Radiant railway switch de-icing/snow removing system

A switch and ice-melting technology, applied in the field of railway turnout snow-melting devices and supporting devices for railway transportation facilities, can solve the problems affecting the normal operation of the switch machine, the failure of the snow-melting system, and the delay of railway transportation, and achieve efficient and reliable snow-melting and de-icing. The effect of melting ice and snow thoroughly and preventing overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The radial railway turnout melting ice and snow removal system of the present invention is realized in this way, and will be described in detail below in conjunction with the accompanying drawings.

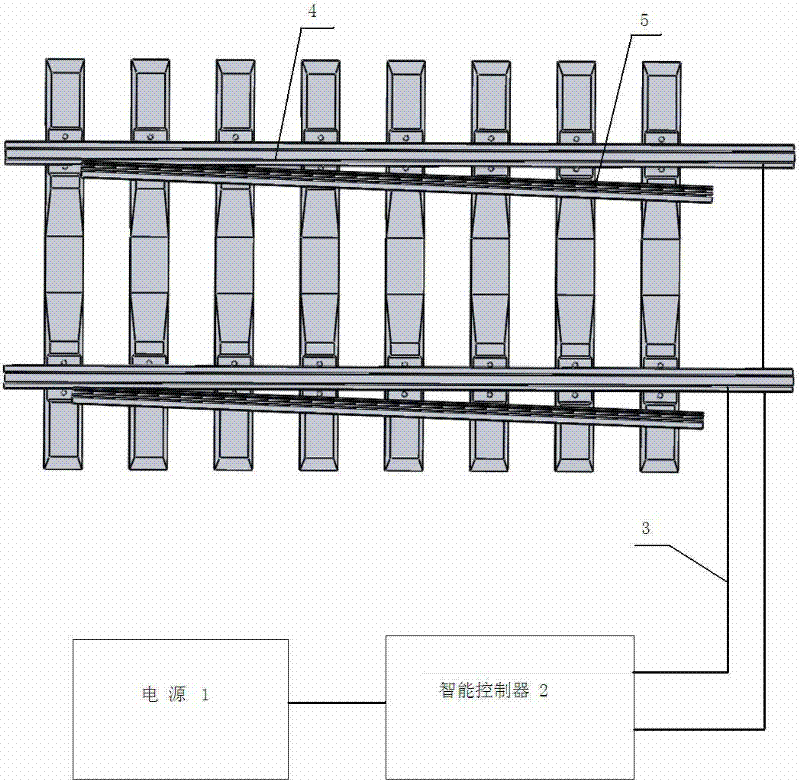

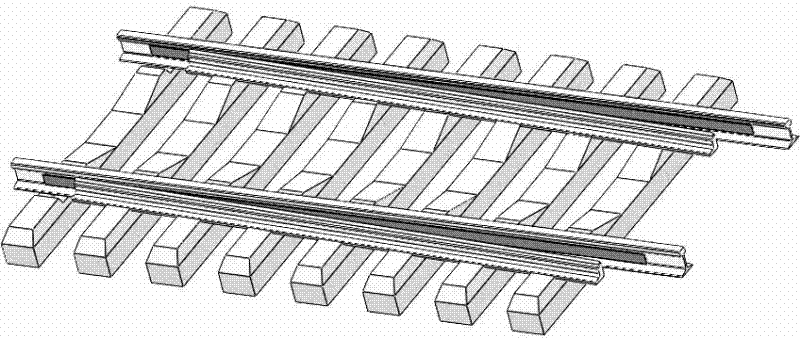

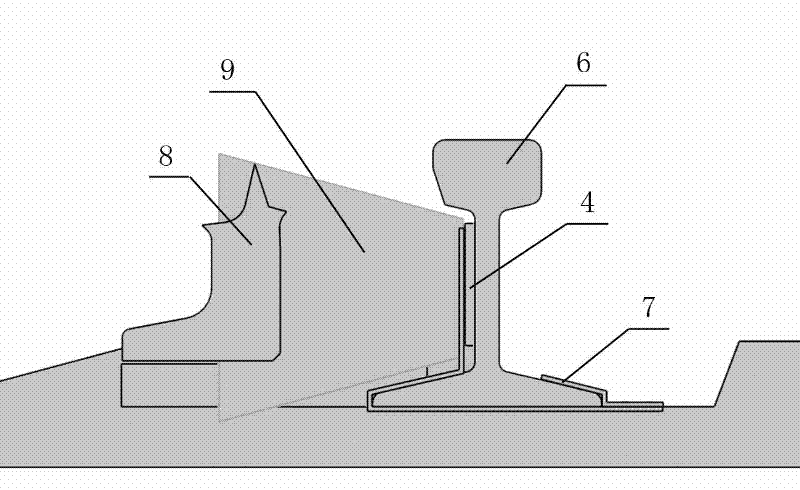

[0016] like figure 1 , figure 2 As shown, the radial railway turnout ice melting and snow removal system is connected by an intelligent power supply 1 and an intelligent controller 2 with a radiator 4 through a buried cable 3, and the radiator 4 is clamped and fixed by a clip 7 installed on the basic rail 6 , the radiator 4 is placed in the inside after the turnout basic rail 6 and the switch rail 8 are closed, and the radiator 4 is fastened to the rail waist of the turnout basic rail 6 with a clip 7 .

[0017] like image 3 , Figure 4 As shown, the radiator 4 is wrapped by a steel shell, which is a flat belt with a width of 80 mm and a thickness of 5 mm. It has a heat insulation layer on the back of the basic rail, and can be conveniently placed on the rail waist afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com