Automobile coating conveyor and application thereof

A conveyor and coating technology, applied to conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of high manufacturing and installation process requirements, complex structures, etc., to save floor space, increase carrying capacity, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Automobile coating conveyer of the present invention is described in detail as follows in conjunction with accompanying drawing and embodiment:

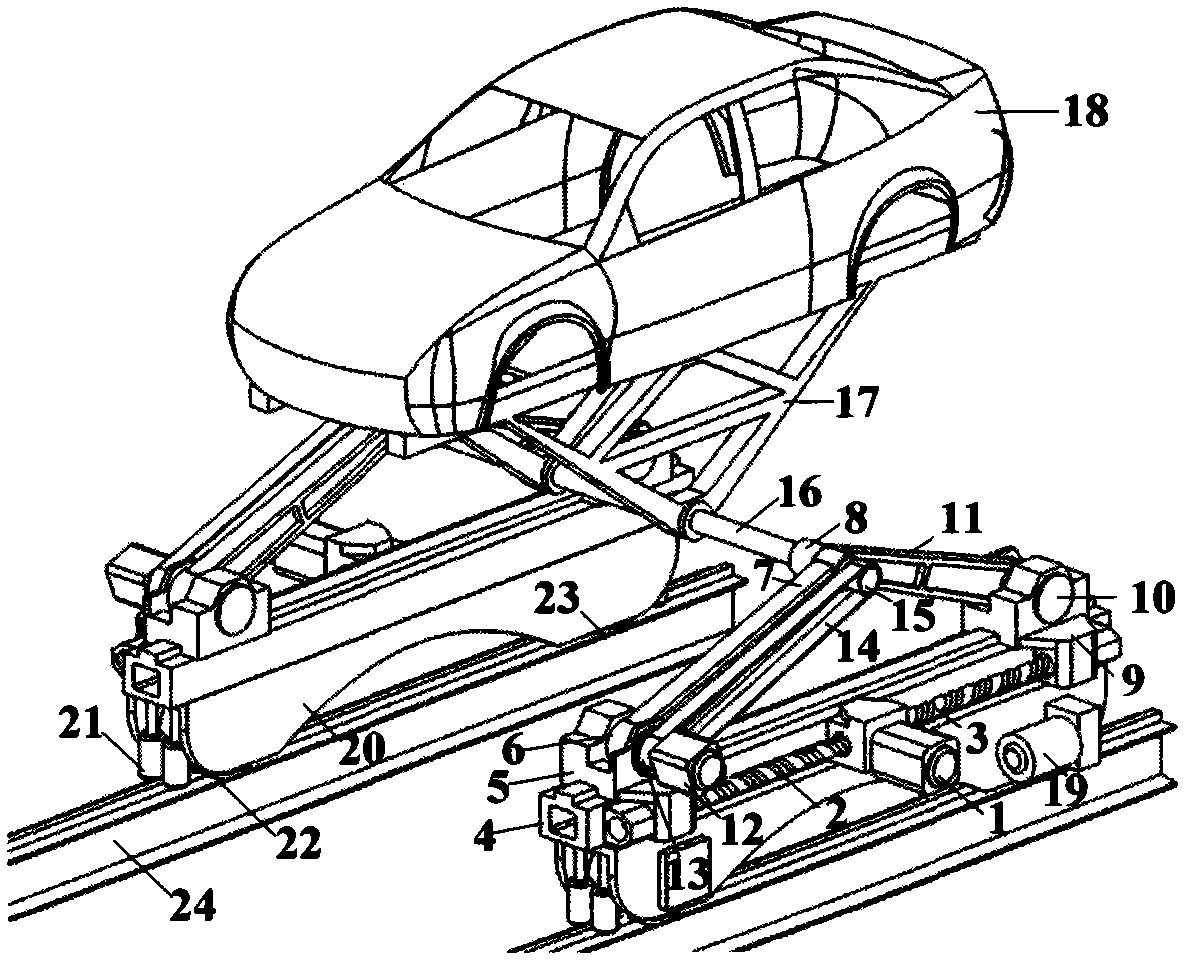

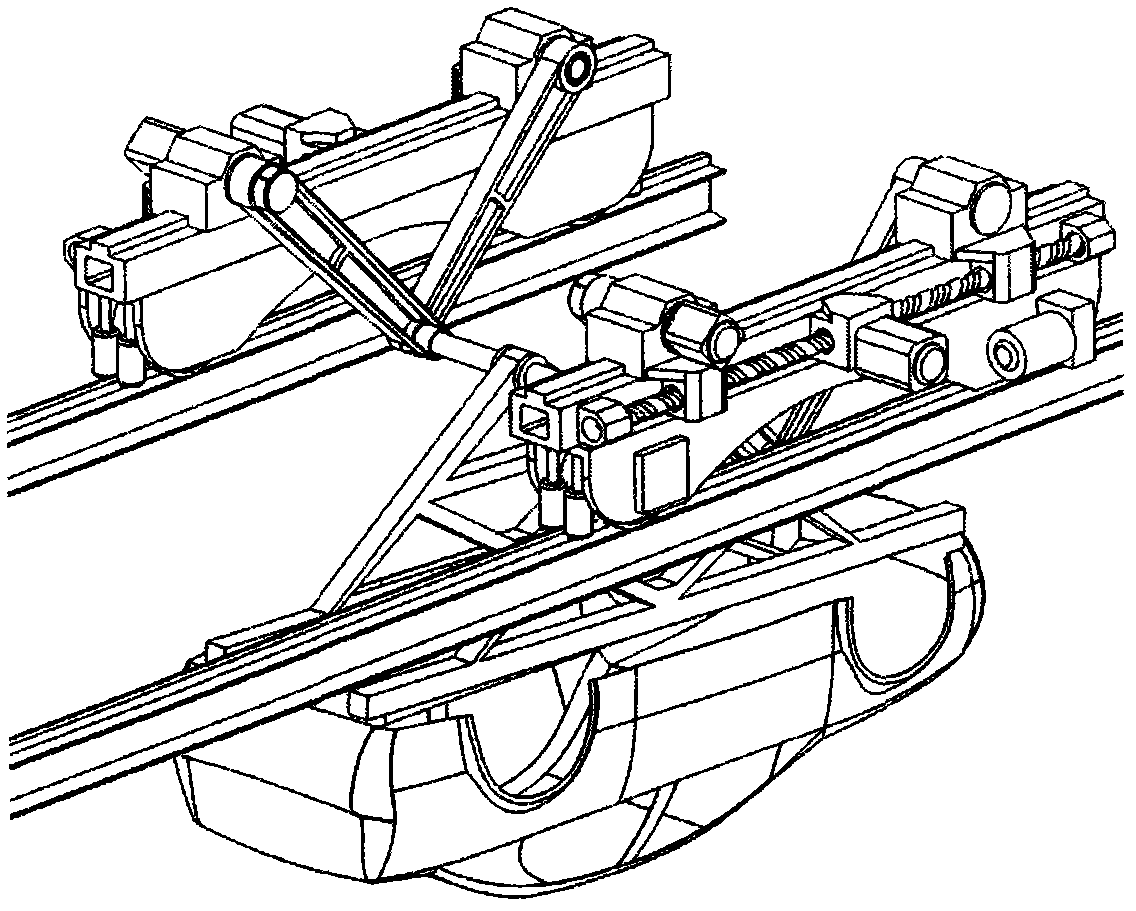

[0017] The embodiment of the present invention is illustrated with two conveyors, in the present invention figure 1 In the shown first embodiment, the conveyor according to the present invention includes a traveling mechanism, a first lifting and turning mechanism, a second lifting and turning mechanism, and a fixed part of the car body. Wherein the first and second lifting and turning mechanisms are identical in structure, and are connected by a connecting rod 16 . The fixed part of the car body includes a connecting rod 16, a car body fixing frame 17 and a car body 18; the car body 18 and the connecting rod 16 are all fixed on the car body fixing frame 17, and relative movement cannot take place between the three. The walking mechanism is divided into two groups, a left walking mechanism and a right walking mechanism, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com