Titanium alloy Ti-62222s and preparation method thereof

A technology of ti-62222s and titanium alloy, which is applied in the field of titanium alloy and its preparation, can solve the problems of inability to meet diversified requirements, fluctuating high and low melting current, and difficult control, etc., and achieves convenience for subsequent processing, low cost, The effect of improving the yield of processed products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

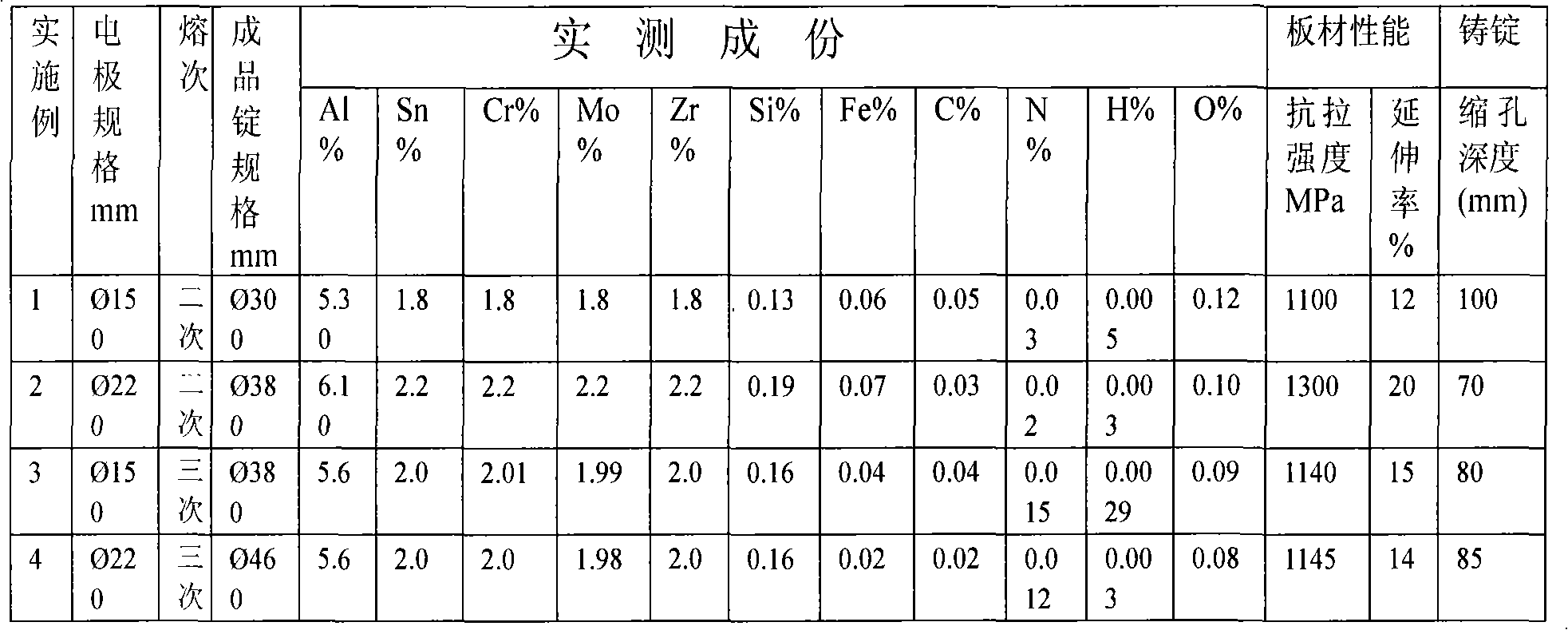

Examples

Embodiment 1

[0020] Concrete preparation process is as follows:

[0021] 1. Prepare the alloy package: spread the raw materials AlSn50, AlCr50, AlMo60, zirconium sponge, industrial silicon, and aluminum beans in layers of aluminum foil with predetermined specifications, seal them tightly, store and transport required level;

[0022] 2. Electrode preparation: Each electrode weighs 18kg to 25kg. Divide the titanium sponge into 4 parts and add 3 packages of alloy. After each layer of titanium sponge is spread out, place 1 package of alloy package horizontally. By analogy, extrude the electrode;

[0023] 3. Electrode drying: The extruded electrodes are mainly placed in the drying room for drying, and the drying temperature is 50-60°C to prevent the electrodes from being damp;

[0024] 4. The extruded electrodes are aligned horizontally and welded vertically. The solder joints must be firm and must not be oxidized into blue;

[0025] 5. Furnace loading: use the starting crane to load the weld...

Embodiment 2

[0031] Concrete preparation process is as follows:

[0032] 1. Prepare the alloy package: spread the raw materials AlSn50, AlCr50, AlMo60, zirconium sponge, industrial silicon, and aluminum beans layer by layer in the aluminum foil of predetermined specifications, seal it tightly, store and transport required level;

[0033] 2. Preparation of electrodes: Divide the titanium sponge into 6 parts with a weight of 38kg to 50kg for each electrode, add 5 packages of alloy bags, after each layer of titanium sponge is spread out, place 1 package of alloy bags horizontally, and so on, extrude the electrodes;

[0034] 3. Electrode drying: The extruded electrodes should be dried in a drying room at a temperature of 160-200°C to prevent the electrodes from being damp.

[0035] 4. The extruded electrodes are aligned horizontally and welded vertically. The solder joints must be firm and must not be oxidized into blue.

[0036] 5. Furnace loading: use the starting crane to load the welded ...

Embodiment 3

[0042] Concrete preparation process is as follows:

[0043] 1. Prepare the alloy package: spread the raw materials AlSn50, AlCr50, AlMo60, zirconium sponge, industrial silicon, and aluminum beans in layers of aluminum foil with predetermined specifications, seal them tightly, store and transport required level.

[0044] 2. Electrode preparation: Each electrode weighs 18kg to 25kg. Divide the titanium sponge into 4 parts and add 3 packages of alloy. After each layer of titanium sponge is spread out, place 1 package of alloy package horizontally. By analogy, extrude the electrode;

[0045] 3. Electrode drying: The extruded electrodes should be dried in a drying room at a temperature of 80-120°C to prevent the electrodes from being damp.

[0046] 4. The extruded electrodes are aligned horizontally and welded vertically. The solder joints must be firm and must not be oxidized into blue.

[0047] 5. Furnace loading: use the starting crane to load the welded electrodes into the fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com