Catalytic thermal oxidizer with sintering prevention function and sintering prevention method thereof

A thermal oxidizer and anti-sintering technology, applied in the direction of combustion method, incinerator, combustion type, etc., can solve the problems of reducing catalyst treatment effect, property loss, excessive heat release, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

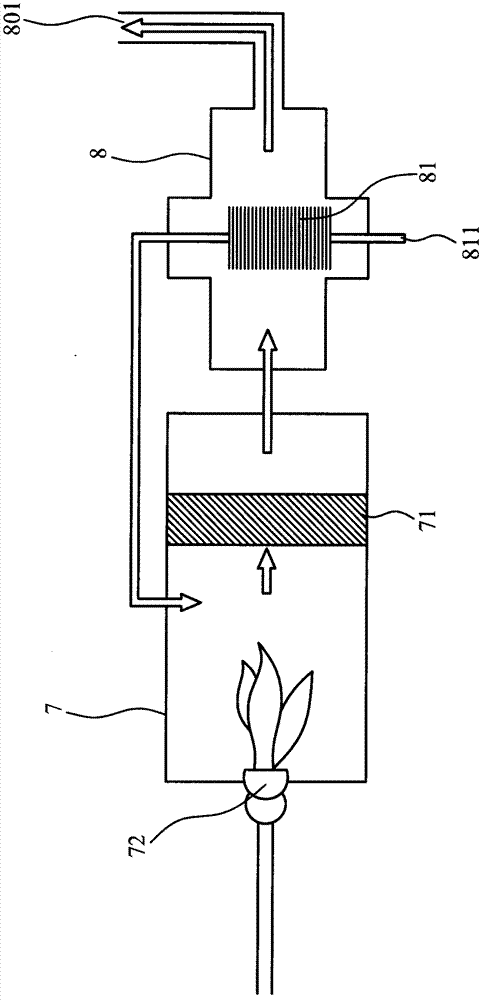

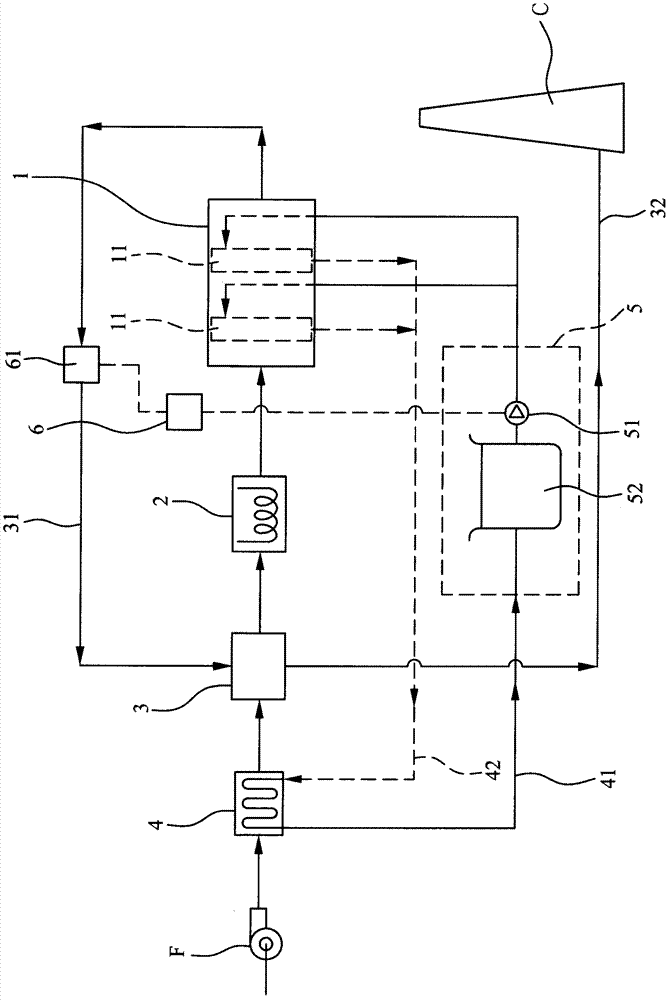

[0018] The present invention provides a catalytic thermal oxidizer with anti-sintering function and its anti-sintering method, such as figure 2 , image 3 Shown is to disclose the structure of catalytic thermal oxidizer of the present invention, as Figure 4 Shown is the flow chart of the anti-sintering method disclosed in the present invention.

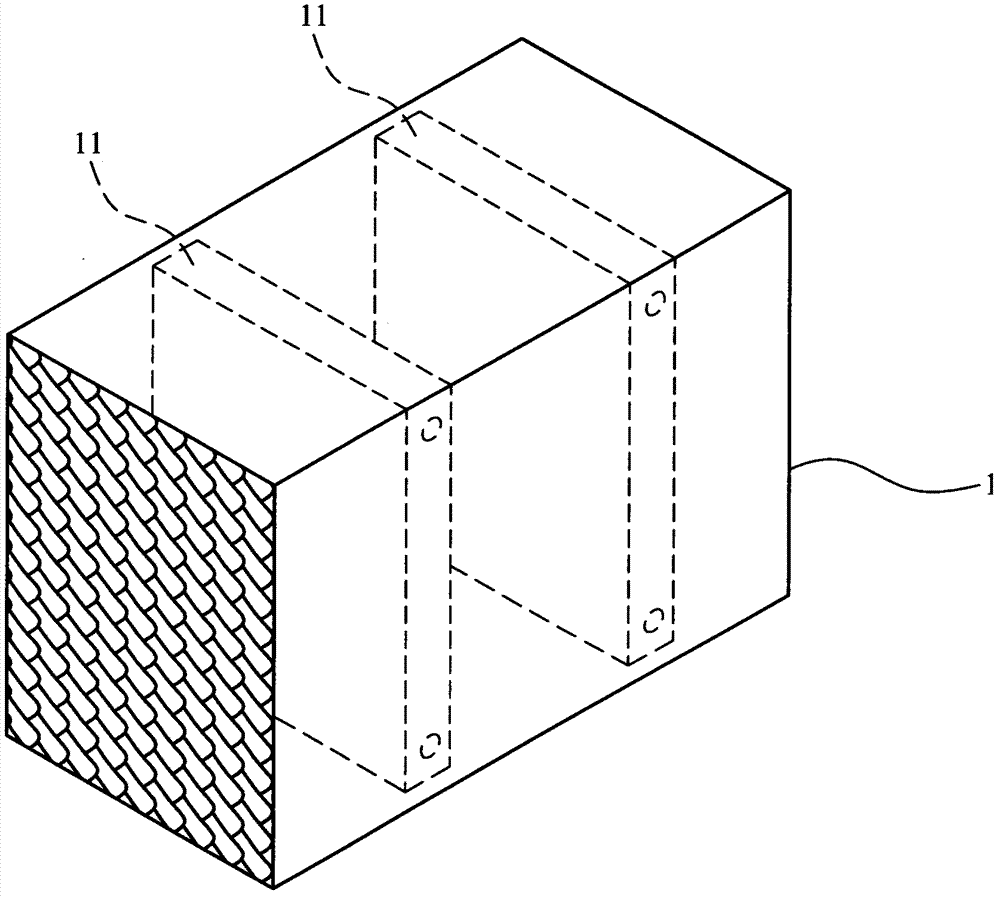

[0019] see figure 2 , image 3 The structure of the catalyst type thermal oxidizer of the present invention shown is to comprise a catalyst bed 1, a heater 2, a first heat exchanger 3, a second heat exchanger 4, a coolant supply and delivery device 5, and a controller 6 .

[0020] The catalyst bed 1 has an outlet and an inlet (the component symbol is not marked), and at least one cooler 11 is arranged between the outlet and the inlet inside it, preferably a plurality of coolers 11 are arranged at intervals.

[0021] The first heat exchanger 3 has first and second passages (unmarked component symbols), and a recovery pipeline 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com