Pump axial force online measuring device and method

A technology for measuring device and axial force, which is applied to parts, pumps, pump components, etc. of pumping devices used for elastic fluids, can solve the problems of inaccurately knowing the axial force of pumps, etc., and maximize economic benefits and improve Rigidity, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below by specific examples.

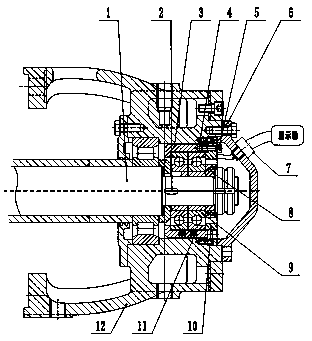

[0020] A pump axial force online measuring device, as attached figure 1 As shown, including the main shaft 1, the main shaft 1 is equipped with a bearing inner sleeve 8, and the bearing inner sleeve 8 is also covered with a bearing outer sleeve 3. There is a thrust bearing between the bearing inner sleeve 8 and the bearing outer sleeve 3, and the thrust bearing can use angular contact balls. The bearing 9 and the sensor are installed in the bearing body 12, and are fastened on the bearing outer shell by screws 5. A cylindrical pin 10 is arranged on one side of the sensor, and a non-porous end cover 6 is arranged between the sensors. Parallel pins and blank end caps prevent radial and axial movement of the sensor.

[0021] The transmitter 7 can also be set, the transmitter is connected to the sensor, the other end of the transmitter is connected to the display and the host, the host automatica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com