Polarizing device for permanent magnet rotor

A technology for magnetizing devices and rotors, applied in electromechanical devices, manufacturing stator/rotor bodies, magnetic objects, etc., can solve problems such as difficulty in demagnetization, large size of current delivery unit, and difficulty in controlling current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

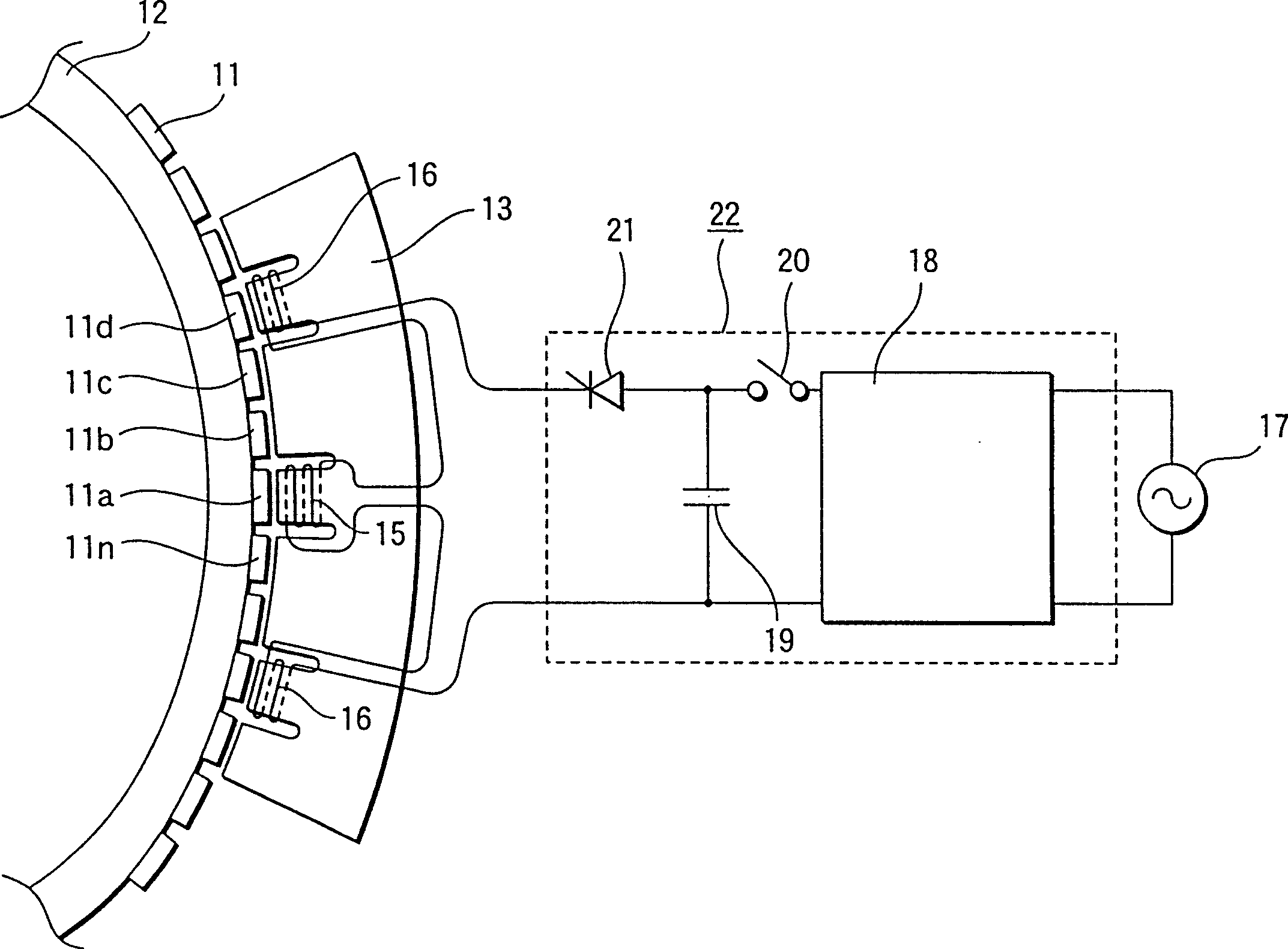

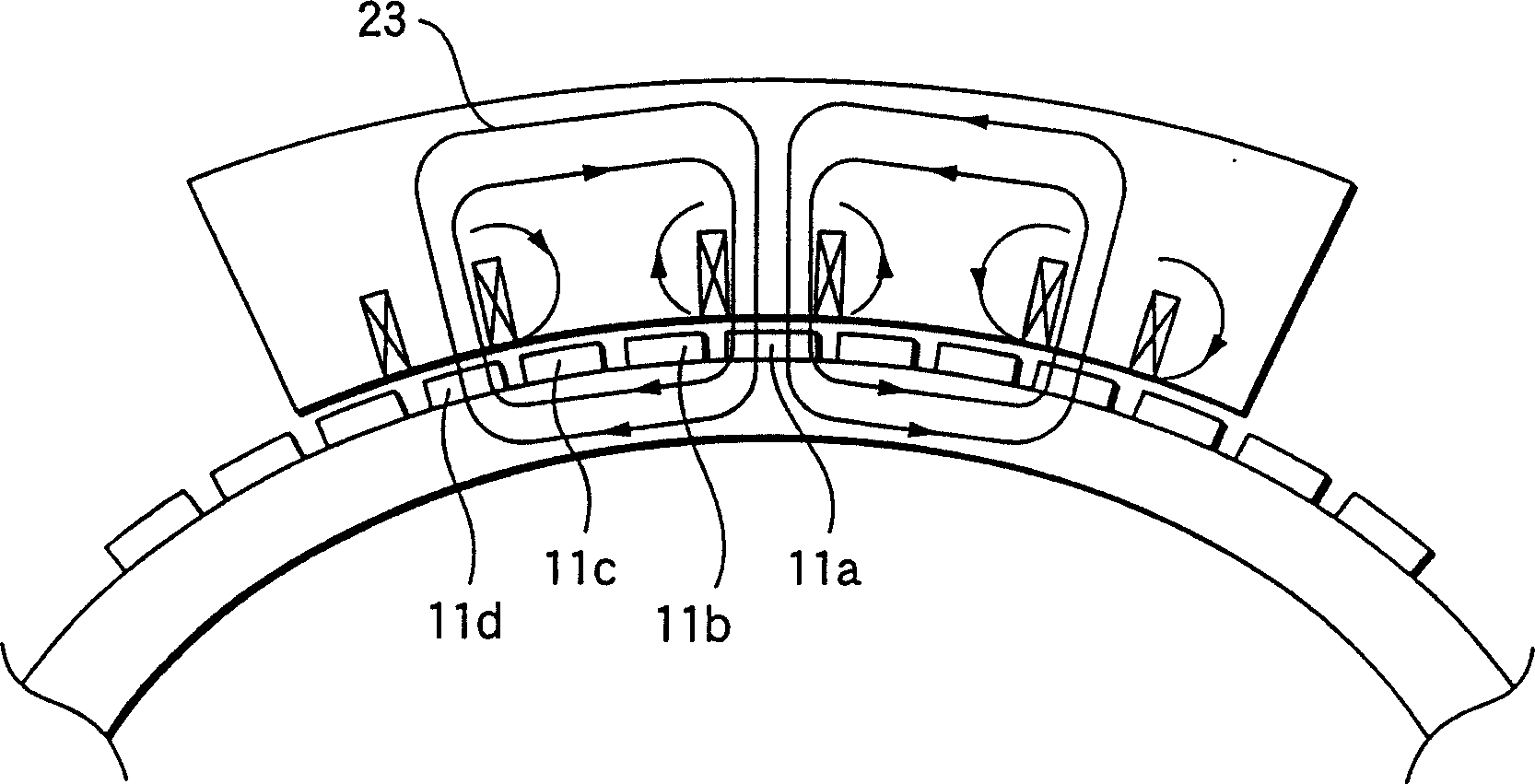

[0022] attached figure 1 Shown is a schematic structural view of the magnetization device of the permanent magnet rotor in Embodiment 1 of the present invention, with figure 2 shown attached figure 1 A perspective view of the structure of the magnetized core, and the attached image 3 shown by the attached figure 1 State diagram of the magnetic flux distribution generated by the magnetization device of the permanent magnet rotor.

[0023] In the drawing, reference numeral 11 denotes a plurality of unmagnetized permanent magnets arranged at specific intervals on the outer surface of the rotor 12 in the circumferential direction, and reference numeral 13 denotes magnetized magnetized magnets disposed facing a specific number of permanent magnets 11. Iron heart, as attached figure 2 As shown, it is formed by laminating a specific number of plate-shaped magnetic materials 14 on which notches 14a having a specific width and a specific depth are provided in pairs at three p...

Embodiment 2

[0035] attached Figure 4A plan view showing the structure of the main part of the magnetization device of the permanent magnet rotor in Embodiment 2 of the present invention is shown.

[0036] In this drawing, the same reference numerals denote similar components to those in the described embodiment 1, and thus their descriptions are omitted.

[0037] Reference numeral 24 denotes a magnetized core formed by laminating a plurality of plate-shaped magnetic materials, similarly to that in Embodiment 1 described (not shown), and notched portions 24a are formed near both sides of the first coil 15 to respectively expand Gap with permanent magnet 11.

[0038] Therefore, according to the above-described Embodiment 2, by forming the notch portions 24a in the vicinity of both sides of the first coil 15 of the magnetized core 24, respectively, the gap with the permanent magnet 11 is expanded, thereby preventing the magnetization caused by the first coil 15. The magnetic flux forms a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com