Combustion system of internal combustion engine

A combustion system and internal combustion engine technology, applied in the direction of internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve the problems of low cycle efficiency and the inability to further increase the compression ratio of gasoline engines, and achieve the effect of reducing the peak value of cylinder pressure and reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

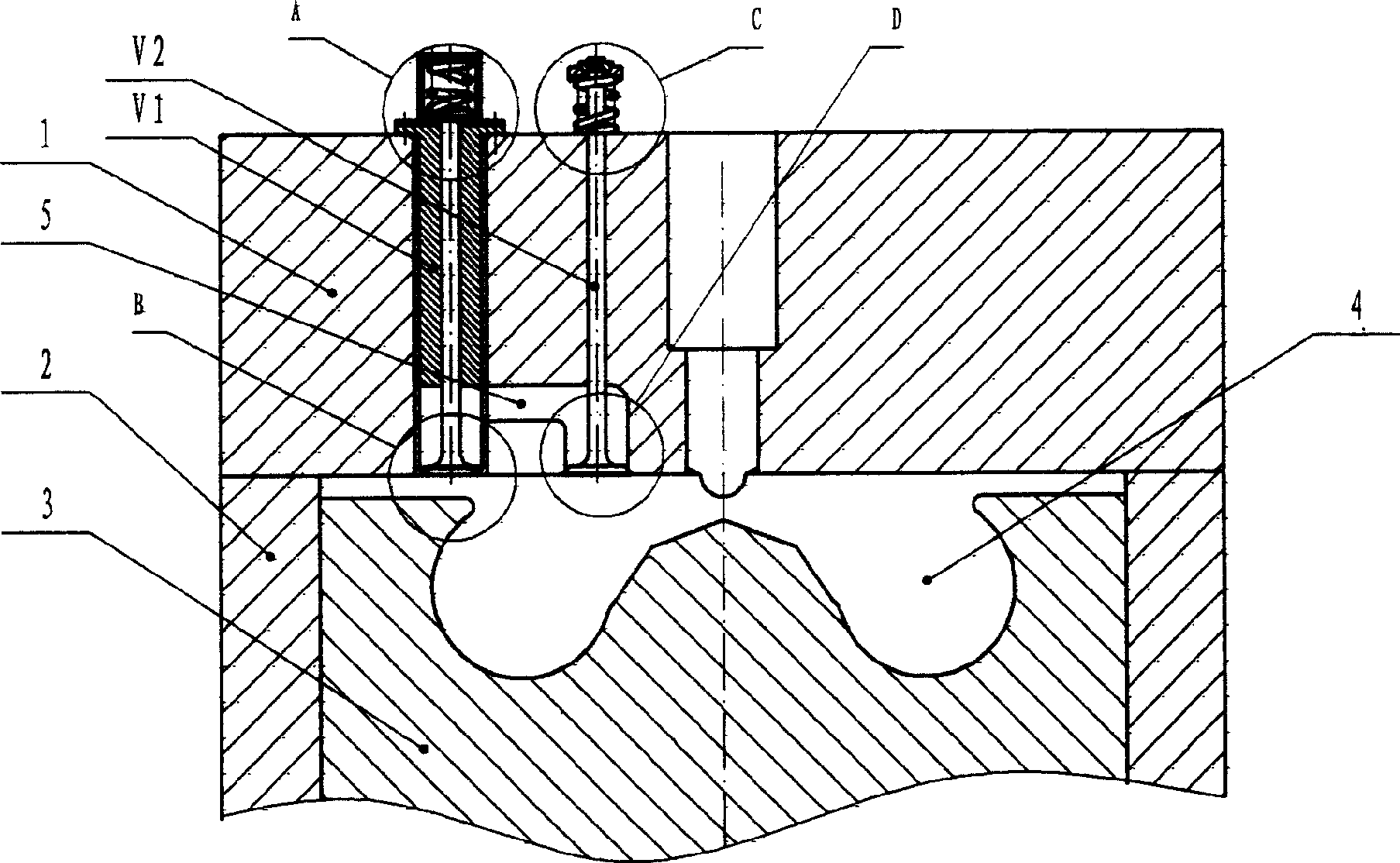

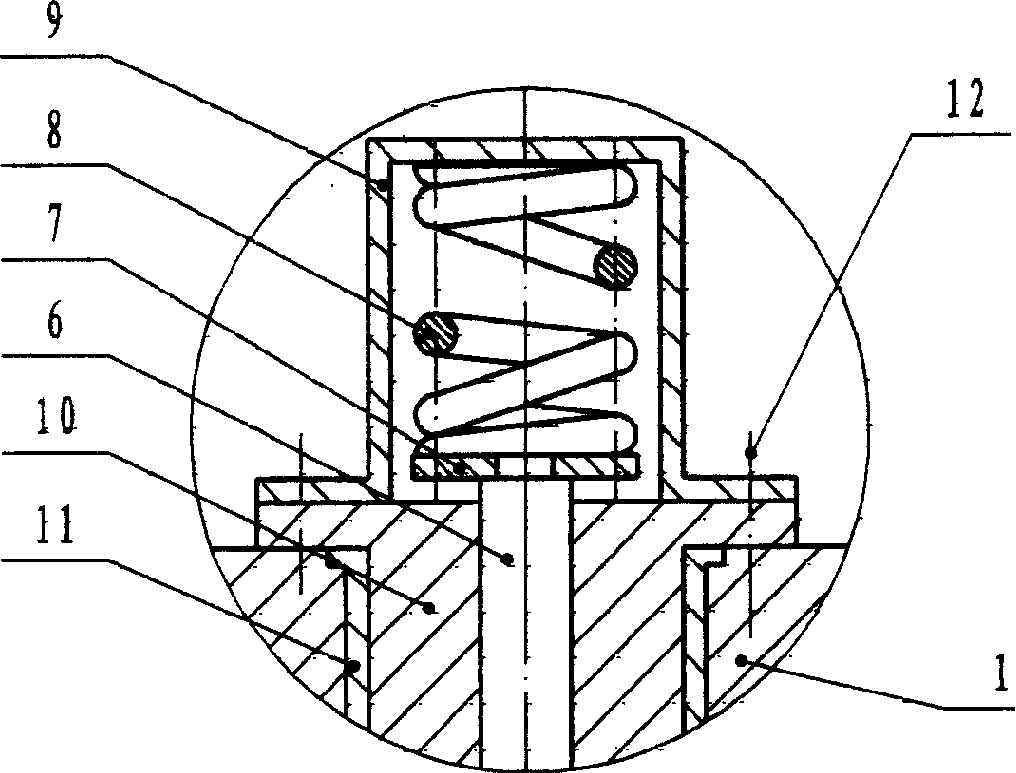

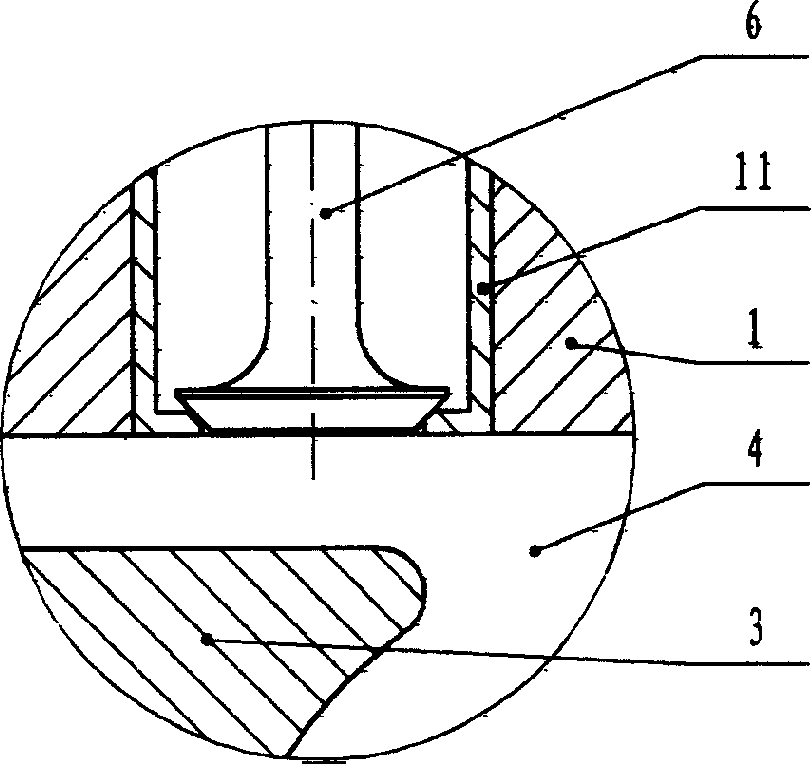

[0019] exist figure 1 In the shown embodiment, the cylinder head (1), the cylinder liner (2) and the piston (3) form a combustion chamber (4), and the pressure accumulator chamber (5) is arranged on the cylinder head (1). Between the accumulator (5) and the combustion chamber (4) there is a valve group (V 1 , V 2 ) two channels for opening and closing, the valve group (V 1 ) opens toward the pressure accumulator, and the valve group (V 2 ) opens towards the combustion chamber. Valve group (V 1 , V 2 ) depends on the pressure difference between the two chambers. Only when the resultant force of the pressure difference acting on the valve disc is greater than the spring preload, the valve will automatically open. In the initial stage of engine combustion, when the explosion pressure rises rapidly, the valve group (V 1 ) increases the total volume of the combustion chamber and curbs the sharp increase of the explosion pressure. When the piston descends, when the pressure o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com