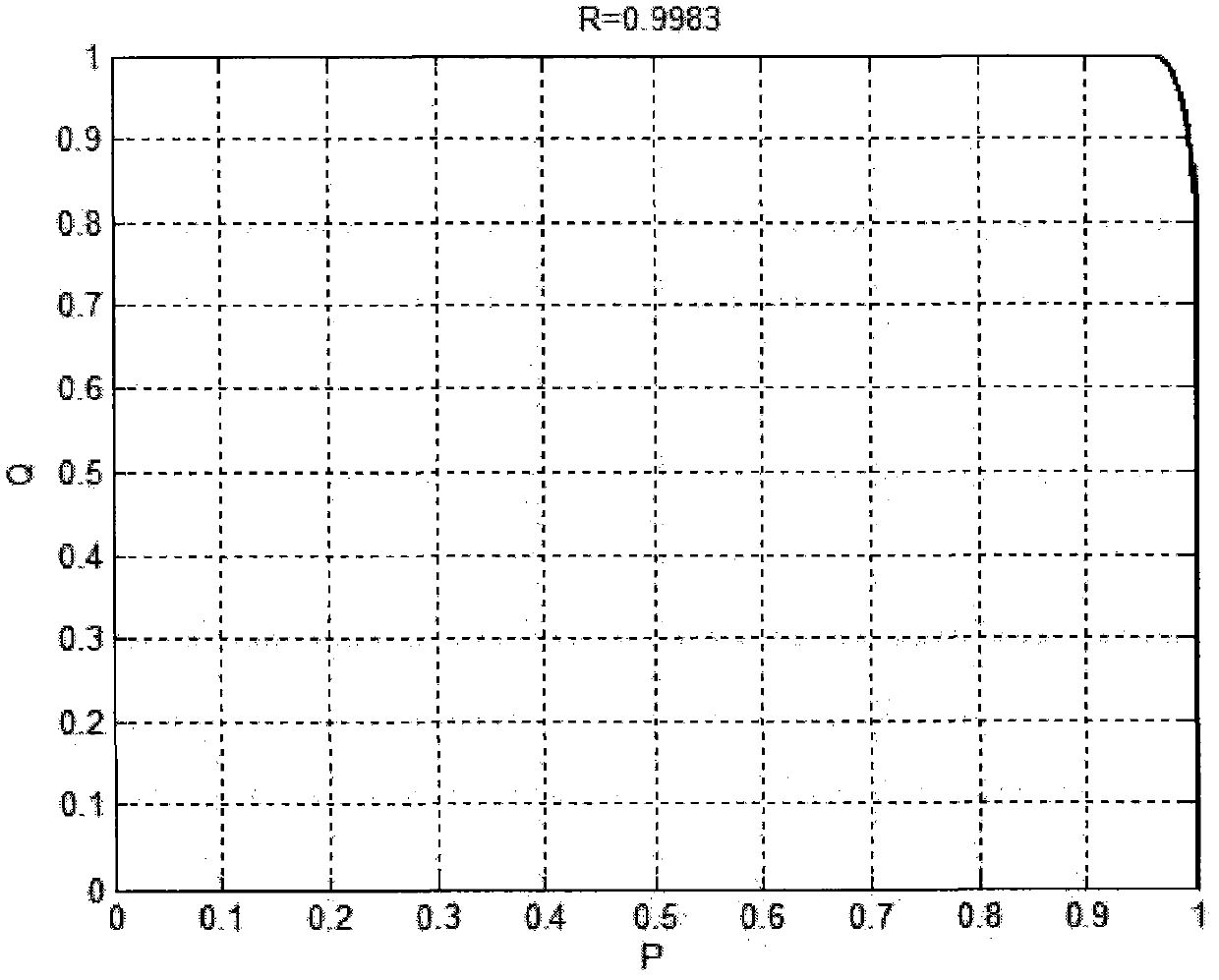

Method for measuring reliability of mechanical/electronic product

InactiveCN102254085AIn line with the actual engineering situationGuide the actual operationSpecial data processing applicationsNormal densityDependability

The invention discloses a method for measuring the reliability of a mechanical / electronic product, relating to a digital computation method especially suitable for special applications. In the method disclosed by the invention, through comprehensively processing probability density functions and membership functions based on a generalized stress-generalized strength interference model, the comprehensive processing on random information and fuzzy information in the process of measuring the reliability of the product is realized so as to obtain the reliability value of the mechanical / electronic product, and the reliability curve and reliability value of the product are intuitively displayed by a computer, thereby overcoming the defect that in the existing product reliability calculation method, under the condition that the random information and the fuzzy information coexist, the reliability of the product is difficult to measure.

Owner:HEBEI UNIV OF TECH

Reliability measurement method for mechanical and electrical product

ActiveCN102682212AIn line with the actual engineering situationConvenient guidanceSpecial data processing applicationsNormal densityDependability

Owner:HEBEI UNIV OF TECH

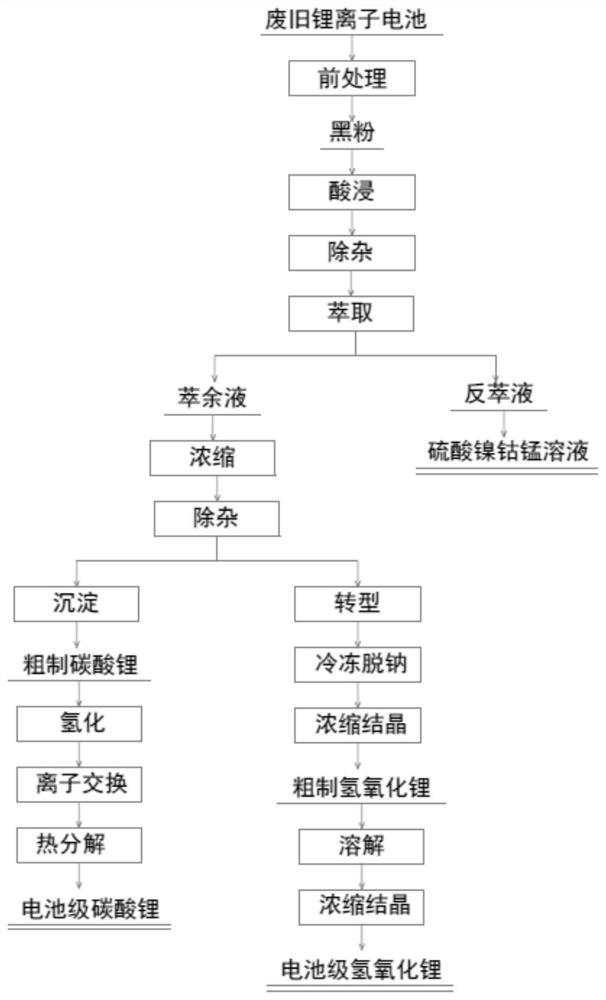

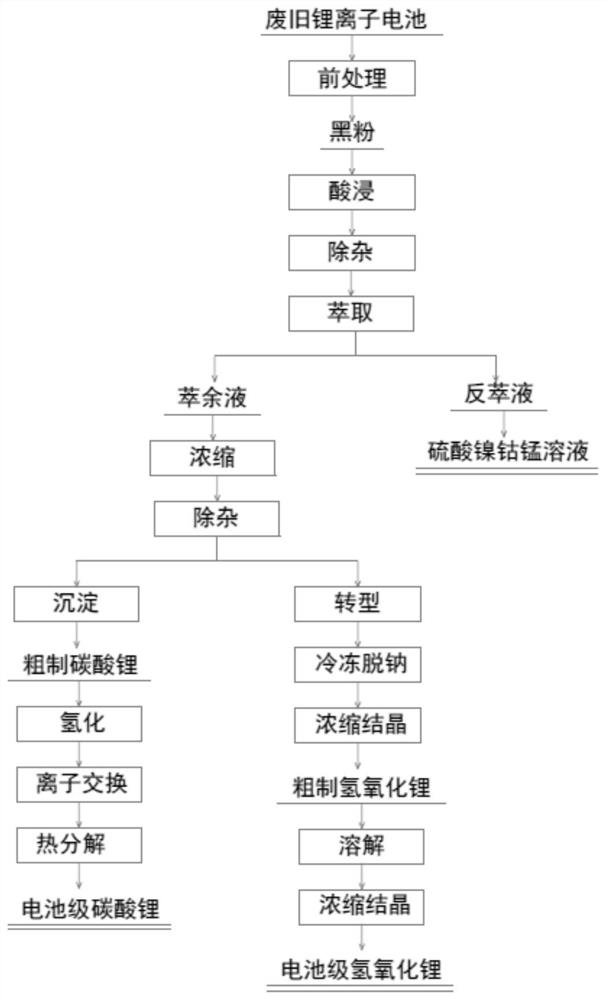

Comprehensive recycling method of waste lithium ion battery

ActiveCN112267024AEconomic benefit maximizationSave resourcesWaste accumulators reclaimingLithium oxides/hydroxidesLithium hydroxideEnvironmental engineering

The invention discloses a comprehensive recycling method of a waste lithium ion battery. The method takes the waste lithium ion battery as a raw material, develops a process for jointly preparing battery-grade lithium carbonate and lithium hydroxide products, and can synchronously recycle metals such as cobalt, nickel, manganese and the like for preparing a precursor. Lithium elements can be recycled and extracted to prepare the battery-grade lithium carbonate and the lithium hydroxide for positive manufacturing of a positive electrode material, wastes can be recycled to protect the environment, maximization of economic benefits can be achieved, and resources are saved.

Owner:JINGMEN GEM NEW MATERIAL

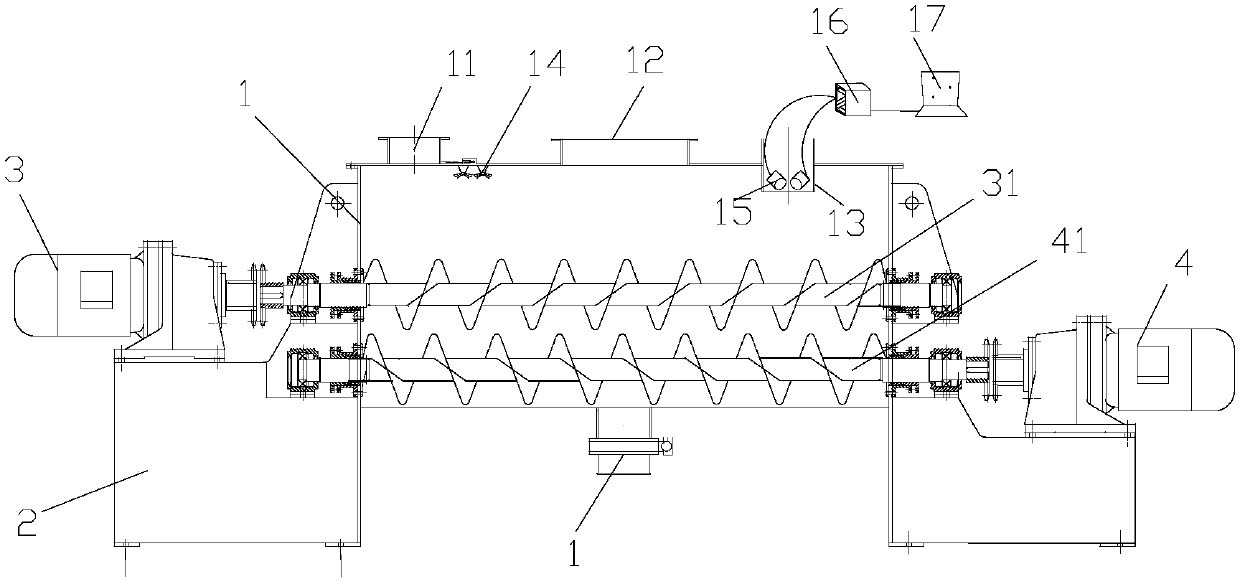

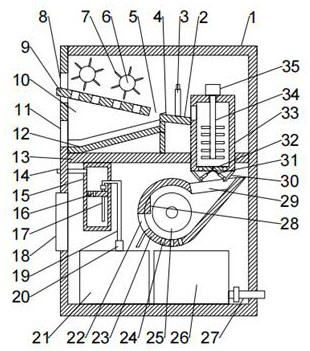

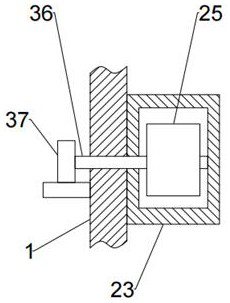

Stirring equipment capable of realizing online near infrared spectrum monitoring of soil stabilizing process

InactiveCN109569358AEconomic benefit maximizationAvoid collisionTransportation and packagingRotary stirring mixersPeak valueEngineering

Stirring equipment capable of realizing online near infrared spectrum monitoring of soil stabilizing process comprises a stirring device and a near infrared detection system. The stirring device comprises a stirring box, the top of the stirring box is provided with a soil feeding port, an agent feeding port and a monitoring port, a first spiral stirrer and a second spiral stirrer are arranged in the stirring box, the near infrared detection system comprises a near infrared detector, a cover made of quartz, an agent nozzle and a processor, the bottom of the monitoring port is closed through thecover, the cover protrudes into the stirring box, and at least one near infrared detection probe connected with the near infrared detector and facing soil in the stirring box are arranged in the cover. H-O peak value change in the soil is detected in real time through the probes to judge solid-liquid ratio of soil to water in the soil so as to judge stirring uniformity of the soil and a solidifying and stabilizing agent, so that reasonable agent adding is ensured, and economic maximization is realized.

Owner:长沙工研院环保有限公司

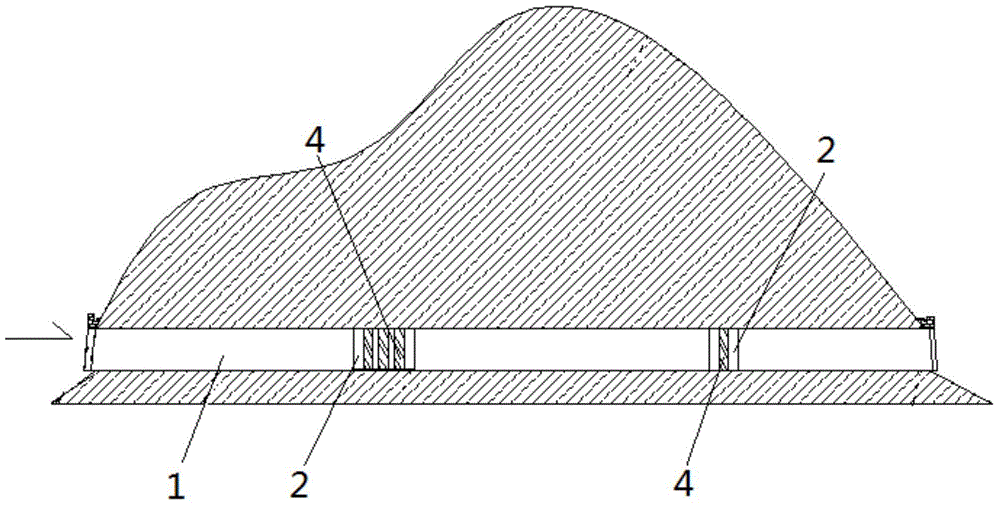

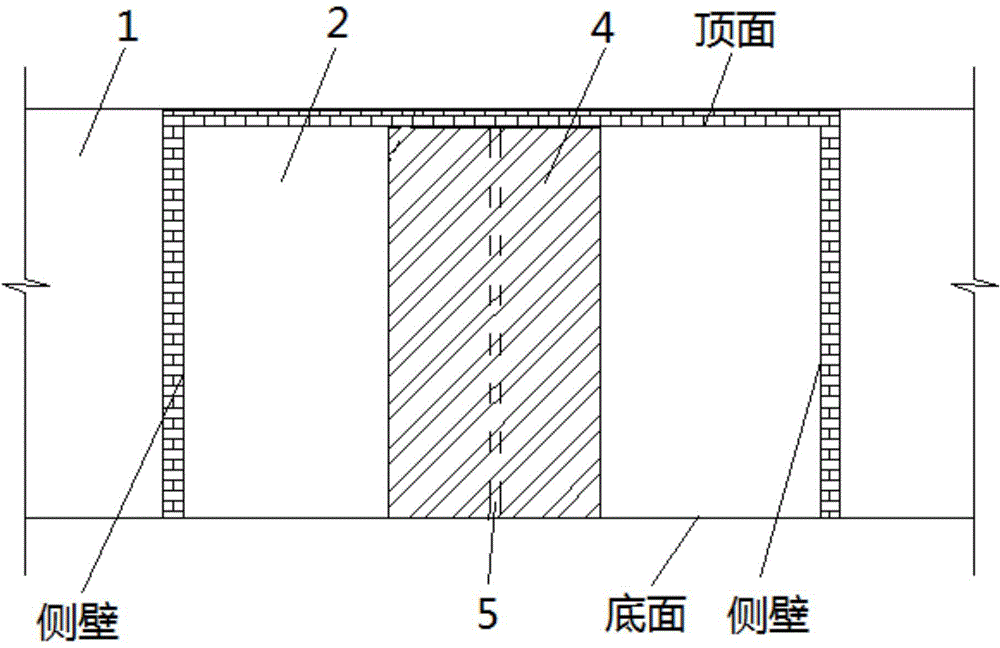

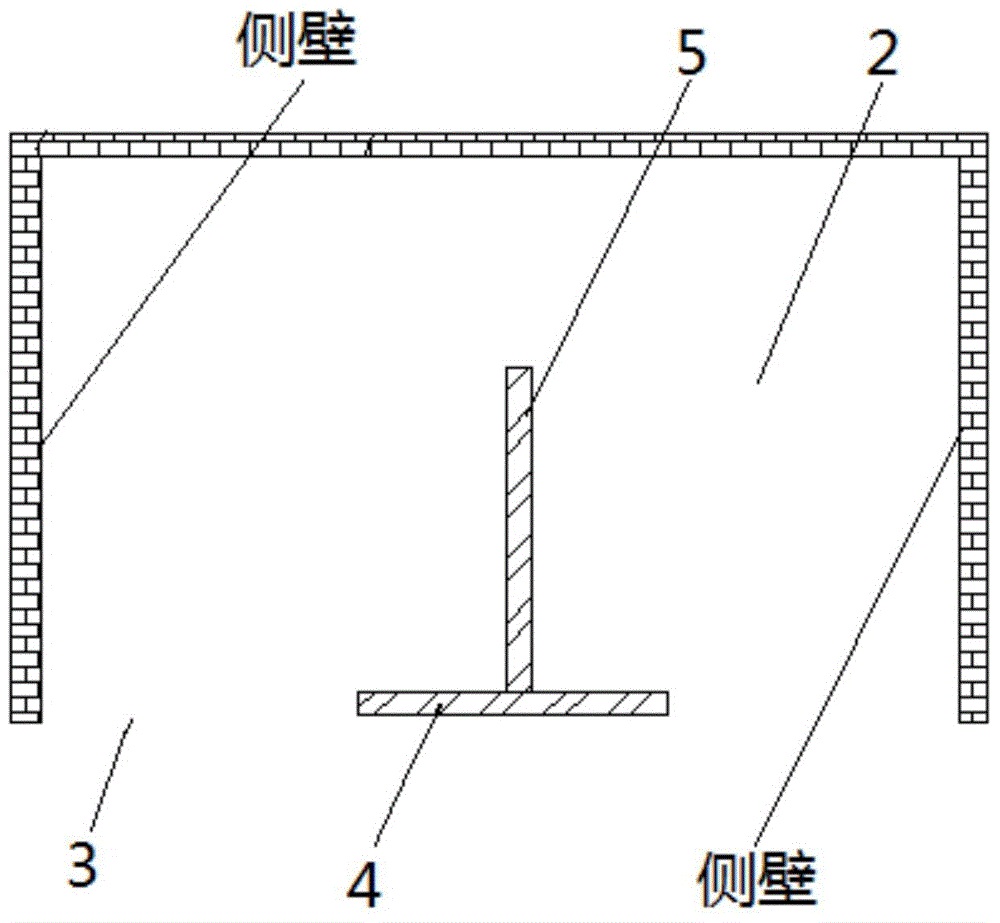

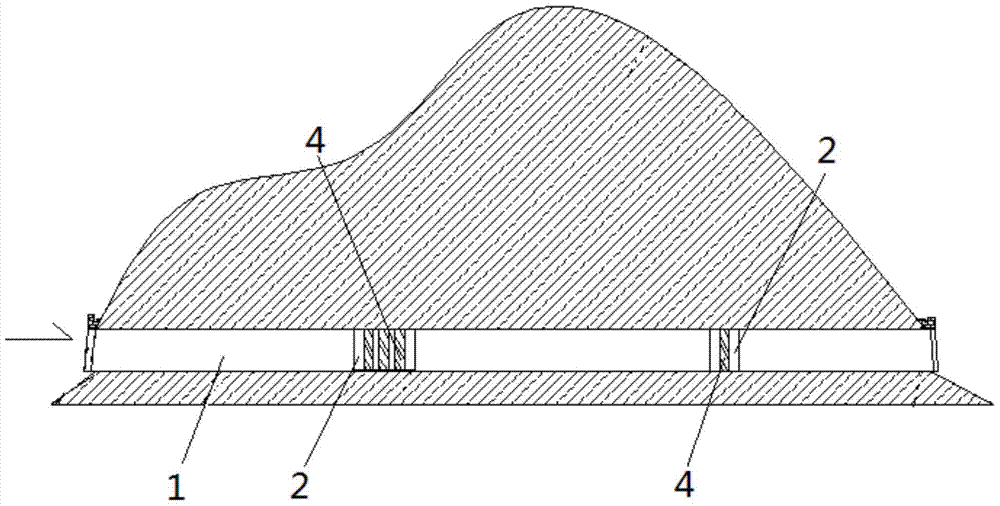

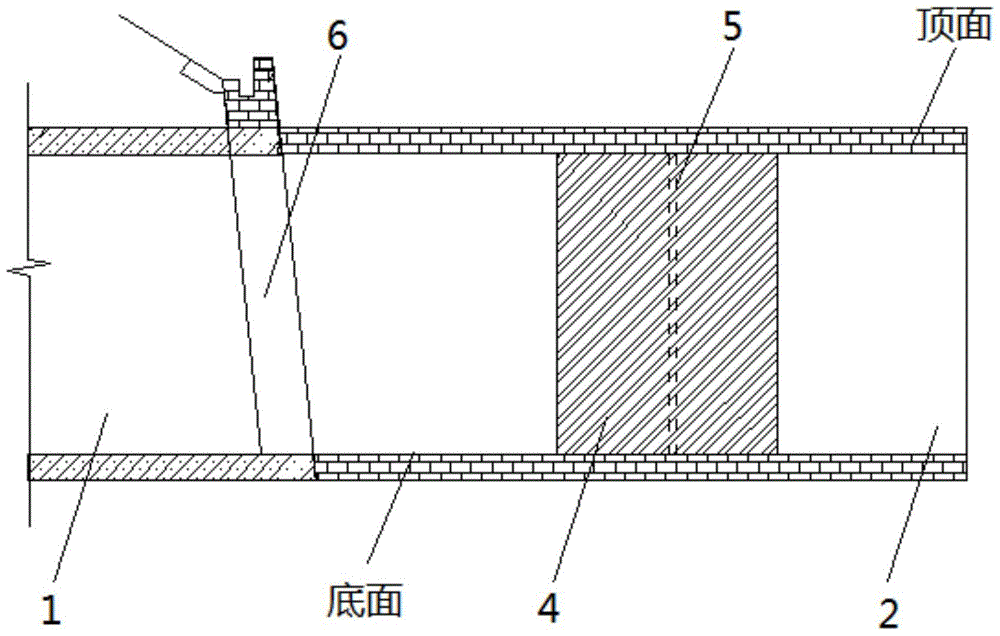

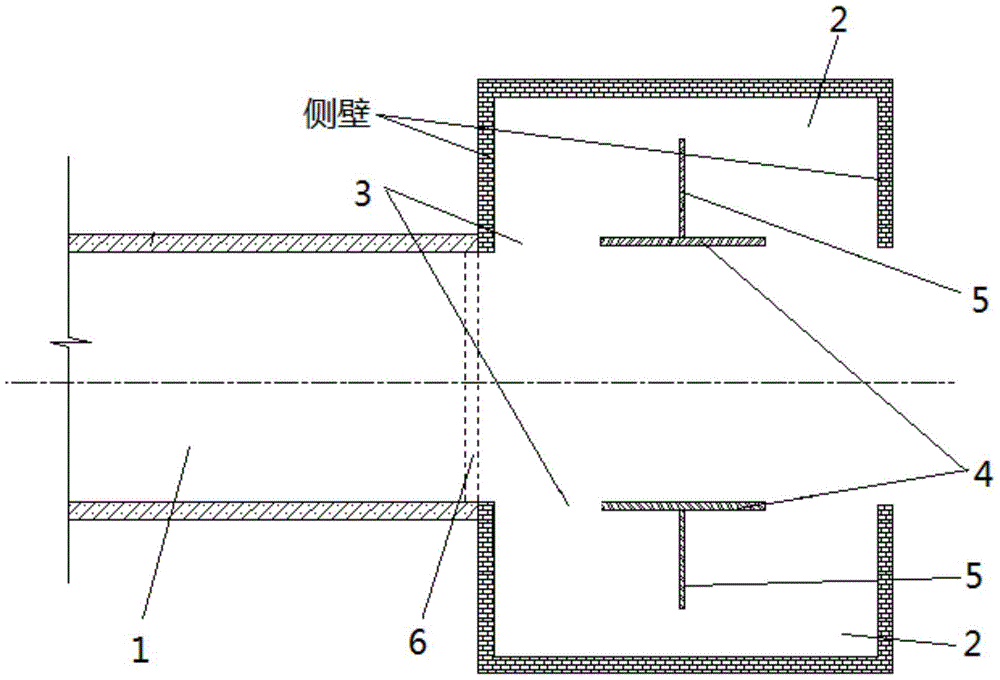

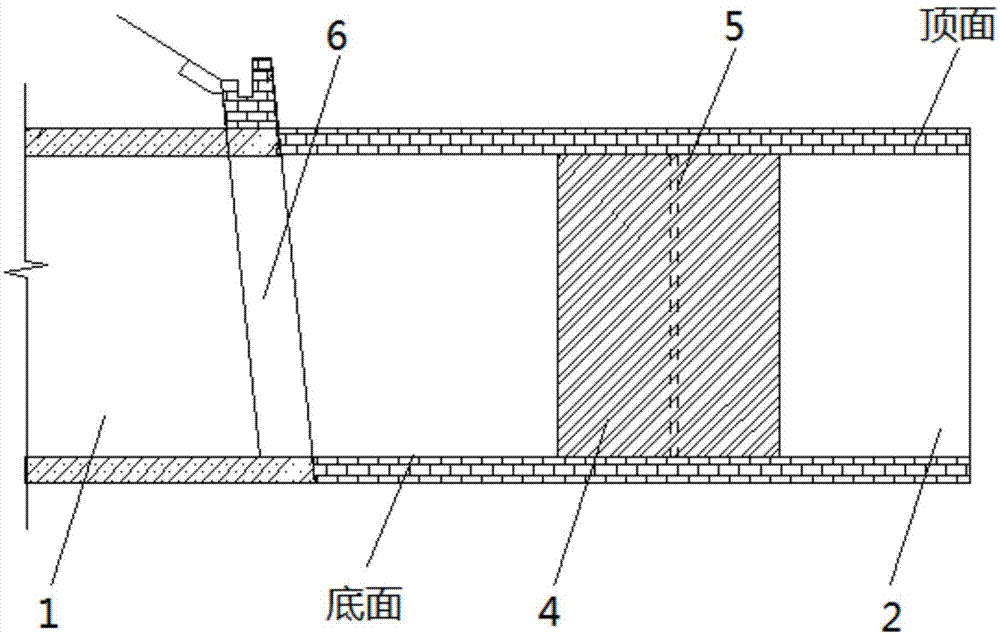

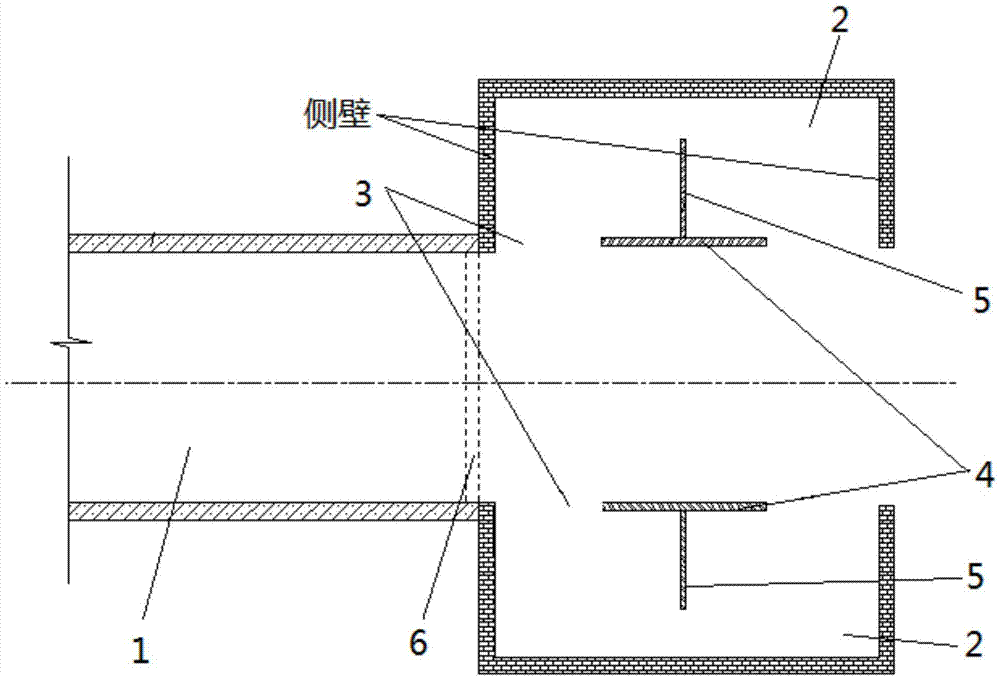

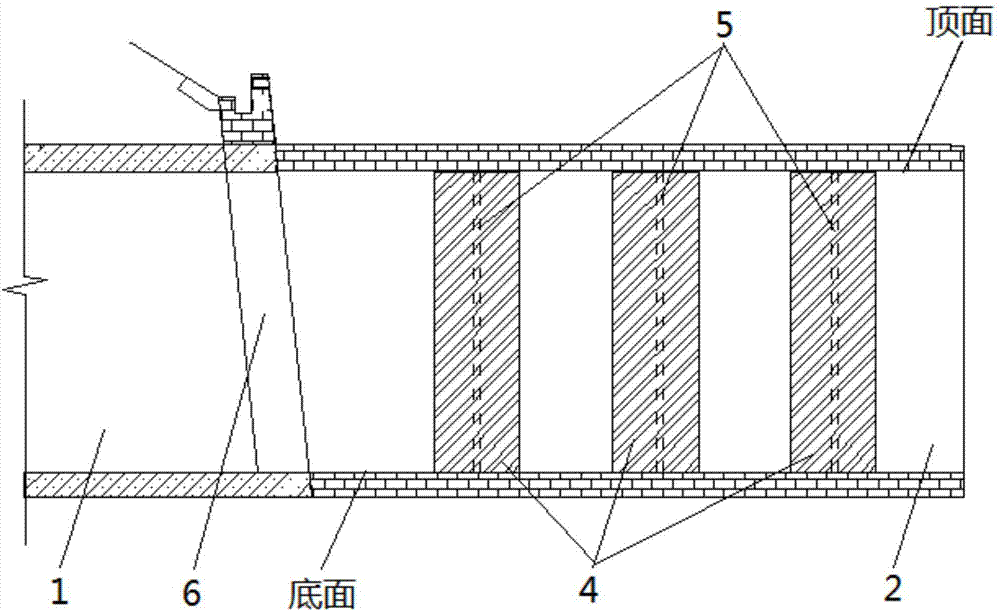

Auxiliary pit type buffering structure in railway tunnel

ActiveCN104453935AReduce pressure peaksMitigate micro pressure wave effectTunnelsRailway tunnelEconomic benefits

The invention discloses an auxiliary pit type buffering structure in a railway tunnel. The auxiliary pit type buffering structure comprises a plurality of auxiliary pit chambers and second retaining plates; the auxiliary pit chambers are positioned on two sides of the tunnel, are arranged along the axial direction of the tunnel at intervals and are communicated with the tunnel through open surfaces, at least one first retaining plate parallel to the corresponding open surface is arranged at each auxiliary pit chamber, two ends of each retaining plate are fixedly connected with the top surface and the bottom surface of the corresponding auxiliary pit chamber respectively, and the sum of the area of the first retaining plates in the same auxiliary pit chamber is smaller than the area of the open surface of the auxiliary pit chamber; one end of each second retaining plate is connected with the corresponding first retaining plate, and the other end of each second retaining plate extends into the corresponding auxiliary pit chamber. The auxiliary pit type buffering structure has the advantages that the retaining plates are arranged in the auxiliary pit chambers, a compression wave is dispersed, and the pressure peak of a micro compression wave is decreased, so that the micro compression wave effect of a tunnel entrance is remarkably relieved, the tunnel can be renovated at a low cost, the micro compression wave effect of the operational tunnel entrance is relieved, and the buffering structure has remarkable economic benefit and high practicability; the buffering structure is applicable to high speed railways, interurban railways and city field railway tunnels.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

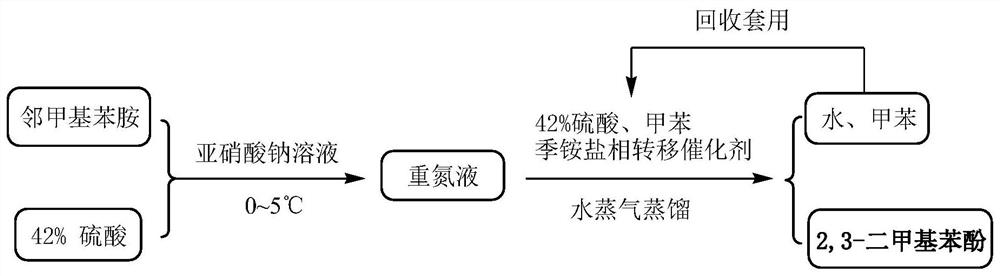

Preparation method of metrafenone

InactiveCN111943823AHigh purityHigh yieldOrganic compound preparationCarbonyl compound preparation by oxidationOrganic synthesisAcyl group

The invention discloses a preparation method of metrafenone, and belongs to the technical field of organic synthesis. The method comprises the following steps: respectively carrying out diazotizationreaction, hydrolysis reaction, etherification reaction, selective oxidation, positioning oxidation, bromination reaction, acylating chlorination reaction, bromination reaction, methylation reaction, methoxylation reaction and Friedel-Crafts acylation reaction to prepare a metrafenone (3'-bromo-2,3,4,6'-tetramethoxy-2',6-dimethyl benzophenone) product crude product; and refining to obtain the target product metrafenone. According to the method, the bottleneck problem in intermediate synthesis is solved, the metrafenone product is synthesized with low raw materials and production cost, and metrafenone with high purity and yield is obtained.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

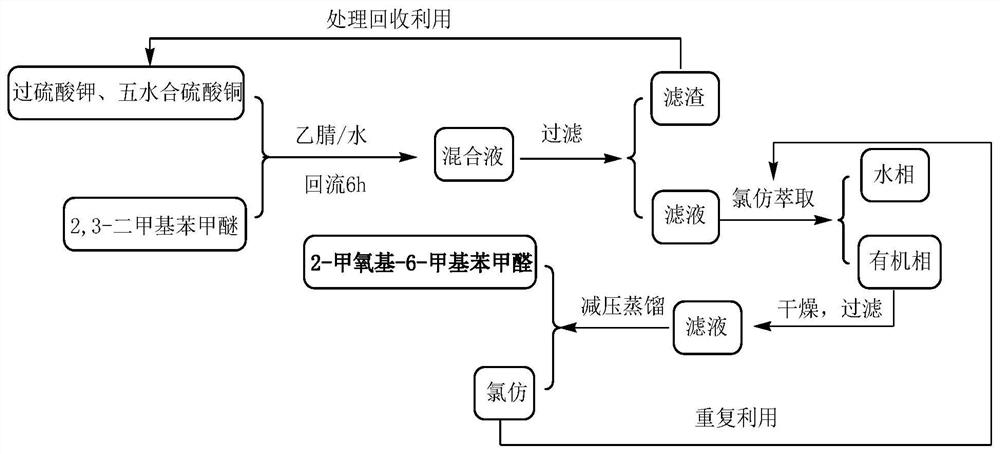

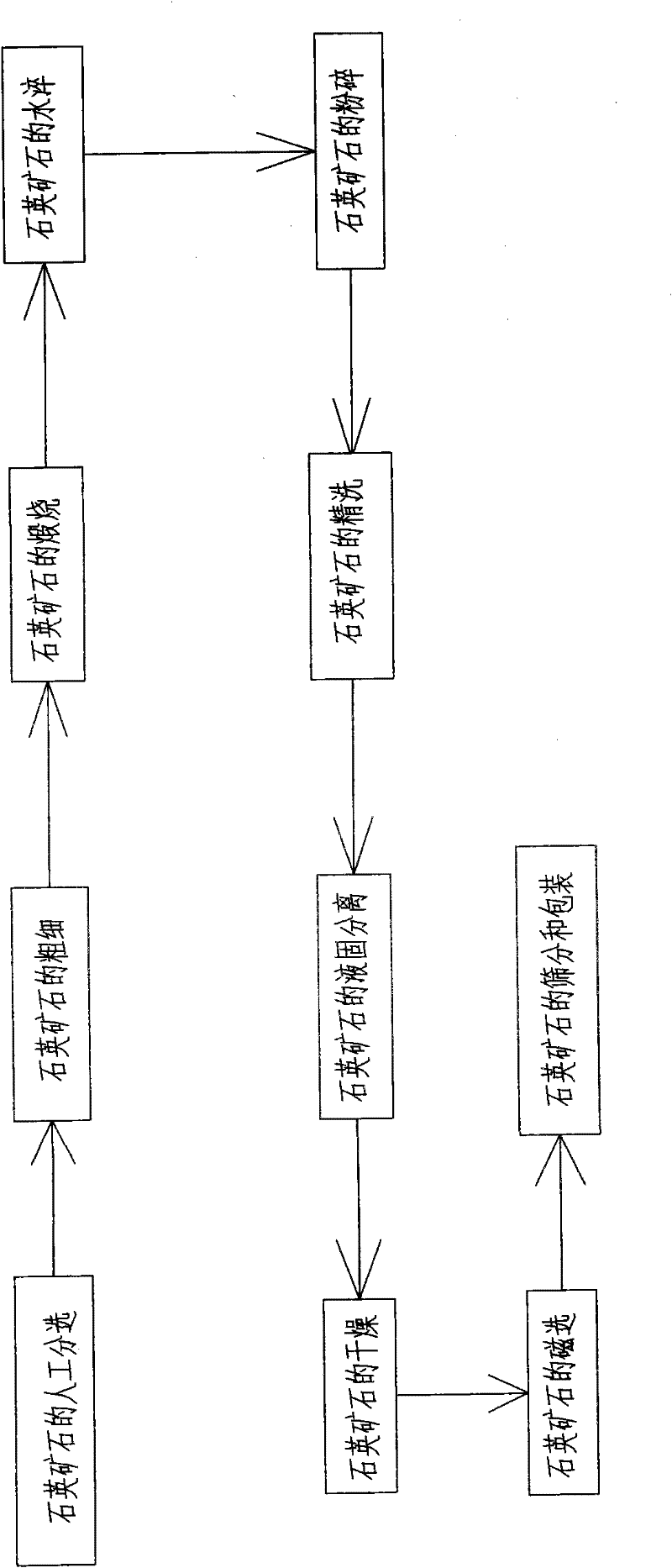

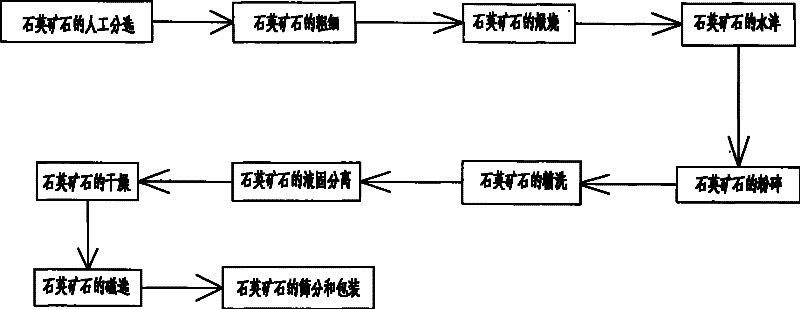

Method for preparing high-purity quartz sand

InactiveCN101948235BTake advantage ofProtect resourcesGlass shaping apparatusHydrofluoric acidFurnace temperature

The invention discloses a method for preparing high-purity quartz sand. The method comprises the following steps of: dividing quartz ore into blocks with size of 30mm*30mm for classification; roughly washing and calcining the quartz ore; calcining the quartz ore twice at the furnace temperature of between 840 and 880 DEG C and at the furnace temperature of between 890 and 910 DEG C; performing water-quenching and pulverizing the quartz ore into quartz sand with particle size of between 0.4 and 0.1mm; placing the pulverized quartz ore sand into a reaction tank; adding ultrapure water with purity level of between 14.5 and 15.5M which is 65 to 75 percent of the volume of the reaction tank, the quartz sand which is 30 to 40 volume percent of the ultrapure water and the mixture of concentratedhydrochloric acid or hydrochloric acid with concentration of 35 to 37 percent and hydrofluoric acid into the reaction tank in turn, wherein based on the ultrapure water, the mixture of the concentrated hydrochloric acid or hydrochloric acid is 5 to 8 volume percent; keeping the temperature of the reaction tank at 60 to 80 DEG C; stirring the mixture in the reaction tank for 20 to 30 minutes, precipitating the mixture for 10 to 15 minutes and then discharging the primary liquid out of the reaction tank; adding a proper amount of ultrapure water again; stirring and cleaning; conveying the mortar of the reaction tank to a cleaning tank; cleaning the mortar in the cleaning tank by using the ultrapure water; performing liquid-solid separation on the quartz ore; drying the quartz ore under the environment with temperature of between 175 and 185 DEG C; and performing magnetic separation, and screening and packaging the quartz ore. Thus, resources are protected and fully utilized, and the maximization of the economic benefit is realized.

Owner:山东海友新材料科技有限公司

Coal mine enterprise cost control system

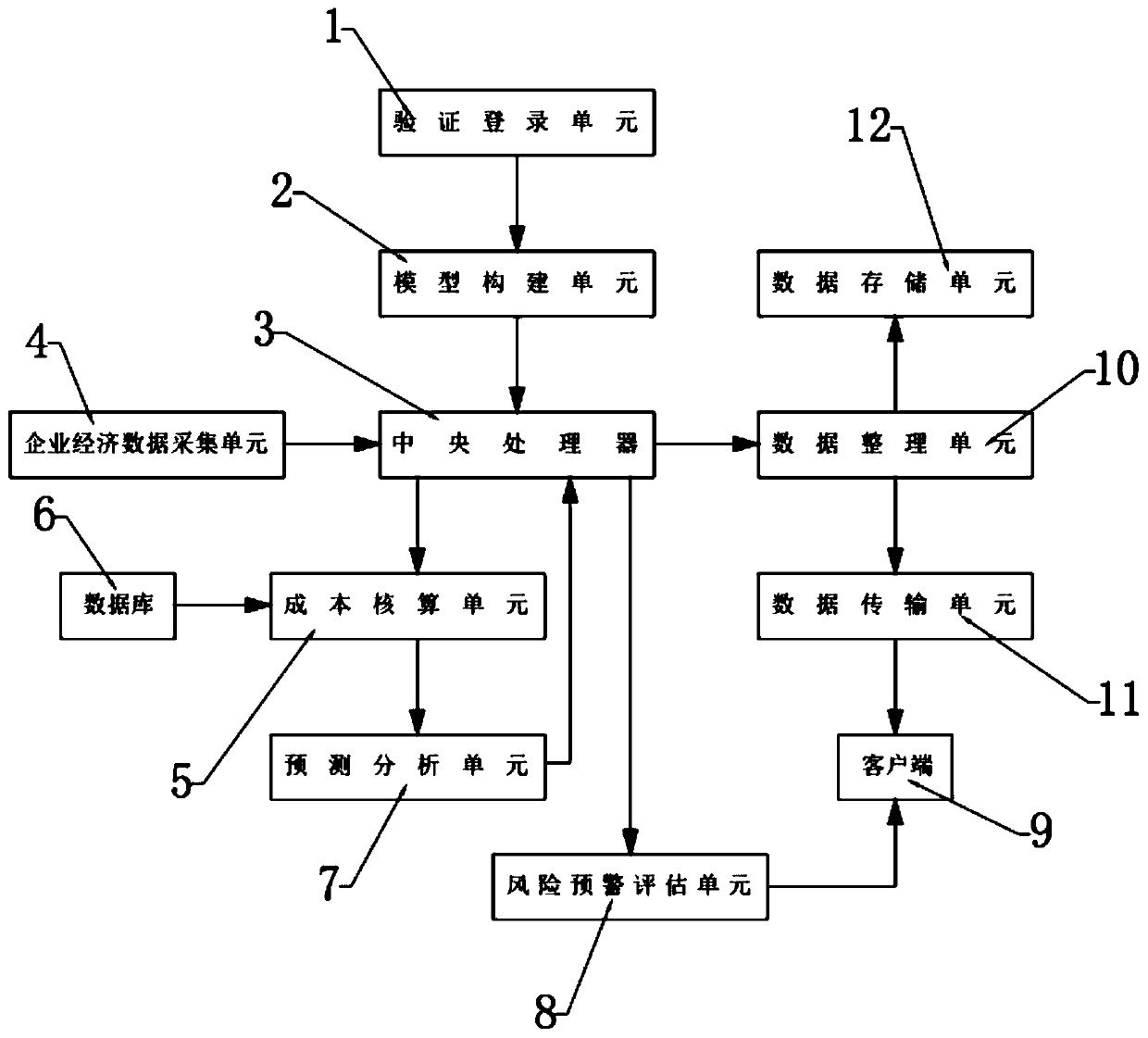

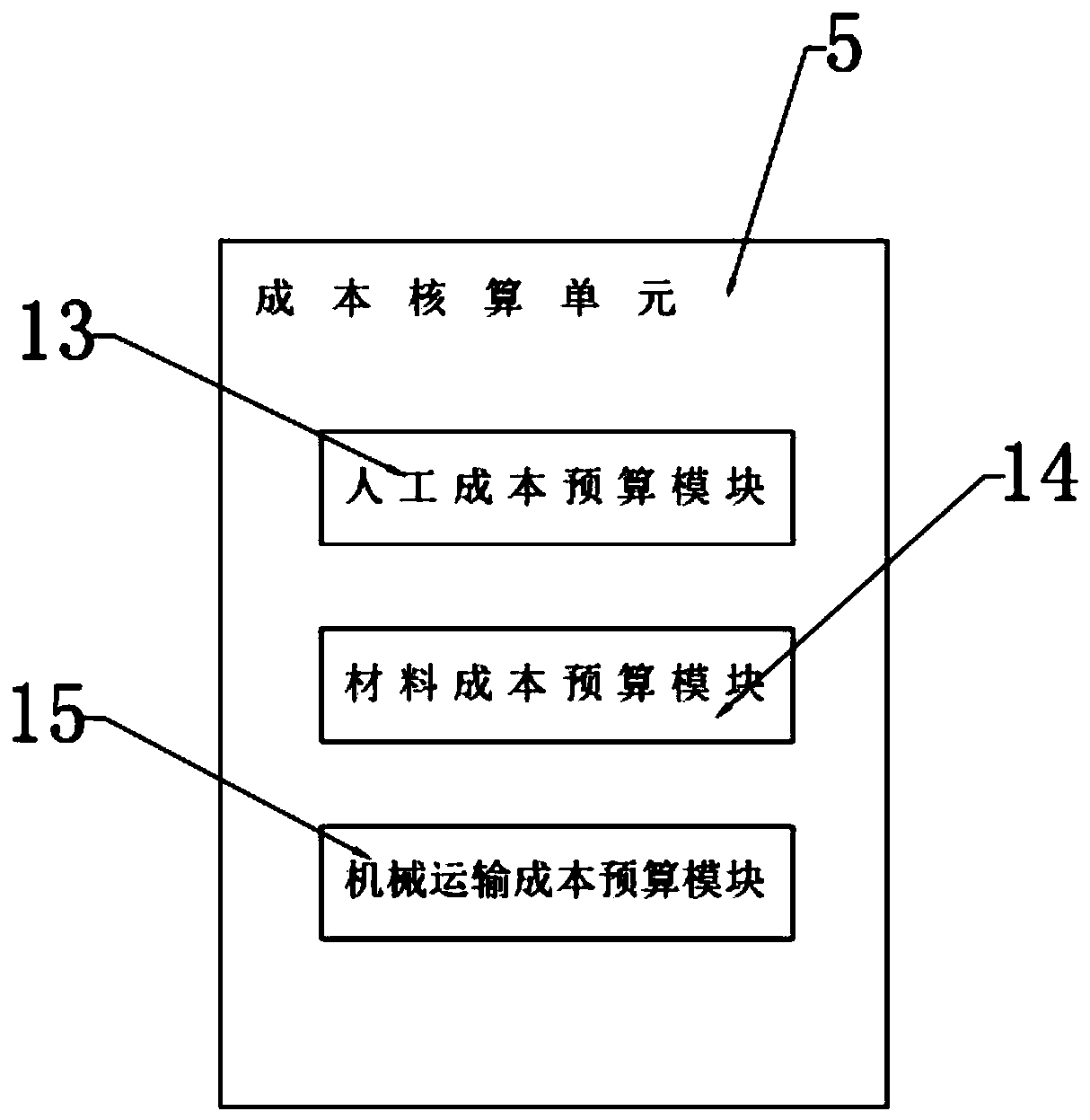

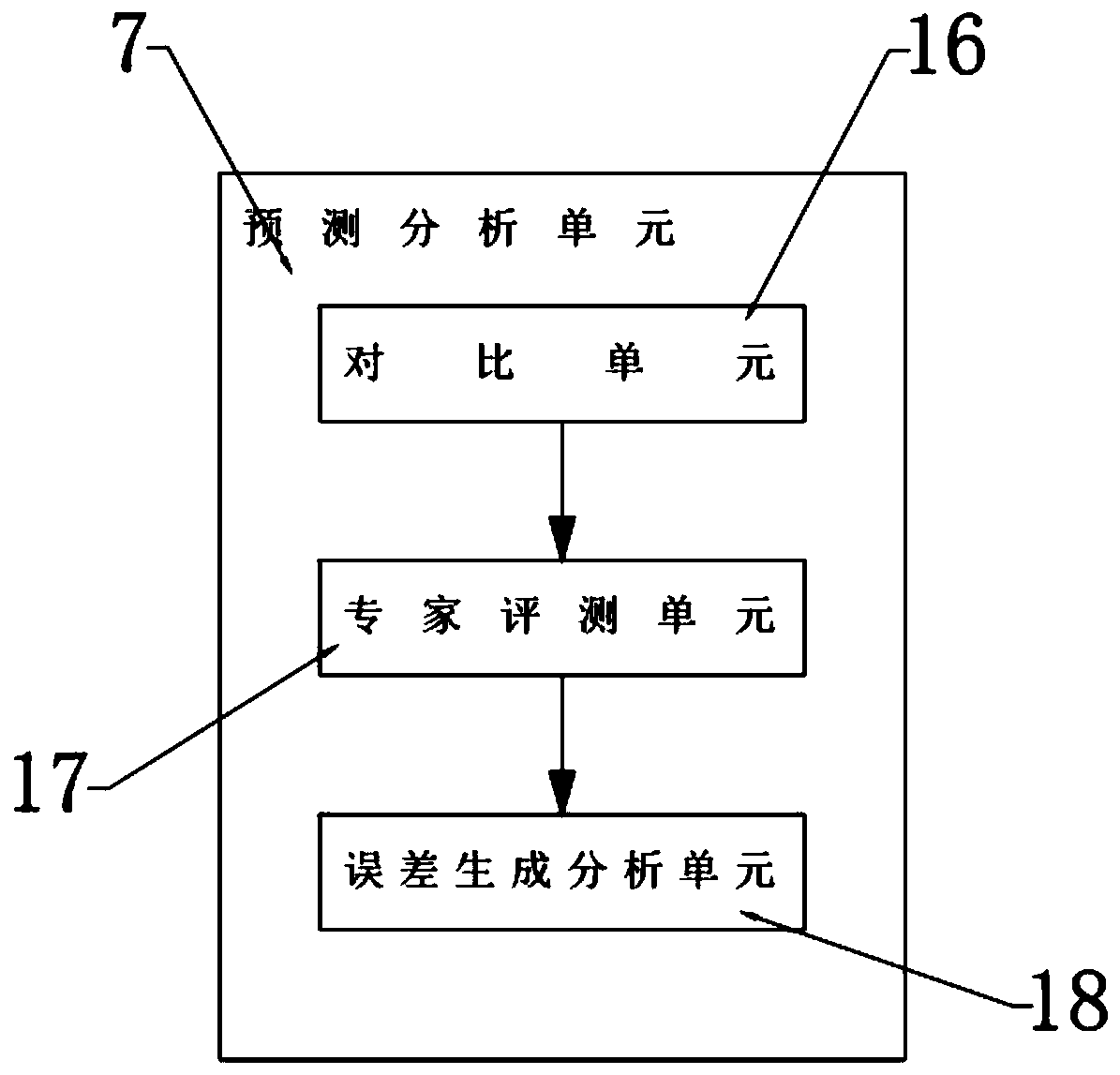

InactiveCN110189005AQuick calculationQuick alertForecastingDigital data protectionEconomic managementData sorting

The invention relates to the technical field of economic management control, in particularly relates to a coal mine enterprise cost control system. The system comprises a central processing unit, thecentral processor is electrically connected with a model construction unit, an enterprise data acquisition unit, a cost accounting unit, a risk early warning and evaluation unit and a data arrangementunit. The input end of the model building module is electrically connected with the output end of the verification login unit, the cost accounting unit is connected with the prediction analysis unitthrough data in the database, and the output end of the prediction analysis unit is connected with the input end of the central processor; the data sorting unit is connected with the data storage unitand the data transmission unit separately, and the output end of the data transmission unit and the output end of the risk early warning evaluation unit are both connected with the input end of the client side. By arranging the cost accounting unit, the prediction analysis unit and the risk early warning evaluation unit, the enterprise cost can be quickly accounted and alarmed, and a manager canadjust the economic management cost real-timely.

Owner:LIAONING TECHNICAL UNIVERSITY

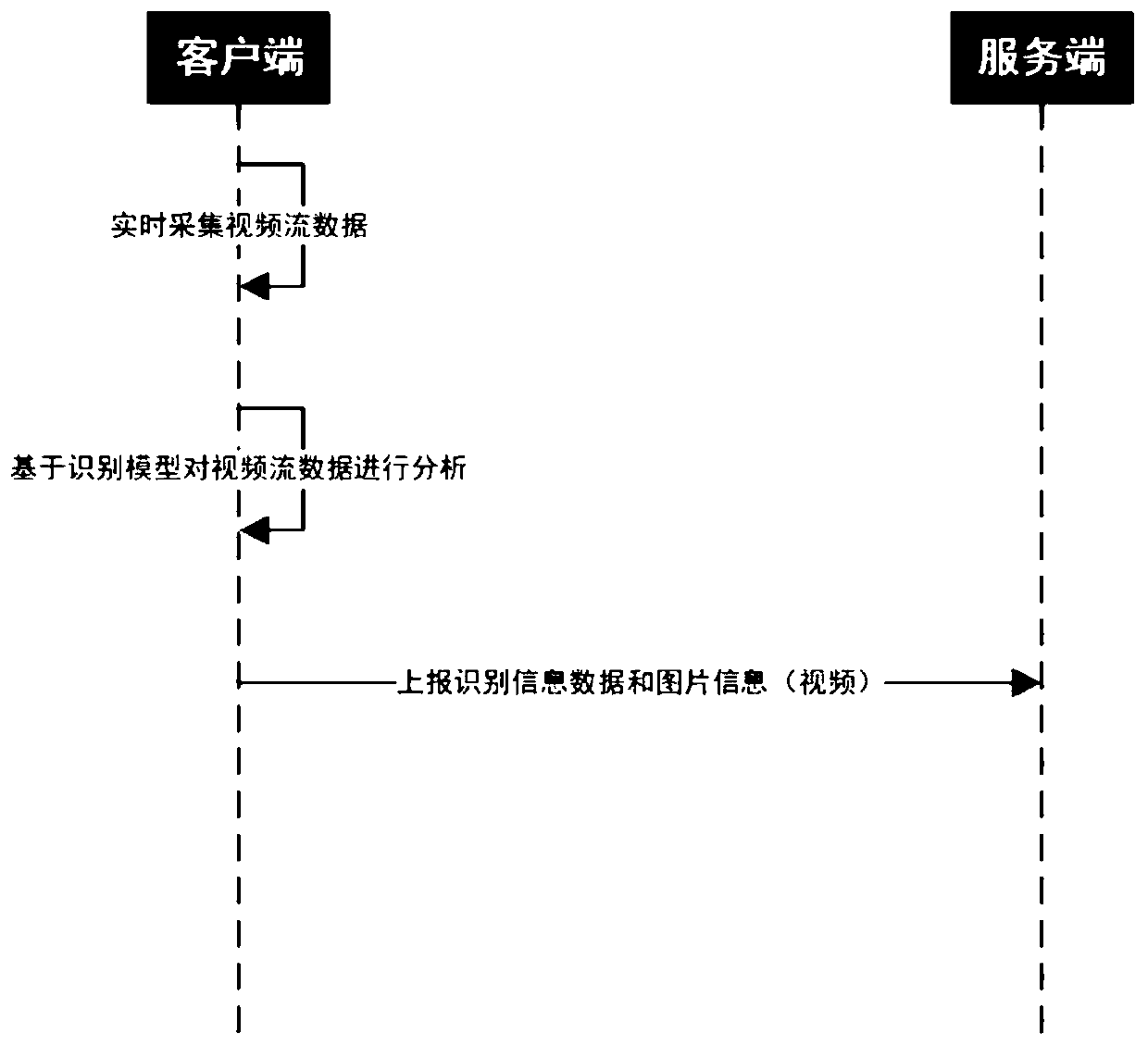

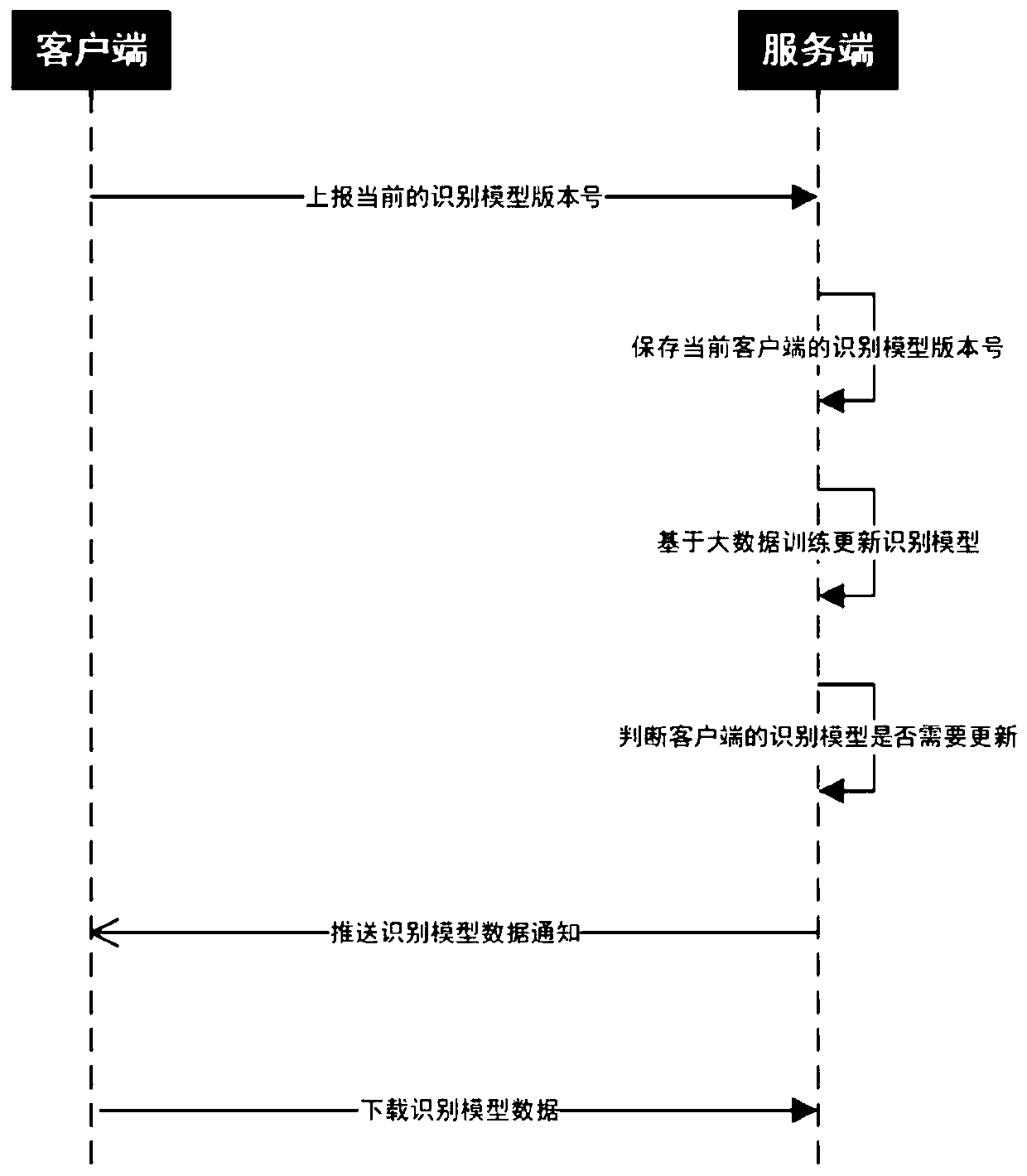

Navigation method and system based on real-time analysis

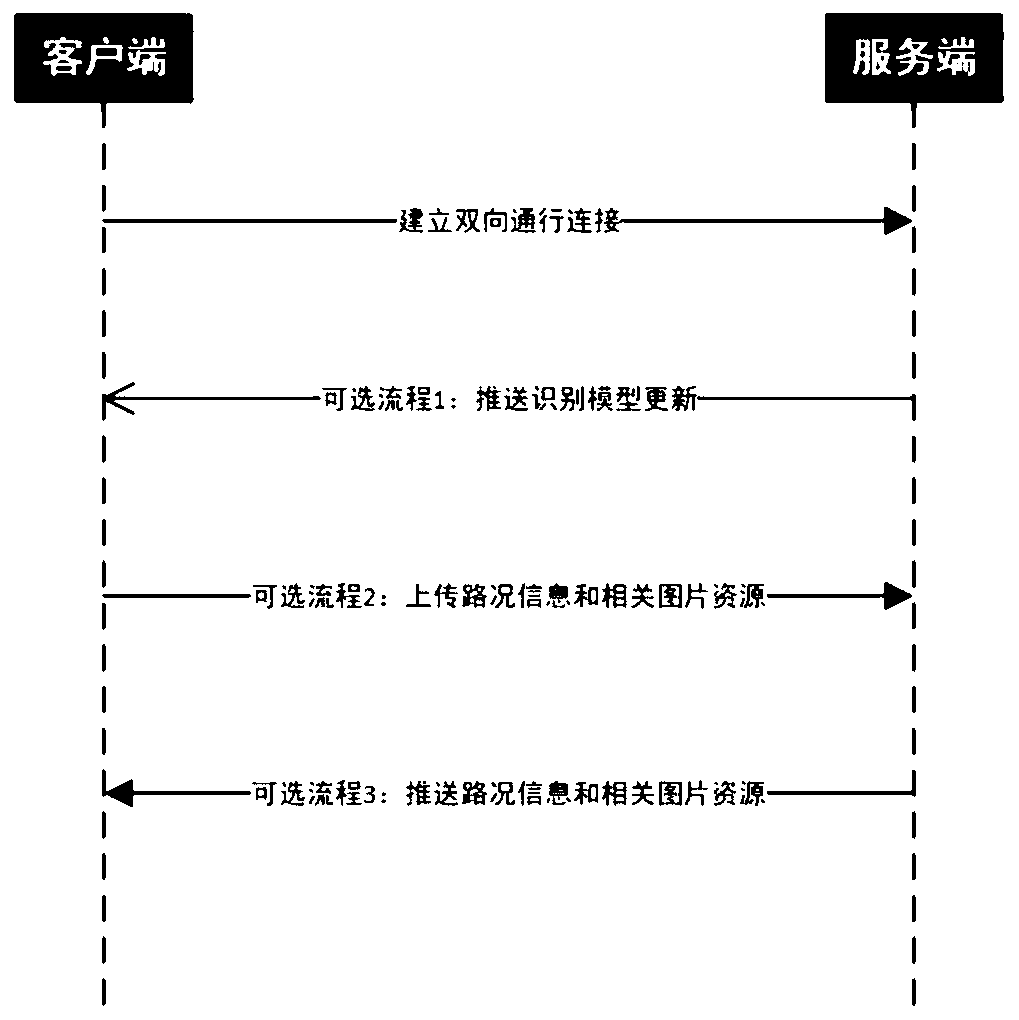

InactiveCN110417809AEconomic benefit maximizationEfficient Service DeploymentRoad vehicles traffic controlTransmissionReal time analysisEdge computing

The invention discloses a navigation method based on real-time analysis, which comprises the following steps: bidirectional communication connection is established between a client and a server; the client collects road condition data in real time for road condition analysis to obtain an effective identification result; the server receives the effective identification result and matches the corresponding effective identification result according to subscription information of other clients; and the other clients receive the effective identification result matched with the subscription information sent by the server. The beneficial effects of the invention are that the method can achieve the recognition of the sudden real-time road condition information to the maximum degree, and transmitsthe recognized diversified information to a target user; edge computing power is fully utilized to perform efficient and low-cost service deployment, and economic benefits of service providers are maximized while convenience is brought to automobile users.

Owner:西藏宁算科技集团有限公司

Equipment for efficiently converting straw waste

InactiveCN113294786ARealize solid-liquid separationPlay a role in squeezingIncinerator apparatusRotary pressEconomic benefitsProcess engineering

The invention discloses equipment for efficiently converting straw waste. The equipment comprises an outer box body, wherein a feeding port and an impurity outlet are formed in the side wall of the outer box body; a feeding plate is fixedly arranged at the inner wall of the outer box body and is located at the feeding port; a pair of electric rollers are arranged above the feeding plate; a supporting plate is fixedly arranged at the inner wall of the outer box body; an inner box body is fixedly arranged in one end of the supporting plate; a material distributing mechanism is arranged between the support frame and the feeding plate; and a cylindrical box body is fixedly arranged at the side wall of the outer box body and is located under the supporting plate. The equipment for efficiently converting straw waste relates to the technical field of straw conversion, the material distribution mechanism is arranged in the outer box body, subsequent processing is facilitated, impurities are discharged at the same time, the grinding roller can grind the materials, and solid-liquid separation of straws is achieved. Compared with traditional straw incineration, the equipment provided by the invention achieve double functions of straw squeezing and incineration, so that economic benefits are maximized.

Owner:辽宁兴东科技有限公司

Anaerobic biogas biological desulfurization treatment device and method

PendingCN113430025AHigh desulfurization removal rateReduce processing costsGaseous fuelsPeristaltic pumpPlate heat exchanger

The invention provides an anaerobic biogas biological desulfurization treatment device and method. The anaerobic biogas biological desulfurization treatment device comprises a cold drying system, a biological desulfurization system and a pressurization system; the cold drying system comprises a coarse filter, a tubular heat exchanger and a gas-liquid separator; the biological desulfurization system comprises a high-pressure fan, a desulfurization tower, a nutrient solution storage tank, a circulating pump, a peristaltic pump and a plate heat exchanger; the pressurization system comprises a gas storage tank, a Roots blower and a fine filter; the device has the advantages that 1, the biological desulfurization removal rate is high and can reach 95% or above; and the treatment cost is low and is about 0.02 yuan / m3 of biogas; 2, the process flow is short, the automation degree is high, and unattended management can be realized; 3, the H2S-removed biogas can be used for power generation or can be merged into a household gas pipe network after being further treated, so that the economic benefit is maximized; and 4, the invention provides a new biogas biological desulfurization technology, and provides a new thought for biogas engineering.

Owner:BIOLAND ENVIRONMENTAL TECH GRP CORP

Auxiliary Pit Type Buffer Structure in Railway Tunnel

ActiveCN104453935BReduce pressure peaksMitigate micro pressure wave effectTunnelsRailway tunnelEconomic benefits

The invention discloses an auxiliary pit type buffering structure in a railway tunnel. The auxiliary pit type buffering structure comprises a plurality of auxiliary pit chambers and second retaining plates; the auxiliary pit chambers are positioned on two sides of the tunnel, are arranged along the axial direction of the tunnel at intervals and are communicated with the tunnel through open surfaces, at least one first retaining plate parallel to the corresponding open surface is arranged at each auxiliary pit chamber, two ends of each retaining plate are fixedly connected with the top surface and the bottom surface of the corresponding auxiliary pit chamber respectively, and the sum of the area of the first retaining plates in the same auxiliary pit chamber is smaller than the area of the open surface of the auxiliary pit chamber; one end of each second retaining plate is connected with the corresponding first retaining plate, and the other end of each second retaining plate extends into the corresponding auxiliary pit chamber. The auxiliary pit type buffering structure has the advantages that the retaining plates are arranged in the auxiliary pit chambers, a compression wave is dispersed, and the pressure peak of a micro compression wave is decreased, so that the micro compression wave effect of a tunnel entrance is remarkably relieved, the tunnel can be renovated at a low cost, the micro compression wave effect of the operational tunnel entrance is relieved, and the buffering structure has remarkable economic benefit and high practicability; the buffering structure is applicable to high speed railways, interurban railways and city field railway tunnels.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

A kind of comprehensive recycling method of waste lithium-ion battery

ActiveCN112267024BEconomic benefit maximizationSave resourcesWaste accumulators reclaimingLithium oxides/hydroxidesLithium hydroxideLithium carbonate

Owner:JINGMEN GEM NEW MATERIAL

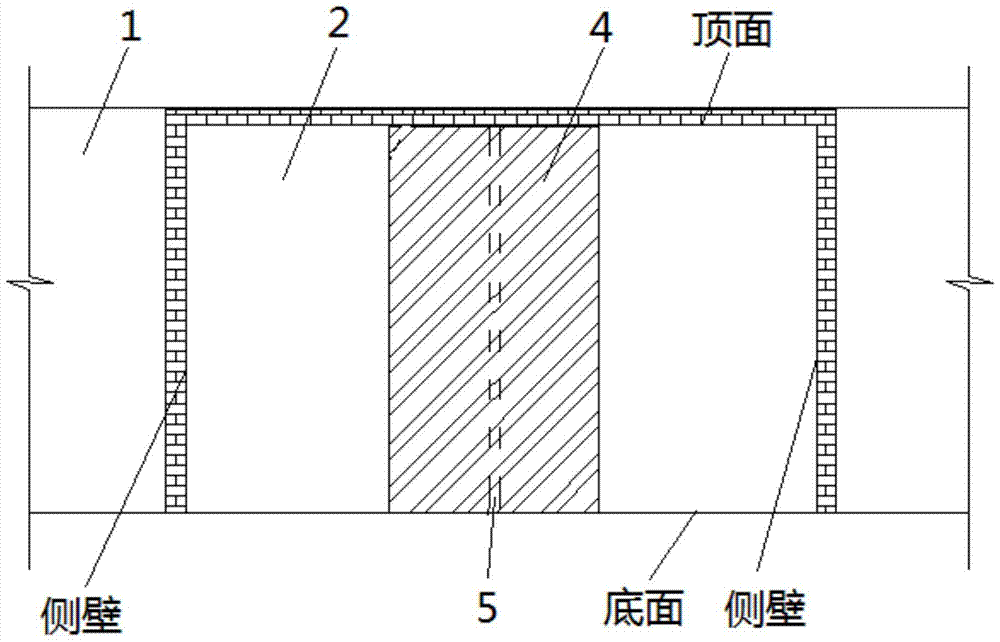

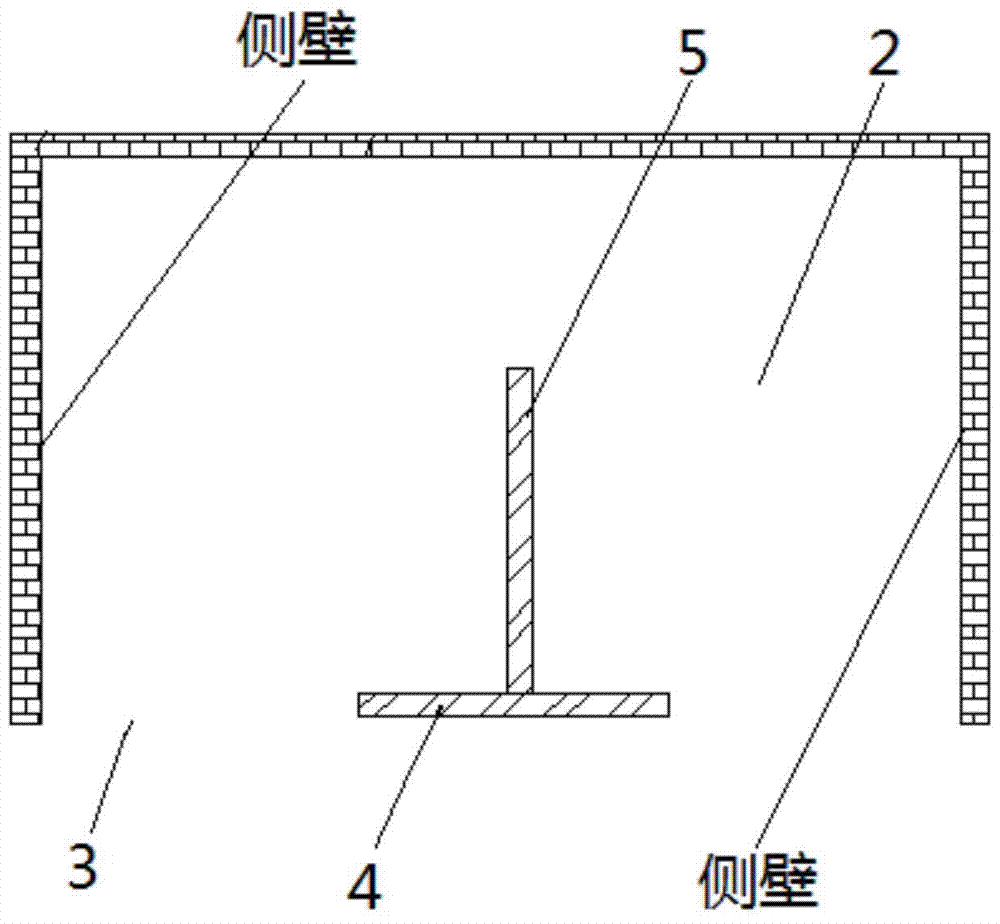

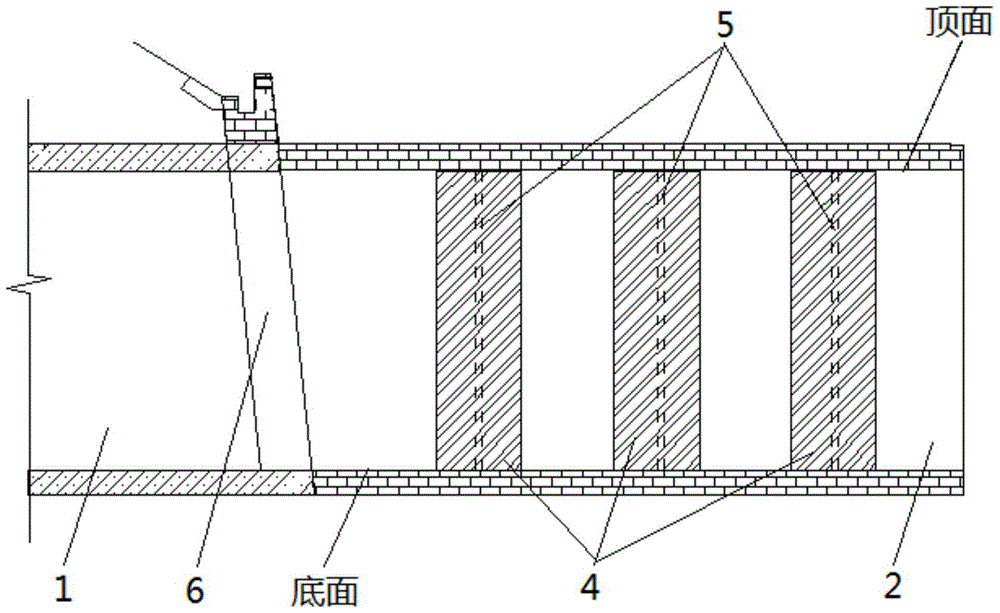

Partition-type buffer structure at the exit of railway tunnel

ActiveCN104500088BMitigate micro pressure wave effectReduce pressure peaksTunnelsRailway tunnelEconomic benefits

The invention discloses a railway tunnel outlet clapboard type buffering structure. A mold box is arranged on each of the two sides of a tunnel outlet; the side wall, close to the middle line of a tunnel, of each mold box is an opening surface; at least one first clapboard parallel to the opening surface is arranged at each mold box; the two ends of each first clapboard are fixedly connected with the top surface and the bottom surface of the corresponding mold box; the sum of the area of the first clapboards at the same mold box is smaller than the area of the opening surface of the mold box; second clapboards are connected with the first clapboards and extend into the mold boxes. Due to the fact that the mold boxes are arranged at the tunnel outlet and the clapboards are arranged at the mold boxes, the defect of tunnel outlet micropressure wave effect due to disability of building a complex buffering structure because of the restraint of landform is relieved, the clapboards can distribute compression wave, the propagation energy of the compression wave is separated, the pressure peak of the micropressure wave is reduced, the micropressure wave effect at the outlet can be obviously relieved, under the condition of the same construction cost, the pressure peak of the micropressure wave at the outlet is greatly reduced, economic benefit is maximized, and the structure has relatively high practicability.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

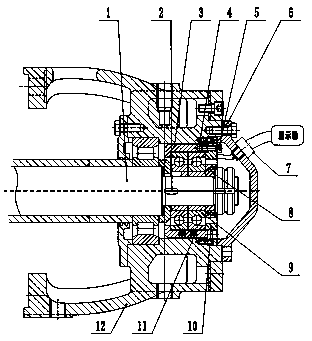

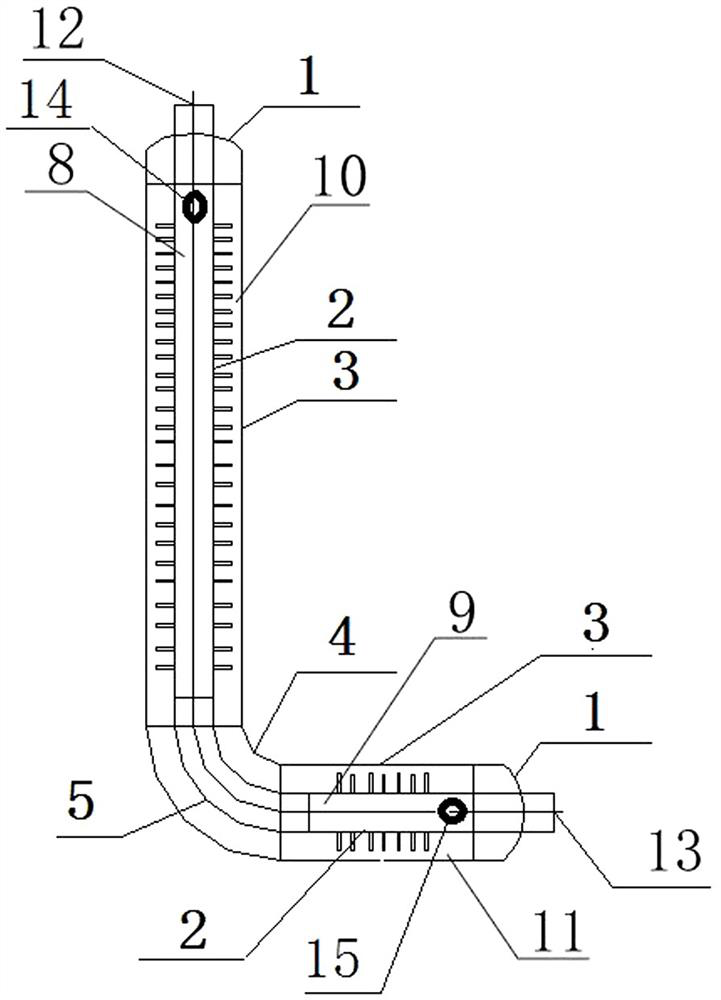

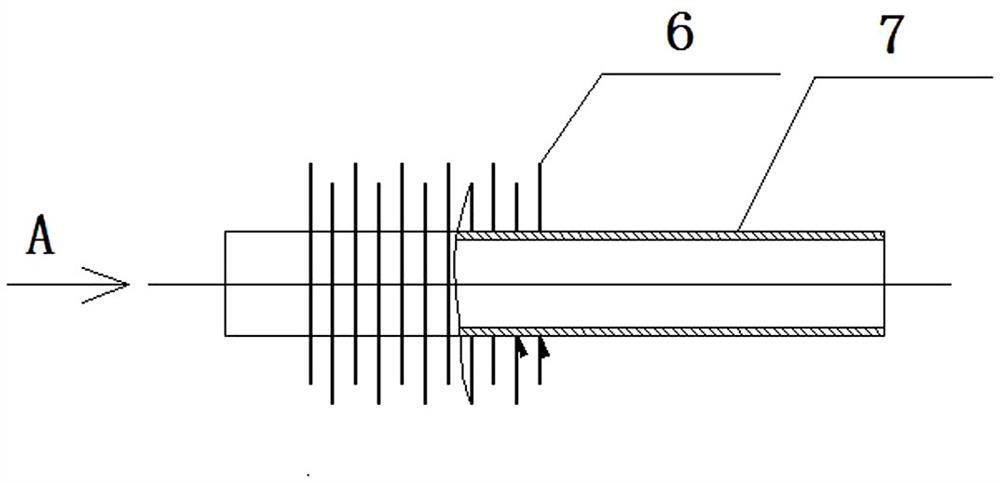

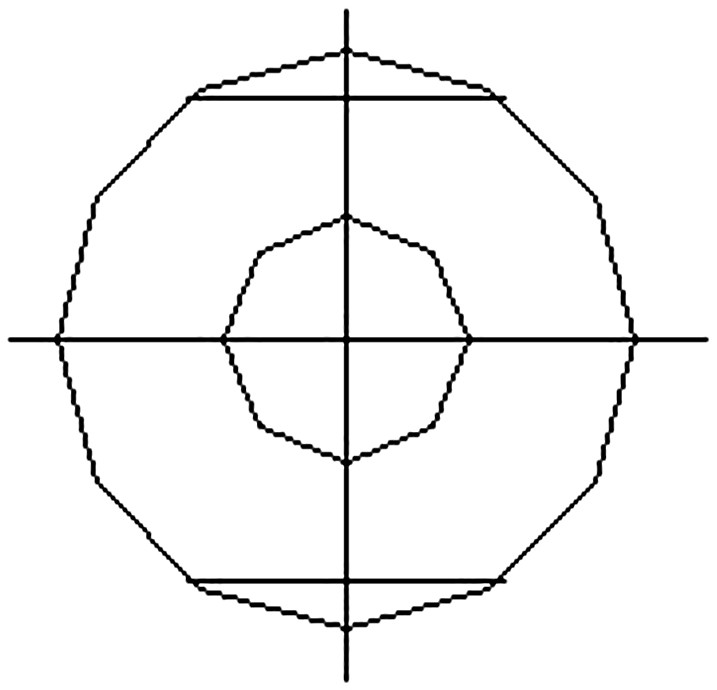

Pump axial force online measuring device and method

ActiveCN106286379BAccurate online measurementExtended service lifePump componentsPumpsEconomic benefitsThrust bearing

The invention discloses an online measuring device for pump axial force. The online measuring device comprises a spindle. A bearing inner sleeve is mounted on the spindle. A bearing outer sleeve sleeves the bearing inner sleeve. A thrust bearing is arranged between the bearing inner sleeve and the bearing outer sleeve. A sensor is mounted in a bearing body and fastened to the bearing outer sleeve through a screw. A cylindrical pin is arranged on one side of the sensor. The other side of the sensor is provided with a hole-free end cover. The cylindrical pin and the hole-free end cover can prevent the sensor from having radial and axial movements. The invention further discloses an online measuring method for pump axial force. The online measuring device and method has the advantages that the signal capturing time interval of the device and method is 0.05 second, the device and method is high in precision and high in sensitivity, online measuring of the pump axial force can be performed accurately, the rigidity of a rotor part can be increased, the service life of a pump can be prolonged, and the economic benefits of the pump can be maximized.

Owner:CHANGSHA CANON GENERAL PUMPS

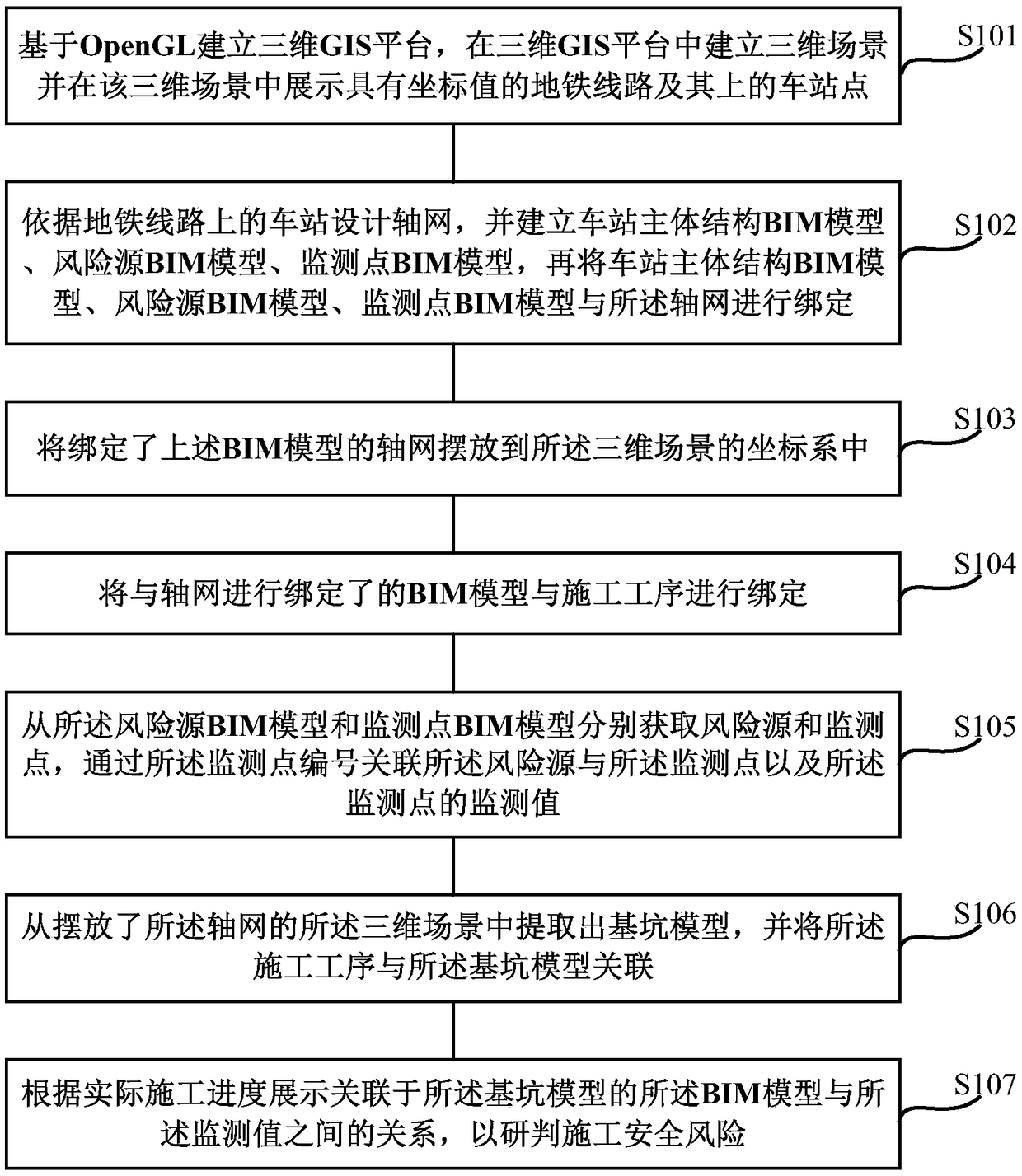

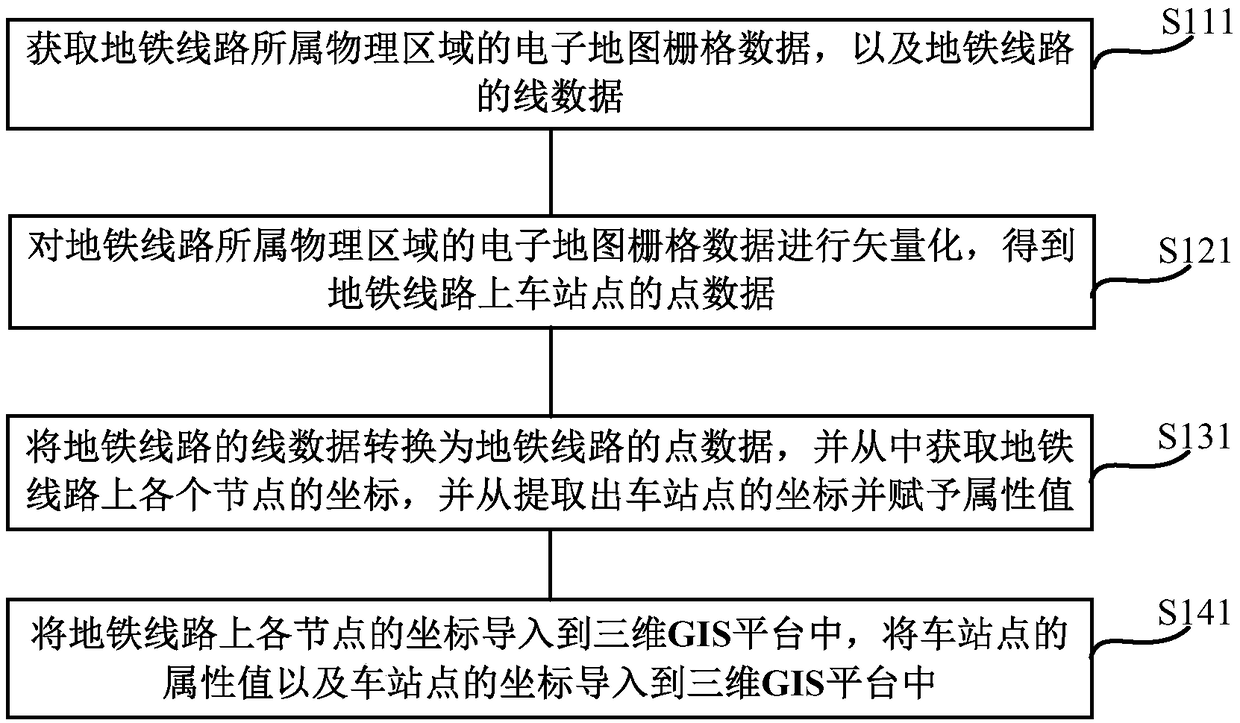

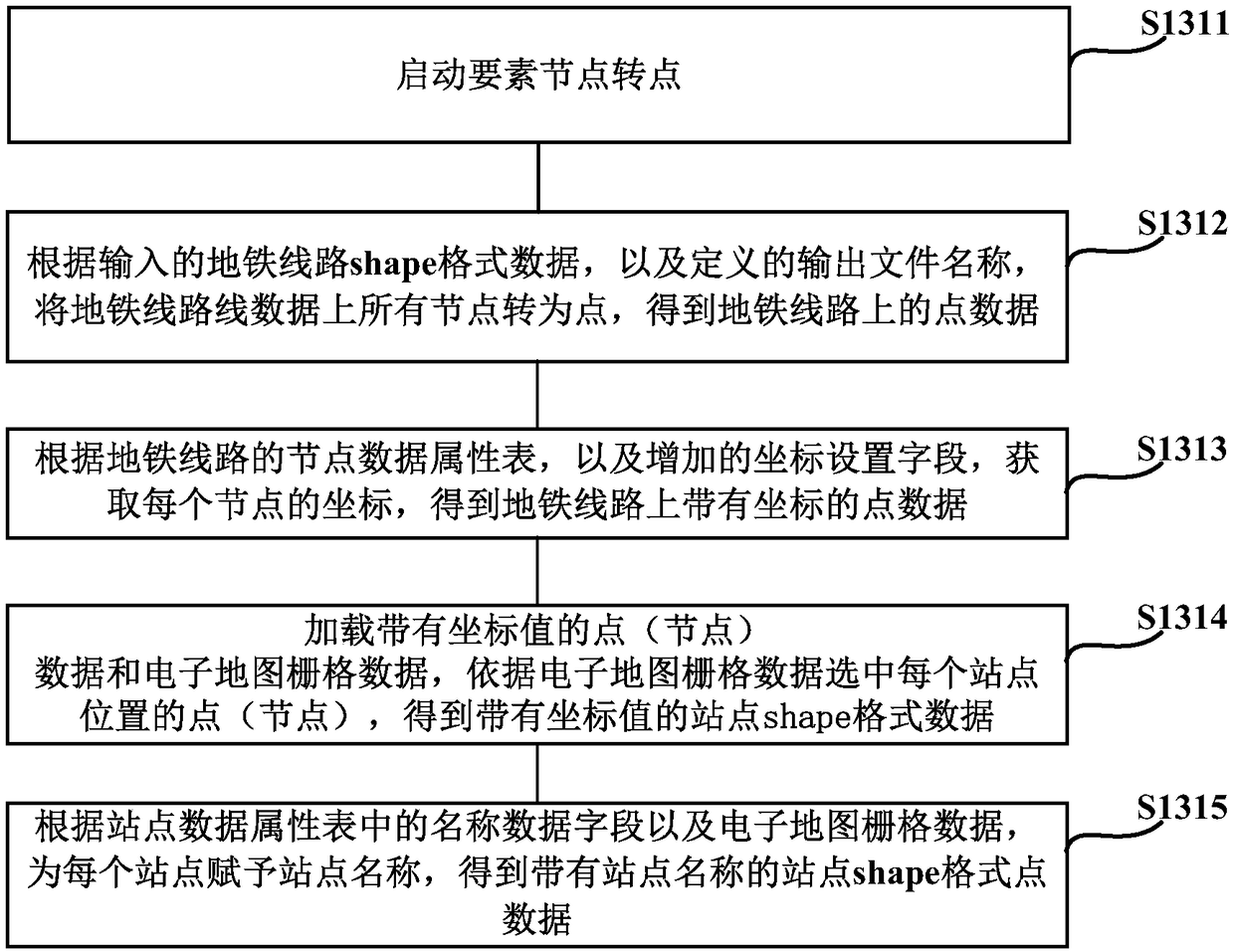

Method and device for judging construction safety risks

ActiveCN107688908BEnsure safetyImprove the efficiency of risk managementResourcesMonitoring siteSafety risk

An embodiment of the invention provides a method and apparatus for researching and determining construction security risk. The method comprises the following steps: arranging an axis net in a three-dimensional scene, binding the axis net to a BIM model, binding the BIM model to a construction procedure, wherein the BIM model comprises a BIM model of a car station main body, a risk source BIM modeland a monitoring site BIM model; separately acquiring a risk source and a monitoring site from the risk source BIM model and the monitoring site BIM model, associating the risk source with the monitoring site and associating the risk source with a monitoring value of the monitoring site according to a number of the monitoring site; extracting a pit model from the three-dimensional scene with theaxis net, and associating the construction procedure with the pit model; and displaying a relationship between the BIM model associated with the pit model and the monitoring value according to an actual construction progress so as to research and determine the construction security risk, wherein the actual construction progress is associated with the construction procedure. By adopting the methodand apparatus for researching and determining the construction security risk, the monitoring value can be reasonably combined with the BIM model in real time, so that the security risk can be controlled and positioned according to the actual construction progress.

Owner:北京城乡建设集团有限责任公司 +1

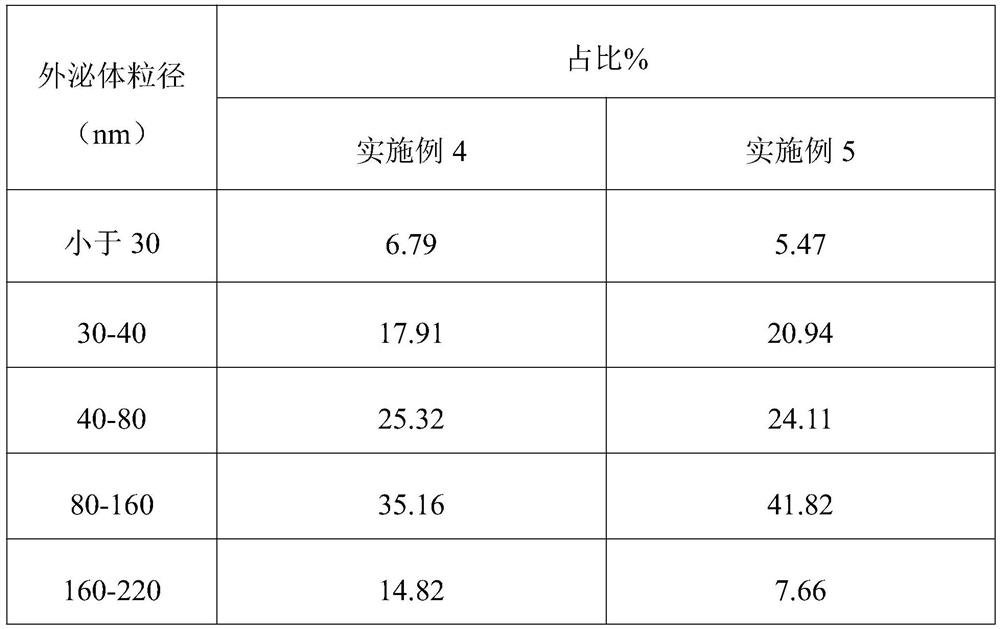

Separation method and application of hair follicle stem cell exosome

PendingCN114540293AReduce adhesionAvoid blockageCell dissociation methodsSkeletal/connective tissue cellsPolyvinyl alcoholMedicine

The invention provides a separation method and application of a hair follicle stem cell exosome, and relates to the technical field of biomedicine. According to the method, polylactic acid and polyvinyl alcohol are used as polymerization raw materials for polymerization to prepare porous microspheres, and the porous microspheres are filled in a size exclusion column, so that the adhesion effect of exosomes can be effectively reduced, the blockage condition is avoided, the separation time can be effectively shortened, and the separation efficiency is improved; a compact and uniform porous structure is formed inside and on the surface of the microsphere through sodium alginate, and the separation effect can be effectively improved, so that the purity and the concentration of the exosome are improved, and an expected effect is achieved; the preparation method of the porous microspheres is simple and convenient, the effect of batch industrial production is easily achieved, and economic benefit maximization is achieved. The exosome separated from the hair follicle stem cells has a good alopecia prevention and treatment effect.

Owner:上海禺泽生物科技有限公司

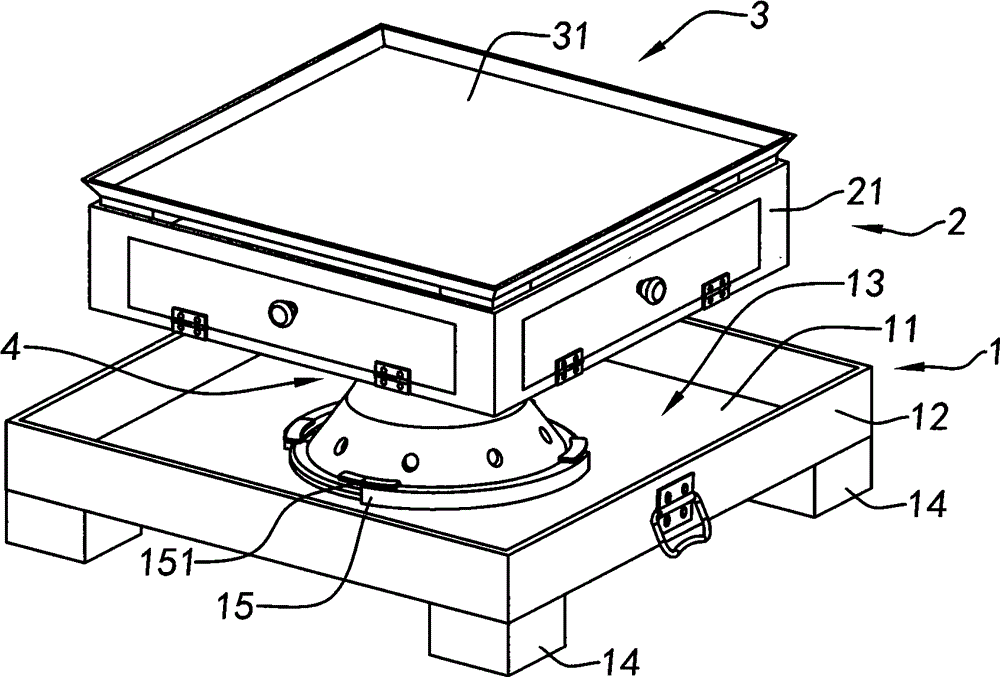

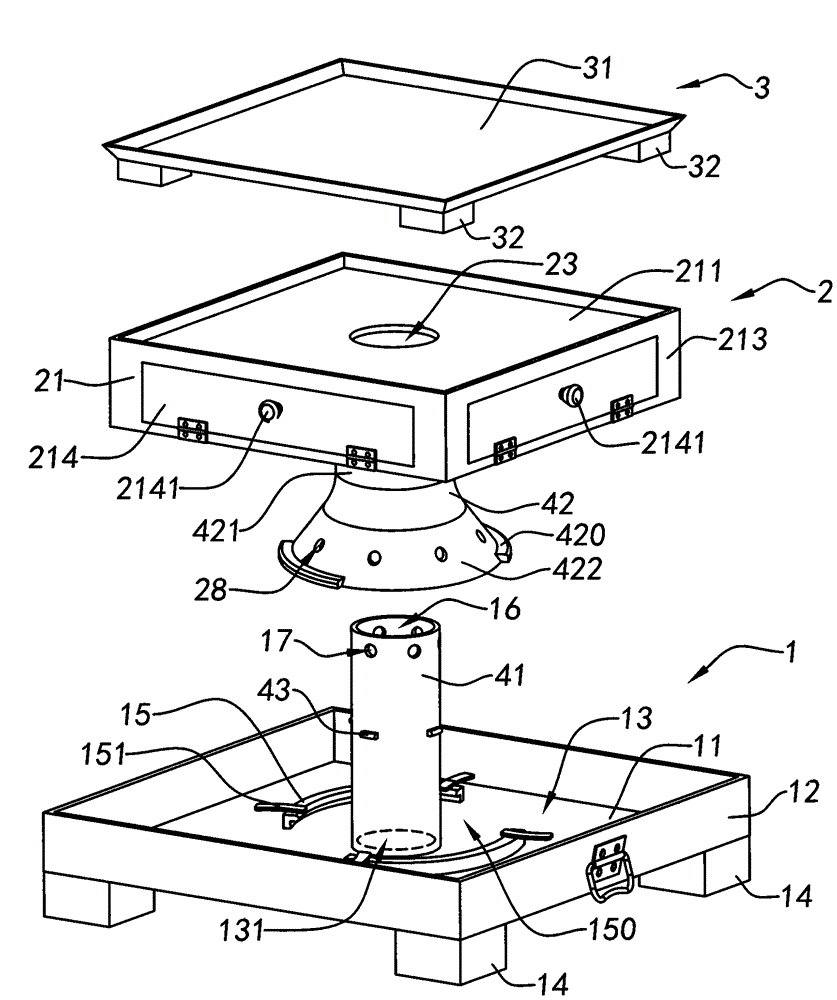

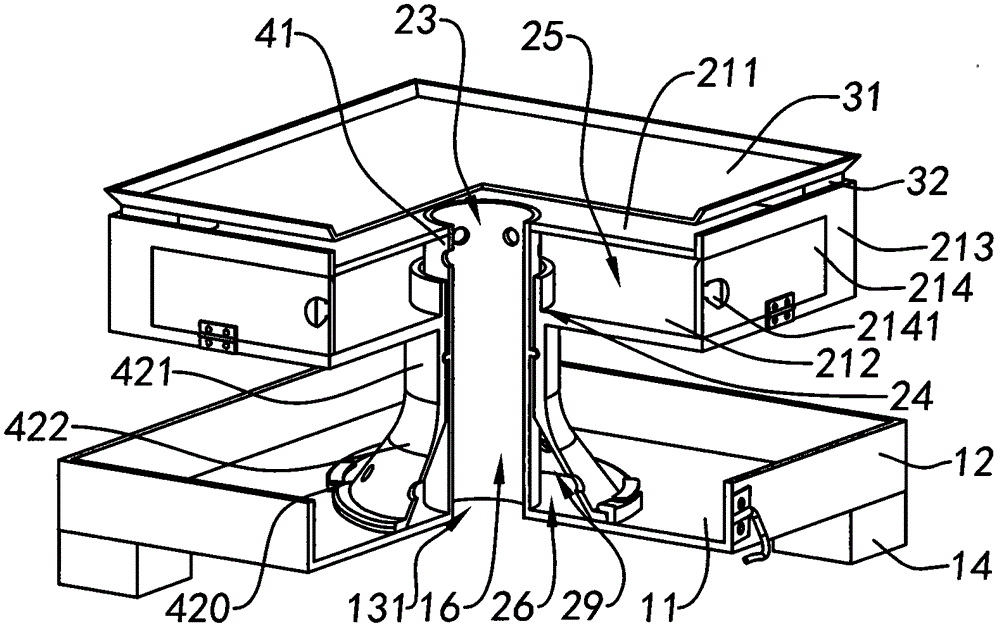

Multifunctional stove

The invention relates to a multifunctional stove. According to the multifunctional stove, a steaming drawer is connected to a base in a rotary mode through a connecting part, the connecting part is provided with a steam channel and a hot air channel, the base is heated through a heating source, so that steam is generated by water in an accommodating cavity of the base, the steam enters a steaming chamber of the steaming drawer through the steam channel, food in the steaming chamber is heated through the steam, the hot air channel faces a top plate located above the steaming drawer, hot air generated by the heating source enters the hot air channel, so that the top plate is heated effectively, and then various cooking modes are achieved through various heating forms.

Owner:梁坤铉

Novel low-temperature liquid jacket finned tube type vaporization device

PendingCN113008055AEconomic benefit maximizationSimple structureHeat exchanger casingsStationary tubular conduit assembliesEngineeringMechanical engineering

A novel low-temperature liquid jacket finned tube type vaporization structure is composed of an outer tube and a finned tube arranged in the outer tube. The finned tube is composed of a first finned tube body and a second finned tube body, wherein the first finned tube body and the second finned tube body are vertically arranged, a finned tube compensation elbow is arranged at the joint of the first finned tube body and the second finned tube body, an L-shaped inner tube is formed among the first finned tube body, the second finned tube body and the finned tube compensation elbow, the outer tube is also provided with a first outer tube body, a second outer tube body and an outer tube compensation elbow which are the same as the inner tube in structure, a sampling gas outlet is formed in the first finned tube body, a sampling liquid inlet is formed in the second finned tube body, a heat source gas outlet is formed in the first outer tube body, a heat source gas inlet is formed in the second outer tube body, and tube caps are arranged at the ends of the outer tube respectively. The novel low-temperature liquid jacket finned tube type vaporization structure has the advantages of being simple in structure, high in practicability, low in cost, safe in performance, convenient to install and the like.

Owner:HANGZHOU HANGYANG

Stone-chip concrete mortar

InactiveCN106517921AImprove the overallImprove workabilitySolid waste managementPebbleUtilization rate

The invention discloses stone-chip concrete mortar. Components of the stone-chip concretemortar comprise water, cement, sand and stone powder, wherein the stone powder is the powder generated during the process of scree crushing; according to mass part, the proportions of the water, the cement, the sand and the stone powder are as follows: 100 parts of the water, 200 to 300 parts of the cement, 150 to 230 parts of the sand and 10 to 20 parts of the stone powder; the grain diameter of the stone powder is less than 0.08mm. The concrete mortar provided by the invention takes the stone powder as the important component, not only can the utilization rate of natural mineral resources be improved, but also the pollution to the environment caused by building construction is reduced.

Owner:四川中核艾瑞特工程检测有限公司 +1

A preparation method of seafood fermented soy sauce with outstanding umami taste through rapid fermentation

The invention relates to a production method of quickly-fermented high-umami seafood fermented soybean sauce, including; preparing small-molecular fish protein enzymatic hydrolysate by means of efficient biological enzymatic hydrolysis, and jointly fermenting through the small-molecular fish protein enzymatic hydrolysate with soybean meal and bran to obtain the seafood fermented soybean sauce. The method is low in cost and has a short production cycle, only 30 d, umami of the obtained soybean sauce can be improved, added value of low-value fishes can also be improved, low-value marine animal resources can be comprehensively utilized, and innovation is also made to zero addition of flavorings; meanwhile, the method of the invention is different from common low-salt solid fermented soybean sauces, the addition of the fish protein enzymatic hydrolysate enables the seafood soybean sauce to be healthy, environment-friendly, low in cost, good in property and excellent in umami, and compared with like products, the seafood soybean sauce will be popular with consumers owing to the excellent flavor.

Owner:TIANJIN UNIV OF SCI & TECH

Railway tunnel outlet clapboard type buffering structure

ActiveCN104500088AMitigate micro pressure wave effectReduce pressure peaksTunnelsRailway tunnelEconomic benefits

The invention discloses a railway tunnel outlet clapboard type buffering structure. A mold box is arranged on each of the two sides of a tunnel outlet; the side wall, close to the middle line of a tunnel, of each mold box is an opening surface; at least one first clapboard parallel to the opening surface is arranged at each mold box; the two ends of each first clapboard are fixedly connected with the top surface and the bottom surface of the corresponding mold box; the sum of the area of the first clapboards at the same mold box is smaller than the area of the opening surface of the mold box; second clapboards are connected with the first clapboards and extend into the mold boxes. Due to the fact that the mold boxes are arranged at the tunnel outlet and the clapboards are arranged at the mold boxes, the defect of tunnel outlet micropressure wave effect due to disability of building a complex buffering structure because of the restraint of landform is relieved, the clapboards can distribute compression wave, the propagation energy of the compression wave is separated, the pressure peak of the micropressure wave is reduced, the micropressure wave effect at the outlet can be obviously relieved, under the condition of the same construction cost, the pressure peak of the micropressure wave at the outlet is greatly reduced, economic benefit is maximized, and the structure has relatively high practicability.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com