Scrubbing tower provided with flow blocking wall

A technology for retaining walls and washing towers, which is applied in the field of washing towers with retaining walls, can solve the problems of tower inner wall corrosion, time-consuming and labor-intensive maintenance, and heavy workload of anti-corrosion layers, and achieve simple structure, corrosion prevention, Create the effect of easy installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

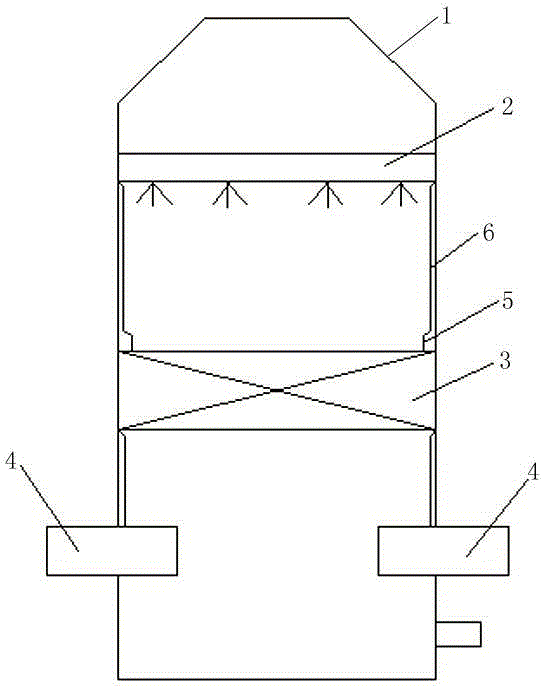

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] As shown in the accompanying drawings, a washing tower with a baffle wall includes a tower body 1, a spray layer 2, a catalytic layer 3, and an air inlet 4. It is characterized in that: the spray layer 2 is located in the catalytic layer 3 In the upper part, the air inlet 4 is located on the side of the lower part of the tower body 1, and an annular flow blocking wall 6 is provided on the inner wall of the tower body 1 from the spray layer 2 to the catalytic layer 3. The inner wall of the tower between the spray layer and the catalytic layer is often severely scoured, and a baffle wall is set in this section to effectively avoid scour.

[0018] further:

[0019] The upper part of the catalytic layer 3 is provided with an annular baffle 5 . It may be that the washing liquid is evenly distributed.

[0020] The baffle wall 6 is connected to the baffle plate 5 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com