A timing alarm device for heat treatment process

A heat treatment process and alarm device technology, applied to alarms, instruments, etc., can solve problems such as high dependence on people and uneven products, and achieve the effects of convenient operation, convenient production, installation and maintenance, and obvious process capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

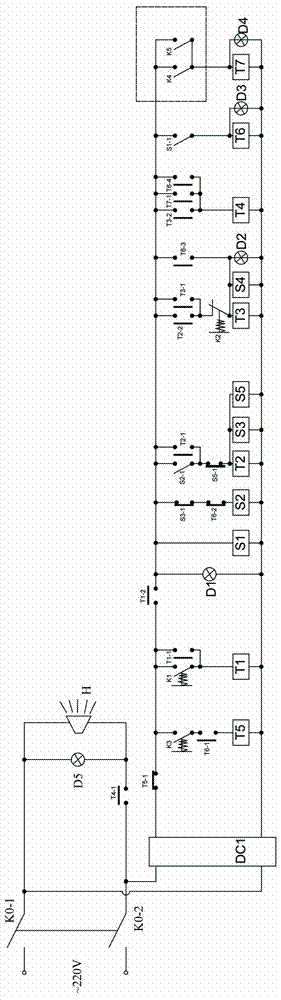

[0024] Depend on figure 1 It can be known from the illustrated embodiment that it includes an AC / DC power supply DC1, a first contactor to a seventh contactor, a first time relay to a fifth time relay, a double-pole double-throw power switch, a manual switch K1~K3, and an indicator light. D1~D4, alarm light D5 and alarm horn H;

[0025] The static contacts of the first contact K0-1 and the second contact K0-2 of the double-pole double-throw power switch are respectively connected to both ends of the AC 220V power supply; the alarm light D5 and the alarm horn H are connected in parallel and then connected to the The first normally open contact T4-1 of the fourth contactor is connected in series to form an alarm circuit, and the alarm circuit is connected to the boom and the second contact of the first contact K0-1 of the double-pole double-throw power switch. Between the booms of K0-2;

[0026] The input ends of the AC / DC power supply DC1 are respectively connected to the boo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com