Auxiliary Pit Type Buffer Structure in Railway Tunnel

A buffer structure and tunnel technology, applied in tunnels, mining equipment, earth-moving drilling, etc., can solve the problems such as the unsuitable use of long shafts in tunnels, the high cost of buffer structures, and the increased efficiency of micro-pressure wave mitigation. Micro-pressure wave effect, the effect of alleviating the micro-pressure wave effect at the opening, and maximizing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

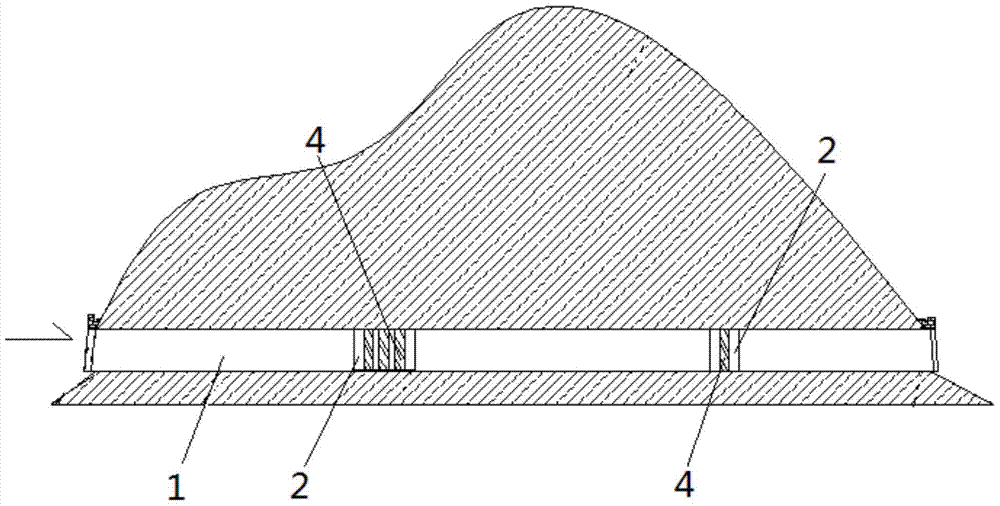

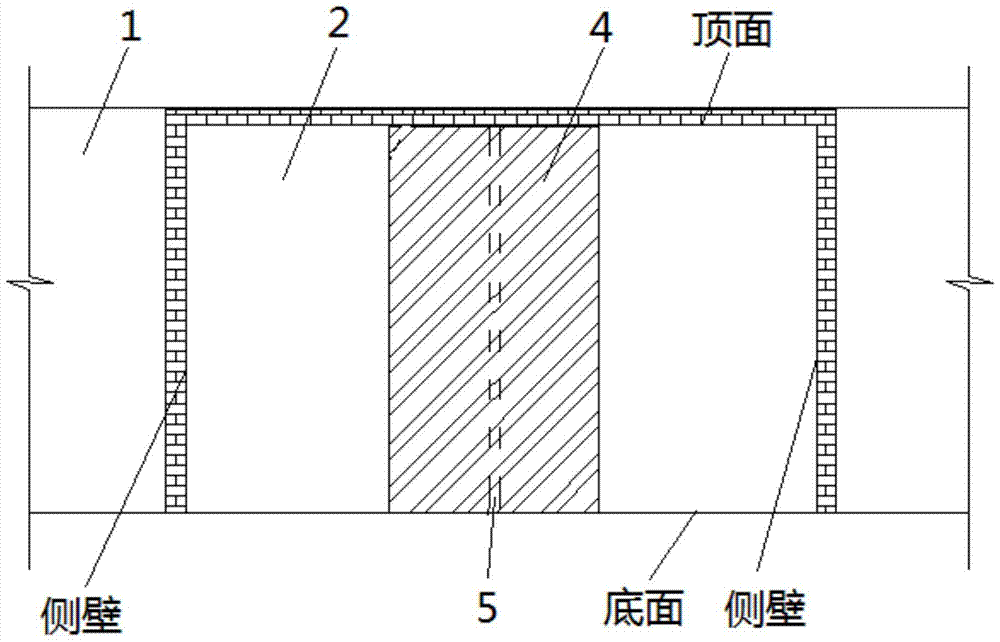

[0028] Such as figure 1 As shown, a plurality of auxiliary pit chambers 2 are arranged on both sides of the tunnel 1, and the plurality of auxiliary pit chambers 2 are arranged at intervals along the axial direction of the tunnel 1, as shown in image 3 with Figure 5 As shown, the auxiliary pit chamber 2 communicates with the tunnel 1 through the opening surface 3 .

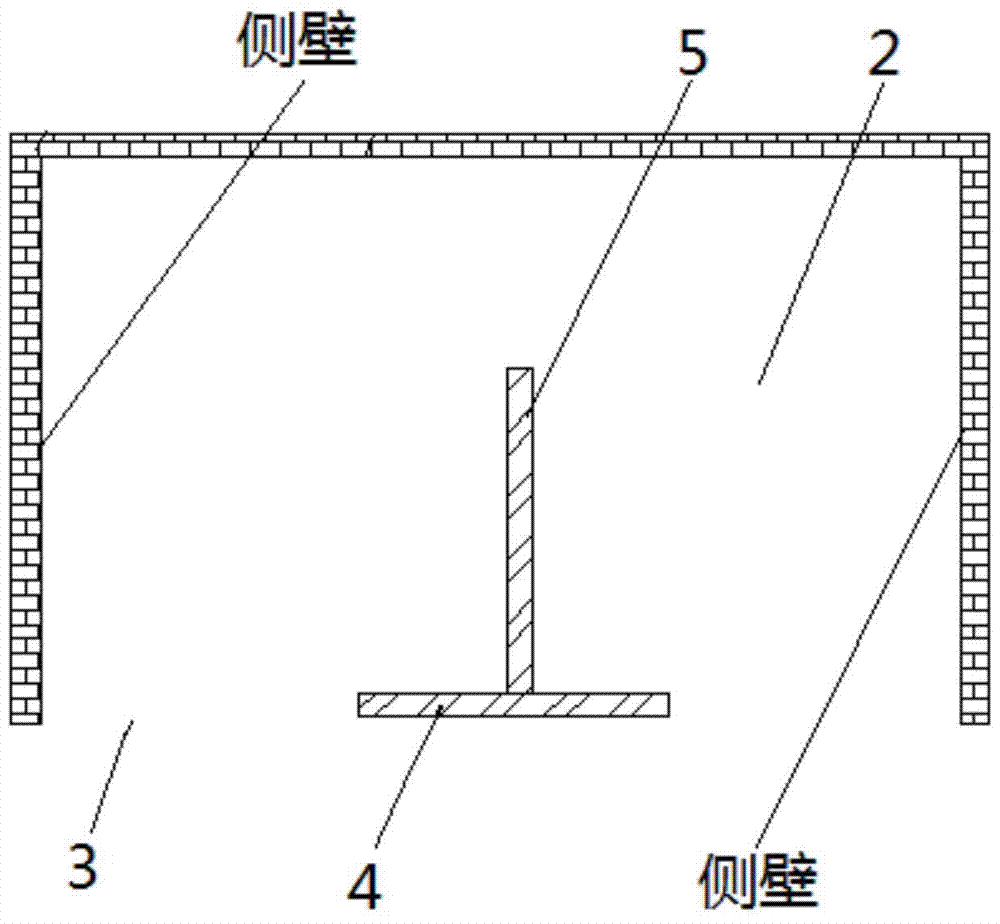

[0029] Such as figure 2 with image 3 As shown, some auxiliary pit chambers 2 in the tunnel 1 are provided with a first baffle plate 4 parallel to the opening surface 3, and both ends of the first baffle plate 4 are fixed to the top and bottom surfaces of the auxiliary pit chamber 2. connected, and the area of the first baffle plate 4 at the same auxiliary pit chamber 2 is smaller than the area of the opening surface 3 of the auxiliary pit chamber 2; and a second baffle plate 5, one end of the second baffle plate 5 is connected to the first baffle plate A baffle plate 4 is connected, and the other end e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com