Method for optimizing preparation process of vanadium-aluminum alloy

A technology of preparation process and optimization method, applied in the direction of improving process efficiency, etc., can solve the problems of large electrical loss, low metal recovery rate, unstable reaction process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

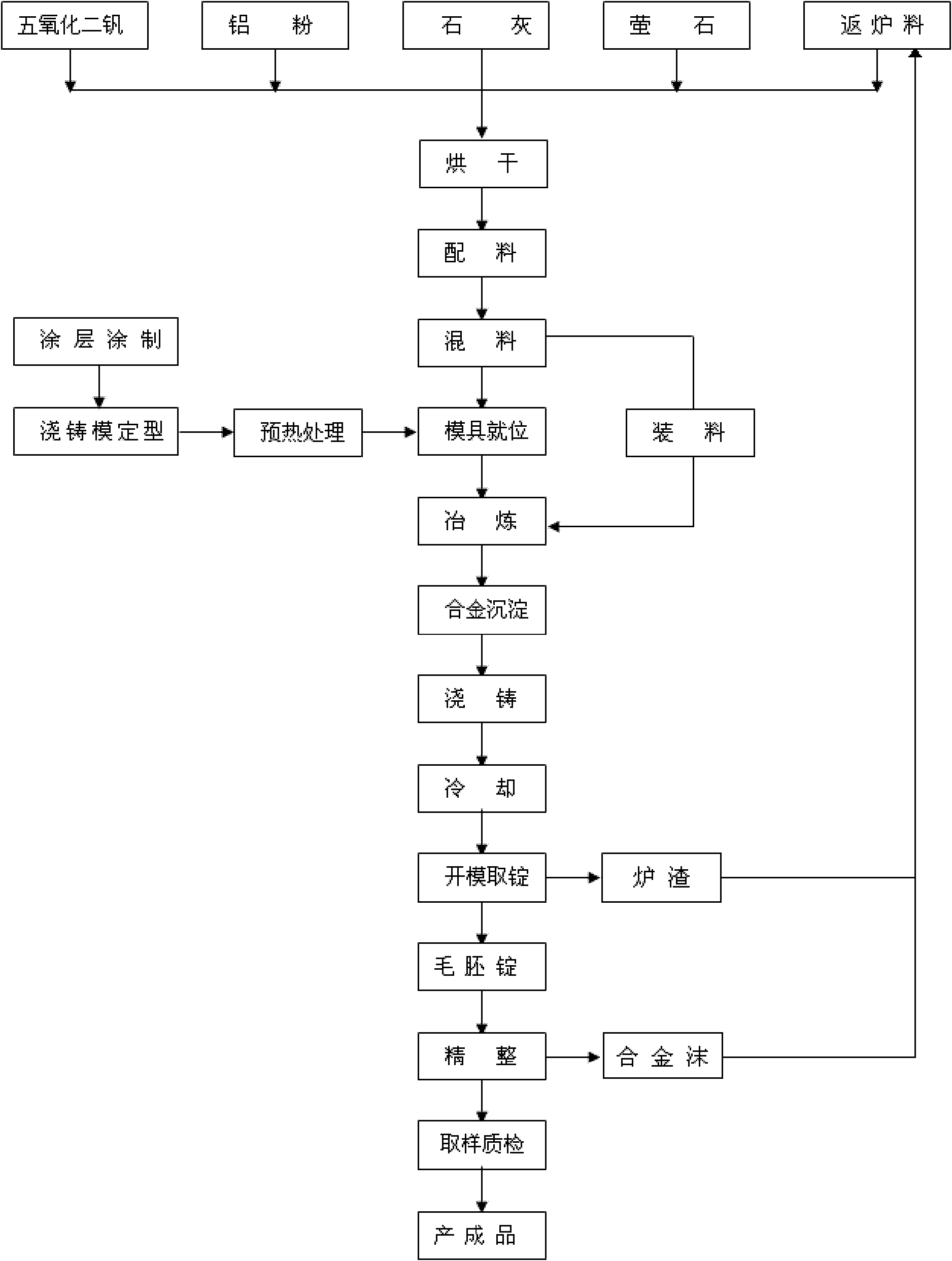

Method used

Image

Examples

Embodiment 1

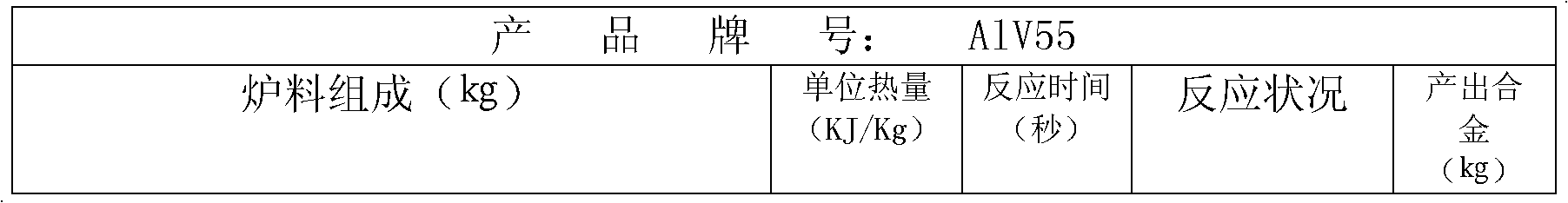

[0056] 1. Raw materials for vanadium-aluminum alloy smelting production

[0057] Vanadium pentoxide: V 2 o 5 99.5%, P0.01%, C0.01%, S0.02%, Pb0.01%, Mo0.01%, K0.1%, Na0.1%, B0.001%, W0.006%, Fe0. 01%, Cu0.01%, Si0.04%, Ni0.002%, Mn0.02%, Mg0.04%, Cr0.01%, Y0.001%, other trace elements 0.1%

[0058] Aluminum powder: Al99.6%, Fe0.15%, Si0.20%, Cu0.02%, P0.03%

[0059] Fluorite: CaF 2 98.0%, S0.02%, C0.03%, SiO 2 1.6%, P0.03%, H 2 O0.1%, Fe 2 o 3 0.22%

[0060] Lime: CaO92.0%, SiO 2 2.0%, P0.01%, S0.05%, C0.8%, lime burning rate + burning rate 5.14%

[0061] 2. Preset conditions for ingredients:

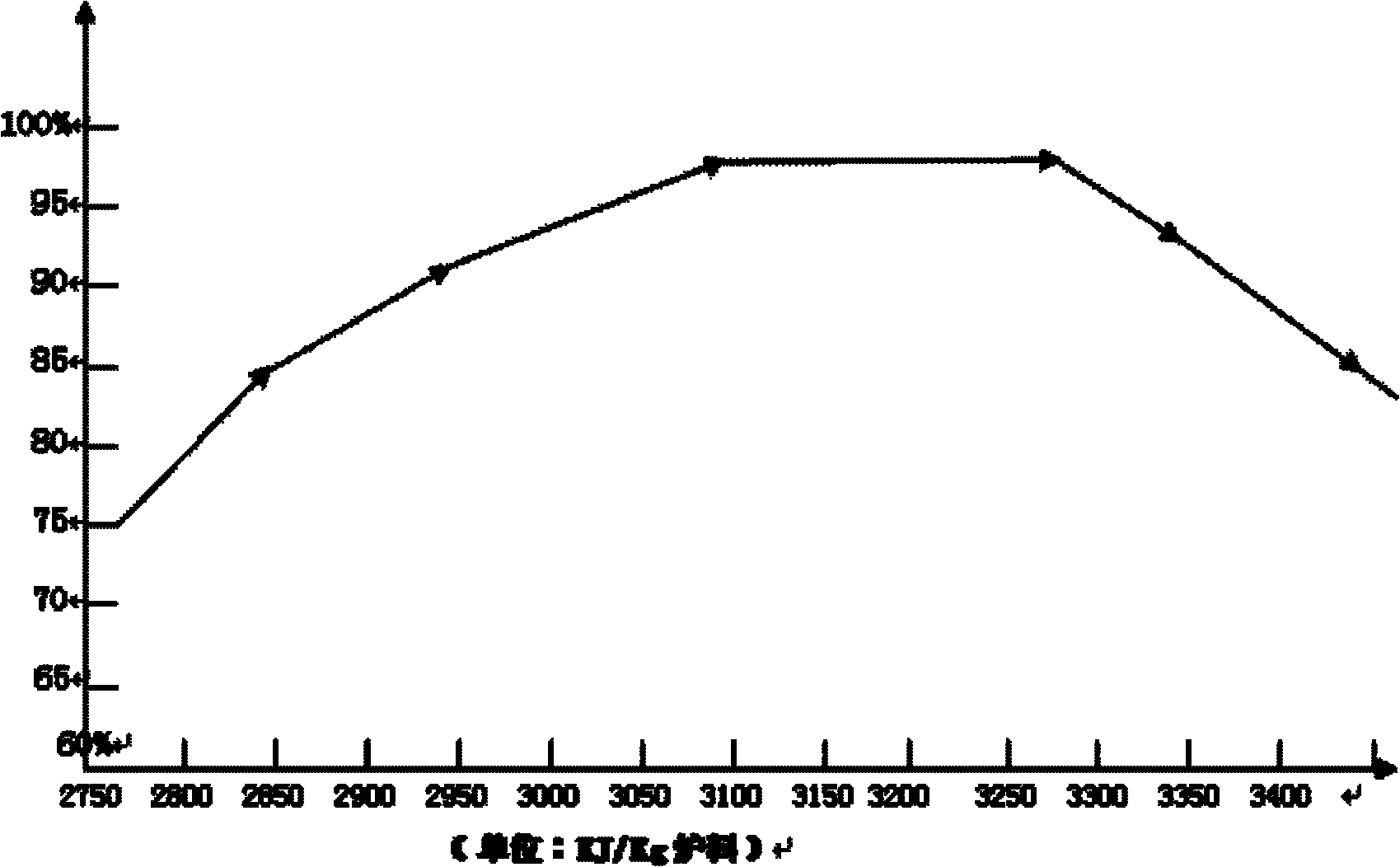

[0062] Pre-refining vanadium-aluminum alloy containing V58% and Al41% as impurities, the amount of vanadium pentoxide used is 15kg / furnace; the amount of aluminum powder participating in the reaction is added in excess of 5%, and the balance of Al in the alloy is added The burning loss of aluminum powder is 6%; the unit heat release value of furnace charge is 3250KJ / Kg. The ...

Embodiment 2

[0100] 1. Raw materials for vanadium-aluminum alloy smelting production

[0101] Vanadium pentoxide: V 2 o 5 99.505%, P0.009%, C0.009%, S0.018%, Pb0.009%, Mo0.01%, K 0.1%, Na0.1%, B0.001%, W0.006%, Fe0.01 %, Cu0.01%, Si0.04%, Ni0.002%, Mn0.02%, Mg0.04%, Cr0.01%, Y0.001%, other trace elements 0.1%

[0102]Aluminum powder: Al99.68%, Fe0.1%, Si0.17%, Cu0.02%, P0.03%

[0103] Fluorite: CaF 2 98.22%, S0.02%, C0.03%, SiO 2 1.4%, P0.03%, H 2 O0.1%, Fe 2 o 3 0.20%

[0104] Lime: CaO92.0%, SiO 2 2.0%, P0.01%, S0.04%, C0.75%, raw burning rate of lime + overburning rate 5.2%

[0105] Reverse charge: slag.

[0106] 2. Preset conditions for ingredients:

[0107] Pre-refining vanadium-aluminum alloy containing V65% and Al34% as impurities, the amount of vanadium pentoxide used is 20kg / furnace; the amount of aluminum powder participating in the reaction is added in excess of 6%, and the balance of Al in the alloy is added The burning loss of aluminum powder is 7%; the unit heat ...

Embodiment 3

[0146] 1. Raw materials for vanadium-aluminum alloy smelting production

[0147] Vanadium pentoxide V 2 o 5 99.79%; P 0.01%; C 0.0083%; S 0.02%; Pb 0.01%; Mo0.0015%; K 0.013%; Na 0.018%; 0.034%; Ni 0.009%; Mn 0.014%; Mg 0.02%; Cr 0.01%; the remaining 0.02% are other trace elements

[0148] Aluminum powder Al 99.58%; Fe 0.15%; Si 0.205%; Cu 0.015%; P 0.05%;

[0149] Lime CaO 92.87%; SiO 2 2.0%; P 0.01%; S 0.04%, C 0.75%, burning rate + burning rate 4.33%

[0150] Fluorite CaF 2 99.13%, S 0.02%, C 0.03%, SiO 2 0.808%, P 0.012%.

[0151] Reverse charge: alloy foam.

[0152] 2. Preset conditions for ingredients:

[0153] Pre-refining vanadium-aluminum alloy containing V63.5%Al35.5% as impurities, the amount of vanadium pentoxide used is 20kg / furnace; the amount of aluminum powder participating in the reaction is added in excess of 6%, and the balance in the alloy The burning loss of aluminum powder mixed with Al is 6%; the unit heat release value of furnace charge is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com