Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75results about How to "Current controllable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

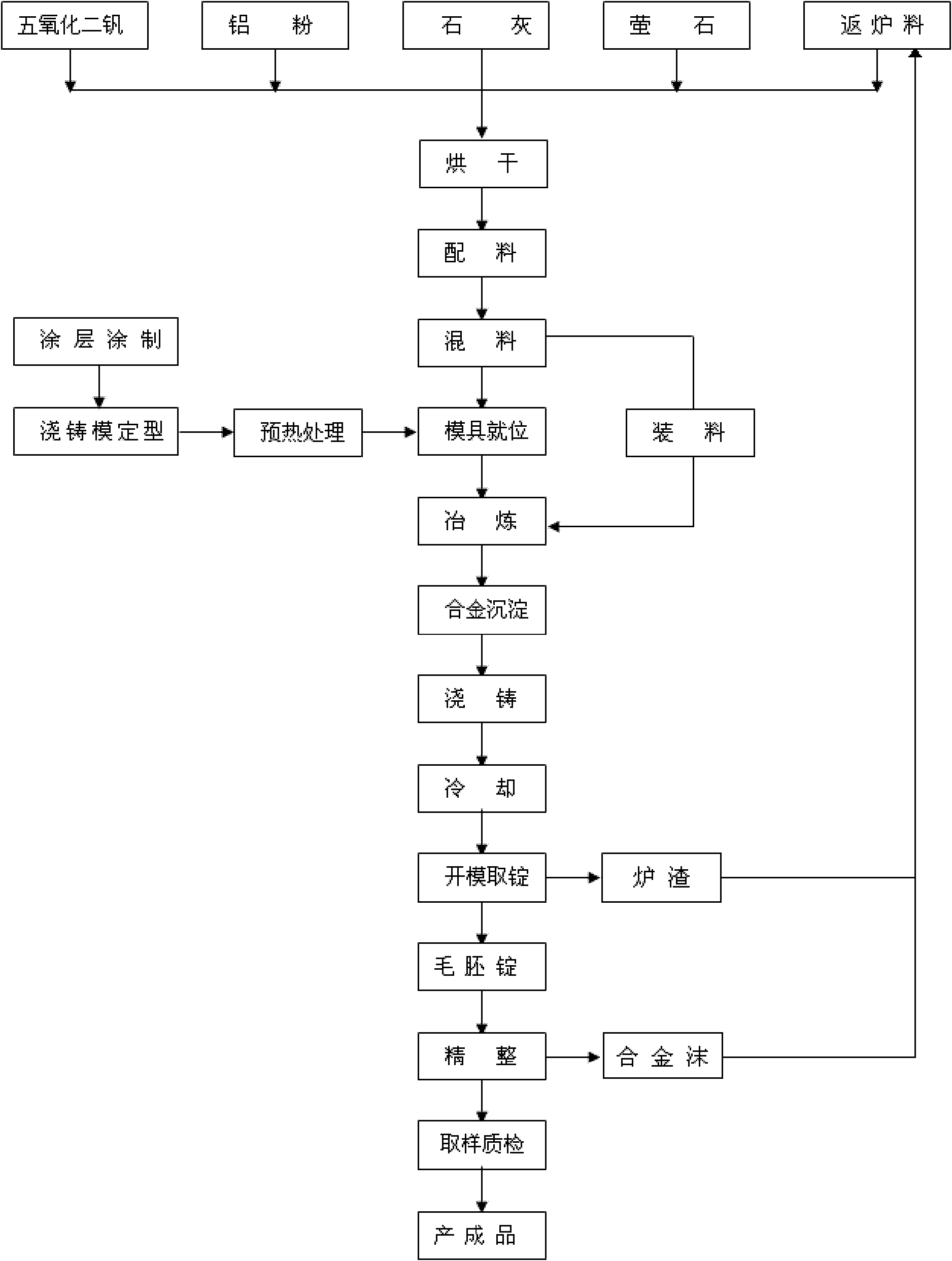

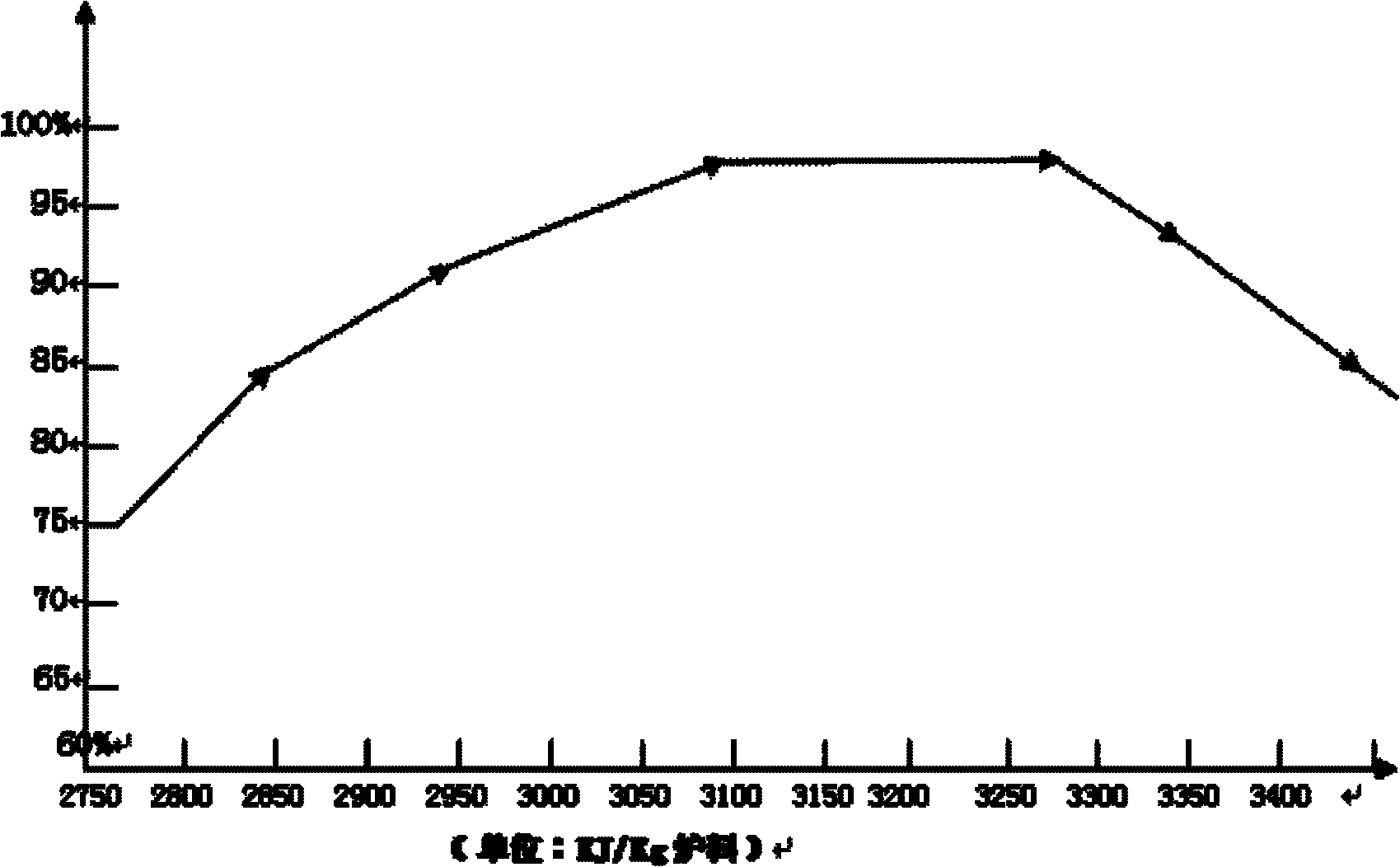

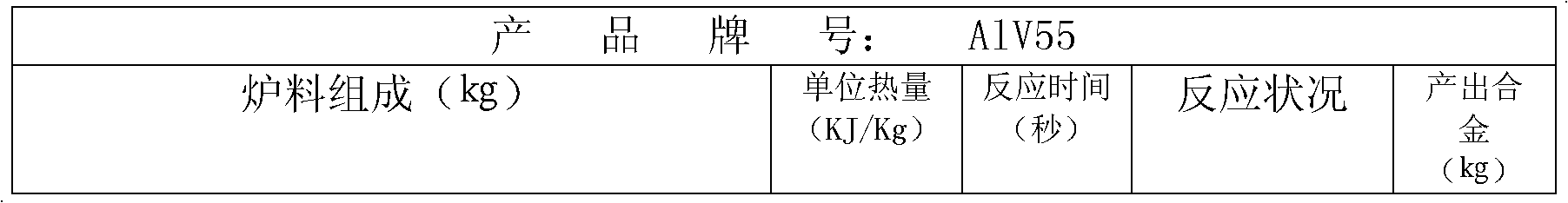

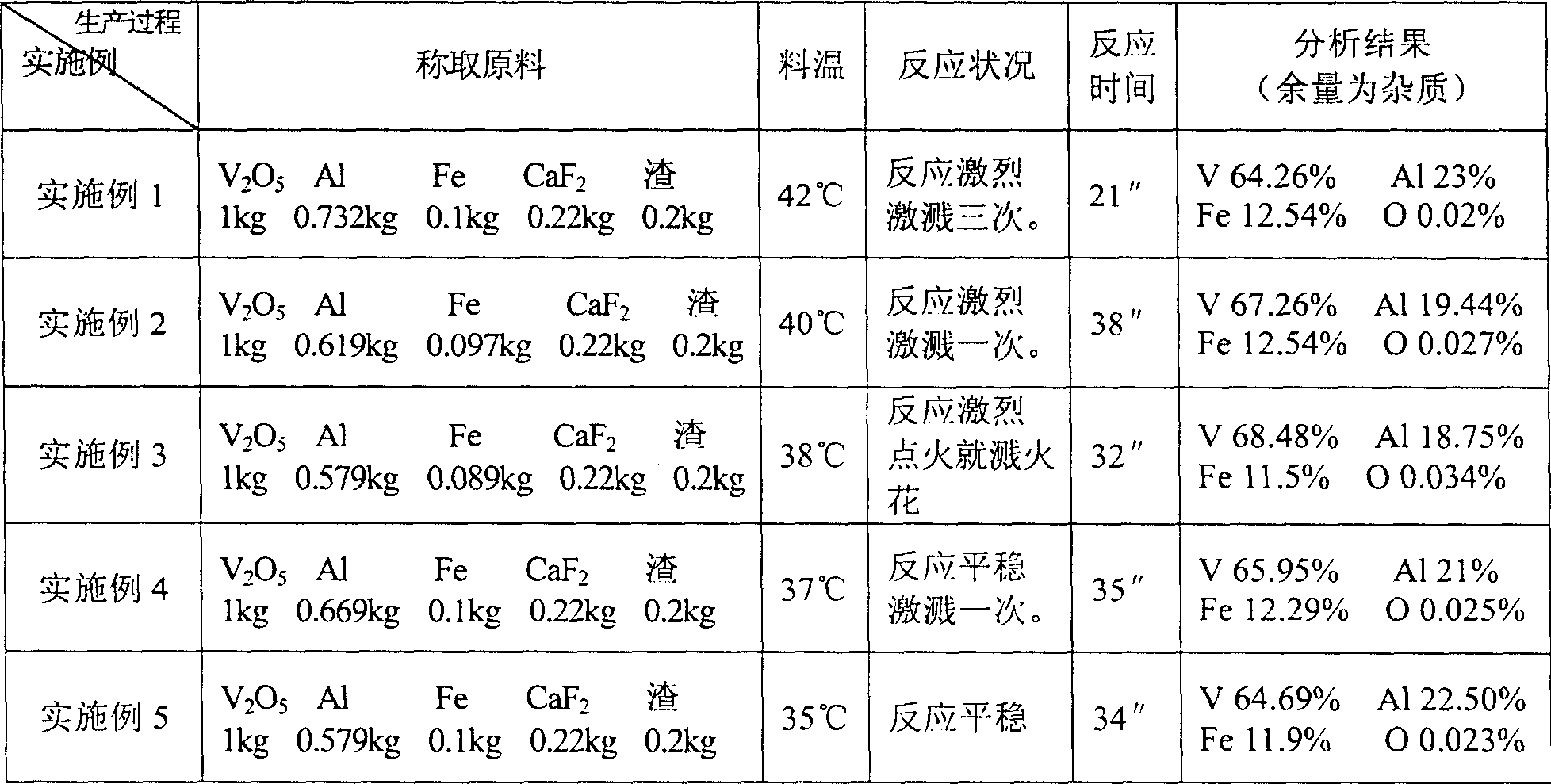

Method for optimizing preparation process of vanadium-aluminum alloy

ActiveCN102134657AEasy to prepareLow melting pointProcess efficiency improvementGranularityMixed materials

The invention discloses a method for optimizing a preparation process of a vanadium-aluminum alloy, which comprises the following steps of: at first, crushing vanadium pentoxide, aluminum powder, lime, fluorite and other materials according to the requirement of charging grain size, baking the crushed materials, dehydrating, removing volatile substances, then proportioning the baked materials appropriately, afterwards, totally pouring the proportioned materials into a material mixing cylinder for material mixing, delivering the sufficiently and uniformly mixed materials into a reaction furnace for smelting, standing still and precipitating upon the end of the smelting, then implementing casting, and finally, carrying out ball blast finishing, sampling and quality inspection. The method disclosed by the invention can effectively raise the metal recovery rate, lower the cost, reduce the content of alloy impurities and improve the quality of alloy.

Owner:METALINK SPECIAL ALLOYS CORP

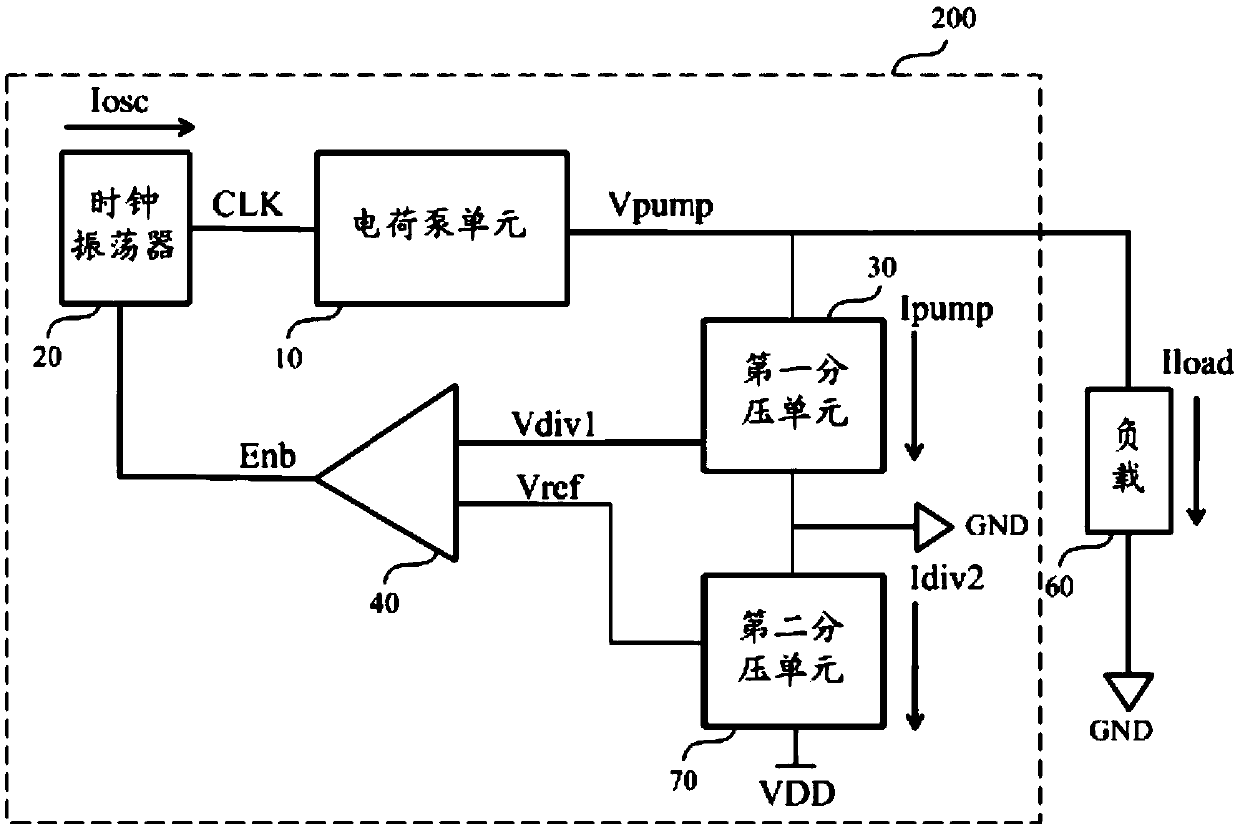

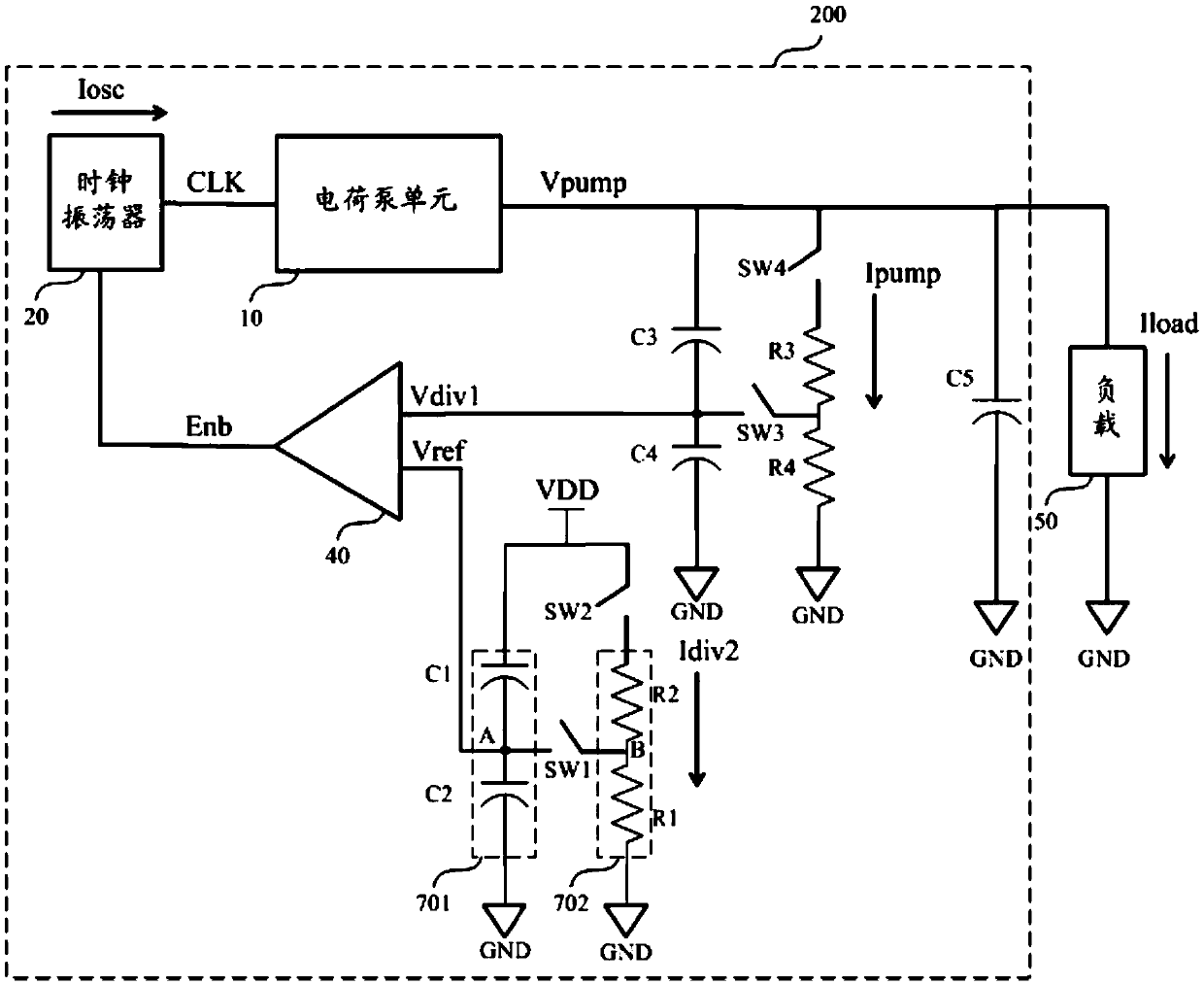

Charge pump circuit and memory

ActiveCN105515370ACurrent controllableControl Standby Power ConsumptionEfficient power electronics conversionApparatus without intermediate ac conversionStandby powerEngineering

The invention provides a charge pump circuit and a memory. The charge pump circuit comprises a charge pump unit, a clock oscillator, a first partial voltage unit and a voltage comparer and further comprises a second partial voltage unit. The output end of the charge pump unit is connected with the output end of the charge pump circuit. The clock oscillator is suitable for providing a drive clock signal for the charge pump unit. The first input end of the first partial voltage unit is connected with the output end of the charge pump unit, the second input end of the first partial voltage unit is grounded, and the first partial voltage unit is suitable for outputting a first partial voltage. A reference voltage and the first partial voltage are input into the first input end and the second input end of the voltage comparer respectively, the voltage comparer is suitable for outputting a first comparison result which is used for controlling the clock oscillator to output the drive clock signal. The first input end of the second partial voltage unit is connected with a power source, the second input end of the second partial voltage unit is grounded, and the second partial voltage unit is suitable for dividing a power voltage so that the reference voltage can be output. The charge pump circuit has a low quiescent current, and the standby power consumption of the memory can be reduced.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

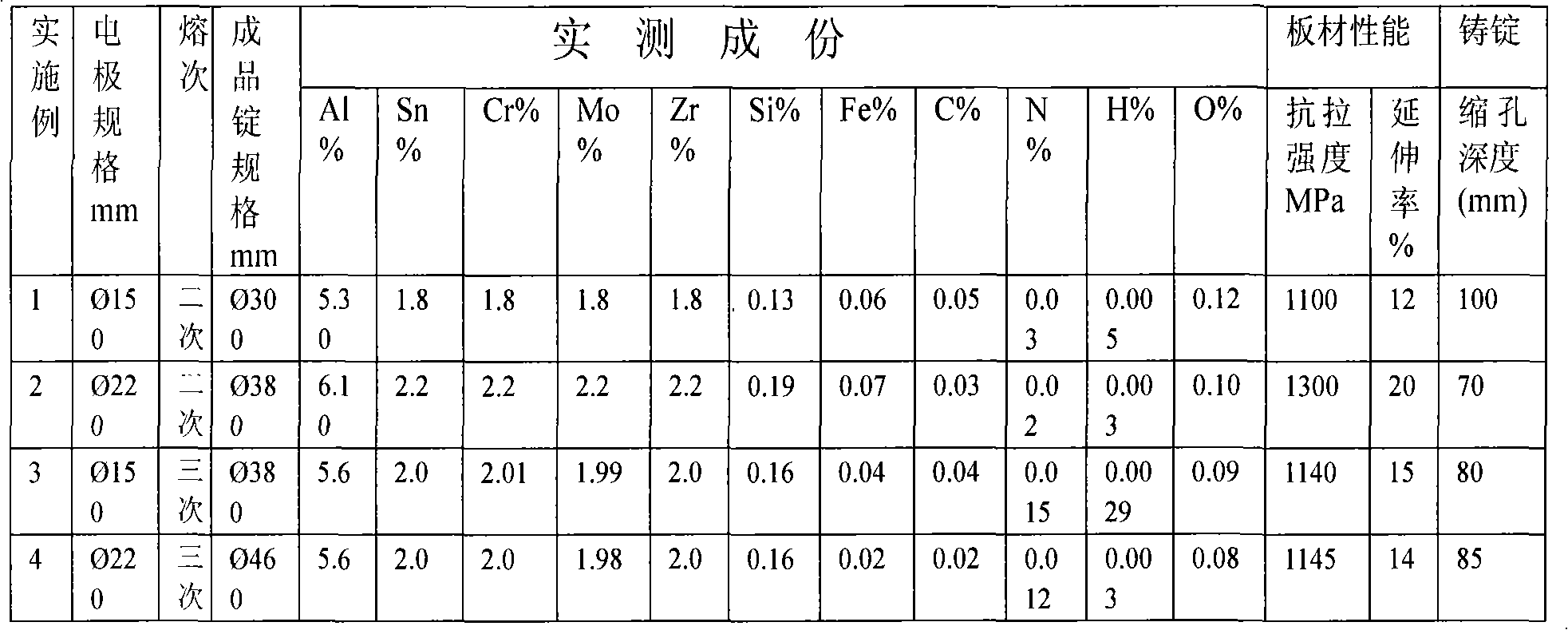

Titanium alloy Ti-62222s and preparation method thereof

The invention relates to a titanium alloy, in particular to a titanium alloy and a preparation method thereof. The titanium alloy comprises the following components in percentage by weight: balanced of Ti, 5.3-6.10 percent of Al, 1.80-2.20 percent of Sn, 1.80-2.20 percent of Zr, 1.80-2.20 percent of Mo, 1.80-2.20 percent of Cr, 0.13-0.19 percent of Si, lower than 0.08 percent of Fe, lower than 0.08 percent of C, not more than 0.03 percent of N, not more than 0.015 percent of H and not more than 0.12 percent of O; the smelting technical parameters are as follows: the vacuum degree before smelting is lower than 3Pa, the leakage rate within 3 min is equal to or lower than 3Pa, the smelting vacuum degree is equal to or lower than 3Pa, and the smelting current and the feeding current range from 2kA to 10kA; and the preparation method comprises the following steps: firstly, preparing the intermediate alloys AlSn50, AlCr50 and AlMo60, and then performing electrode preparation, electrode baking, electrode welding, furnace loading, smelting, cooling, furnace tapping, turning and sampling analysis by budgeting. The invention has the advantages that the refined grains of the alloy for silicon are added in, the processing and the forging are easy, the tensile strength in the performances of a plate processed by the alloy reaches 1100-1300MPa, the elongation rate reaches 12-20 percent, and meanwhile, the Beta phase can be stabilized.

Owner:忠世高新材料股份有限公司

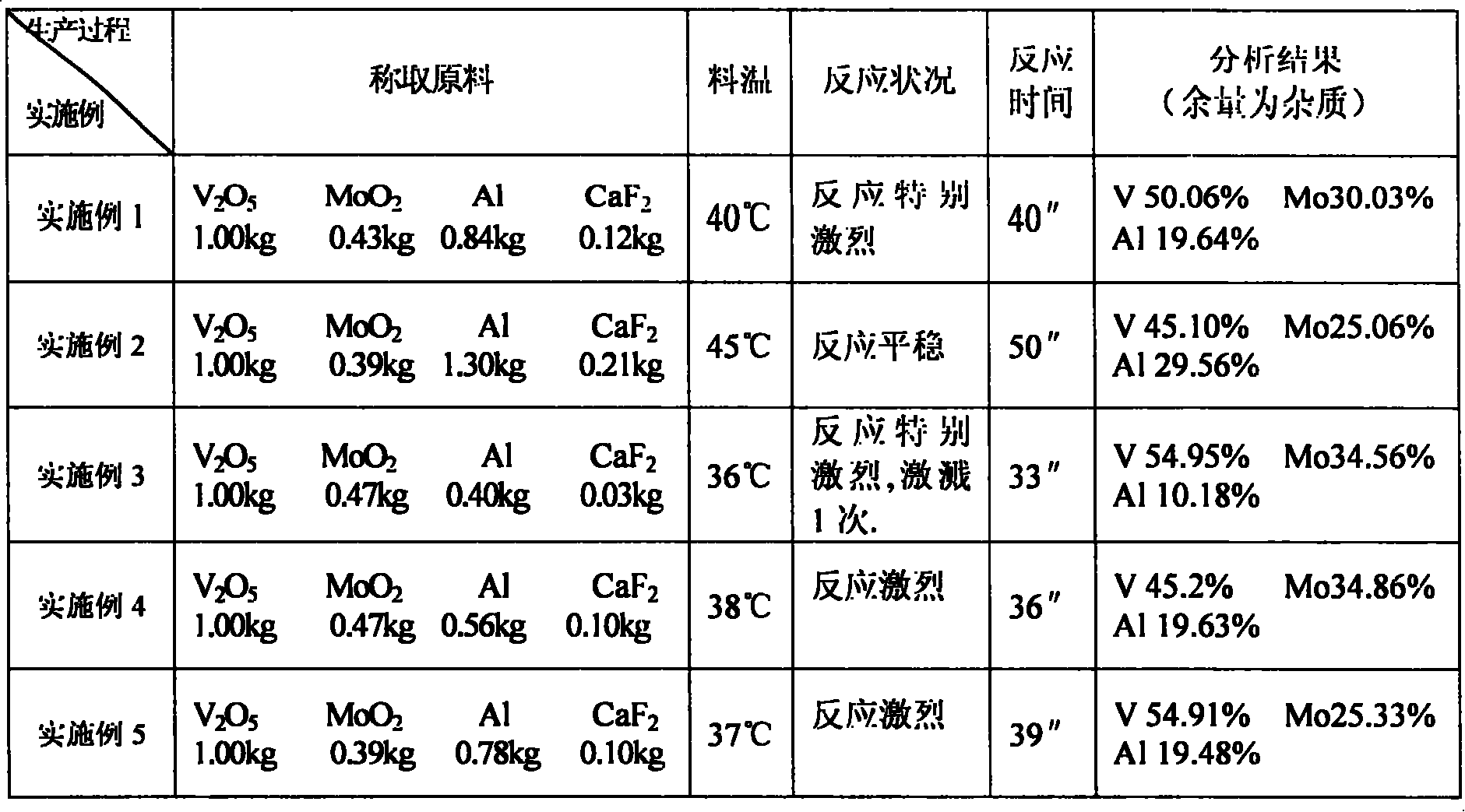

Intermediate alloy of aluminum, vanadium and molybdenum, and method for producing the same

The invention relates to the preparation of titanium alloy, in particular to aluminum-vanadium-molybdenum master alloy and the preparation method thereof. The alloy is composed of the following components calculated according to the weight percentage: V is 45 to 55 percent, Mo is 25 to 35 percent, and the residual is Al. The preparation process comprises the following steps: an outside-furnace ignition smelting method is adopted, the preparation is operated according to the conventional steps, the raw material drying temperature is 70 to 80 DEG C, the drying time is not less than 24 hours; the blending weight of the composition comprises that V2O5 is 1.00 kg, MoO2 is 0.39 to 0.47 kg, Al is 0.40 to 1.30 kg, CaF2 is 0.03 to 0.21 kg; the raw material charging temperature is 30 to 60 DEG C, the reaction is steady, and the alloy formation is good. The invention has the advantages that the invention is convenient for the preparation of the titanium alloy, the cost is low, and the alloying is even; the oxidation resistant performance is good, the alloy is easy to be stored and transported, and easy to be crushed.

Owner:张忠世

An Al-Nb-Ta intermediate alloy and process for preparing same

The invention relates to the preparation of titanium alloy, more specifically an Al-Nb-Ta intermediate alloy for titanium alloy preparation and process for preparing the same, wherein the constituents (by weight percent) of the alloy include, Al 19-28%, Ta 23-27%, and balancing Nb. The preparing process comprises, employing furnace outside ignition smelting method, operating according to routine procedures, the raw material drying temperature being 70-80 deg. C, the drying time no less than 24 hours, calculated based on 1kg of Nb2O5, the charged mixture includes, Ta2O5 0.383-0.42kg, Al 0.75-0.913kg, CaF2 0.15-0.20kg, KCLO3 0.30-0.40kg, the raw material shoving temperature being 30-60 deg. C. The advantages of the invention include facilitated preparation of titanium alloy, low making cost, homogeneous alloying, good oxidation resistance, easy storing, transport and fragmenting.

Owner:忠世高新材料股份有限公司

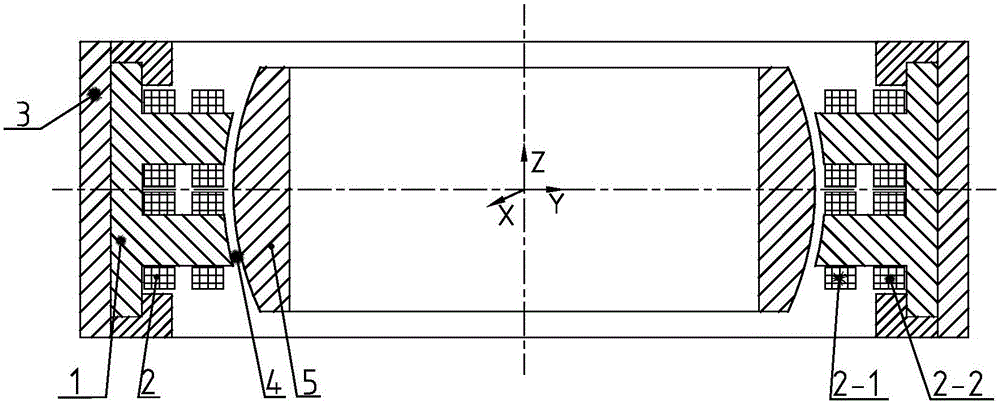

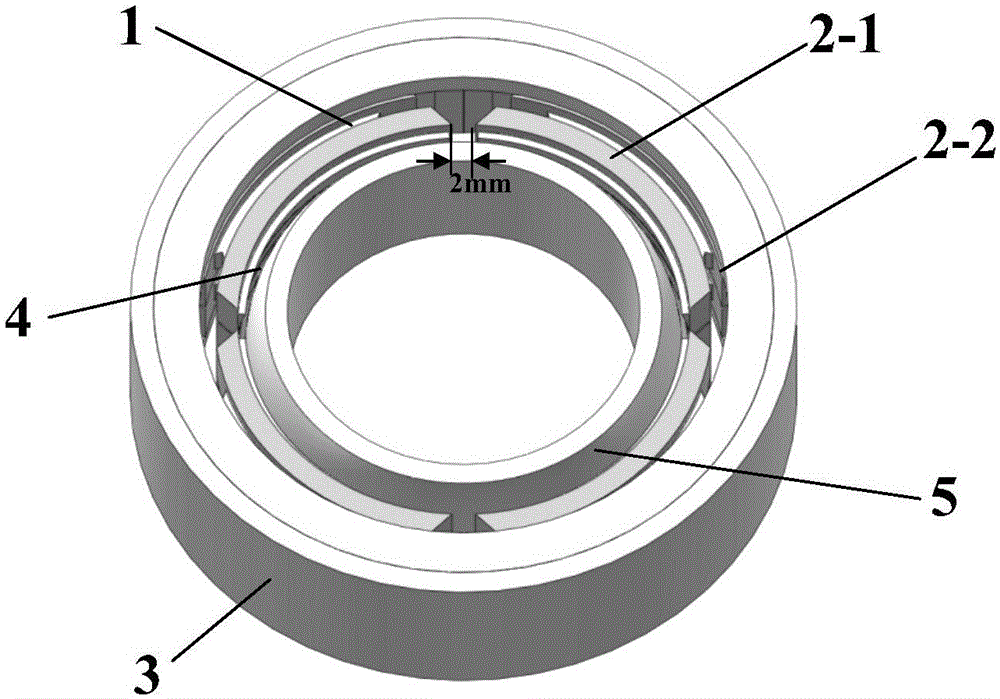

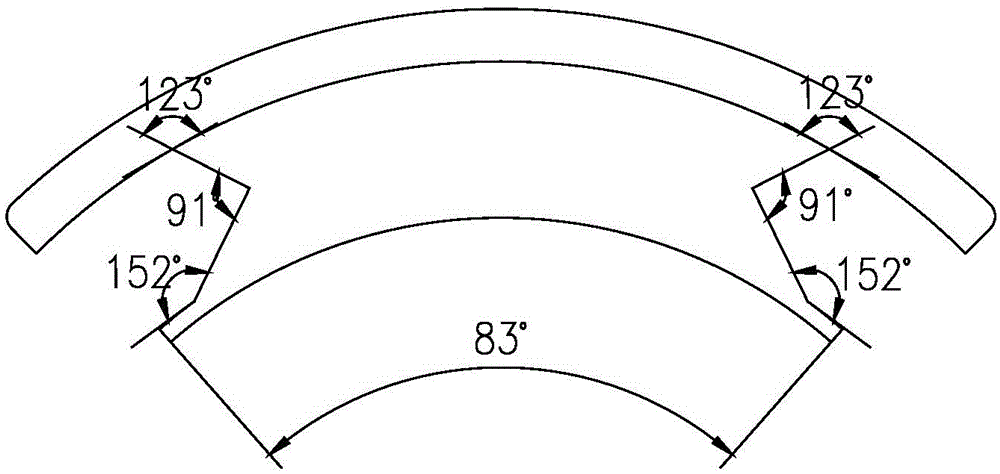

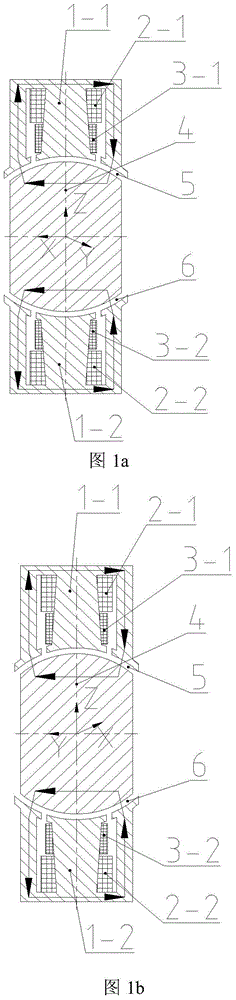

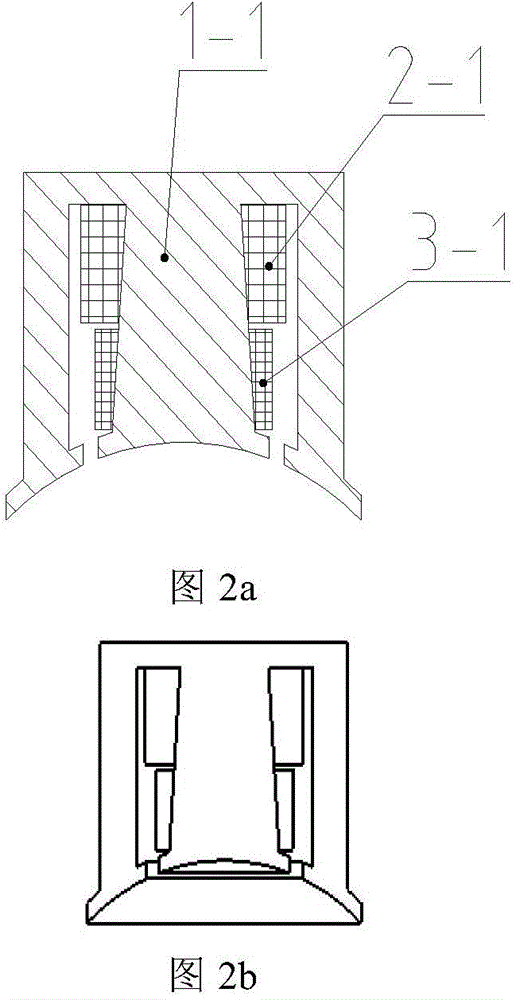

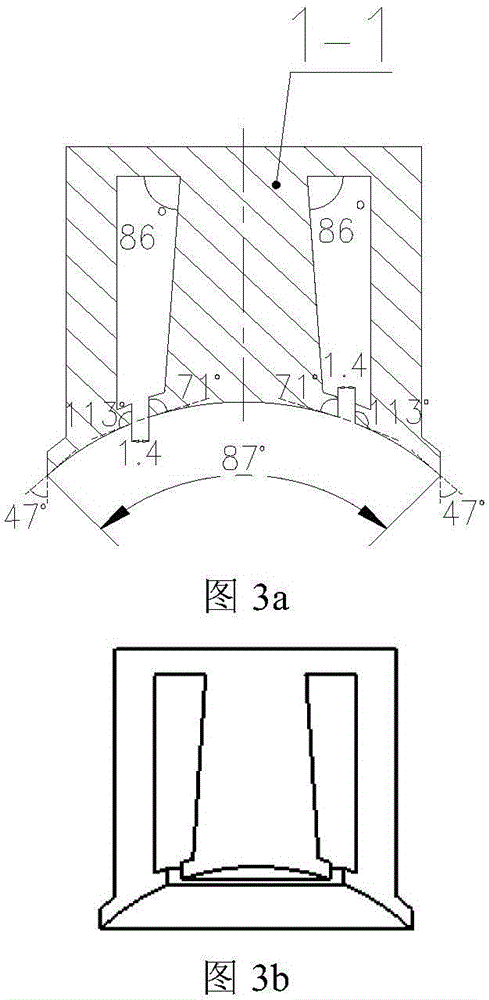

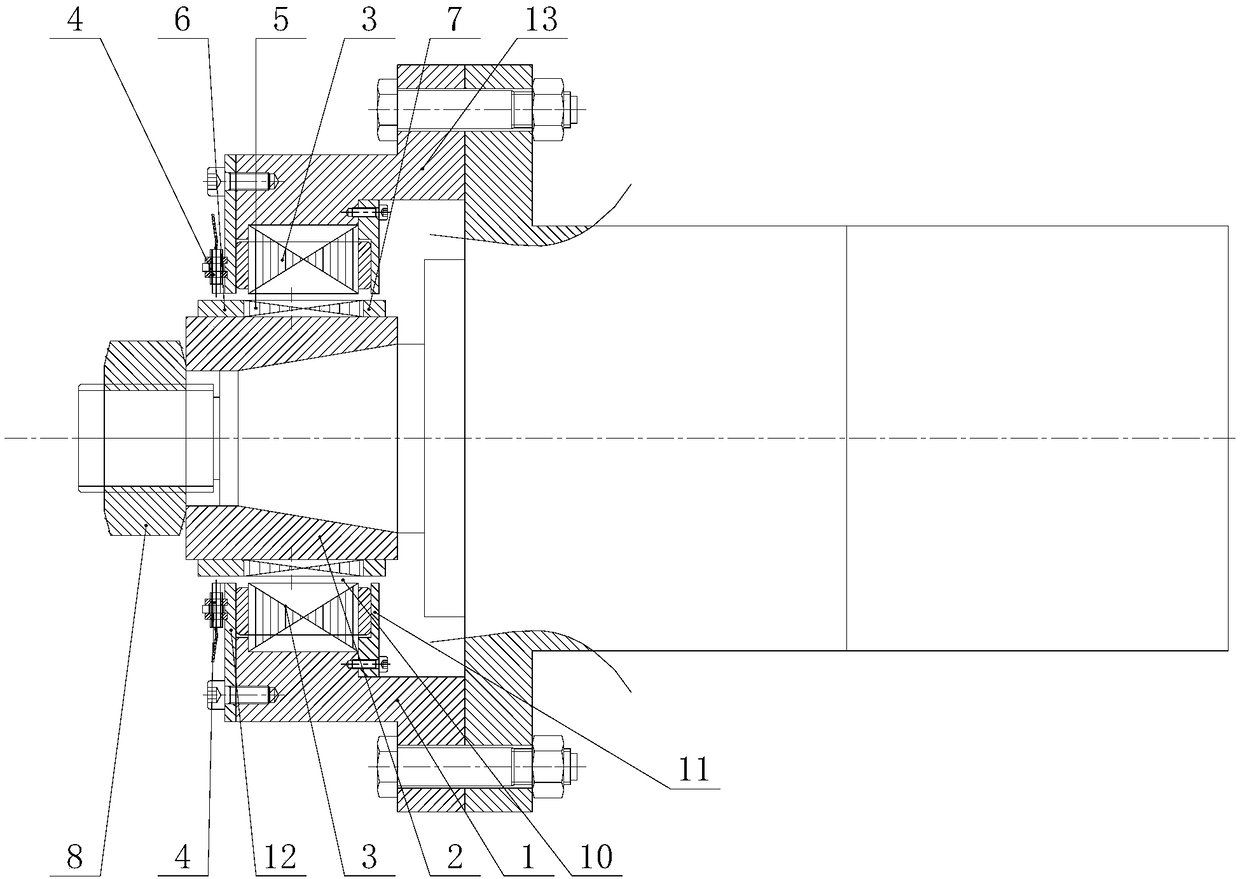

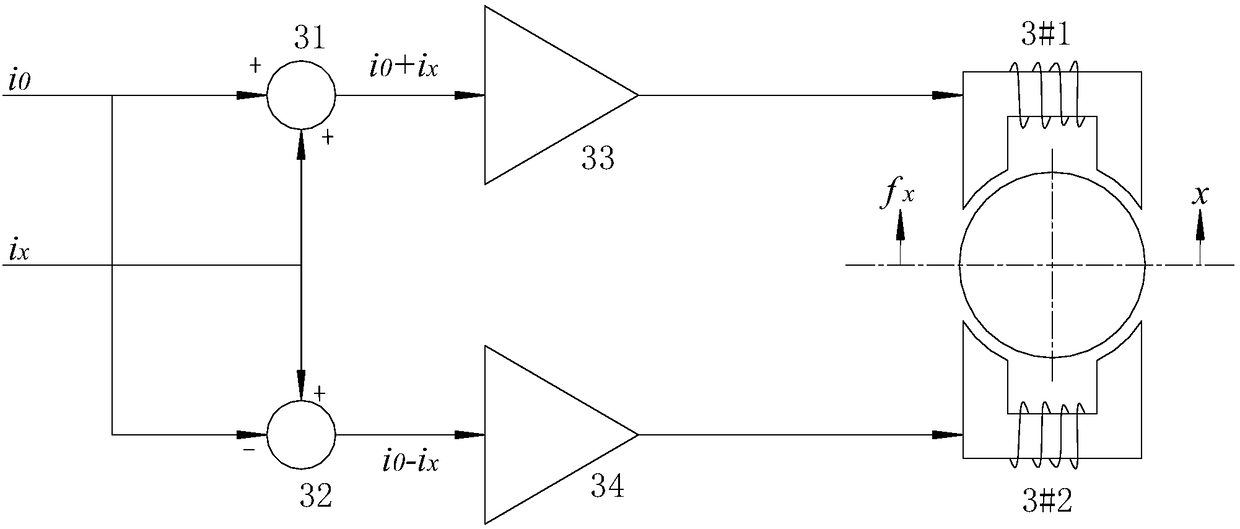

Double-coil radial and spherical pure-electromagnetic bearing

ActiveCN105156474AUniform magnetic densityHigh control precisionBearingsElectricityMagnetic tension force

The invention discloses a double-coil radial and spherical pure-electromagnetic bearing. The double-coil radial and spherical pure-electromagnetic bearing mainly comprises four stator cores arranged in the + / - X direction and the + / - Y direction, a first coil, a second coil, a sleeve, an air gap and a rotor. By adopting the spherical magnetic bearing structure, the electromagnetic force exerted on a rotation shaft always passes through the sphere center, when the sphere center of the rotation shaft coincides with the mass center, the torque generated by the electromagnetic force relative to the rotation shaft is zero, and therefore interference of radial twisting to axial translation is removed. In addition, by adopting the specific pole shoe structure in the stator cores, magnetic field distribution is more uniform in the peripheral direction; the double-coil structure is adopted in field coils of the stator cores, the turns of the two coils are different, the current of the coil smaller in turn is controllable, the current of the coil higher in turn is unchangeable, and the current response rate is increased compared with the single-coil structure; the differential mode is adopted in the controllable current, so that the control accuracy of the magnetic bearing is further improved.

Owner:BEIHANG UNIV

An Al-Ti-Nb intermediate alloy and process for preparing same

The invention relates to the preparation of titanium alloy, more specifically an Al-Ti-Nb intermediate alloy for titanium alloy preparation and process for preparing the same, wherein the constituents (by weight percent) of the alloy include, Al 2-10%, Si 3-30%, and balancing Nb. The preparing process comprises, employing furnace outside ignition smelting method, operating according to routine procedures, the raw material drying temperature being 70-80 deg. C, the drying time no less than 24 hours, calculated based on 1kg of Nb2O5, the charged mixture includes, TiO2 0.25-0.66kg, Al 0.115-0.46kg, CaF2 0.05-0.10kg, KclO3 0.07-0.12 kg, the raw material shoving temperature being 30-60 deg. C. The advantages of the invention include facilitated preparation of titanium alloy, low making cost, homogeneous alloying, good oxidation resistance, easy storing, transport and fragmenting.

Owner:张忠士

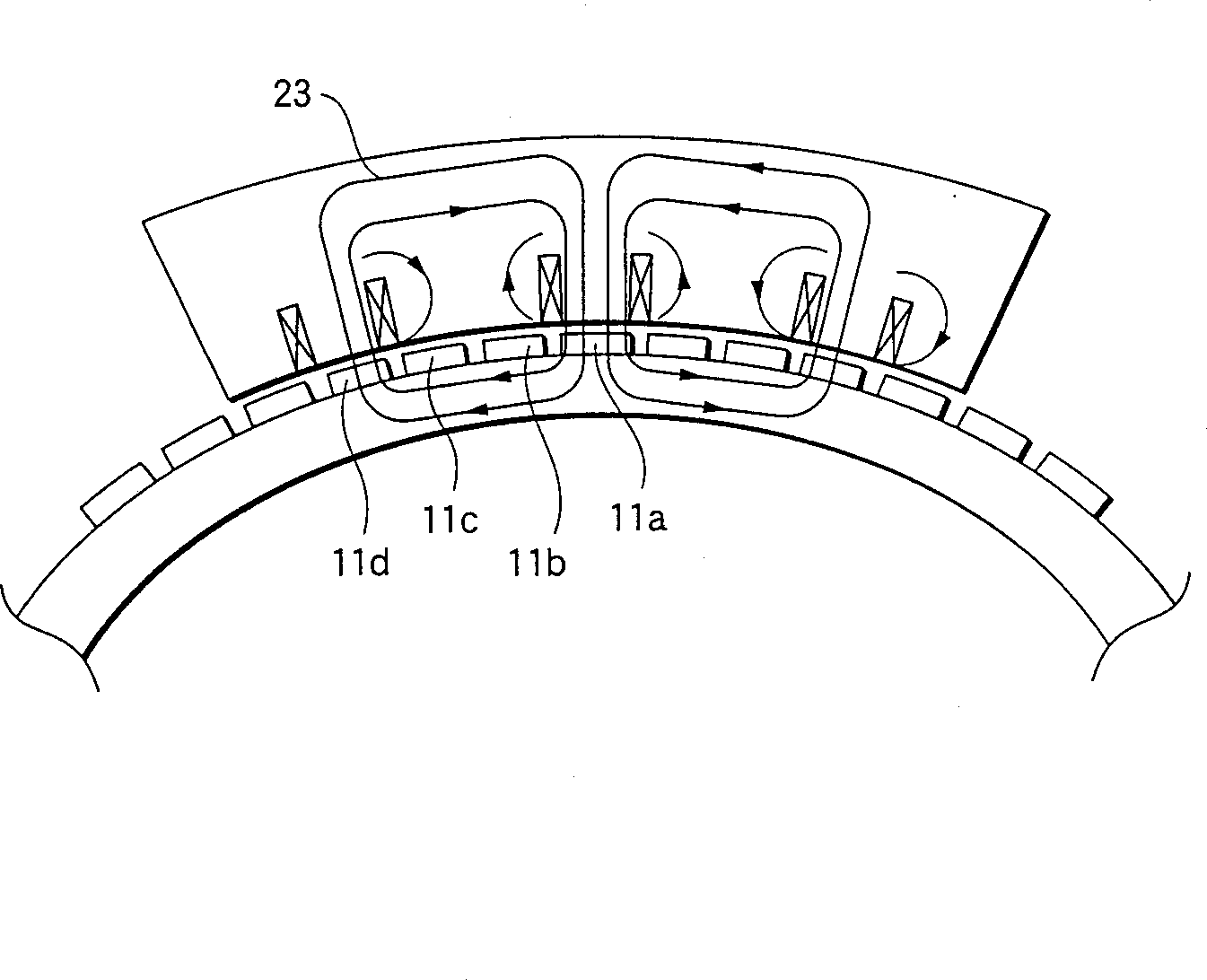

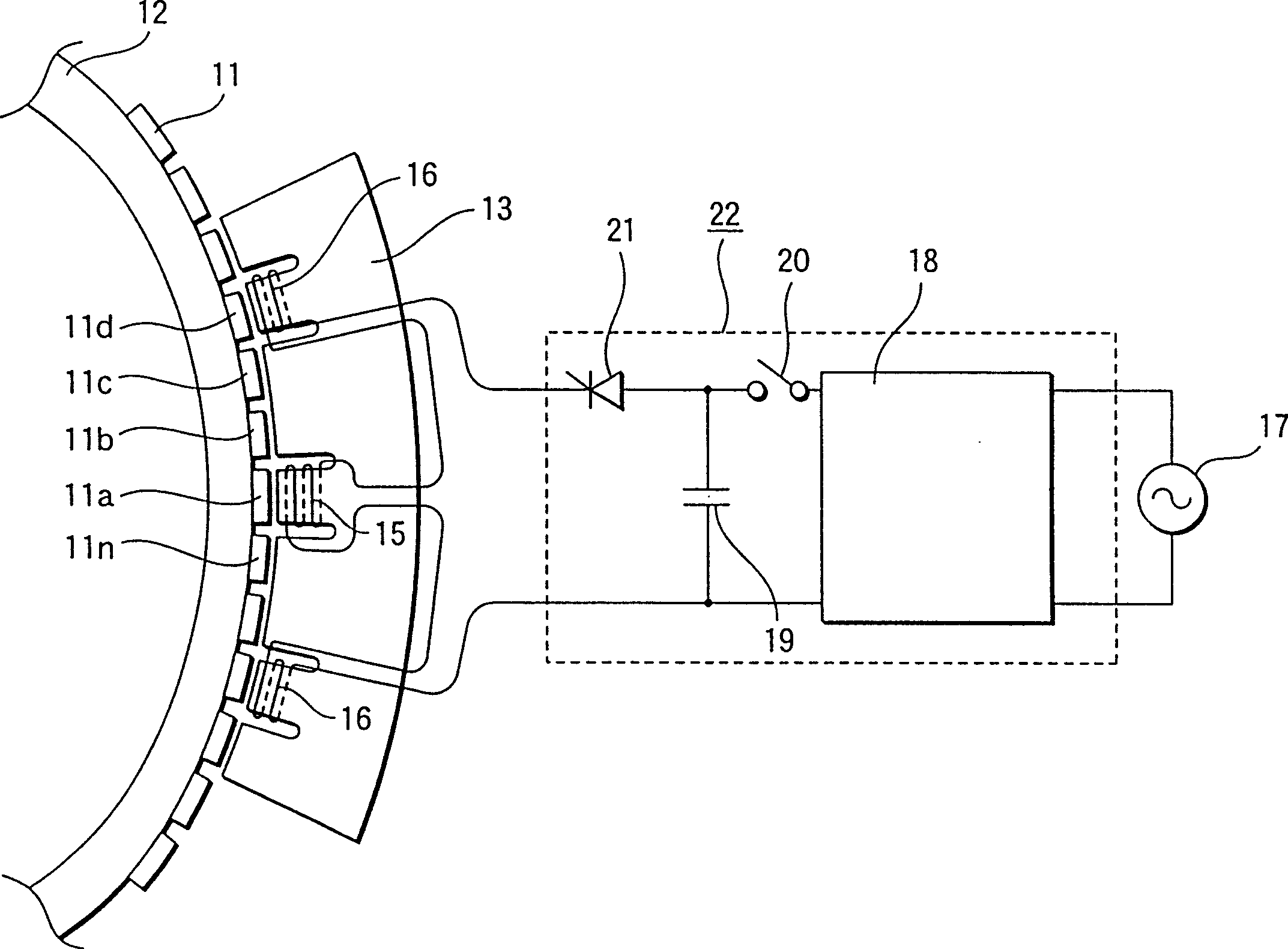

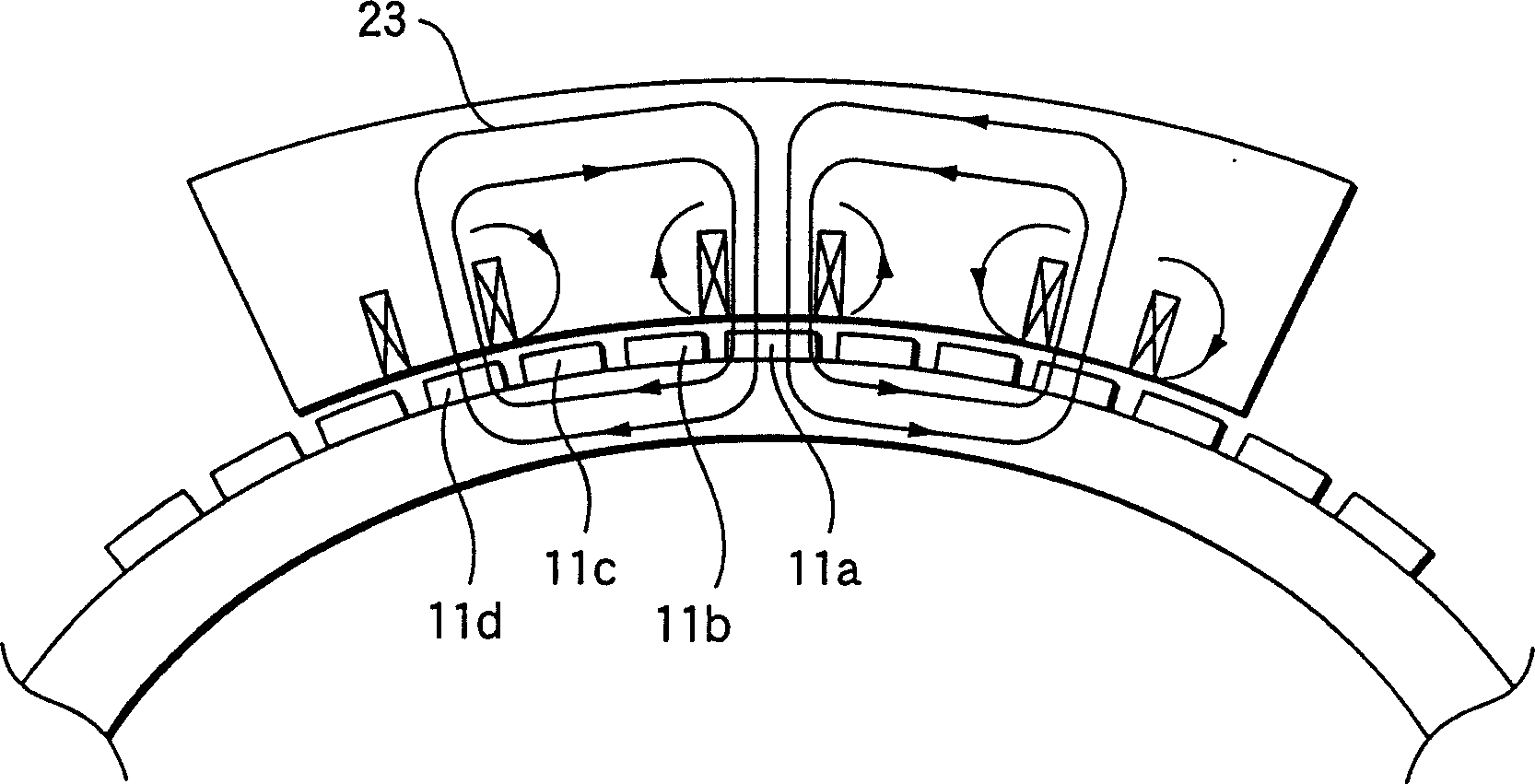

Polarizing device for permanent magnet rotor

InactiveCN1338807AEliminates the effects of reverse magnetic fieldsCurrent controllableMagnetic bodiesManufacturing stator/rotor bodiesPhysicsPermanent magnet rotor

A polarizing device includes: a polarizing iron core (13) facing to a specified number of permanent magnets (11) among plural unmagnetized permanent magnets (11) arranged at specified intervals circumferentially on a rotor (12); a first coil (15) wound at a position facing to a desired permanent magnet (11a) of the polarizing iron core (13); a pair of second coils (16) each arranged having a specified interval according to the first coil (15) circumferentially on the polarizing iron core (13) and whose direction of the flowing current is different from that of the first coil (15); and a power source (22) for supplying the current to the first and second coils (15, 16), and either of the permanent magnet (11a) and first coil (15) is relatively moved and each permanent magnet (11) is magnetized to form a magnetic pole in turn by the current fed from the power source (22).

Owner:MITSUBISHI ELECTRIC CORP

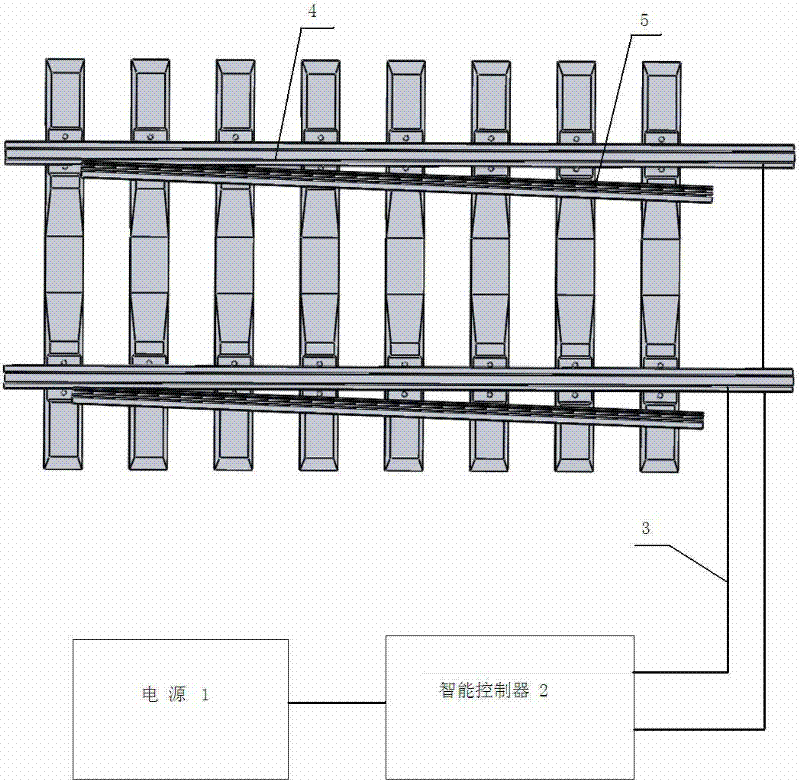

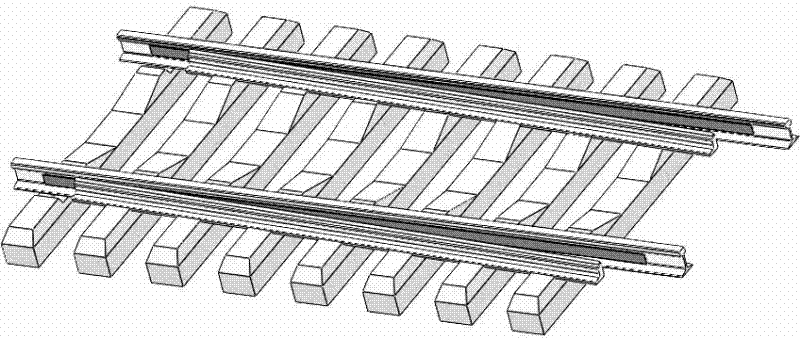

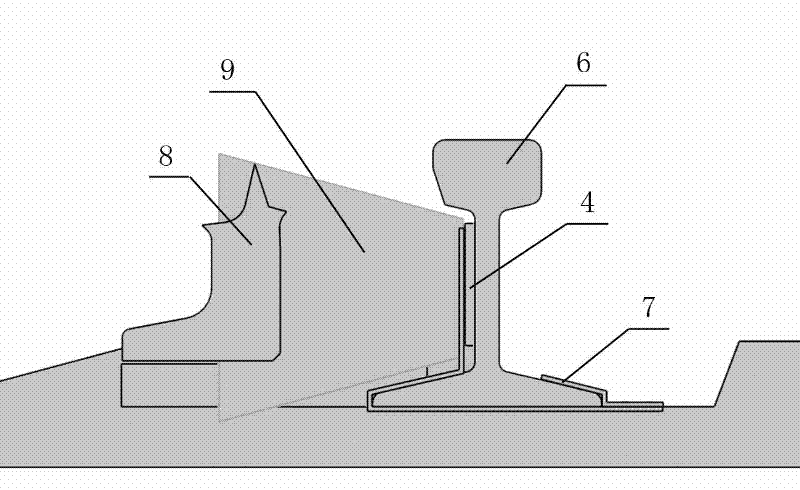

Radiant railway switch de-icing/snow removing system

ActiveCN102444058AOutput voltage controllableCurrent controllableRail switchesClimate change adaptationSnow removalThermal energy

The invention relates to a railway switch anti-ice / snow solution for automatically melting down ice and snow at the closely jointed parts of a switch. A radiant railway switch de-icing / snow removing system comprises an intelligent power source, an intelligent controller and a radiator, wherein the intelligent power source is connected to the radiator through the intelligent controller and a buried cable; the radiator is arranged inside after a switch stock rail and a point rail are closed up; the radiator is fastened to the rail web of the switch stock rail by means of a clamp; and the radiator is started according to an instruction to directly melt down accumulated snow at the closely jointed parts of the switch by means of the infrared radiation heating technology. The device of the system is simple and convenient to mount without interference with any other railway electrical system; the working time is short; heat energy conversion and de-icing and snow removal efficiencies are high; and in the working process, reliable de-icing and snow removal at the closely jointed parts of the switch can be ensured; therefore, turn-out and locking of the switch in place are ensured and railway transportation is normal.

Owner:孙健

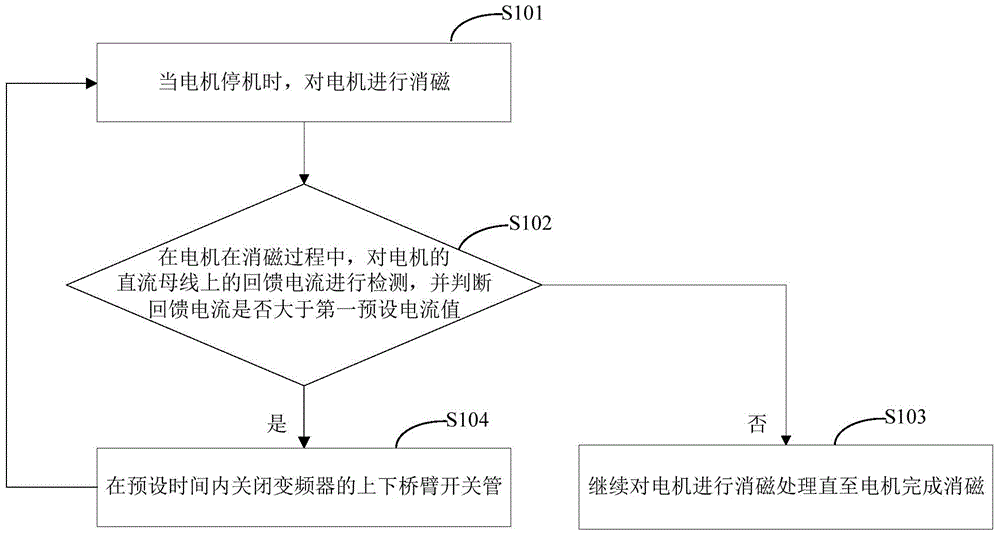

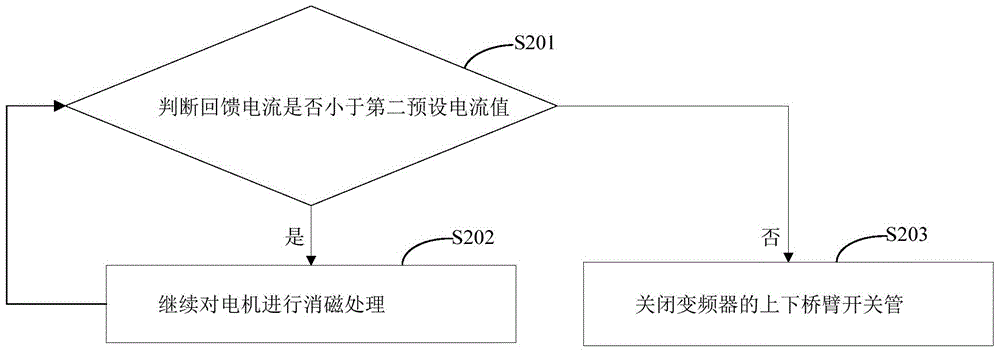

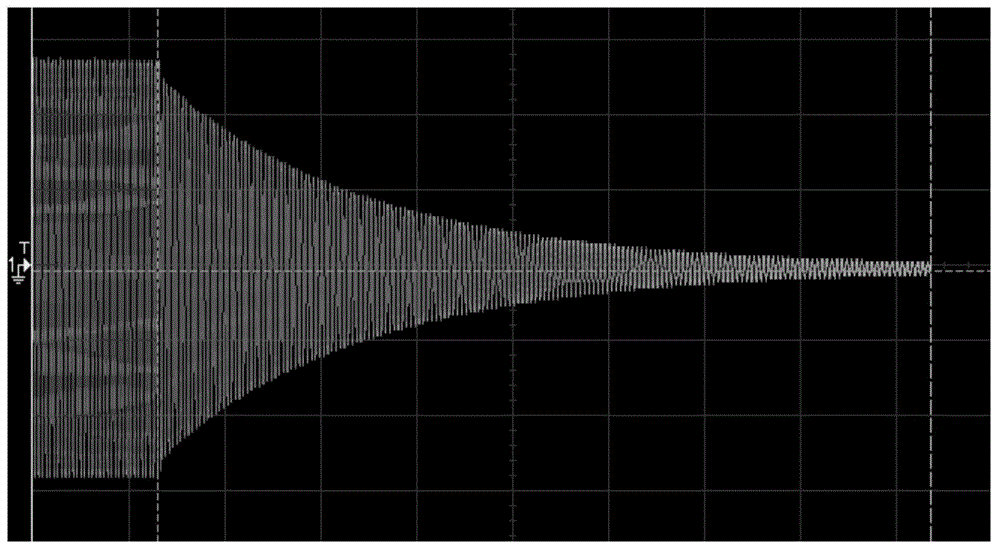

Motor demagnetization method and apparatus

ActiveCN105281634AReduce waiting timeImprove reliabilityMotor parameters estimation/adaptationFrequency changerDC-BUS

The invention relates to the technical field of motor demagnetization and provides a motor demagnetization method and apparatus. The motor demagnetization method comprises the following steps of: demagnetizing a motor when the motor is shut down; in a motor demagnetization process, detecting feedback current on a DC bus of the motor and determining whether the value of the feedback current is greater than a first preset current value; when the value of the feedback current is less than the first preset current value, continuing demagnetizing the motor until the demagnetization of the motor finishes; when the value of the feedback current is greater than the first preset current value, switching off the switch tubes of the upper bridge arm and the lower bridge arm of a frequency converter within preset time, and executing the above steps cyclically until the demagnetization of the motor finishes. The method and the apparatus achieve controllable motor demagnetization time and current and may manually set demagnetization time as required. The demagnetized motor fast enters a rotating speed tracking state and thus, not only is rotating speed tracking waiting time shorten, but also the reliability of rotating speed tracking is improved.

Owner:SUZHOU WEICHUANG ELECTRICAL EQUIP TECH

An Al-Nb intermediate alloy and process for preparing same

The invention relates to the preparation of titanium alloy, more specifically an Al-Nb intermediate alloy for titanium alloy preparation and process for preparing the same, wherein the constituents (by weight percent) of the alloy include, Al 15-55%, and balancing Nb. The preparing process comprises, employing furnace outside ignition smelting method, operating according to routine procedures, the raw material drying temperature being 70-80 deg. C, the drying time no less than 24 hours, calculated based on 1kg of Nb2O5, the charged mixture includes, Al 0.423-1.07kg, CaF2 0.07-0.16kg, KCLO3 0.065-0.28kg, the raw material shoving temperature being 30-60 deg. C. The advantages of the invention include facilitated preparation of titanium alloy, low making cost, homogeneous alloying, good oxidation resistance, easy storing, transport and fragmenting.

Owner:张忠士

An Al-Mo-V-Fe intermediate alloy and process for preparing same

The invention relates to the preparation of titanium alloy, more specifically an Al-Mo-V-Fe intermediate alloy for titanium alloy preparation and process for preparing the same, wherein the constituents (by weight percent) of the alloy include, Al 5.5-17.2%, V 35-39%, Fe 3.8-5.5%, and balancing Mo. The preparing process comprises, employing furnace outside ignition smelting method, operating according to routine procedures, the raw material drying temperature being 70-80 deg. C, the drying time no less than 24 hours, calculated based on 1kg of MoO3, the charged mixture includes, V2O3 0.879-0.979kg, Fe 0.047-0.069%, Al 0.69-1.457kg, CaF2 0.05-0.4kg, KCLO3 0.14-0.20%, the raw material shoving temperature being 30-60 deg. C. The advantages of the invention include facilitated preparation of titanium alloy, low making cost, homogeneous alloying, good oxidation resistance, easy storing, transport and fragmenting.

Owner:忠世高新材料股份有限公司

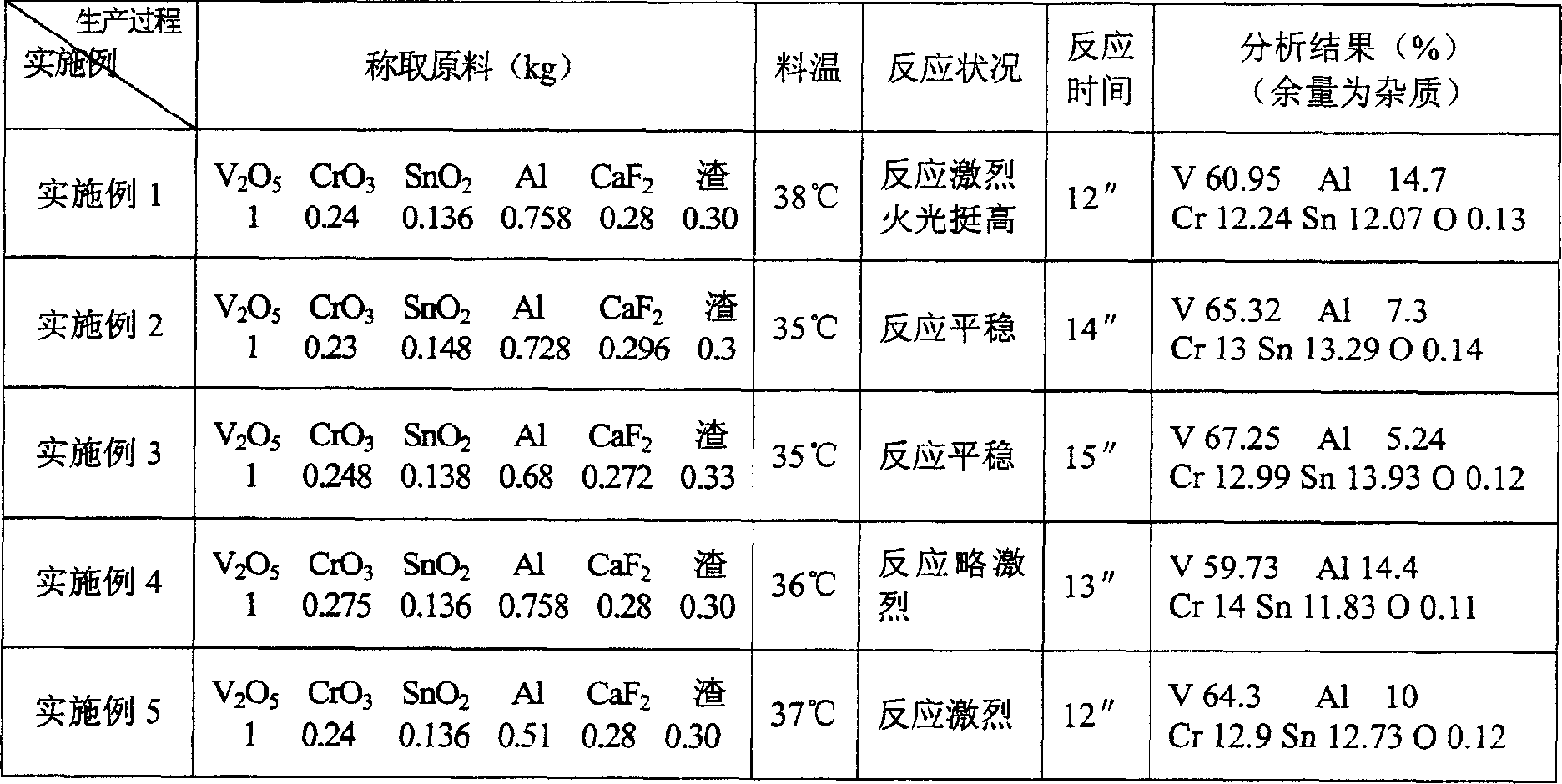

A V-Al-Sn-Cr intermediate alloy and process for preparing same

The invention relates to the preparation of titanium alloy, more specifically an V-Al-Sn-Cr intermediate alloy for titanium alloy preparation and process for preparing the same, wherein the constituents (by weight percent) of the alloy include, Al 5.5-13.5%, Sn 11-14%, Cr 11-14%, and balancing V. The preparing process comprises, employing furnace outside ignition smelting method, operating according to routine procedures, calculated based on 1kg of V2O5, the charged mixture includes, Al 0.51-0.758kg, SnO2 0.136-0.148 kg, CrO3 0.23-0.275kg, CaF2 0.2-0.3kg, furnace slag 0.25-0.35kg (produced during vanadium-chrome-aluminum alloy smelting), the raw material shoving temperature being 30-60 deg. C. The advantages of the invention include facilitated preparation of titanium alloy, low making cost, homogeneous alloying, good oxidation resistance, easy storing, transport and fragmenting.

Owner:张忠士

Double-coil axial spherical surface pure electromagnetic bearing

ActiveCN104948583AHigh control precisionGood circumference uniformityBearingsMagnetic tension forceElectricity

A double-coil axial spherical surface pure electromagnetic bearing is mainly composed of a stator system and a rotating shaft. The stator system mainly comprises an upper stator iron core, a lower stator iron core and exciting coils. An upper spherical surface magnetic bearing and a lower spherical surface magnetic bearing are adopted, and electromagnetic force borne by the rotating shaft passes through a sphere center all the time; when the sphere center of the rotating shaft coincides with a mass center, torque generated by the electromagnetic force relative to the rotating shaft is zero, and therefore the disturbance of radial twisting to axial translational motion is eliminated; in addition, pole shoe structures are adopted in the upper stator iron core and the lower stator iron core, and magnetic field distribution on the circumference is more even; double-coil structure is adopted in the exciting coils of the upper stator iron core and the lower stator iron core, and the numbers of turns of the two coils are different; and the coil with the small turn number is controllable in current, and the coil with the large turn number is constant in current; compared with a single-coil structure, the current response rate is improved, the differential manner is adopted in the controllable current, and the control precision of the magnetic bearings is further improved.

Owner:UNIV OF SCI & TECH BEIJING

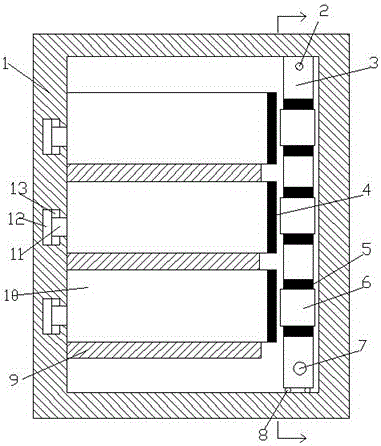

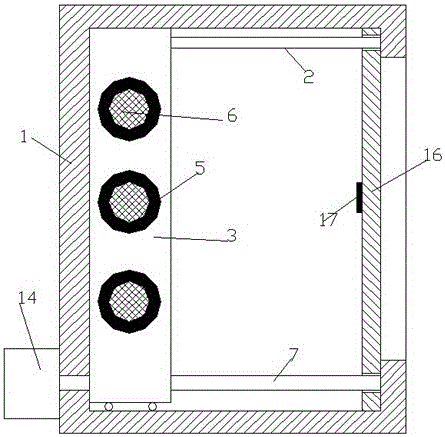

Power drawer device

InactiveCN106329375ACurrent controllableCurrent size can be controlledSwitchgear with withdrawable carriageEngineeringPower component

The invention discloses a power drawer device, comprising a drawer body, and multiple horizontal fixing plates fixedly installed in the drawer, wherein the drawer body for installing power components is installed on each horizontal fixing plate in sliding; sliding arms are fixedly installed at the left end of the drawer body; multiple sliding grooves extended forward and backward are formed in the left end wall of the drawer body; communicated grooves communicated with the drawer body are formed in the right ends of the sliding grooves; sliding blocks are installed in the sliding grooves; the sliding arms penetrate through communicated grooves and are fixedly connected with the sliding blocks; guide slide bars are fixedly installed between the front end wall and the back end wall at the upper end of the drawer body; screw thread drive rods are installed between the front end wall and the rear end wall at the lower end of the drawer body in a rotary way; front and rear drive plates are installed on the guide slide bars; the lower ends of the front and rear drive plates are in screw thread fit with the screw thread drive rods, so that the front and rear drive plates can slide forward and backward through the screw thread drive rods.

Owner:广州广缆义明电气有限公司

An Al-Mo-Cr-Fe-Si intermediate alloy and process for preparing same

The invention relates to the preparation of titanium alloy, more specifically an Al-Mo-Cr-Fe-Si intermediate alloy for titanium alloy preparation and process for preparing the same, wherein the constituents (by weight percent) of the alloy include, Al 11.4-35%, Cr 20-28%, Fe 6-10%, Si 4.0-5.6%, and balancing Mo. The preparing process comprises, employing furnace outside ignition smelting method, operating according to routine procedures, the raw material drying temperature being 70-80 deg. C, the drying time no less than 24 hours, calculated based on 1kg of MoO3, the charged mixture includes, CrO3 0.71-0.99kg, Fe 0.20-0.33kg, Si 0.046-0.065kg, Al 0.663-1.92kg, CaF2 0.05-0.4kg, the raw material shoving temperature being 30-60 deg. C.

Owner:忠世高新材料股份有限公司

An Al-Mo-Si intermediate alloy and process for preparing same

The invention relates to the preparation of titanium alloy, more specifically an Al-Mo-Si intermediate alloy for titanium alloy preparation and process for preparing the same, wherein the constituents (by weight percent) of the alloy include, Mo 38-48%, Si 3.5-4.5%, and balancing Al. The preparing process comprises, employing furnace outside ignition smelting method, operating according to routine procedures, the raw material drying temperature being 70-80 deg. C, the drying time no less than 24 hours, calculated based on 1kg of Al, the charged mixture includes, industrial Si 0.034-0.044kg, MoO3 0.781-0.935kg, CaF2 0.36-0.42kg, KCLO3 0.149-0.174kg, the raw material shoving temperature being 30-60 deg. C. The advantages of the invention include facilitated preparation of titanium alloy, low making cost, homogeneous alloying, good oxidation resistance, easy storing, transport and fragmenting.

Owner:忠世高新材料股份有限公司

A V-Al-Cr-Mo intermediate alloy and process for preparing same

The invention relates to the preparation of titanium alloy, more specifically an V-Al-Cr-Mo intermediate alloy for titanium alloy preparation and process for preparing the same, wherein the constituents (by weight percent) of the alloy include, Al 10%, Mo 22%, Cr 30%, and balancing V. The preparing process comprises, employing furnace outside ignition smelting method, operating according to routine procedures, calculated based on 1kg of V2O5, the charged mixture includes, CrO3 0.808-1.64kg, MoO3 0.136-0.42kg, Al 0.958-2.87kg, CaF2 0.03-0.08kg, furnace slag 0-0.20kg (produced during vanadium-chrome-aluminum alloy smelting), the raw material shoving temperature being 30-60 deg. C. The advantages of the invention include facilitated preparation of titanium alloy, low making cost, homogeneous alloying, good oxidation resistance, easy storing, transport and fragmenting.

Owner:张忠士

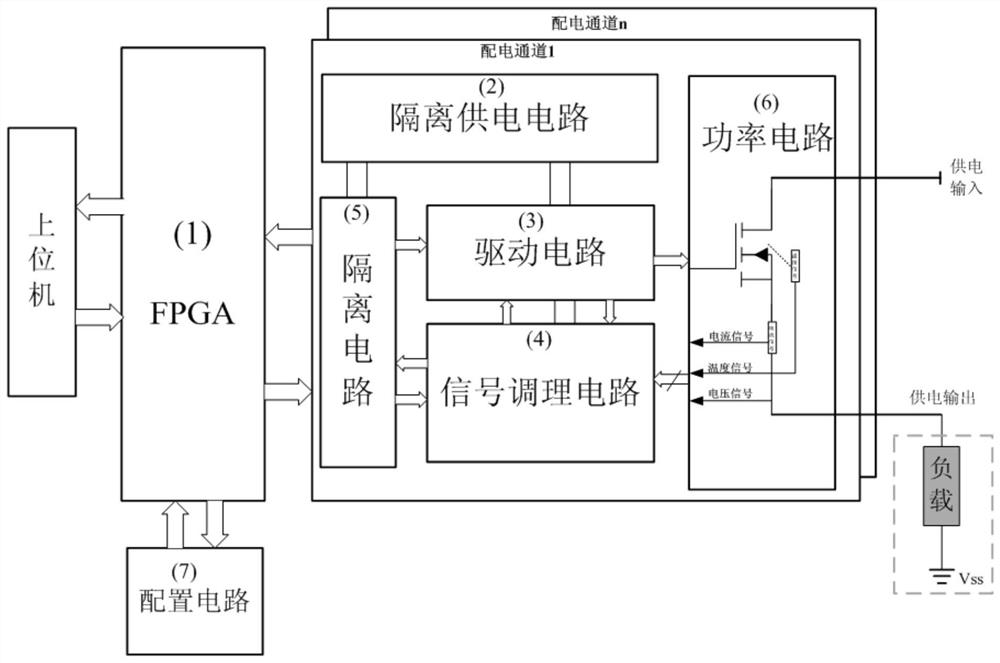

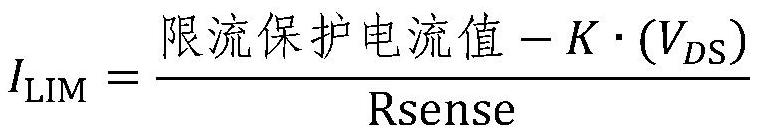

FPGA-based configurable digital solid-state power distribution system

ActiveCN113655739AIncrease loading capacityImprove reliabilityProgramme controlComputer controlElectronic switchDistribution system

The invention relates to a brand-new FPGA-based configurable digital solid-state power distribution system, which has the advantages of configurable key characteristic parameters and programmable protection characteristics, avoids the influence on the application range of application due to the limitation of load characteristics on power distribution caused by fixed key parameters, fixed protection characteristics and the like, has a reconfigurable function and can realize selection of protection characteristics, so that different solid-state electronic switch types are reconstructed, and application working condition limitation and application range limitation caused by a single solid-state power distribution mode are avoided.

Owner:BEIJING SATELLITE MFG FACTORY

Rotation-modulation radial spherical pure electromagnetic bearing

The invention relates to a rotation-modulation radial spherical pure electromagnetic bearing which mainly comprises four stator cores, coils, sleeves, air gaps, rotors, a stator installation disk, a rotation-modulation rotor bearing sleeve, a rotation-modulation bearing, a rotation-modulation rotor lock nut, an ultrasonic motor rotor, an ultrasonic motor stator, a rotation-modulation stator bearing sleeve and a rotation-modulation stator lock nut, wherein the four stator cores are placed along the positive and negative X direction and the positive and negative Y direction. The stator of the radial spherical pure electromagnetic bearing is driven by an ultrasonic motor, so that the rotation of the stator is realized, a rotation-modulation function is realized, gyro drift caused by the rotation of a gyrorotor can be eliminated, and the detection precision during angular rate detection is greatly increased.

Owner:UNIV OF SCI & TECH BEIJING +1

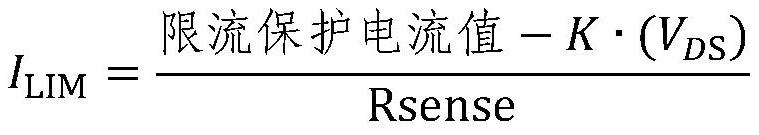

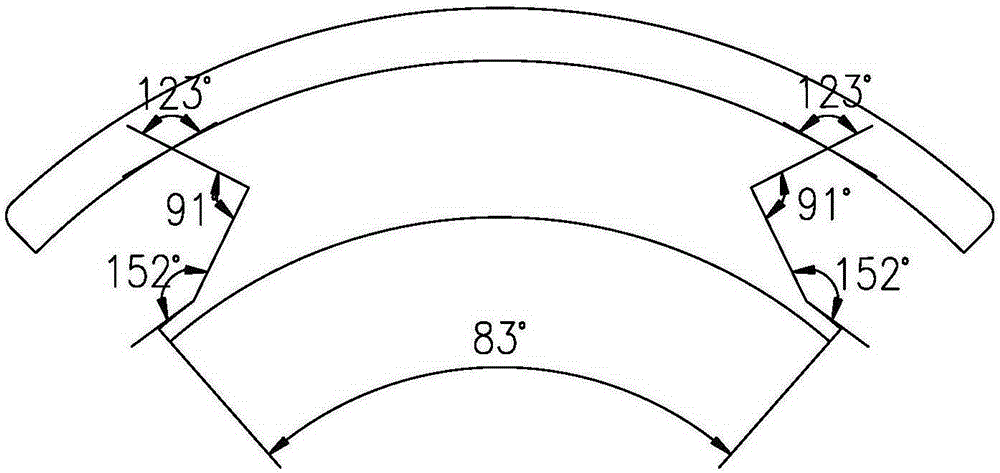

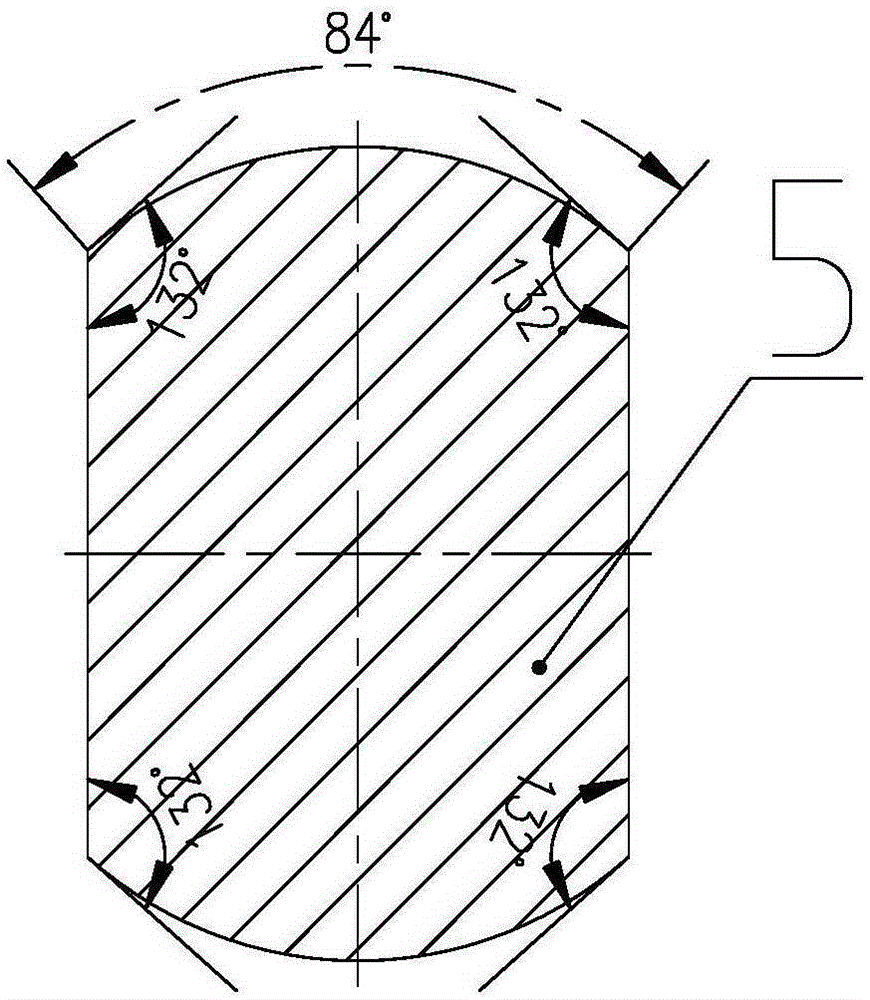

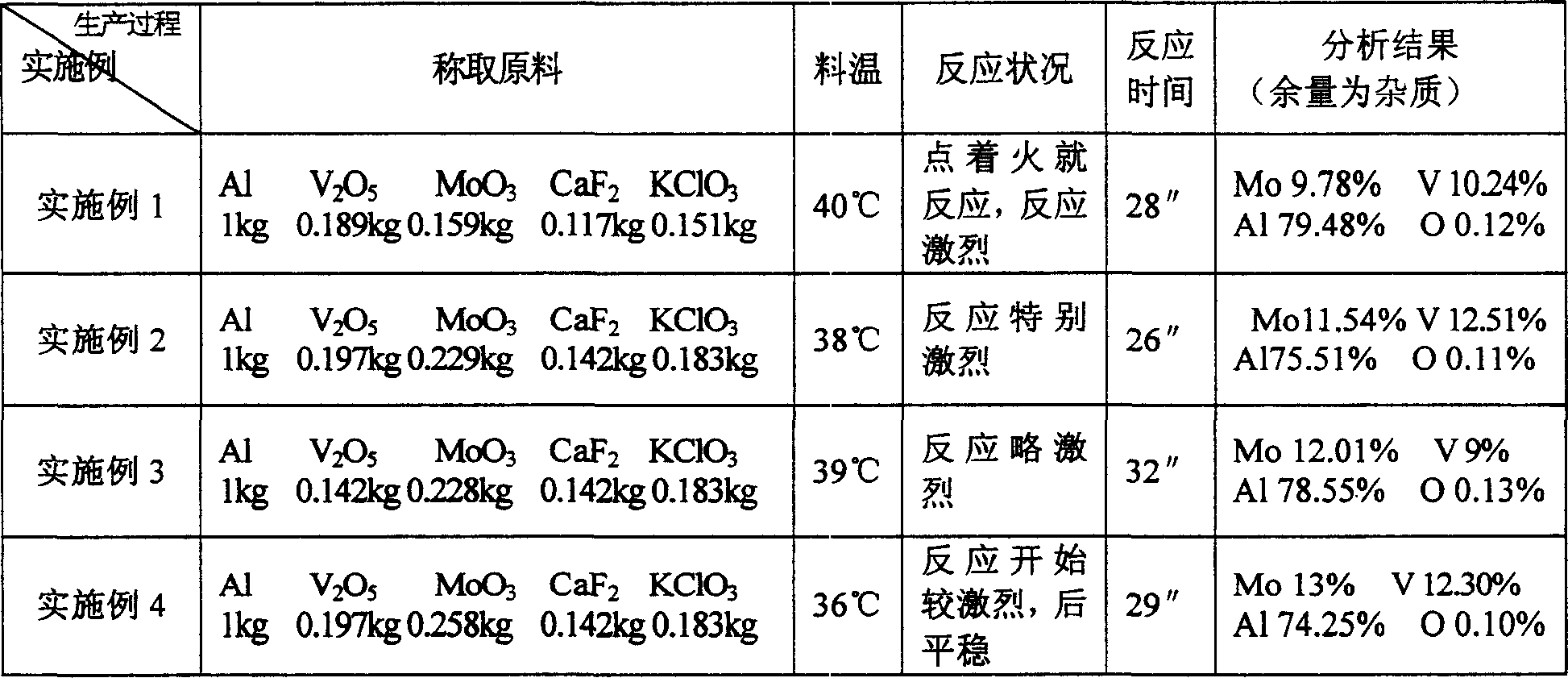

An Al-Mo-V intermediate alloy and process for preparing same

The invention relates to the preparation of titanium alloy, more specifically an Al-Mo-V intermediate alloy for titanium alloy preparation and process for preparing the same, wherein the constituents (by weight percent) of the alloy include, Mo 9-13%, V 9-13%, and balancing Al. The preparing process comprises, employing furnace outside ignition smelting method, operating according to routine procedures, the raw material drying temperature being 70-80 deg. C, the drying time no less than 24 hours, calculated based on 1kg of Al, the charged mixture includes, V2O5 0.142-0.197kg, MoO3 0.159-0.258kg, CaF2 0.117-0.142kg, KClO3 0.151-0.183kg, the raw material shoving temperature being 30-60 deg. C. The advantages of the invention include facilitated preparation of titanium alloy, low making cost, homogeneous alloying, good oxidation resistance, easy storing, transport and strong tenacity.

Owner:忠世高新材料股份有限公司

A V-Al-Fe intermediate alloy and process for preparing same

Owner:忠世高新材料股份有限公司

High speed rotating shafting dynamic radial loading stiffness test method and device

ActiveCN108414202AReduce non-linearityEvenly loadedMachine part testingRotational axisDynamic stiffness

The invention discloses a high speed rotating shafting dynamic radial loading stiffness test method and device. The method comprises the steps that driving current is outputted to electromagnetic windings; the driving current and the radial displacement outputted by a displacement sensor are recorded; the radial displacement of the rotating spindle and the radial magnetic attraction force appliedto the rotating spindle are determined; and the specific value of the radial magnetic attraction force applied to the rotating spindle to the radial displacement of the rotating spindle is calculatedas the first dynamic stiffness and / or the specific value of the Fourier transform results of the radial magnetic attraction force and the radial displacement is calculated as the second dynamic stiffness. The device comprises a stator fixing base and a rotor clamp. An accommodating hole, the displacement sensor and two electromagnetic windings symmetrically arranged relative to the rotor clamp arearranged on the stator fixing base. The rotor clamp is arranged in the accommodating hole. The external wall of the rotor clamp is provided with a silicon steel rotor which is arranged between the two electromagnetic windings. The method and the device have the advantages of being high in measurement accuracy, high in applicability, convenient to measure and low in energy consumption and can realize stable linear loading.

Owner:HUNAN UNIV

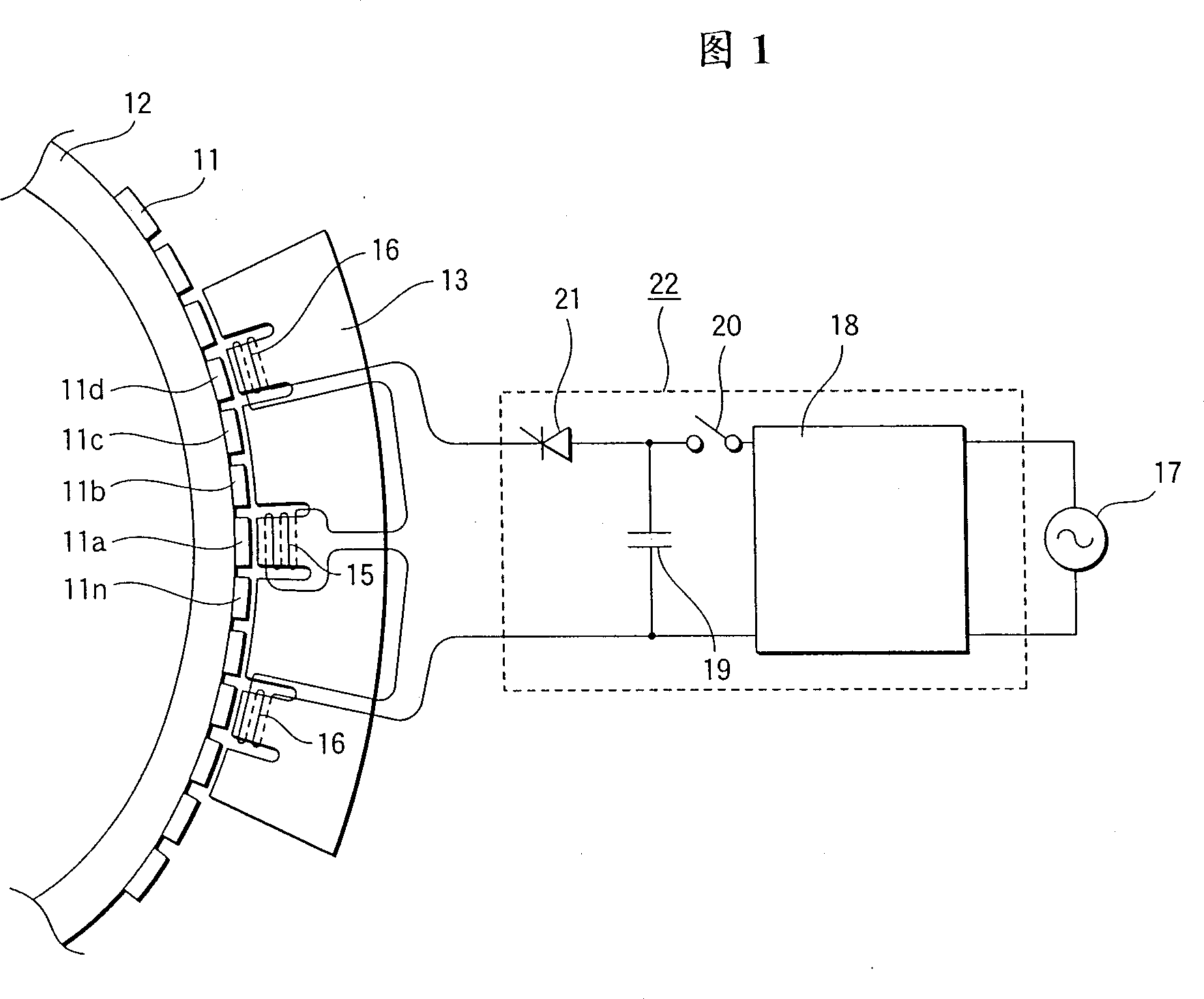

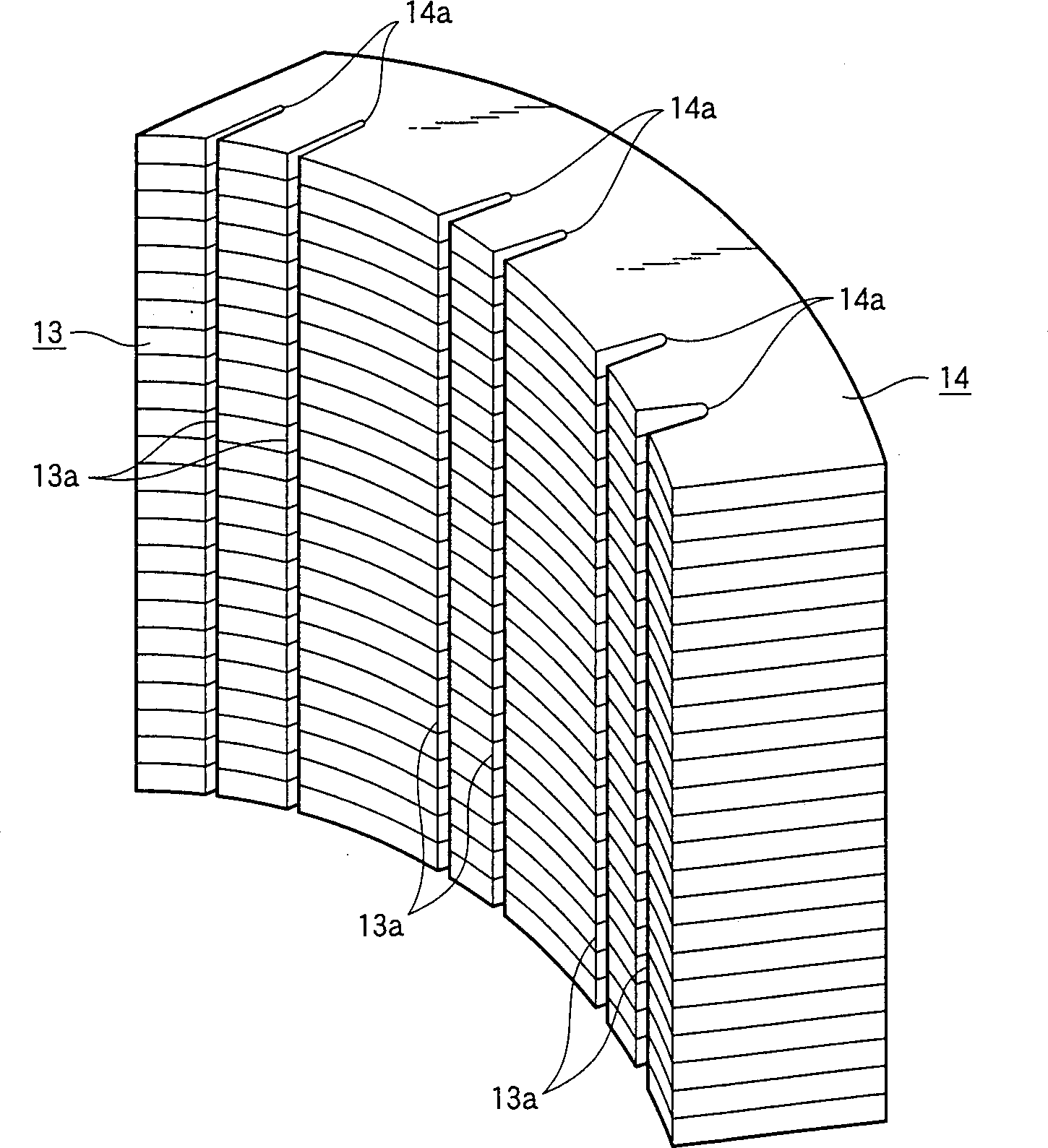

Polarizing device for permanent magnet rotor

InactiveCN1227800CEliminates the effects of reverse magnetic fieldsCurrent controllableMagnetic bodiesManufacturing stator/rotor bodiesPermanent magnet rotorMagnetic poles

A polarizing device includes: a polarizing iron core (13) facing to a specified number of permanent magnets (11) among plural unmagnetized permanent magnets (11) arranged at specified intervals circumferentially on a rotor (12); a first coil (15) wound at a position facing to a desired permanent magnet (11a) of the polarizing iron core (13); a pair of second coils (16) each arranged having a specified interval according to the first coil (15) circumferentially on the polarizing iron core (13) and whose direction of the flowing current is different from that of the first coil (15); and a power source (22) for supplying the current to the first and second coils (15, 16), and either of the permanent magnet (11a) and first coil (15) is relatively moved and each permanent magnet (11) is magnetized to form a magnetic pole in turn by the current fed from the power source (22).

Owner:MITSUBISHI ELECTRIC CORP

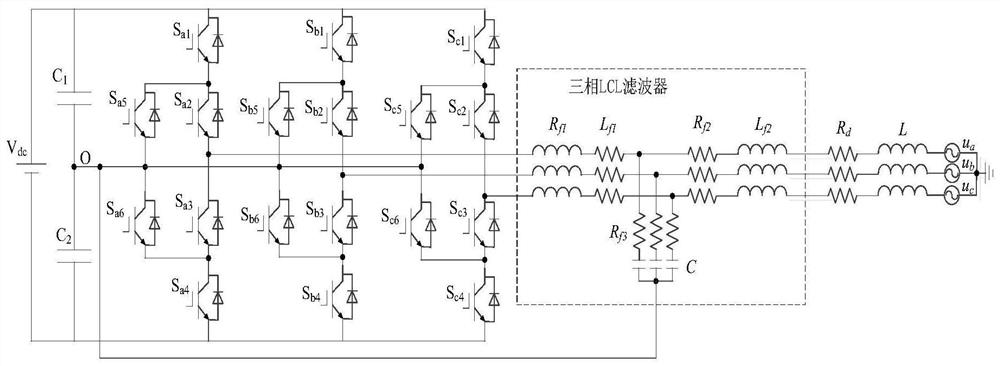

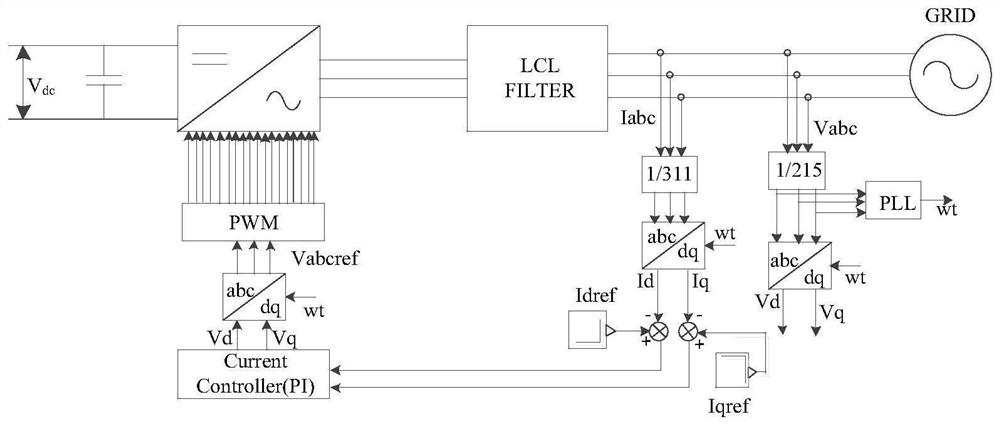

Active neutral point clamped three-level converter and adjustment and control method thereof

ActiveCN113765428ABalanced conduction lossControl Junction Temperature BalanceConversion with reversalCapacitanceHarmonics

The invention discloses an active neutral point clamped three-level converter and an adjustment and control method thereof. The converter comprises an inverter bridge, a three-phase LCL filter and a control circuit, the inverter bridge comprises DC bus support capacitors C1 and C2 and three bridge arms which have the same structure and are connected in parallel; each bridge arm is composed of six switching tubes Sx1-Sx6 and diodes which are respectively connected with the switching tubes Sx1-Sx6 in an anti-parallel manner, and x is equal to a, b or c; the control circuit is respectively connected with the AC power grid and the inverter bridge; the control circuit performs phase-locked tracking on the frequency of the AC power grid according to the voltage of the AC power grid detected in real time, calculates and generates an SPWM (sinusoidal pulse width modulation) signal required during grid-connected operation of the converter, and controls the switching action of a corresponding switching tube; the output end of each bridge arm serves as an AC output end xC and is connected to an AC power grid through a three-phase LCL filter. The three-phase LCL filter is used for filtering higher harmonic current caused by switching action. According to the invention, the conduction loss of the switch tube can be balanced, and junction temperature balance can be controlled.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

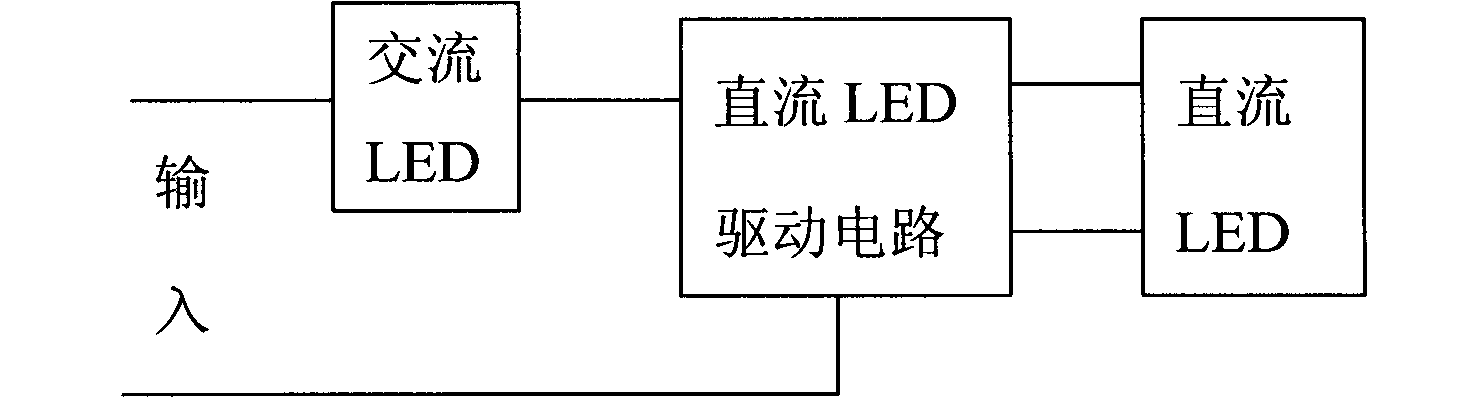

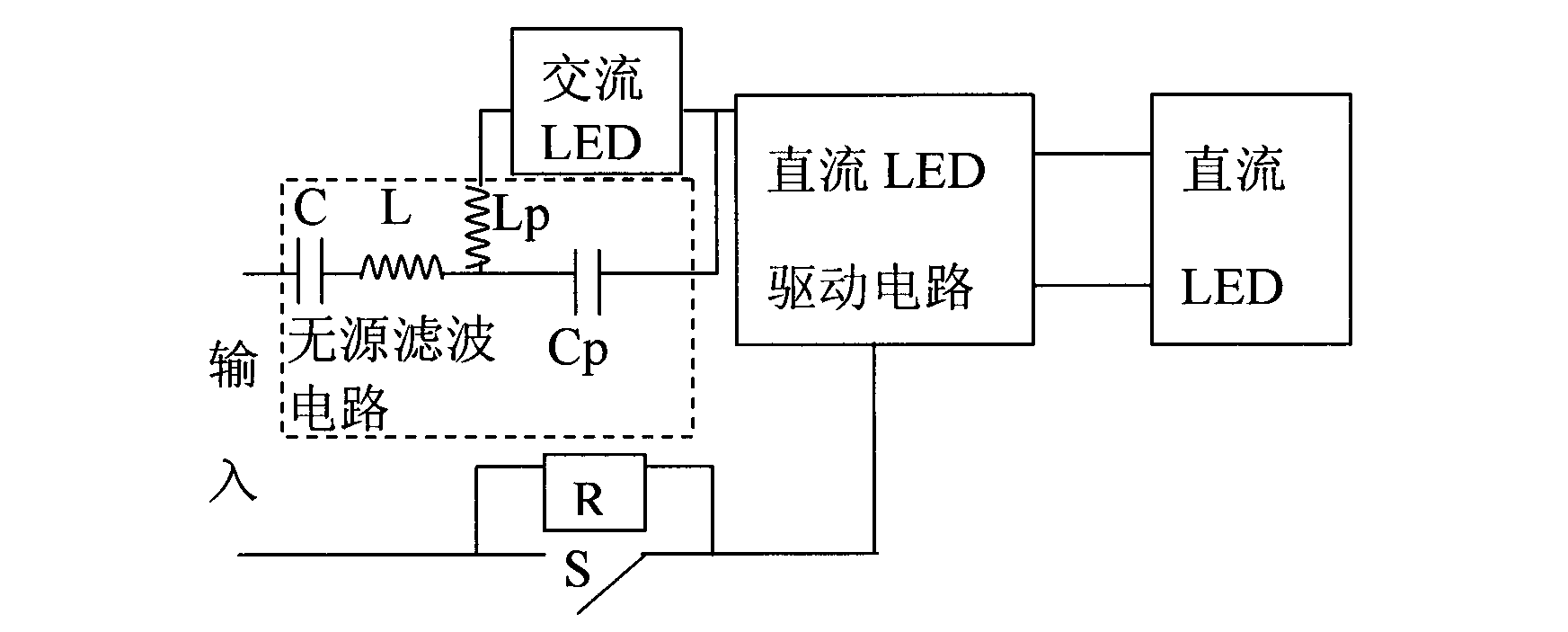

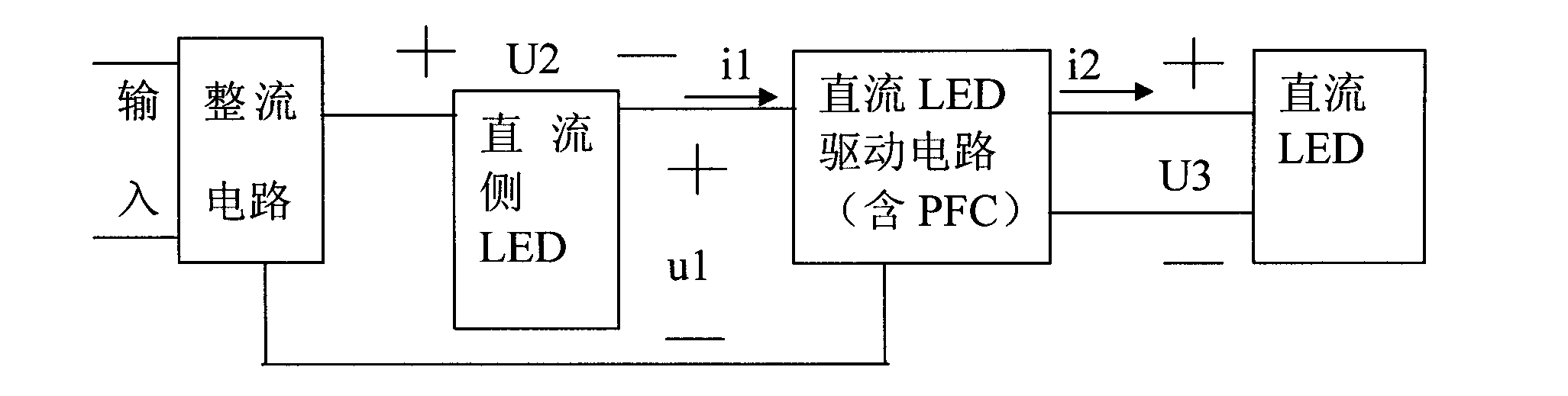

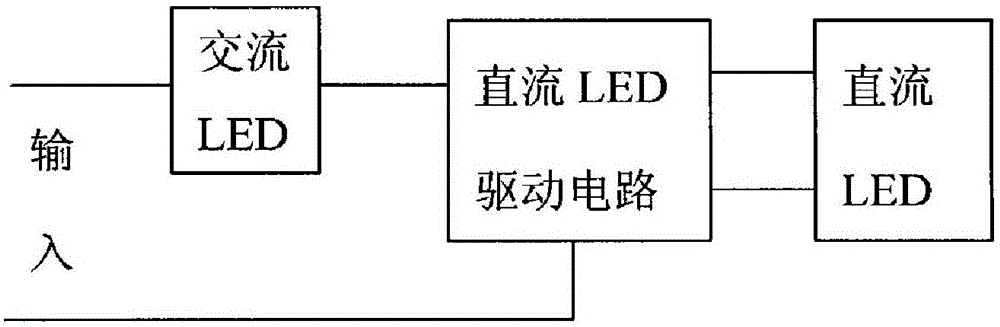

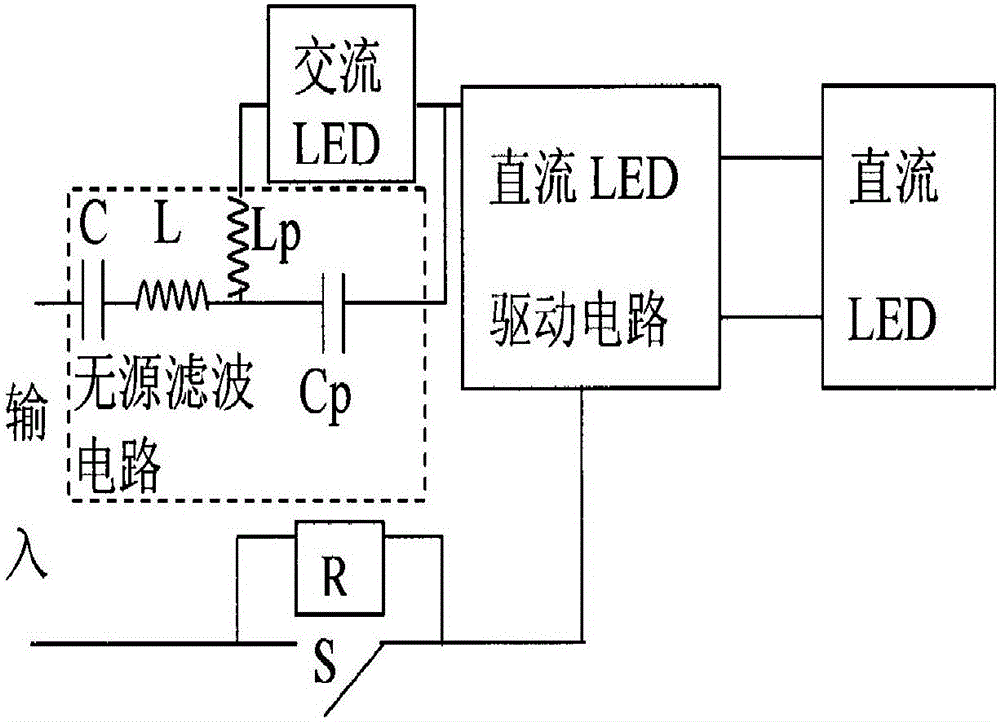

Mixed type LED illumination circuit and control strategy thereof

InactiveCN103857142AWith linear dimming functionLow efficiencyElectric light circuit arrangementHybrid typeEngineering

The invention relates to a mixed type LED circuit. The mixed type LED circuit is characterized in that the power supply side of a controllable LED circuit is connected with a voltage-dividing LED in series, currents flowing through the voltage-dividing LED are regulated by controlling output power of an controllable LED, and therefore output power of the whole illumination circuit is controlled; the voltage-dividing LED can be an alternating-current LED and can also be a direct-current LED, and the controllable LED can be a direct-current LED and a drive of the direct-current LED and can also be an alternating-current LED and a drive of the alternating-current LED; as part of LEDs in the mixed type LED illumination circuit do not need driving circuits, higher efficiency is achieved, voltage resistance and power of the controllable LED circuit are low after voltage dividing conducted by the voltage-dividing LED connected in series, cost is lower, and the mixed type LED circuit is suitable for an illuminating system using high-voltage power supply like commercial power supply.

Owner:刘晓博

Equilibrium charging method of batteries

PendingCN110460133ALess control signalBalanced chargingCharge equalisation circuitElectric powerElectrical resistance and conductanceElectrical battery

The invention discloses an equilibrium charging method of batteries, and belongs to the field of equilibrium charging. The equilibrium charging method comprises a main circuit, a plurality of single lithium batteries, a plurality of single lithium battery protection chips, a charge control MOS transistor grid, a discharge control MOS transistor grid, a charge control switching device, a control circuit and a discharge control switching device, wherein one pin of each single lithium battery protection chip is connected with a shunt discharge branch, and the shunt discharge branch is further provided with a branch resistor and a shunt discharge branch switching device. The equilibrium charging method can protect the battery pack and automatically charge and cut off the power supply, can realize the advantage of equilibrium charge, and solves the problem that the existing battery equilibrium charging method mostly realizes equilibrium charge at the charger end, the chargers for equilibrium charge are mostly customized and thus only suitable for batteries with corresponding models, the limitation is great, and the design and application cost of the lithium battery pack charger is increased.

Owner:SICHUAN SIMEI TECH

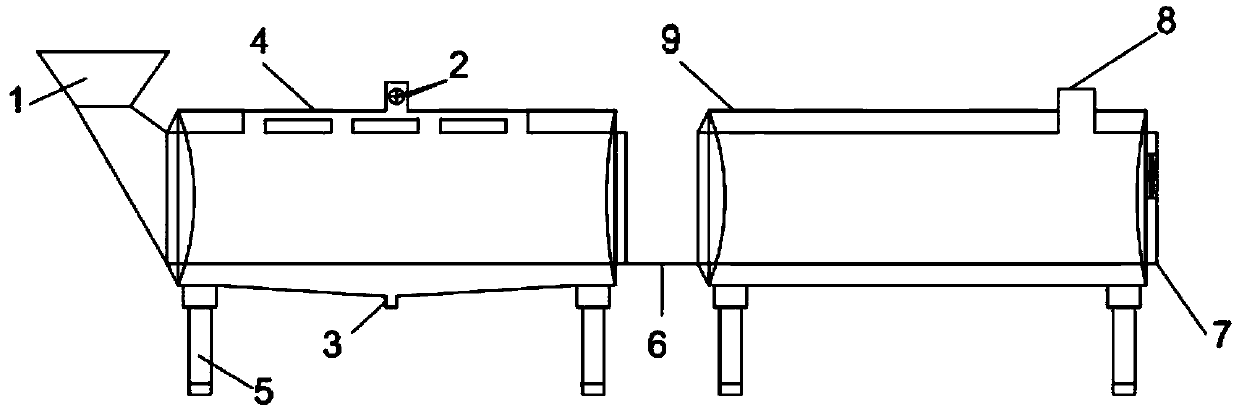

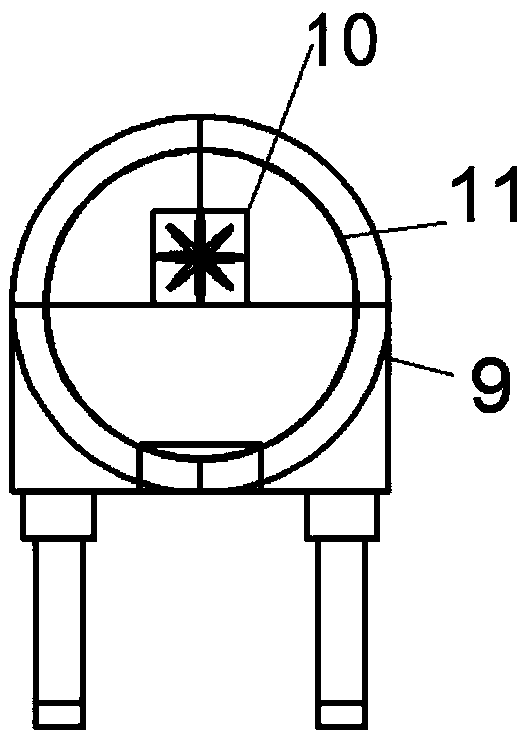

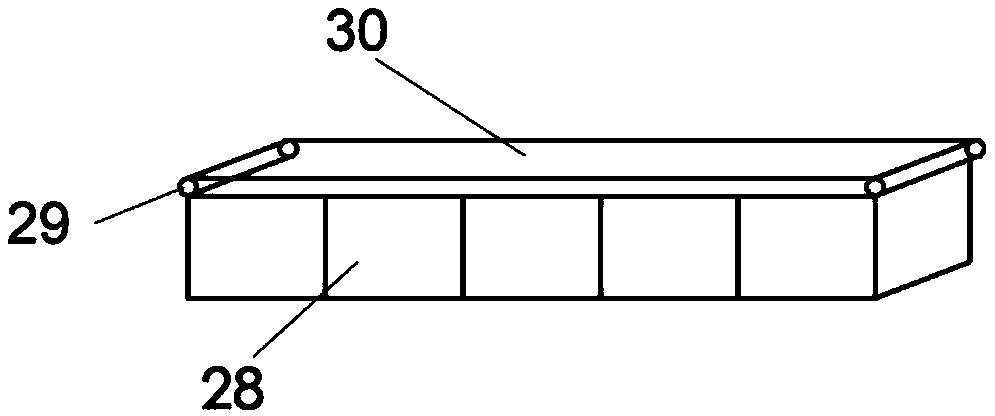

Vibration stirring type aggregate screening device

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

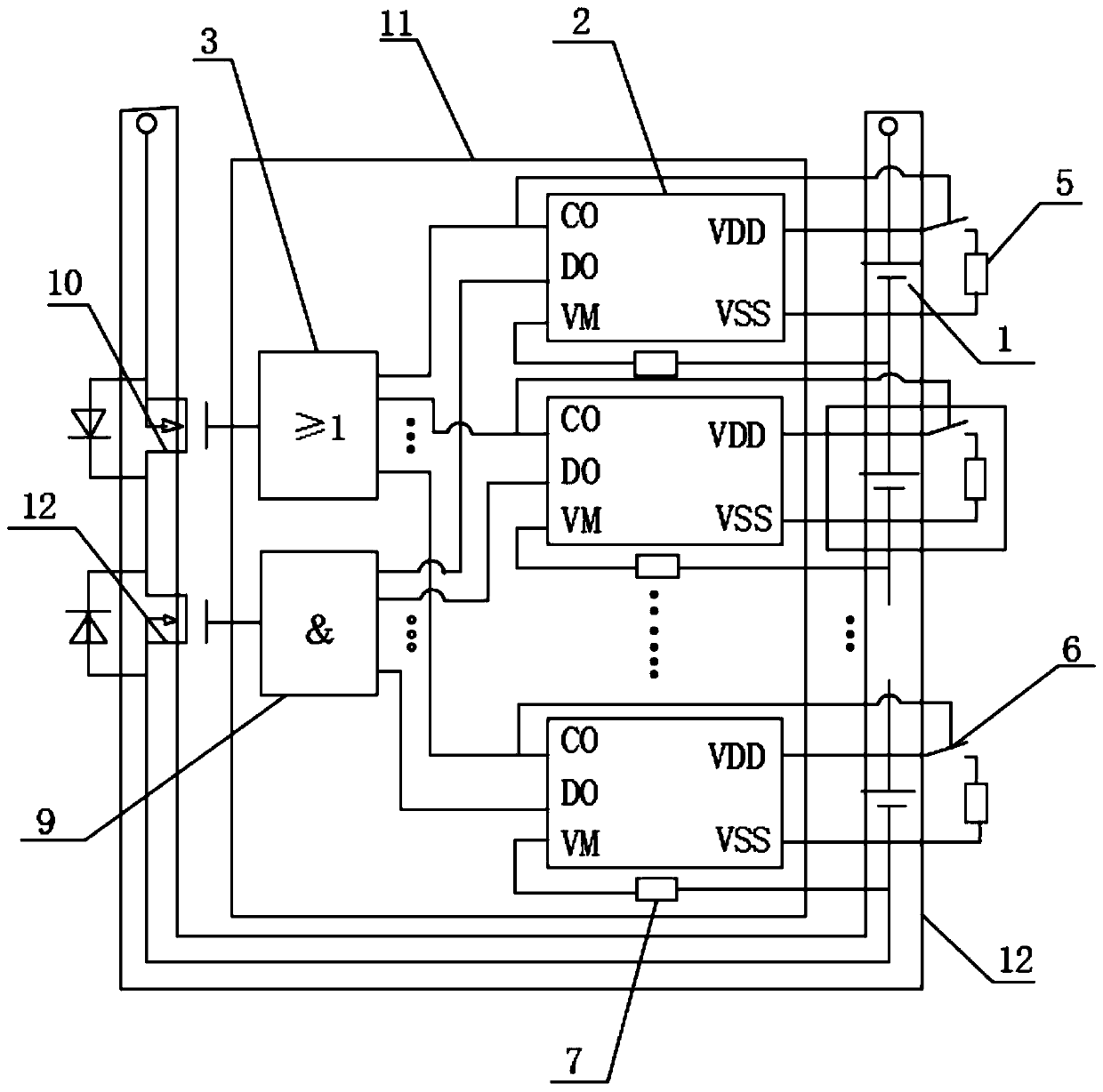

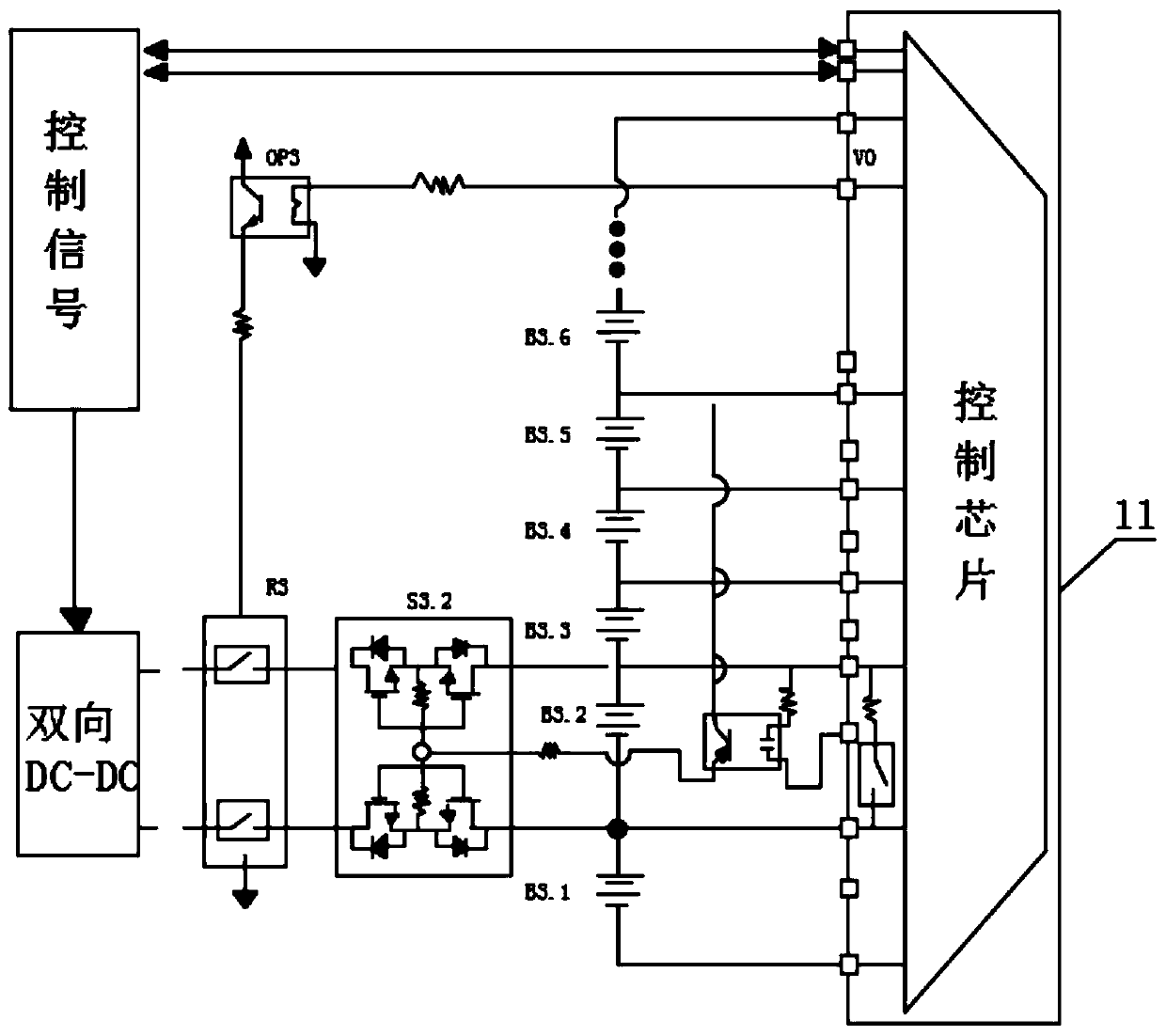

LED illumination control system

InactiveCN106793270AReduced pressure resistanceReduce the required powerElectrical apparatusElectroluminescent light sourcesDriver circuitControl system

The invention discloses an LED illumination control system. A mixed type LED circuit is characterized in that a power supply side of a controllable LED circuit is serially connected with a voltage dividing LED; by controlling the output power of the controllable LED, the current flowing through the voltage dividing LED is adjusted, so the output power of the whole illumination circuit is controlled; the voltage dividing LED can be an alternating-current LED or a direct-current LED; the controllable LED can be a direct-current LED and the drive thereof or be an alternating-current LED and the drive thereof; and one part of LEDs in the LED illumination control system are free from a driving circuit, so the efficiency is quite high. Through the voltage division of the serially connected voltage dividing LED, the voltage resistance and the power of the controllable LED circuit are quite low, so the cost is lower. Thus, the system is suitable for an illumination system with quite high voltage power supply, such as commercial voltage power supply.

Owner:韦尚仁

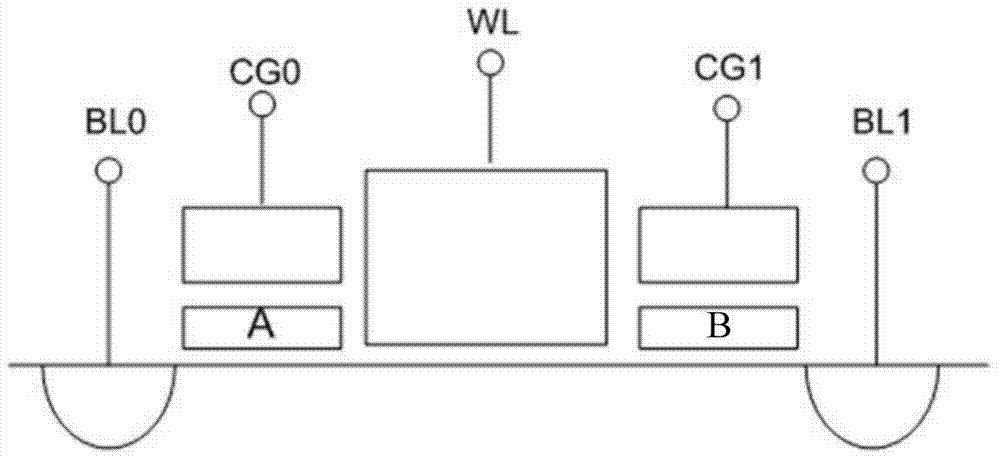

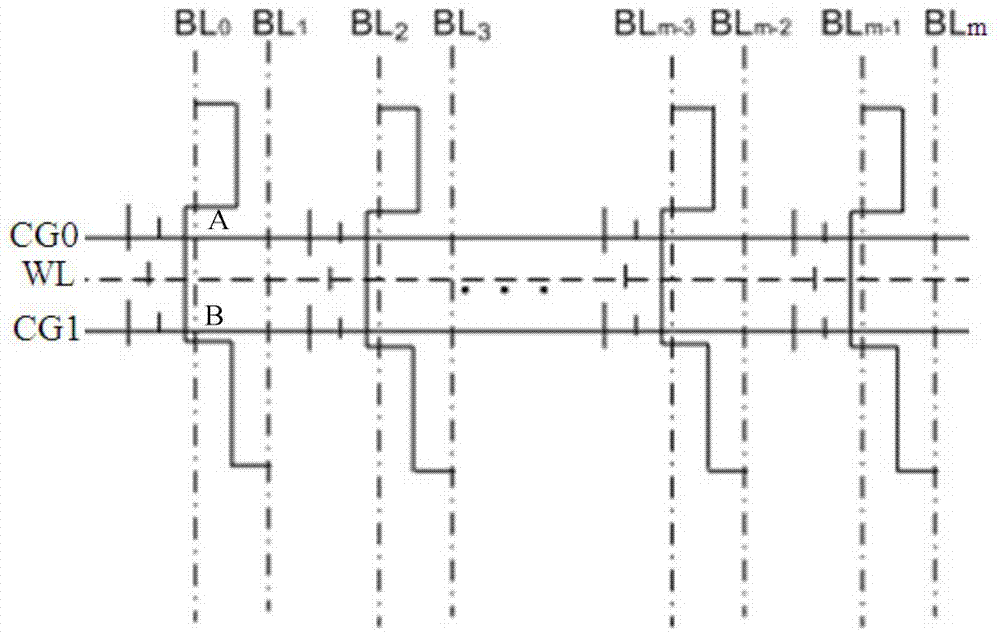

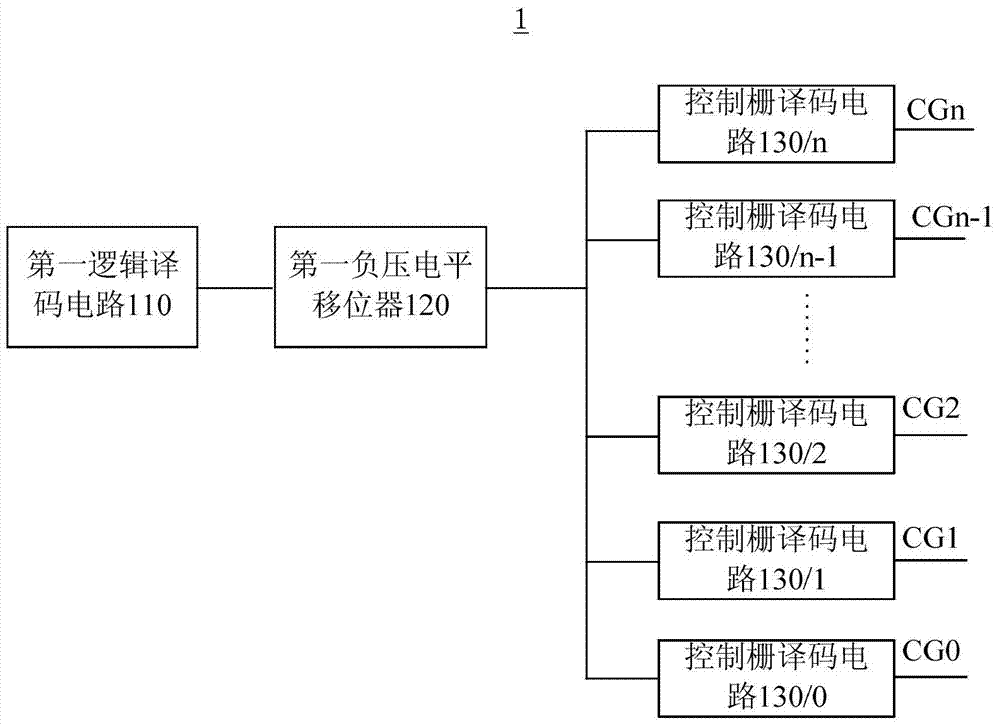

Row decoding circuit and memory

The invention reveals a row decoding circuit, which comprises n+1 control grid decoding circuits and current limiting biasing circuit; the current limiting biasing circuit comprises a first mirror image NMOS transistor and a resistive element, a source of the first mirror image NMOS transistor is input into an input voltage, a grid electrode of the first mirror image NMOS transistor is connected to a drain electrode, the drain electrode of the first mirror image NMOS transistor is connected to the resistive element in series, and the grid electrode of the first mirror image NMOS transistor outputs a bias signal; each control grid decoding circuit comprises a first NMOS transistor, a first PMOS transistor, a second NMOS transistor and a second mirror image NMOS transistor, the grid electrode of the second mirror image NMOS transistor accepts the bias signal, and a source of the second mirror image NMOS transistor is connected to the drain electrode of the first NMOS transistor. The invention also reveals a memory comprising the row decoding circuit, the row decoding circuit and the memory can provide negative pressure of controllable voltage transition rate for the control grid.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com