Double-crank automobile coating conveyor and application thereof

A double-crank mechanism and conveyor technology, which is applied to conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of high manufacturing and installation process requirements and complex structures, and achieve floor space savings, increased carrying capacity, and investment saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

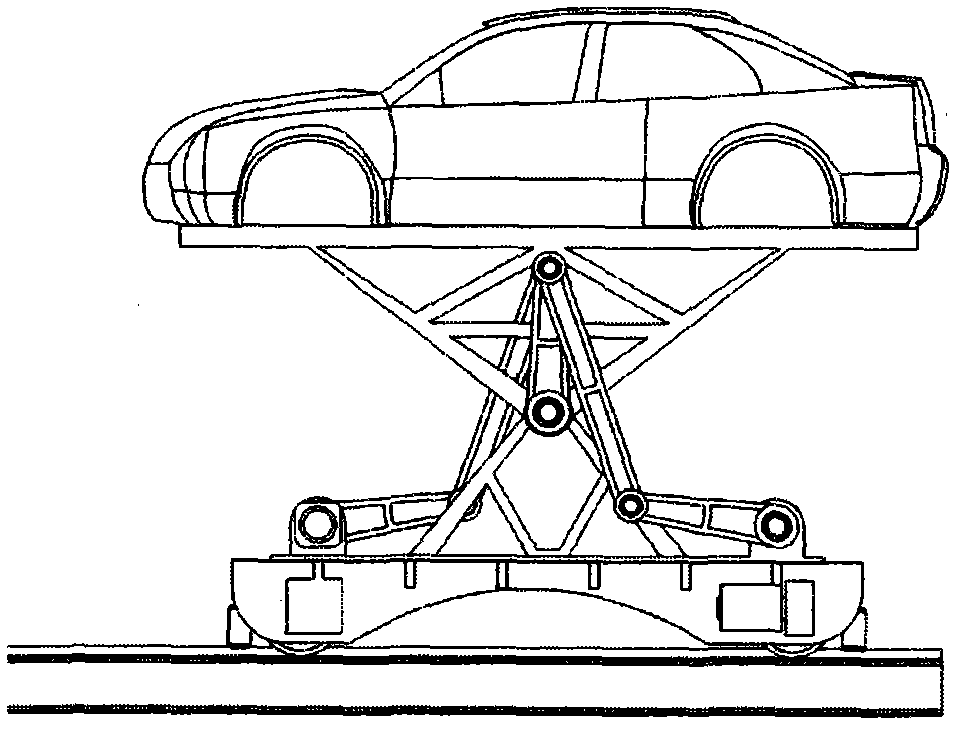

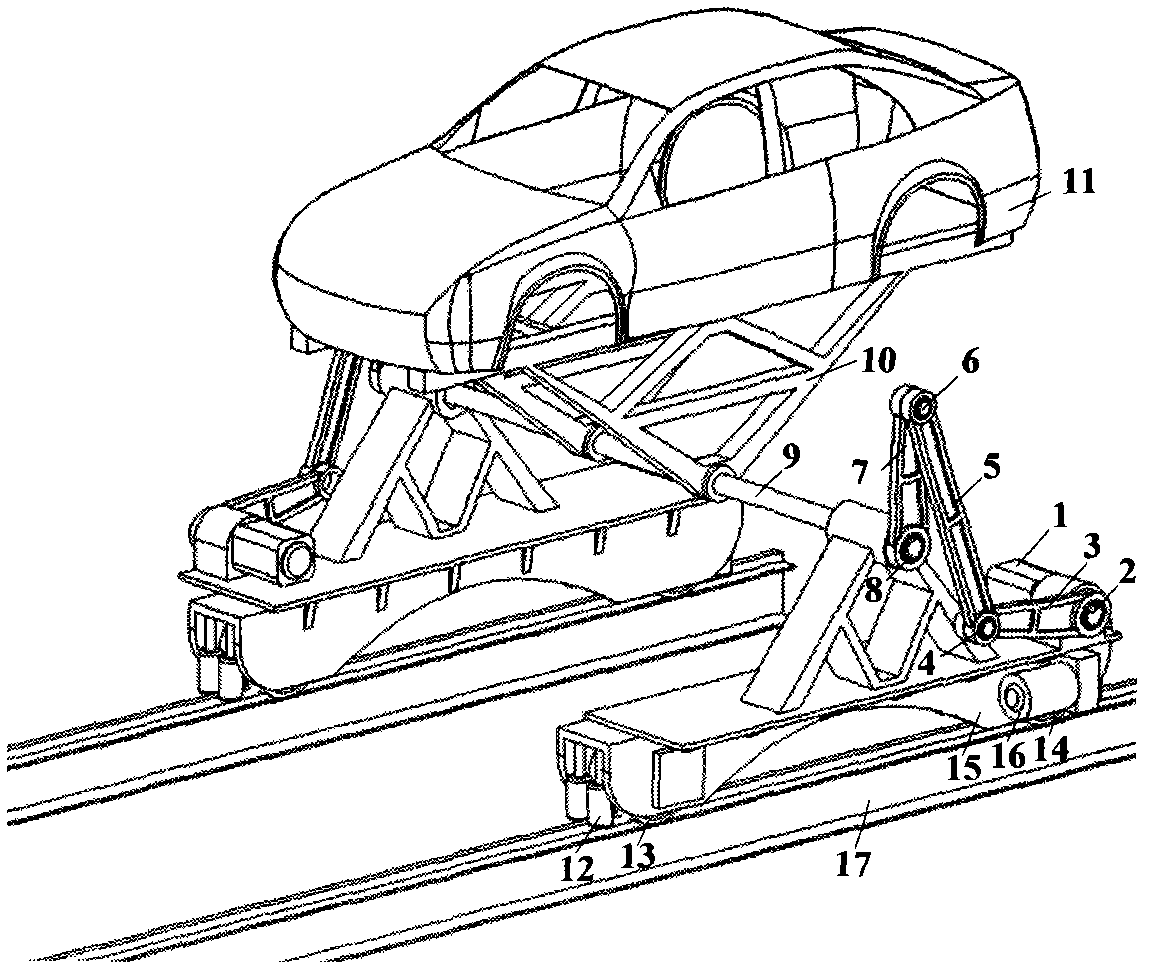

[0016] Double-crank automobile coating conveyor of the present invention is described in detail as follows in conjunction with accompanying drawing and embodiment:

[0017] The embodiment of the present invention is illustrated with an automobile coating conveyor, in the present invention figure 1 In the shown first embodiment, the conveyor according to the present invention includes a walking mechanism, a first double crank mechanism and a second double crank mechanism, wherein the first double crank mechanism and the second double crank mechanism The surface is symmetrically arranged at 90° (the parallel vertical plane of the guide rail refers to the plane perpendicular to the axial direction of the guide rail and located at the midpoint of the vertical line segment of the two guide rails), with the same structure and different dead center positions. And link to each other by connecting rod 9. The walking mechanism is divided into a left traveling mechanism and a right trav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com