Reinforced convection heat exchange type water distribution and collection device for cold source machine room

A technology of convective heat exchange and water diversion, which is applied in the types of heat exchangers, household heating, indirect heat exchangers, etc., and can solve the problem of large volume of shell-and-tube heat exchangers, long plate sealing perimeter, and high metal consumption. problems, to achieve the effect of high cost performance, small flow resistance and large unfolded surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

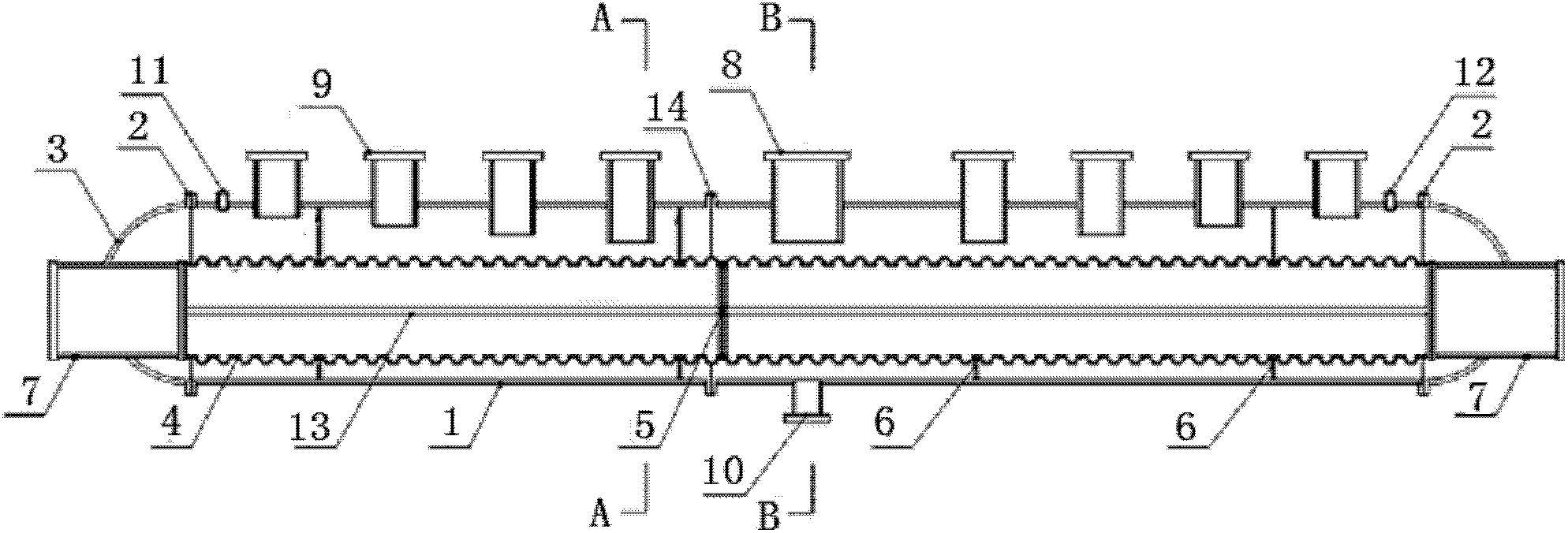

[0021] Such as Figure 1-3 As shown, a kind of enhanced convection heat transfer water diversion device for a cold source machine room according to the embodiment of the present invention includes a cylinder body 1, a first inspection flange 14 is provided in the middle of the cylinder body 1, and the two sides of the cylinder body 1 The cylinder end caps 3 are respectively provided at the ends, and the second maintenance flange 2 is provided at the connection between the cylinder body 1 and the cylinder end cap 3. There are several stainless steel bellows 4 inside the cylinder body 1, and the adjacent stainless steel bellows 4 The stainless steel bellows 4 and the cylinder 1 are fixed by a number of limit brackets 6, and the stainless steel bellows 5 located at both ends of the cylinder 1 are respectively connected to the bellows. The pipe joint 7 and the bellows joint 7 are connected to the heat exchange pipeline through the end cap 3 of the cylinder body; the top surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com