Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Easy to manufacture, install and maintain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

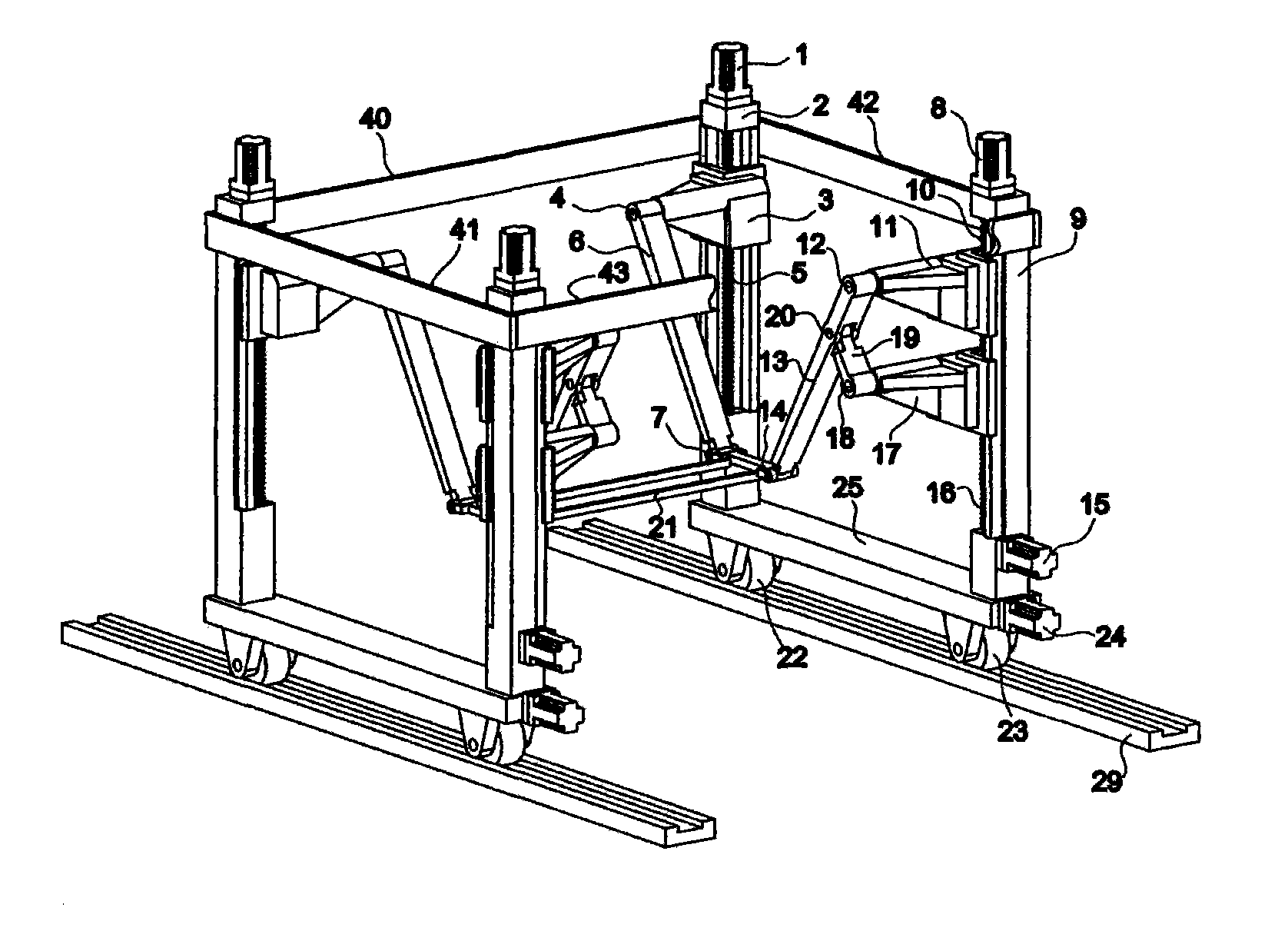

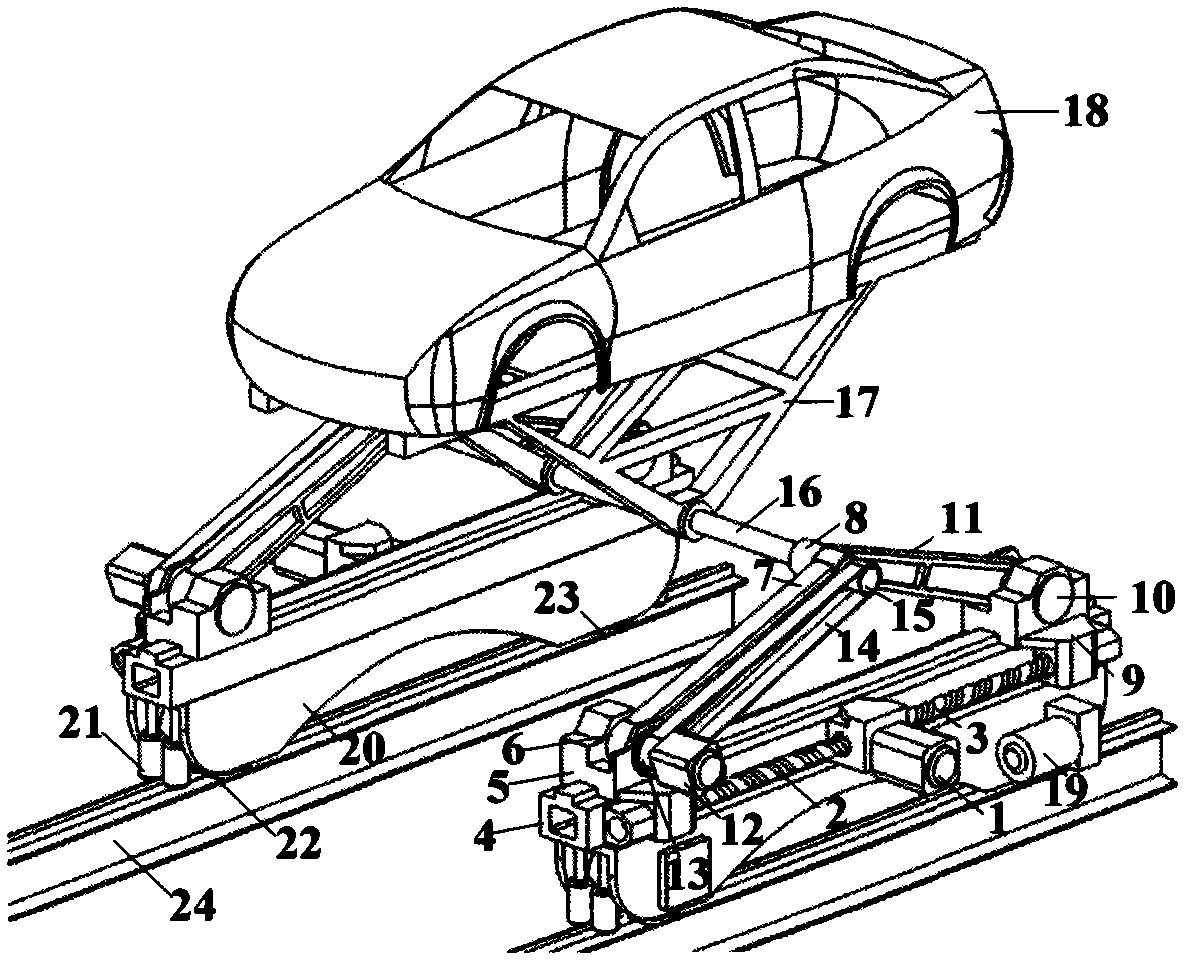

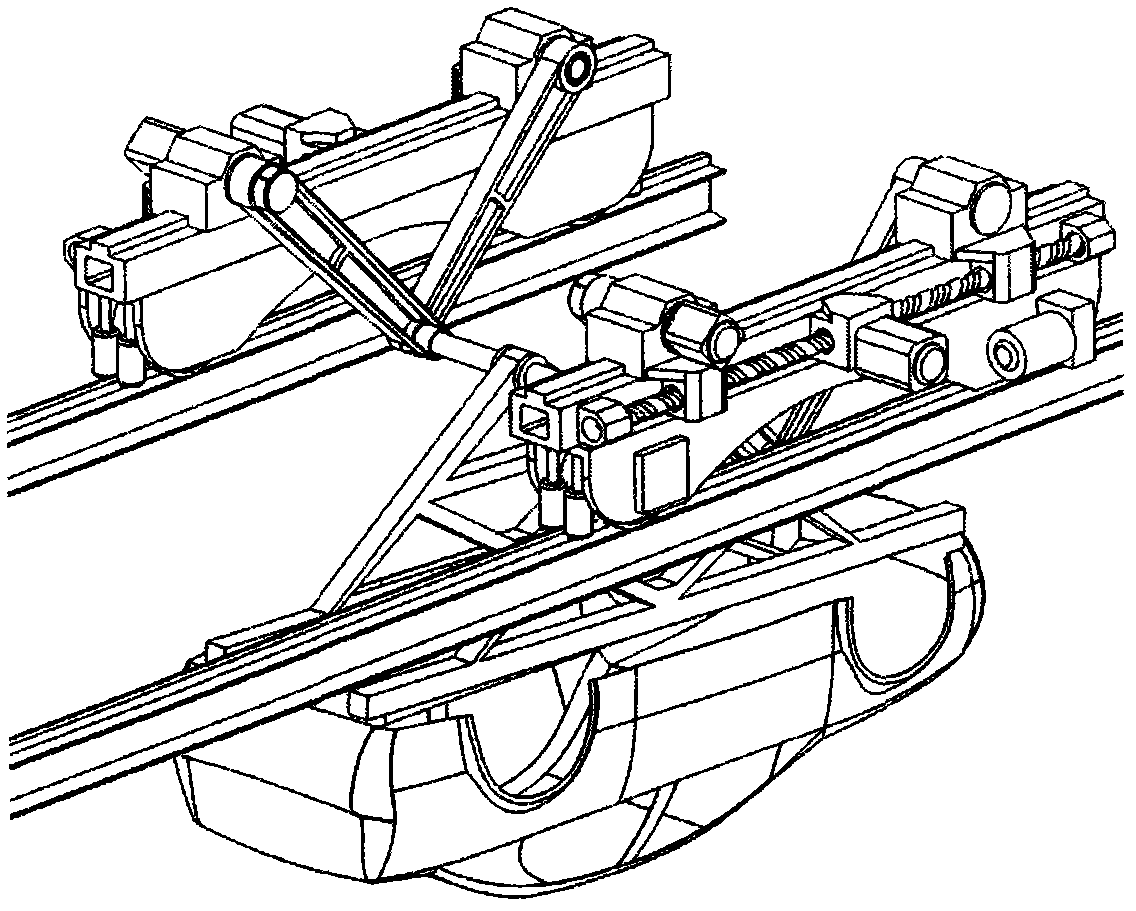

Automobile coating parallel mechanism conveyer and application thereof

ActiveCN101812716ASmall footprintLow costLiquid surface applicatorsElectrophoretic coatingsElectrophoresesProduction line

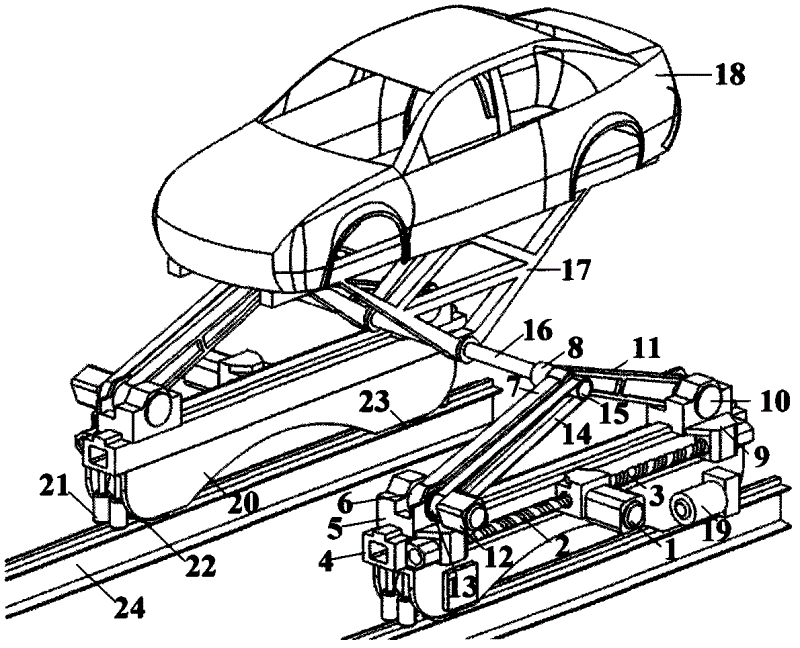

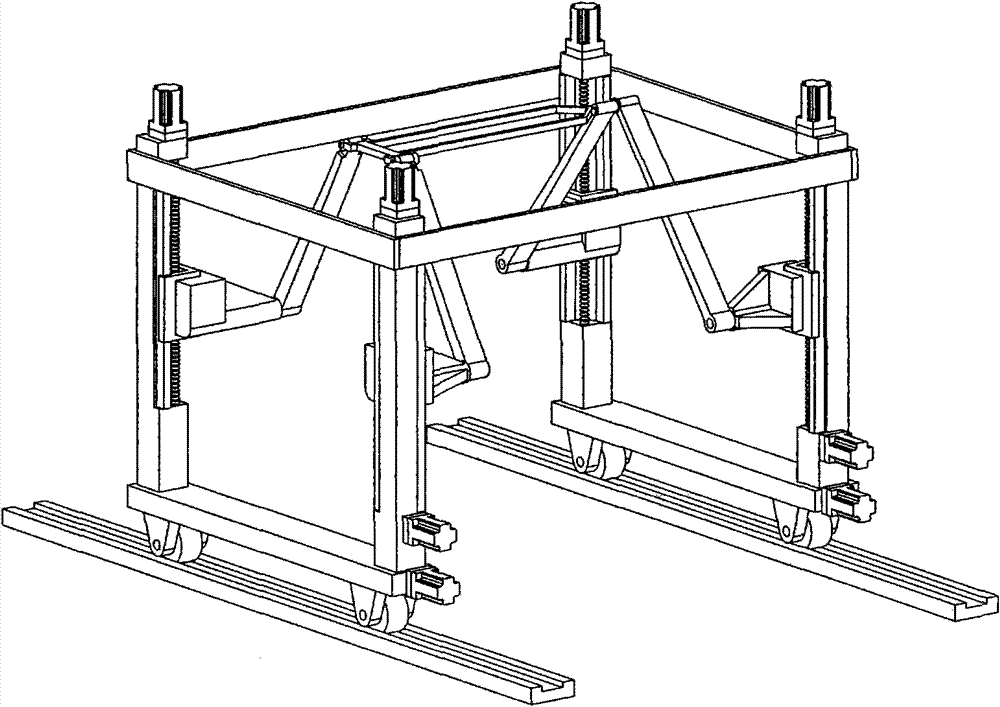

The invention relates to an automobile coating parallel mechanism conveyer, which comprises two functional parts: a traveling mechanism and a lifting and turning mechanism. The traveling mechanism finishes the traveling and transporting functions of the conveyer; the lifting and turning mechanism consists of one or more parallel mechanisms; the body of the automobile or other objects to be conveyed are arranged on a moving platform of the parallel mechanism; and the parallel mechanism is driven to finish the lifting and turning of the object to be conveyed. The movement of the traveling mechanism is combined with that of the parallel mechanism; the body is driven to realize advancing and retreating, lifting, tilting or composite movement thereof so as to be fully stirred in an electrophoresis tank to achieve the purpose of completely eliminating bubbles on the top of the automobile body during the electrophoresis. Because the parallel mechanism is adopted by the conveyer, the bearing capacity of the conveyer is increased so as to be suitable for conveying the bodies of different types or sizes, and the flexibility of the conveyer is also increased; and because the suspending and conveying system has a gantry structure, the conveyer successfully overcomes the defect of dropping liquid pollution and is therefore an environment-friendly conveyer on the automobile coating production line.

Owner:JIANGSU CHANGHONG INTELLIGENT EQUIP CO LTD +1

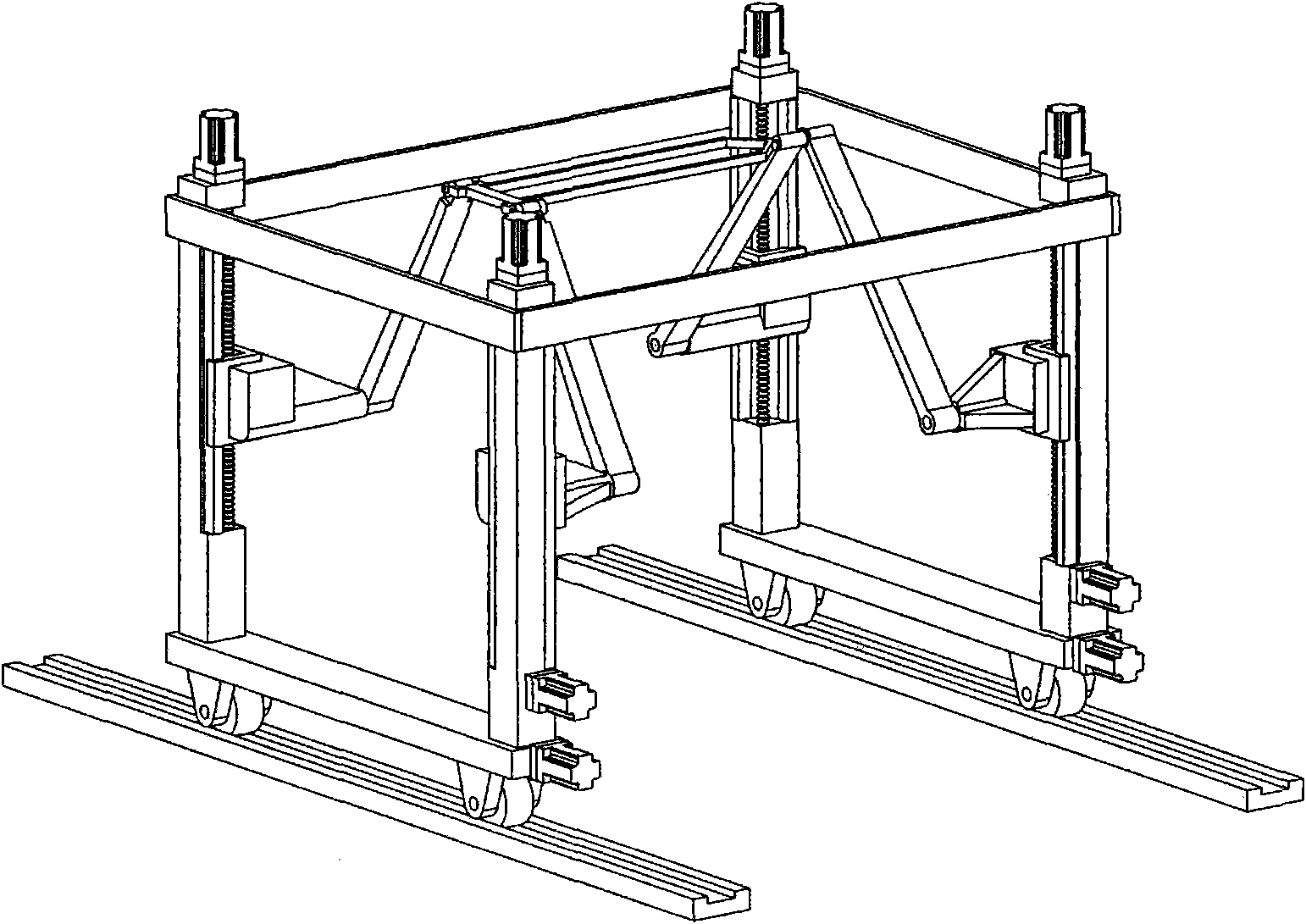

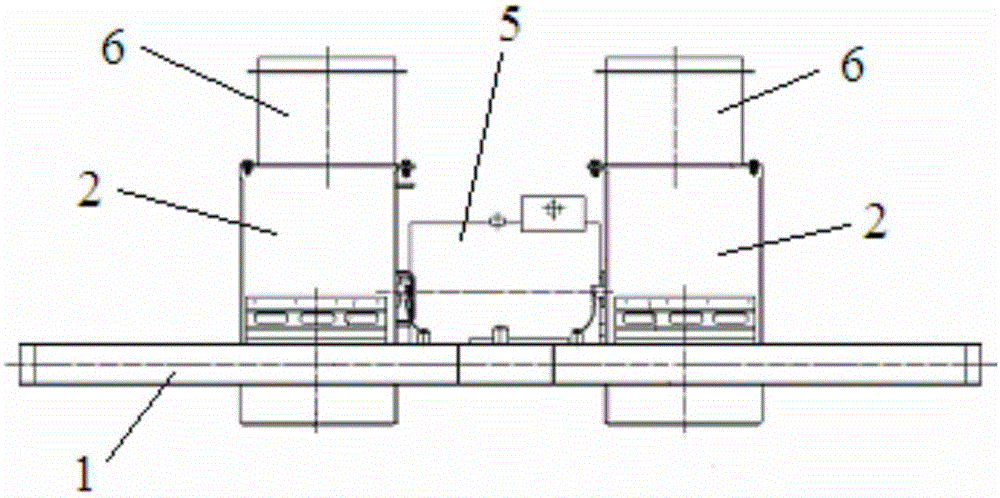

Automobile coating conveyer having three degrees of freedom

InactiveCN102817064ASmall footprintLow costLiquid surface applicatorsCharge manipulationThree degrees of freedomDegrees of freedom

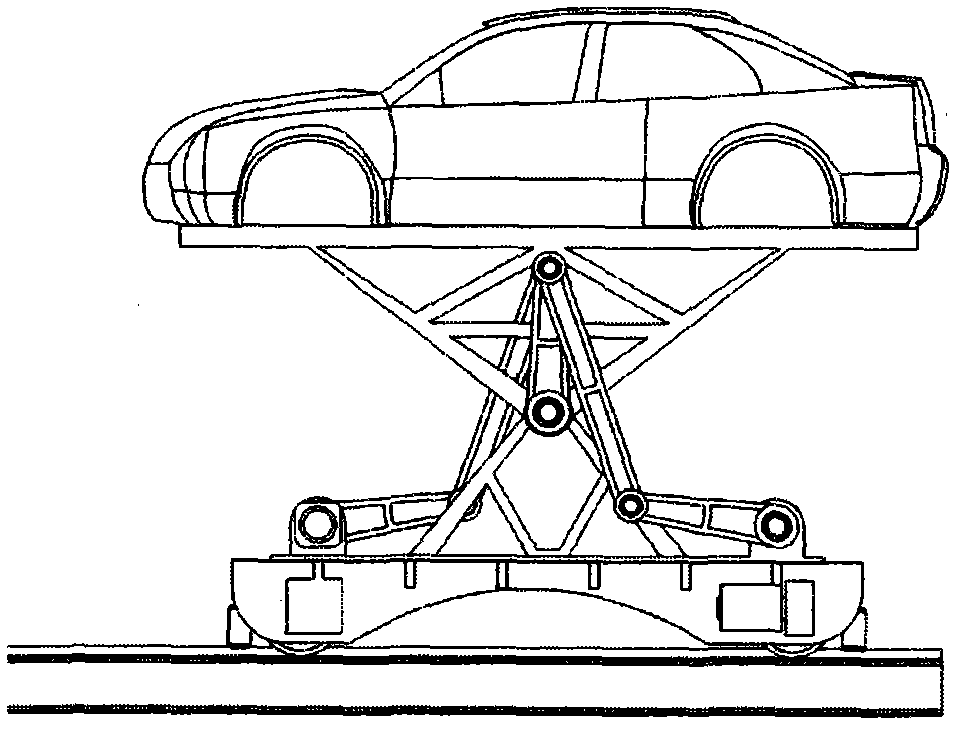

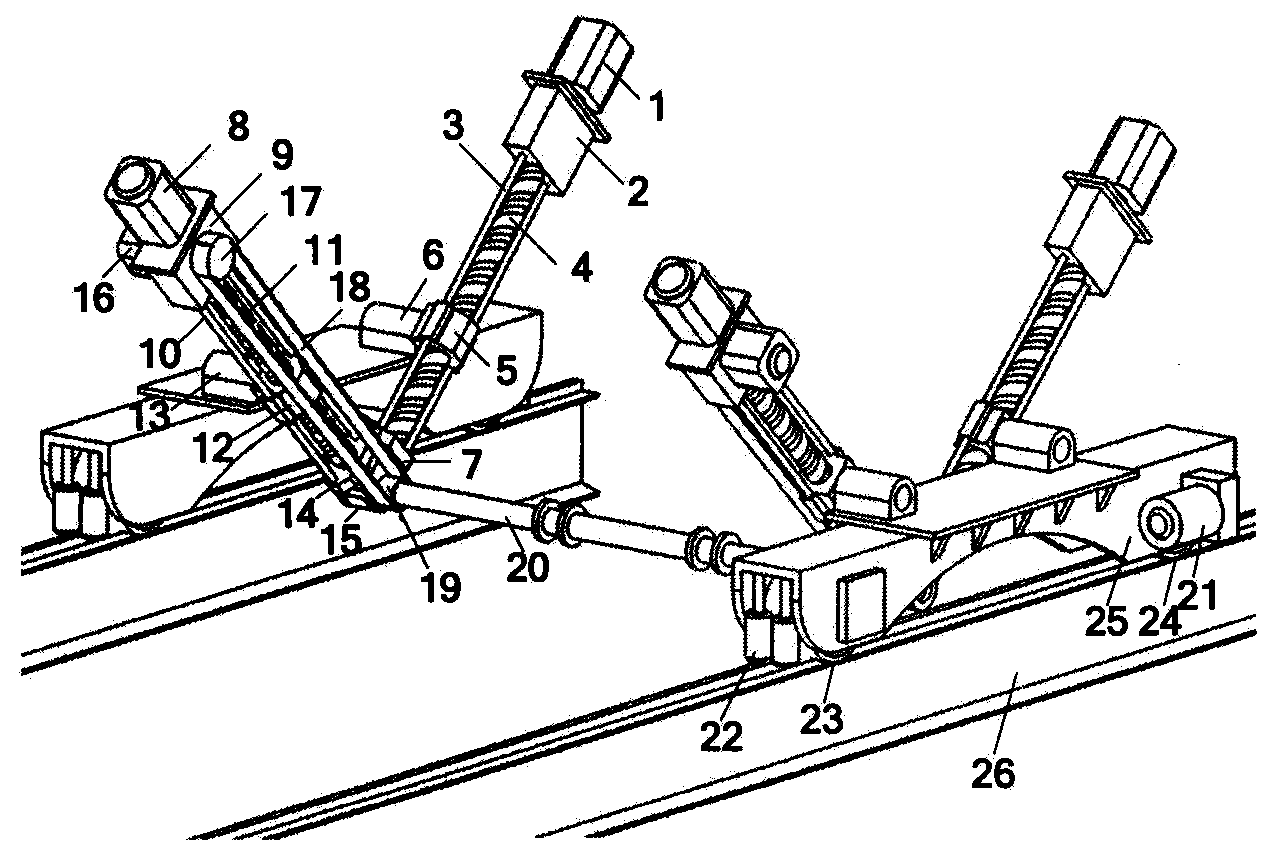

The invention relates to an automobile coating conveyer. The conveyer comprises two function parts comprising a walking mechanism and a translating, elevating and overturning mechanism, wherein the walking mechanism completes the walking transport function of a transporter; and the translating, elevating and overturning mechanism is formed by one or a plurality of plane mechanism, and completes the translation, elevation and overturn of a conveyed object through driving the plane mechanism(s). The load bearing capability of the conveyer is increased because of the adoption of the plurality of plane mechanism in the conveyer disclosed in the invention, so the conveyer is suitable for conveying vehicle bodies having different models and different sizes, thereby the flexibility of the conveyer is increased; and suspension and convey functions can be realized through the translating, elevating and overturning mechanism without extract support, so the conveyer has a light weight and a low height.

Owner:TSINGHUA UNIV

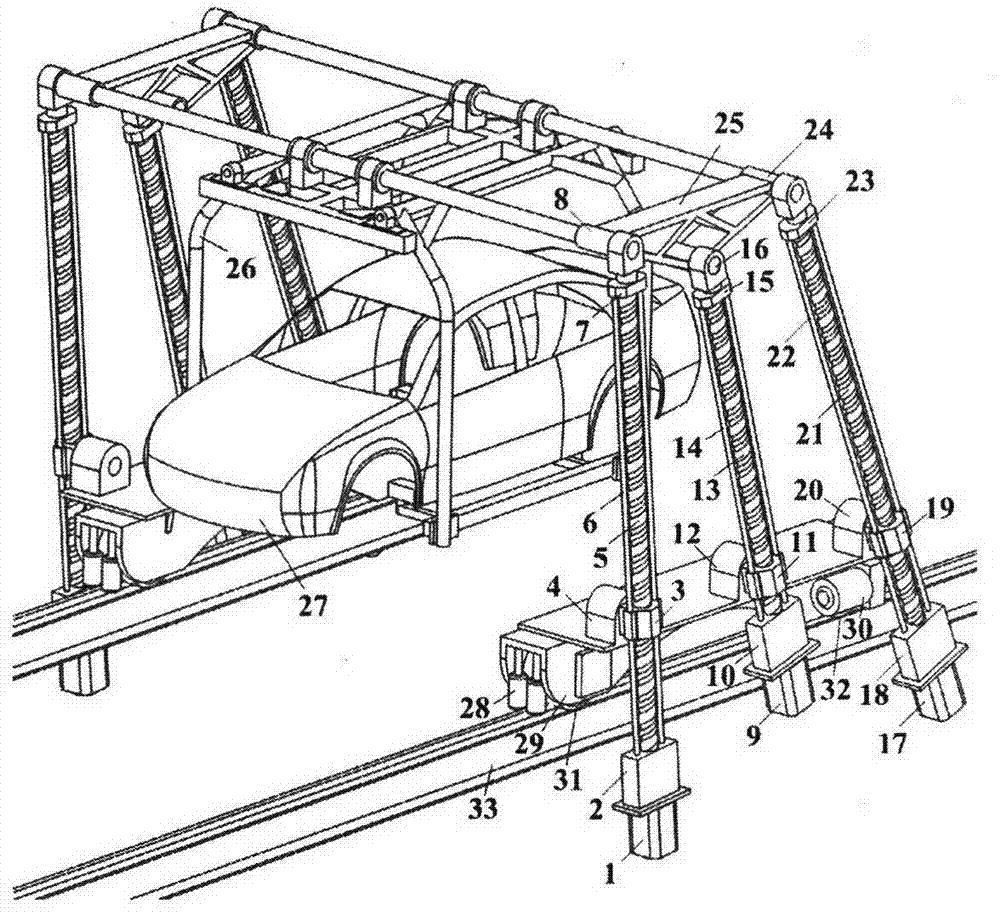

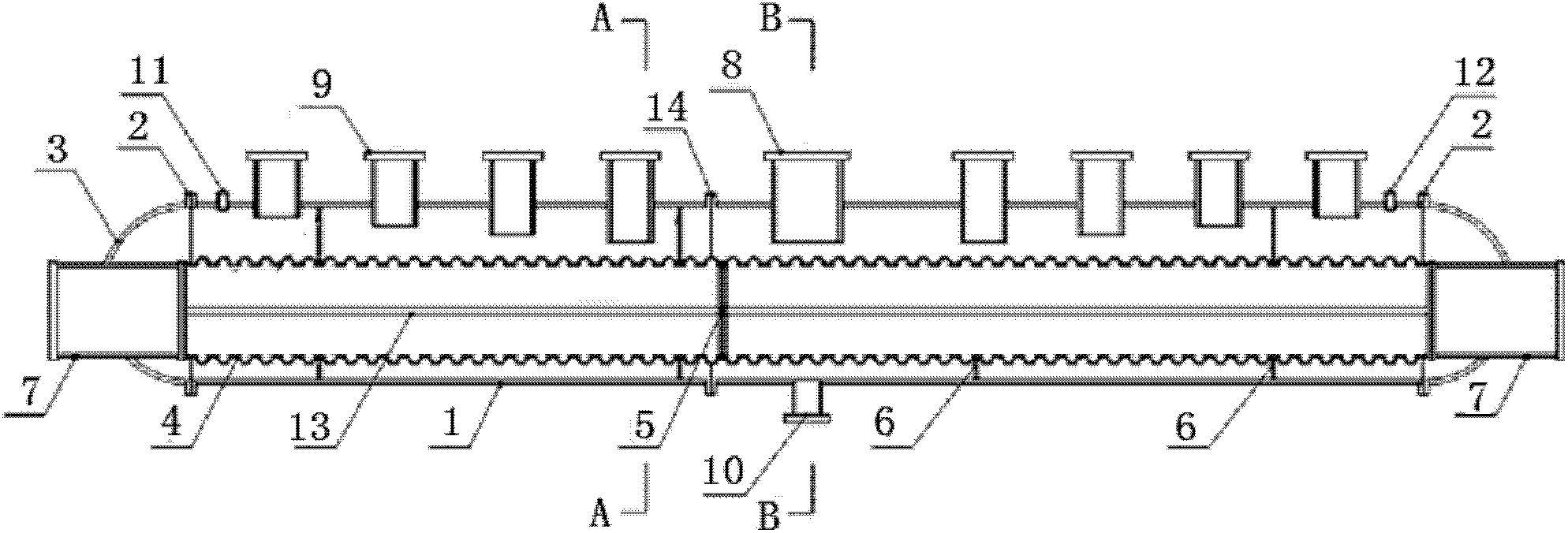

Automobile coating conveyor and application thereof

ActiveCN102616539AAchieve advance and retreatAchieve liftingCharge manipulationConveyor partsProduction lineCoating

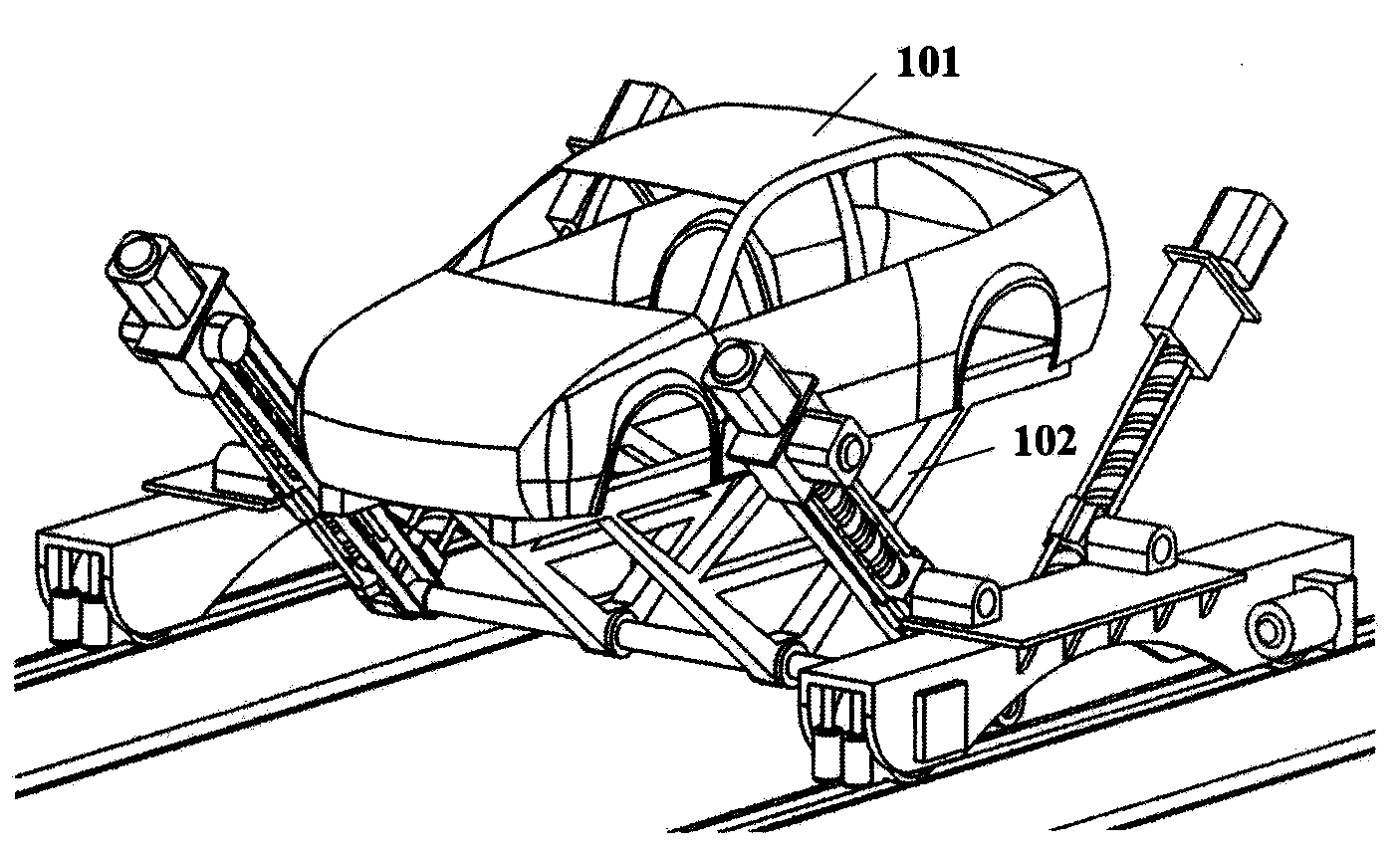

The invention relates to an automobile coating conveyor. The automobile coating conveyor comprises a traveling mechanism and a lifting turnover mechanism which serve as two functional parts, wherein traveling and transporting functions of the conveyor can be finished by the traveling mechanism; and lifting motion and turnover motion of conveyed objects can be finished through the lifting turnover mechanism. The motion of the traveling mechanism is combined with the motion of the lifting turnover mechanism, so that an automobile body can do advance and retreat motion, lifting motion and turnover motion or can do composite motion of the three kinds of motion; and the automobile coating conveyor can be used for an electrophoretic coating production line of the automobile body.

Owner:JIANGSU CHANGHONG INTELLIGENT EQUIP CO LTD +1

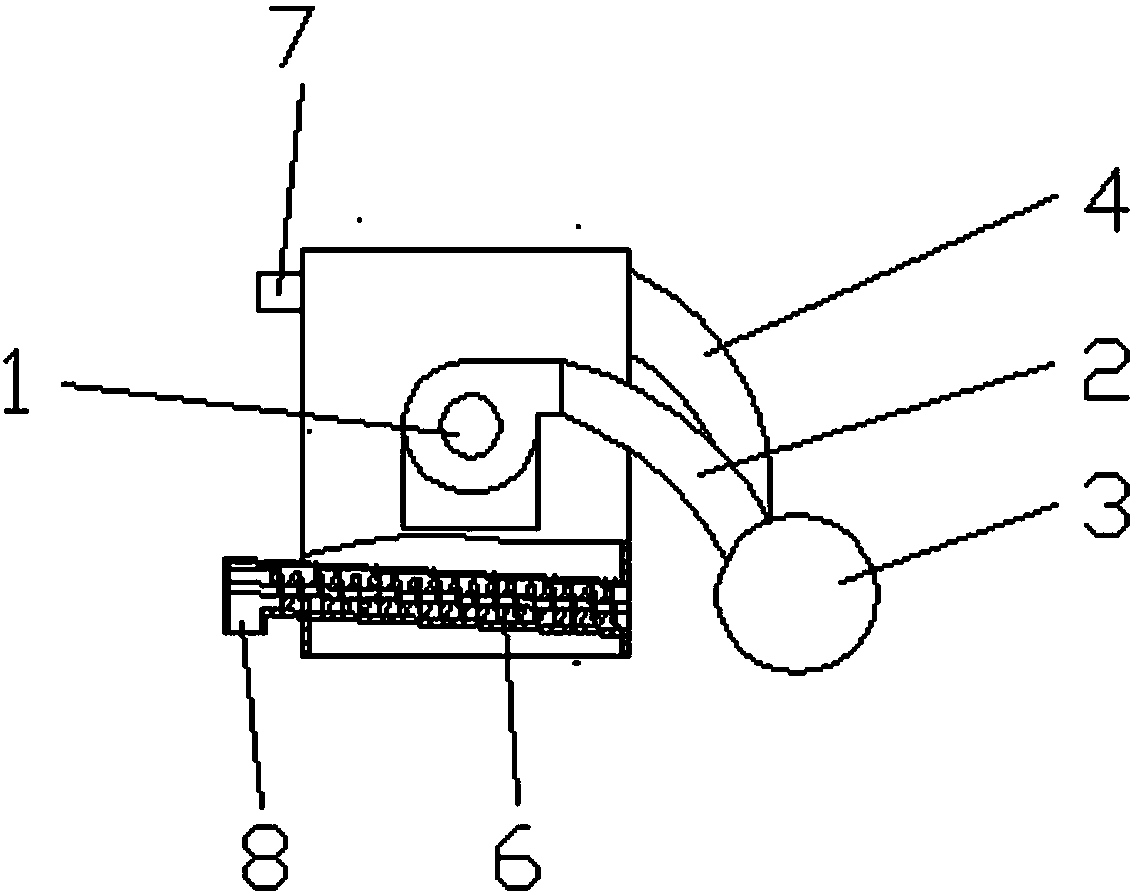

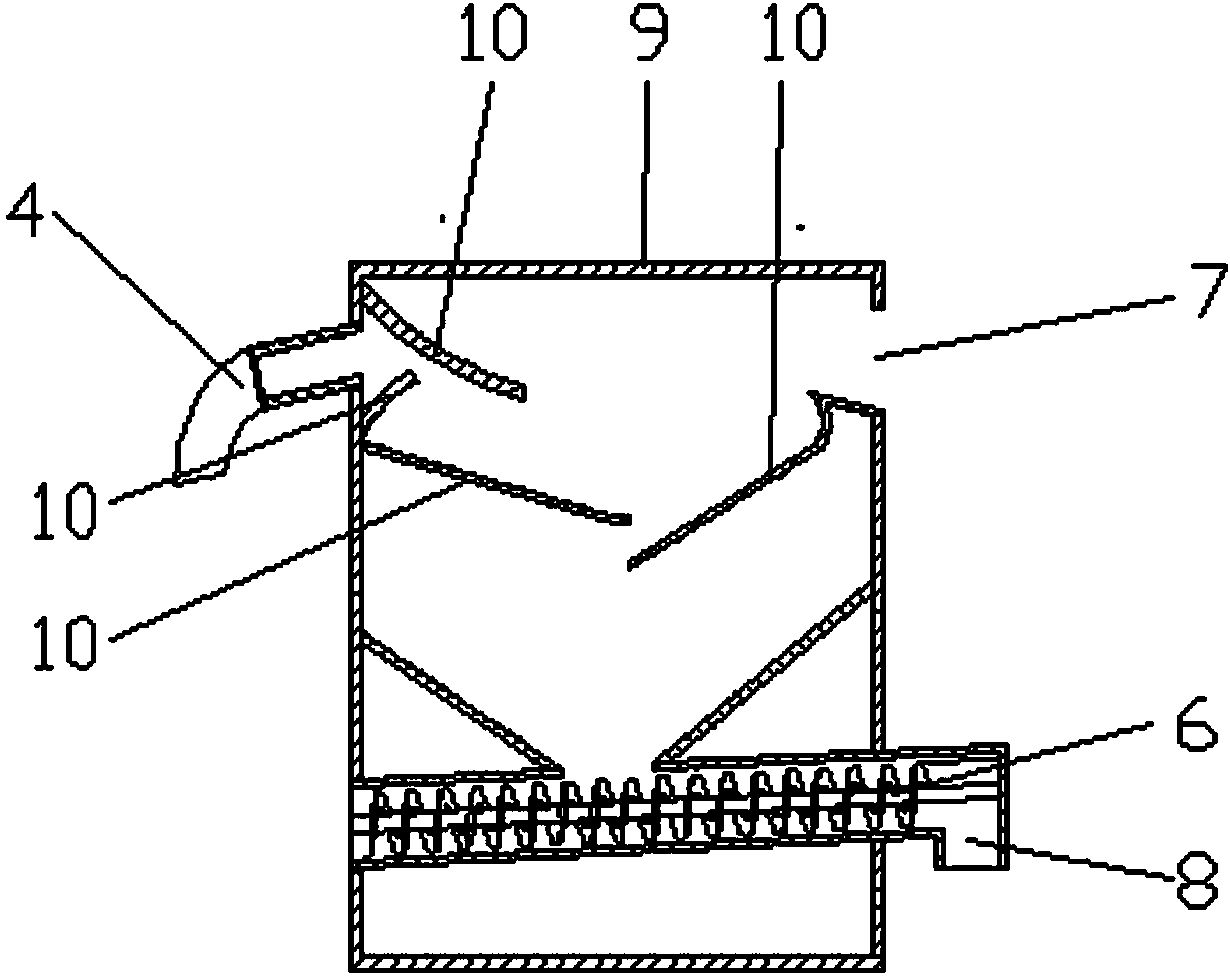

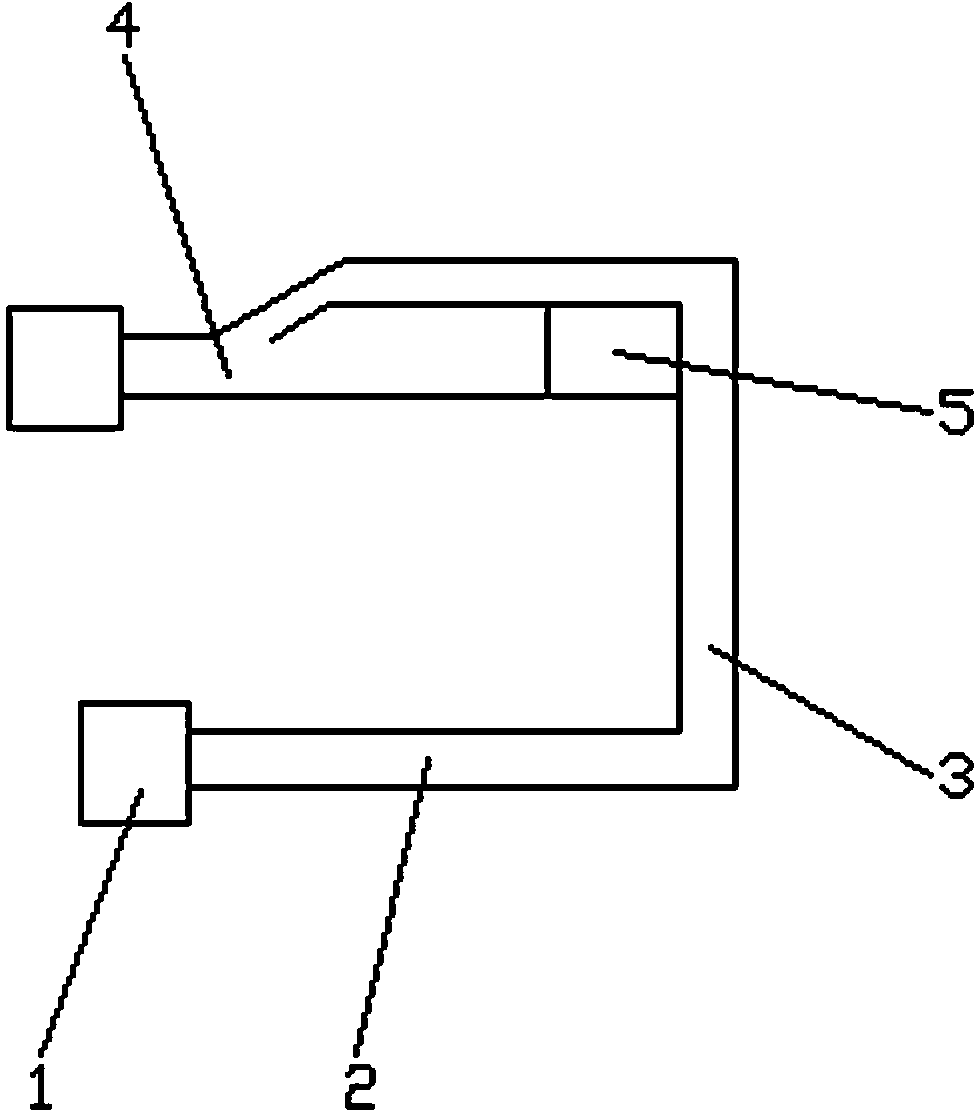

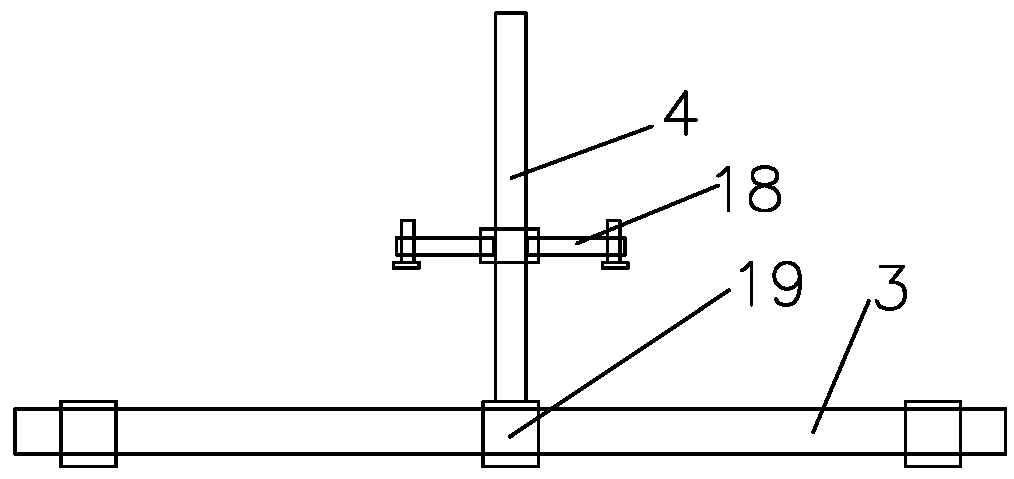

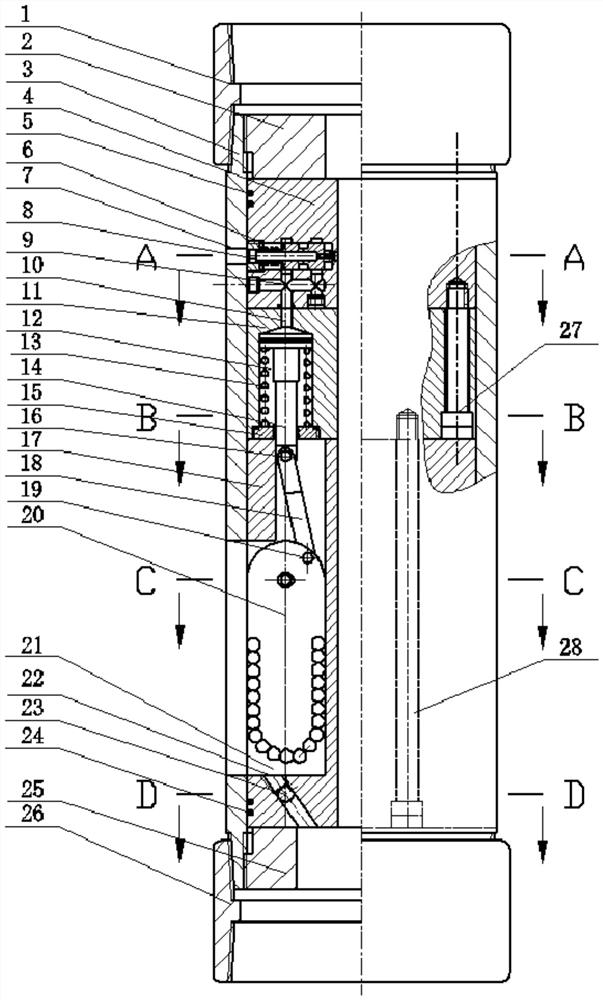

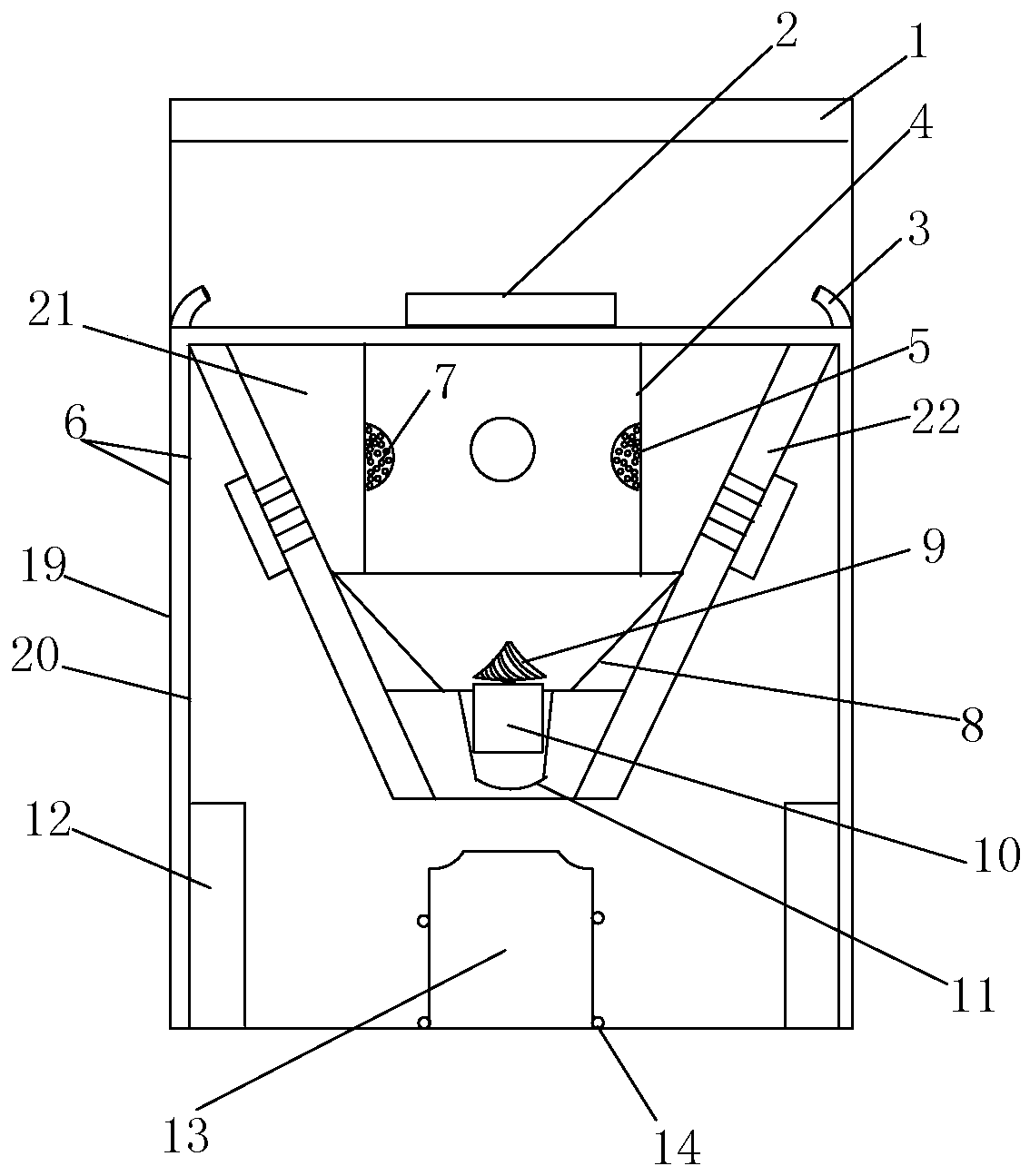

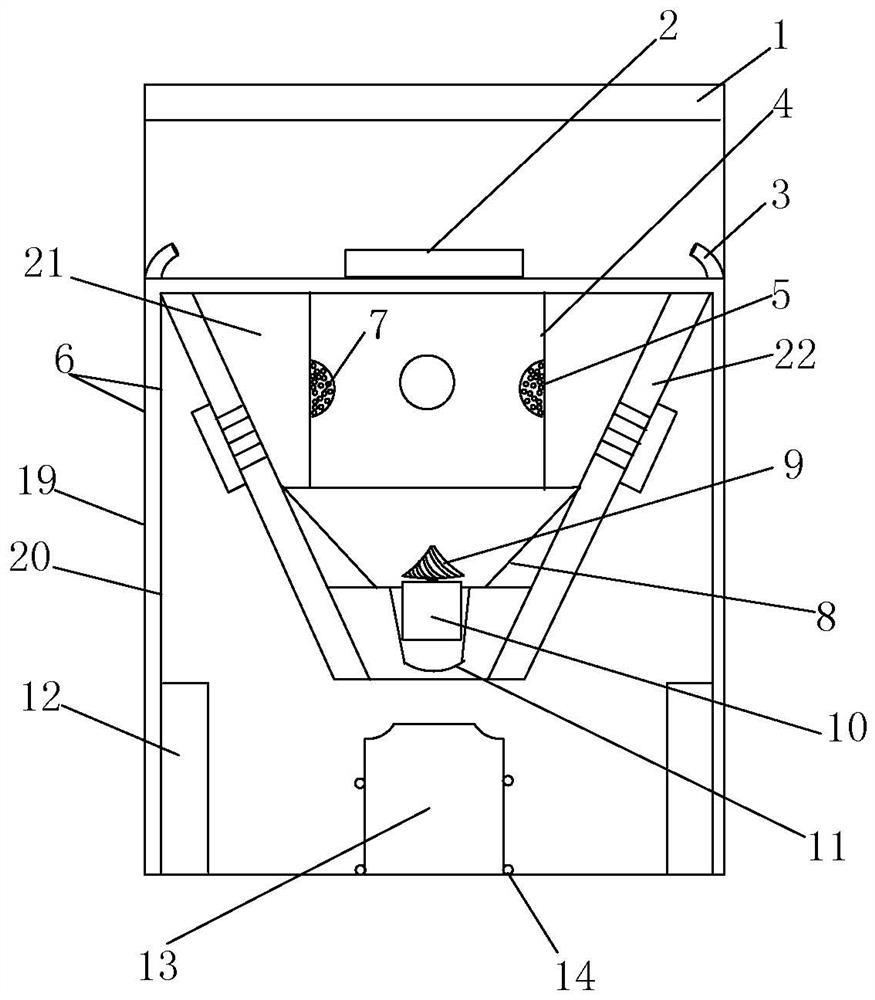

Apparatus for removing iron in powder

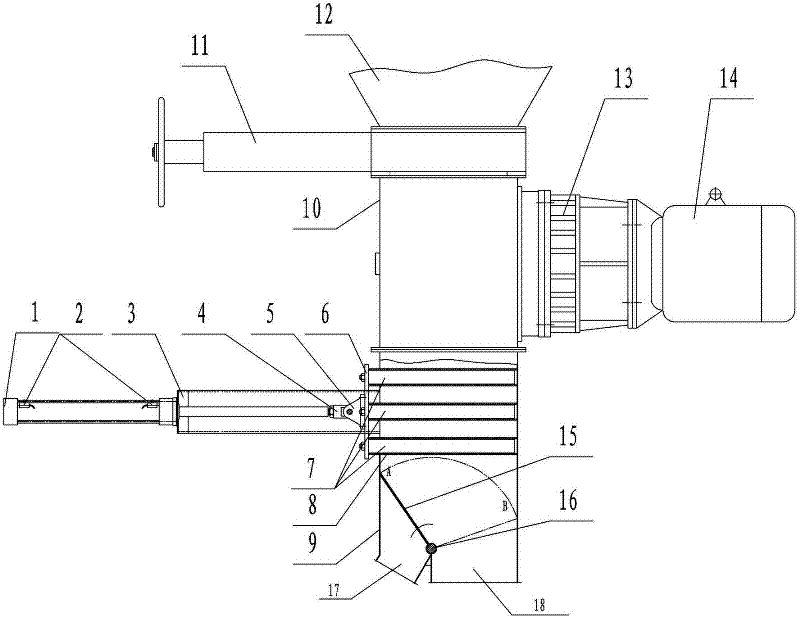

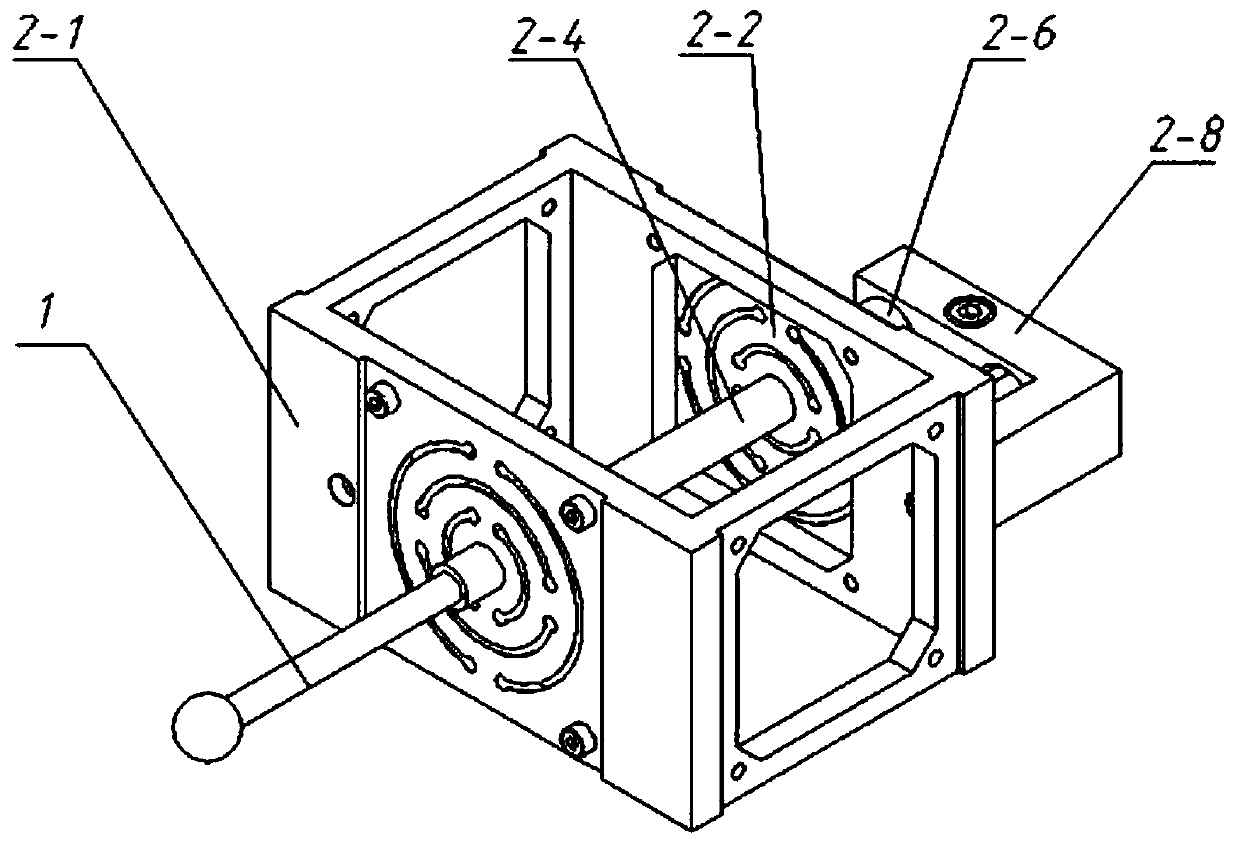

ActiveCN102441485AImprove the effect of iron removalReduce energy consumptionMagnetic separationEngineeringFlap valve

The invention relates to an apparatus for removing iron in powder. The apparatus comprises a feeding mechanism, a magnetic separation mechanism and a support; the magnetic separation mechanism comprises a box, at least a magnetic rod set, magnetic rod sleeves with an amount corresponding to the amount of magnetic rods, a magnetic rod set driving unit and a flap valve, wherein, the magnetic rod sleeves are transversely arranged at the middle and upper parts of the box, one end of every magnetic rod of the magnetic rod set is fixed by a connection board and is then connected with a power output terminal of the magnetic rod set driving unit, the other end of every magnetic rod passes through a corresponding magnetic rod sleeve, every magnetic rod slidely moves in its corresponding magnetic rod sleeve under the driving of the magnetic rod set driving unit, an iron discharging outlet and a material discharging outlet are arranged at the bottom of the box, and the flap valve is installed above the iron discharging outlet and the material discharging outlet. The apparatus has the following advantages: a good iron-moving effect, low energy consumption, low cost for operation and maintenance, particular suitability for fine removal of iron in a powder material, a simple structure, small occupation space, convenient fabrication, installation and maintenance, a low price and easy popularization and usage.

Owner:洛阳宜墨新材料有限公司

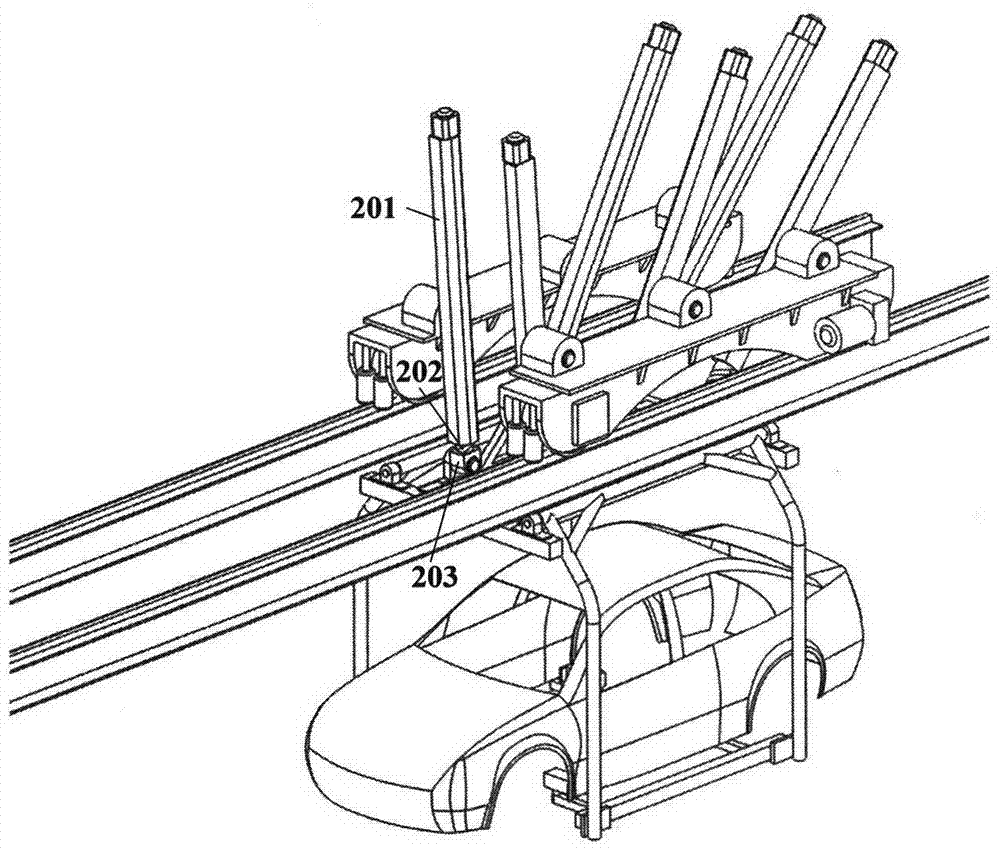

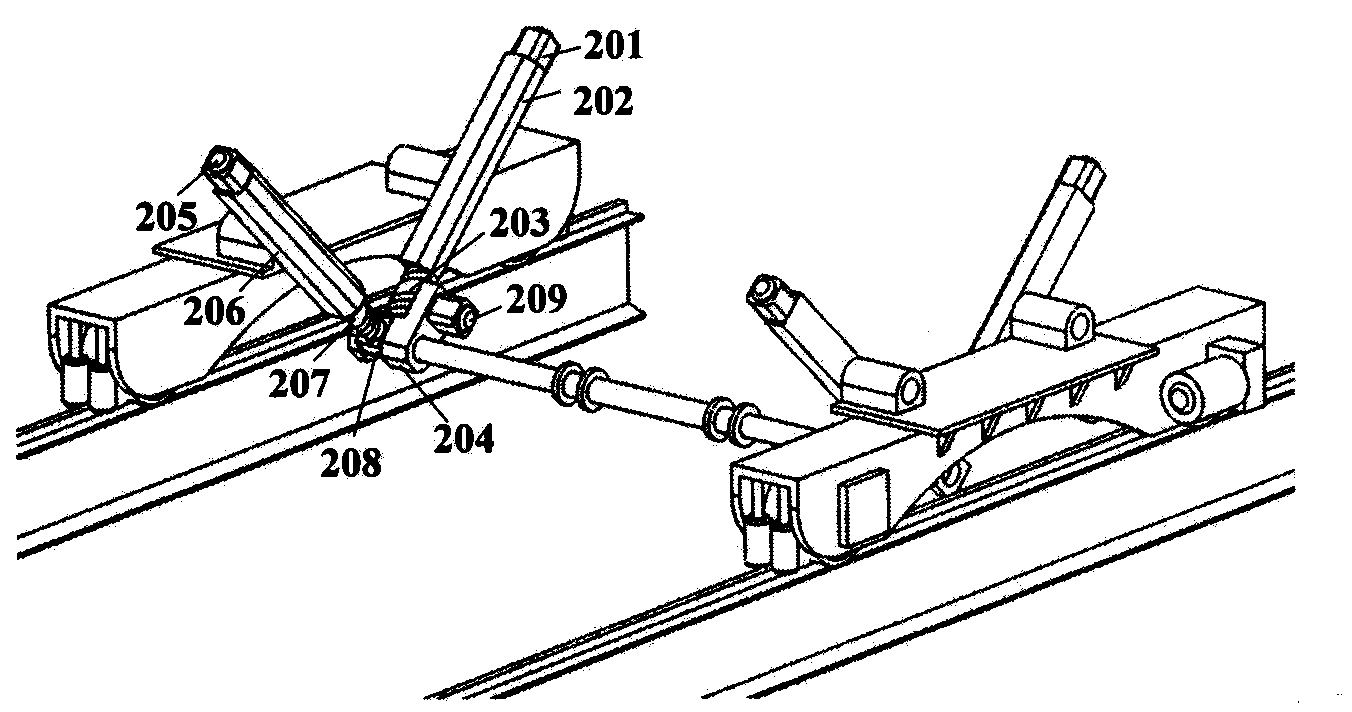

Double-crank automobile coating conveyor and application thereof

InactiveCN102583022ASame structureDifferent dead center positionsElectrophoretic coatingsConveyor partsProduction lineEngineering

The invention relates to a double-crank automobile coating conveyor and application thereof. The double-crank automobile coating conveyor comprises two function parts including a running mechanism and a turnover mechanism, wherein the running mechanism realizes a running conveying function of the conveyor, the turnover mechanism consists of a plurality of double-crank mechanisms with different mid-gear positions, conveyed automobiles can be turned over by driving the double-crank mechanisms, and the automobiles can be driven to be conveyed forwards, inclined and turned over or subjected to combined actions of the above various actions by combining the running mechanism with the turnover mechanism. The double-crank automobile coating conveyor can be applicable to conveying of automobiles which are in different types and sizes and conveying of automobile electrophoretic coating production lines and is a flexible conveyor on an automobile coating production line. Flexibility of the conveyor is improved.

Owner:JIANGSU CHANGHONG INTELLIGENT EQUIP CO LTD +1

Novel fully feeding combine harvester

The invention relates to a novel fully feeding combine harvester. The novel fully feeding combine harvester comprises a harvester frame, wherein a header is arranged at the front end of the harvester frame; a threshing device is directly connected and installed behind the header; a threshing cylinder in a threshing device is connected to two drive shafts in a manner of a motive power; a grain receiving hopper is arranged below the threshing cylinder; an exhaust inlet is arranged at the lower end of the grain receiving hopper; the exhaust inlet is communicated with a multi-cylinder grain and sundry separation device through an air suction pipe, so that grain and sundry in the grain receiving hopper enter into the multi-cylinder grain and sundry separation through the air suction pipe for separation; grains are discharged from a grain outlet for bagging; and sundries are blown away by a draught fan. The novel fully feeding combine harvester has the advantages of a simple and rational structure, strong practicability, convenience in production, installation as well as maintenance, and good use effects.

Owner:SHAOGUAN FENGYI IND & TRADE

Stripping type combine harvester

The invention relates to a stripping type combine harvester. A blade type crop-poking device is arranged at the front end of a harvester frame; the harvester frame is provided with upper and lower double-roller type threshing devices behind the blade type crop-poking device; a vibrating sieve and a grain receiving hopper are arranged below the upper and lower double-roller type threshing devices; a lower threshing roller is connected to the vibrating sieve and the grain receiving hopper through an eccentric wheel in a manner of a motive power; an upper threshing roller is connected to the blade type crop-poking device in a manner of the motive power; a rotary spiral roller stem-crushing device is arranged on the harvester frame and below the vibrating sieve and the grain receiving hopper; a back threshing roller is arranged on the harvester frame and behind the upper and lower double-roller type threshing devices; the vibrating sieve and the grain receiving hopper are arranged below the back threshing roller; an air suction hole is arranged at the bottoms of both the vibrating sieve and the grain receiving hopper; the air suction hole is communicated with a multi-cylinder grain and sundry separation device through an air suction pipe, so that the grains and the sundries enter into the multi-cylinder grain and sundry separation device for separation through the air suction pipe; the grains are discharged from a grain outlet for bagging; and the sundries are blown away from a draught fan opening.

Owner:SHAOGUAN FENGYI IND & TRADE

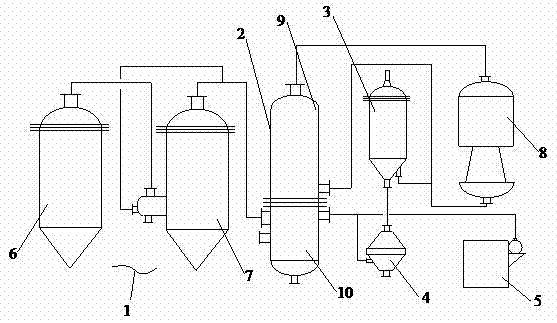

Regeneration process and regeneration device for heavy metal containing nitric acid waste liquor

InactiveCN103172214AHigh recovery rateHigh market valueWaste water treatment from metallurgical processMultistage water/sewage treatmentLiquid wasteNitrate

The invention discloses a regeneration process and regeneration equipment for heavy metal containing nitric acid waste liquor. The regeneration process comprises the following steps of: evaporating nitric acid by virtue of an evaporative crystallization device under the action of negative pressure, condensing and recycling the nitric acid steam to obtain regenerated nitric acid; mixing heavy metal nitrate, which is recycled by a discharging system of the evaporative crystallization device, with concentrated sulfuric acid, stirring the mixture, cooling the mixture to room temperature, and filtering the mixture to obtain a heavy metal sulphate product in suction. The regeneration equipment comprises an evaporating device, a condensing and cooling device, a cooling and crystallizing device, a suction-filtering device and a horizontal ejection vacuum device, wherein the evaporating device, the condensing and cooling device and the cooling and crystallizing device are communicated in sequence. The regeneration process is high in nitric acid recovery rate, almost free of secondary pollution, capable of recycling the heavy metal to the greatest extend and high in market value of the recycled product. And the complete equipment is easy to manufacture, install, maintain and repair, low in energy consumption, and high in economical benefits and environment-friendly benefits.

Owner:昆山市台鑫五金厂

Coke discharge dedusting system of coke oven

InactiveCN103131434AReduce air leakage rateLow input costCombination devicesCoke quenchingCoke ovenExpansion joint

The invention belongs to a smoke dust purification system in the process of coke discharging of a coke oven and provides a coke discharge dedusting system of the coke oven. The coke discharge dedusting system comprises a coke discharge suction hood, coke discharge dedusting dry tubes, a cyclone dust collector, a pulse-jet bag dust collector, a ventilation fan and a silencer device which are connected in sequence. A fixed connector valve is arranged between the coke discharge suction hood and the coke discharge dedusting dry tubes. A balance valve is arranged at the tail end of the coke discharge dedusting dry tubes. Expansion joints are arranged inside the coke discharge dedusting dry tubes. An electric butterfly valve is arranged between the coke discharge dedusting dry tubes. Each coke discharge dedusting dry tube is formed by a fixed flap valve. The coke discharge dedusting system of the coke oven has the advantages of being good in dust removal effects, high in dust removal efficiency, convenient to install and maintain, low in invested cost and the like.

Owner:扬州康龙环保工程有限公司

Blowing type lifting separating device for combine harvester

The invention relates to a blowing type lifting separating device for a combine harvester. The blowing type lifting separating device is provided with an air inlet pipe which is communicated with a draught fan, the other end of the air inlet pipe is communicated with one end of an air flue at the bottom of a material collection hopper, the other end of the air flue at the bottom of the material collection hopper is connected with an air outlet pipe, a grain and impurity discharge opening is formed in the upper end of the joint of the air flue and the air outlet pipe, the grain and impurity discharge opening is communicated with the air flue and the air outlet pipe, the other end of the air outlet pipe is communicated with a grain and impurity separating device, and a spiral conveying device is arranged at the bottom of the grain and impurity separating device. The blowing type lifting separating device is simple and reasonable in structure, strong in practicability, convenient to manufacture, install and maintain, and good in use effect.

Owner:SHAOGUAN FENGYI IND & TRADE

Cement stirring machine

InactiveCN109849180APrevent splashWell mixedDischarging apparatusMixing operation control apparatusPulp and paper industryCement

The invention designs a cement stirring machine. The cement stirring machine comprises a cylindrical hollow stirring barrel, wherein a feeding opening, a water inlet and a discharging opening are formed in the side surfaces of the stirring barrel; a dismountable end surface cover is mounted on one of the end surfaces of the stirring barrel; a stirring shaft is arranged in the stirring barrel; blades are fixed on the stirring shaft; sealing rings are arranged at positions where the stirring shaft is in contact with the end surface and the end surface cover of the stirring barrel; and bearings are respectively arranged at two ends extending out of the stirring barrel, of the stirring shaft. The cement stirring machine disclosed by the invention is a horizontal type cement pulping machine with a simple supporting beam structure; and the simple supporting beam structure is adopted, so that materials can be sufficiently mixed, the mixing uniformity and the production efficiency are notablyimproved, and the stirring effect of cement is greatly improved.

Owner:WUHAN UNIV OF TECH

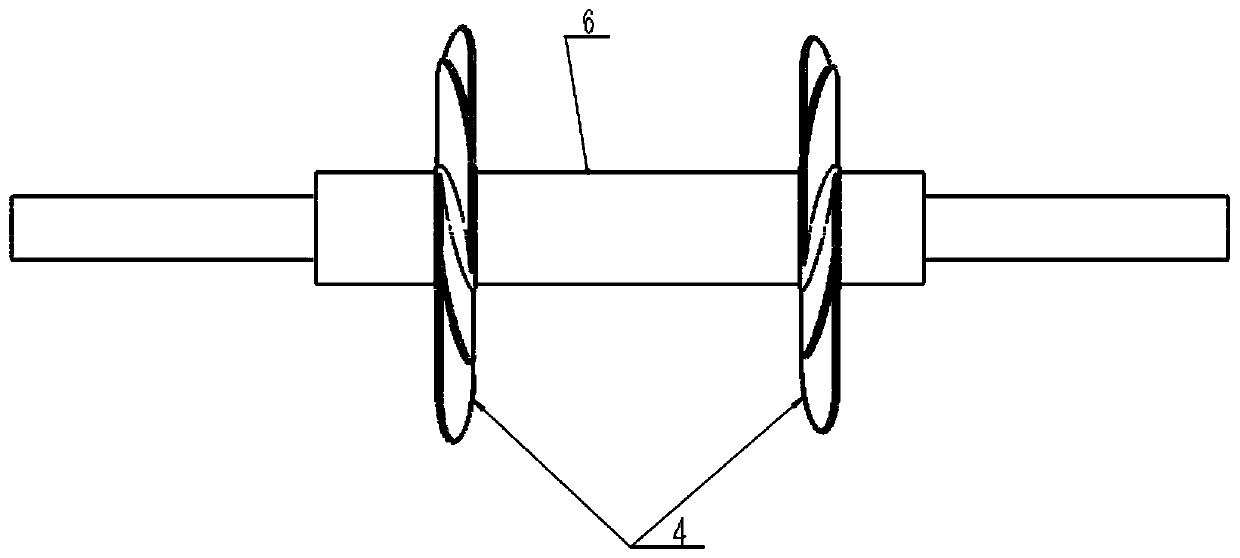

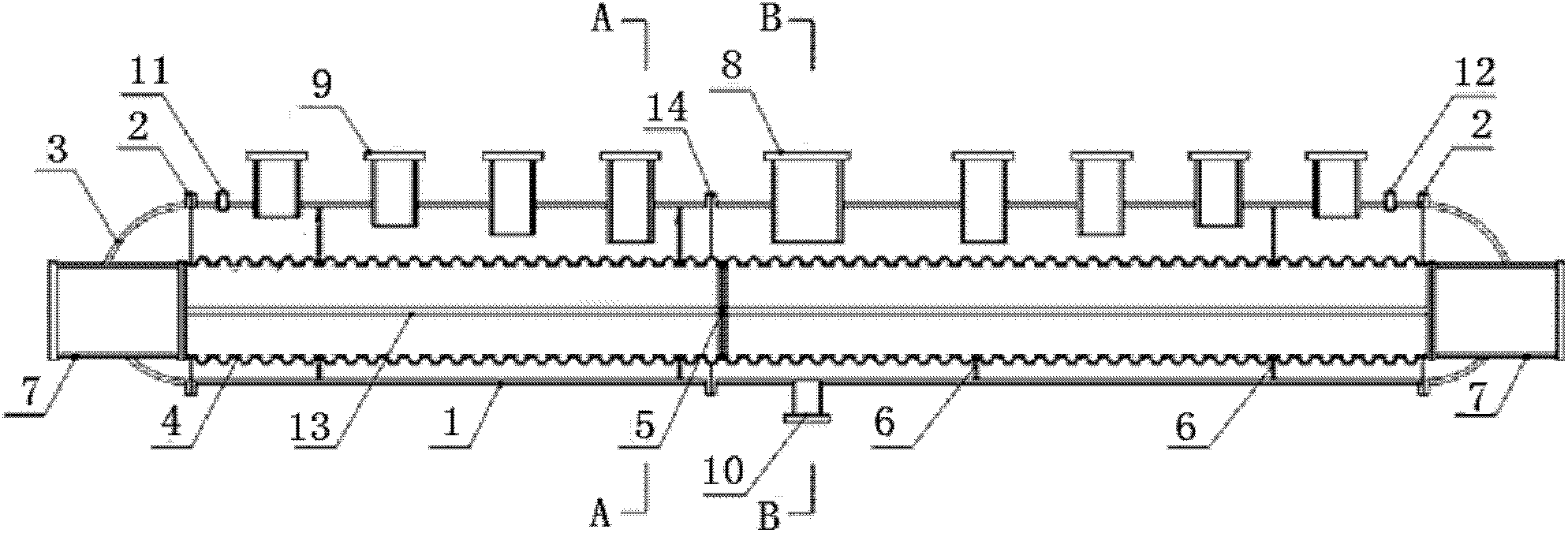

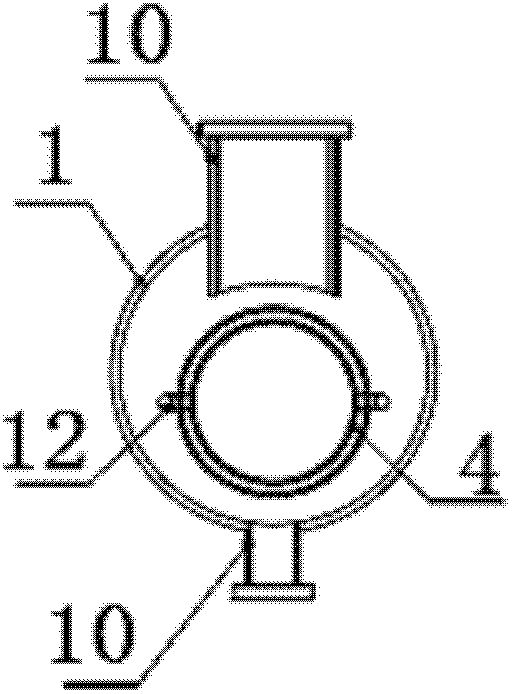

Reinforced convection heat exchange type water distribution and collection device for cold source machine room

ActiveCN102425814AWith heat exchange functionGood value for moneyStationary tubular conduit assembliesHot-water central heatingEngineeringConvection heat

The invention relates to a reinforced convection heat exchange type water distribution and collection device for a cold source machine room. The device comprises a barrel, wherein a first overhauling flange is arranged on the middle part of the barrel, barrel end caps are arranged at two ends of the barrel, second overhauling flanges are arranged at the joints of the barrel and the barrel end caps, a plurality of stainless steel corrugated pipes are arranged in the barrel, the adjacent stainless steel corrugated pipes are connected through a corrugated pipe segmentation flange and a corrugated pipe reinforcing connecting rod, the stainless steel corrugated pipes are fixed with the barrel through a plurality of limiting supports, the stainless steel corrugated pipes positioned at two ends in the barrel are connected with corrugated pipe joints, and the corrugated pipe joints pass through the barrel end caps and are connected with a heat exchange pipeline; and a main water pipe is arranged on the top of the middle part of the barrel, a plurality of branched pipes are uniformly distributed on two sides of the main water pipe, and the main water pipe and the branched pipes extend into the barrel. The device has the advantages of two purposes, high cost performance, good heat exchange effect, low flow resistance, reasonable shunt, space saving and capability of selectively exchanging heat, and is easy and convenient to manufacture, install and maintain.

Owner:CHINA RAILWAY CONSTR GROUP

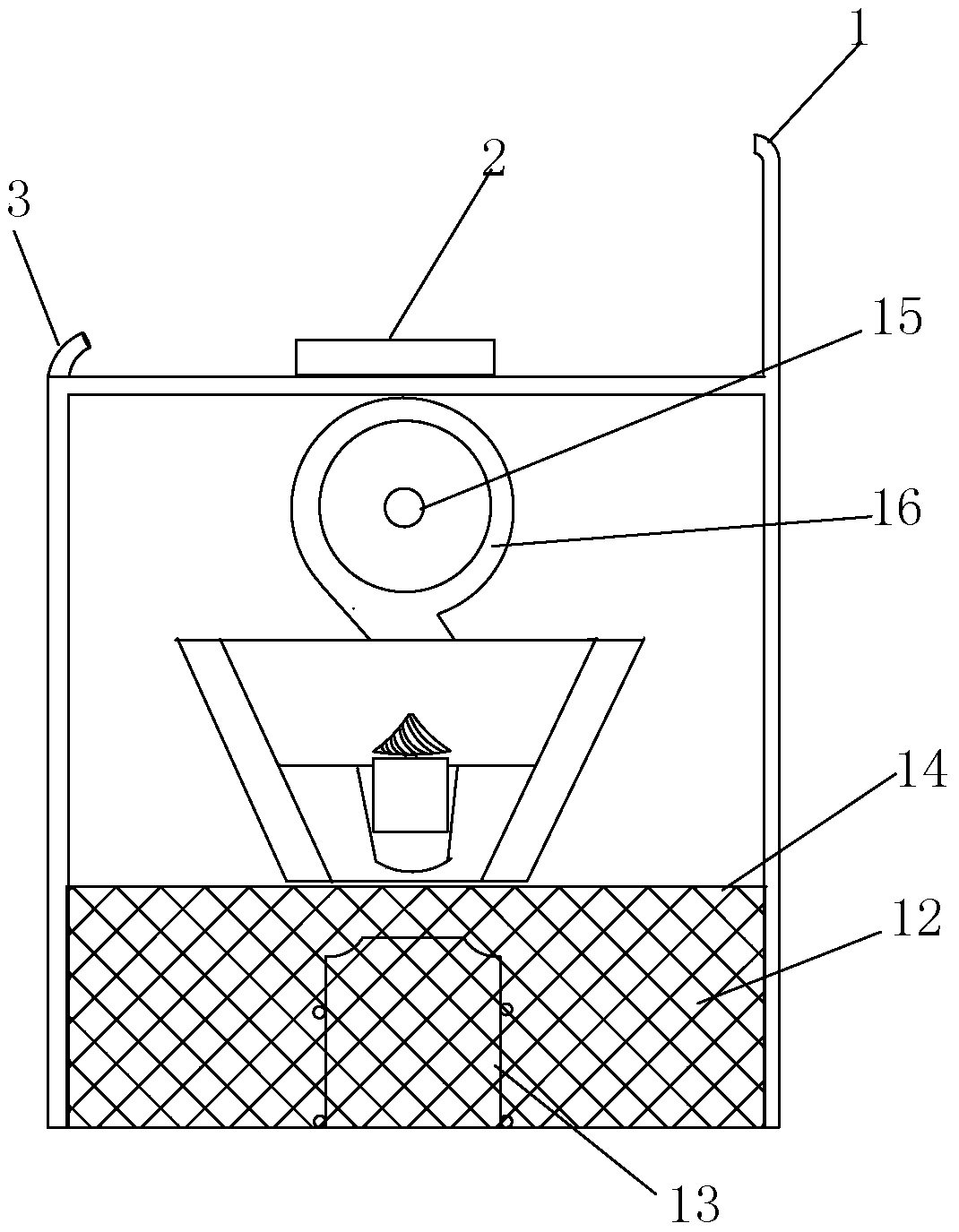

Suction type multi-drum grain and impurity separating device

InactiveCN103252319ATo achieve the purpose of separation of grain and miscellaneousSimple structureGas current separationThreshersEngineeringMechanical engineering

The invention relates to a suction type multi-drum grain and impurity separating device which comprises a body, wherein the body is formed by two or more cavities through series connection. The cavities are communicated inside, and are identical or different in structure. One side of the upper portion of one cavity is provided with a large round drum communicated with a fan, and a small round drum is arranged in the large round drum in sleeved mode. A clearance used as a suction channel is formed between the inside of the large round drum and the small round drum, and a clearance used as a suction channel is formed between the bottom of the large round drum and the bottom of the small round drum. An opening in the bottom of the large round drum is connected with the fan, and at least one grain outlet is formed in the bottom of each cavity. A feeding inlet is formed in the upper face of one cavity, and the cavities are communicated through suction bent pipes. The suction type multi-drum grain and impurity separating device has the advantages of being simple and reasonable in structure, strong in practicability, convenient to manufacture, install and maintain, and good in using effect.

Owner:SHAOGUAN FENGYI IND & TRADE

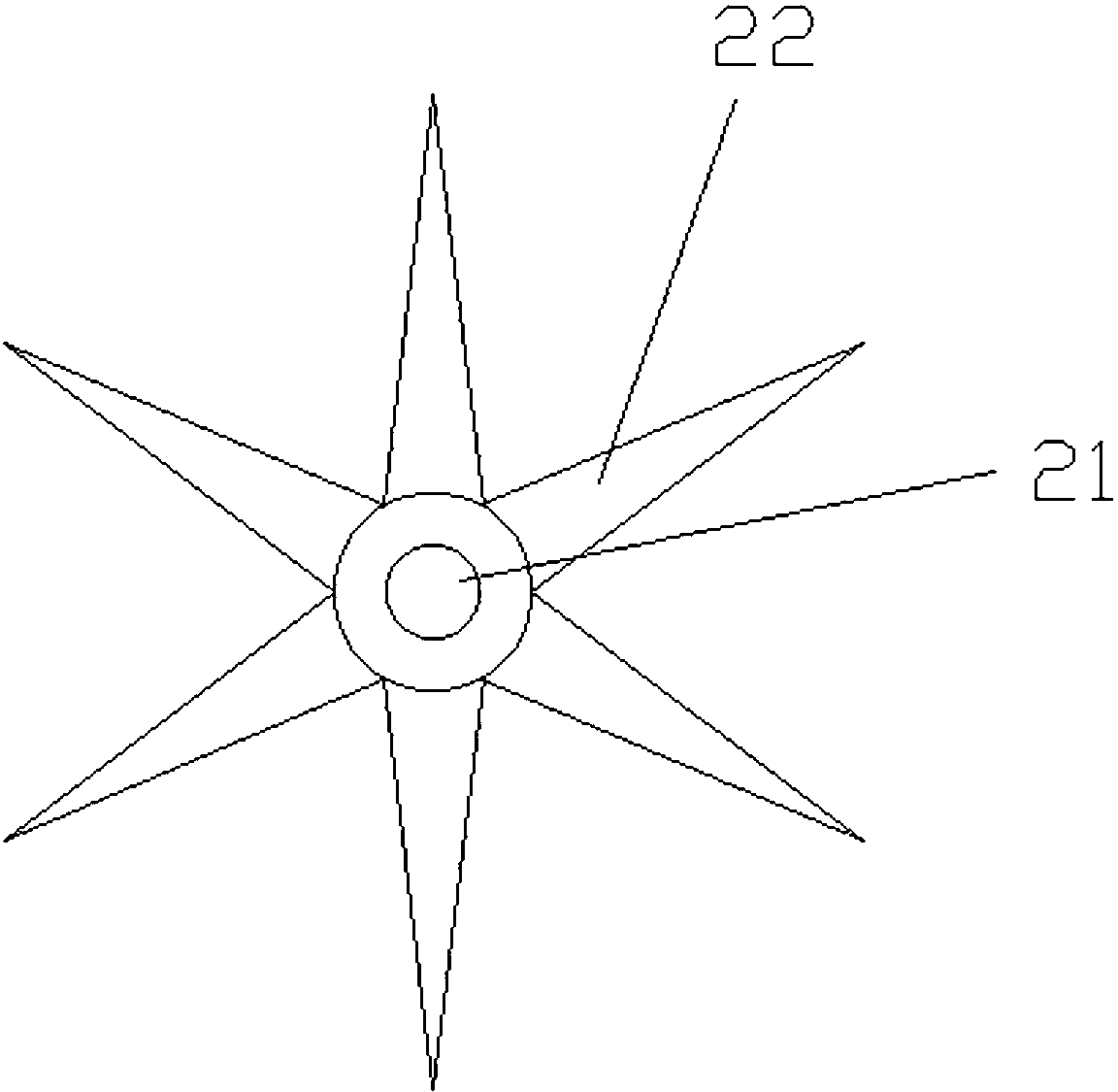

A kind of smoke extraction and dust removal equipment

Disclosed is a smoke extraction and dust removal apparatus, comprising a casing (1). The casing (1) is provided with an exhaust port, the exhaust port is in communication with an air inlet of an inner air duct (11), the inner air duct (11) is mounted in a pressurized air cavity (12), a lower end of the pressurized air cavity (12) is connected to an outer edge of the air inlet of the inner air duct (11), and an upper end of the pressurized air cavity (12) is in communication with an outer air pipe (22); and an air-exhausting device (13) capable of radially exhausting air in the inner air duct (11) so as to form negative pressure in the inner air duct (11) and thus facilitate the intake of smoke and dust into the inner air duct is mounted on a lower end wall face of the inner air duct (11), air located between the inner air duct (11) and the pressurized air cavity (12) is pressurized so as to rapidly flow to the outer air pipe (22) at the same time as negative pressure is produced in the inner air duct (11) by means of the air-exhausting device (13), and the pressurized air drives the air in the inner air duct (11) to be rapidly exhausted to the outer air pipe (22). The apparatus has a simple structure, is convenient to manufacture, install and maintain, and can work for a long time without cleaning.

Owner:韩波

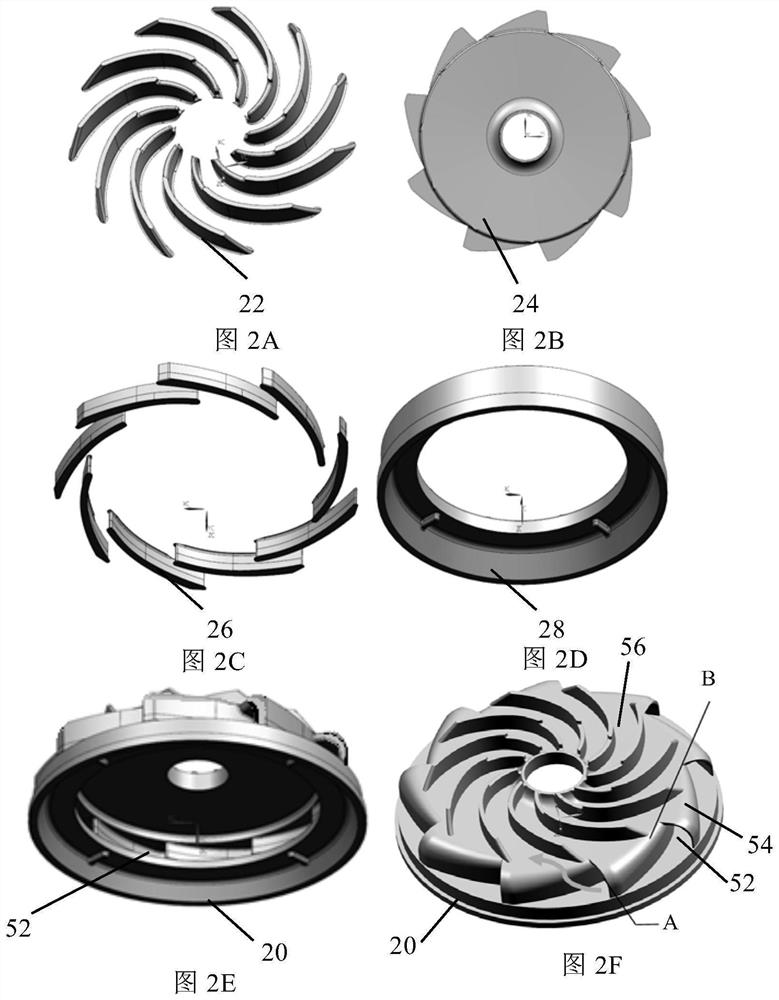

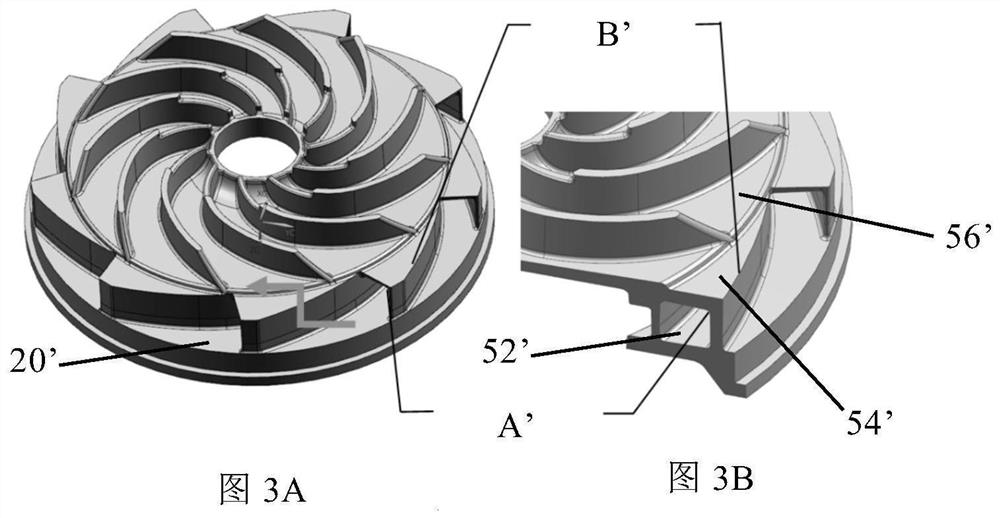

A centrifugal pump with double-variable curvature flow channel

ActiveCN112392768BImprove hydraulic efficiencyReduce vibrationPump componentsHydro energy generationWater flowEngineering

The invention provides a centrifugal pump, comprising a guide vane body, wherein the tail portion of the positive guide vane blade of the guide vane body is an arc surface, so that the flow channel section of the positive guide vane flow channel of the guide vane body is fan-shaped , and / or the curved space flow channel of the guide vane body has a double-variable curvature flow channel curved surface. By using a centrifugal pump with a double-variable curvature flow channel, the right-angle bending formed by the two planes of the curved space flow channel is turned into a curved surface bending of a double-variable curvature space curved surface, thereby making the water flow smoother and improving the hydraulic efficiency of the pump , and reduce the vibration and noise of the pump.

Owner:KSB SHANGHAI PUMP

Apparatus for removing iron in powder

ActiveCN102441485BImprove the effect of iron removalReduce energy consumptionMagnetic separationEngineeringFlap valve

The invention relates to an apparatus for removing iron in powder. The apparatus comprises a feeding mechanism, a magnetic separation mechanism and a support; the magnetic separation mechanism comprises a box, at least a magnetic rod set, magnetic rod sleeves with an amount corresponding to the amount of magnetic rods, a magnetic rod set driving unit and a flap valve, wherein, the magnetic rod sleeves are transversely arranged at the middle and upper parts of the box, one end of every magnetic rod of the magnetic rod set is fixed by a connection board and is then connected with a power output terminal of the magnetic rod set driving unit, the other end of every magnetic rod passes through a corresponding magnetic rod sleeve, every magnetic rod slidely moves in its corresponding magnetic rod sleeve under the driving of the magnetic rod set driving unit, an iron discharging outlet and a material discharging outlet are arranged at the bottom of the box, and the flap valve is installed above the iron discharging outlet and the material discharging outlet. The apparatus has the following advantages: a good iron-moving effect, low energy consumption, low cost for operation and maintenance, particular suitability for fine removal of iron in a powder material, a simple structure, small occupation space, convenient fabrication, installation and maintenance, a low price and easy popularization and usage.

Owner:洛阳宜墨新材料有限公司

Automobile coating parallel mechanism conveyer and application thereof

ActiveCN101812716BSmall footprintLow costLiquid surface applicatorsElectrophoretic coatingsElectrophoresesProduction line

The invention relates to an automobile coating parallel mechanism conveyer, which comprises two functional parts: a traveling mechanism and a lifting and turning mechanism. The traveling mechanism finishes the traveling and transporting functions of the conveyer; the lifting and turning mechanism consists of one or more parallel mechanisms; the body of the automobile or other objects to be conveyed are arranged on a moving platform of the parallel mechanism; and the parallel mechanism is driven to finish the lifting and turning of the object to be conveyed. The movement of the traveling mechanism is combined with that of the parallel mechanism; the body is driven to realize advancing and retreating, lifting, tilting or composite movement thereof so as to be fully stirred in an electrophoresis tank to achieve the purpose of completely eliminating bubbles on the top of the automobile body during the electrophoresis. Because the parallel mechanism is adopted by the conveyer, the bearing capacity of the conveyer is increased so as to be suitable for conveying the bodies of different types or sizes, and the flexibility of the conveyer is also increased; and because the suspending and conveying system has a gantry structure, the conveyer successfully overcomes the defect of dropping liquid pollution and is therefore an environment-friendly conveyer on the automobile coating production line.

Owner:JIANGSU CHANGHONG INTELLIGENT EQUIP CO LTD +1

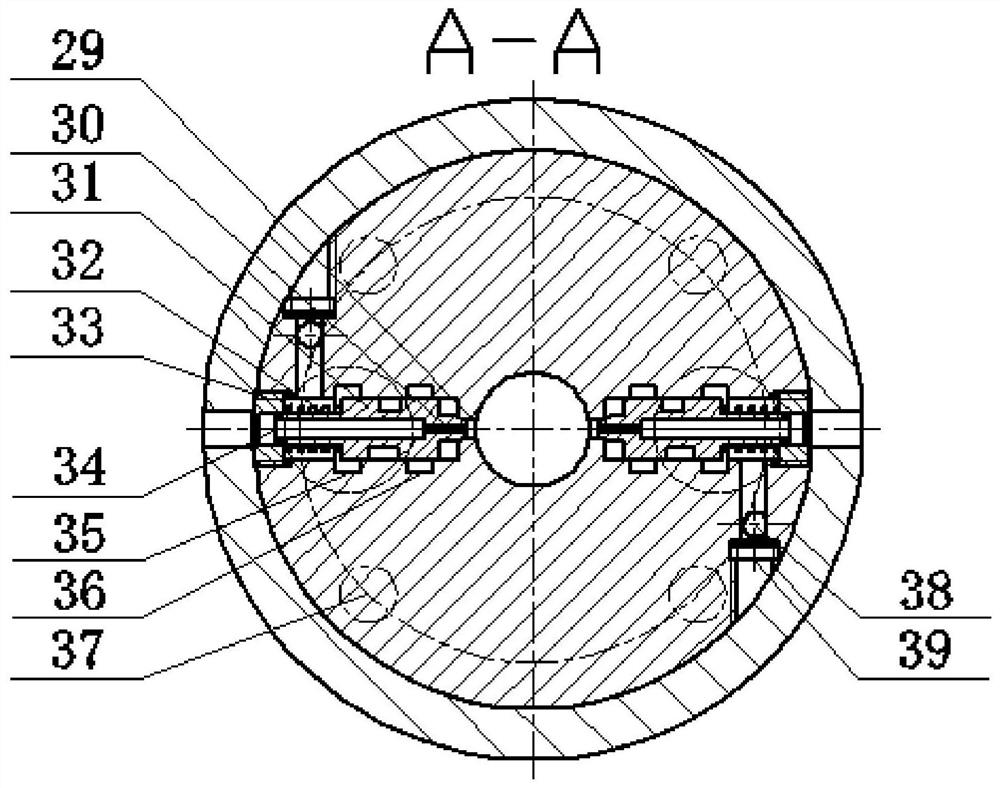

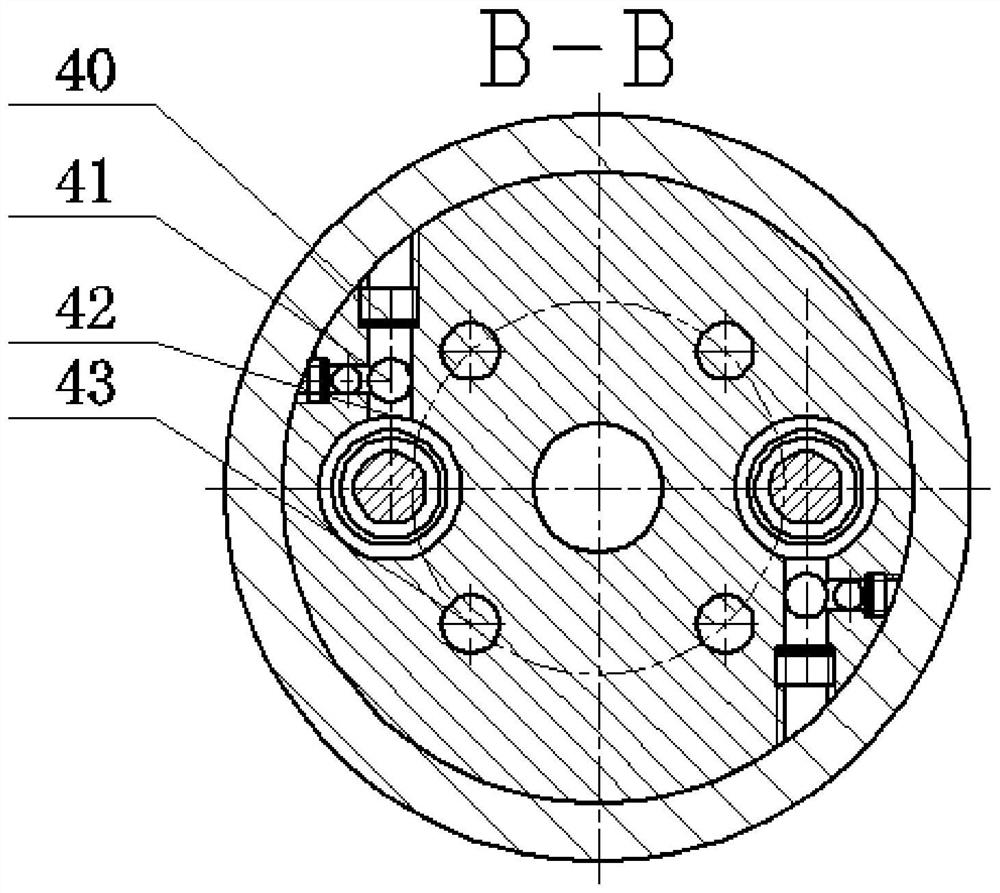

A three-dimensional decoupling scanning probe

ActiveCN109373878BEliminate cosine errorThere is no coupling errorUsing electrical meansMeasuring instrumentEngineering

The invention relates to the technical field of precision measuring instruments and particularly relates to a three-dimensional decoupling type scanning probe. The three-dimensional decoupling scanning probe comprises an X and Y direction measuring mechanism, a Z direction measuring mechanism, a probe housing, a measuring rod and a spring balancing mechanism. According to the probe, X direction, Ydirection and Z direction moving guide rails are formed through three sets of mutually perpendicularly installed diaphragm guiding mechanisms, an inductive sensor is installed in each of the three directions to measure the micro-displacement of a test needle in the three directions of X, Y, and Z. According to the probe of the invention, the mutual decoupling is performed in three directions, theprobe has the advantages of compact structure, small volume, high measurement precision, high sensitivity and good long-term stability, and one-dimensional, two-dimensional and three-dimensional scanning measurement can be realized.

Owner:XIAN TECH UNIV

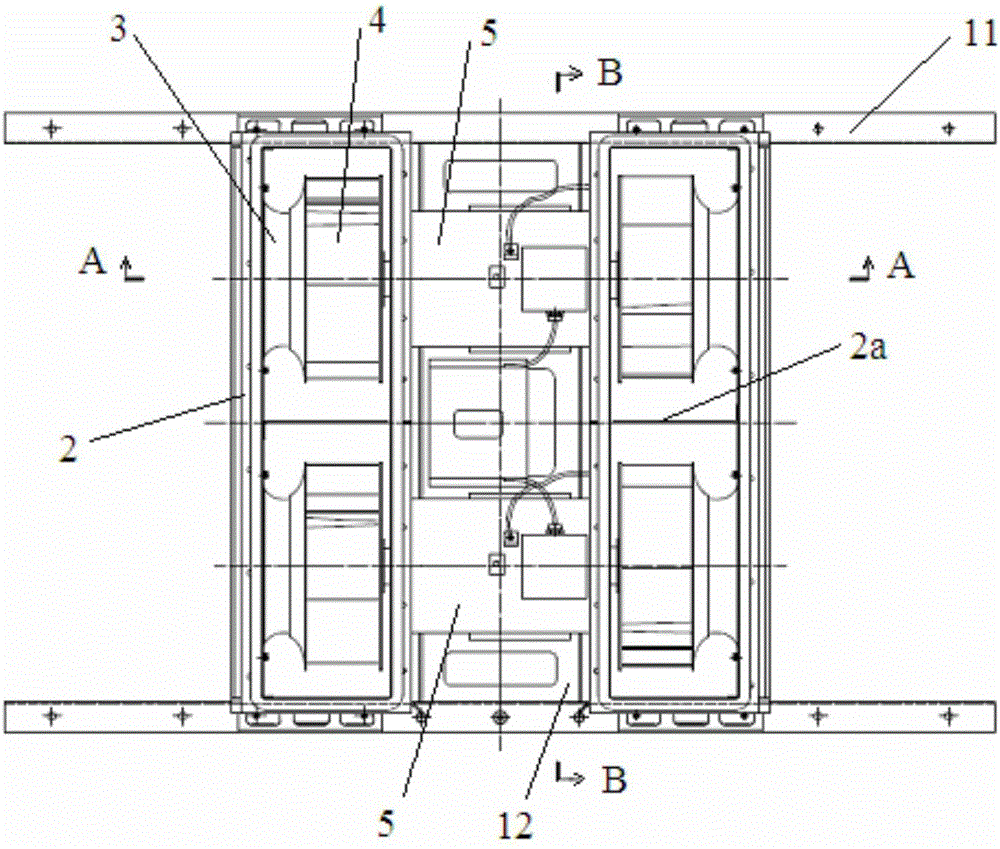

Automobile coating conveyor with multi-rod mechanisms

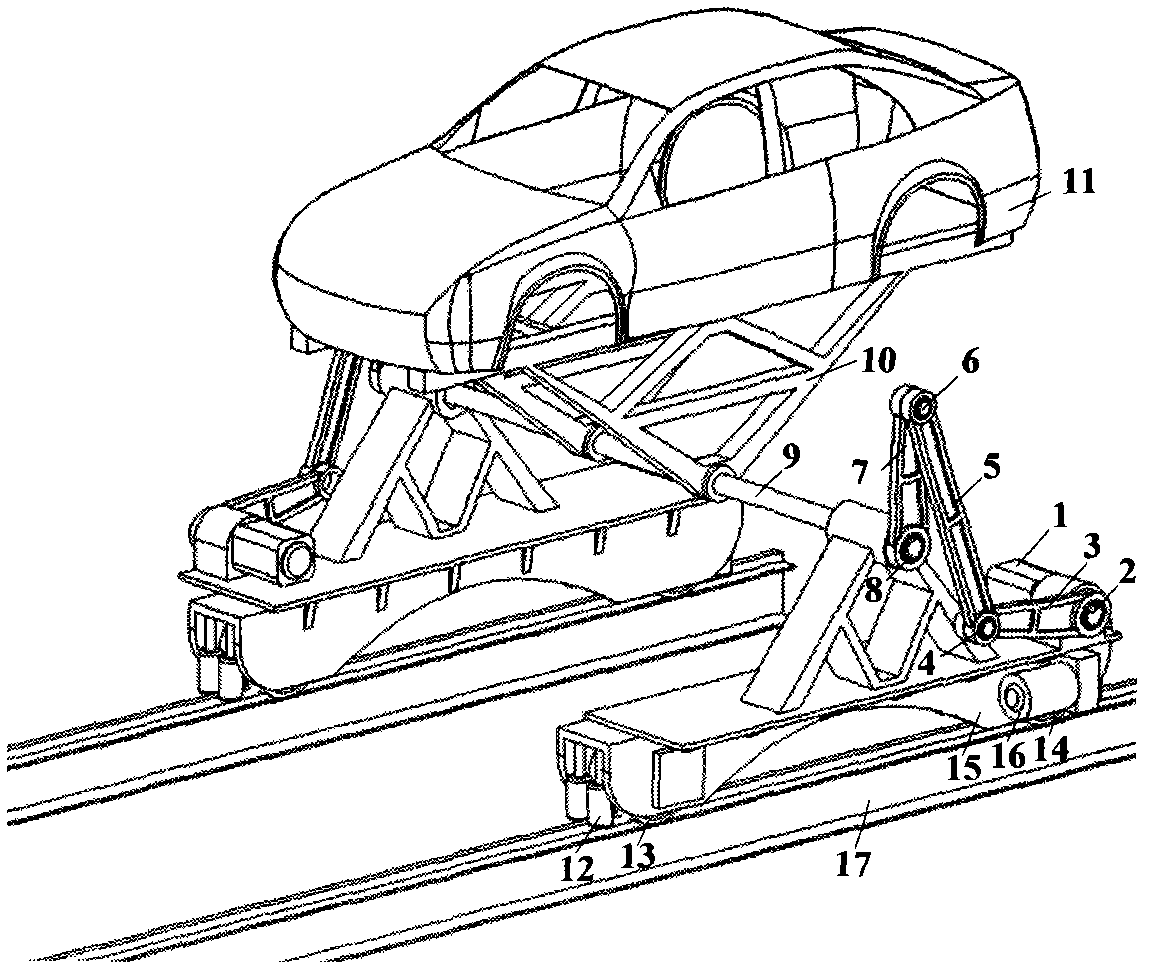

InactiveCN102560603BSmall footprintLow costLiquid surface applicatorsCharge manipulationProduction lineElectrophoresis

The invention relates to an automobile coating conveyor with multi-rod mechanisms and application of the automobile coating conveyor in an electrophoretic coating production line. The automobile coating conveyor comprises two functional parts, namely a traveling mechanism and a translating, lifting and turning mechanism, wherein the traveling mechanism is used for finishing a traveling transportation function of the conveyor; the translating, lifting and turning mechanism comprises one or more plane multi-rod mechanisms and can be used for finishing lifting, turning and translating motions of the conveyed objects by driving the plane multi-rod mechanisms. A plurality of groups of plane multi-rod mechanisms are applied to the automobile coating conveyor disclosed by the invention, so that the bearing capacity of the automobile coating conveyor is increased, the automobile coating conveyor can be used for conveying automobile bodies with different models and sizes and the flexibility of the automobile coating conveyor is improved. The translating, lifting and turning mechanism can realize the entrance into a tank in advance and delayed leaving from the tank, so that the length of the electrophoresis tank can be shortened and an electrophoretic solution is saved. The automobile coating conveyor is an environment-friendly conveyor on the automobile coating production line.

Owner:TSINGHUA UNIV

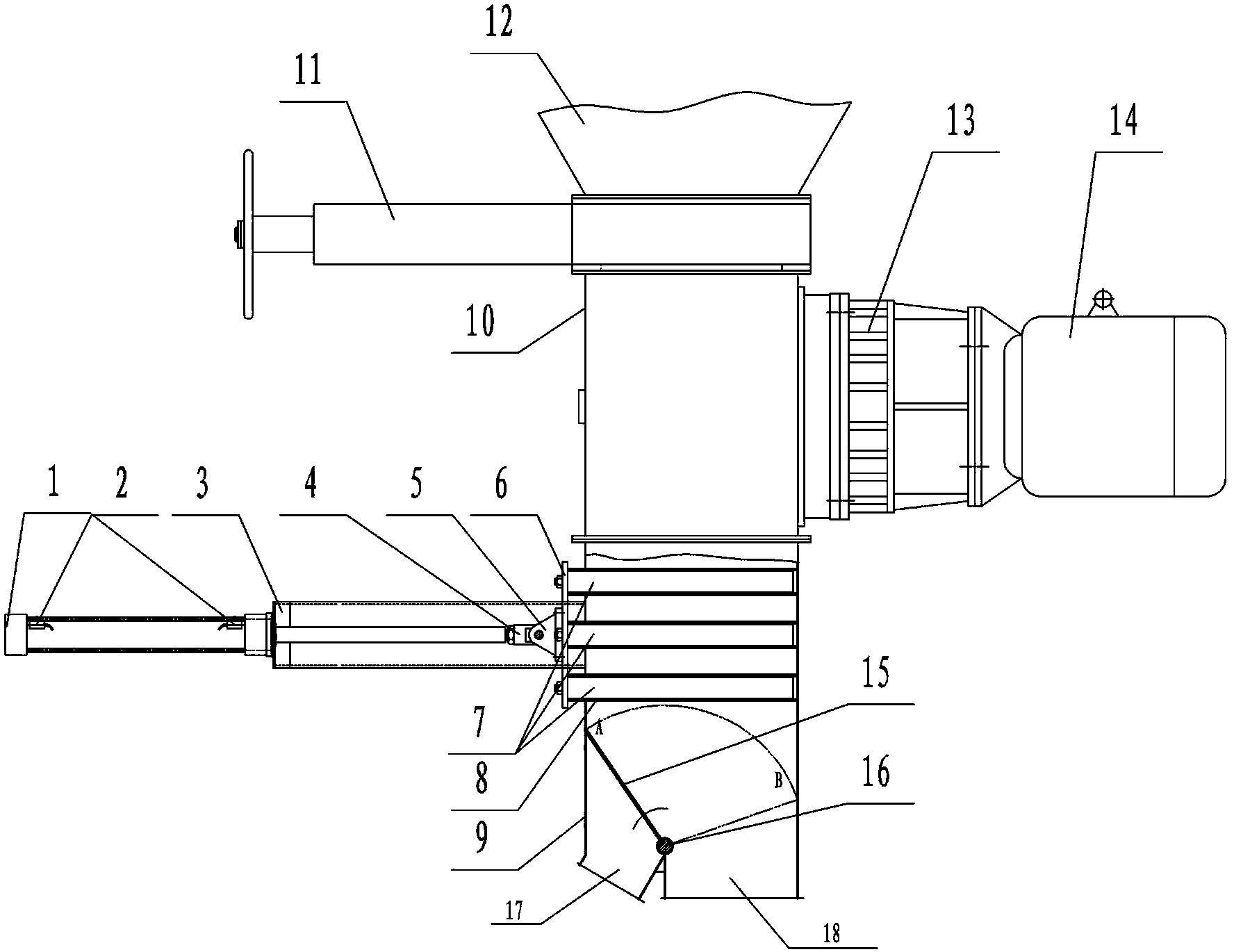

Cooling ventilator for locomotive traction transformer

ActiveCN106678062ASimple and compact structureEasy to manufacture, install and maintainTransformers/inductances coolingPump componentsImpellerMotor shaft

Owner:ZHUZHOU LINCE GRP

Automobile coating conveyor and application thereof

ActiveCN102616539BAchieve advance and retreatAchieve liftingLiquid surface applicatorsCharge manipulationProduction lineEngineering

The invention relates to an automobile coating conveyor. The automobile coating conveyor comprises a traveling mechanism and a lifting turnover mechanism which serve as two functional parts, wherein traveling and transporting functions of the conveyor can be finished by the traveling mechanism; and lifting motion and turnover motion of conveyed objects can be finished through the lifting turnover mechanism. The motion of the traveling mechanism is combined with the motion of the lifting turnover mechanism, so that an automobile body can do advance and retreat motion, lifting motion and turnover motion or can do composite motion of the three kinds of motion; and the automobile coating conveyor can be used for an electrophoretic coating production line of the automobile body.

Owner:JIANGSU CHANGHONG INTELLIGENT EQUIP CO LTD +1

Hydraulically-driven reaming-while-drilling tool

ActiveCN112196468AEasy to replaceEasy to manufacture, install and maintainDrill bitsWell/borehole valve arrangementsHydraulic cylinderWell drilling

The invention discloses a hydraulically-driven reaming-while-drilling tool. The hydraulically-driven reaming-while-drilling tool mainly solves the problem that an existing reaming-while-drilling toolis small in reaming range. The hydraulically-driven reaming-while-drilling tool is characterized by comprising three parts including a starting device main body, a driving device main body and an executing device main body; a throttling reversing valve is arranged in the starting device main body and comprises a throttling reversing valve cavity, a throttling reversing valve element, a throttlingspring and a throttling reversing valve gland; and a throttle reversing valve switch is controlled to be started by the displacement of a drilling pump, and after the throttle reversing valve is opened, a piston of a hydraulic cylinder in the driving device main body descends under the action of liquid pressure to drive a cutter wing of a four-rod mechanism in the executing device main body to extend out to start reaming work. According to the hydraulically-driven reaming-while-drilling tool, under the condition that drilling is not affected, the reaming range can be enlarged, and the reamingrate can reach 60%.

Owner:NORTHEAST GASOLINEEUM UNIV

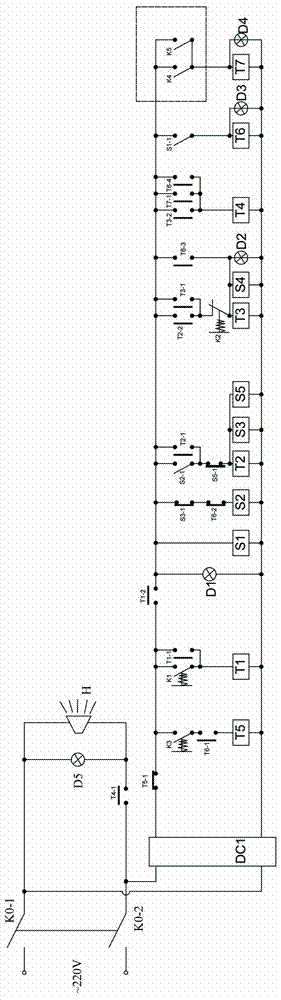

Thermal treatment process timed prompting and alarming device

The invention discloses a thermal treatment process timed prompting and alarming device, which comprises an AC / DC power supply DC1, contactors from the first to the seventh, time relays from the first to the fifth, a double-pole double-throw power switch, a manual switch K1, a manual switch K2, a manual switch K3, indicating lamps from D1 to D4, an alarming lamp D5 and an alarming loudspeaker H. The thermal treatment process timed prompting and alarming device has the beneficial effects that: the device can prompt the operator to carry out process confirmation at regular intervals, solves the problems of instability and randomness of working parameter data acquisition during the thermal treatment production process, has obvious stable processing capability, and prevents falsification. The thermal treatment process timed prompting and alarming device has the functions of manual / automatic starting, sound-light alarming, prompting alarming of timed prompting on operator to carry out process confirmation, thermal treatment completion prompting alarming, water level abnormity alarming, furnace door abnormity alarming, calculation of duration that the operator fails to operate as required, and manual misoperation prevention. The thermal treatment process timed prompting and alarming device has the advantages of simple structure, convenient operation, good expansibility and convenient manufacturing, installation and maintenance.

Owner:HEBEI SHENGYUE RAILWAY ELECTRIFICATION EQUIP

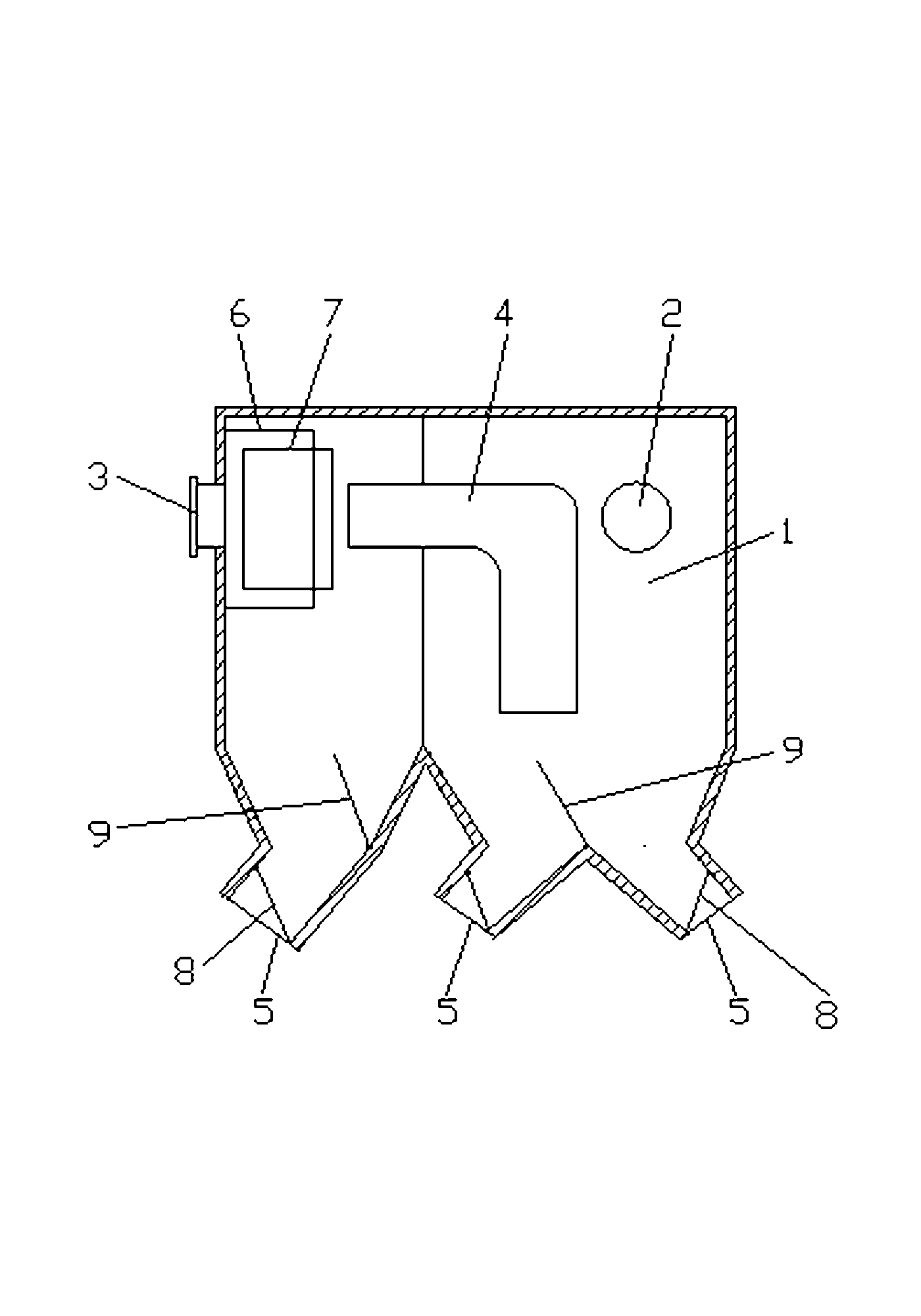

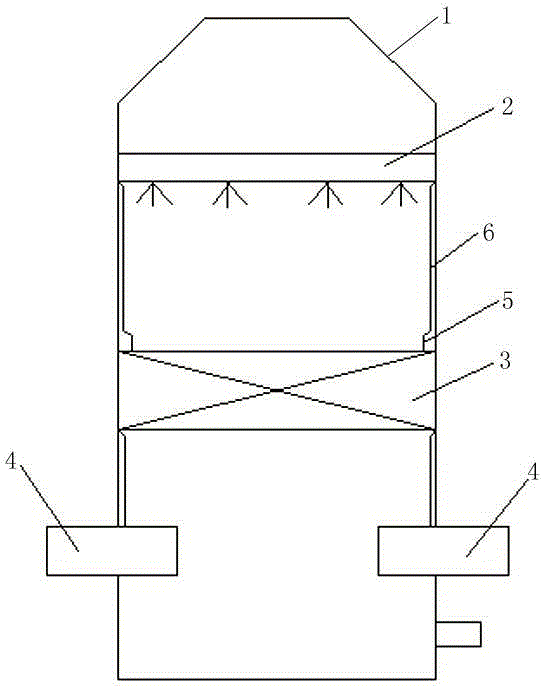

Integrated kitchen range without lampblack discharge

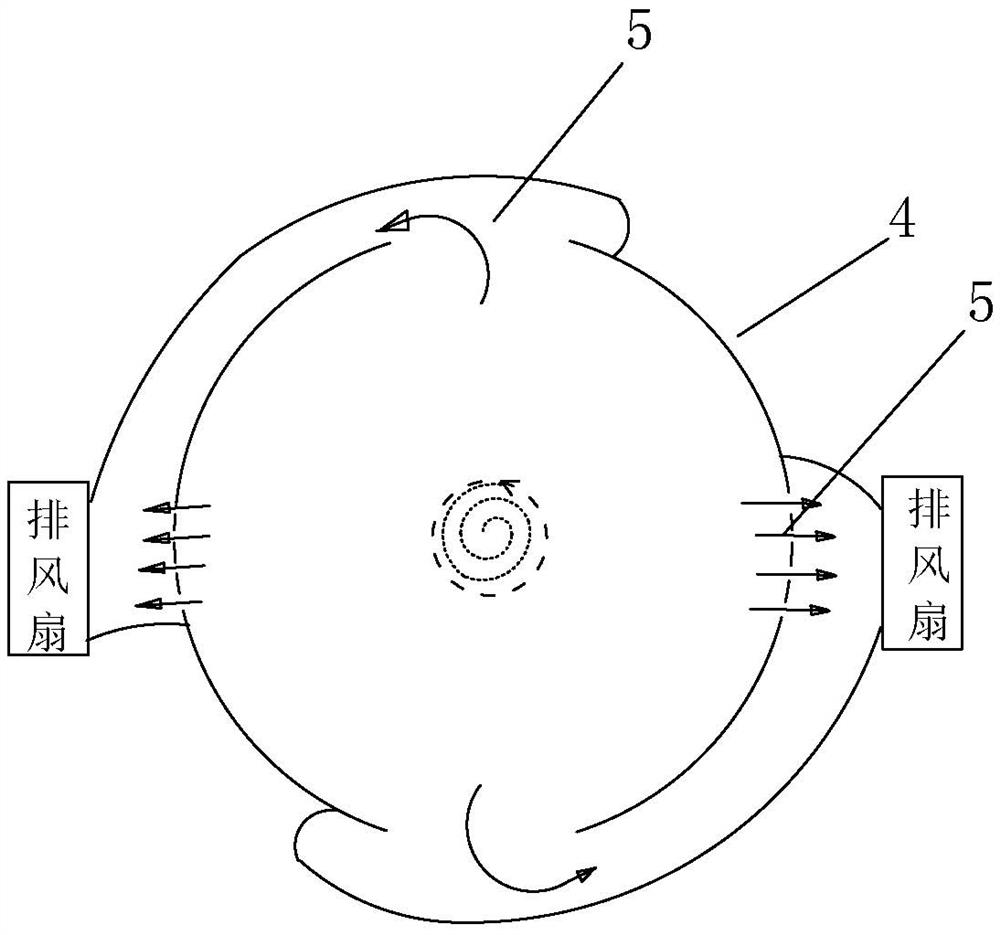

ActiveCN111174263ASolve the pollution problemEliminate the pain of cleaningDomestic stoves or rangesLighting and heating apparatusFlue gasEnvironmental engineering

An integrated kitchen range without lampblack discharge comprises a shell (6), and an air inlet (1) is arranged at the upper part of the shell (6). The integrated kitchen range is characterized in that an inner air duct body (4) is arranged in the shell (6) and located on the lower part of a range head (2), positive pressure air outlets (5) forming central negative pressure are symmetrically arranged on the inner air duct body (4), the outer side of the inner air duct body (4) is provided with an air duct (21) and a lampblack duct (22), and oily particles in a central negative pressure cavityof the inner air duct body (4) rotate downwards rapidly; an inverted cone-shaped outflow channel (8) is connected to the lower part of the inner air duct body (4), and an oil throwing wheel (9) is installed in the inverted cone-shaped outflow channel (8); and oily particles generated by center separation of the inner air duct body (4) pass through the inner air duct body (4) to fall on the oil throwing wheel (9) and flow into a waste oil container (13) arranged at the inner bottom of the shell along the inner wall of the inverted cone-shaped outflow channel (8), and a filter element (12) for filtering flue gas to achieve zero emission is arranged on the inner wall of the lower part of the shell (6). The integrated kitchen range without lampblack discharge has simple structure, is convenient to manufacture, install and maintain, and can realize zero emission without pollution.

Owner:韩波

Scrubbing tower provided with flow blocking wall

A scrubbing tower provided with a flow blocking wall comprises a tower body, a spray layer, a catalysis layer and gas inlets and is characterized in that the spray layer is located at the upper part of the catalysis layer, the gas inlets are formed in the side surface of the lower part of the tower body, and the annular flow blocking wall is arranged on the inner wall of the tower body from the spray layer to the catalysis layer. According to the scrubber, the flow blocking wall is arranged, so that corrosion of the tower wall by a scrubbing solution is prevented, and the scrubbing tower is simple in structure and convenient to manufacture, mount and maintain.

Owner:SUZHOU RHYMEBLUE ENVIRONMENTAL TECH CO

An integrated cooker without oil fume emission

ActiveCN111174263BSolve the pollution problemEliminate the pain of cleaningDomestic stoves or rangesLighting and heating apparatusFlue gasEngineering

An integrated cooker without oil fume discharge, which includes a shell (6), the upper part of the shell (6) is provided with an air inlet (1), and it is characterized in that the lower part of the cooker (2) and the middle of the shell (6) The inner air duct body (4) is installed, and the positive pressure exhaust outlet (5) forming the central negative pressure is symmetrically arranged on the inner air duct body (4), and the outer side of the inner air duct body (4) is provided with an air guide duct (21 And the smoke guide air duct (22), the oily particles in the negative pressure chamber in the center of the inner air duct body (4) spin down quickly; the lower part of the inner air duct body (4) is connected with an inverted tapered outflow channel (8) , an oil thrower (9) is installed in the inverted cone-shaped outflow channel (8), and the oily particles produced by the center separation of the inner air channel body (4) fall on the oil thrower (9) through the inner air channel body (4) and It flows into the waste oil container (13) installed at the inner bottom of the shell along the inner wall of the inverted cone-shaped outflow channel (8), and a filter element for filtering smoke to achieve zero emission is installed on the inner wall of the lower part of the shell (6) ( 12).The invention has simple structure, convenient manufacture, installation and maintenance, and can realize no pollution and zero discharge.

Owner:韩波

A timing alarm device for heat treatment process

The invention discloses a thermal treatment process timed prompting and alarming device, which comprises an AC / DC power supply DC1, contactors from the first to the seventh, time relays from the first to the fifth, a double-pole double-throw power switch, a manual switch K1, a manual switch K2, a manual switch K3, indicating lamps from D1 to D4, an alarming lamp D5 and an alarming loudspeaker H. The thermal treatment process timed prompting and alarming device has the beneficial effects that: the device can prompt the operator to carry out process confirmation at regular intervals, solves the problems of instability and randomness of working parameter data acquisition during the thermal treatment production process, has obvious stable processing capability, and prevents falsification. The thermal treatment process timed prompting and alarming device has the functions of manual / automatic starting, sound-light alarming, prompting alarming of timed prompting on operator to carry out process confirmation, thermal treatment completion prompting alarming, water level abnormity alarming, furnace door abnormity alarming, calculation of duration that the operator fails to operate as required, and manual misoperation prevention. The thermal treatment process timed prompting and alarming device has the advantages of simple structure, convenient operation, good expansibility and convenient manufacturing, installation and maintenance.

Owner:HEBEI SHENGYUE RAILWAY ELECTRIFICATION EQUIP

Upper table top moving device for microscope

InactiveCN102707424AReduce finale forceStable finale forceMicroscopesFriction gearingsEngineeringMicroscope

The invention discloses an upper table top moving device for a microscope, relating to the technical field of microscope parts. The upper table top moving device for the microscope comprises a steel wire rope, a first pulley, a second pulley and a hand wheel assembly shaft, wherein the first pulley is connected with the hand wheel assembly shaft, the second pulley is fixedly connected with an upper table top, the first pulley is connected with the second pulley through the steel wire rope, at least two rings of the steel wire rope are wound on the first pulley and the second pulley, and two ends of the steel wire rope are connected through a tension spring. By adopting the steel wire rope gearing, the upper table top moving device has the advantages of simple structure, convenience for manufacture and installation and maintenance, capability of absorbing shaking, and stability in transmission.

Owner:NANTONG JIANGZHONG PHOTOELECTRIC

Air-blowing type double-duct lifting and separating device

The invention relates to an air-blowing type double-duct lifting and separating device (b). The air-blowing type double-duct lifting and separating device (b) comprises a fan, a collection hopper and a grain and impurity separating device. The fan is connected with two air inlet pipes. One air inlet pipe is connected with an air inlet in the grain and impurity separating device, the other air inlet pipe is connected with the collection hopper, and the other end of the collection hopper is communicated with a feeding opening of the grain and impurity separating device. A spiral conveying device is arranged at the bottom of the grain and impurity separating device. The air-blowing type double-duct lifting and separating device has the advantages of being simple and reasonable in structure, high in practicability, convenient to manufacture, mount and maintain, and good in using effect.

Owner:SHAOGUAN FENGYI IND & TRADE

Reinforced convection heat exchange type water distribution and collection device for cold source machine room

ActiveCN102425814BWith heat exchange functionGood value for moneyStationary tubular conduit assembliesHot-water central heatingInsertion stentEngineering

The invention relates to a reinforced convection heat exchange type water distribution and collection device for a cold source machine room. The device comprises a barrel, wherein a first overhauling flange is arranged on the middle part of the barrel, barrel end caps are arranged at two ends of the barrel, second overhauling flanges are arranged at the joints of the barrel and the barrel end caps, a plurality of stainless steel corrugated pipes are arranged in the barrel, the adjacent stainless steel corrugated pipes are connected through a corrugated pipe segmentation flange and a corrugated pipe reinforcing connecting rod, the stainless steel corrugated pipes are fixed with the barrel through a plurality of limiting supports, the stainless steel corrugated pipes positioned at two ends in the barrel are connected with corrugated pipe joints, and the corrugated pipe joints pass through the barrel end caps and are connected with a heat exchange pipeline; and a main water pipe is arranged on the top of the middle part of the barrel, a plurality of branched pipes are uniformly distributed on two sides of the main water pipe, and the main water pipe and the branched pipes extend into the barrel. The device has the advantages of two purposes, high cost performance, good heat exchange effect, low flow resistance, reasonable shunt, space saving and capability of selectively exchanging heat, and is easy and convenient to manufacture, install and maintain.

Owner:CHINA RAILWAY CONSTR GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com