An integrated cooker without oil fume emission

A technology of no oil fume and cooking utensils, applied in the direction of removing oil fume, household stoves, household appliances, etc., can solve the problems of incomplete separation of oil fume, secondary pollution of the environment, etc., achieve simple structure, reduce production cost, and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

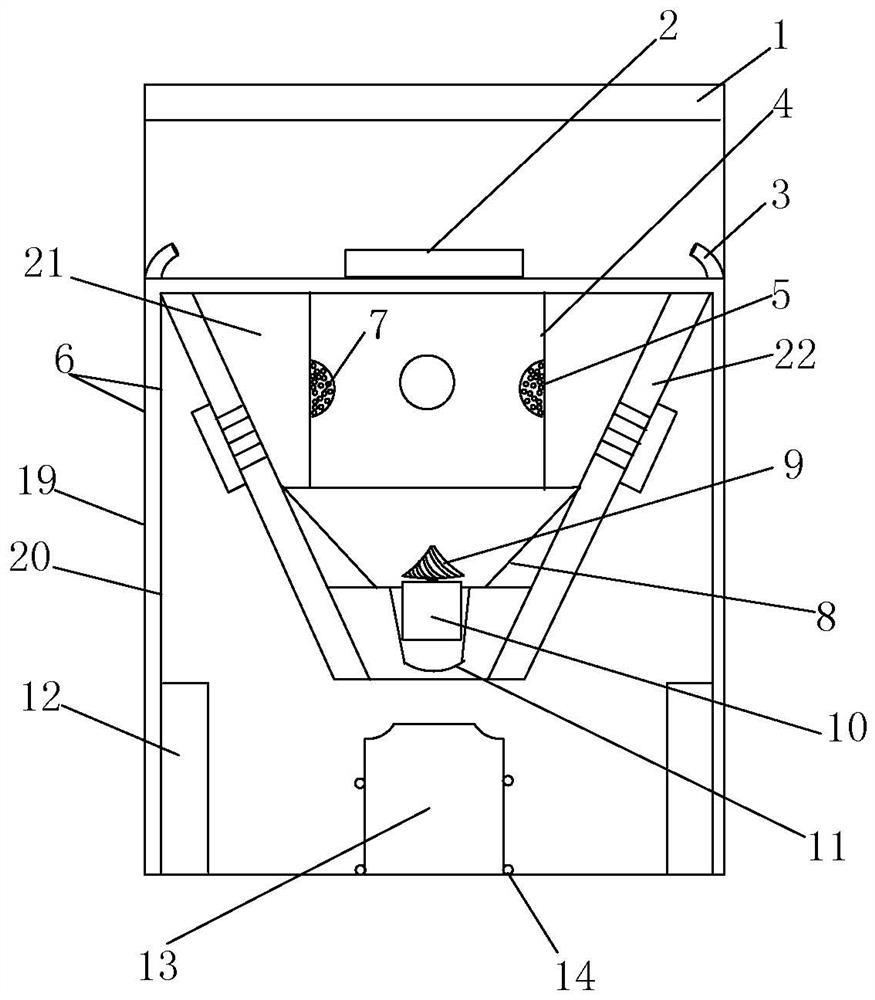

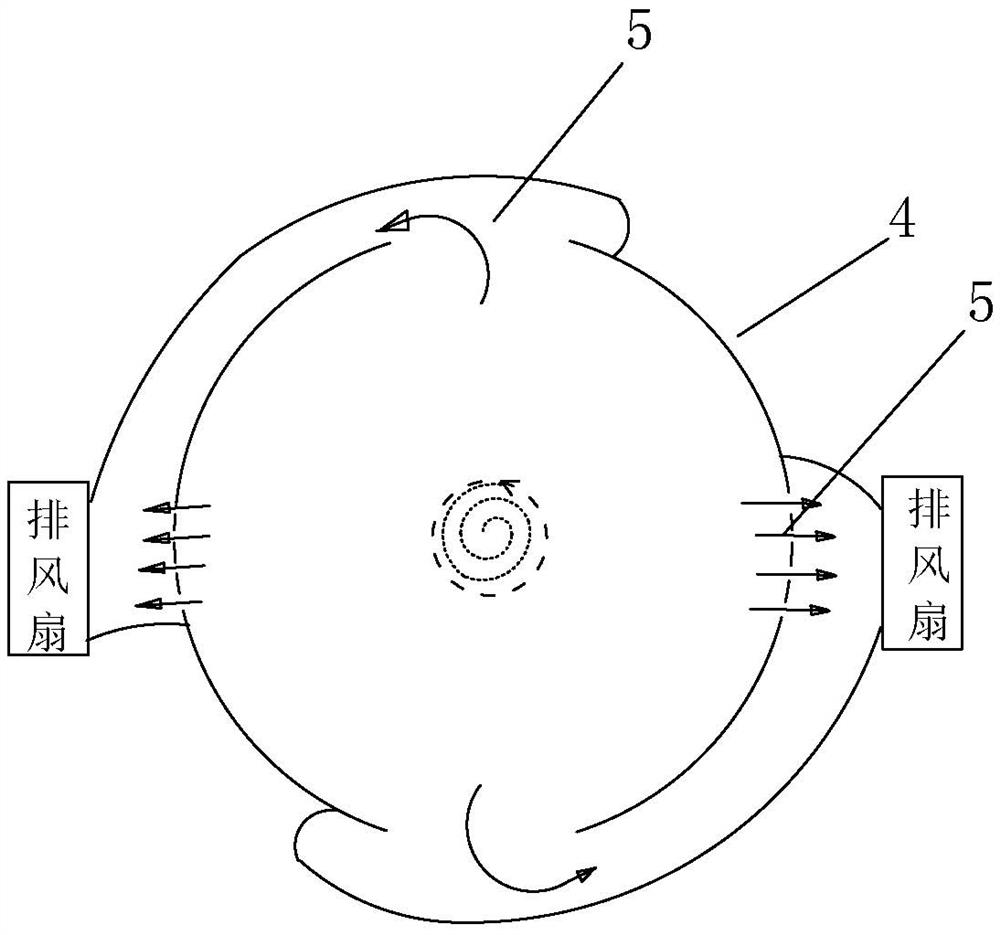

[0027] Such as Figure 1-3 shown.

[0028] An integrated cooking range without oil fume discharge, which includes a housing 6, the upper part of the housing 6 is provided with an air inlet 1, such as figure 2 As shown, the cooking head 2 is installed on the table top of the casing 6, and the inner air duct body 4 is installed in the lower part of the cooking head 2 and the housing 6, and the positive pressure forming the central negative pressure is symmetrically arranged on the inner air duct body 4. The air outlet 5 and the positive pressure air outlet 5 are equipped with a positive pressure exhaust fan. The positive pressure exhaust fan sucks the cooking fume generated by the stove into the inner air duct body 4. Under the action of the positive pressure exhaust fan, the center of the inner air duct body 4 forms a A negative pressure chamber, and under the action of the rotation binding force (tornado rotation binding), the separation of oil, water and smoke is realized. ...

Embodiment 2

[0033] Such as Figure 5 shown.

[0034]The difference between this embodiment and Embodiment 1 is that the oil fumes are in the upper row structure, the waste oil thrown out by the oil thrower is introduced into the waste oil collection container 13 through the oil guide pipe 24, and the smoke in the upper row is filtered by the filter installed on the upper part and then discharged. . The rest are the same or similar to Embodiment 1 and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com