Double-coil axial spherical surface pure electromagnetic bearing

A magnetic bearing and double-coil technology, applied in the field of non-contact support of magnetic suspension flywheel and spherical pure electromagnetic magnetic bearing, can solve the problems of increasing the torsional bearing load of the flywheel, uneven electromagnetic force, uneven air gap, etc. The effect of the disturbance to the translation, improving the current response rate and improving the control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] specific implementation plan

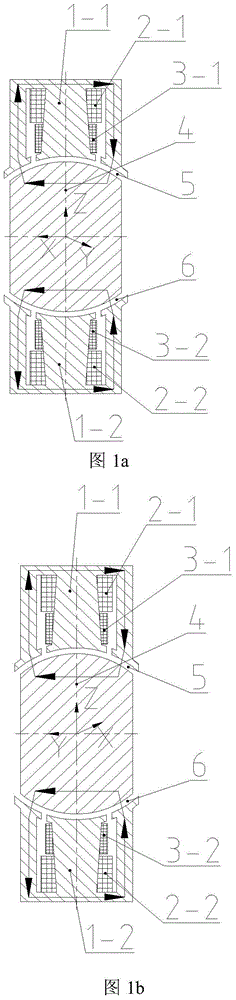

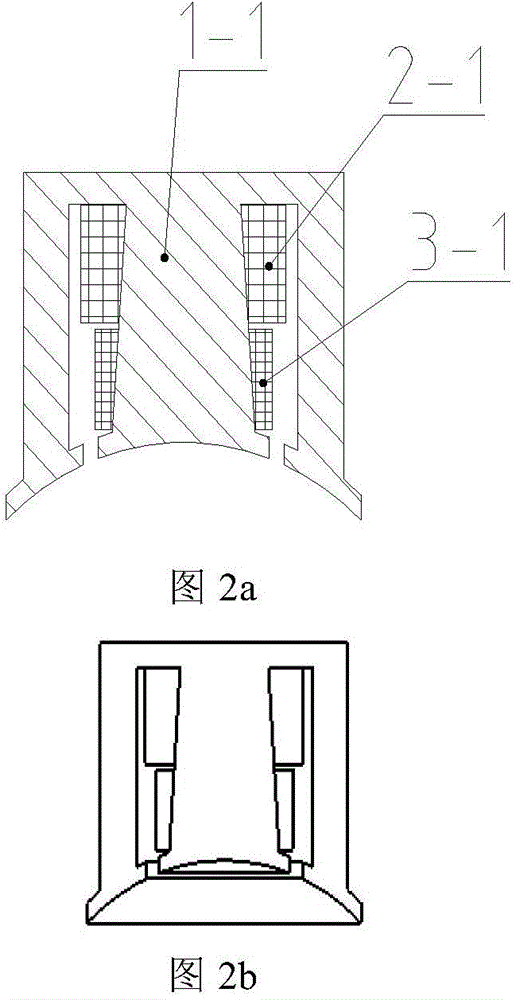

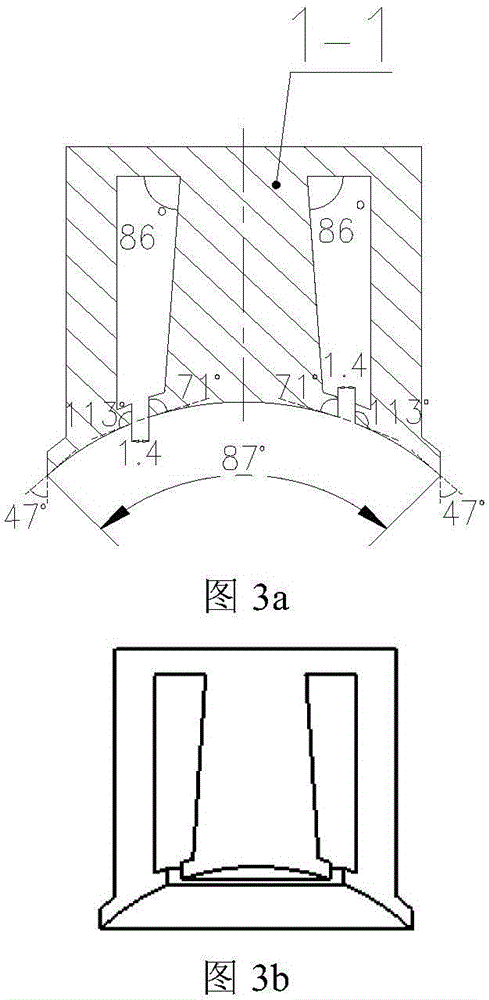

[0022] like figure 1 As shown, a double-coil axial spherical pure electromagnetic bearing is mainly composed of a stator system and a rotating shaft. The stator system mainly includes: an upper stator core 1-1, a lower stator core 1-2, and an upper end excitation coil 2 on the upper shaft. -1, the upper axial lower end excitation coil 3-1, the lower axial lower end excitation coil 2-2 and the lower axial upper end excitation coil 3-2; the upper stator core 1-1 includes spherical left magnetic pole, spherical middle magnetic pole and spherical right Magnetic poles, the upper stator core includes a spherical left magnetic pole, a spherical middle magnetic pole and a spherical right magnetic pole, and the area of the spherical middle magnetic pole is greater than the sum of the areas of the spherical left magnetic pole and the spherical right magnetic pole, preferably the area of the spherical middle magnetic pole is the spherical left ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com