Removing system for dioxin and metallic mercury in flying ash

A technology for metal mercury and dioxin removal, which is applied in the field of fly ash treatment, can solve the problem that it is difficult to remove dioxins and metal mercury from fly ash at the same time, and achieves the effect of efficiently removing mercury and solving pollution problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

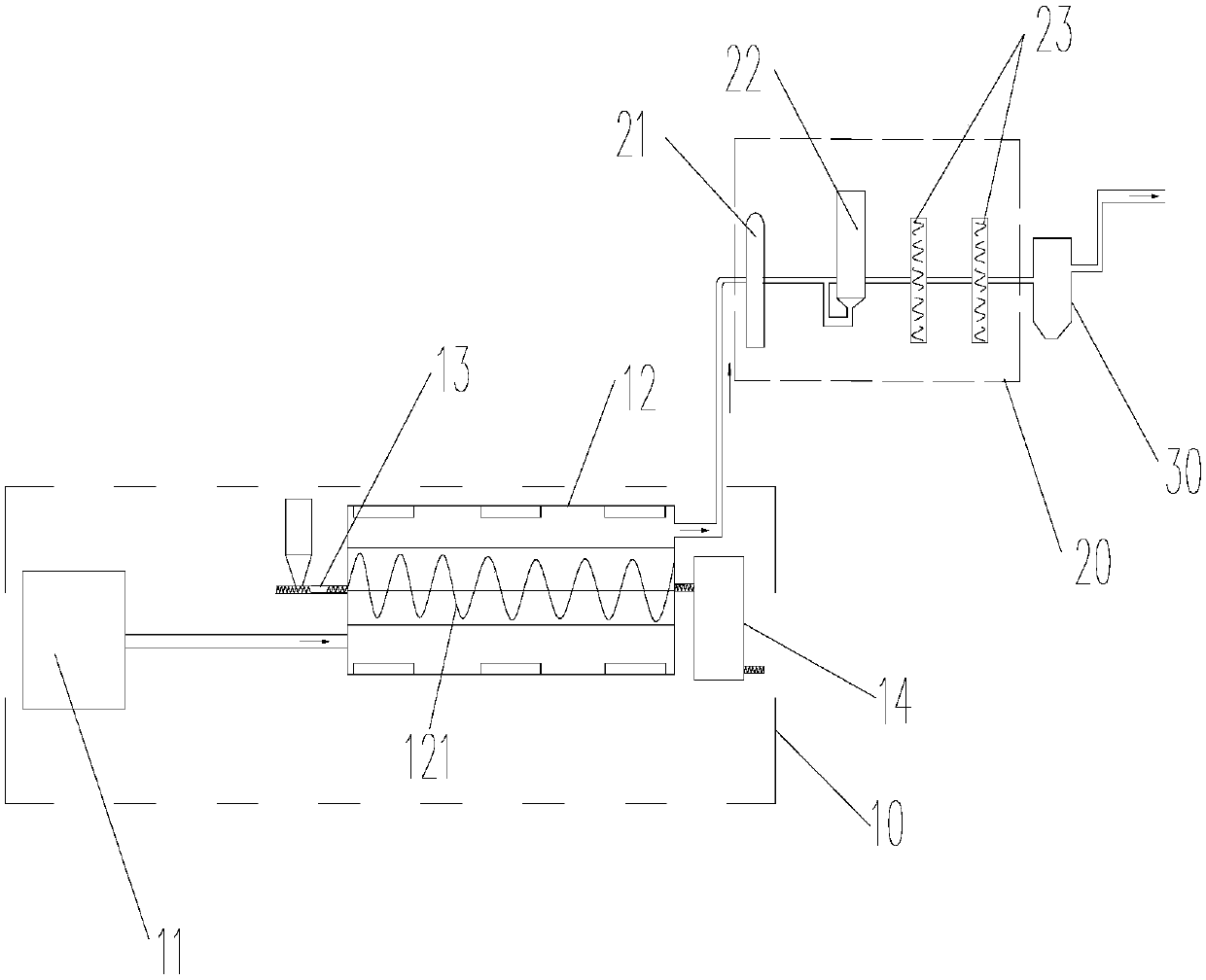

Image

Examples

Embodiment 1

[0046] The domestic waste incineration fly ash with a water content of 1% is added to the dioxin dechlorination reaction chamber through the middle disconnected screw feeder. Before the normal operation of the device, N 2 Replace the air in the dioxin dechlorination reaction chamber;

[0047] Control the spiral in the dioxin dechlorination reaction chamber so that the fly ash continuously rotates from the fly ash inlet to the dioxin dechlorination fly ash outlet, and during the rotation, control the oxygen content in the dioxin dechlorination reaction chamber to 5ppm , the temperature is 400°C, so that the dioxins in the fly ash undergo dechlorination reaction in the dioxin dechlorination reaction chamber, and the dechlorination reaction lasts for 60 minutes, and the dedioxin fly ash and the dioxins carried in the non-oxidizing gas are obtained. Mercury vapor;

[0048] The de-dioxin fly ash is put into the quenched fly ash bin from the outlet of the de-dioxin fly ash, and the...

Embodiment 2

[0053] Domestic waste incineration fly ash with a water content of 0.1% is fed into the dioxin dechlorination reaction chamber through a middle disconnected screw feeder, and N 2 Replace the air in the dioxin dechlorination reaction chamber;

[0054] Control the spiral in the dioxin dechlorination reaction chamber so that the fly ash is continuously rotated from the fly ash inlet to the dioxin dechlorination fly ash outlet, and during the rotation, the oxygen content in the dioxin dechlorination reaction chamber is controlled to be 1%, the temperature is 500°C, so that the dioxins in the fly ash undergo a dechlorination reaction in the dioxin dechlorination reaction chamber, and the dechlorination reaction lasts for 60 minutes to obtain the dedioxin fly ash and carry it in the non-oxidizing gas mercury-containing vapor;

[0055] The de-dioxin fly ash is put into the quenched fly ash bin from the outlet of the de-dioxin fly ash. The dioxin content calculation shows that the d...

Embodiment 3

[0060] The incineration fly ash of medical waste with a water content of 5% is fed into the dioxin dechlorination reaction chamber through the middle disconnected screw feeder. Before the normal operation of the device, Ar is introduced to replace the air in the dioxin dechlorination reaction chamber;

[0061] Control the spiral in the dioxin dechlorination reaction chamber so that the fly ash continuously rotates from the fly ash inlet to the dioxin dechlorination fly ash outlet, and during the rotation, control the oxygen content in the dioxin dechlorination reaction chamber to 10ppm , the temperature is 350°C, so that the dioxins in the fly ash undergo a dechlorination reaction in the dioxin dechlorination reaction chamber, and the dechlorination reaction lasts for 60 minutes to obtain the dedioxin fly ash and the dioxins carried in the non-oxidizing gas. Mercury vapor;

[0062] The de-dioxin fly ash is put into the quenched fly ash bin from the outlet of the de-dioxin fly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com