Suction type multi-drum grain and impurity separating device

A separation device and air suction technology, applied in the direction of solid separation, separating solids from solids with airflow, threshing equipment, etc., can solve the problems of low work efficiency, inability to adapt to use, low work efficiency, etc., and achieve convenient production, installation and maintenance , Simple and reasonable structure, good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

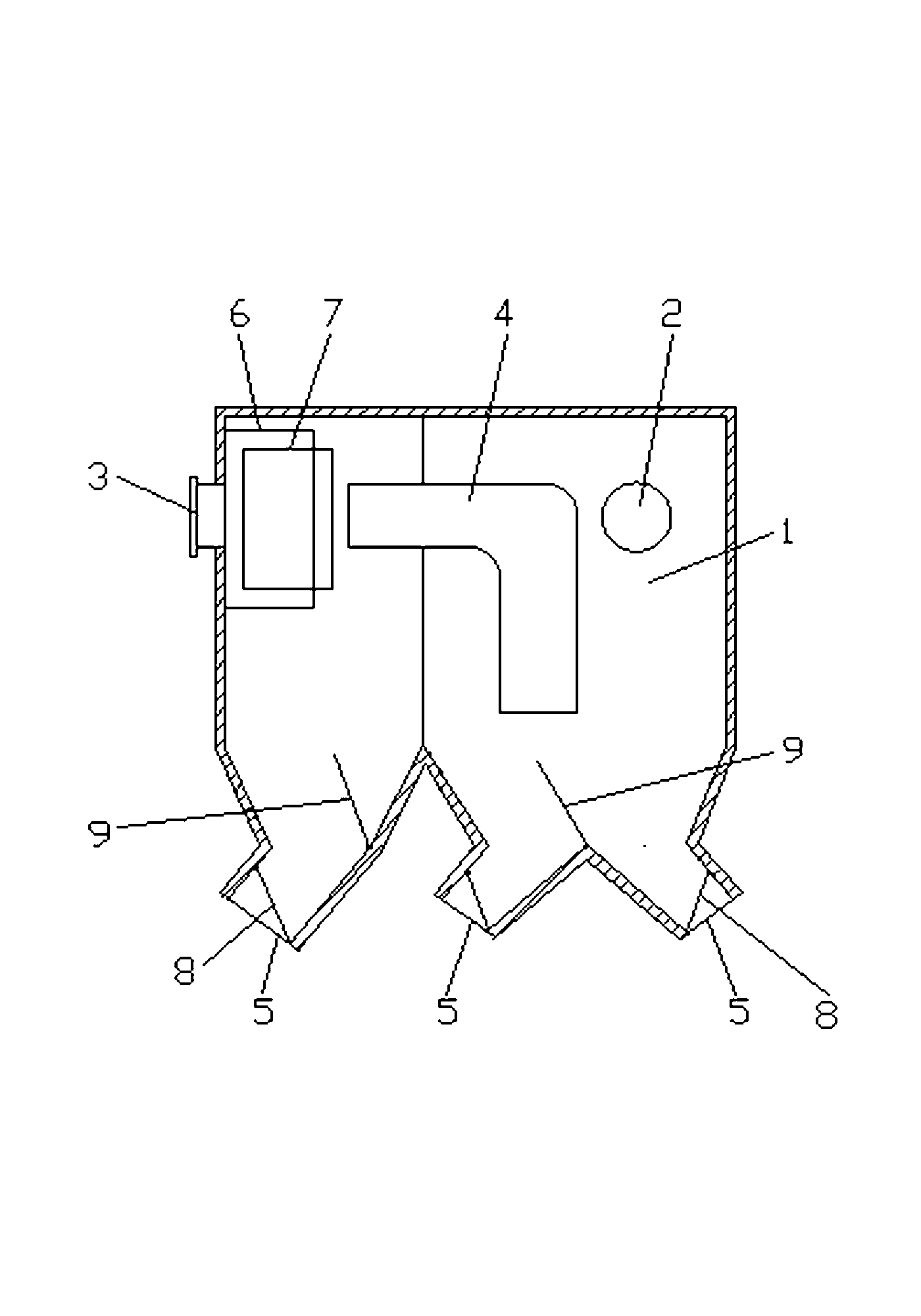

[0012] see figure 1 , an air-suction multi-tube grain and miscellaneous separation device, including a body, which is composed of two or more cavities 1 connected in the same or different structures in series, above one of the cavities 1 One side of the fan 3 is equipped with a large drum 6 connected to the fan 3, and a small drum 7 is sleeved in the large drum 6. A gap as a suction channel is provided between the large drum 6 and the small drum 7. The large drum There is a gap between the bottom of 6 and the bottom of the small drum 7 as a suction channel, and the opening at the bottom of the large drum 6 is connected to the fan 3, and a feed port 2 is provided on one of the cavities 1, and the passage between the cavities 1 The suction elbow 4 is connected; at least one outlet 5 is provided at the bottom of each cavity 1, and a loose-leaf baffle 8 connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com