Rotation-modulation radial spherical pure electromagnetic bearing

A rotary modulation, magnetic bearing technology, applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of increasing the torsional bearing load of the flywheel, uneven electromagnetic force, reducing the control accuracy of the flywheel rotor and the control torque accuracy, etc. Radial translation interference, good circumferential uniformity, and the effect of eliminating gyro drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] specific implementation plan

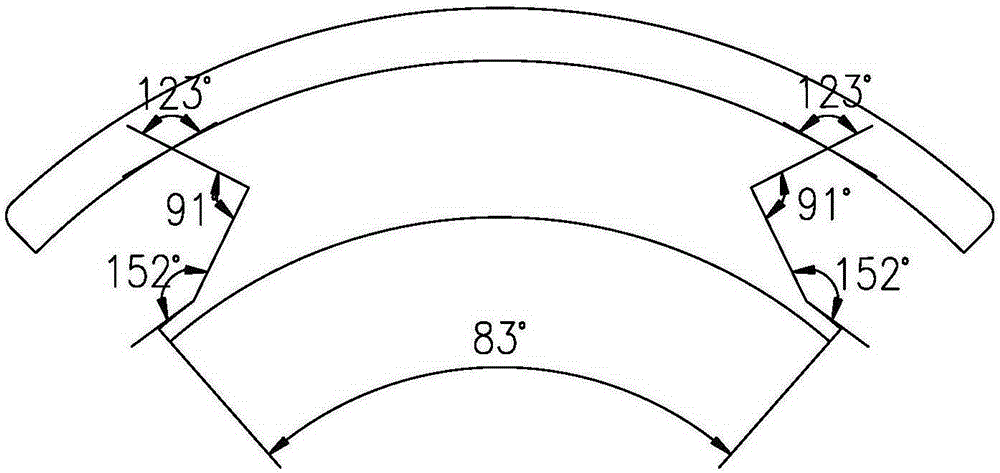

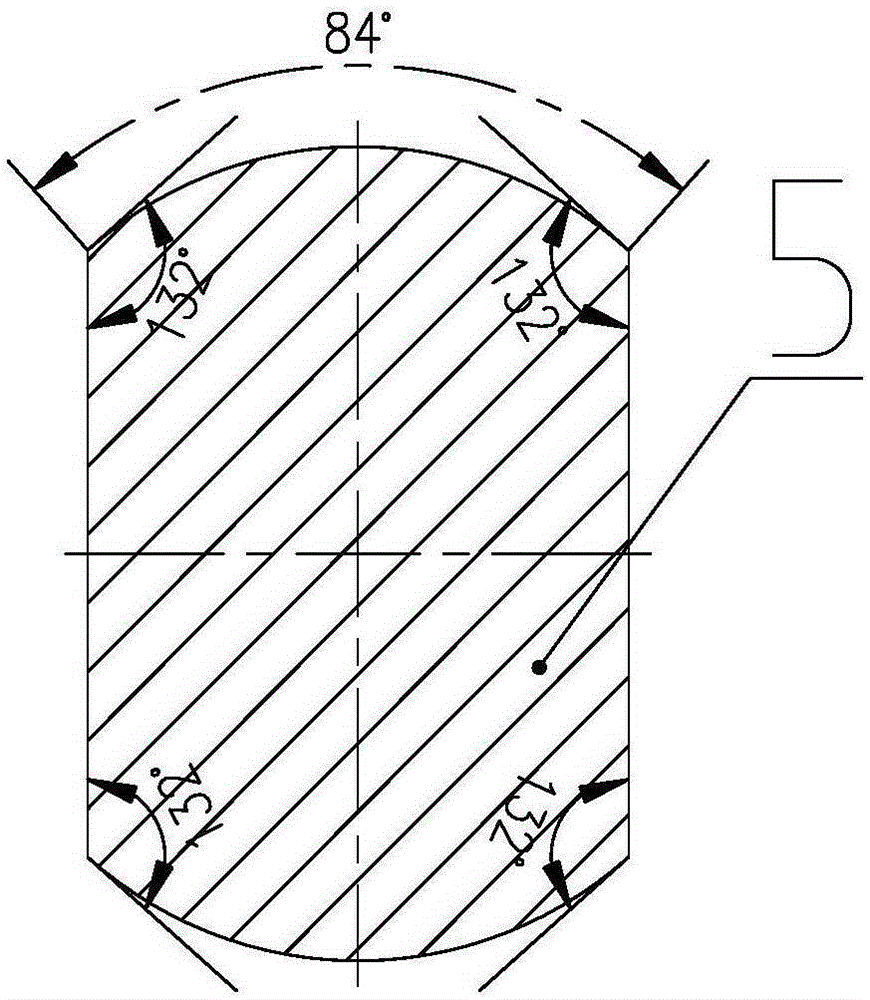

[0021] Such as figure 1 with figure 2As shown, a rotary modulation radial spherical pure electromagnetic bearing mainly includes: four stator cores (1), coils (2), sleeves (3), air gaps ( 4), rotor (5), stator mounting plate (6), rotation modulation rotor bearing sleeve (7), rotation modulation bearing (8), rotation modulation rotor lock nut (9), ultrasonic motor rotor (10), ultrasonic motor stator (11), rotation adjustment stator bearing sleeve (12) and rotation adjustment stator lock nut (13) form. The radial bearing coils (2) are wound on the two magnetic poles of each stator core (1), the radial inner side of the four stator cores (1) is the rotor (5), the stator core (1) and the rotor (5 ) to form a radial magnetic air gap (4), the radial outer side of the stator core (1) is a sleeve (3), the sleeve (3) and the stator mounting plate (6) are fixedly connected by screws, and the stator mounting plate ( The axial outer side of 6) is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com