Buffer cylinder

A buffer cylinder and buffer cavity technology, applied in the field of hydraulic cylinders, can solve the problems of shortening the service life of the cylinder, large impact of the cylinder, and affecting the buffering effect, etc., and achieve the effects of smooth pressure transition, increased life, and reduced pressure peaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

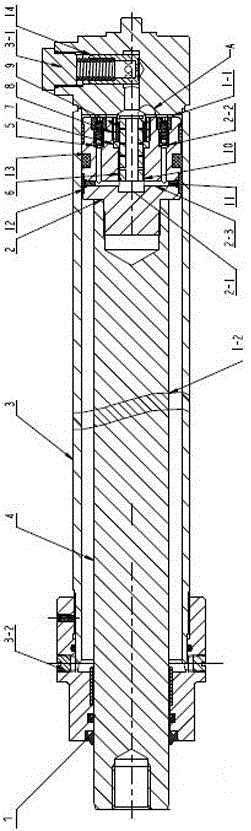

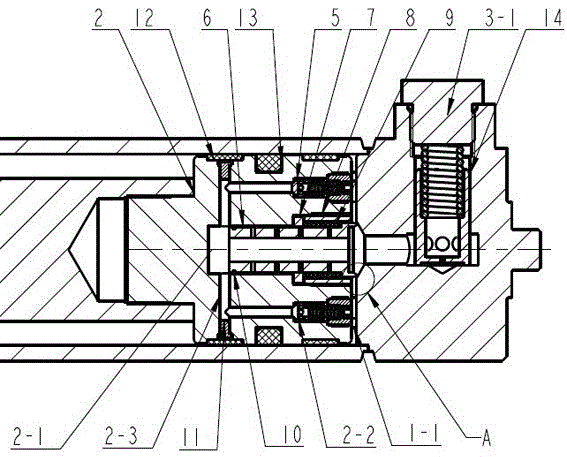

[0021] figure 1 The buffer cylinder shown is a lifting cylinder for a forklift, which mainly includes a cylinder head 1, a cylinder body 3, a cylinder head 14, a piston rod 4, a piston 2, a one-way valve 2-2, a buffer plunger 6 and a spring 9. The cylinder head 1 and the cylinder head 14 are respectively installed on both ends of the cylinder body 3, one end of the piston rod 4 extends into the cylinder body 3 through the through hole in the middle of the cylinder head 1, and the other end is exposed outside the cylinder, and the piston rod 4 is set to The extension direction of the rod 4 is the front, and it is the rear anyway. The piston rod 4 and the cylinder head 1 seal the cylinder mouth of the cylinder body 3 together, and the piston 2 is connected with one end of the piston rod 4 placed in the cylinder body 3. The inner chamber of the body 3 is separated to form a rod chamber 1-2 and a rodless chamber 1-1. The cylinder head 1 is provided with a large chamber oil port 3-...

Embodiment 2

[0024] In this example, the first unilateral gap between the buffer plunger and the buffer cavity is a=0.5 mm; the snap ring and the buffer cavity are clearance fit, and the second unilateral gap is b=0.05 mm; the retaining ring and the buffer plunger are clearance fit, Its fit gap c=0.01 mm; in the same oil cylinder, the relationship of the three fit gaps is a>b>c; a check valve is installed in the piston close to the side of the rodless chamber, the one-way valve of this embodiment The valve is a ball valve, and the number of one-way valves is one. Each one-way valve is connected to the buffer cavity through a drainage hole. The rodless cavity and the small hole in the axial through hole, the small hole is a radial small hole opened radially inward from the outer surface of the buffer plunger, the number of the small hole is 1, and the diameter of the small hole is 5mm; the piston and the cylinder The seal between the internal walls adopts the sealing form of setting a seali...

Embodiment 3

[0026] In this example, the first unilateral gap between the buffer plunger and the buffer cavity is a=3 mm; the snap ring and the buffer cavity are clearance fit, and the second unilateral gap is b=1 mm; the retaining ring and the buffer plunger are clearance fit, Its matching gap c=0.1 mm; in the same oil cylinder, the relationship between the three matching gaps is a>b>c; a check valve is installed in the piston near the side of the rodless chamber, and the one-way valve in this embodiment The valve is a ball valve, and the number of one-way valves is 6. Each one-way valve is connected to the buffer chamber through a drainage hole. The small hole of the rodless cavity and the axial through hole, the small hole is a radial small hole opened radially inward from the outer surface of the buffer plunger, the number of small holes is 1000, and the diameter of the small hole is 0.01mm; other features Same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com