Gas well drainage and production process evaluation system integration and method

An evaluation system and evaluation method technology, applied in the field of gas well drainage and production process evaluation system integration, can solve problems such as insufficient utilization of test platforms, waste of costs, etc., and achieve the effects of saving device configuration costs, convenient operation, and reducing device space occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

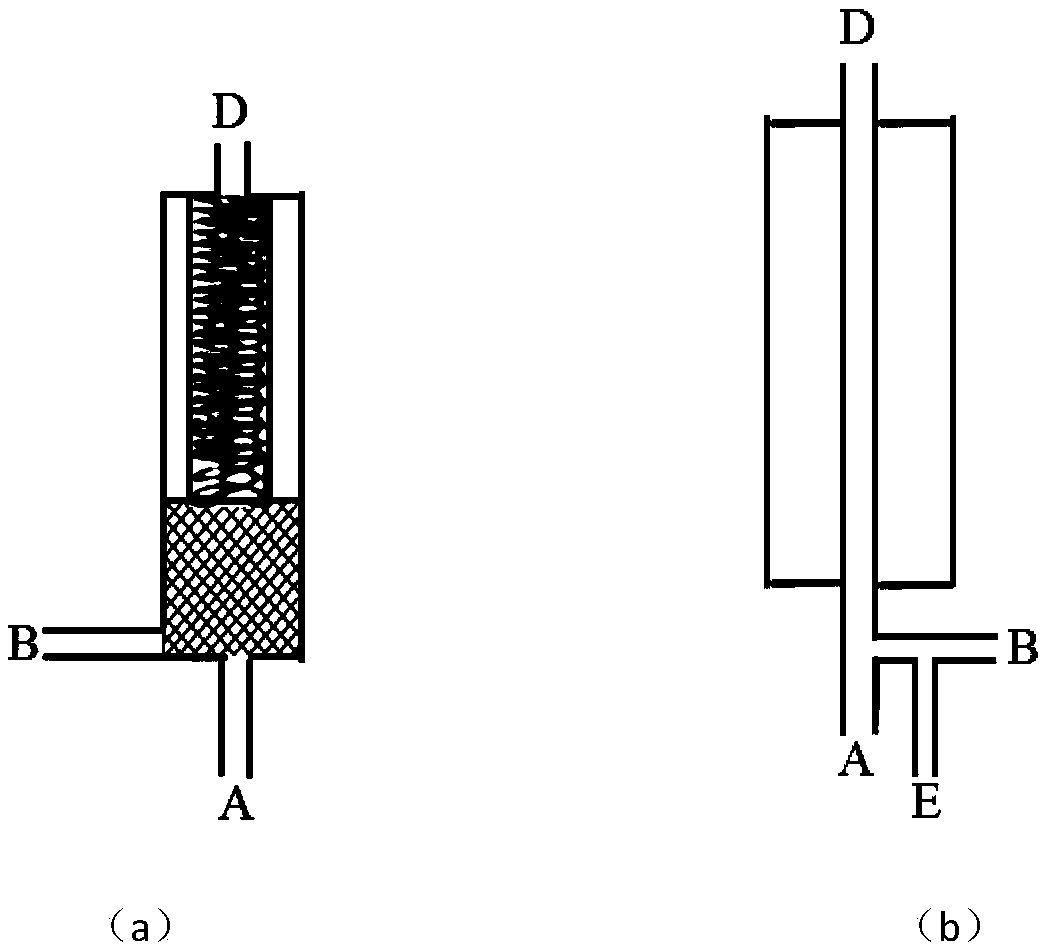

[0037] Example 1: Downhole cyclone separator gas-liquid separation efficiency method;

[0038] The separation efficiency of the downhole cyclone separator is calculated by experimentally measuring the gas output from the gas phase outlet after separation and the gas output from the liquid phase outlet of the separator. The calculation formula is as follows:

[0039]

[0040] Among them, η is the gas phase separation efficiency of the cyclone separator; Q g(d) Is the gas output after separation; Q g(l) It is the gas output of the liquid phase outlet of the separator.

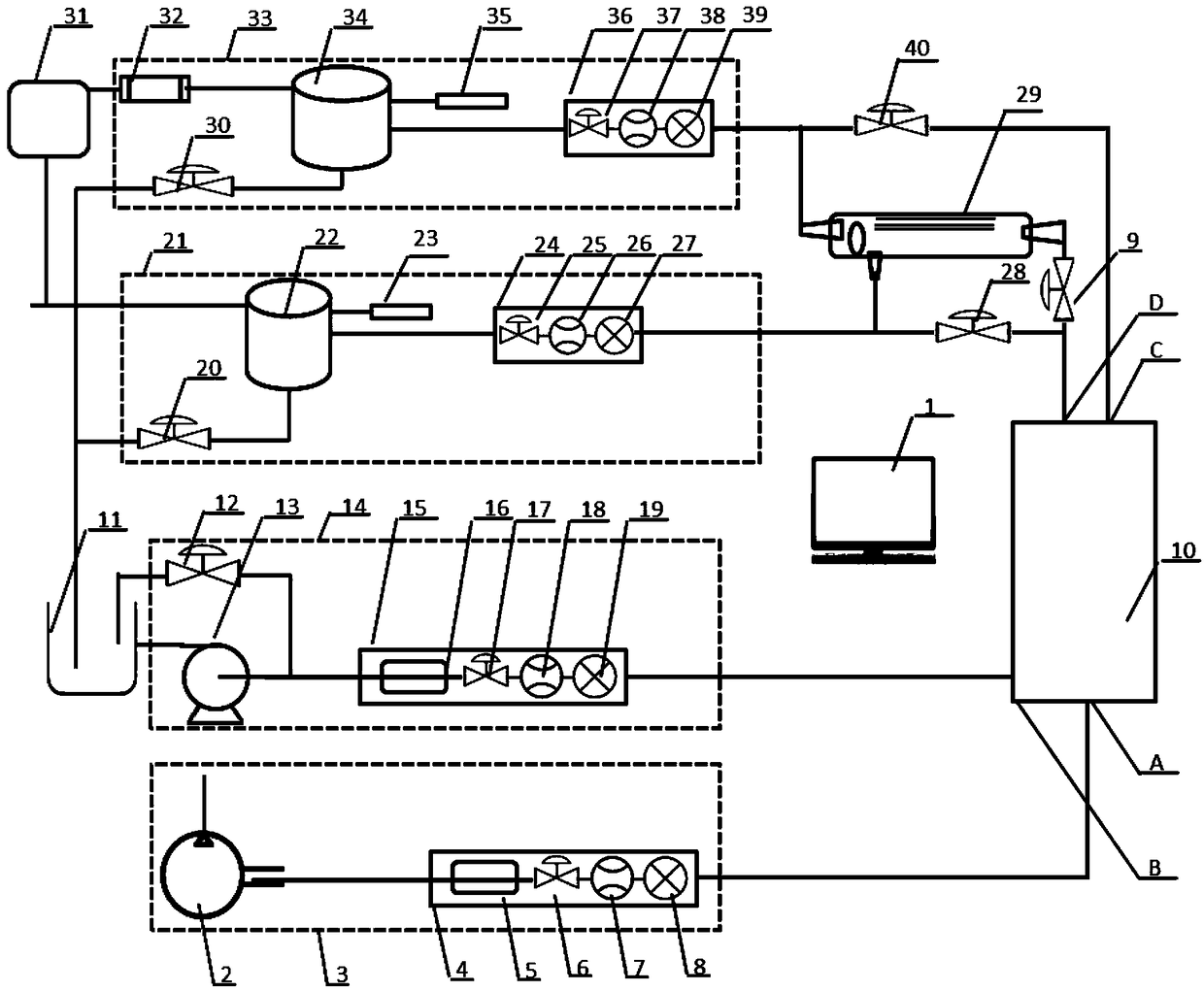

[0041] Experiment: Install a gas-liquid separator in the gas well drainage process evaluation device 10; close the valve 9. Start the plunger pump 13 in the liquid supply device 14. The plunger pump 13 pumps the liquid to the liquid regulator 15 for liquid temperature and pressure adjustment and delivery to the gas well drainage process evaluation device 10, and at the same time starts the gas supply device 3 The gas c...

Embodiment 2

[0043] Example 2: Critical liquid-carrying velocity method for gas wells;

[0044] The critical liquid-carrying velocity of gas wells is calculated by experimentally measuring the minimum gas production volume of continuous gas-carrying liquid under different temperature, pressure and different liquid accumulation conditions. The calculation formula is as follows:

[0045]

[0046] Where υ t Indicates the minimum critical liquid carrying speed; q c It is the minimum gas production volume of continuous liquid carrying in the gas well; T is the temperature; p is the pressure; A is the cross-sectional area of the pipe string; z is the gas deviation factor under the conditions of p and T.

[0047] Experiment: Install the gas lift device of the drainage tool in the gas well drainage process evaluation device 10, start the plunger pump 13 in the liquid supply device 3, and the plunger pump 13 pumps the liquid to the liquid regulator 15 for liquid temperature and pressure adjustment , The...

Embodiment 3

[0049] Embodiment 3: Liquid-gas jet pump pump efficiency method;

[0050] Calculated by experimentally measuring jet pump power fluid pressure, suction port pressure, discharge port pressure, power fluid flow and suction gas flow, the calculation formula is as follows:

[0051]

[0052] Among them, η represents the pumping efficiency of the liquid-gas jet pump; p 1 Represents power hydraulic pressure; p 2 Indicates the pressure of the sucked gas; p 3 Indicates discharge outlet pressure; Q 1 Indicates the flow of power fluid; Q 2 Indicates the flow of gas being sucked in.

[0053] Experiment: Install the drainage tool liquid-gas jet pump in the gas well drainage process evaluation device 10, start the plunger pump 13 in the liquid supply device 14, and the plunger pump 13 pumps the liquid to the liquid regulator 15 for liquid temperature , Pressure adjustment, after adjustment, the liquid enters the gas well drainage process evaluation device 10, and at the same time the gas compresso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com