Method for repairing front delivery channel of continuous miner

A technology of continuous miner and tank transport, applied in the field of repair, can solve the problem that the tank body cannot be welded, and achieve the effect of avoiding welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

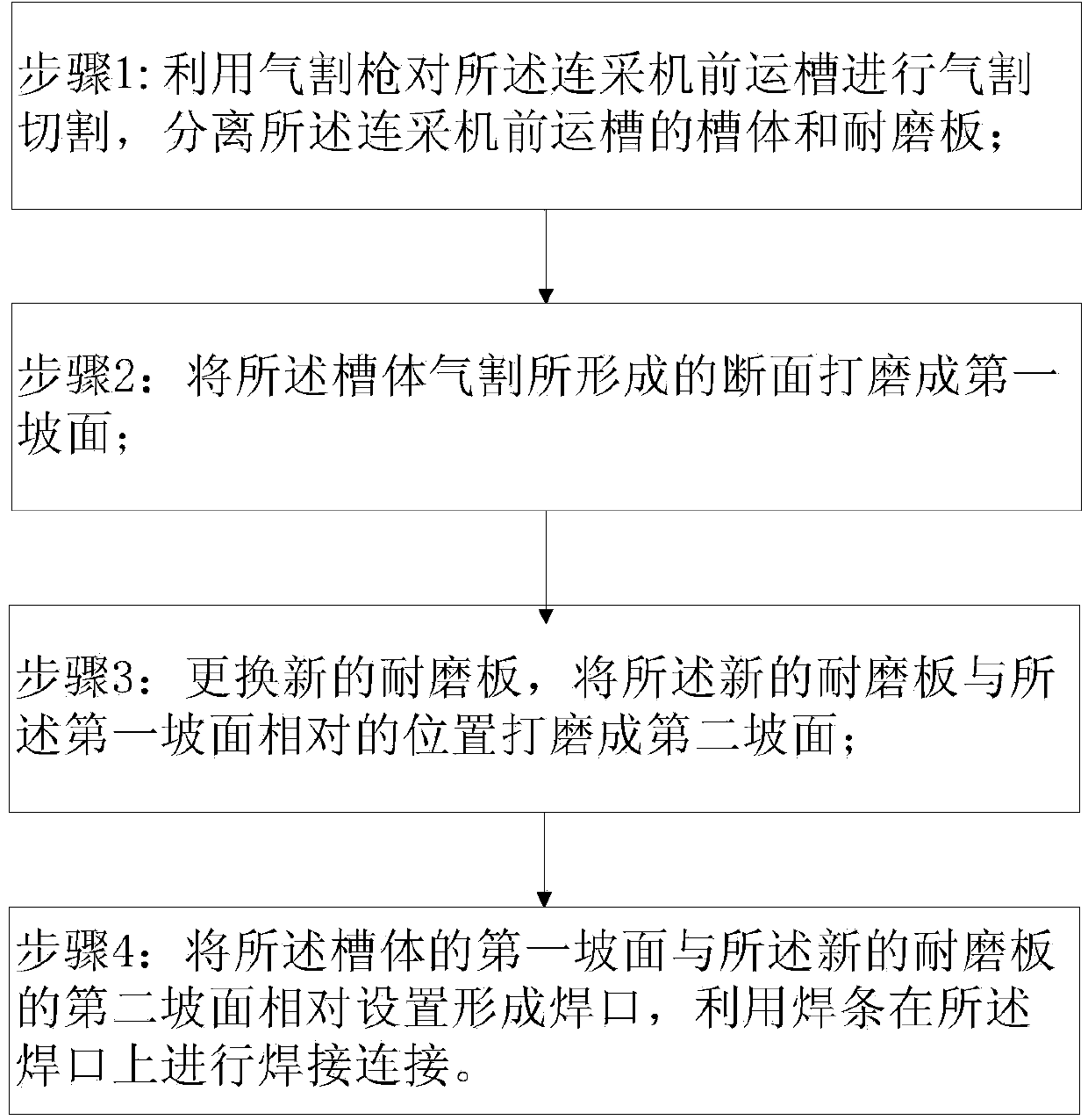

[0026] Such as figure 1 As shown, the present invention provides a method for repairing the front transport groove of the continuous miner, comprising the following steps:

[0027] Step 1: utilize gas cutting gun to carry out gas cutting and cutting to the front transport groove of described continuous mining machine, separate the groove body and wear-resistant plate of the front transport groove of described continuous mining machine;

[0028] Step 2: grinding the section formed by the gas cutting of the tank body into the first slope;

[0029] Step 3: replacing a new wear-resistant plate, and grinding the position of the new wear-resistant plate opposite to the first slope into a second slope;

[0030] Step 4: arranging the first slope of the tank body opposite to the second slope of the new wear-resistant plate to form a welding joint, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com