Whole black liqucd large liqucd rate cercal grass cooking technology with digester

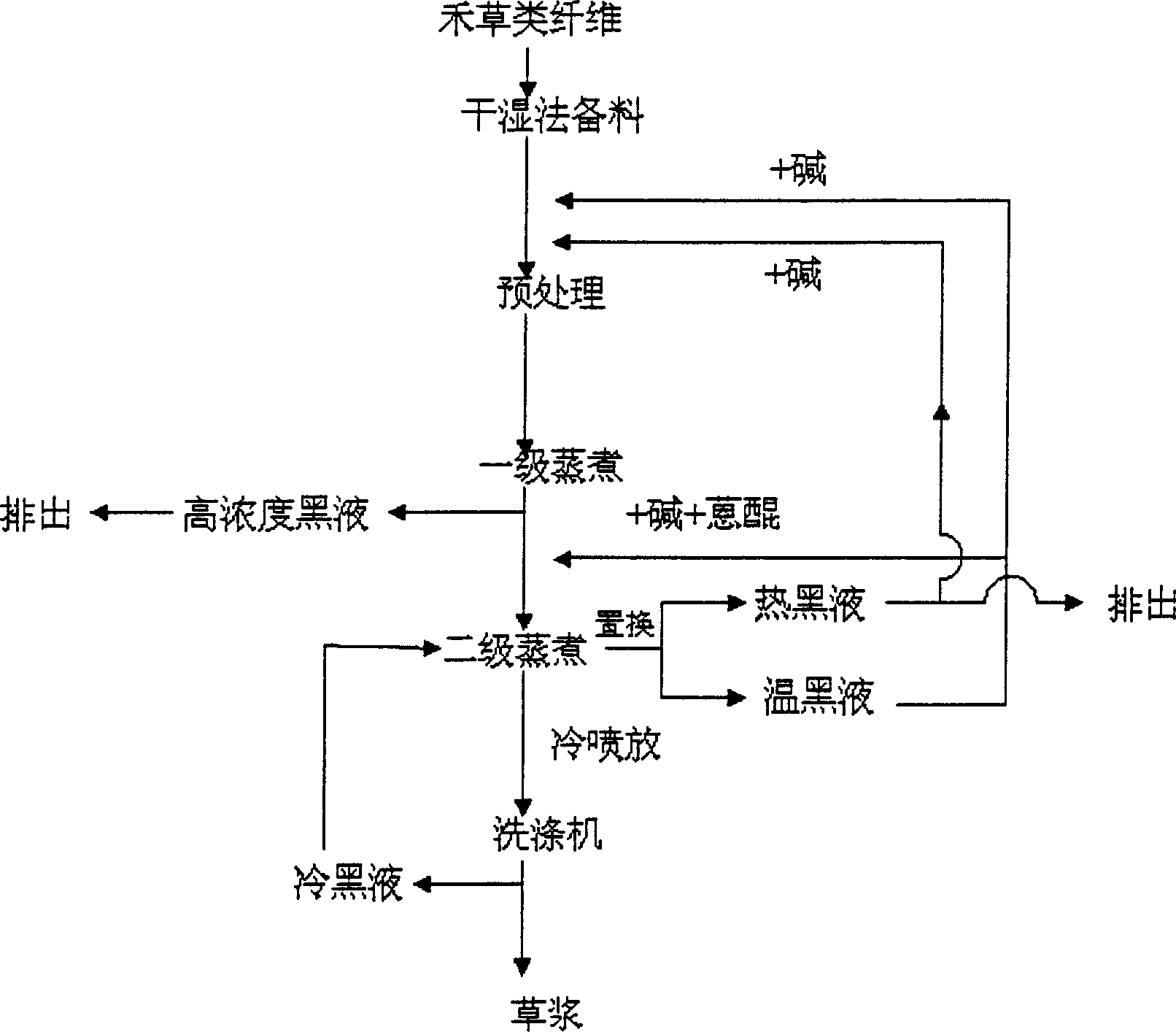

A technology of grasses and cooking pots, which is applied in the field of cooking process of grasses pulp, can solve the problems of high carbohydrate content, high viscosity of black liquor, difficult recovery, etc., achieve light black liquor, high concentration, and reduce pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Wheat straw is selected as the raw material, prepared by dry and wet methods, and after cutting, screening, dust removal, wet washing and rubbing, the water is removed. At this time, the length of the wheat straw slices is about 20mm.

[0065] Then pre-impregnate the wheat straw, impregnate the wheat straw with 85°C black liquor containing a certain alkali concentration, the liquid ratio is controlled at 1:4.8, the addition of caustic soda (NaOH) is about 30 g / L, and the impregnation is under normal pressure for 30 minutes .

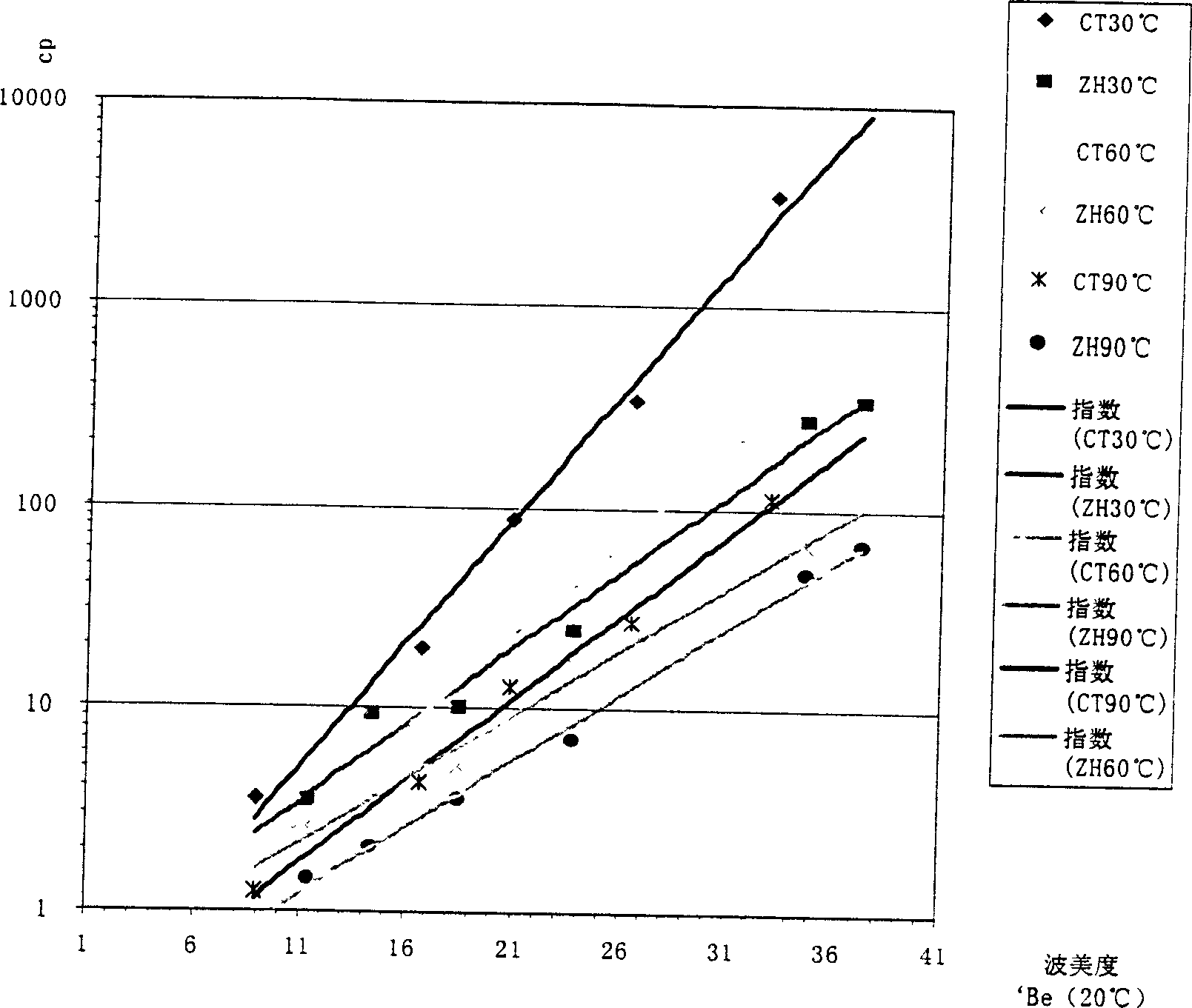

[0066] The black liquor used in the pre-soaking treatment is obtained from the waste liquor discharged from wheat straw during the pulping and cooking process. The Baume degree of the black liquor is 12.22°Be' at 20°C, and the solid content concentration is 16.52%.

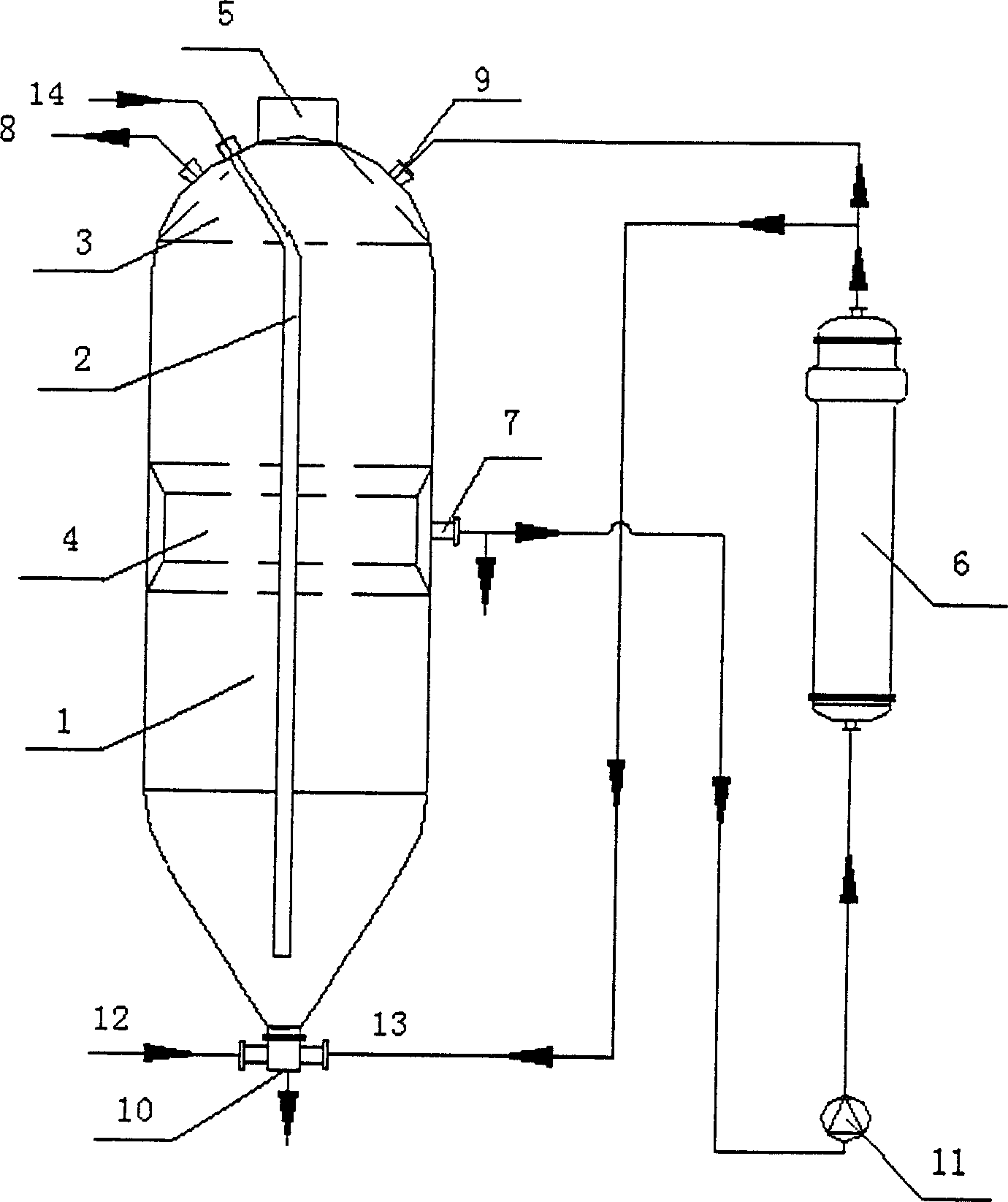

[0067] Put the pre-impregnated wheat straw into 50m through the pot loader 3 In the cooking pot, the average pot capacity of 1 cubic meter is 125 kg, and then the first stage of cook...

Embodiment 2

[0078] The technological process is the same as in Example 1, except that the grass fiber raw material used is reed, and during the pre-impregnation process, the temperature of the black liquor is 95°C, the amount of caustic soda is controlled at 34 grams per liter, and the liquid ratio is 1: 4.5. Immersion at atmospheric pressure for 60 minutes.

[0079] The Baume degree at 20°C of the black liquor used in the pre-dipping treatment is 13.15°Be', and the solids concentration is 17.58%.

[0080] After pre-impregnation, the inner pot capacity of the cooking pot is an average of 145 kg per cubic meter. During the first-level cooking and washing, it is cooked for 60 minutes at a temperature of 120 ° C. The pH value of the high-concentration black liquor discharged from the first-level cooking and washing is 13.3. , the residual alkali is 9.8g / L, the Baume degree is 16.88°Be'(20°C), the solid content concentration is 22.5%, and the COD is 235,000 mg / L.

[0081] In the secondary co...

Embodiment 3

[0083] The technological process is the same as that in Example 1, except that the grass fiber raw material used is Arundis, during the pre-impregnation treatment, the temperature of the black liquor is 95°C, the amount of caustic soda is controlled at 32 g / L, and the liquid ratio is 1:5.5 , impregnated at atmospheric pressure for 80 minutes.

[0084] The Baume degree of the black liquor used in the pre-dipping treatment is 11.75°Be' at 20°C, and the solid content concentration is 18.86%.

[0085] After pre-impregnation, the inner pot capacity of the cooking pot is an average of 150 kg per cubic meter. During the first-stage cooking and washing, it is cooked for 40 minutes at a temperature of 100°C. The pH value of the high-concentration black liquor discharged from the first-stage cooking and washing is 11.4. , the residual alkali is 5.6g / L, the concentration is 15.76°Be'(20°C), the solid content concentration is 24.351%, and the COD is 229,000 mg / L.

[0086] In the secondar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com