Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Easy to bleach" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

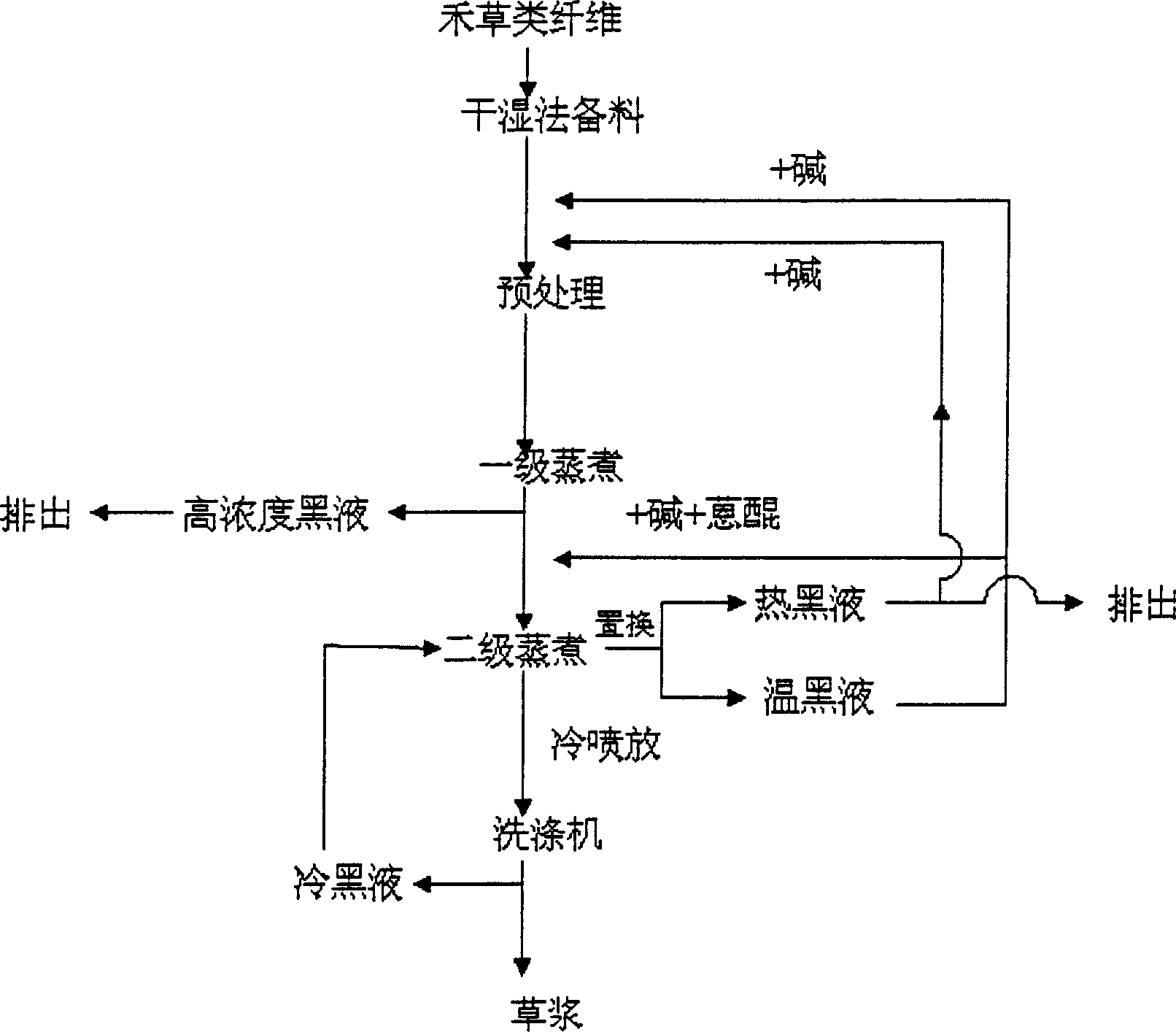

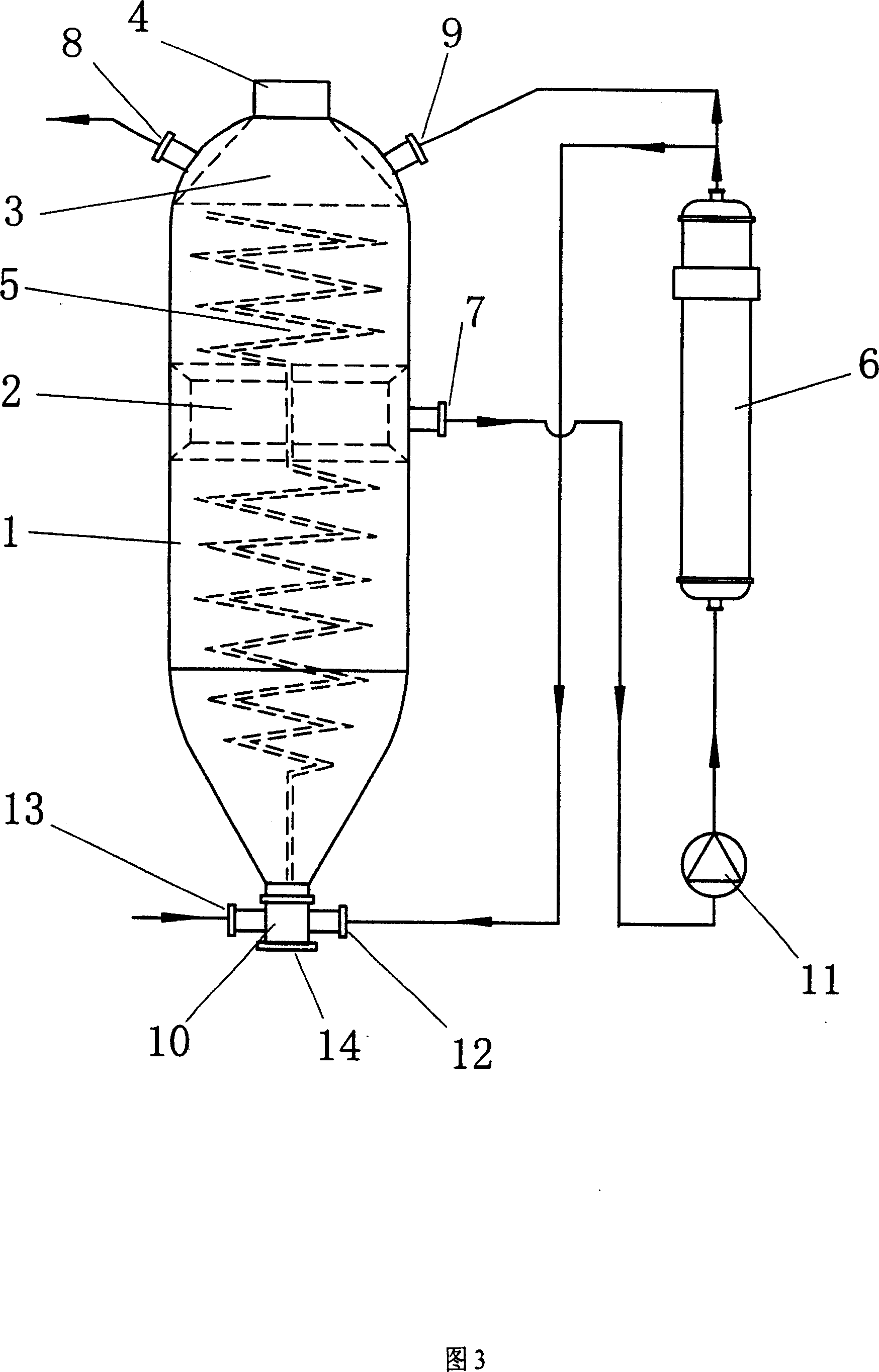

Whole black liqucd large liqucd rate cercal grass cooking technology with digester

ActiveCN1598127AReduce consumptionReduce hardnessFinely-divided material pretreatmentCellulose material pulpingHigh concentrationFiber

The invention relates to a whole black liquor large liquor rate cercal grass cooking technology with digester, comprising the following steps: after stocking, preimpregnating the grass raw fiber; loading the preimpregnated raw material into cooking equipment to perform first stage boiling washing to discharge black liqucd of high concentration to obtain straw pulp intermediate product; supplying cooking liquor to the said cooking equipment, and second stage boiling washing the straw pulp intermediate product, and then straw pulp being obtained through washing; repective cycle operating ryegrass large liquor rate displacement cooking and ryegrass large liquor rate displacement cooking black liquor and implementing grading displacement cooking in cooking pan, the research and design of cooking pan grading displacement cooking technology and the corresponding device design and parttern selection being done. The said technology can be used in rebuilting the domestic ryegrass pulp mill. The pulp strength can be enhanced and the quality of the waste liquor is improved. The invention benifits for recovery processing and reduces the discharge of the waste liquor and BOD, COD.

Owner:高唐绿荫环保科技有限公司

Pearl bleaching process

The invention discloses a pearl bleaching technology, which comprises the following steps that: in the sufficient sunshine, pearls after being polished are put into prepared bleaching liquid and soaked at the temperature ranging from 14 to 17 DEG C for 48 to 50 hours for bleaching treatment, and then rinsed and dried; the step is repeated for at least one time; classification: unqualified pearls are screened out and the bleaching treatment for unqualified pearls continues to be repeated for at least one time. In the invention, the format of the bleaching liquid, consisting of a hydrogen peroxide bleaching agent, a composite interface agent, a composite catalyst and a methanol solvent, is adopted for bleaching at the low temperature of 14 to 17 DEG C so as to realize the good bleaching effect under low concentrations of the hydrogen peroxide bleaching agent within a short time, thus effectively reducing the damage to the skin of the pearl and improving the glossiness of the pearl. By adopting the method of the invention, the pearls bleached have better gloss, smooth surface, higher whiteness and good stability.

Owner:浙江梵沛珍珠股份有限公司

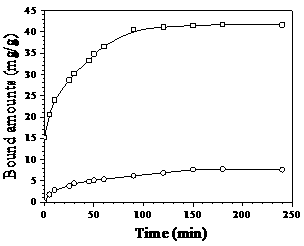

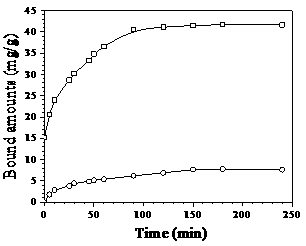

Preparation method of Fe3O4@PEG@SiO2 artificial antibody for detecting thifensulfuron methyl

ActiveCN106970215AImprove adsorption capacityHigh magnetizationOther chemical processesColor/spectral properties measurementsPolyethylene glycolAbsorption rate

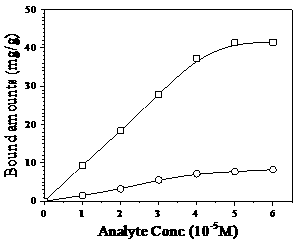

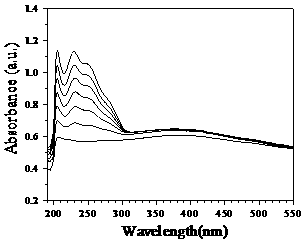

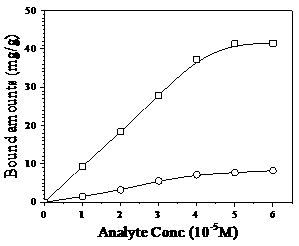

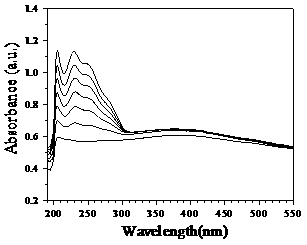

A preparation method of Fe3O4@PEG@SiO2 artificial antibody for detecting thifensulfuron methyl comprises modifying the surface of Fe3O4 magnetic nanoparticles with polyethylene glycol 2000, coating the surface with SiO2 shell layer to form a core-shell-shell structure, diluting marker molecules in the SiO2 shell layer to form specific recognition site holes complementary with marker molecular structure, size and functionality so as to arrive at molecular selective recognition and detection for target analyses. The preparation method of the artificial antibody comprises the steps of first, preparing Fe3O4 magnetic nanoparticles, and modifying their surface with polyethylene glycol; second, adding the target molecule thifensulfuron methyl, a crosslinking agent and a catalyst, and hydrolyzing to obtain Fe3O4@PEG@SiO2 particles with surface-marked thifensulfuron methyl; third, diluting template molecule with a mixed solution of acetic acid and acetone having a volume ratio of 1:4 to obtain the Fe3O4@PEG@SiO2 artificial antibody with selective recognition marker molecules, the antibody having maximum saturated binding capacity of 41.28 mg / g for thifensulfuron methyl, the absorption rate reaches 0.45 mg / g.min within first 30 min which is 5.34 times and 3.46 times that of a non-marking method.

Owner:HEFEI UNIV

Technology for preparing ryegrass slurry by pharmaceutical soak without boiling

InactiveCN1621610AQuality improvementPromote filamentationCellulose material pulpingSulfurPapermaking

The present invention is one digestion-free wheat straw-soaking pulp making process. The present invention treats wheat straw and similar papermaking material with the soaking chemical comprising sulfur 20-50 weight portions, magnesium carbonate 10-30 weight portions, aluminum hydroxide 10-30 weight portions and magnesia 30-60 weight portions. During soaking, the material consists of wheat straw in 100 weight portions, sodium hydroxide 5-15 weight portions, hydrogen peroxide 1-5 weight portions, the soaking chemical 0.1-1 weight portions and water 60-85 weight portions. Compared with traditional digesting pulp making process, the present invention has simple technological process, low production cost, high pulp quality, no waste water exhaust, high pulp yield and other advantages.

Owner:刘长如 +1

A combined pulping method

InactiveCN102268826AImprove efficiencyReduce pollutionPulping with inorganic basesPulp beating/refining methodsMature technologyPulp industry

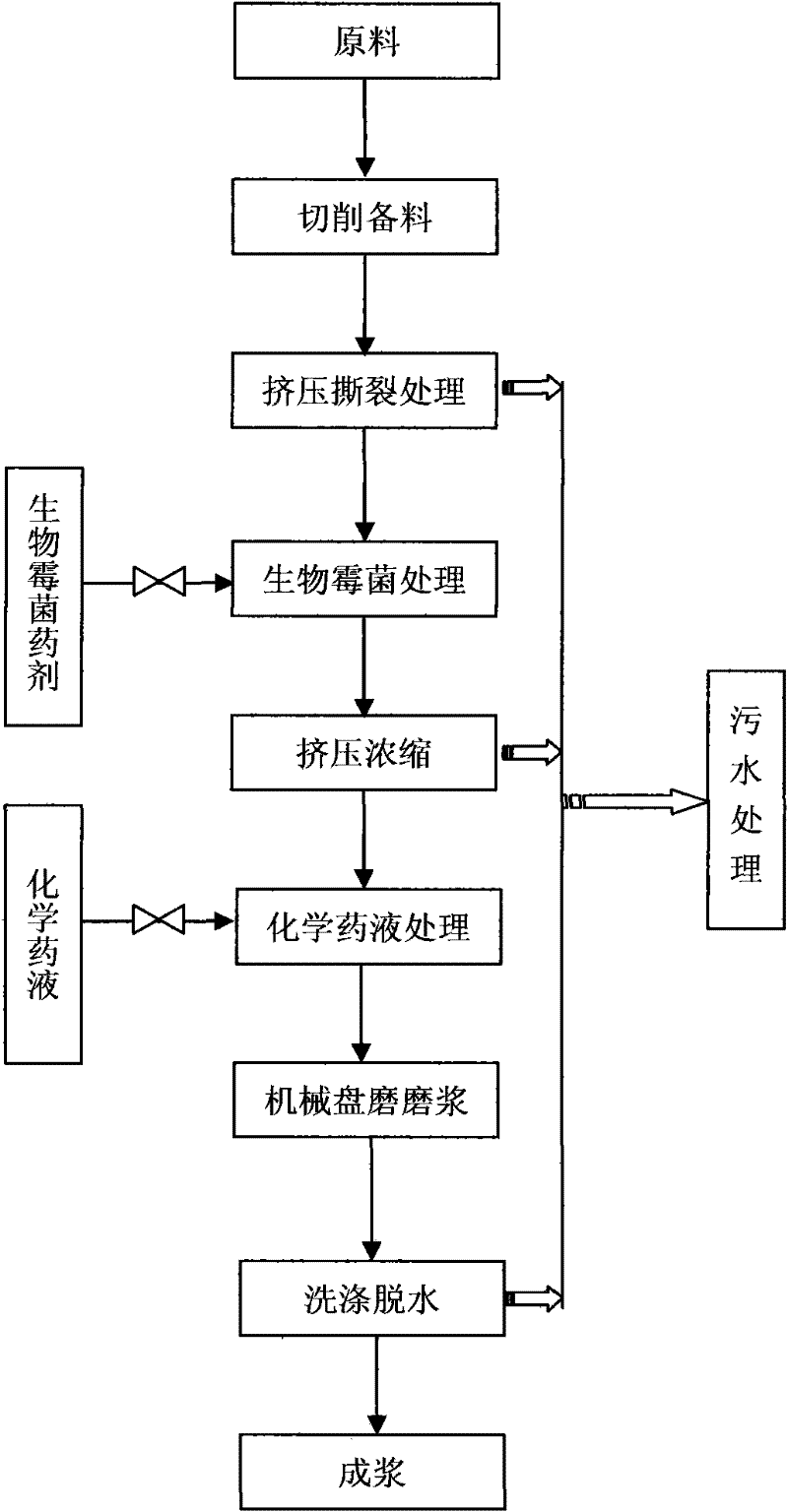

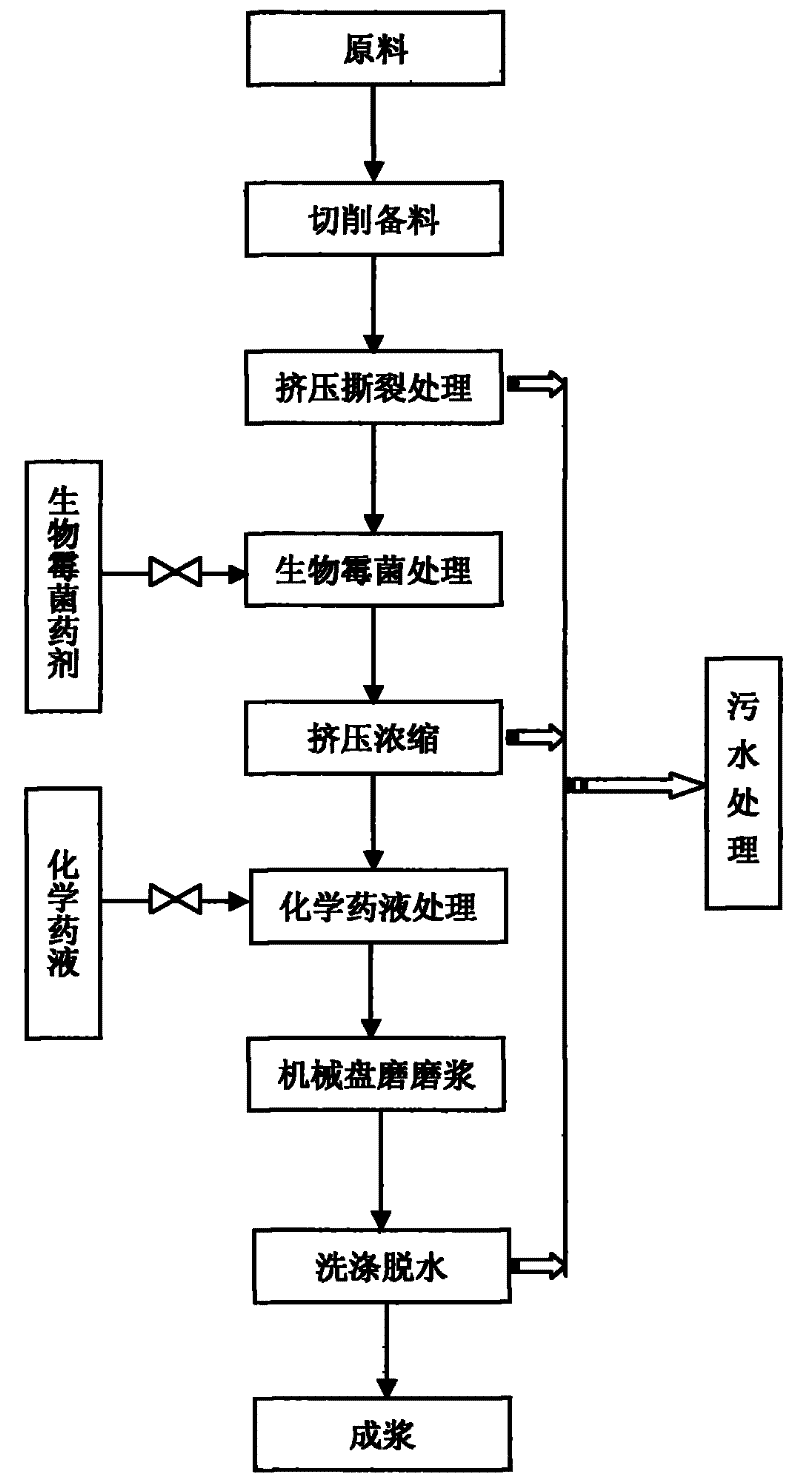

A combined pulping method, using bamboo wood as raw material. The present invention relates to a combined pulping method, in particular to a biological, chemical and mechanical combined pulping method, which belongs to the technical field of pulping and papermaking, especially biochemical and mechanical Combined pulping technology. The present invention combines the current advanced biotechnology, mature chemical pulping technology and high-efficiency mechanical pulping technology through organic integration, comprehensively utilizes the advantages of the above technologies, conducts targeted combination, and develops a new pulping method. The method of the invention reduces the pollution of the pulping industry and improves the economic benefits of the pulping industry. The combined pulping method has strong raw material adaptability, good pulping performance, and good pulp is suitable for compounding various papers.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

Method of using plant fibrous materials to produce xylose, high boiling solvent lignin and fiber

InactiveCN108179646ATake advantage ofEfficient use ofPulp liquor regenerationPulp bleachingState of artPlant fibre

The invention discloses a method of using plant fibrous materials to produce xylose, high boiling solvent lignin and fiber. The problem in the prior art that a traditional paper industry only uses thefiber, causes the waste of other elements and environmental pollutionis solved. By adopting a gas explosion method, the xylose is extracted from the plant fibrous materials, after that, the high boiling solvent lignin is extracted from the rest of materials, and the materials which the xylose and high boiling solvent lignin are previously extracted from are used for papermaking and dissolving thefiber. The method of using plant fibrous materials to produce the xylose, the high boiling solvent lignin and the fiber has a simple process and convenient operation, can fully and respectively extract the fiber, the xylose, and hemicellulose so that the elements are effectively utilized, completely utilizes the materials, and reduces the environmental pollution.

Owner:SICHUAN GOLDEN ELEPHANT SINCERITY CHEM CO LTD

Active pulp-making agent for paper making

InactiveCN101070687AConserve waterReduce water consumptionNon-macromolecular organic additionPaper/cardboardChemistryEmulsion

This invention involves a papermaking active pulp making, belongs to the papermaking technology. It is composed by the active ingredient, the host medicinal preparation and the auxiliary medicinal. The active ingredient components is: propyl butyl-carbinol polyethyleneoxide ether, oxidized polyethylene emulsion, ethyl alcohol, lauryl benzene sulfonic acid sodium, sodium monoperoxy, alkalinity proteinase and talcum powder; The main medicinal preparation's components is: calcium hydroxide, anthraquinone, sodium monoperoxy, lauryl benzene sulfonic acid sodium, anhydrous sodium sulfite and talcum powder; The auxiliary medicinal preparation's ingredient is: alkalinity proteinase, sodium monoperoxy and talcum powder; Mix the active ingredient, the host medicinal preparation and the auxiliary medicinal preparation. This invention's papermaking active system paste, may not use the alkali, does not need the massive laundering, has avoided the sewage emissions, greatly economize on water. Its thick liquid rate compares with the strong alkali method, may enhance 20%. The use of industrial chemicals is greatly reduced, and so on.

Owner:WUYUAN DAMINCAI PAPER IND

Pulping technique for fibers in grass class

ActiveCN1760445AQuality improvementReduce energy consumptionNon-woody plant/crop pulpCellulose material pulpingChemistryPre treatment

The present invention discloses a pulp-making process of straw fibre. Said process adopts the steps of pretreatment, first digestion and second digestion so as to obtain the invented straw pulp. Said pulp-making process can reduce black liquor discharge by 50%, the silicon content in the black liquor also can be reduced by 50%, and the water also can be saved by 50%.

Owner:SHANDONG TRALIN PAPER

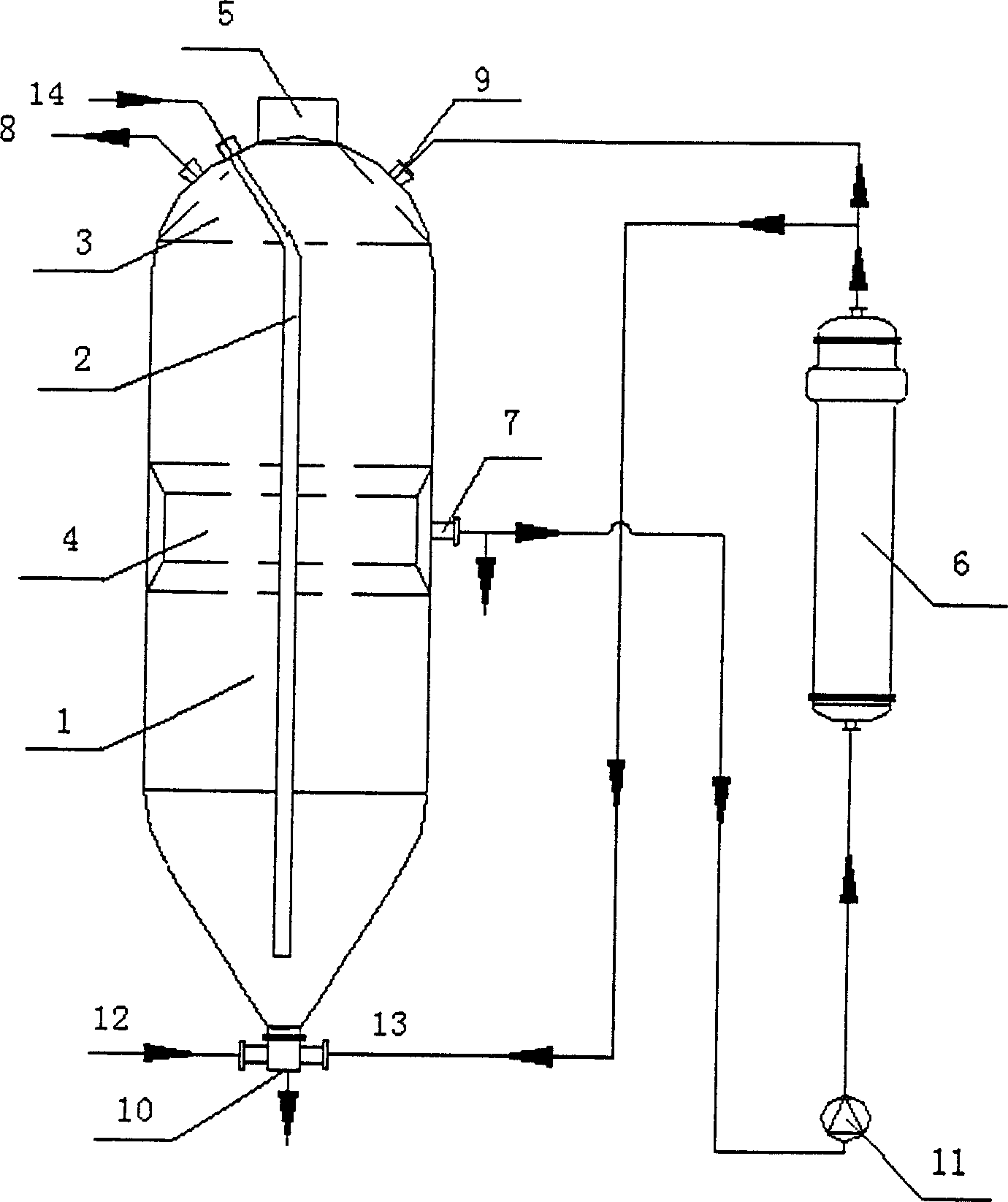

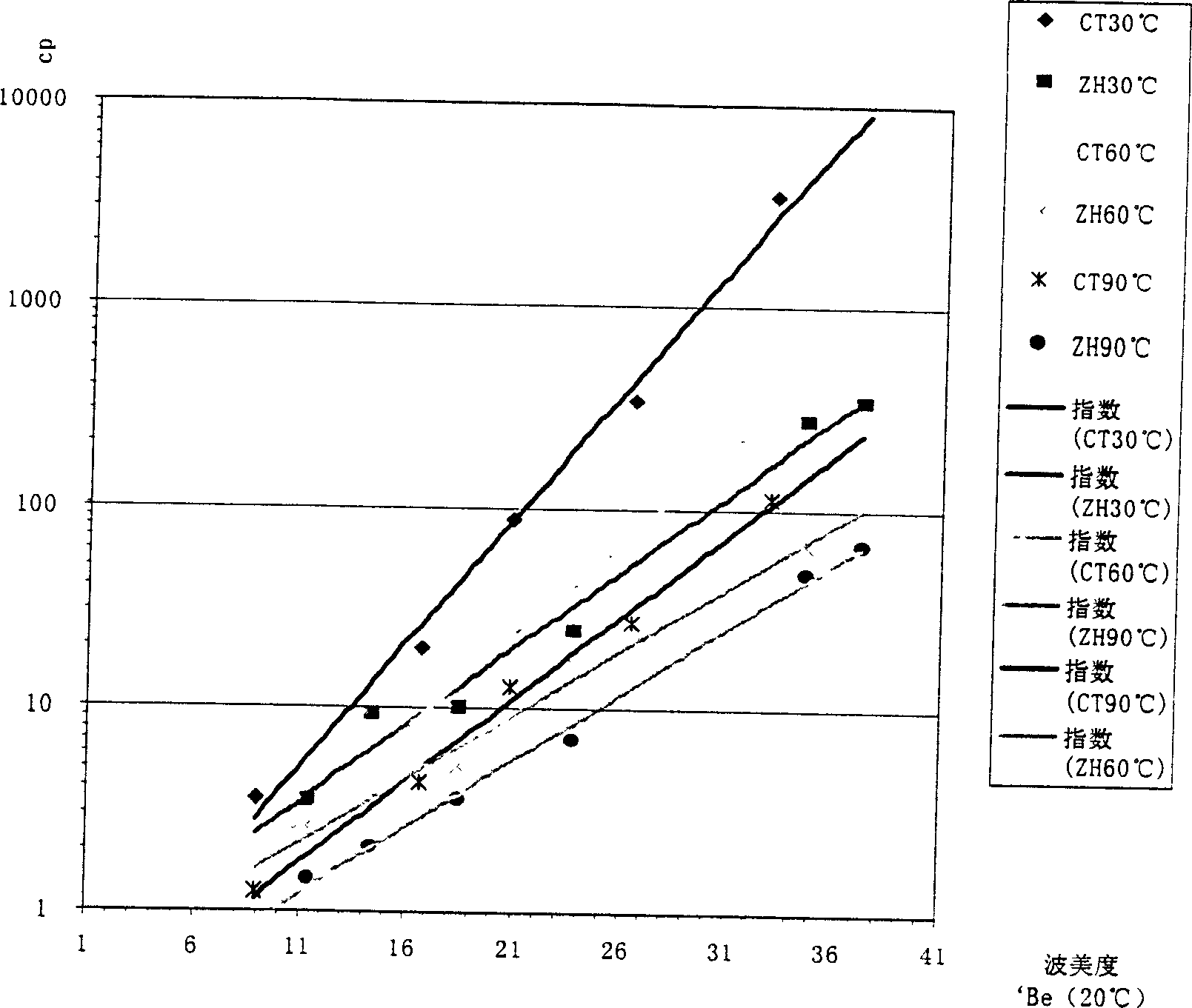

Impregnation pretreatment technology of raw material used in soda process pulp making

ActiveCN1590639ADip evenly and completelyLow viscosityPulping with inorganic basesFinely-divided material pretreatmentFiberBlack liquor

The invention relates to paper stuff manufacturing process by using grain grass fiber raw material, more concretely, a method of pre-impregnation treatment for raw material. The method uses grain grass fiber as raw material, after first treatment, impregnates the raw material by using heated impregnation liquor. The method cyclically utilizes black liquor thereby reducing environmental pressure caused by the black liquor treatment. Because of the impregnation treatment, fiber can be easily separated from the thick black liquor at first boiling.

Owner:高唐绿荫环保科技有限公司

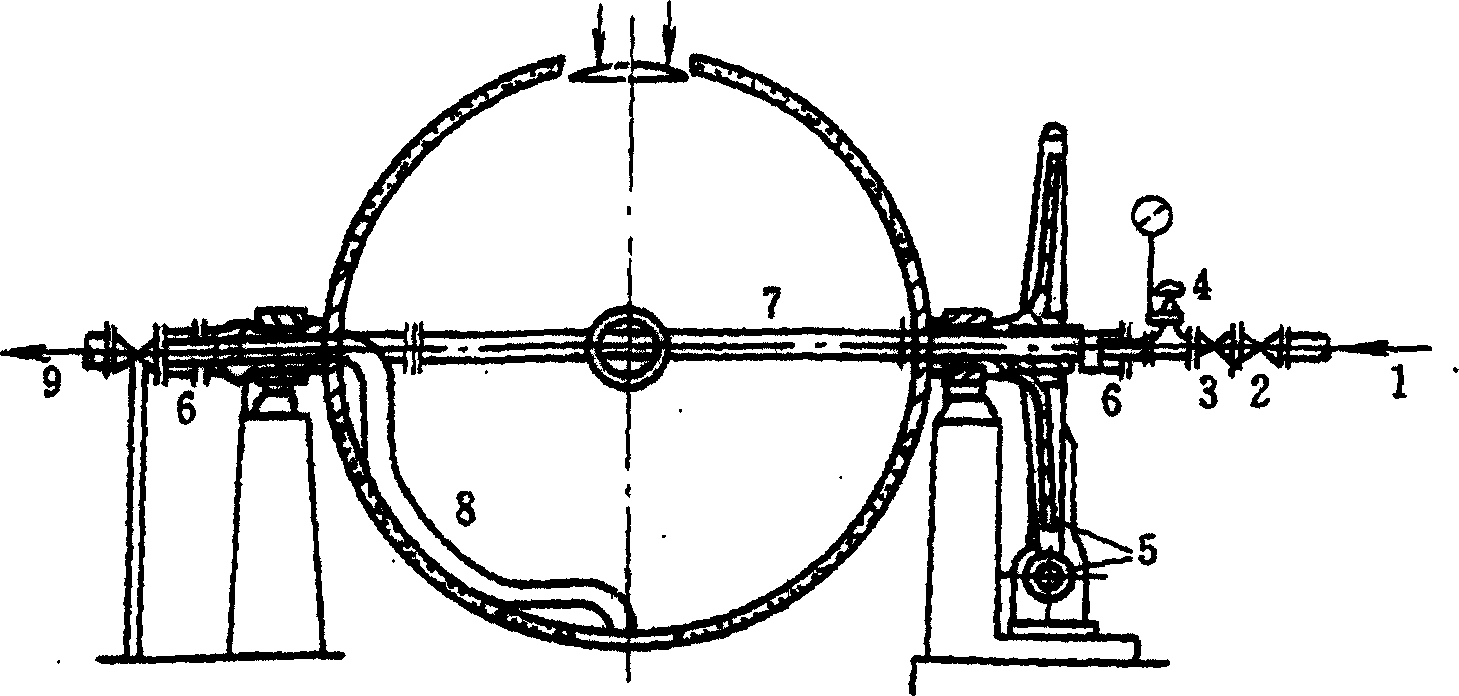

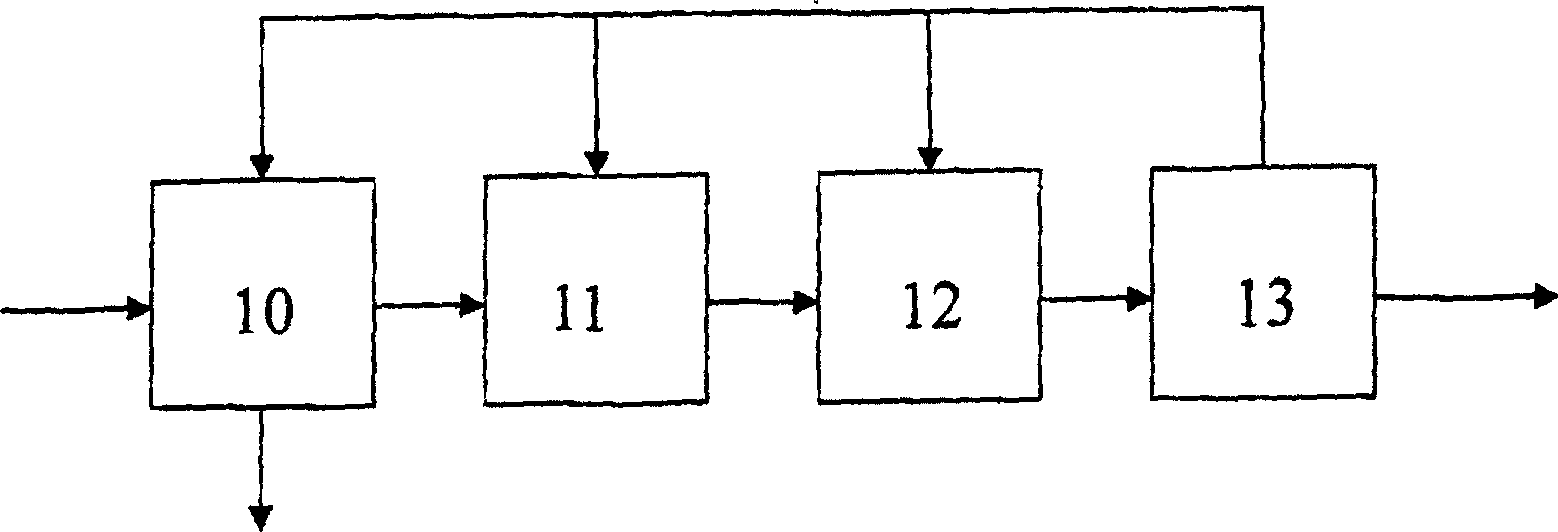

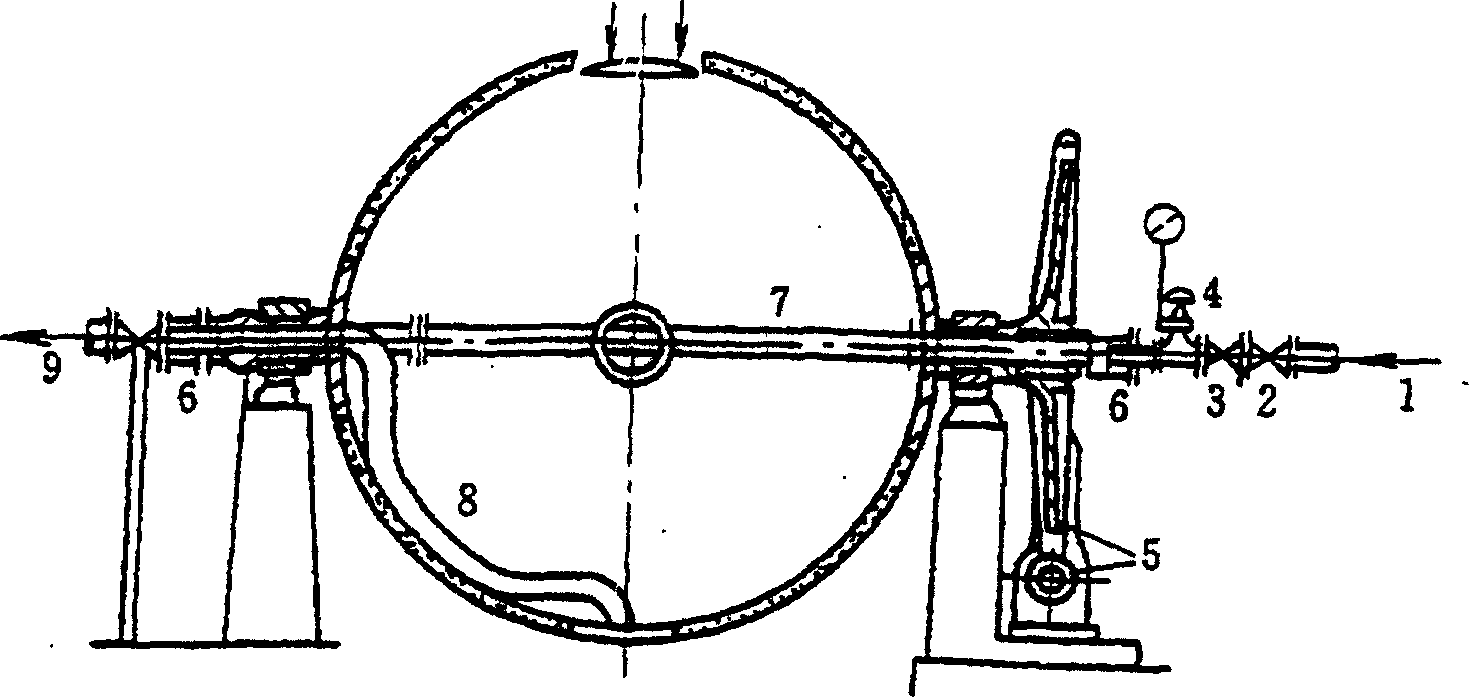

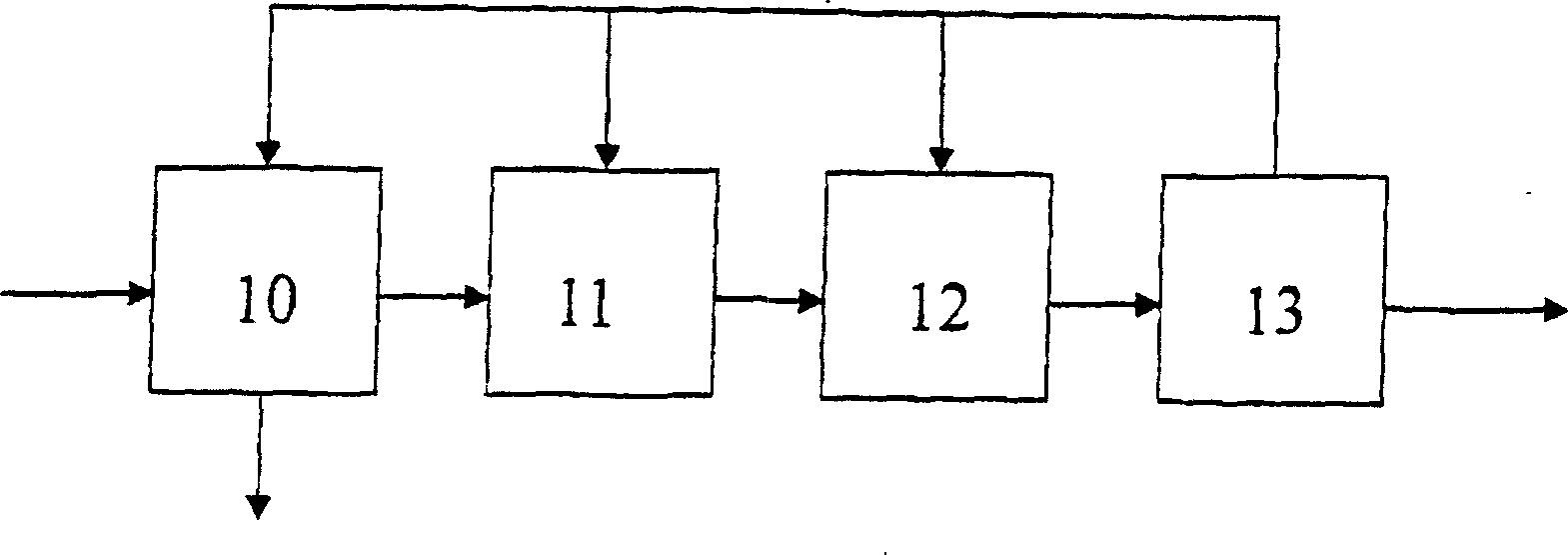

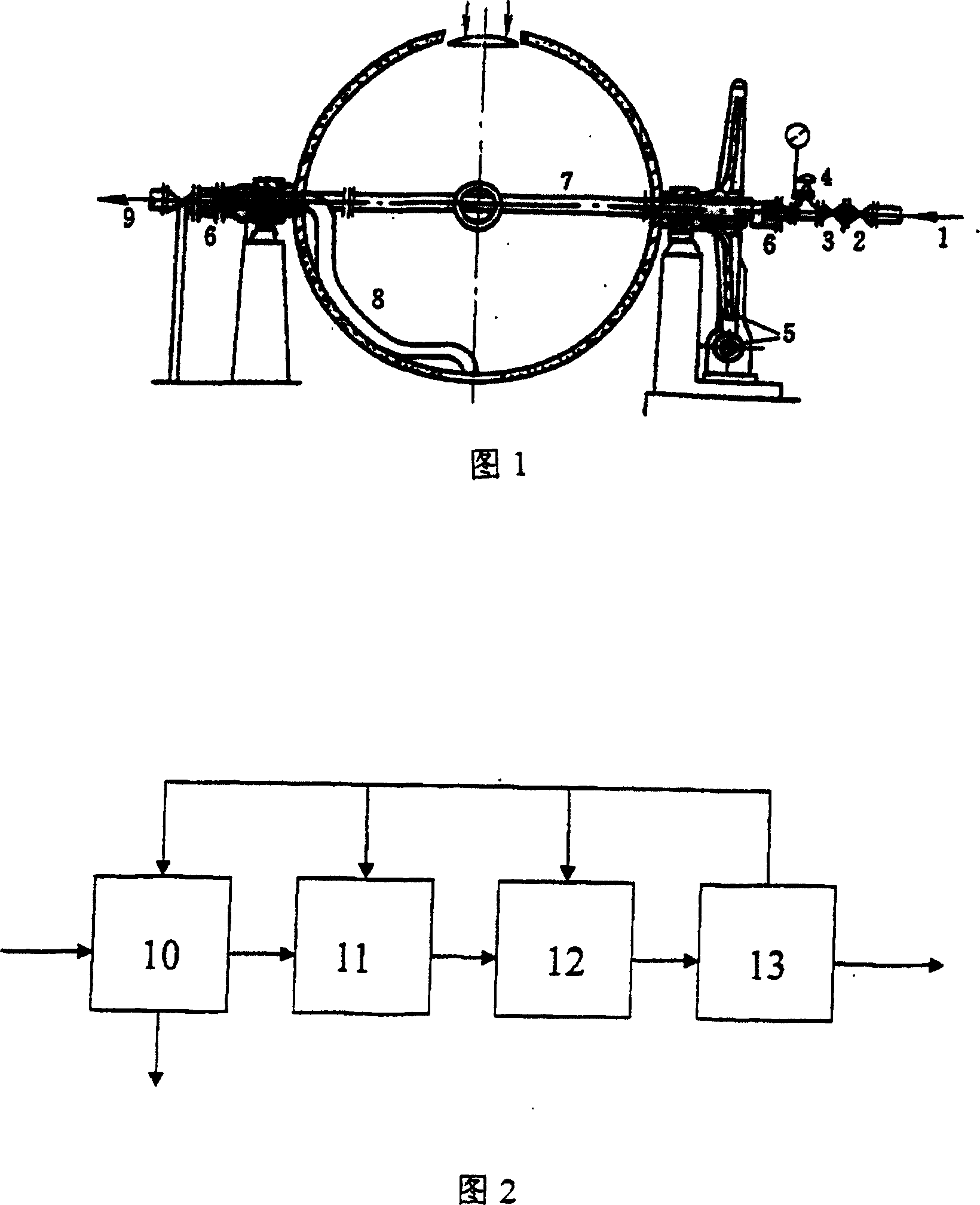

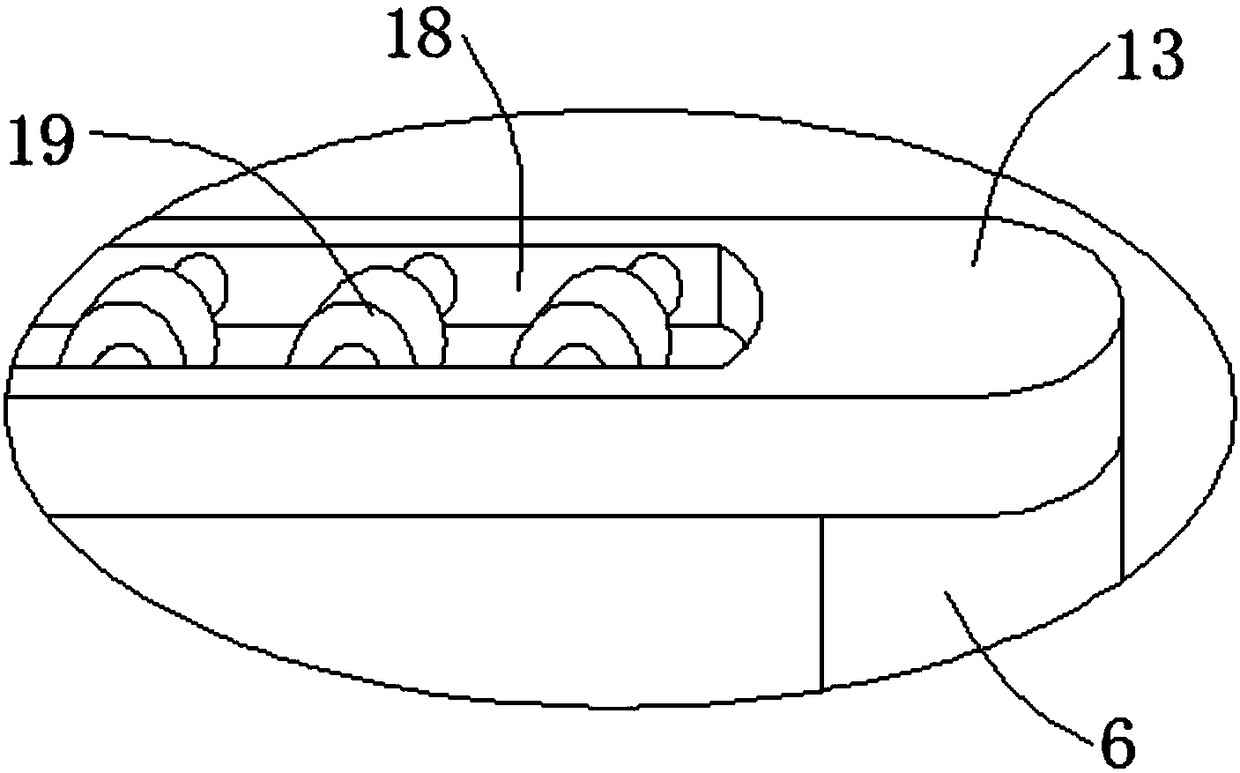

In ball washing classifying digesting technology

ActiveCN1590640ADip evenly and completelyLow viscosityWashing/displacing pulp-treating liquorsPulping with inorganic basesFiberBlack liquor

The invention relates to paper stuff manufacturing process by using grain grass fiber raw material, more concretely, a method of using black liquor as raw material for primary and secondary boiling liquor for cyclic utilization. The primary boiling is implemented under lower temperature, and while using secondary boiling liquor to displace and discharge the thick black liquor, the fiber in spherical digester which has subjected to the primary boiling is washed, and subjects to the secondary boiling in high temperature, and then pulp is subject to countercurrent washing. The process is used in pulping, and the black liquor can be periodic used thereby reduce environment pollution. Black liquor that per ton of pulp discharges can reduce 50%, and water can be saved for 50%.

Owner:高唐绿荫环保科技有限公司

Pulping technique for straw fibre

ActiveCN101165267AQuality improvementReduce energy consumptionPretreatment with water/steamPulp liquor regenerationPre treatmentDigestion

The grass fiber pulp producing process includes the steps of pre-treatment, the first digestion, and the second digestion. The present invention features less environmental pollution, saving in water, low power consumption and high pulp quality. The grass fiber pulp product has high whiteness, low hardness, high breaking strength and easy bleaching.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Pearl bleaching process

InactiveCN100566622CSustained uniform releaseOvercome or weaken surface tensionJewellerySolventMethanol

The invention discloses a pearl bleaching technology, which comprises the following steps that: in the sufficient sunshine, pearls after being polished are put into prepared bleaching liquid and soaked at the temperature ranging from 14 to 17 DEG C for 48 to 50 hours for bleaching treatment, and then rinsed and dried; the step is repeated for at least one time; classification: unqualified pearls are screened out and the bleaching treatment for unqualified pearls continues to be repeated for at least one time. In the invention, the format of the bleaching liquid, consisting of a hydrogen peroxide bleaching agent, a composite interface agent, a composite catalyst and a methanol solvent, is adopted for bleaching at the low temperature of 14 to 17 DEG C so as to realize the good bleaching effect under low concentrations of the hydrogen peroxide bleaching agent within a short time, thus effectively reducing the damage to the skin of the pearl and improving the glossiness of the pearl. By adopting the method of the invention, the pearls bleached have better gloss, smooth surface, higher whiteness and good stability.

Owner:浙江梵沛珍珠股份有限公司

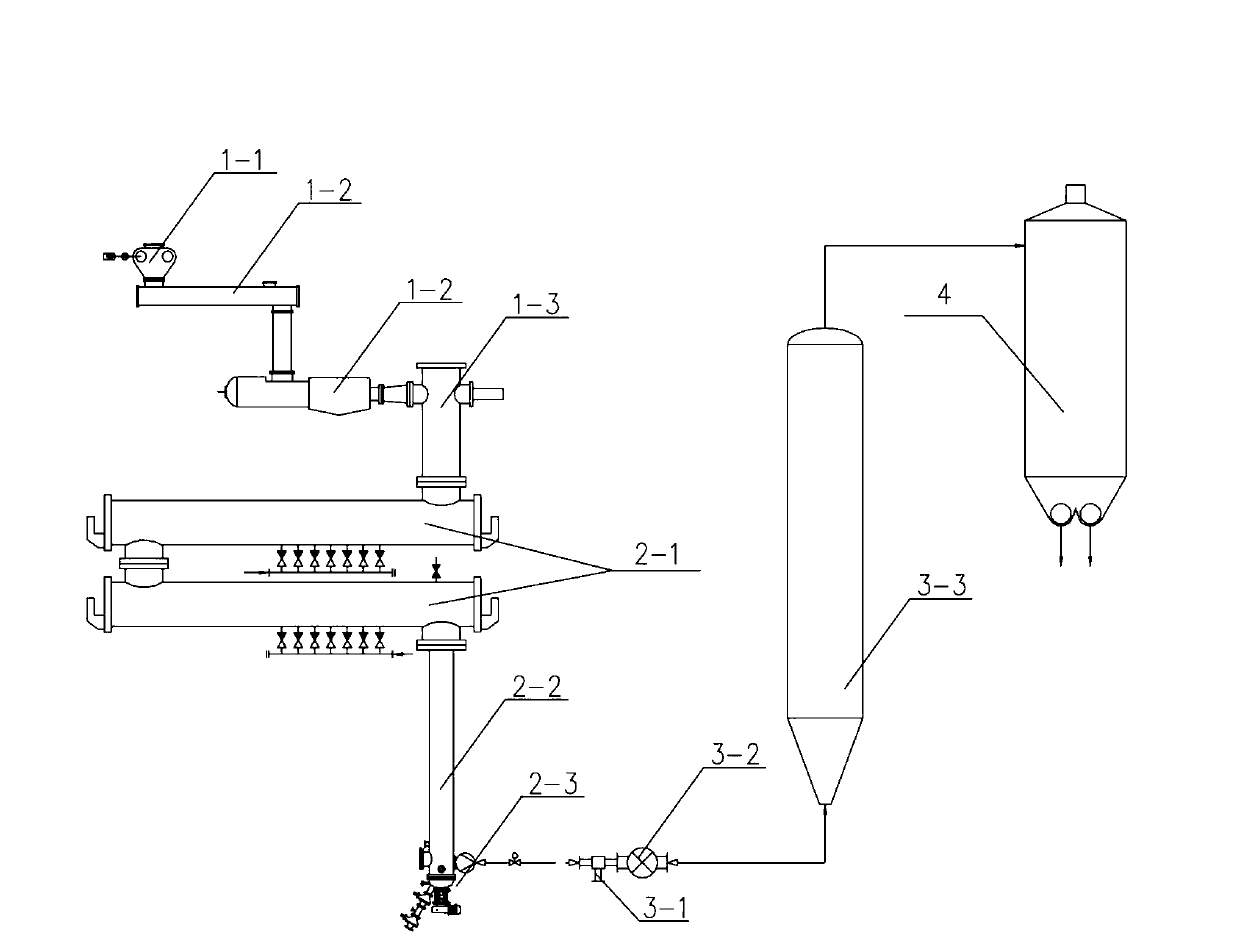

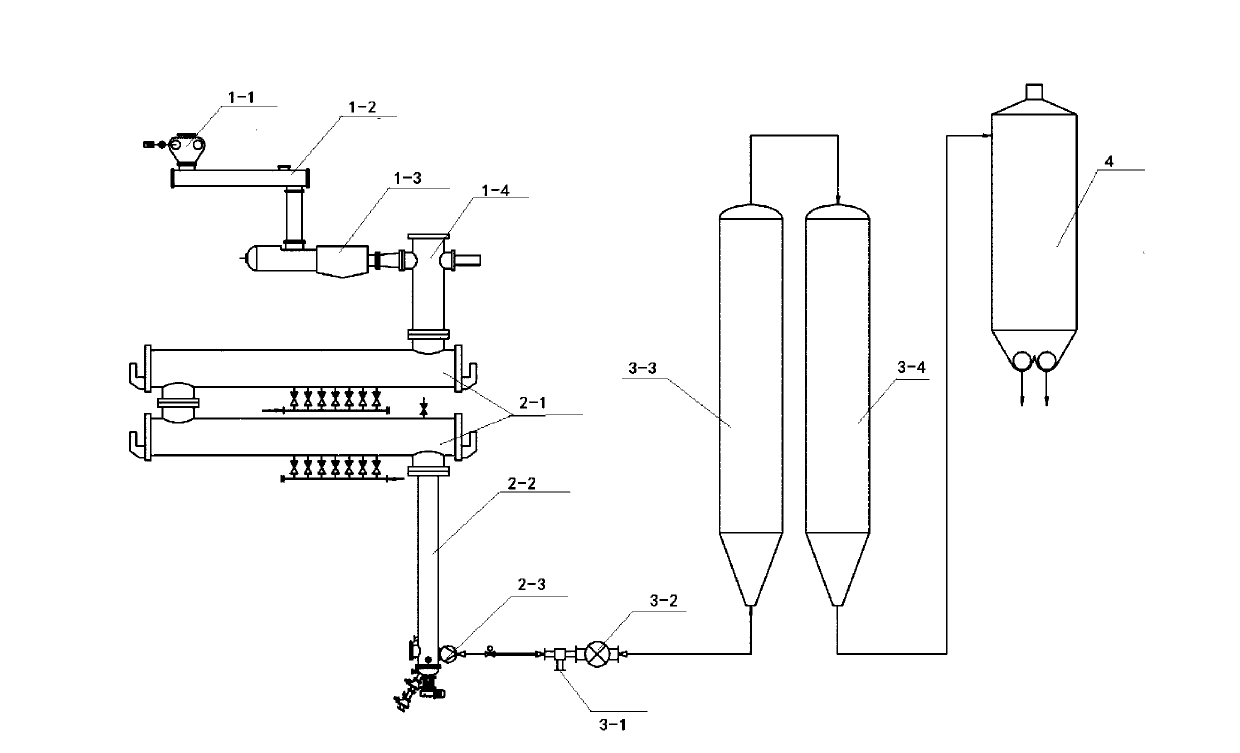

Oxygen alkaline pulping cooking device

InactiveCN103276617AReduce foulingGood clarificationPulping with inorganic basesWhite liquorBlack liquor

The invention discloses an oxygen alkaline pulping cooking device which comprises a feeding device, a pre-cooking device, a cooking device and a spraying device, wherein the feeding device is connected with the first end of the pre-cooking device and is used for conveying the pulping raw material into the pre-cooking device for pre-cooking; the second end of the pre-cooking device is connected with the first end of the cooking device, and the pre-cooking device is used for conveying the pre-cooked pulping raw material into the cooking device for cooking; and the second end of the cooking device is connected with the spraying device, and the cooking device is used for conveying the cooked pulp into the spraying device for spraying. The oxygen alkaline pulping cooking device can be used for carrying out oxygen-alkaline cooking pulping on straw pulp and wood pulp, the prepared straw pulp contains more than 10% of silicon dioxide, the yield of a cooking work section reaches up to be more than 50%, and the whiteness reaches 50-60%, so that the device is easy to bleach, reduces the scaling phenomenon of a black liquor concentration evaporator pipeline, is beneficial to clarifying the white liquor in the subsequent causticization process, and improves the alkali recovery rate.

Owner:JIAMUSI AMUR PULP & PAPER

Chlorine-free bleaching powder for textile materials and preparation method thereof

The invention discloses chlorine-free bleaching powder for textile materials, made from 15-30 parts of rare earth, 10-28 parts of hydrogen peroxide, 5-15 parts of sodium percarbonate, 5-10 parts of sodium percarbonate, 2-5 parts of sodium sulfate, 4-9 parts of primary alcohol ethoxylate, 1-7 parts of a sodium salt of maleic anhydride-acrylic acid copolymer, 2-7 parts of sodium hydroxyethyl sulfonate, 2-7 parts of a brightener, 5-12 parts of an activator, 0.5-3.5 parts of a catalyst, and 1.5-5.5 parts of a stabilizer. The chlorine-free bleaching agent for textile materials and a preparation method thereof are provided herein; the bleaching agent is friendly to equipment and personnel, and is suitable for bleaching in an acid environment; the bleaching steps are simple and quick, and a textile material bleached is better for dyeing.

Owner:HEFEI YUANKE GARMENT DESIGN CO LTD

Pulping technique for straw fibre

ActiveCN101100818AQuality improvementReduce energy consumptionPretreatment with water/steamPulp liquor regenerationFiberBlack liquor

The invention discloses grass series fiber pulping technology. It includes preprocessing, once and secondary steam boiling. Its advantages are that it can reduce environment pollution that the discharged black liquor can be reduced by 50% per ton; silicon content can be reduced by 50%; water can be saved by 50%; the formed slurry has light color, high brightness, low hardness, high strength, easy pulping and bleaching.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Method for making paper-pulp by cold immersion for paper-making

InactiveCN100510246CAvoid emissionsConserve waterNon-macromolecular organic additionPaper/cardboardCardboardWater use

Owner:WUYUAN DAMINCAI PAPER IND

Low energy consumption clean paper pulp extracting method and papermaking process thereof

InactiveCN101694075BAchieve recyclingGood flexibilityPretreatment with alkaline reacting compoundsPulp de-wateringFiberChemical solution

The invention relates to a low energy consumption clean paper pulp extracting method and a papermaking process thereof, solving the problems that fibrous raw materials need to be boiled at high temperature and pressure in the pulp preparing and papermaking processes and chemical solutions produce a large quantity of black or red liquid in the pulp preparing and papermaking processes to cause great waste to resources and great pollution to the environment in the prior art. The invention adopts the following technical scheme: the low energy consumption clean paper pulp extracting method is realized by removing impurities from biomass raw materials rich of fiber, crushing, softening and soaking, separating organic matters, grinding and pulping, wherein a softening and soaking solution contains the following components in percent by weight: 10-20 sodium oxide, 3-5 sodium carbonate, 0.5-2.5 penetrating agent T, 0.5 magnesium oxide and 0.05-0.15 chelating agent EDTA. The papermaking processmatched with the method comprises the following steps: getting materials ready, rubbing to devillicate, soaking to react, separating liquid medicine, spirally squeezing pulp, refining with high consistency, removing slag, coarsely screening and making paper. The pulp preparing process has simple course, no high requirements on environment and equipment condition, easily popularized technology, norequirement on the scale of production, low costs for building production lines and purchasing equipment and less running expense.

Owner:林宣禧

Fast identification method for plant dyed cotton fabric and chemical dyed cotton fabric through bleaching

ActiveCN109900687AShorten identification timeSimple and fast operationMaterial analysis by observing effect on chemical indicatorDistilled waterColor changes

The invention discloses a fast identification method for plant dyed cotton fabric and chemical dyed cotton fabric through bleaching. The method comprises steps that the chlorite, the activator and thepenetrant are respectively added to the distilled water so that concentrations are 10-15% of the chlorite, 4-6% of the activator and 2-3% of the penetrant respectively to obtain the solution, mineralacid is then added to the solution, the pH is adjusted to 1-3, and a special reagent is prepared; the special reagent is measured and obtained, a pair of tweezers are utilized to completely immerse the fabric in the special reagent for 3-5 seconds, and then the fabric is quickly removed and placed on a white identification plate; the color change of the fabric on the white identification plate isobserved within 1-10 s after the fabric is taken out, if the fabric fades or turns white, the fabric is the plant dyed fabric; if the fabric has no color change, the fabric is the chemical dyed fabric. The method is advantaged in that operation is simple and convenient, identification is simple and easy, the consumption time is short, the result is accurate, universality is realized, and the identification time of the plant dyed fabric is shorter than 10s.

Owner:QINGDAO UNIV

In ball washing classifying digesting technology

ActiveCN1318690CDip evenly and completelyLow viscosityWashing/displacing pulp-treating liquorsPulping with inorganic basesFiberBlack liquor

The invention relates to paper stuff manufacturing process by using grain grass fiber raw material, more concretely, a method of using black liquor as raw material for primary and secondary boiling liquor for cyclic utilization. The primary boiling is implemented under lower temperature, and while using secondary boiling liquor to displace and discharge the thick black liquor, the fiber in spherical digester which has subjected to the primary boiling is washed, and subjects to the secondary boiling in high temperature, and then pulp is subject to countercurrent washing. The process is used in pulping, and the black liquor can be periodic used thereby reduce environment pollution. Black liquor that per ton of pulp discharges can reduce 50%, and water can be saved for 50%.

Owner:高唐绿荫环保科技有限公司

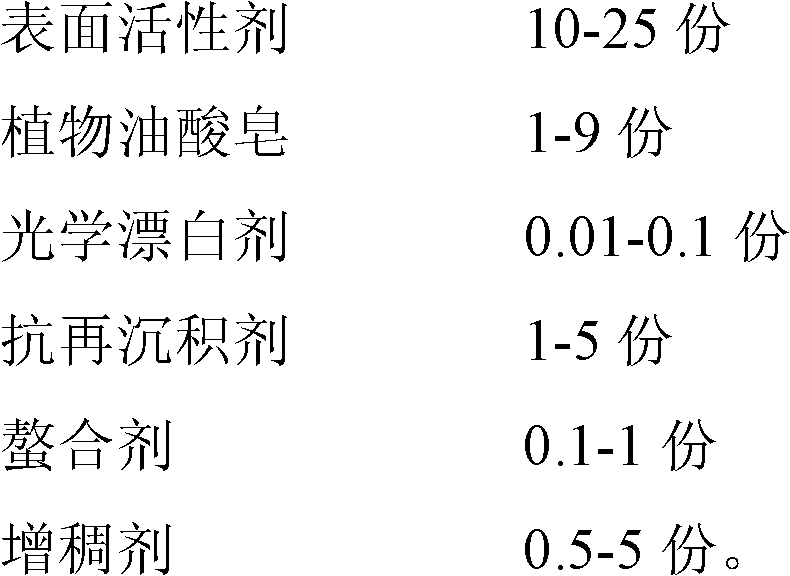

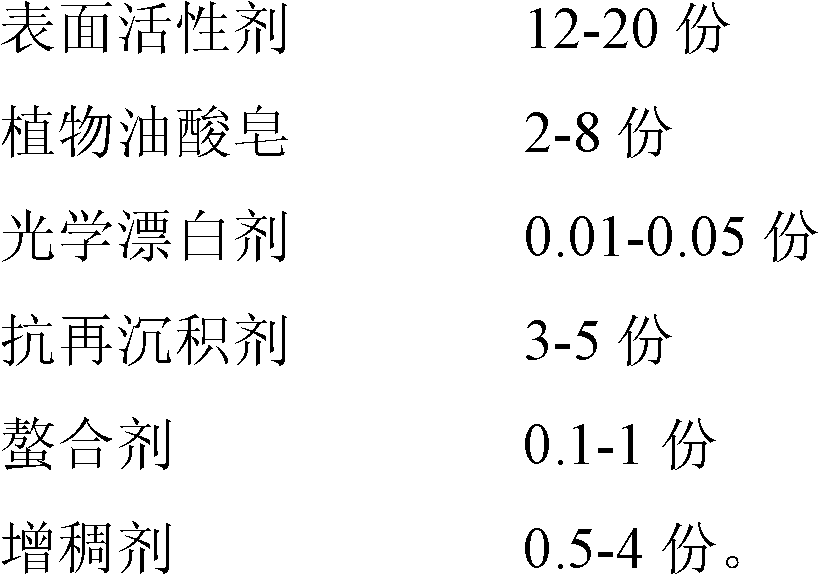

Neutral low foam laundry detergent containing optical bleaching agent

ActiveCN102618407BExcellent decontaminationMeet needsSurface-active non-soap compounds and soap mixture detergentsActive componentBleach

The invention relates to a neutral low foam laundry detergent containing an optical bleaching agent. Main active components of the laundry detergent by mass comprise a surface active agent 10-25 parts, plant oleic acid soap 1-9 parts, the optical bleaching agent 0.01-0.1 part, a chelating agent 0.1-1 part, a redeposit-resistant agent 1-5 parts and a thickening agent 0.5-5 parts. The neutral low foam laundry detergent containing the optical bleaching agent can have a great whitening effect on clothes after the clothes are washed, is neutral and free of stimulation, and produces low foam easy to rinse.

Owner:BEIJING REWARD HOME CARE CHEM

Pulping technique for straw fibre

ActiveCN101100818BLight colorHigh whitenessPretreatment with water/steamPulp liquor regenerationFiberBlack liquor

The invention discloses grass series fiber pulping technology. It includes preprocessing, once and secondary steam boiling. Its advantages are that it can reduce environment pollution that the discharged black liquor can be reduced by 50% per ton; silicon content can be reduced by 50%; water can be saved by 50%; the formed slurry has light color, high brightness, low hardness, high strength, easypulping and bleaching.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Pulping technique for fibers in grass class

ActiveCN100373001CQuality improvementReduce energy consumptionNon-woody plant/crop pulpCellulose material pulpingFiberBlack liquor

The present invention discloses a pulp-making process of straw fibre. Said process adopts the steps of pretreatment, first digestion and second digestion so as to obtain the invented straw pulp. Said pulp-making process can reduce black liquor discharge by 50%, the silicon content in the black liquor also can be reduced by 50%, and the water also can be saved by 50%.

Owner:SHANDONG TRALIN PAPER

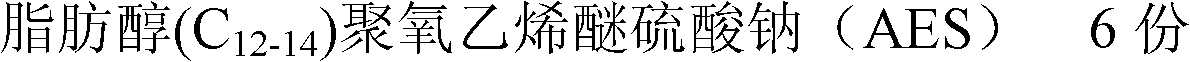

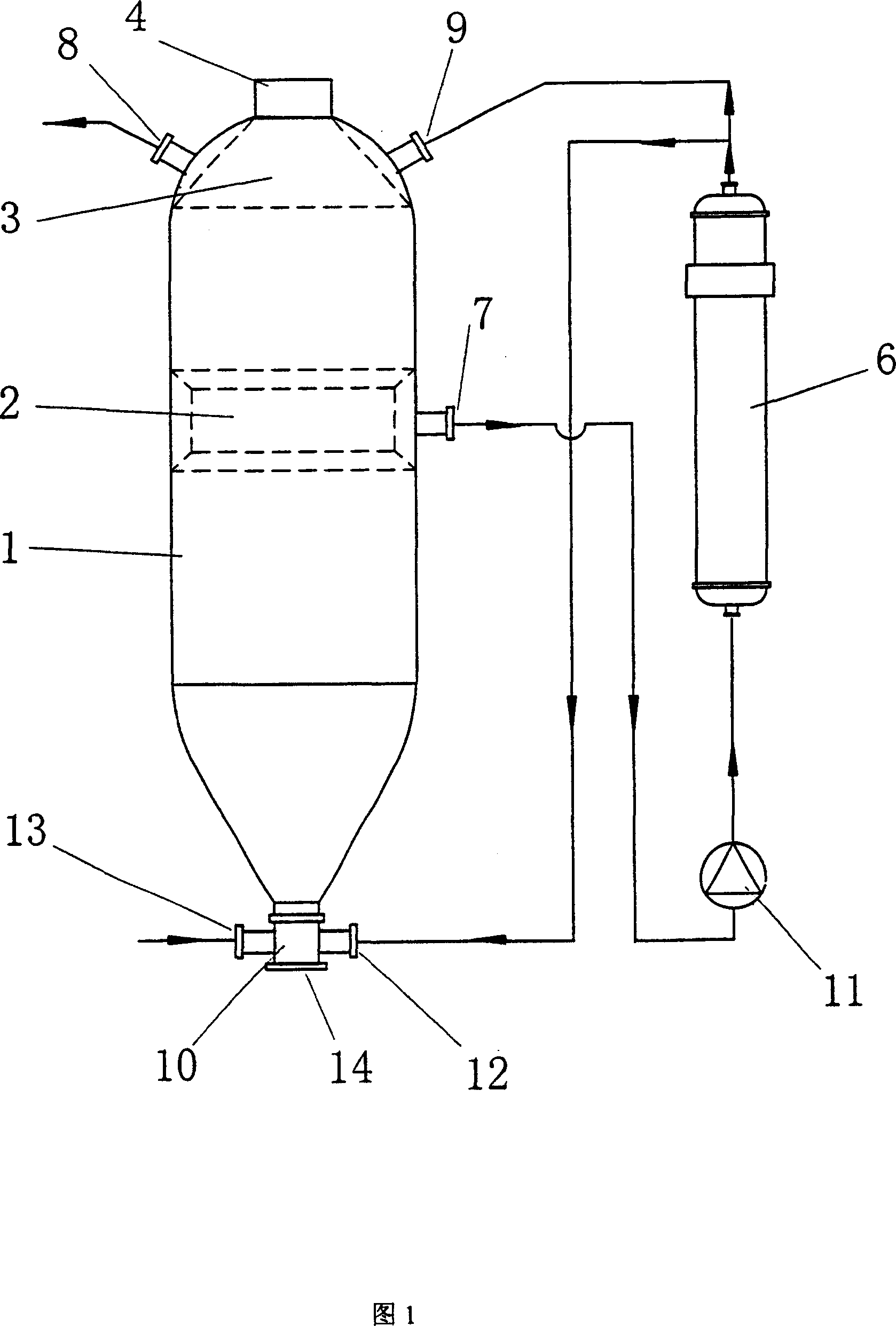

Vertical boiling pot for paper pulp

ActiveCN1308545CFast cookingIncrease productionDigestersPaper material treatmentBlack liquorHardness

The vertical paper pulp boiling pot has steam heating pipe with steam inlet on its one end and steam pores on its wall. By means of the steam heating pipe and the circular heating, the paper pulp boiling pot has homogeneous pulping, raised boiling speed, raised straw pulp quality and yield. The prepared straw pulp may be used to replace wood pulp, and hw light color, high whiteness, low hardness, high strength and other advantages. In addition, the black liquor may be reused to reduce drainage and save water.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

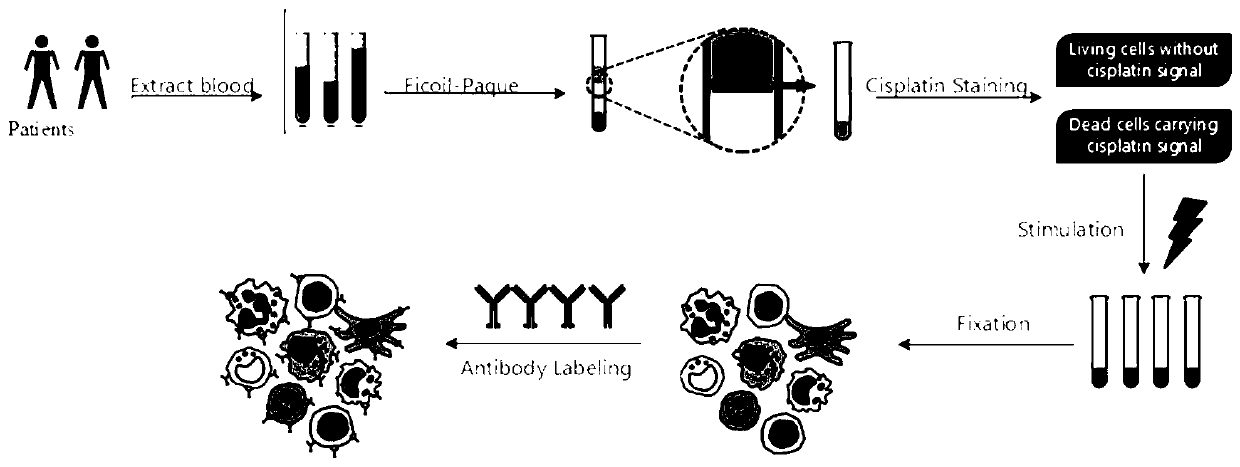

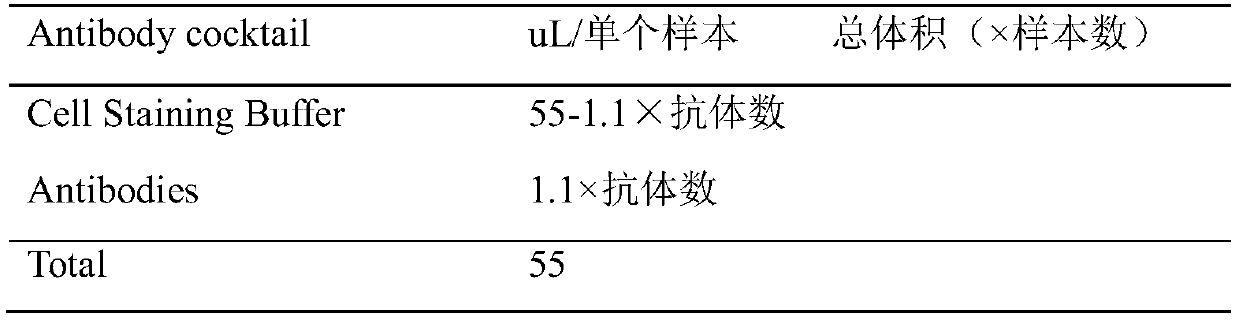

Sample pretreatment method based on flow cytometry combined with icp-ms single-cell protein detection

ActiveCN107314965BEasy to handleSimple and fast operationMaterial analysis by electric/magnetic meansIndividual particle analysisPeripheral blood mononuclear cellCell Surface Antigens

The invention discloses a sample pretreatment method based on flow combination ICP-MS (Inductively Coupled Plasma Mass Spectrometry) single cell protein detection, and belongs to the technical field of sample pretreatment of flow cytometry. The sample pretreatment method comprises the following steps: (1) collecting and transporting a whole blood sample; (2) performing PBMC (Peripheral Blood Mononuclear Cell) cell separation; (3) performing cell active dyeing; (4) performing cell stimulation; (5) performing cell immobilization; (6) performing surface antibody dyeing; (7) performing intracellular phosphorylated protein dyeing; (8) performing single cell labeling, and the like. With the combination of a metal element labeled antibody with cell surface antigen, labeled cells are mixed with beads as internal reference for standardization, dead cells and living cells are distinguished in the pretreatment process, then the situation that the testing result analysis and description are affected by too many dead cells is avoided, single cells are distinguished from cell dimmers, cell trimers or even cell multimers, and flow combination ICP-MS single cell protein detection requirements can be very well met.

Owner:马鞍山普梅森医学检验实验室有限公司

Bleaching agent composition and detergent composition

ActiveCN103320240BMore effective oxygen lossElimination of available oxygen lossWater/sewage treatment by irradiationSurface-active detergent compositionsBleachRare earth

Owner:吉林省亨泰服装洗染科学技术研究所

Active pulp-making agent for paper making

InactiveCN100510254CAvoid emissionsConserve waterNon-macromolecular organic additionPaper/cardboardActive agentSulfite salt

The invention relates to an active pulping agent for papermaking and belongs to the technical field of papermaking. The pulping agent is composed of an active agent, a main agent and an auxiliary agent, wherein the active agent is composed of: secondary octanol polyoxyethylene ether, oxidized polyethylene emulsion, ethanol, sodium dodecylbenzenesulfonate, sodium percarbonate , alkaline protease and talcum powder; the ingredients of the main agent are: calcium hydroxide, anthraquinone, sodium percarbonate, sodium dodecylbenzenesulfonate, anhydrous sodium sulfite and talc powder; the ingredients of the auxiliary agent are: alkaline protease , sodium percarbonate and talcum powder; mix active agent, main agent and auxiliary agent with each other, and stir evenly. The active pulping agent for papermaking of the present invention can be used for papermaking without using alkali and washing with a large amount of water, avoiding the discharge of sewage and greatly saving water. Compared with the strong alkali method, its pulp yield can be increased by 20%. The amount of chemical raw materials used is much less than that of the traditional papermaking process, which makes the pulp easy to bleach, consumes less water, contains less pollutants, and makes the middle water in the papermaking process easy to treat.

Owner:WUYUAN DAMINCAI PAPER IND

A preparation method of fe3o4@peg@sio2 artificial antibody for detecting thifensulfuron-methyl

ActiveCN106970215BImprove adsorption capacityHigh magnetizationOther chemical processesColor/spectral properties measurementsPolyethylene glycolPhotochemistry

A preparation method of Fe3O4@PEG@SiO2 artificial antibody for detecting thifensulfuron methyl comprises modifying the surface of Fe3O4 magnetic nanoparticles with polyethylene glycol 2000, coating the surface with SiO2 shell layer to form a core-shell-shell structure, diluting marker molecules in the SiO2 shell layer to form specific recognition site holes complementary with marker molecular structure, size and functionality so as to arrive at molecular selective recognition and detection for target analyses. The preparation method of the artificial antibody comprises the steps of first, preparing Fe3O4 magnetic nanoparticles, and modifying their surface with polyethylene glycol; second, adding the target molecule thifensulfuron methyl, a crosslinking agent and a catalyst, and hydrolyzing to obtain Fe3O4@PEG@SiO2 particles with surface-marked thifensulfuron methyl; third, diluting template molecule with a mixed solution of acetic acid and acetone having a volume ratio of 1:4 to obtain the Fe3O4@PEG@SiO2 artificial antibody with selective recognition marker molecules, the antibody having maximum saturated binding capacity of 41.28 mg / g for thifensulfuron methyl, the absorption rate reaches 0.45 mg / g.min within first 30 min which is 5.34 times and 3.46 times that of a non-marking method.

Owner:HEFEI UNIV

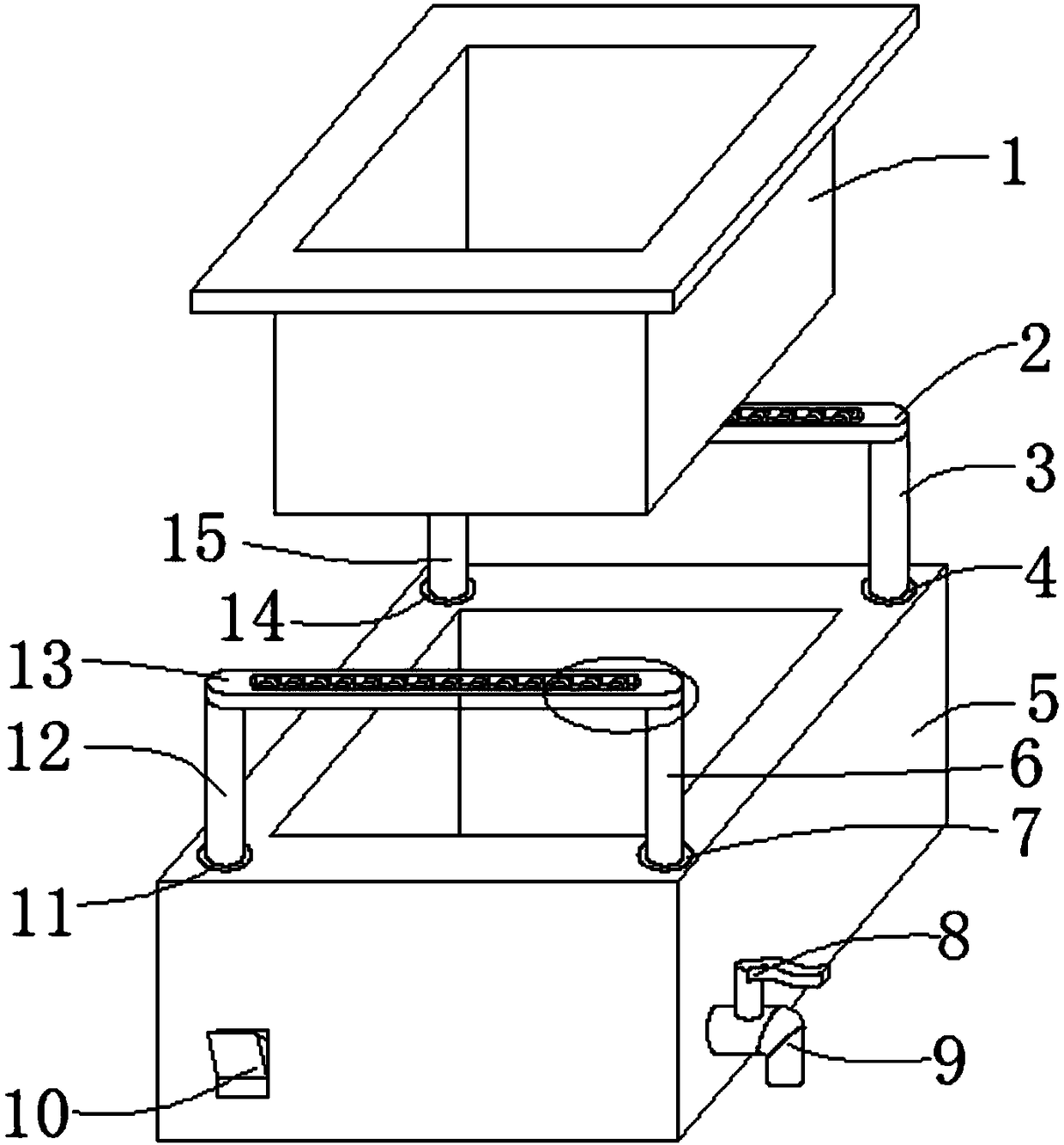

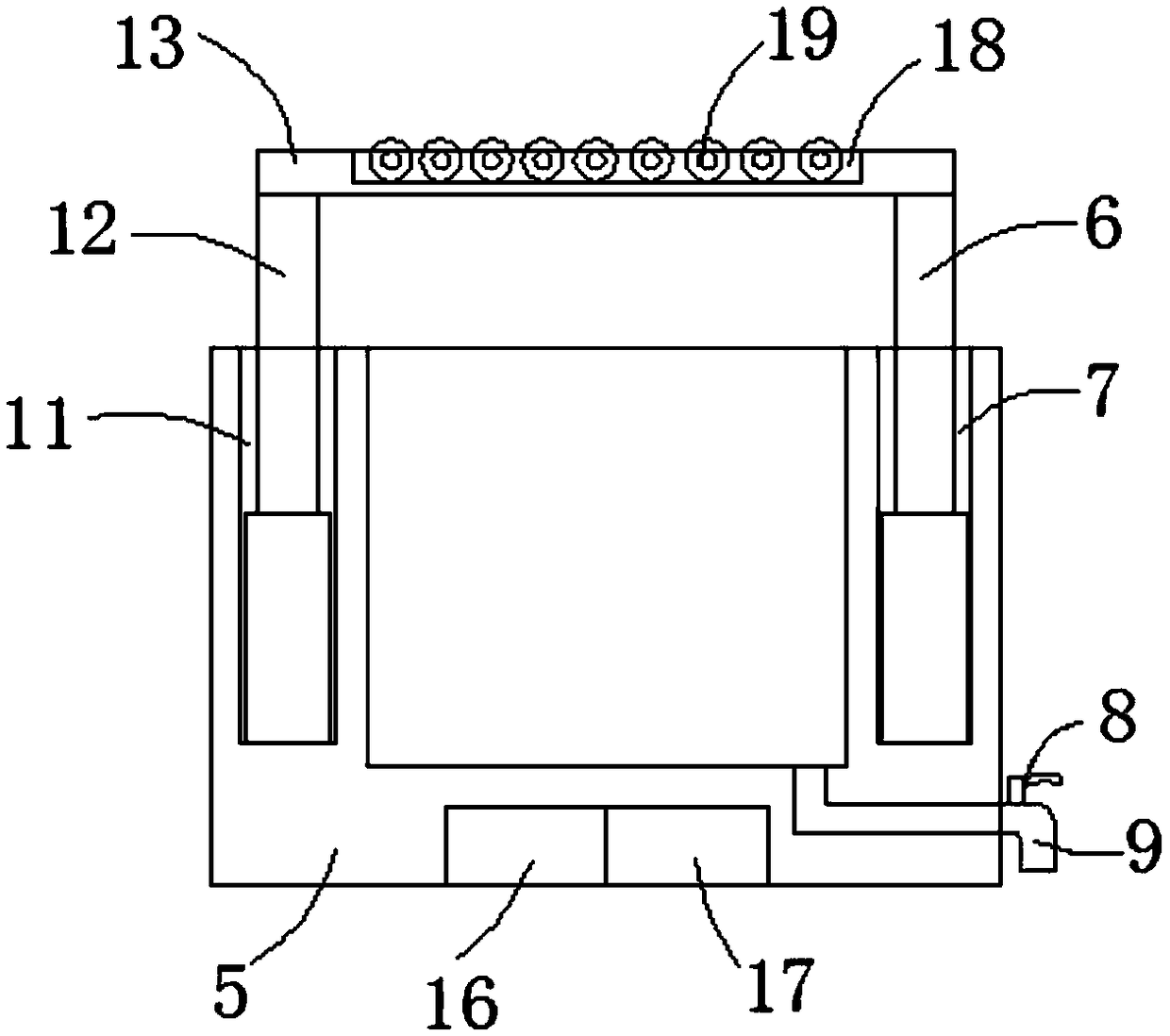

A bleaching device for paper product processing

The invention discloses a bleaching plant for converting paper. The bleaching plant comprises a bleaching pond and a draining pond, a filter screen is embedded and sleeved on the bottom end face of an inner cavity of the draining pond, a support plate is installed on the edge of the top end of the draining pond, a first electric hydraulic push rod, a second electric hydraulic push rod, a third electric hydraulic push rod and a fourth electric hydraulic push rod are respectively fixedly connected in inner cavities of a first placement groove, a second placement groove, a third placement groove and a fourth placement groove in an inserted manner, a first support beam is fixedly connected between the top end of the first electric hydraulic push rod and the top end of the second electric hydraulic push rod, a second support beam is fixedly connected between the top end of the third electric hydraulic push rod and the top end of the fourth electric hydraulic push rod, a processor is fixedly installed at the bottom end of an inner cavity of the bleaching pond, and the right side of the processor is electrically connected with a controller through a wire. The bleaching plant reduces the labor force of a worker, and the paper pulp and a bleaching agent are fully contacted through the vertical lifting of the draining pond, so that the paper pulp is thoroughly bleached.

Owner:湖南盛顺纸业有限公司

Production process of bamboo-dissolving pulp

ActiveCN102127877BHigh viscosityReduce Osmotic DiffusionCellulose material pulpingFiberDissolving pulp

The invention provides a production process of bamboo-dissolving pulp, relating to a treatment method in the field of textile chemical fiber. The process comprises the following procedures of: preparing materials; steaming and pre-hydrolyzing; exchanging steaming and boiling; hermetically screening; bleaching in oxygen-alkali; carrying out acid treatment; manufacturing paper with pulp; and the like. The bamboo-dissolving pulp produced by the invention has the advantages of good product quality, uniform viscosity, high alphacellulose content, high whiteness, yellowing resistance, low pentaose content and good reaction performance and is favorable to production of post-procedures, chlorine-free bleaching and environment-friendly production.

Owner:YIBIN GRACE GROUP CO LTD

Pulping technique for straw fibre

ActiveCN101165267BQuality improvementReduce energy consumptionPretreatment with water/steamPulp liquor regenerationWood fibrePulp and paper industry

The grass fiber pulp producing process includes the steps of pre-treatment, the first digestion, and the second digestion. The present invention features less environmental pollution, saving in water, low power consumption and high pulp quality. The grass fiber pulp product has high whiteness, low hardness, high breaking strength and easy bleaching.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com