Regeneration process and regeneration device for heavy metal containing nitric acid waste liquor

A technology for process equipment and heavy metals, which is applied to the regeneration process of nitric acid waste liquid containing heavy metals and the field of regeneration equipment, can solve the problems of low economic benefit, consumption of waste chemicals, secondary pollution, etc., and achieves no secondary pollution, high market value, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A heavy metal-containing nitric acid waste liquid regeneration process, under the negative pressure of 0.05 MPa, the nitric acid is first passed through the first-effect evaporation crystallization device, and the temperature of the first-effect evaporation crystallization device is controlled at 60°C, and then enters the second-effect evaporation crystallization device. The temperature of the two-effect evaporation and crystallization device is controlled at 50°C, and the nitric acid vapor is condensed and recovered to obtain regenerated nitric acid. At the same time, the heavy metal nitrate recovered from the discharge system of the evaporation and crystallization device and the mass percentage concentration are 98% concentrated sulfuric acid according to 3: 1, and stirred, while cooling to room temperature, after suction filtration, the heavy metal sulfate product was obtained.

Embodiment 2

[0019] A heavy metal-containing nitric acid waste liquid regeneration process. Under the action of negative pressure of 0.03 MPa, the nitric acid is first passed through the first-effect evaporation crystallization device, and the temperature of the first-effect evaporation crystallization device is controlled at 65°C, and then enters the second-effect evaporation crystallization device. The temperature of the two-effect evaporation and crystallization device is controlled at 40°C, and the nitric acid vapor is condensed and recovered to obtain regenerated nitric acid. At the same time, the heavy metal nitrate recovered from the discharge system of the evaporation and crystallization device and the mass percentage concentration of 95% concentrated sulfuric acid are calculated according to 1: 1, and stirred, while cooling to room temperature, after suction filtration, the heavy metal sulfate product was obtained.

Embodiment 3

[0021] A heavy metal-containing nitric acid waste liquid regeneration process, under the negative pressure of 0.07 MPa, the nitric acid is first passed through the first-effect evaporation crystallization device, and the temperature of the first-effect evaporation crystallization device is controlled at 70°C, and then enters the second-effect evaporation crystallization device, The temperature of the two-effect evaporation and crystallization device is controlled at 45°C, and the nitric acid vapor is condensed and recovered to obtain regenerated nitric acid. At the same time, the heavy metal nitrate recovered from the discharge system of the evaporation and crystallization device and the mass percentage concentration are 96% concentrated sulfuric acid according to 2: 1, and stirred, while cooling to room temperature, after suction filtration, the heavy metal sulfate product was obtained.

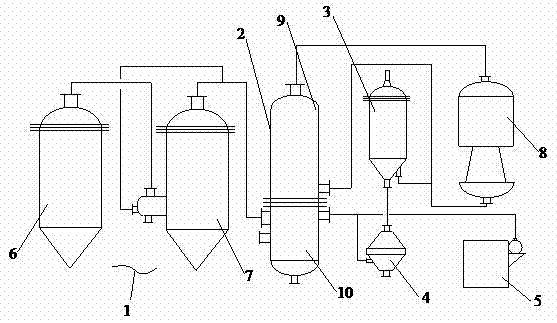

[0022] see figure 1 , the present invention is used for the process equipment of heavy m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com