Reliability measurement method for mechanical and electrical product

A measurement method and reliability technology, applied in the fields of electrical digital data processing, special data processing applications, instruments, etc., can solve the situation where one is a fuzzy variable and the other is a random variable, limit the practicability of the first type of method, disadvantageous And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

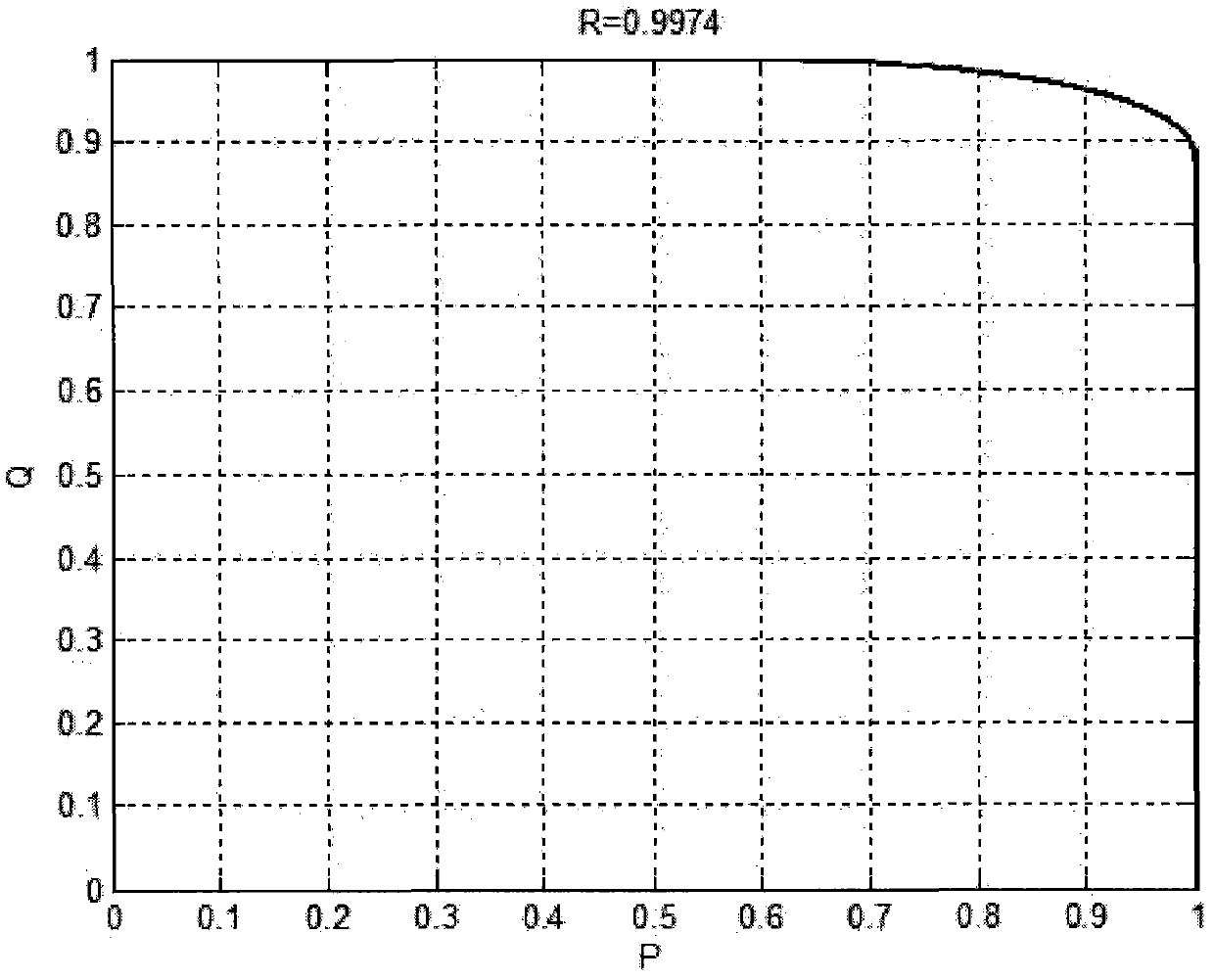

[0065] A measure of the reliability of a linkage mechanism.

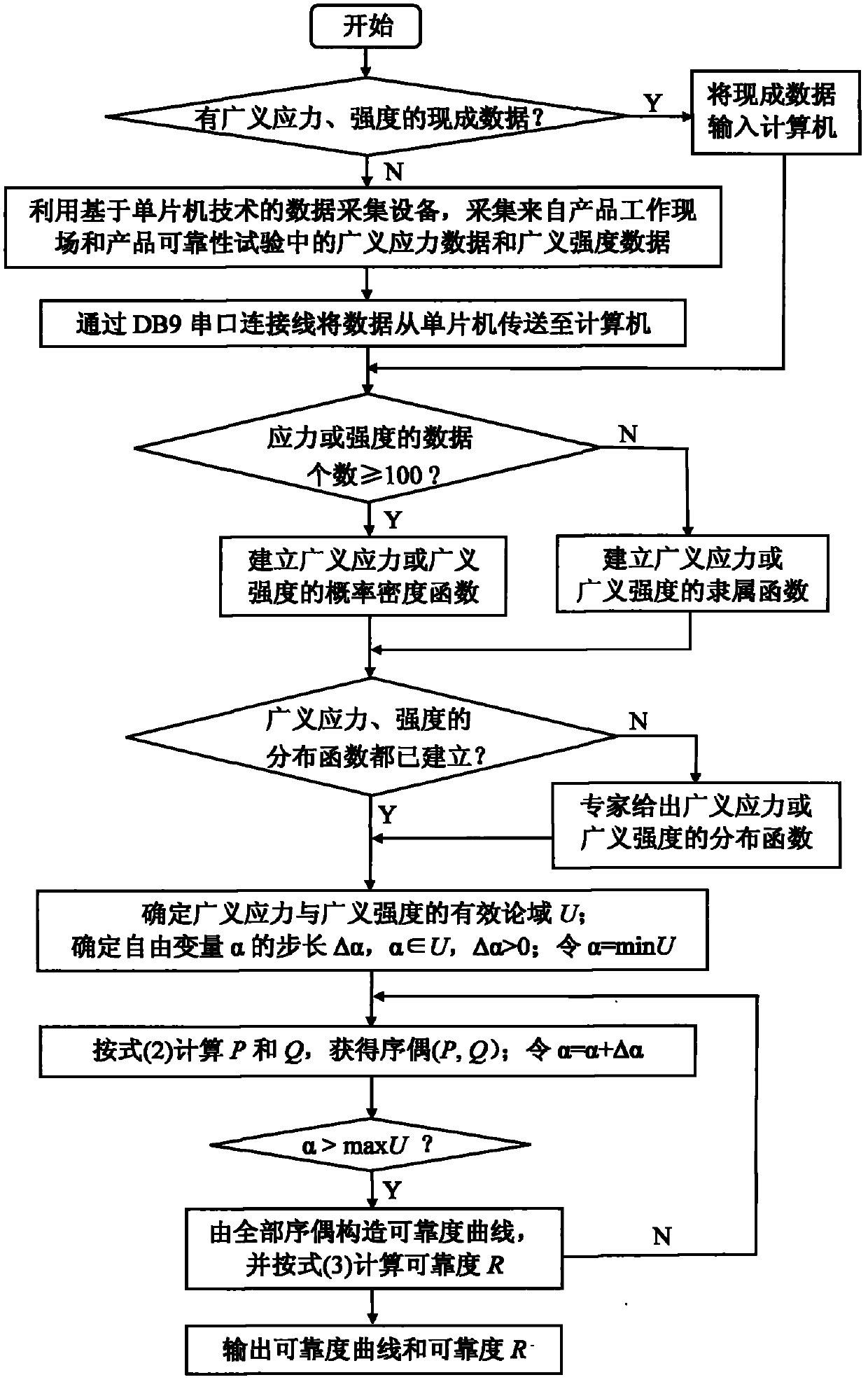

[0066] The first step, the acquisition and classification of the stress data and strength data of the linkage mechanism

[0067]The link mechanism is subjected to tension when it is working. Currently, there are 150 tension or stress data available, and these 150 data are directly input into the computer by manual input; the tensile strength of the link mechanism has no ready-made data available. The destructive reliability test of the same type of connecting rod mechanism measured 80 pieces of tensile strength data. These data were collected and recorded by the data acquisition equipment based on single-chip technology, and these data were transmitted from the single-chip to the computer through the DB9 serial port connection line. From the number of stress data and strength data of the linkage mechanism, it can be judged that the stress here is a random variable and the strength is a fuzzy variable.

[0068] In t...

Embodiment 2

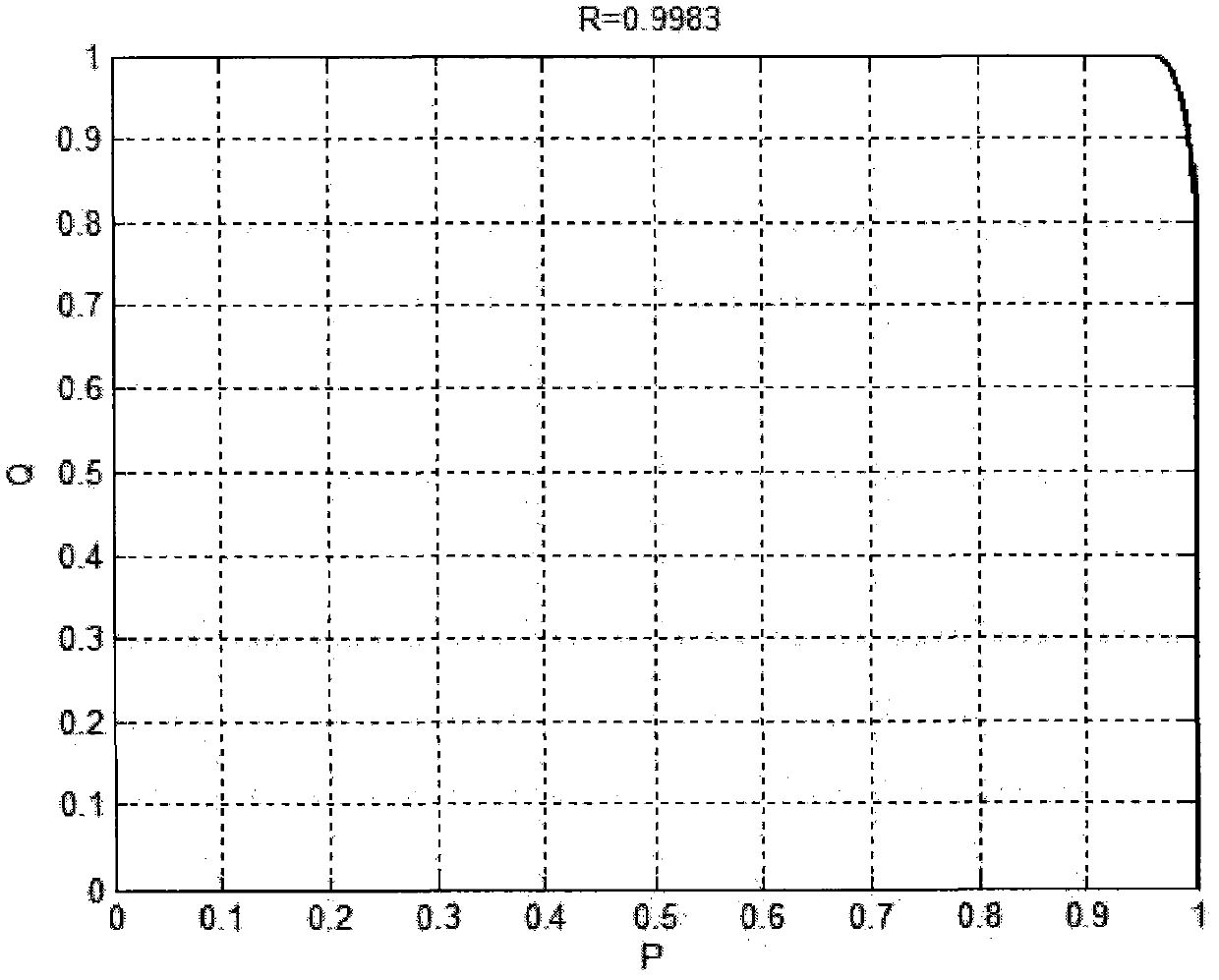

[0085] A reliability measurement of the pull-in function of the electromagnetic system of a new relay product.

[0086] The first step is to obtain and classify the generalized stress data and generalized strength data of the electromagnetic system of the new relay product

[0087] The failure criterion for the pull-in function of the electromagnetic system of the new relay product is: if the excitation voltage value when the electromagnetic system of the new relay product completes the pull-in action in the working state is greater than the given value of the stable pull-in voltage of the electromagnetic system, then it is judged that the The product fails, otherwise it is good. Therefore, when the electromagnetic system of the new relay product completes the pull-in action, the excitation voltage value is the generalized stress, and the given value of the stable pull-in voltage of the electromagnetic system is the generalized strength.

[0088] Generalized stress has no rea...

Embodiment 3

[0101] A reliability measure of an engine compressor disk.

[0102] The first step, the acquisition and classification of the stress data and strength data of the compressor disk of the engine

[0103] When the engine is working, the engine compressor disk will bear a certain force, and there are 1000 available stress data; the engine compressor disk is made of a specific material, and the manufacturer provides 200 strength data. Data is entered into the computer by manual entry. From the number of stress data and strength data of the engine compressor disk, it can be judged that the stress and strength here are both random variables.

[0104] The second step is the establishment of the stress probability density function and strength probability density function of the compressor disk of the engine

[0105] The stress data and strength data of the engine compressor disc obtained and classified in the first step are processed as follows to obtain the probability density func...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com