Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

100results about How to "Easy solder connection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

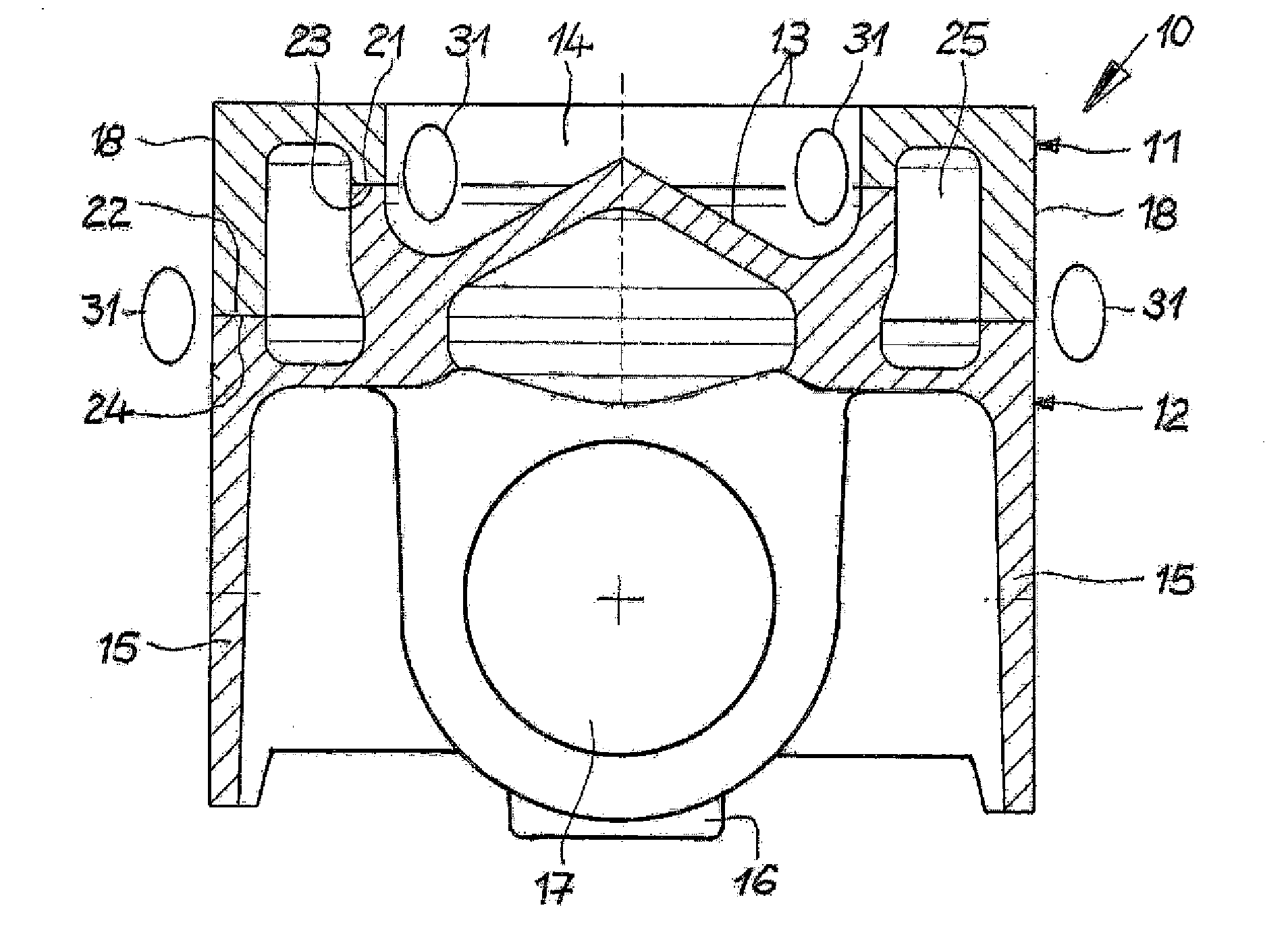

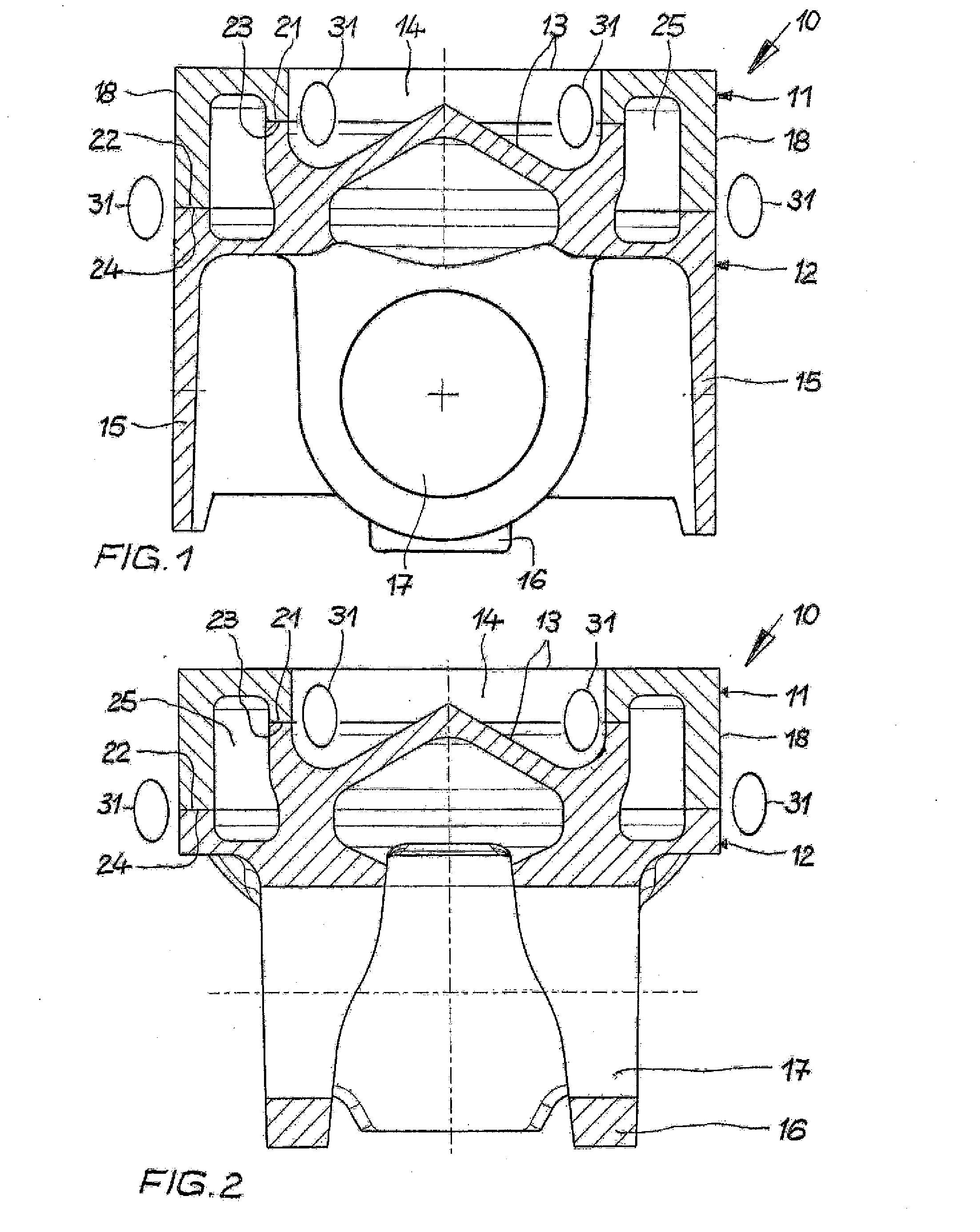

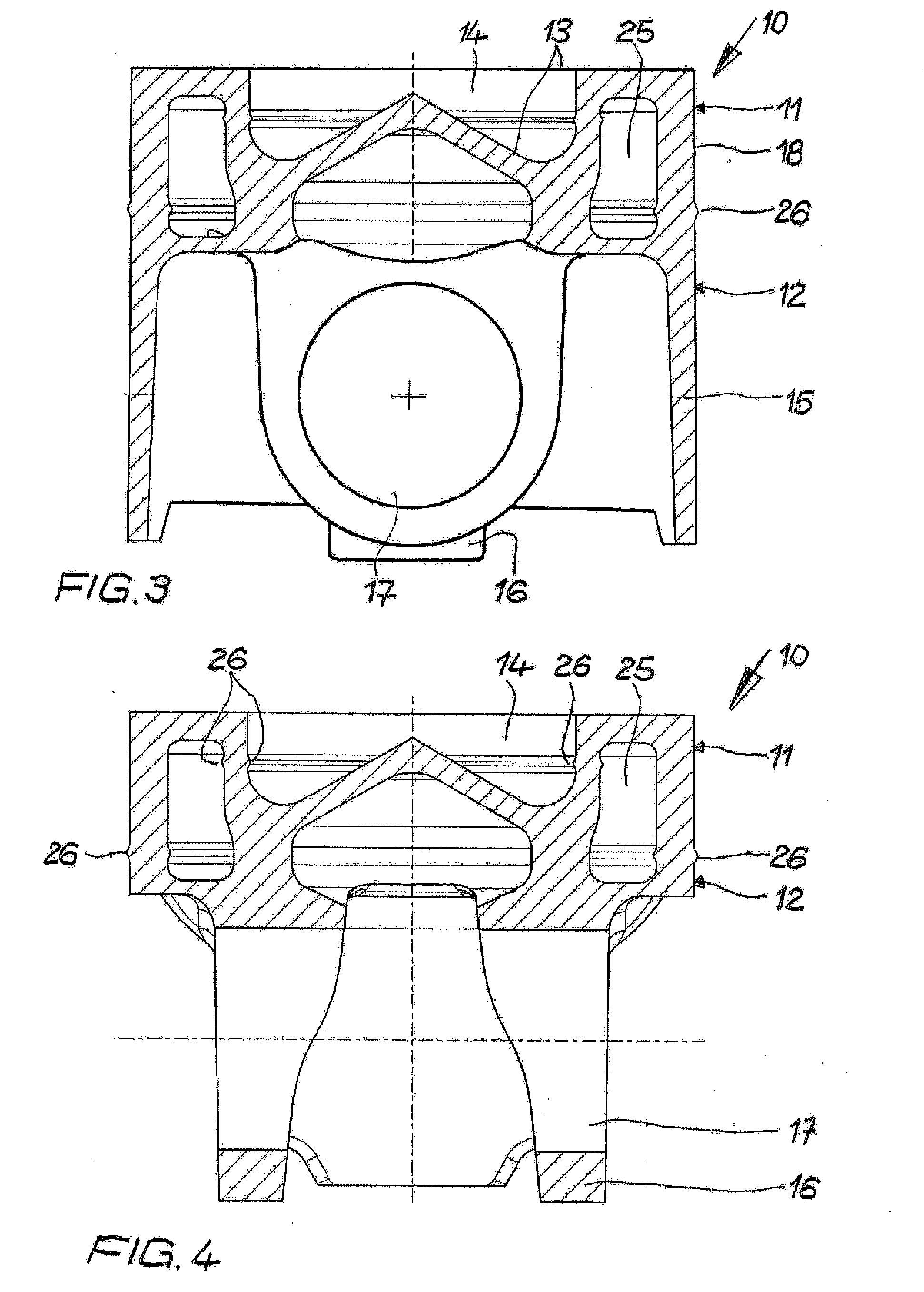

Method for the production of a piston for an internal combustion engine and piston for an internal combustion engine

InactiveUS20120037115A1Optimize carrying away heatOptimize pressureValve arrangementsMachines/enginesExternal combustion engineEngineering

A method for the production of a piston for an internal combustion engine has the following steps: producing an upper piston part having at least one joining surface, b) producing a lower piston part having at least one joining surface, c) producing a direct contact between the at least one joining surface of the upper piston part and the at least one joining surface of the lower piston part, d) heating the upper piston part and the lower piston part by induction or by a direct flow of current over the joining surfaces in the region of the joining surfaces that have been brought into direct contact, e) connecting the upper and lower piston parts with one another to produce a piston by a pressing process, and machining the piston to finish it.

Owner:MAHLE INT GMBH

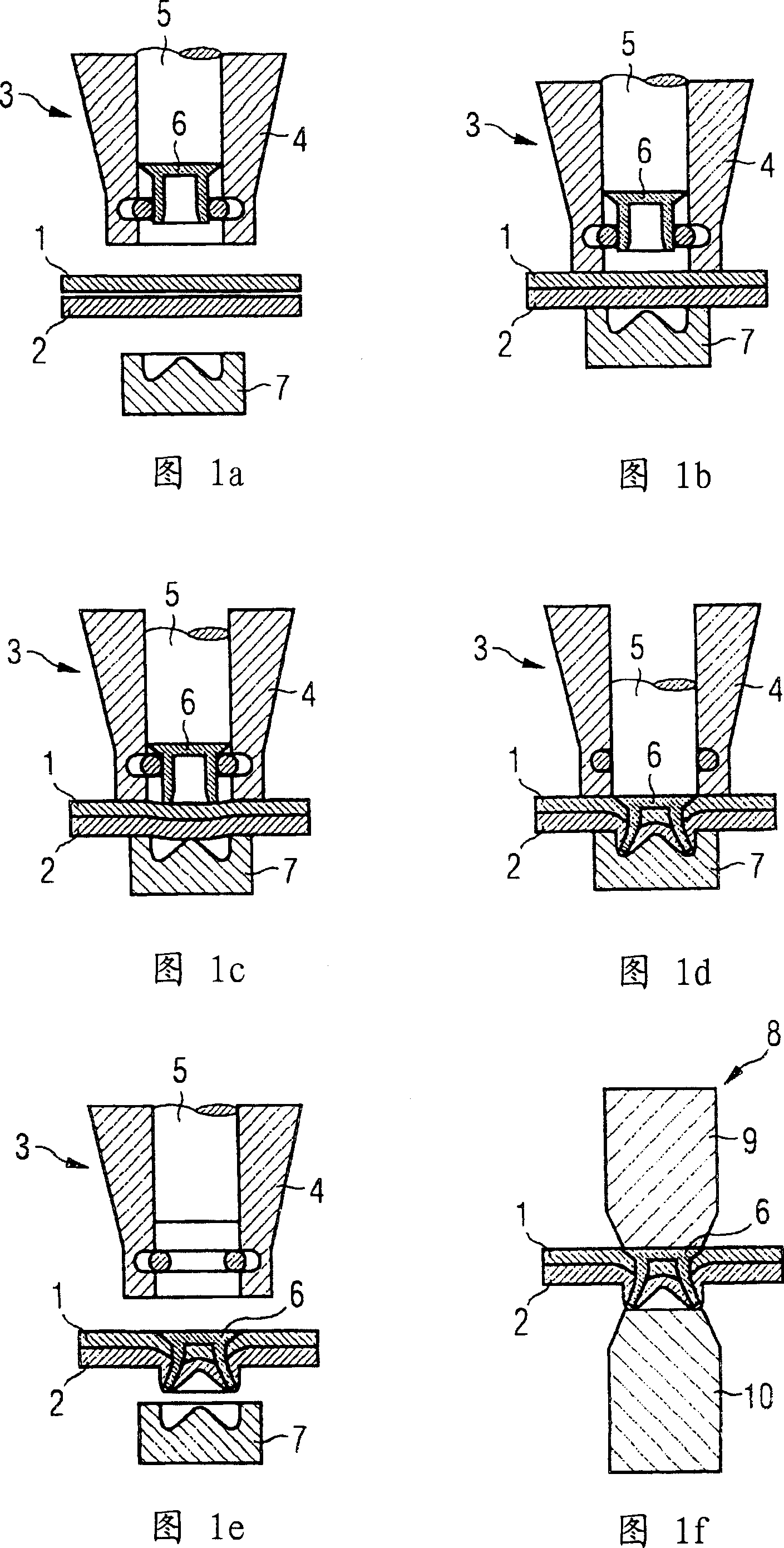

Method for joining two or several profiled parts or metal sheets which are mechanically joined and pressure-welded at one or several connection points

InactiveCN1938120ALow cost of equipmentQuality Inspection SimplifiedRivetsSheet joiningBody segmentHigh intensity

Disclosed are a method for joining two or several metal sheets or profiled parts, particularly of a vehicle body segment, and a vehicle body segment. Said method for joining two or several metal sheets or profiled parts, one of which is typically made of a higher-strength steel, comprises the following steps: a) the metal sheets or profiled parts are mechanically connected in a positive and / or non-positive manner at one or several junctions, whereupon b) the junctions are thermally joined using pressure welding. The inventive method makes it possible to produce body segments that are provided with top quality spot-welded joints, especially in the motor vehicle sector.

Owner:GM GLOBAL TECH OPERATIONS LLC

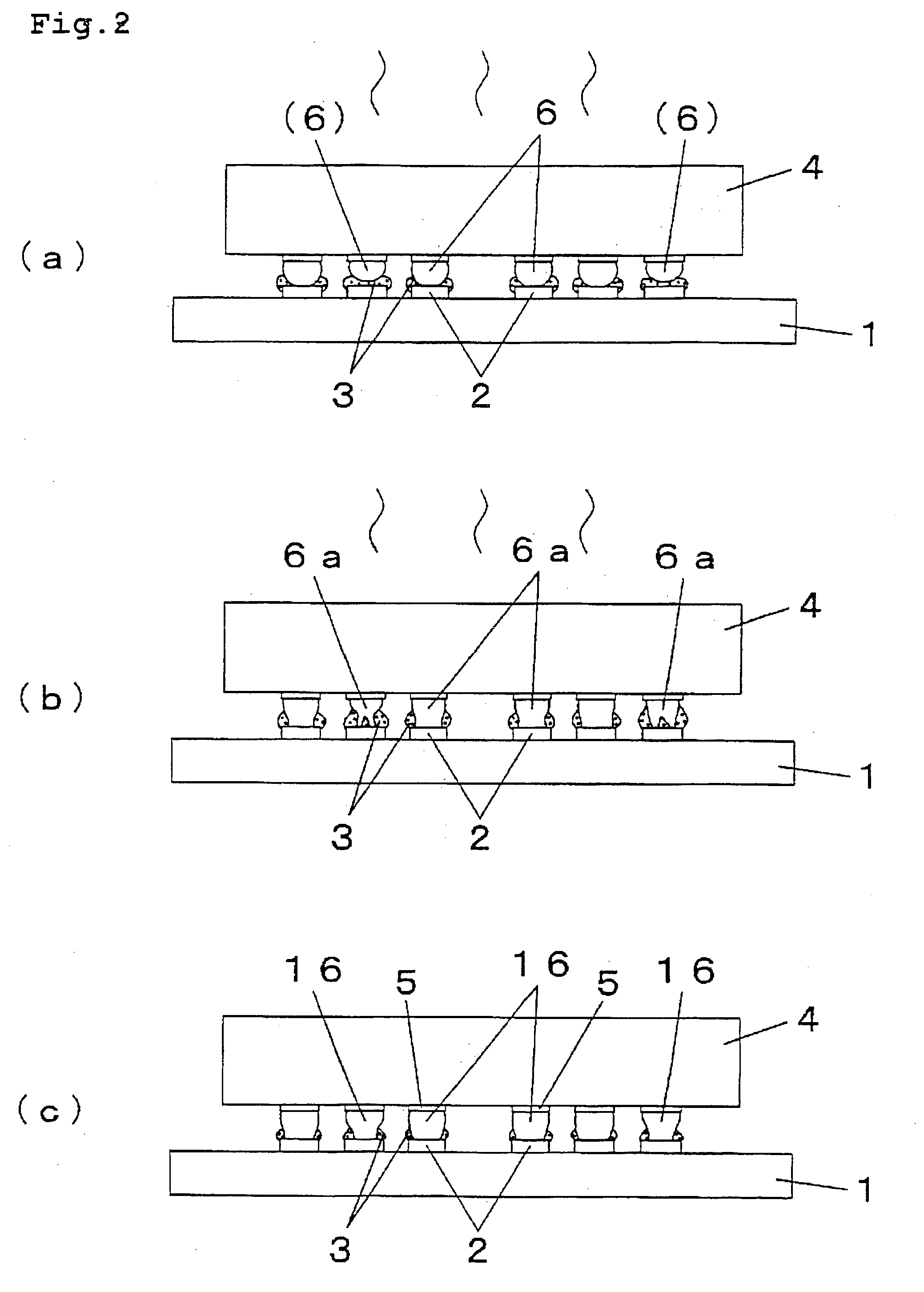

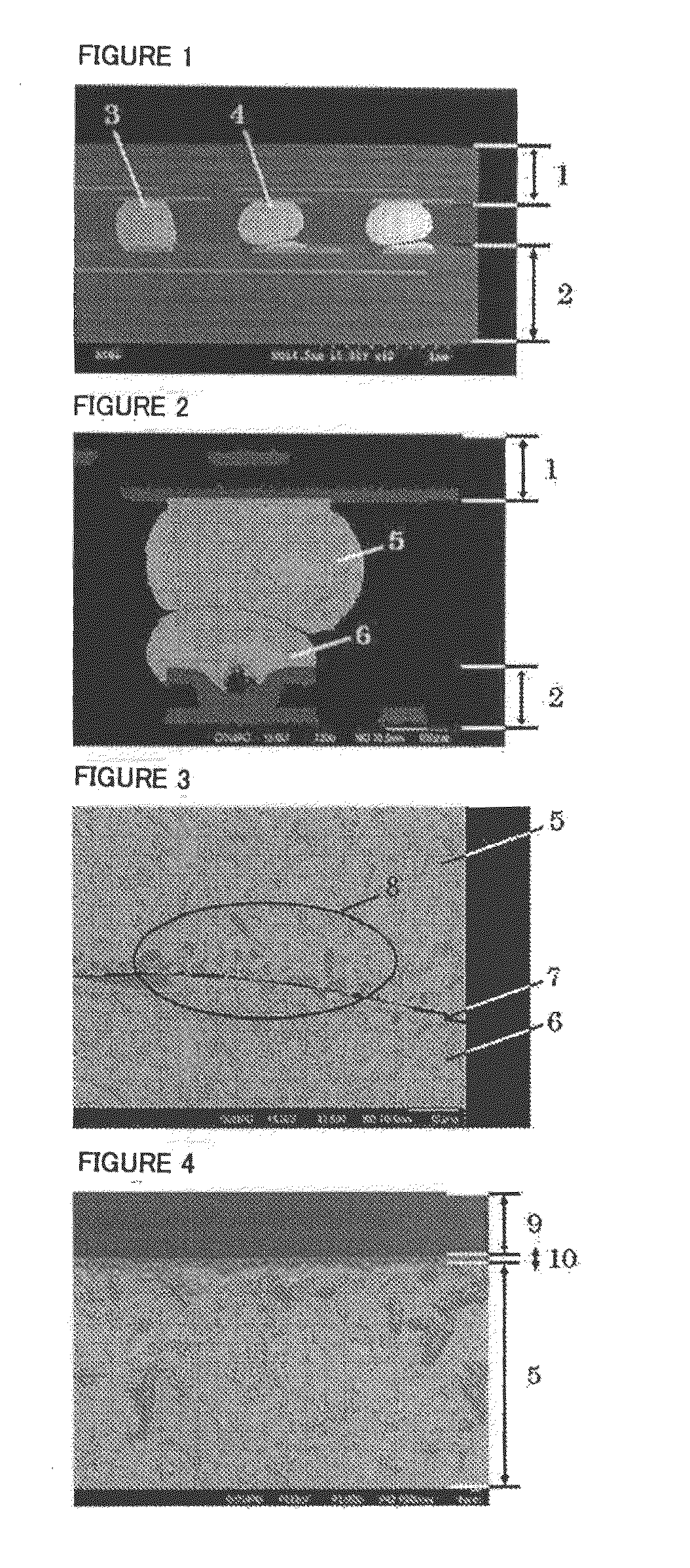

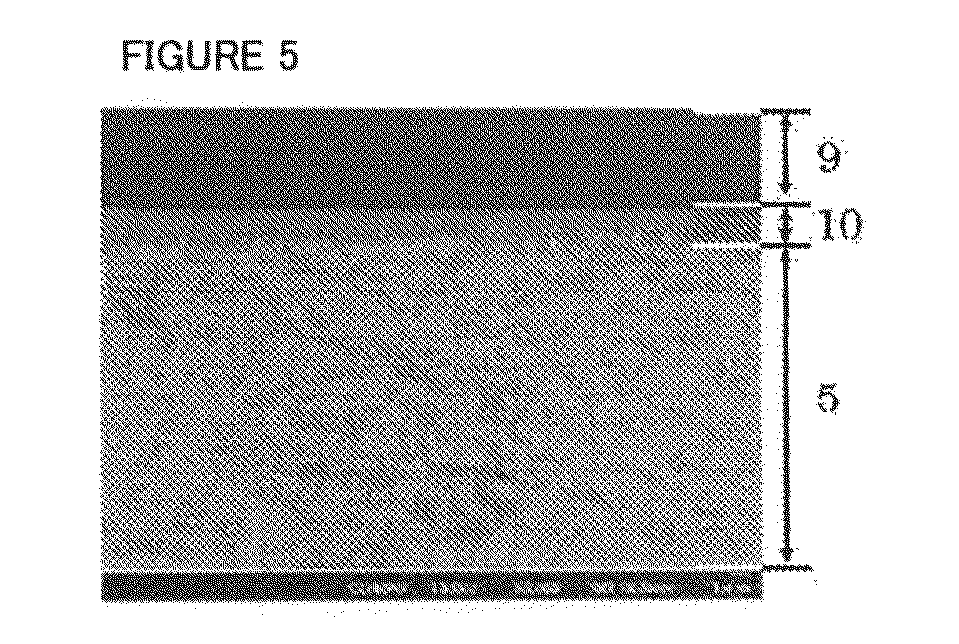

Method and apparatus for manufacturing semiconductor device

InactiveCN104145328AEasy solder connectionImprove yieldLamination ancillary operationsSolid-state devicesPower semiconductor deviceSemiconductor chip

Provided is a method for manufacturing a semiconductor device that solders to connect a semiconductor chip having bumps via a heat-hardened bonding agent layer to a substrate having an electrode corresponding to the bumps that includes, in succession, (A) a process for forming the heat-hardened bonding layer in advance on a surface having the bumps of a semiconductor chip; (B) a process that matches the surface on the heat-hardened bonding agent layer side of the semiconductor chip formed with a heat-hardened bonding agent layer to a substrate, and pre-bonds by using a heat seal to obtain a pre-bonded layer; and (C) places a protective film having thermal conductivity of at least 100 W / mK between the heat seal and the surface on the semiconductor chip side of the pre-bonded layer and uses a heat seal to harden the heat-hardened bonding agent layer simultaneously to melting the solder between the semiconductor chip and the substrate. A method for manufacturing a semiconductor device is that obtains good connections without sandwiching resin between the solder bumps and an electrode pad is provided.

Owner:TORAY IND INC

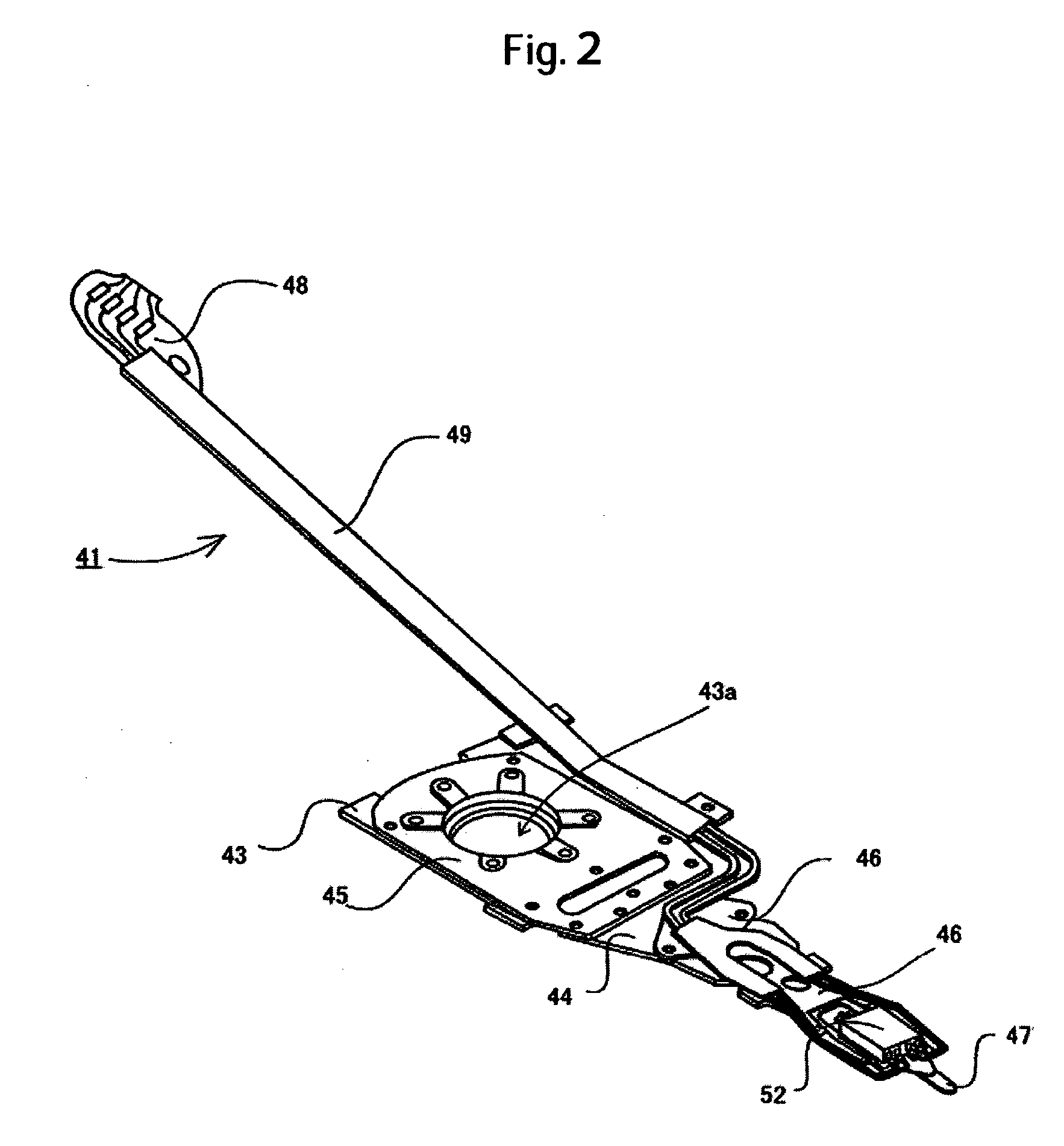

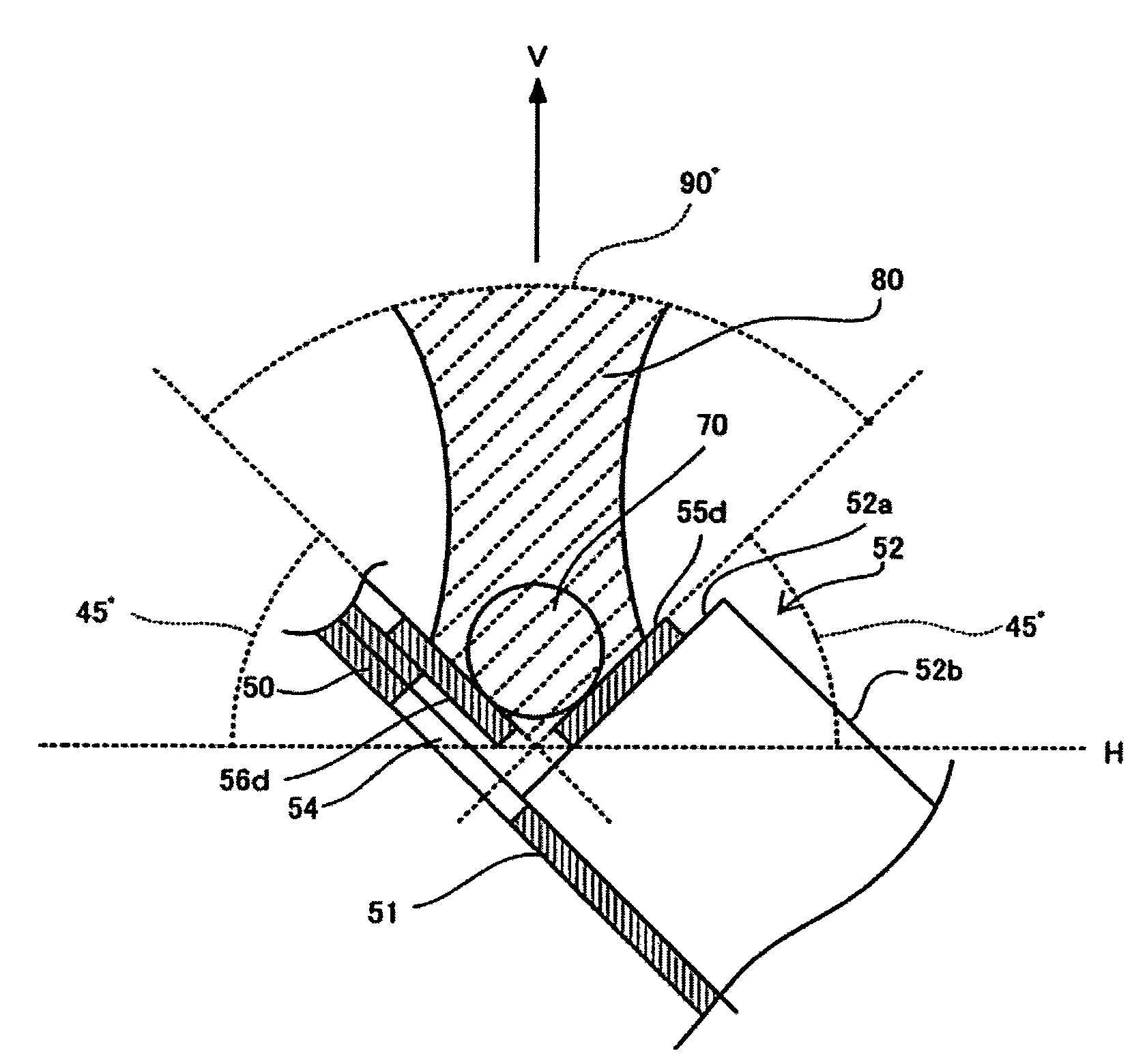

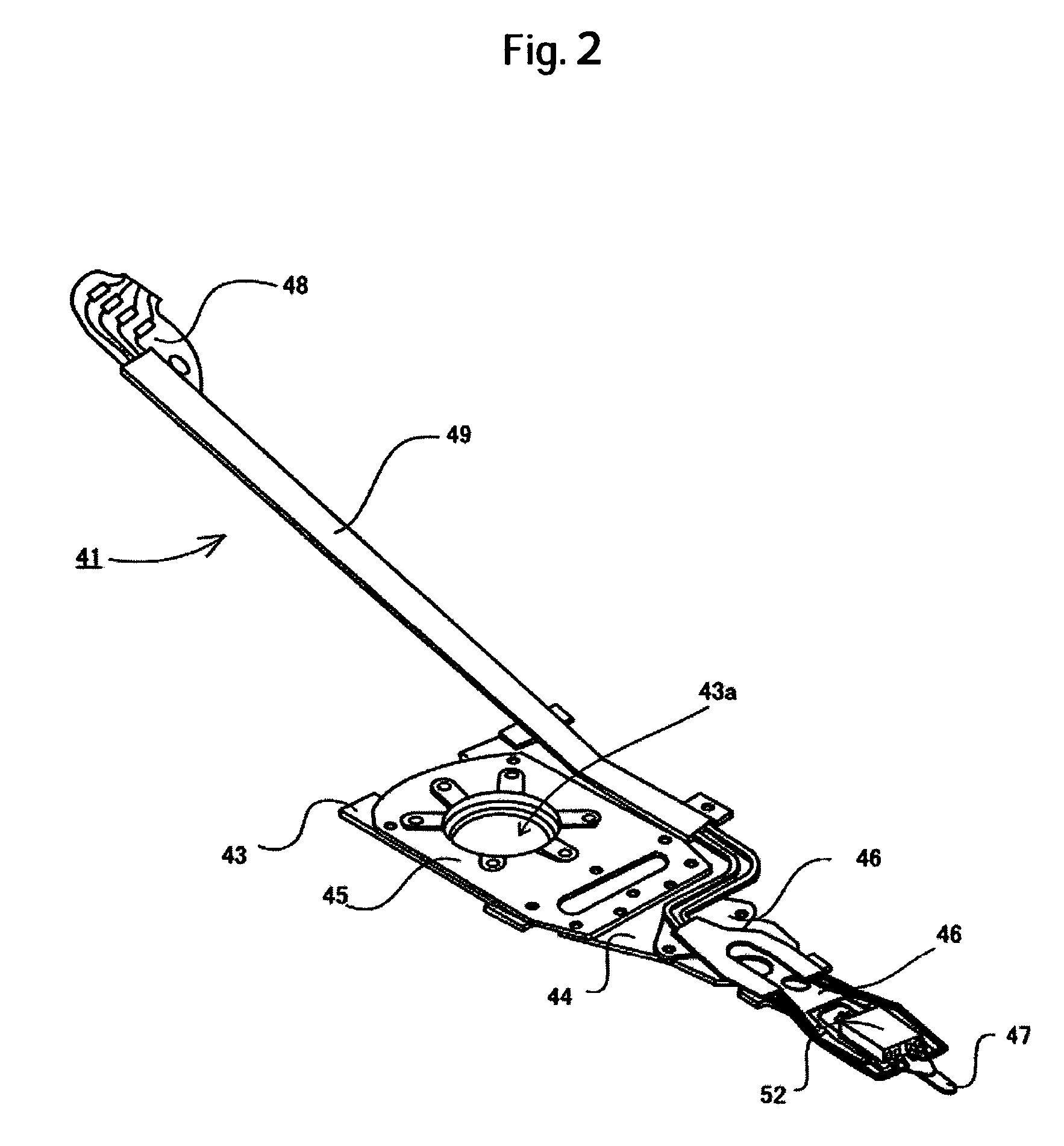

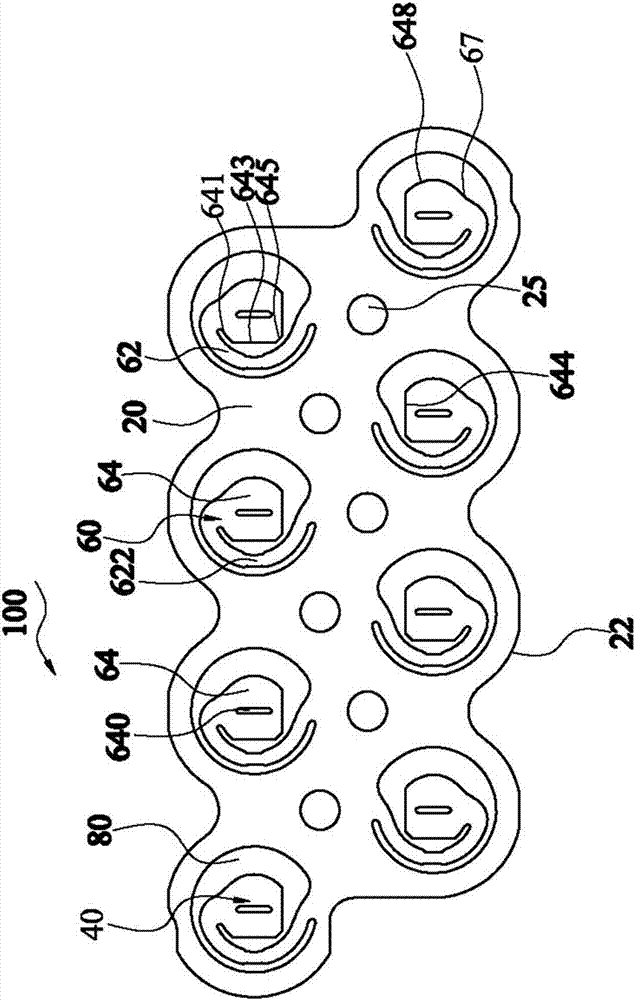

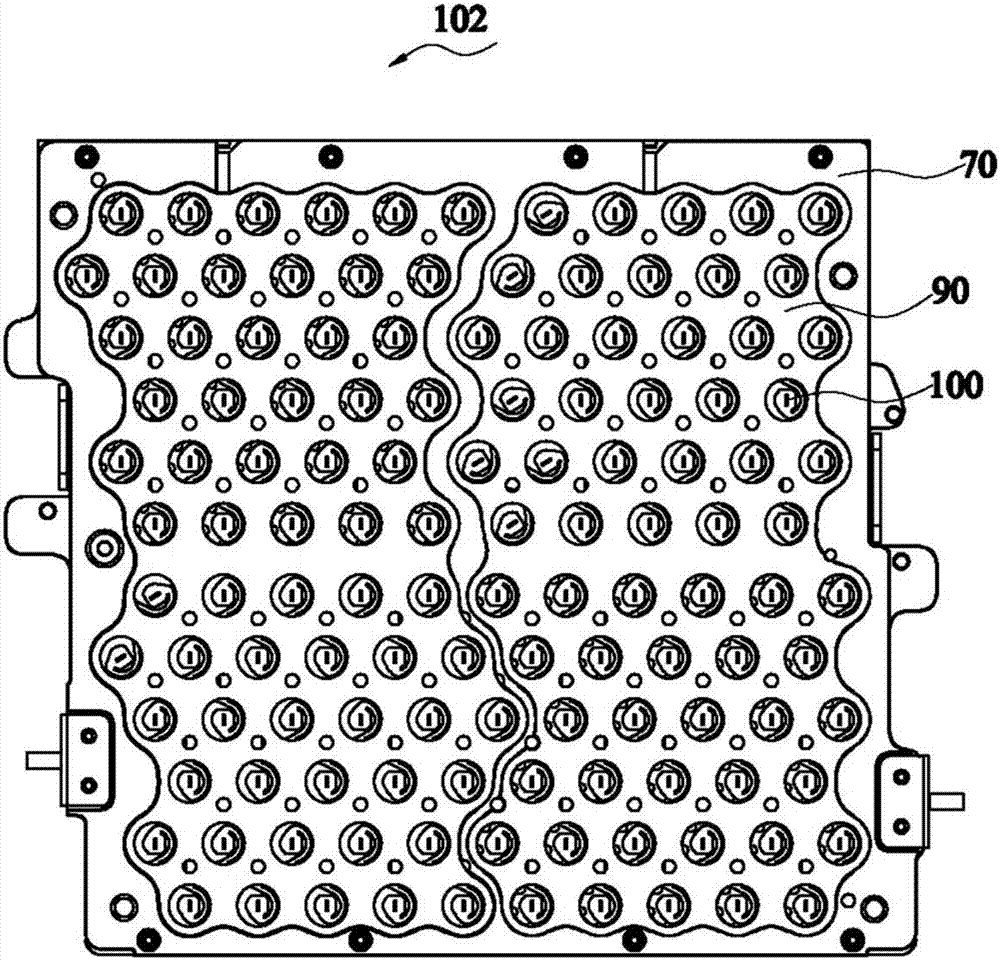

Manufacturing method of head gimbal assembly with solder fillet and head gimbal assembly

InactiveUS20060193084A1Easy solder connectionIncrease productionElectrical connection between head and armFinal product manufactureMagnetic disksGimbal

Embodiments of the invention relate to making reconnection when a soldered connection fails in a head / slider used in a magnetic disk drive. In one embodiment, a solder mass deposited on a slider pad of a head / slider is separated from a lead pad and a solder ball connection is yet to be made between the slider pad and the lead pad. A shaping tip is heated to a temperature near a melting point of a solder. The shaping tip is moved in parallel with a surface of the slider pad toward the side of the lead pad to soften the solder mass. The solder mass is thereafter irradiated with a laser beam so as to form a solder fillet, thereby making a soldered connection between the lead pad and the slider pad.

Owner:WESTERN DIGITAL TECH INC

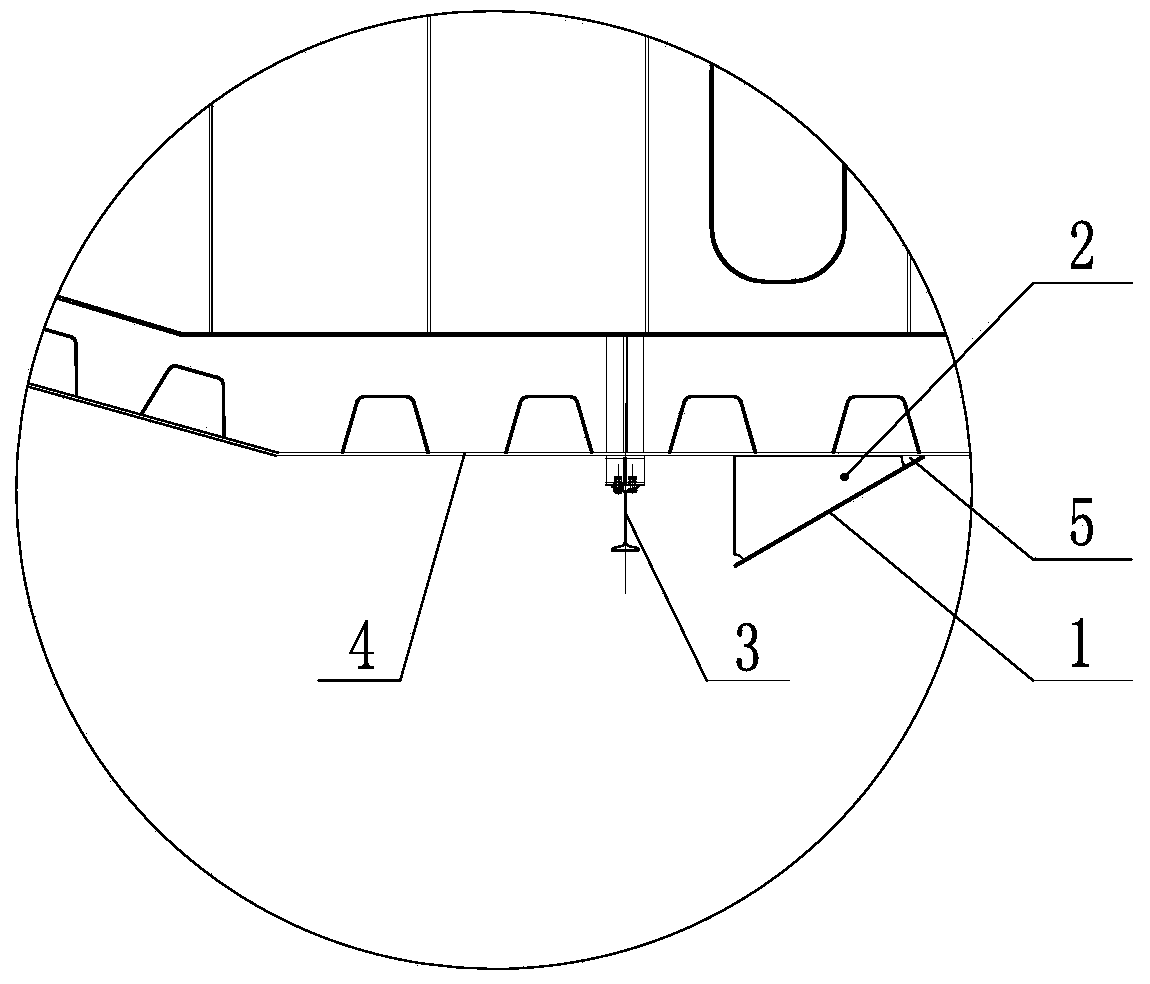

Enclosed bus installing device and method

ActiveCN110977257AEasy solder connectionSimple detection equipmentWelding/cutting auxillary devicesTotally enclosed bus-bar installationsEngineeringLaser light

The invention discloses an enclosed bus installing device and method. The enclosed bus installing device comprises a laser lamp and a reflector, wherein the laser lamp is detachably connected to one enclosed bus shell, the reflector is arranged on the other enclosed bus shell. The two shells are each provided with an adjusting mechanism. Each adjusting mechanism comprises a horizontal adjusting mechanism and a vertical adjusting mechanism. Each horizontal adjusting mechanism comprises a base connected to the ground, wherein a sliding block is connected to the base in a sliding manner, the baseis provided with a sliding mechanism driving the sliding block to move, and the sliding mechanism is provided with a locking mechanism capable of limiting movement of the sliding block. Each verticaladjusting mechanism is connected to the corresponding sliding block, an arc plate is fixed to the vertical adjusting mechanism, the vertical adjusting mechanism can drive the arc plate to move in thevertical direction, and the axis of the arc plate and the movement direction of the sliding block are perpendicular. A supporting mechanism is arranged below the ends, close to each other, of the twoshells. The enclosed bus installing device has the effect of conveniently and rapidly adjusting the coaxiality between two enclosed buses.

Owner:北京中科中电电力工程管理有限公司

Diversion device for flat steel box beam bridge vortex vibration control

InactiveCN103821074AChange the flow field characteristicsInhibitionBridge structural detailsVibration controlCable stayed

The invention discloses a diversion device for flat steel box beam bridge vortex vibration control. The diversion device comprises a diversion plate which is arranged on the inner side of a detecting rail in the bridge direction. The diversion plate is oblique relative to a bottom plate of a flat steel box beam, and a field angle between the diversion plate and the bottom plate of the flat steel box beam faces outwards. One end of the diversion plate is connected with the bottom plate of the flat steel box beam in a welding mode, the diversion plate is connected with the bottom plate of the flat steel box beam in a welding mode through diversion plate stiffening plates arranged at intervals, and the diversion plate stiffening plates are arranged corresponding to diaphragm plates of the flat steel box beam. Two angular points where the diversion plate stiffening plates and the diversion plate are connected are respectively provided with an over-welding hole. The diversion device is mainly applied to cable-stayed bridges or suspension bridge flat steel box beams, the flat steel box beam bridge vortex-induced amplitude can be effectively restrained, guarantee is provided for traffic safety and comfort, and the measures are simple, economical and practical.

Owner:TIANJIN MUNICIPAL ENG DESIGN & RES INST

Flux for Soldering and Soldering Process

ActiveUS20080244900A1Easy solder connectionPrinted circuit assemblingPrinted circuit aspectsActive componentSolvent

There is provided a flux for soldering and a soldering process which form better solder connection without the occurrence of the poor connection nor the insulation degradation.Such flux which is placed between a solder portion formed on a first electrode and a second electrode when the first electrode is soldered to the second electrode contains:a liquid base material made of a resin component which is dissolved in a solvent,an active component which removes an oxide film, anda metal powder made of a metal of which melting point is higher than that of a solder material which forms the solder portion, andthe flux contains the metal powder in an amount in the range between 1% and 9% by volume based on a volume of the flux.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Lead-Free Solder Ball

ActiveUS20150221606A1Reduce the amount requiredFusion defectPrinted circuit assemblingNon-insulated conductorsBond interfaceThermal fatigue

A lead-free solder ball is provided which suppresses interfacial peeling in a bonding interface of a solder ball, fusion defects which develop between the solder ball and solder paste, and which can be used both with Ni electrodes plated with Au or the like and Cu electrodes having a water-soluble preflux applied atop Cu. The lead-free solder ball for electrodes of BGAs or CSPs consists of 1.6-2.9 mass % of Ag, 0.7-0.8 mass % of Cu, 0.05-0.08 mass % of Ni, and a remainder of Sn. It has excellent resistance to thermal fatigue and to drop impacts regardless of the type of electrodes of a printed circuit board to which it is bonded, which are Cu electrodes or Ni electrodes having Au plating or Au / Pd plating as surface treatment. The composition may include at least one element selected from Fe, Co, and Pt in a total amount of 0.003-0.1 mass % or at least one element selected from Bi, In, Sb, P, and Ge in a total emount of 0.003-0.1 mass %.

Owner:SENJU METAL IND CO LTD

Solar Cell With Structured Gridline Endpoints Vertices

InactiveUS20100319761A1Improved yieldLow costSemiconductor/solid-state device manufacturingPhotovoltaic energy generationMesh gridBusbar

Owner:SOLARWORLD IND GMBH

Head gimbal assembly method with solder fillet formed by laser irradiating a shaped solder mass

InactiveUS7486480B2Increase productionLower component costsElectrical connection between head and armFinal product manufactureSolder ballEngineering

Embodiments of the invention relate to making reconnection when a soldered connection fails in a head / slider used in a magnetic disk drive. In one embodiment, a solder mass deposited on a slider pad of a head / slider is separated from a lead pad and a solder ball connection is yet to be made between the slider pad and the lead pad. A shaping tip is heated to a temperature near a melting point of a solder. The shaping tip is moved in parallel with a surface of the slider pad toward the side of the lead pad to soften the solder mass. The solder mass is thereafter irradiated with a laser beam so as to form a solder fillet, thereby making a soldered connection between the lead pad and the slider pad.

Owner:WESTERN DIGITAL TECH INC

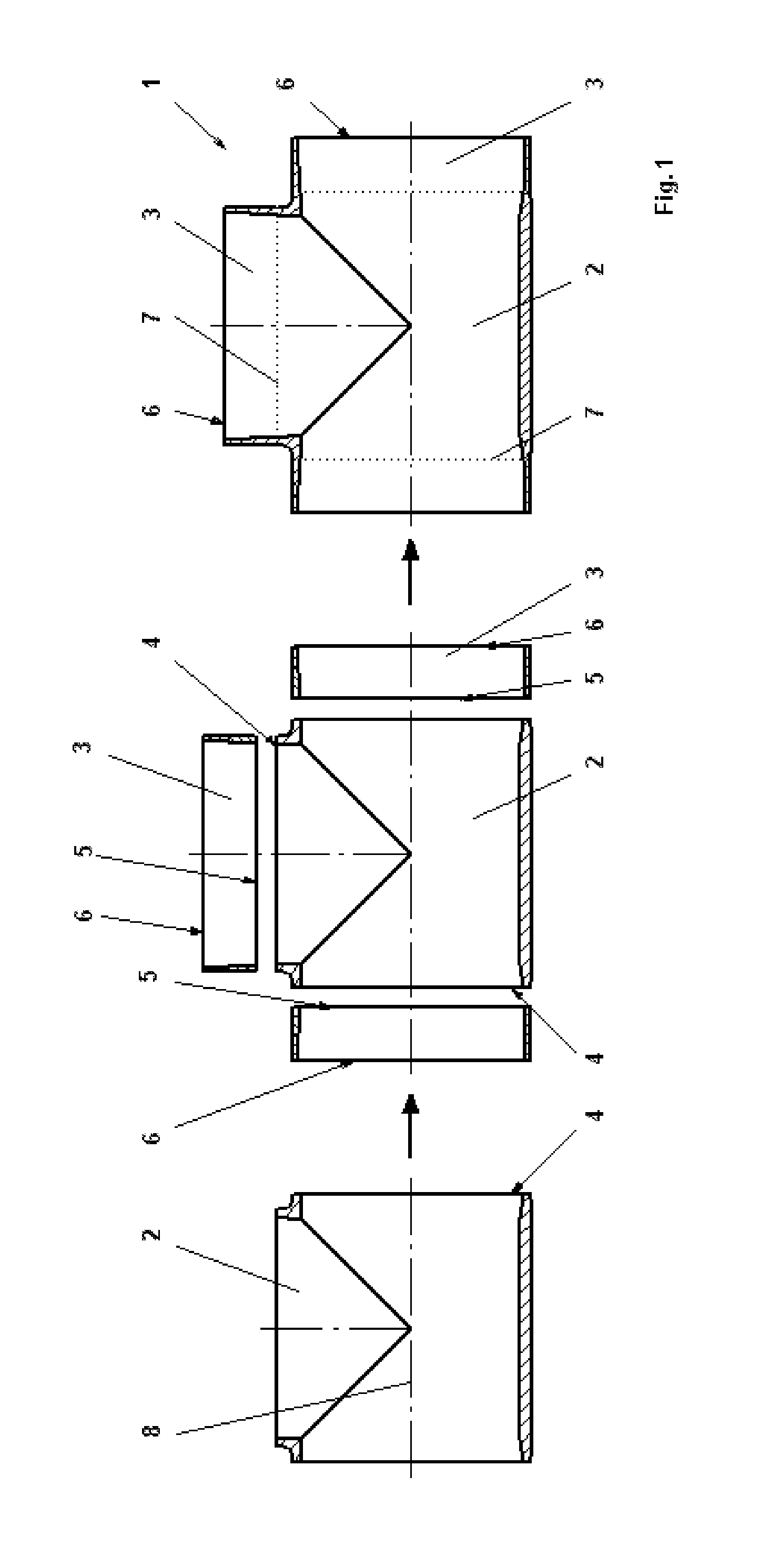

Modular fitting

ActiveUS20140020811A1Easy solder connectionSimple processLaminationLamination apparatusEngineeringModular structure

A fitting (1) of weldable, thermoplastic material of a modular structure, comprising a number of elements (2, 3, 9, 10, 11, 12), at least one main element (2, 9) and at least one connecting element (3, 10, 11, 12), characterized in that the elements (2, 3, 9, 10, 11, 12) have end faces (4, 5) at right angles to the centre axis (8), and the elements (2, 3, 9, 10, 11, 12) are welded to one another exclusively at the end faces (4, 5).

Owner:GEORG FISCHER ROHRLEITUNGSSYST

Soldering device for forming electrical soldering point in magnetic disc driver

InactiveCN102717162AThe size of the inner diameter can be controlledSo as not to damageMetal working apparatusSolder feeding devicesSolder ballEngineering

The invention discloses a soldering device for forming an electrical soldering point in a magnetic disc driver. The soldering device comprises a nozzle device, an actuating device, a solder ball feeding device, a pressurized gas feeding device and a laser generator, wherein the nozzle device comprises at least two separated movable casings; a passage is formed by the two casings; an inlet is formed by the upper ends of the two casings; a nozzle is formed by the lower ends of the two casing; the actuating device is connected with the nozzle device, and is used for controlling the two casings of the nozzle device to move close or separate so as to control the inside diameter of the nozzle; the solder ball feeding device is used for delivering a solder ball at the inlet or the nozzle to the passage; the pressurized gas feeding device is used for feeding pressurized gas into the passage to control the falling speed of the solder ball in the passage; and the laser generator is used for emitting laser to the passage so as to melt and return the solder ball. According to the soldering device, the size of the nozzle is controllable, so as to facilitate soldering.

Owner:SAE MAGNETICS (HK) LTD

Double T-shaped composite beam provided with prestressed steel tube concrete core rods and fabrication method of double T-shaped composite beam

InactiveCN103031926AImprove bearing capacityImprove leaping abilityLoad-supporting elementsCeramic shaping apparatusHigh strength concreteRebar

The invention provides a double T-shaped composite beam provided with prestressed steel tube concrete core rods, which is formed by utilizing the prestressed steel tube concrete core rods as tensioned lower flanges, adopting corrugated steel plates as web plates and pouring an upper flange top plate with high-strength concrete. The prestressed steel tube concrete core rods consist of steel tubes, intra-tube concrete and prestressed steel bars, and have high tension capacities; as the prestressed steel tube concrete core rods are combined with the corrugated steel web plates for use, the advantages are complemented, the shear capacity and flexural capacity of a crossbeam are improved, and the crossing ability of the crossbeam is improved. The composite beam has the advantages of light weight, great crossing ability, high bearing ability, high stiffness, low cost and the like, can be suitable for volume production in prefabricated part factories, can serve as a roof beam for constructing a 30-48m oversized-span single-storey industrial factory building, and as a floor beam for constructing a 21-30m large-span multi-storey industrial factory building, meets the requirements of industrial production on a large space, and saves land.

Owner:SOUTHEAST UNIV

Connecting structure between water chamber and main slices of novel vehicle radiator

InactiveCN101362452AEasy solder connectionReduce manufacturing costStationary conduit assembliesHeat exchanger casingsEngineeringHeat spreader

The invention relates to a connecting structure between a water chamber and a main leaf of a novel automobile radiator. The connecting structure comprises an upper water chamber (3), an upper main leaf (4), a lower water chamber (9) and a lower main leaf (11); wherein, a circle of outer folded-edges I (3.1) extending outwards are arranged on the lower edge of the upper water chamber (3), relative to the circle of the outer folded-edges I, a circle of inner folded-edges I (4.1) are vertically arranged on the outer edge of the upper main leaf (4), and the outer folded-edges I (3.1) on the lower edge of the upper water chamber (3) are closely covered outside the circle of inner folded-edges I (4.1) on the outer edge of the upper main leaf (4), and fixedly connected in a braze welding way; a circle of outer folded-edges II (9.1) extending outwards are arranged on the upper edge of the lower water chamber (9), relative to the circle of the outer folded-edges II, a circle of inner folded-edges II (11.1) are upward vertically arranged on the outer edge of the lower main leaf (11), and the outer folded-edges II (9.1) on the upper edge of the lower water chamber (9) are closely covered outside the circle of the inner folded-edges II (11.1) on the outer edge of the lower main leaf (11), and are fixedly connected in a braze welding way. By adopting the connecting method that the main leaves are loaded in the water chambers, the outline of the product is an integral structure on the construction, therefore, the water chambers are firmly welded with the main leaves.

Owner:许惠新

Method for producing a plastic article and blow molding tool

ActiveCN102802916AEasy solder connectionDomestic articlesHollow articlesBlow moldingDifferential pressure

The invention relates to a method for producing a plastic article and a blow molding tool for performing the method. The method comprises extruding an approximately tube-shaped perform (2), dividing the melt flow within the extrusion head or separating the extrudate exiting or already exited from the extrusion head, such that a preform having an approximately C-shaped cross section is obtained, forming the preform into a hollow part within a multipart blow molding tool (8) using differential pressure, wherein an expansion and partial preforming of the preform first takes place with the blow molding tool partially closed, then in a further step at least one insert (18) is inserted into the interior of the partially preformed article between the not completely closed blow molding tool and through the open side of the preform, and in a further step the blow molding tool is completely closed, wherein the article is completely formed, forming at least one at least partially circumferential pinch-off seam.

Owner:考特克斯机械制造有限公司

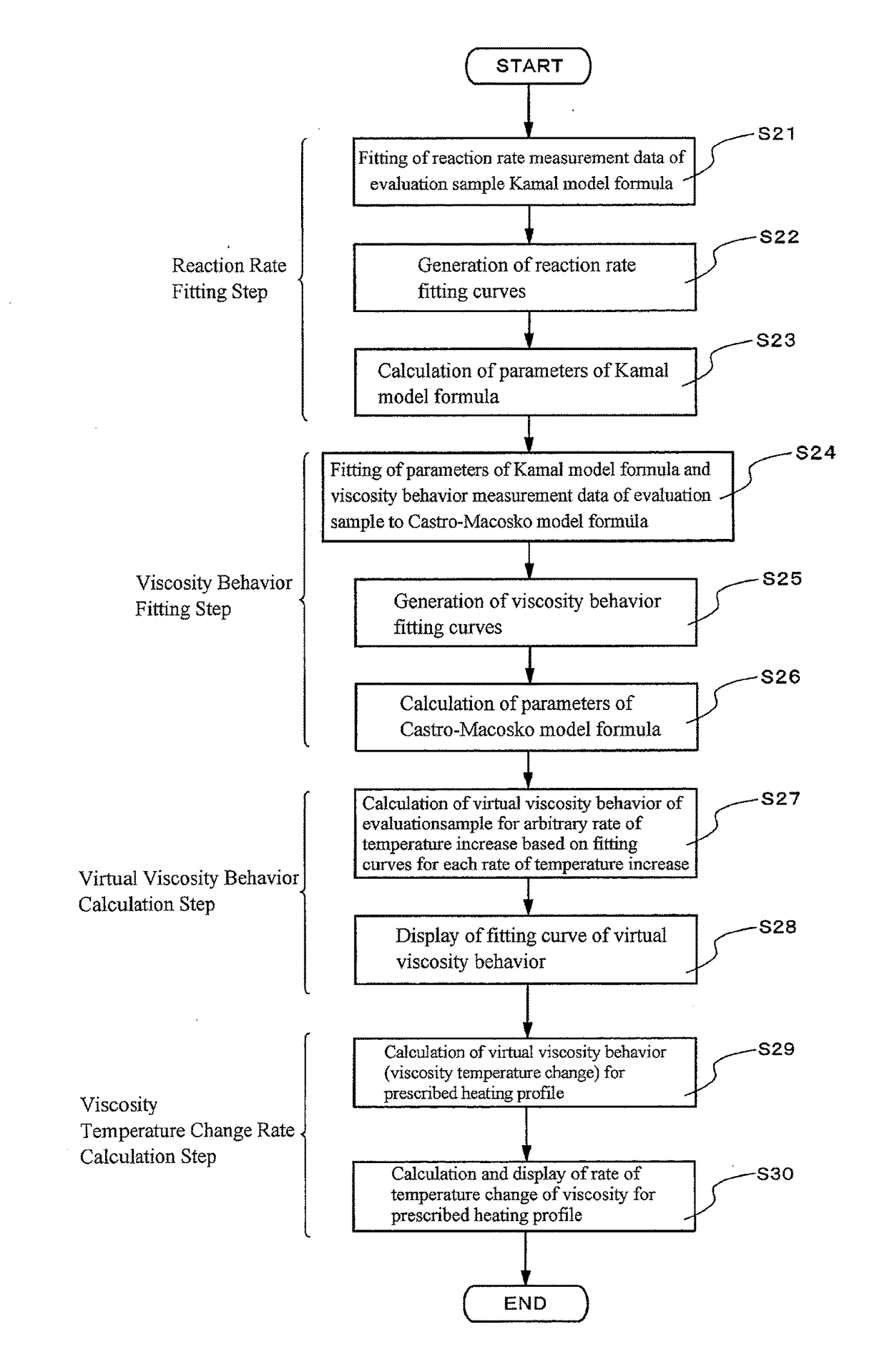

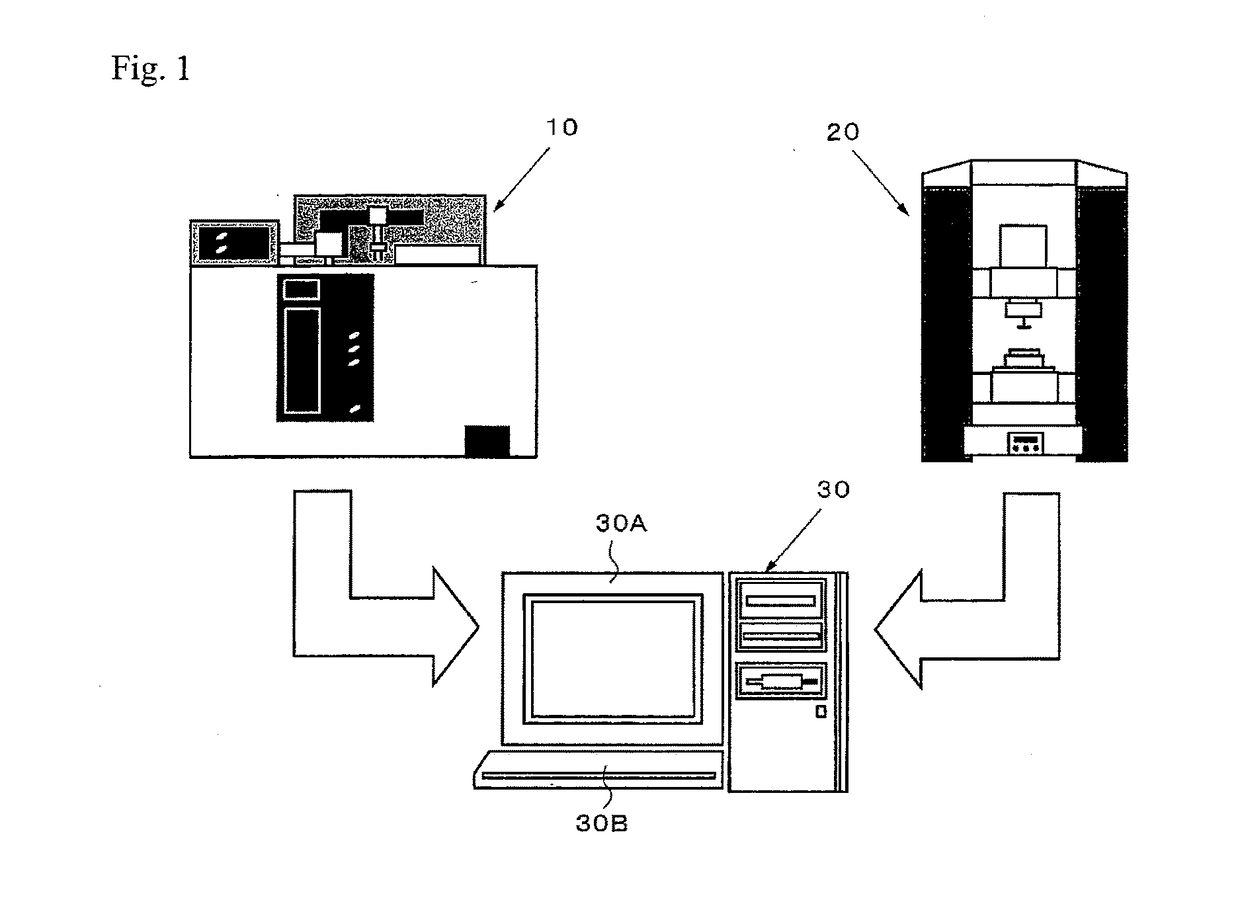

Thermosetting resin composition and method of producing same

ActiveUS20170301597A1Easy solder connectionSuppressing formation of voidNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsThermal compressionSemiconductor chip

Provided is a thermosetting resin composition, which can be used as underfill for obtaining favorable solder connectivity while suppressing the formation of voids in the case of treating under heating conditions required by the underfill in a semiconductor chip thermocompression bonding step using the thermal compression bonding technique. The thermosetting resin composition contains a thermosetting resin, a curing agent and a fluxing agent, and the temperature at which the rate of temperature change of viscosity when temperature is increased according to a prescribed heating profile reaches 30 Pa·s / ° C. is 200° C. to 250° C.

Owner:NAMICS CORPORATION

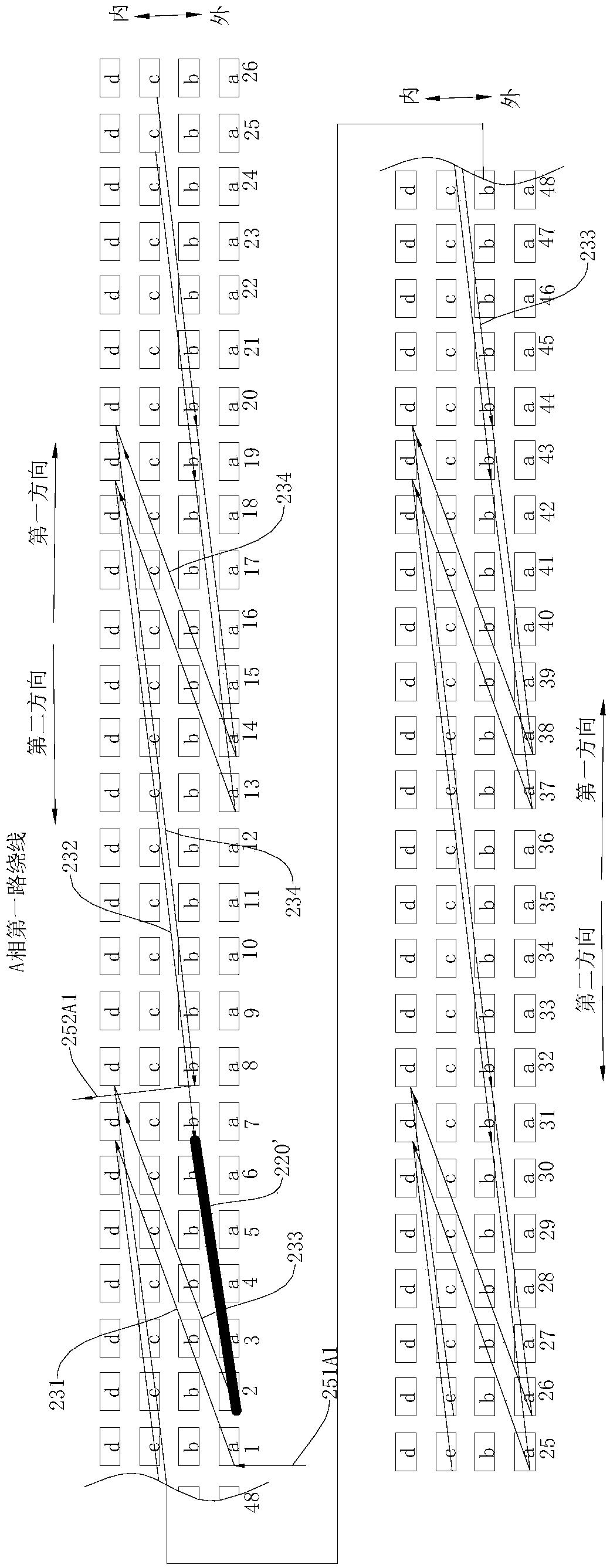

Stator assembly and motor with stator assembly

ActiveCN110784039AReduced risk of insulation breakdownImprove reliabilityManufacturing dynamo-electric machinesWindings conductor shape/form/constructionElectrical conductorElectric machine

The invention discloses a stator assembly and a motor with the stator assembly. The stator assembly comprises a stator core and a stator winding; the stator core is provided with a plurality of statorgrooves, the stator winding is formed by a plurality of U-shaped conductor sections, each U-shaped conductor section comprise a first type conductor section and a second type conductor section; the stator winding comprises an A-phase first winding and an A-phase second winding, the A-phase first winding comprises a first sub-winding section, a second sub-winding section, a third sub-winding section and a fourth sub-winding section which are connected in sequence, and the A-phase second winding comprises a fifth sub-winding section, a sixth sub-winding section, a seventh sub-winding section, and an eighth sub-winding section which are connected in sequence; welding ends corresponding to the second sub-winding section of the A-phase first winding and the seventh sub-winding section of the A-phase second winding is designed to span (y-1) stator grooves, whereby the distance at the welding end can be reduced, while for the entire winding process of the phase A, the distance between the Aphase star point line and the outgoing line can be reduced, and the welding connection is facilitated.

Owner:BYD CO LTD

Automobile silencer welding machine

ActiveCN102500972AEasy solder connectionEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesDrive motorEngineering

The invention discloses an automobile silencer welding machine, which comprises a base, a silencer connecting mechanism arranged on the base, an exhaust pipe connecting mechanism arranged on the base and a welding gun connecting mechanism arranged on the base. The silencer connecting mechanism and the exhaust pipe connecting mechanism are arranged on two sides of the welding gun connecting mechanism, a silencer is horizontally fixed on the silencer connecting mechanism, and exhaust pipes are horizontally fixed on the exhaust pipe connecting mechanism. The welding gun connecting mechanism is provided with a welding gun aiming at the connecting position of the silencer and the exhaust pipe, and a drive motor is arranged on the base and drives the silencer connecting mechanism and the exhaust pipe connecting mechanism to rotate synchronously through a transmission mechanism. By adopting the technical scheme, synchronous rotation of the silencer and the exhaust pipes at two ends is achieved through rotation of a corresponding mechanism, welding connection of the silencer and the exhaust pipes is facilitated, operation is simple, welding efficiency is high, welding quality is good, and disadvantages produced by manual welding are overcome.

Owner:江阴金属材料创新研究院有限公司

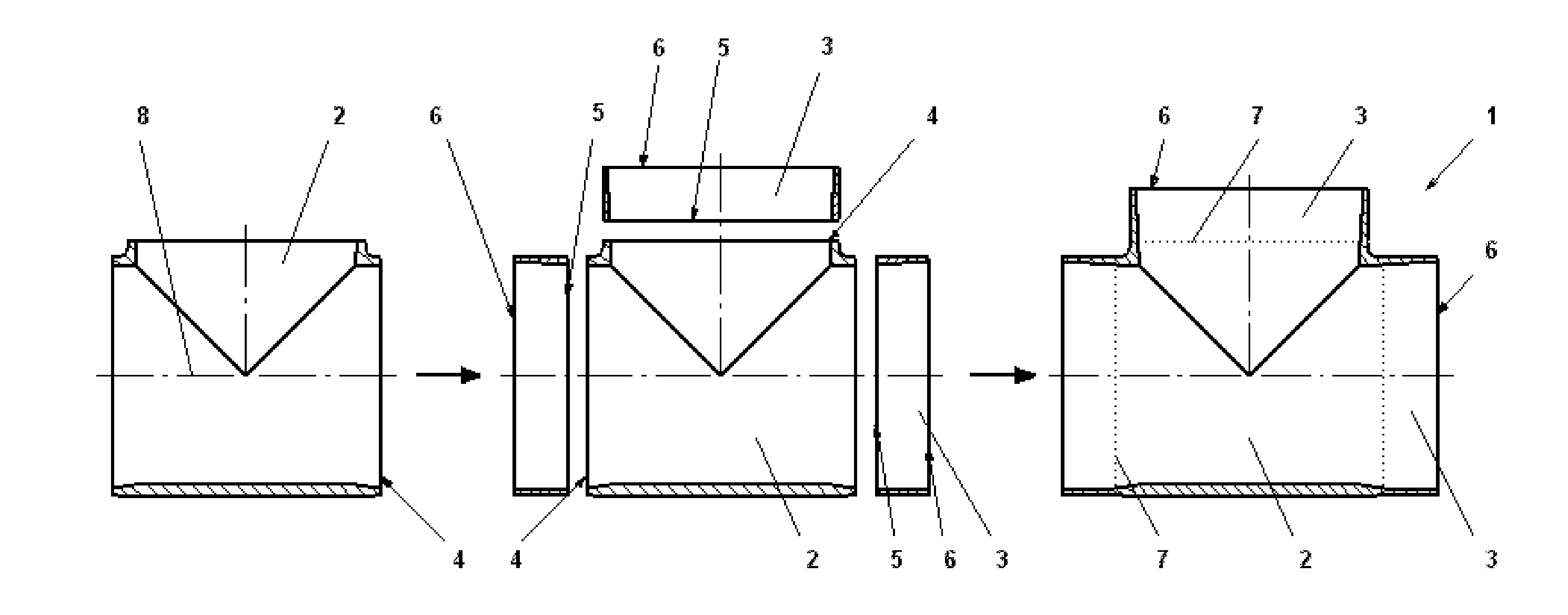

Method for producing a piston for an internal combustion engine and piston for an internal combustion engine

InactiveCN103118831AAvoid cooling downEasy solder connectionMachines/enginesPistonsEngineeringInternal combustion engine

The invention relates to a method for producing a piston (10, 110, 210) for an internal combustion engine, characterized by the following steps: a) producing an upper piston part (11, 111, 211) having at least one joining surface (21, 22; 121, 122), b) producing a lower piston part (12, 112, 212) having at least one joining surface (23, 24; 123, 124), c) establishing a direct contact between the at least one joining surface (21, 22; 121, 122) of the upper piston part (11, 111, 211) and the at least one joining surface (23, 24; 123, 124) of the lower piston part (12, 112, 212), d) heating the upper piston part (11, 111, 211) and the lower piston part (12, 112, 212) in the region of the joining surfaces (21, 23; 22, 24; 121, 123; 122, 124) brought in direct contact by induction or by a direct current flow through the joining surfaces (21, 23; 22, 24; 121, 123; 122, 124), and (e) connecting the upper piston part (11, 111, 211) and the lower piston part (12, 112, 212) to form a piston (10, 110, 210) by means of a pressing process and optionally finishing the piston (10, 110, 210).

Owner:MAHLE INT GMBH

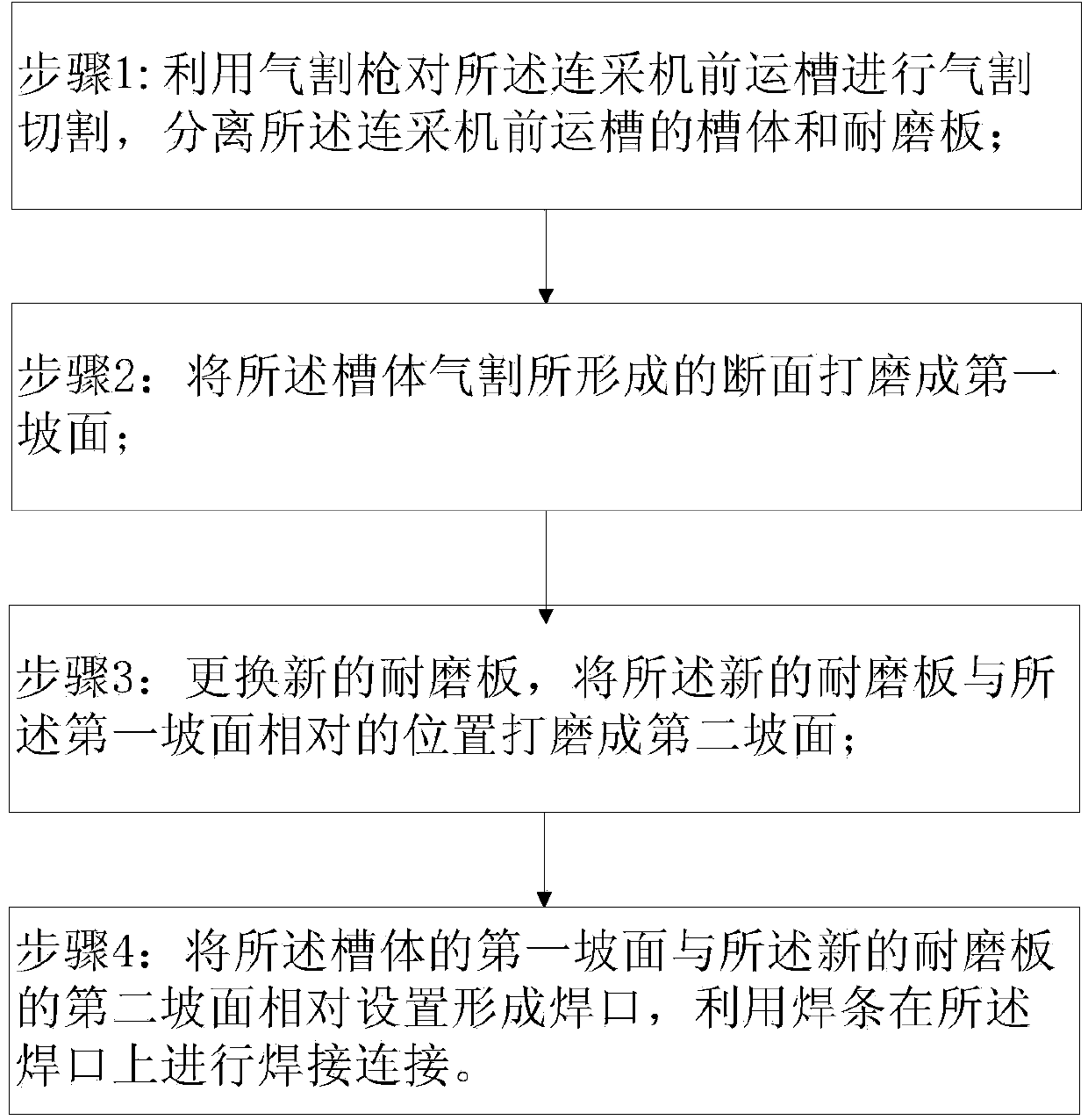

Method for repairing front delivery channel of continuous miner

InactiveCN103624380AEasy solder connectionAvoid welding deformationArc welding apparatusTorchEngineering

The invention discloses a method for repairing a front delivery channel of a continuous miner. The method comprises the following steps: step 1, a gas cutting torch is used for gas cutting of the front delivery channel of the continuous miner so as to separate a channel body of the front delivery channel of the continuous miner from a wear-resisting plate; step 2, a fracture surface formed after gas cutting of the channel body is polished into a first slope; step 3, the wear-resisting plate is replaced by a new one, and the position, opposite to the first slope, of the new wear-resisting plate is polished into a second slope; step 4, the first slope of the channel body and the second slope of the new wear-resisting plate are arranged to be opposite to each other so as to form a welded junction, and a welding rod is used for conducting welded connection on the welded junction. According to the method for repairing the front delivery channel of the continuous miner, the first slope and the second slope are polished between the channel body and the new wear-resisting plate so that an operator can conveniently conduct welded connection on the front delivery channel of the continuous miner from the outside in an aligned mode; besides, the channel body and the new wear-resisting plate are fixed through a shaft sleeve in a spot welding mode before being welded, so that welding deformation is avoided.

Owner:CHINA SHENHUA ENERGY CO LTD +1

Stator assembly and motor with stator assembly

ActiveCN110784045AReduced risk of insulation breakdownImprove reliabilityManufacturing dynamo-electric machinesWindings conductor shape/form/constructionElectric machineEngineering

The invention discloses a stator assembly and a motor with the stator assembly. The stator assembly comprises a stator core and a stator winding; the stator core is provided with a plurality of statorgrooves; the stator winding comprises an A-phase winding; the A-phase winding comprises a plurality of first sub-winding sections, a second sub-winding section, a plurality of third sub-winding sections, a fourth sub-winding section, a bridging line, a fifth sub-winding section, a plurality of sixth sub-winding sections, a seventh sub-winding section and a plurality of eighth sub-winding sectionswhich are sequentially connected; the initial end of the A-phase winding is connected with an A-phase outgoing line; the termination end of the eighth sub-winding section is connected with an A-phasestar point line; the corresponding welding end of the second sub-winding section and the seventh sub-winding section of the A-phase winding is designed to span (y-1) stator grooves, so that the distance at the welding end can be reduced, and for the whole winding process of the A phase, the distance between the A-phase star point line and the A-phase outgoing line can be reduced, and welding connection is easy to realize.

Owner:BYD CO LTD

Battery lug and battery module

ActiveCN107195842AImprove protectionImprove seismic performanceCell component detailsHeight differenceBattery cell

The invention discloses a battery lug and a battery module. The lug comprises a body and a lug unit which is arranged on the body and formed by extending from the body, wherein the lug unit comprises an elastic sheet formed by extending from the body, and an irregular spiral elastic sheet groove formed around the elastic sheet; the elastic sheet comprises a guide part of a long-narrow arc-shaped main body formed by extending from the body, and a main body part formed by extending from the other end of the guide part; the guide part is provided with a fused part; and the main body part is provided with a through hole. In the battery lug and the battery module, the lug unit is provided with the guide part of the long-narrow arc-shaped main body formed by extending from the body, so that the lug unit is elastic; the height differences or height errors of different battery cells are adapted; and the welding quality is enhanced. The main body part and the battery cells are welded in a contact way, so that the lug unit and the battery cells can be connected conveniently by welding. The fused part is arranged on the guide part of the high-elasticity long-narrow arc-shaped main body, so that design and fusing are facilitated. Moreover, the fused part is a weak position of structural heat, so that the fusing position is reasonable, and the module can be protected.

Owner:深圳福源特新能源有限公司

A large-scale special dry-type transformer after-loading operation table for production

ActiveCN109216001AEasy to assemblePrevent dumpingInductances/transformers/magnets manufactureManufacturing technologyTransformer

A technology for manufacture electric power equipment A large-scale special dry-type transform after-loading operation table is disclose, including workshop floors, A roll shaft erection groove is excavated on that floor of the workshop, At that bottom of the inn wall of the roller erection groove, a human groove is excavate, The inner wall of the human groove is provided with a step, the bottom of the roller erecting groove is fixedly connected with the bottom of the first fixed sleeve, the inner wall of the first fixed sleeve is sleeved with one end of the shaft rod, the outer surface of theshaft rod is fixedly connected with the inner wall of the shaft rod, and the outer surface of the shaft rod is sleeved with the inner wall of the second fixed sleeve. As that lif mechanism is arranged on the floor of the workshop and the processing mechanism arranged between the first force arm and the second force arm is cooperated, the operation of the sleeve coil, the iron core insert piece and the welding row and the like are facilitated, the potential safety hazards in the assembling process of the large-scale dry-type transformer are reduced, and the safety accidents in the workshop areavoided.

Owner:南通晓星变压器有限公司

Stator assembly and motor with same

ActiveCN110971040AReduced risk of insulation breakdownImprove reliabilityMagnetic circuit stationary partsWindings conductor shape/form/constructionElectrical conductorElectric machine

The invention discloses a stator assembly and a motor with the same. The stator assembly comprises a stator core and a stator winding. The stator core is provided with a plurality of stator slots, thestator winding is formed by a plurality of U-shaped conductor sections, and the U-shaped conductor sections comprise a first type conductor section and a second type conductor section. The stator winding comprises an A-phase first winding and an A-phase second winding, the A-phase first winding comprises an A-phase first sub-circuit and an A-phase second sub-circuit, the A-phase first sub-circuitand the A-phase second sub-circuit are wound in parallel, the A-phase second winding comprises an A-phase third sub-circuit and an A-phase fourth sub-circuit, and the A-phase third sub-circuit and the fourth sub-circuit are wound in parallel. At the corresponding welding ends of the second sub-winding section of the A-phase first winding and the seventh sub-winding section of the A-phase second winding, the welding ends span the (y-1) stator slots, so that the distance at the welding ends can be reduced, the welding connection is easy to realize, the conductor area is reduced, and the skin effect can be effectively reduced.

Owner:BYD CO LTD

Stator assembly and motor with stator assembly

ActiveCN110784040AReduce volumeReduce distanceManufacturing dynamo-electric machinesWindings conductor shape/form/constructionElectric machineEngineering

The invention discloses a stator assembly and a motor with the stator assembly. The stator assembly comprises a stator core and a stator winding; the stator core is provided with a plurality of statorgrooves; the stator winding comprises an A-phase winding; the A-phase winding comprises a plurality of first sub-winding sections, a second sub-winding section, a plurality of third sub-winding sections, a fourth sub-winding section, a bridging line, a fifth sub-winding section, a plurality of sixth sub-winding sections, a seventh sub-winding section and a plurality of eighth sub-winding sectionswhich are sequentially connected; the initial end of the A-phase winding is connected with an A-phase outgoing line; the termination end of the eighth sub-winding section is connected with an A-phasestar point line. A corresponding welding end of the second sub-winding section and the seventh sub-winding section of the A-phase winding is designed to span (y-1) stator grooves, and bridging line shape is improved, so that the distance at the welding end can be reduced, and the distance between the A-phase star point line and an A-phase outgoing line can be reduced for the whole winding processof the A phase, and welding connection is easy to realize.

Owner:BYD CO LTD

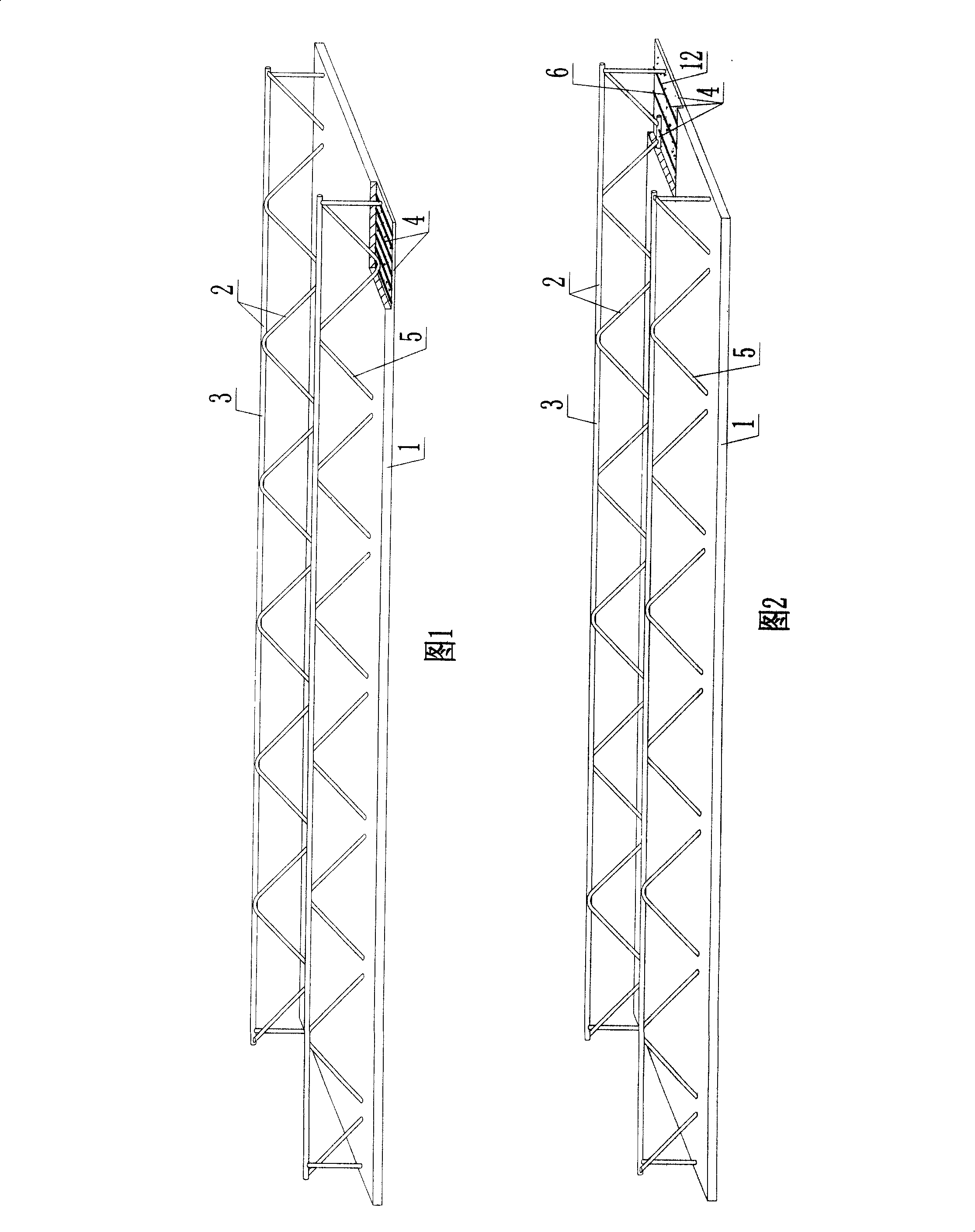

Web-tapped partial combined shear wall-combined connecting beam coupled wall and production method thereof

PendingCN108571094AReduce on-site construction man-hoursFast construction on siteWallsGirdersH shapedShear wall

The invention relates to a web-tapped partial combined shear wall-combined connecting beam coupled wall and a production method thereof. The coupled wall comprises at least two PEC shear walls and a combined connecting beam, wherein each PEC shear wall is formed by combining an H-shaped steel framework connected through a plurality of T-shaped steels and concrete filled in the H-shaped steel framework; openings are formed in the centers of webs in an equal interval manner along the length direction of the H-shaped steel frameworks; and the combined connecting beam comprises an H-shaped steel beam, the H-shaped steel beam comprises a steel beam web and steel beam wing edges arranged at two ends of the steel beam web, a hole is formed in the center of the steel beam web, and the PEC shear walls are sequentially connected through the combined connecting beam so as to form the novel combined shear wall-combined connecting beam coupled wall. According to the coupled wall, the partial combined prefabricated component is prepared in a web tapping pouring manner, the once pouring and the once maintenance can be realized, and the preparation period of the component is shortened.

Owner:ZHEJIANG GREEN BUILDING INTEGRATION TECH CO LTD

Automobile warm-air

InactiveCN101226029AFirmly connectedGuaranteed mechanical strengthStationary conduit assembliesHeat exchanger casingsEngineering

The invention relates to an automobile heater, which comprises a water feeding chamber(3), a drain chamber(8), a water inlet pipe(1), a main leaf(4), a side board(5), a heat dissipation belt(7) and a flat tube(6); wherein a plurality of tooth bits (4.1) meshed at the bottom edge (3.1) of the water feeding chamber(3) and the drain chamber(8) are arranged at the periphery of the main leaf(4) at the joint between the water feeding chamber(3) and the drain chamber(8); two bulges (5.1) or elbows (5.2) are respectively arranged at the sidewall of the position of the side board(5) corresponding to both ends of the heat dissipation belt(7); a lug (4.2) occluded at the terminal of the side board(5) is positioned at the joint between the terminal of the side board(5)and the main leaf(4); a buffer plate(9) is arranged between the water outlet of the water inlet pipe(1) and the water inlet of flat tube(6) facing to the water outlet of the water inlet pipe(1). The automobile heater has the advantages that: the connection between the water chambers and the main leaf is firm, which can prevent the part melting and dropping of the heat dissipation belt in the process of welding production; the connection between the side board and the main leaf can be firm and reliable; and can make balanced water feeding flow of all flat tube.

Owner:许惠新

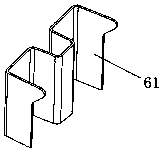

Force-bearing type template component for building lid

InactiveCN101230655ANot easy to loosen and fall offEasy solder connectionFloorsBuilding reinforcementsReinforced concrete

The invention relates to a stressed template component used for a floor system, and the component is composed of a template (1) and is characterized in that the invention also comprises trusses (2) which are parallel and arranged at intervals, and the trusses (2) are arranged on the template (1) and are connected with the template (1) into a whole; the trusses (2) are provided with a top boom (3), a lower boom (4) and a web member (5); wherein, the web member (5) is connected with the top boom (3) and the lower boom (4); the lower boom (4) of the trusses (2) is of an integral elongated template (1); the trusses (2) are of a rodless lower boom (4). The invention is applicable to cast-in-situ reinforced concrete or a hollow floor system, a roof system, walls and a foundation slab of the prestressed reinforced concrete as well as a vierendeel bridge girder, and is particularly suitable for a hollow flat slab.

Owner:邱则有

Auxiliary frame

PendingCN111376977AReduce difficultyAvoid complex welding processesUnderstructuresVehicle frameStringer

The invention discloses an auxiliary frame. The auxiliary frame comprises a front cross beam, a first longitudinal beam, a rear cross beam and a second longitudinal beam which are connected in sequence, and the front cross beam, the first longitudinal beam, the rear cross beam and the second longitudinal beam are connected to form a rectangular frame structure; and the connecting face, connected with the first longitudinal beam and the second longitudinal beam, of the rear cross beam is an inclined face, and the end, connected with the front cross beam, of the first longitudinal beam and the end, connected with the front cross beam, of the second longitudinal beam are provided with notch grooves for buckling the front cross beam. According to the invention, the types of materials requiredfor producing the auxiliary frame are reduced, the mold opening cost is saved, and meanwhile, the welding process requirement is reduced.

Owner:FJ MOTOR GRP YUDO NEW ENERGY AUTOMOBILE CO LTD

Pressure-tight wire connection device

InactiveCN104577936AGood sealing performanceEasy to installCable junctionsCable inlet sealing meansEngineeringSmall hole

The invention discloses a pressure-tight wire connection device which comprises sub-wire support plates, a joint, a seal ring, a filling and sealing material and wires for communicating the inner part and the outer part of a tank, wherein the joint is an unequal-diameter cylinder in the outline, which has a through hole formed by combining a straight hole with a taper hole; a large end of the taper hole faces the pressure gas direction; both ends of the through hole are respectively provided with steps; the joint is a screwed joint which has external threads on the outer diameter of the small end, or a flange joint, the large end of which is a flange plate; n small holes for threading the wires are formed in the sub-wire support plates; in assembly state, two sub-wire support plates are respectively placed on the steps at both ends of the through hole in the joint; m wires penetrate through the hole in the joint and n small holes corresponding to the sub-wire support plates; the through hole in the joint is filled with the filling and sealing material to bond the sub-wire support plates, the joint and the wires into a whole; the seal ring is located at cable entrances of the joint and a sealed tank; and n is not less than m, and n is not less than 1 and not greater than 20. The pressure-tight wire connection device is reliable in sealing under a certain gas pressure, simple in structure, and convenient to install.

Owner:LIUZHOU OVM MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com