Method for joining two or several profiled parts or metal sheets which are mechanically joined and pressure-welded at one or several connection points

A technology of mechanical connection and metal plate, which is applied in the direction of connection components, mechanical equipment, metal processing, etc., can solve the problems of reduced production volume of finished product lines, prolonged cycle time, and reduced production volume, so as to improve welding connection and production safety Improvement of performance and low cost of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

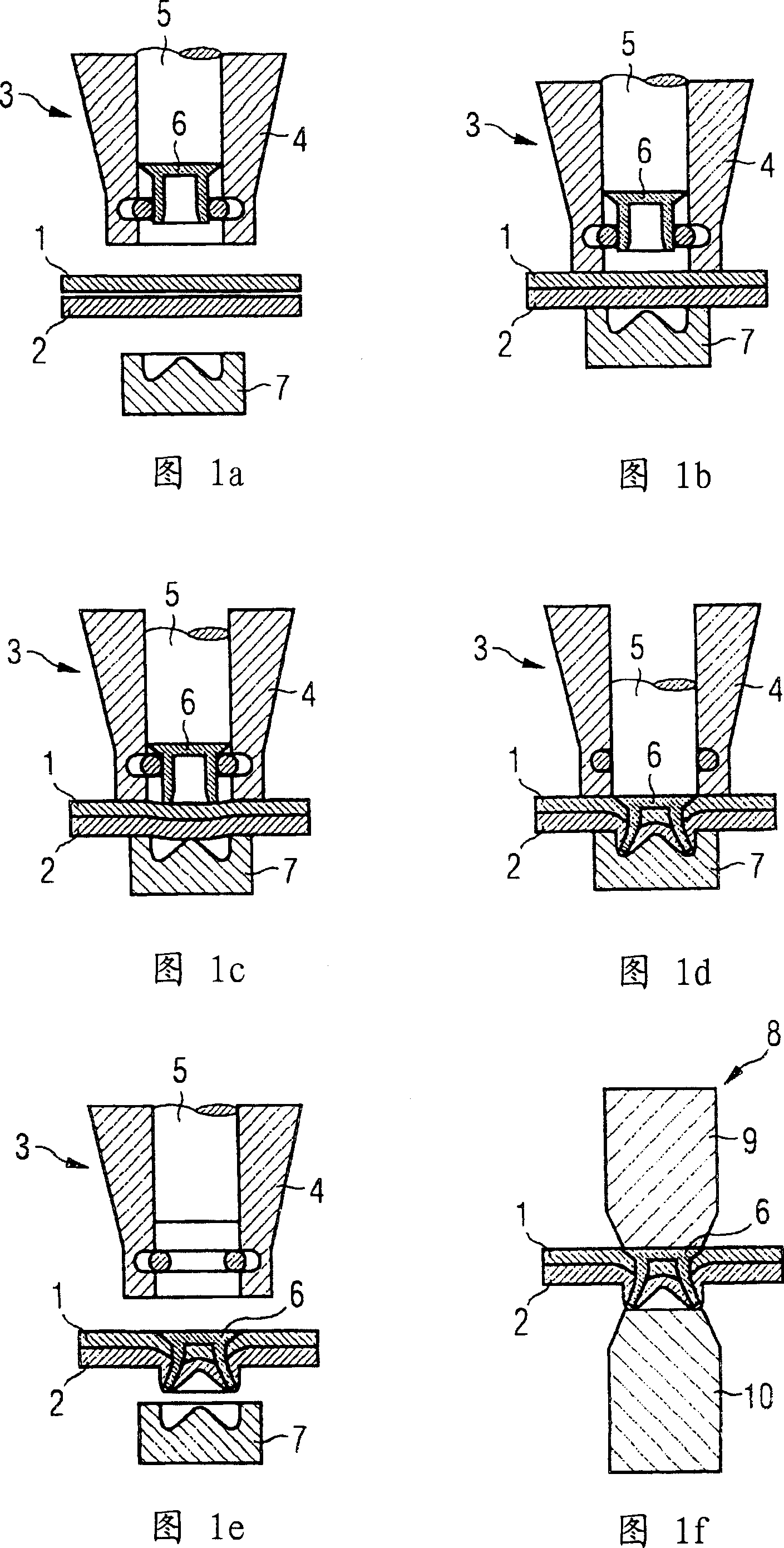

[0045] According to the figures, firstly a first metal plate 1 and a second metal plate 2 are arranged to be connected to each other and form an assembly. The first metal sheet 1 shown and the second metal sheet 2 shown here both consist of high-strength steel. The two metal plates have a thickness of approximately 1.5 mm.

[0046] Next, the first sheet metal 1 and the second sheet metal 2 are introduced into the piercing riveting assembly tool 3 . The piercing riveting tool 3 comprises a feed nose 4 in which a punch is arranged. The feed lug 4 guides the punch 5 at the bottom end of which a piercing rivet 6 is provided. A feed lug 4 in which the punch 5 is positioned and a guided piercing rivet 6 are located above the assembly for joining the first 1 and second 2 metal sheets together. Below the components to be joined is the mold 7 .

[0047] After the first sheet metal 1 and the second sheet metal 2 have been introduced into the piercing riveting assembly tool 3 as show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com