A combined pulping method

A technology for pulping and biological pulping, which is applied in pulp beating/refining methods, pulping with inorganic alkalis, pulping with cellulose raw materials, etc. Good pulp performance and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

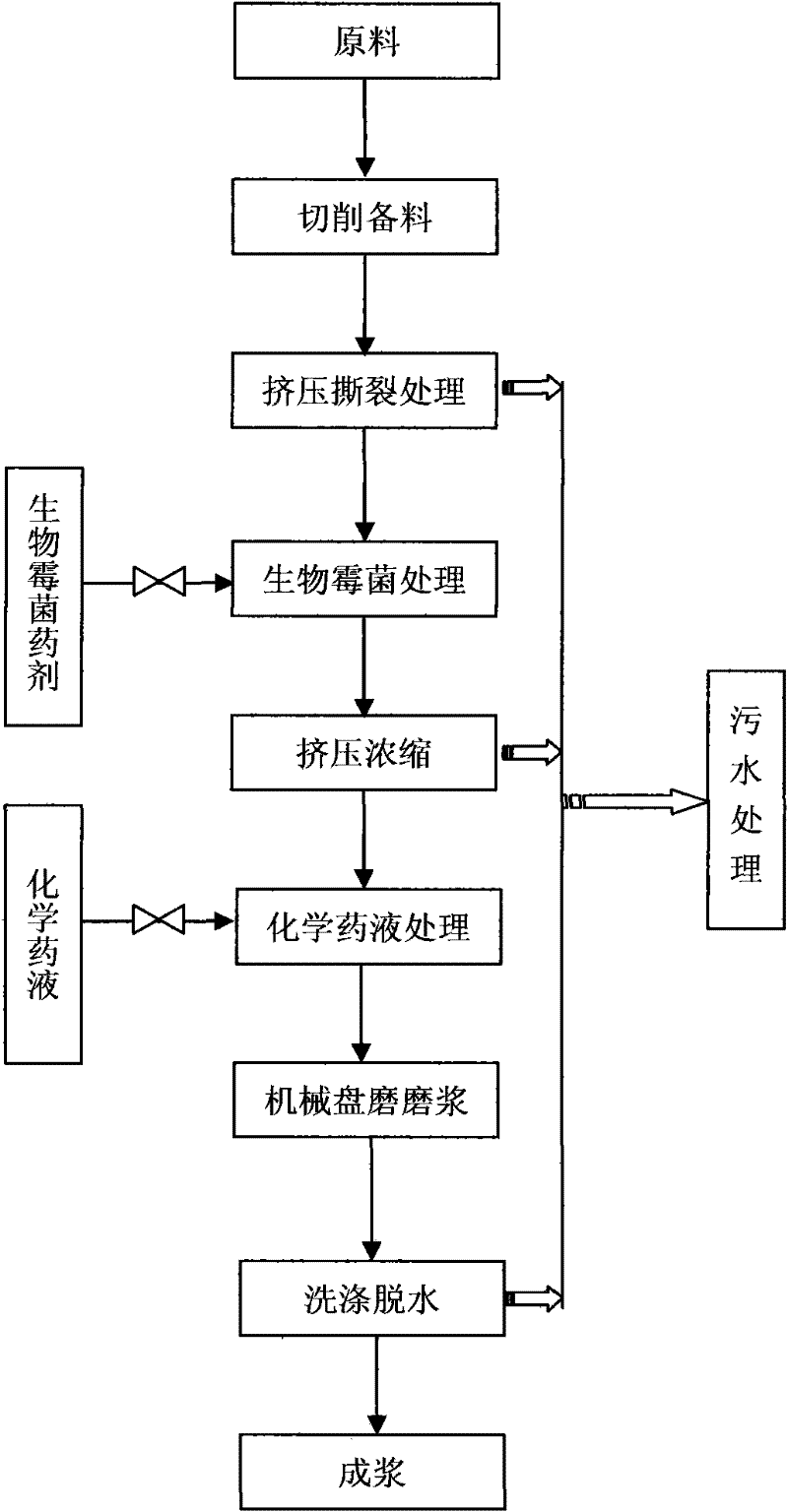

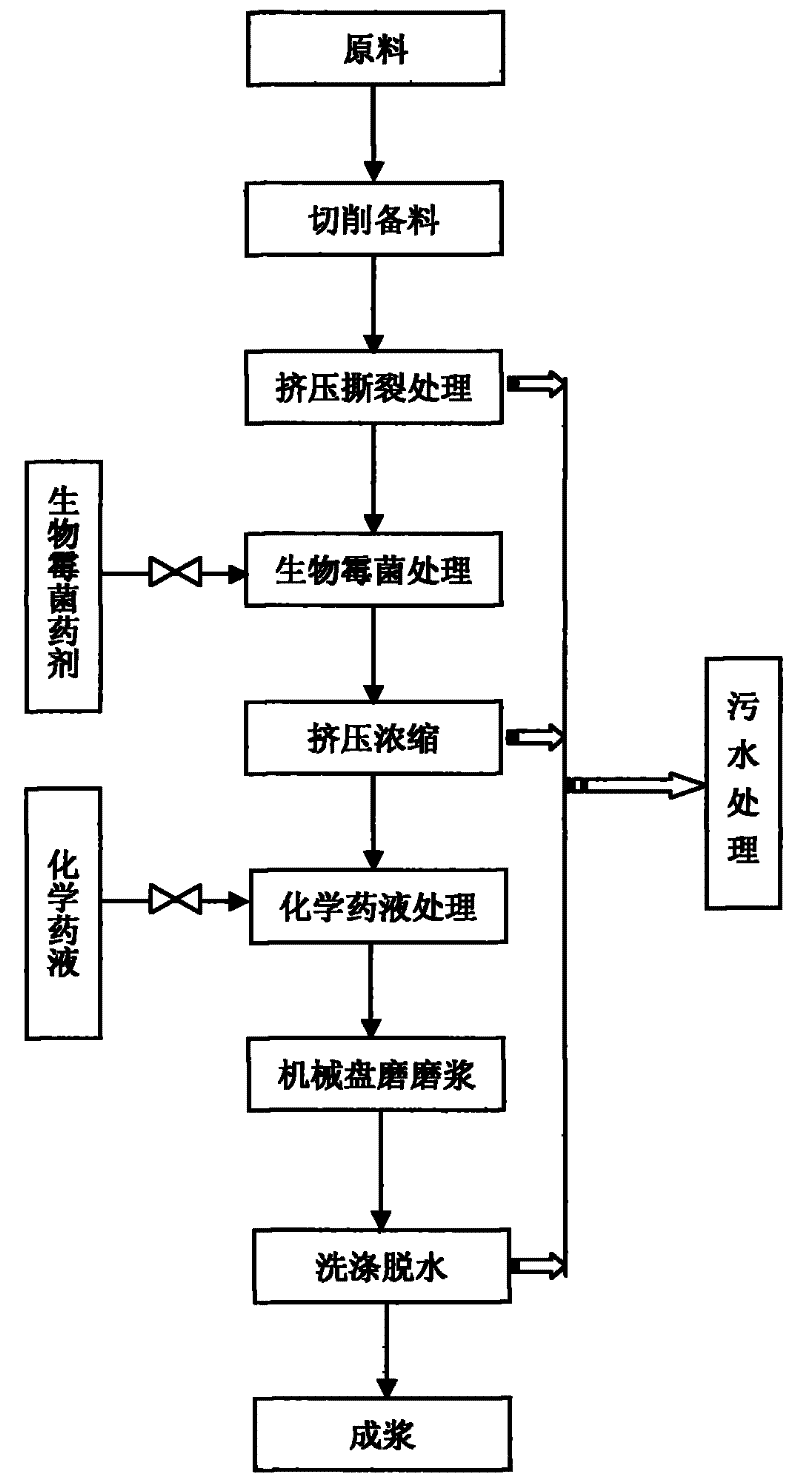

Method used

Image

Examples

Embodiment 1

[0026] The raw material of this embodiment is the bark tree bark. The raw materials are cut into 2-4cm knots, squeezed and torn, and soaked in the biological fluid of 10% white rot fungi, 4% brown rot fungi, and 6% soft rot fungi. The soaking conditions are temperature 40°C, concentration 15%, Time 68 hours. The raw materials after biological immersion are directly concentrated and soaked in chemical liquid. The composition of chemical liquid is 80% of magnesium hydroxide, 5% of sodium hydroxide, 5% of potassium hydroxide, 10% of hydrogen peroxide, and the dosage of chemical liquid is 6%. , the treatment conditions are temperature 110°C, concentration 15%, time 30min. Finally, it is treated with a disc refiner. The refining temperature is 60°C, the concentration is 30%, and the pulp yield is 55%. After the pulp is washed, the paper is made. The paper whiteness is 50% ISO, the paper breaking length is 3.5km, and the tear index is 3mN. m 2 / g.

Embodiment 2

[0028] The raw material of this embodiment is peeled poplar. The raw material is chipped, squeezed and torn, and the raw material is soaked in a biological solution of 6% white rot fungi, 5% brown rot fungi, and 8% soft rot fungi. The soaking conditions are temperature 40°C, concentration 12%, and time 72 hours. The raw materials after biological soaking are directly concentrated and then soaked in chemical liquid. The composition of chemical liquid is 65% magnesium hydroxide, 10% sodium hydroxide, 7% potassium hydroxide, 18% hydrogen peroxide, and the dosage of chemical liquid is 8%. , the treatment conditions are temperature 120°C, concentration 25%, time 30min. Finally, it is treated with a disc refiner, the refining temperature is 35°C, the refining concentration is 35%, and the pulp yield is 68%. After the pulp is washed, the paper is made, the paper whiteness is 46% ISO, the fracture length is 4.4km, and the tear index 3.5mN·m 2 / g.

Embodiment 3

[0030] The raw material of this embodiment is peeled eucalyptus. The raw material is chipped, squeezed and torn, and soaked in a biological solution of 10% white rot fungi, 5% brown rot fungi, and 8% soft rot fungi. The soaking conditions are temperature 38°C, concentration 12%, and time 96 hours. The raw materials after biological immersion are directly concentrated and then soaked in chemical liquid. The composition of chemical liquid is 50% magnesium hydroxide, 20% sodium hydroxide, 10% potassium hydroxide, 20% hydrogen peroxide, and 10% chemical liquid. , the treatment conditions are temperature 120°C, concentration 20%, time 30min. Finally, use a disc refiner to refine the pulp, the refining temperature is 85°C, the refining concentration is 30%, and the pulp yield is 65%. After the pulp is washed, the paper is made, the paper whiteness is 40% ISO, the paper fracture length is 4.2km, and the tear index 4.0mN·m 2 / g.

[0031] From above Example 1, Example 2 and Example ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com