Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

100results about How to "Beautiful style" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

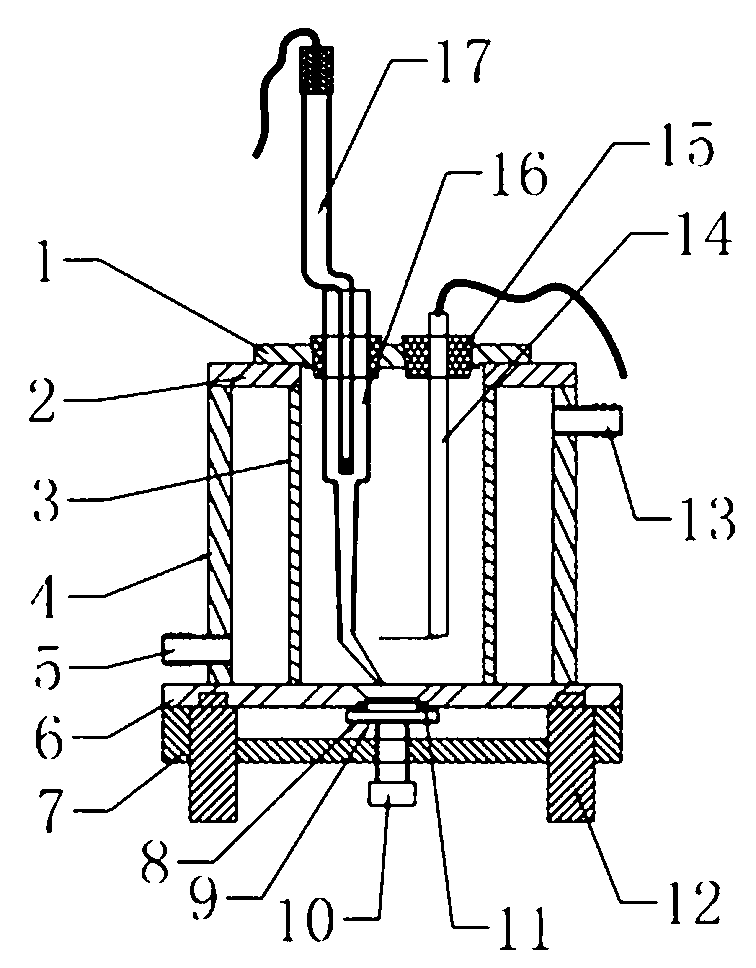

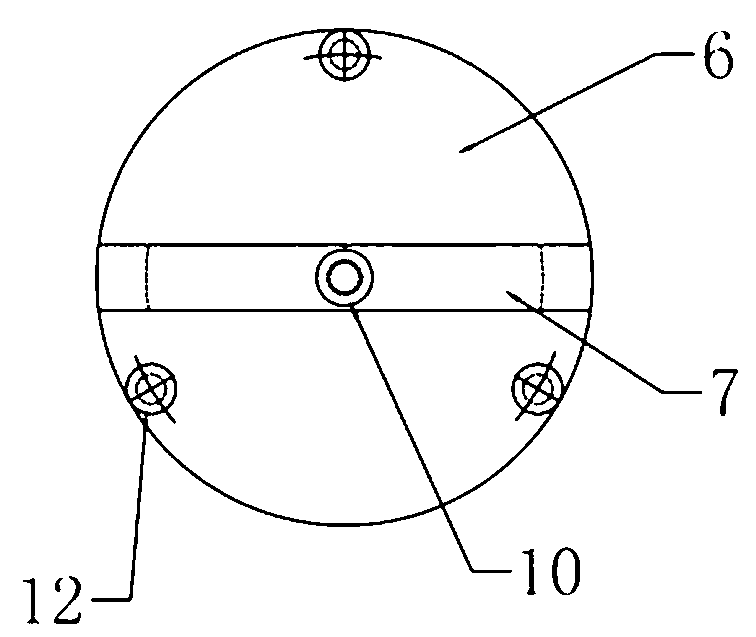

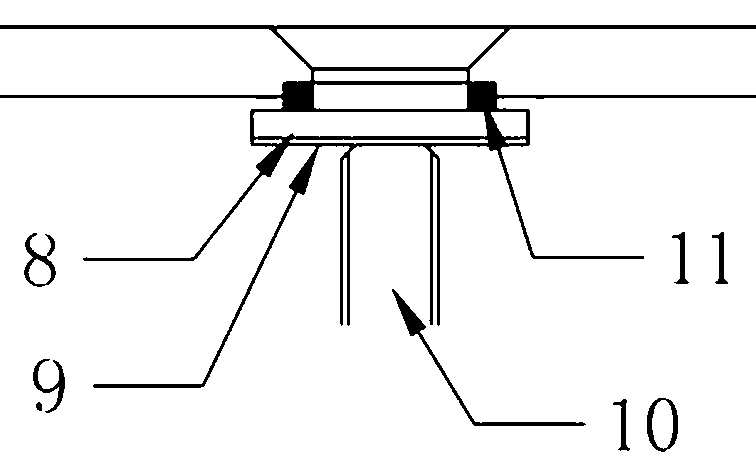

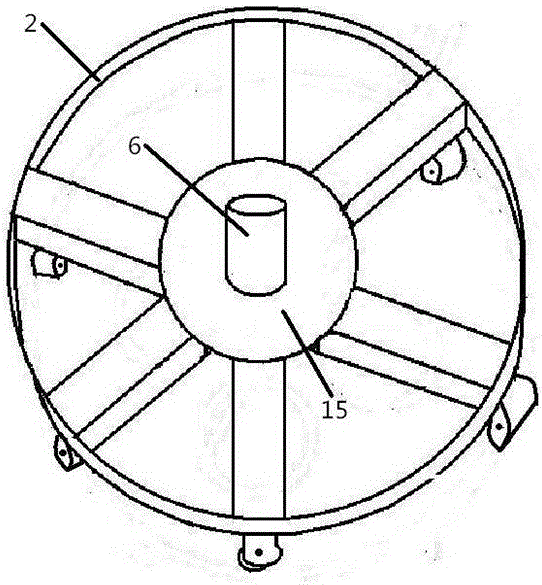

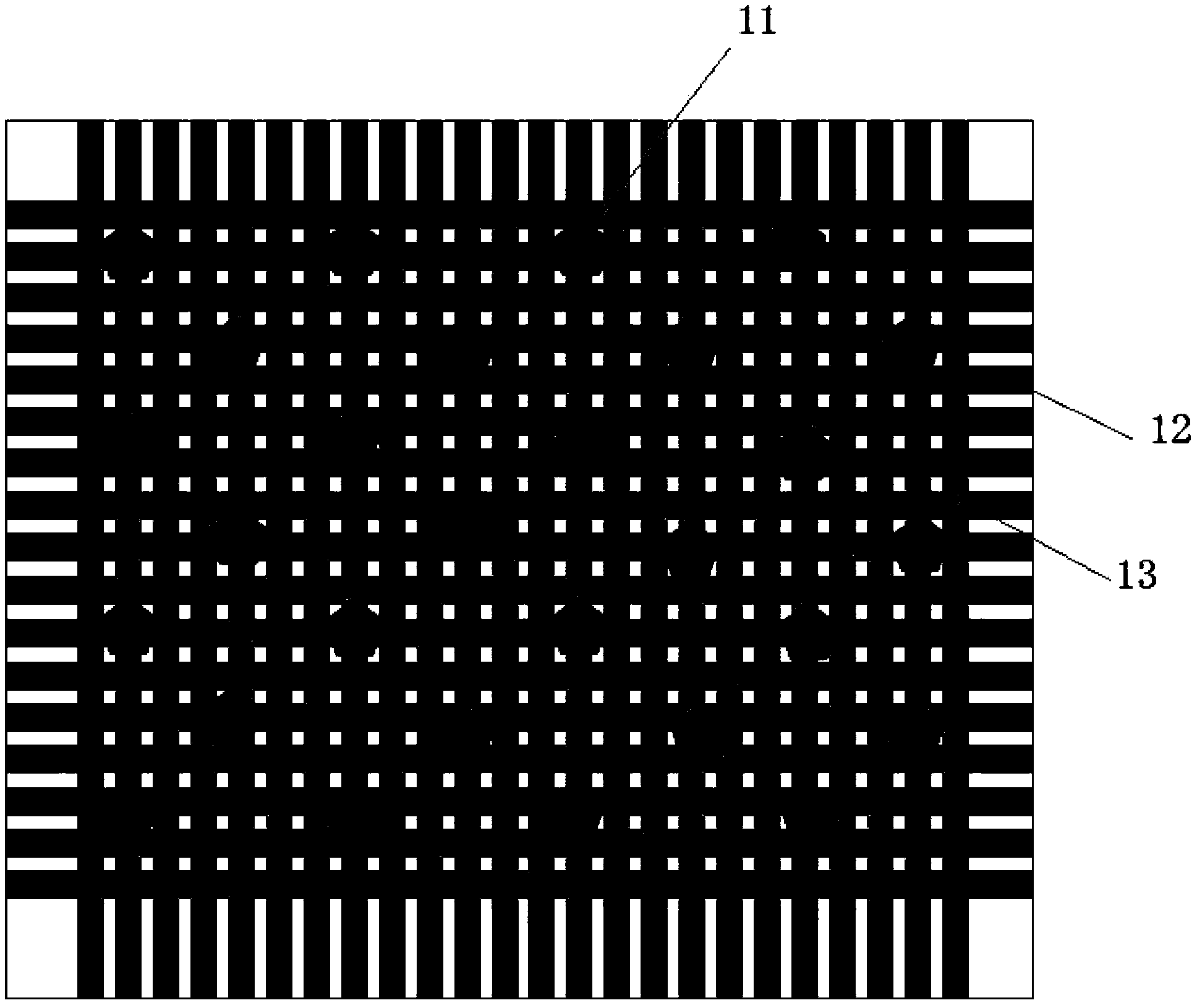

Electrolytic cell with controllable temperature used for electrochemical measurement

InactiveCN102937616AEasy to disassemble and replacePrevent rust and corrosionMaterial electrochemical variablesAdhesiveSalt bridge

The invention provides an electrolytic cell with a controllable temperature used for electrochemical measurement. The electrolytic cell comprises an upper cover (1), a sleeve top board (2), a electrolytic cell container (3), a circulating water sleeve pipe (4), a water inlet (5), a sleeve bottom board (2), a fixed support plate (7), a working electrode (8), a gasket (9), a fastening bolt (10), a sealing ring (11), container legs (12), a water outlet (13), a platinum electrode (14), a rubber plug (15), a salt bridge (16), a reference electrode (17), etc. Only need to align a sample to a central hole of the sleeve bottom board and screw a nut to make the sample contacted and sealed with the sealing ring, with no need of welding and sealing the sample, the electrolytic cell can directly measure electrochemical properties of the samples, and is convenient for replacing the sample. Temperature of the electrolyte can be controlled by externally connecting circulating water, so that interference electrochemical signals caused by eddy current produced by electric heating can be prevented. The whole container is made of corrosion resistant organic glass members; and the connecting parts are adhered with organic glass adhesives, so that the electrolytic cell is convenient in preparation and has long service life.

Owner:BEIJING UNIV OF CHEM TECH

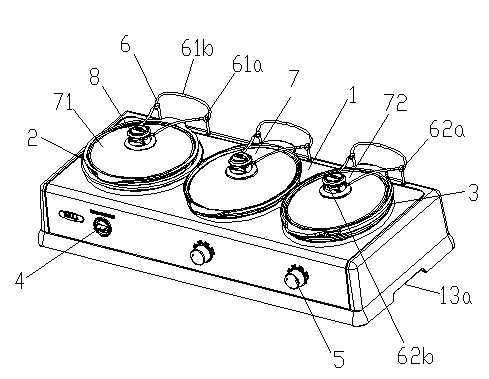

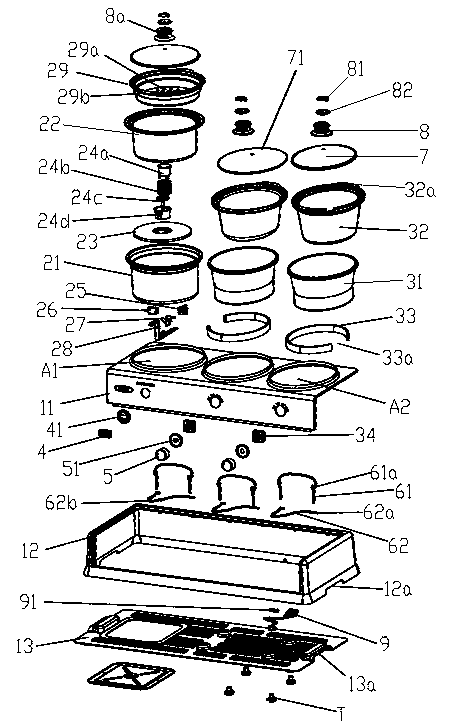

Three-in-one multi-purpose pot

InactiveCN103070608ACatering for Dining Dietary NeedsNovel and beautiful structureMultiple-unit cooking vesselsEngineeringCooker

The invention discloses a three-in-one multi-purpose pot, which comprises a rectangular furnace casing with three pot position holes arranged in a length direction, at least one of the three pot position holes is a round pot position hole, the remaining pot position holes are oval pot position holes, a round structural electric cooker is sleeved in the round pot position hole seat, an oval structural slow-stewing pot is sleeved in the oval pot position hole seat, a switch press button for controlling the electric cooker and a switch knob for regulating and controlling the slow-stewing pot are respectively arranged on the furnace casing, rotary pot cover supports capable of vertically turning over and with a rotation angle larger than 90 degrees and smaller than 130 degrees are fixedly arranged in the rear part on a top face of the furnace cashing above the furnace casing, the pot cover supports correspond to the electric cooker and the slow-stewing pot one by one, and the electric cooker and the slow-stewing pot are assembled through the furnace casing to form a combination type multi-purpose pot structure with functions of cooking rice, stewing soup and slow sewing. The three-in-one multi-purpose pot has the advantages of novel structure, attractive appearance, practical functions, convenience in operation, and capability of realizing diversified cooking.

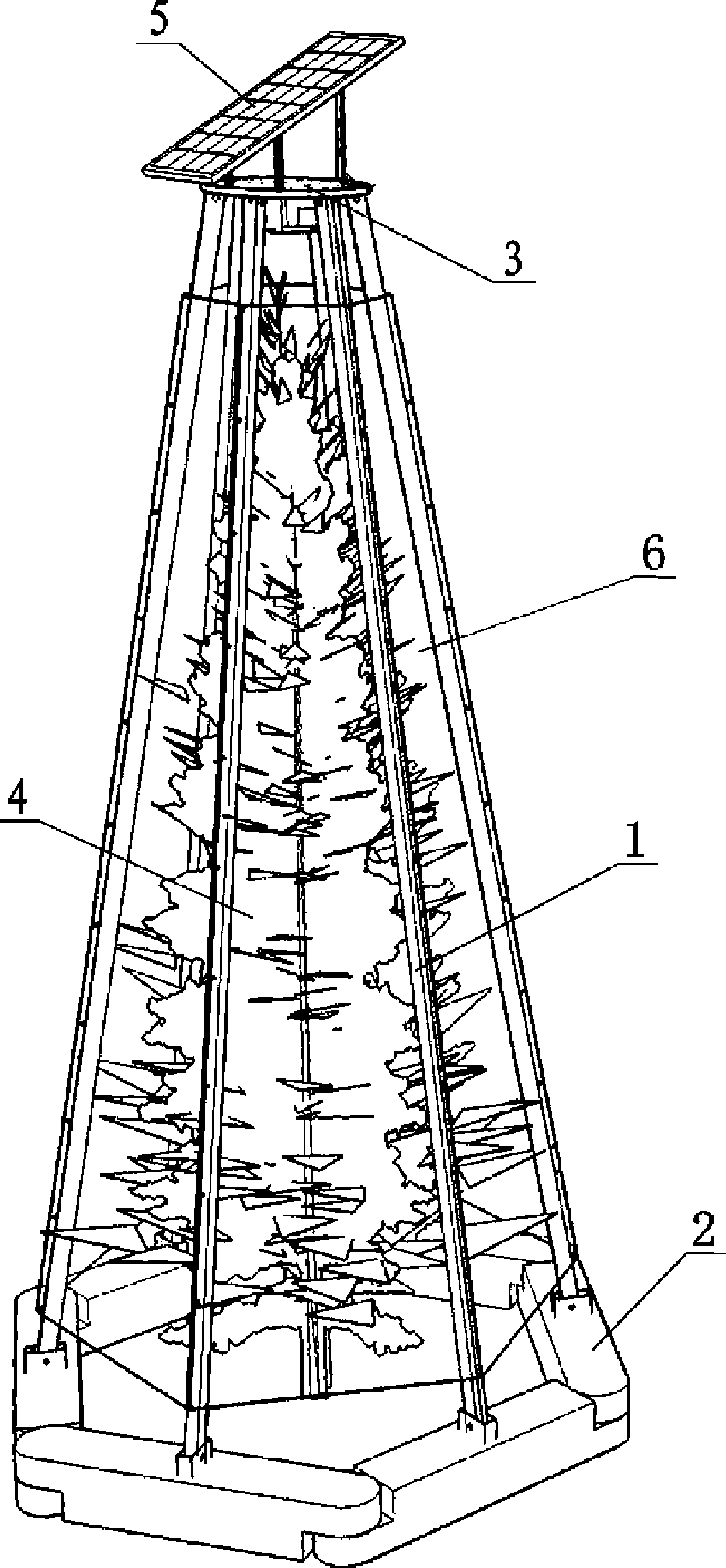

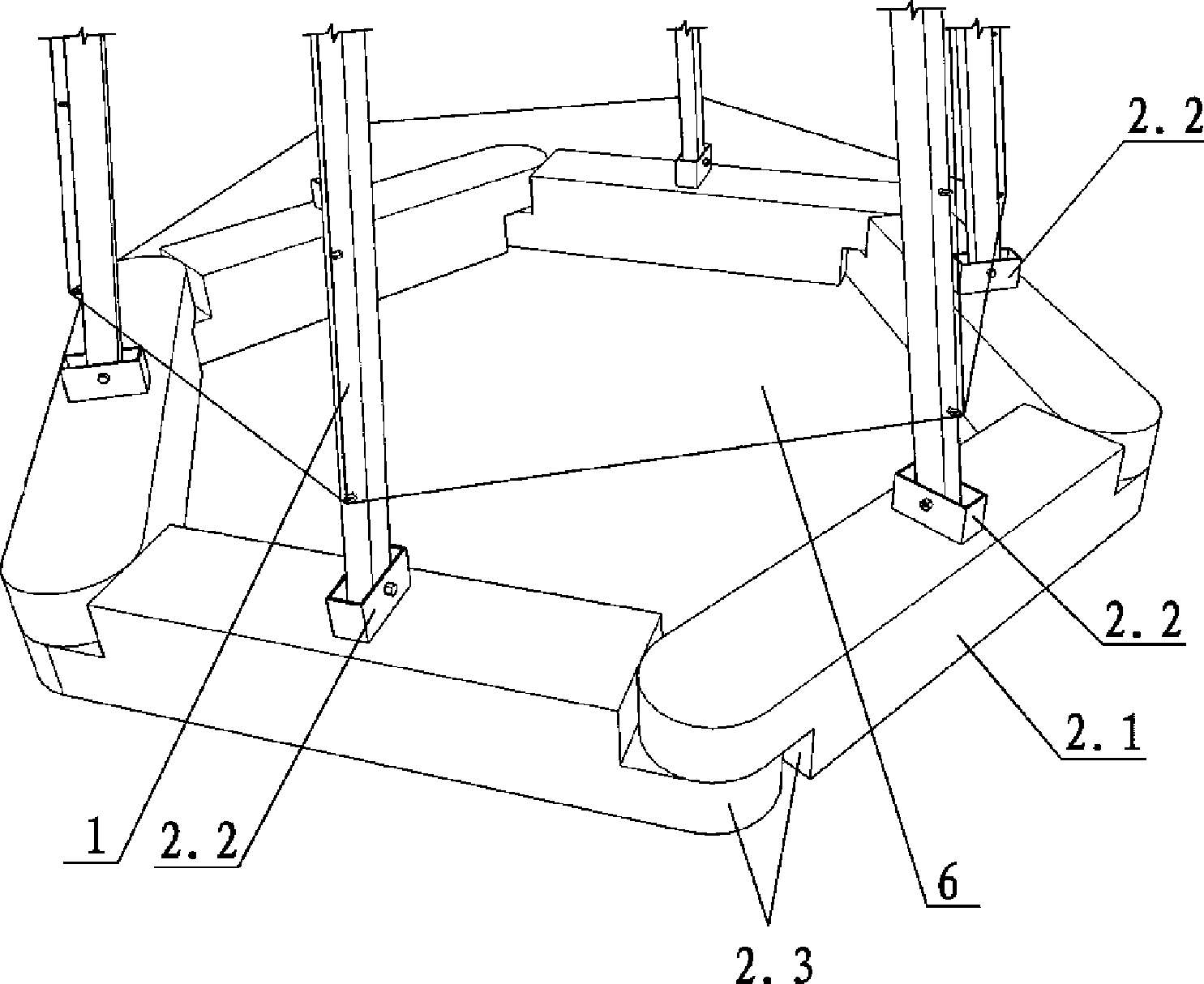

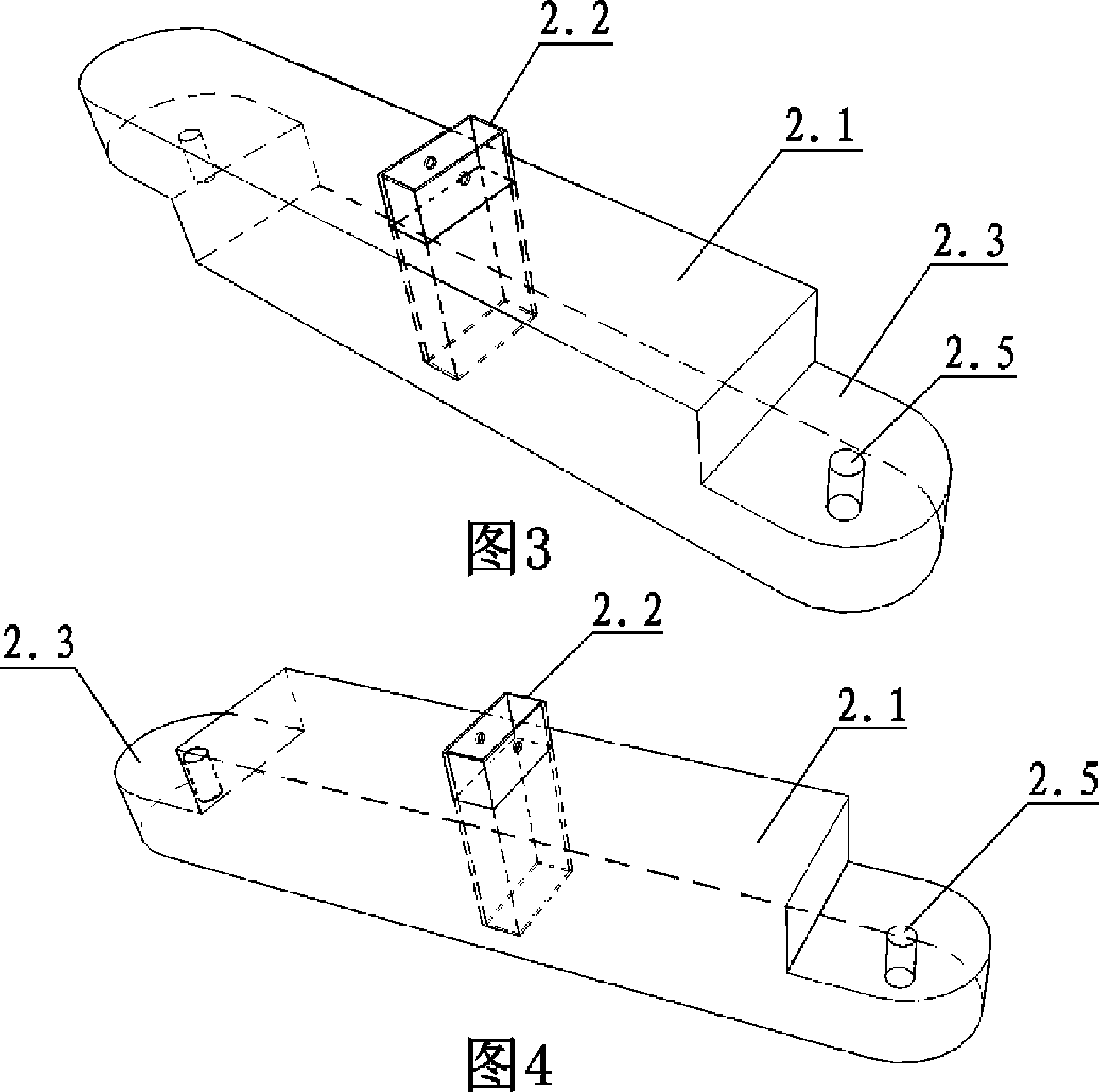

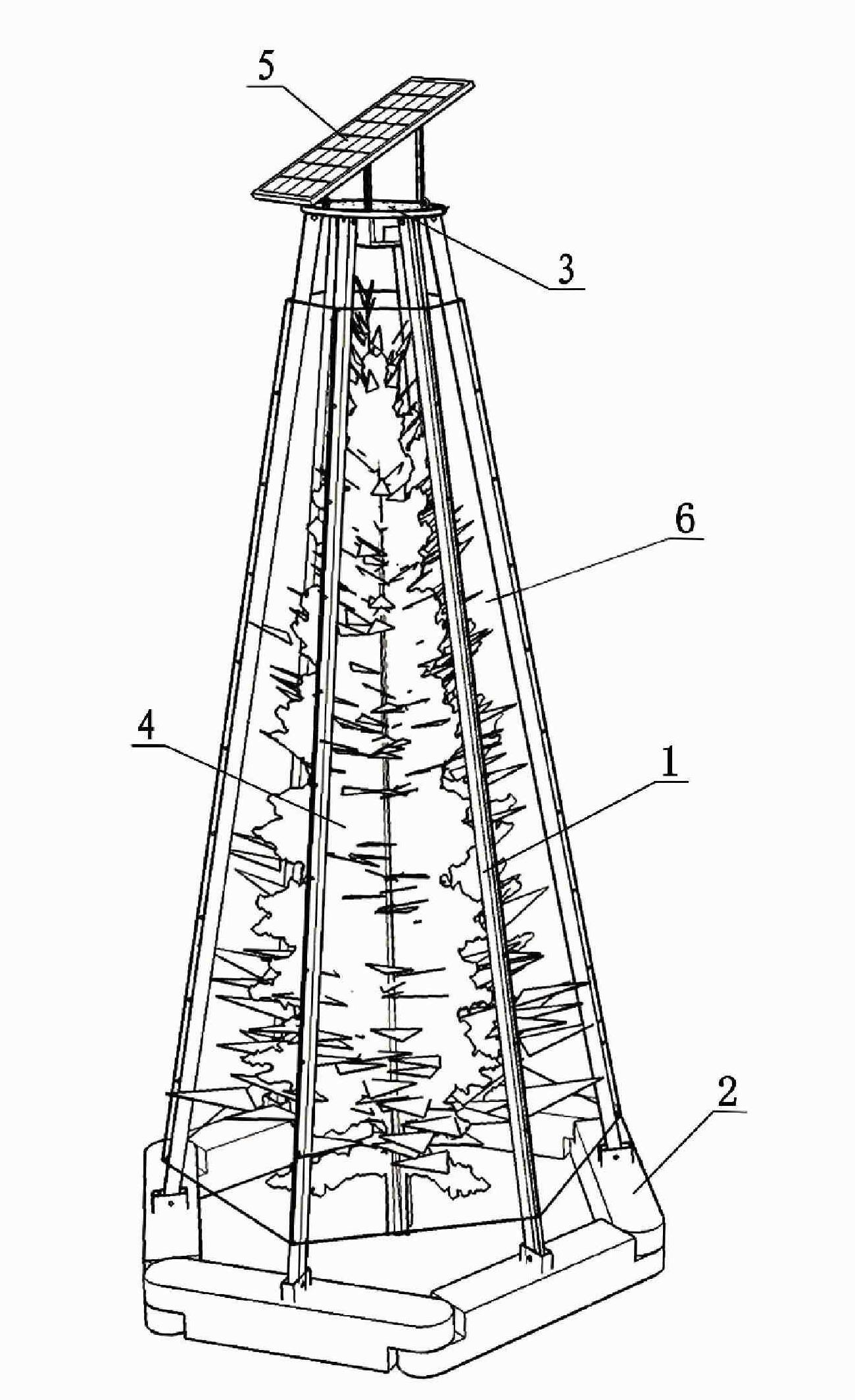

Solar energy tree cap and production method thereof

InactiveCN101416600ASuitable for needsEasy to install on siteElectric circuit arrangementsLighting elementsEngineeringLighting system

The invention relates to a solar energy tree cap and making method thereof. The solar energy tree cap comprises a skeleton structure supported around a plant and an enclosure shade. Wherein the skeleton structure is formed by connecting a pedestal, supporting rods in the middle and a chuck at the top from the downside to the upside; the pedestal is formed by splicing at least three preformed components end to end around the root part of the plant; rod shoes which are opened with holes connected with the supporting rods are connected on the preformed components; the chuck on which solar energy decorative lighting system is fixed is above the plant, with the bottom connected with pins in intervals and the top connected with lifting lugs; the supporting rods are distributed along lateral faces of the plant, with the bottom connected with the rod shoes of the pedestal, the top connected with the pins of the chuck and the middle part connected with hanging components which are connected with the enclosure shade enclosing and connected on the supporting rods. The invention integrates using function and decorative function, can not only prevent wind and preserve temperature for rare trees in the winter and provide parks and scenic spots with effective tools to prevent wind and preserve temperature for rare trees in the winter, but also add ornamentation for landscape environment.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

Oriented strand board composite decorative board and manufacturing method

InactiveCN105966143ASimple processImprove internal bond strengthSpecial ornamental structuresWood working apparatusWood shavingsRoom temperature

The invention provides an oriented strand board composite decorative board which comprises a substrate layer and an overlaying layer or overlaying layers, wherein the overlaying layer or overlaying layers is / are glued at the single side or double sides of the substrate layer through a formaldehyde-free adhesive, and the substrate layer is an oriented strand board taking wood or wheat straw shavings as the raw material and taking isocyanate resin and / or phenolic resin as the adhesives or the adhesive. A manufacturing method of the oriented strand board composite decorative board comprises the following steps that by taking the wood or wheat straw shavings as the raw material and taking isocyanate resin and / or phenolic resin as the adhesives or the adhesive, the oriented strand board is manufactured according to directional pavement and hot-pressing technologies; the both sides of the oriented strand board are sanded and puttied; one side or both sides of the substrate layer is / are coated with the formaldehyde-free adhesive, and is / are bonded with the overlaying layer or the overlaying layers; and room temperature cold pressing treatment is carried out to allow the adhesive(s) to be solidified, wherein the pressing temperature is 20-35 degrees, the pressing pressure is 0.5-1.5MPa, and the pressing time is 0.5-4h. According to the oriented strand board composite decorative board, the problems that the conventional decorative board is high in formaldehyde content, complicated in technology, and high in cost are solved.

Owner:NINGBO ZHONGJIA LOW CARBON NEW TECH RES INST

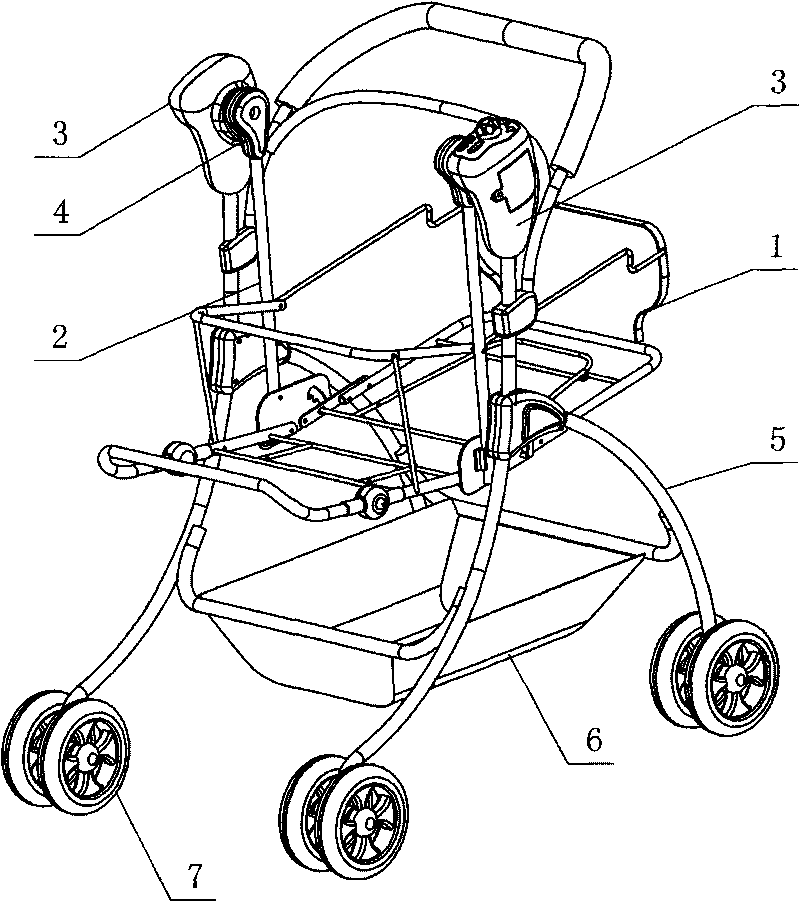

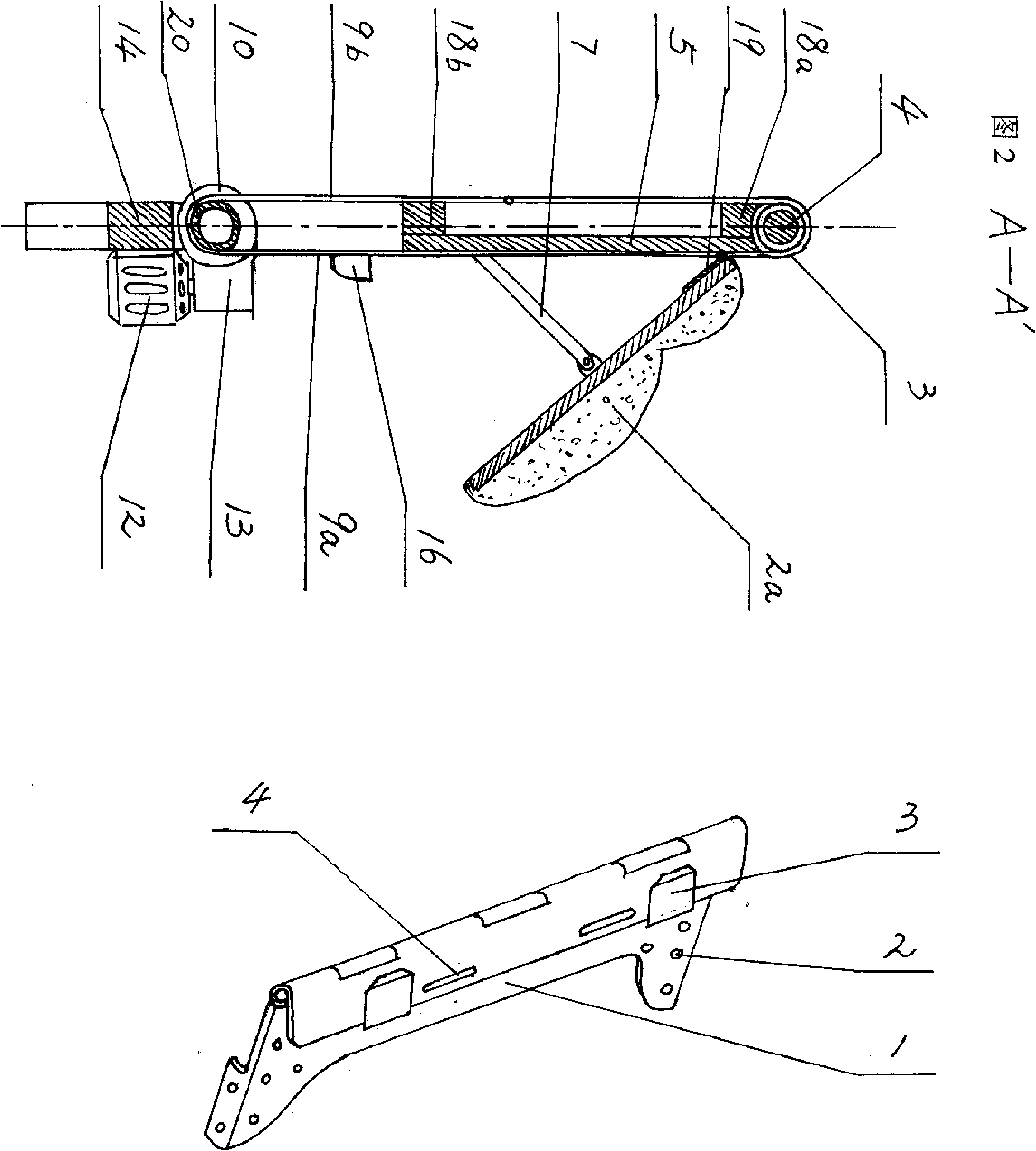

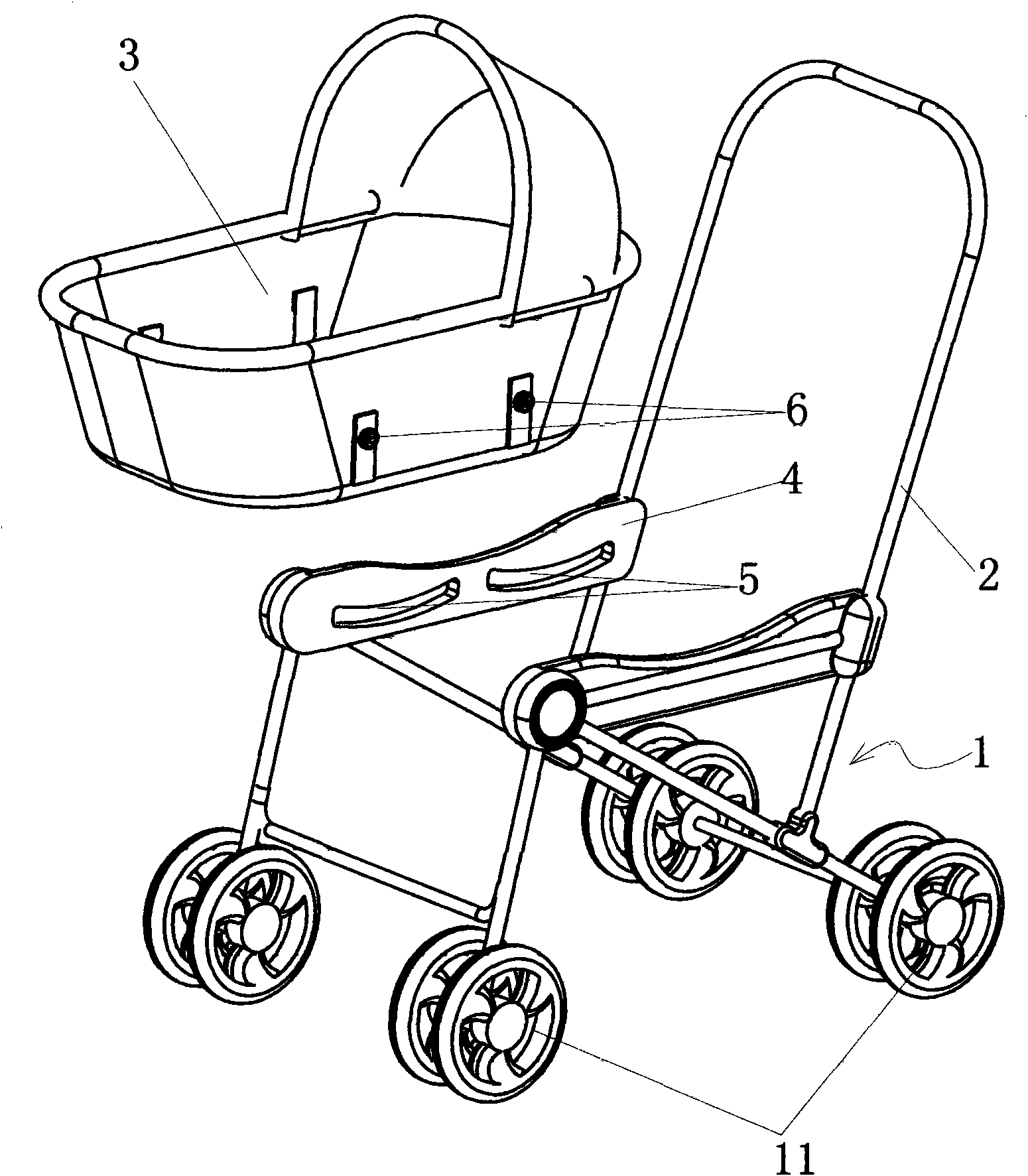

Baby carrier, manufacturing method and using method thereof

InactiveCN101691123AEasy to appeaseEasy to carryCarriage/perambulator accessoriesCarriage/perambulator with multiple axesVehicle frameAutomatic control

The invention provides a baby carrier, which relates to a trolley and is used for placating a crying child. The baby carrier comprises a frame (5), wheels (7) and a baby carrier seat (1), and is characterized in that the frame (5) and the baby carrier seat (1) have independent split structures; two sides of the baby carrier seat (1) are provided with an oscillating arm (2) respectively; and the baby carrier seat (1) is pivoted on the frame (5) through the two oscillating arms (2). The baby carrier has the following advantages that: the frame and the baby carrier seat of the baby carrier have the independent split structures which can achieve the function of oscillating forward and backward through manual operation or electric power automatic control to better placate the child, and the structure is simple, is convenient to fold and has a lower cost; and the baby carrier also has the functions of convenient carrying and placating the child, and the baby carrier can also conveniently achieve the function of oscillating forward and backward while traveling. Compared with non-pendulum type swaying motions, the pendulum type swaying motions of the baby carrier have a better effect of placating children, particularly infants.

Owner:ZHONGSAN CITY TOGYINBABY CO LTD

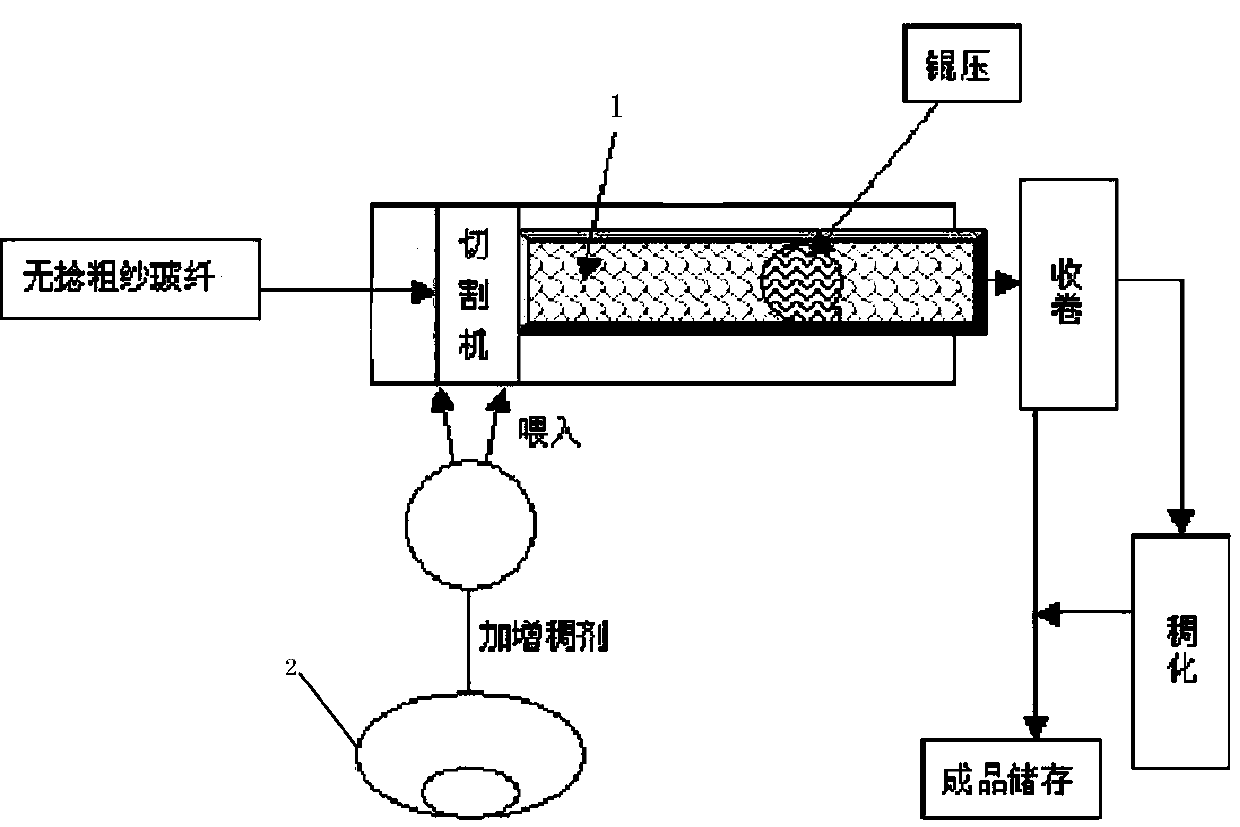

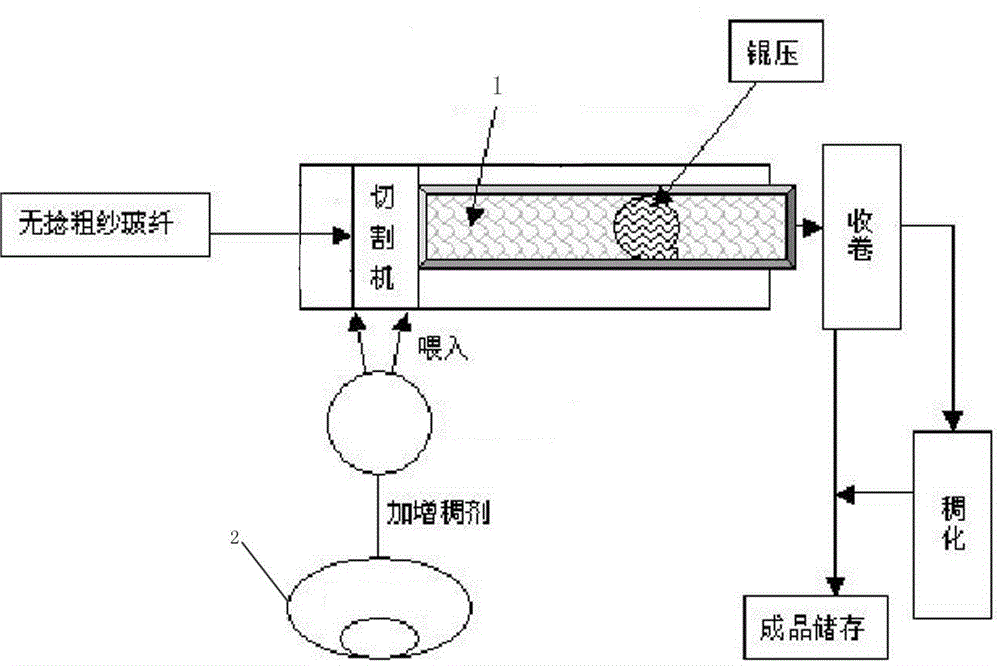

Sheet-shaped mould plastic for manufacturing inspection well lid and preparation method for sheet-shaped mould plastic

The invention firstly provides an environment-friendly and low-cost sheet-shaped mould plastic for manufacturing an inspection well lid. A middle core material of the sheet-shaped mould plastic consists of glass fiber cloth which is soaked with resin paste, wherein the content of glass fibers is 20-40 parts, and the resin paste comprises the following materials in parts by weight: 19-23 parts of unsaturated resin, 6-8 parts of a low shrinkage agent, 1.4-1.6 parts of styrene, 0.5-1.5 parts of a curing agent, 1.5-1.7 parts of zinc stearate, 0.01-0.03 part of benzoquinone, 0.2-0.3 part of pigment paste, and 40-50 parts of ground calcium carbonate of 800-1000 meshes. The invention further provides a method for preparing the sheet-shaped membrane plastic. The sheet-shaped mould plastic provided by the invention adopts base raw materials, and further adopts waste ground calcium carbonate, is low in cost and beneficial to environmental protection and energy conservation. The sheet-shaped mould plastic manufactured by virtue of the method is high in technical content, stable in process, relatively low in cost, strong in bearing capacity; and a product manufactured by virtue of the sheet-shaped mould plastic has the characteristics of tight matching, wear resistance, corrosion resistance, a light structure, an attractive style, light weight and easiness in installation, is remarkable in social benefit and economic benefit.

Owner:LINAN JUFENG URBAN SUPPORT EQUIP

Method for manufacturing colored metal model by three-dimensional (3d) digital model

ActiveCN103241054ALow costNo mass production quantity requiredSpecial ornamental structuresGraphicsManufacturing technology

The invention belongs to a metal model manufacturing technology, and in particular relates to a method for manufacturing a colored metal model by a three-dimensional (3d) digital model. The method comprises the following steps of: arranging the model, unfolding the model, composing graphs, manufacturing etching graphs, etching a metal sheet material, manufacturing an etching sheet surface coating and a colored printing graph, and printing and assembling etching sheets to form the metal model. A die is not required to be opened, and the 3D digital model can be composed to form a planar graph for processing a metal thin plate so as to produce various types of metal models. A planar metal plate can be directly printed and colored, various high-precision colored patterns can be printed or stamped on the metal plate, and the metal model is bright in color and vivid in pattern. The method is suitable for small-batch production and can meet humanized requirements of different objects.

Owner:陈琰

Aldehyde-free composite artificial board and manufacturing method thereof

InactiveCN105966004AImprove the level of environmental protectionSimple processLamination ancillary operationsLaminationWood veneerResin adhesive

The invention provides a formaldehyde-free composite wood-based panel, comprising a substrate layer and a veneer layer, the veneer layer is bonded to one or both sides of the base material layer by an formaldehyde-free adhesive, the base The material layer is formaldehyde-free plywood with wood veneer as raw material and thermoplastic resin film as adhesive. The method for manufacturing the formaldehyde-free composite wood-based panel comprises the following steps: using wood veneer as a raw material, using a thermoplastic resin film as an adhesive, first hot-pressing and then cold-pressing to form formaldehyde-free plywood; using formaldehyde-free plywood as a base material, Repair and scrape putty on both sides of the base material; after sanding the above base material, apply formaldehyde-free adhesive on one or both sides of the base material, and glue the veneer layer; cold press the above board at room temperature to make the adhesive solidify. The invention solves the problems of high formaldehyde content, complex process and high cost of the existing decorative boards, and has the advantages of many kinds of patterns, beautiful styles, paint-free and environmental protection, convenient processing and use, and low cost.

Owner:NINGBO ZHONGJIA LOW CARBON NEW TECH RES INST

Flake molding compound for manufacturing manhole cover and preparation method of flake molding compound

The invention firstly provides a flake molding compound for manufacturing a manhole cover which is environment-friendly and low in cost. The middle core of the flake molding compound is composed of glass fiber cloth dipped with resin paste, the glass fiber content is 20-40 parts, the resin paste comprises the following materials: 19-23 parts of unsaturated resin, 6-8 parts of low shrinking agent, 1.4-1.6 parts of styrene, 0.5-1.5 parts of curing agent, 1.5-1.7 parts of zinc stearate, 0.01-0.03 part of benzoquinone, 0.2-0.3 part of pigment paste, and 40-50 parts of 800-1000-mesh heavy calcium carbonate. The invention further provides a method for preparing the flake molding compound. The flake molding compound provided by the invention adopts base raw material in low cost, and waste heavy calcium carbonate is adopted, so that the flake molding compound is environmentally friendly and energy-saving. The flake molding compound manufactured by using the method disclosed by the invention is high in technical content, stable in process, low in cost and strong in bearing capacity. The product disclosed by the invention is manufactured as an article which is tight in matching, wear-resistant, corrosion-resistant, light in structure, beautiful in style, light in self weight and easy to install. The social benefit and the economic benefit are obvious.

Owner:LINAN JUFENG URBAN SUPPORT EQUIP

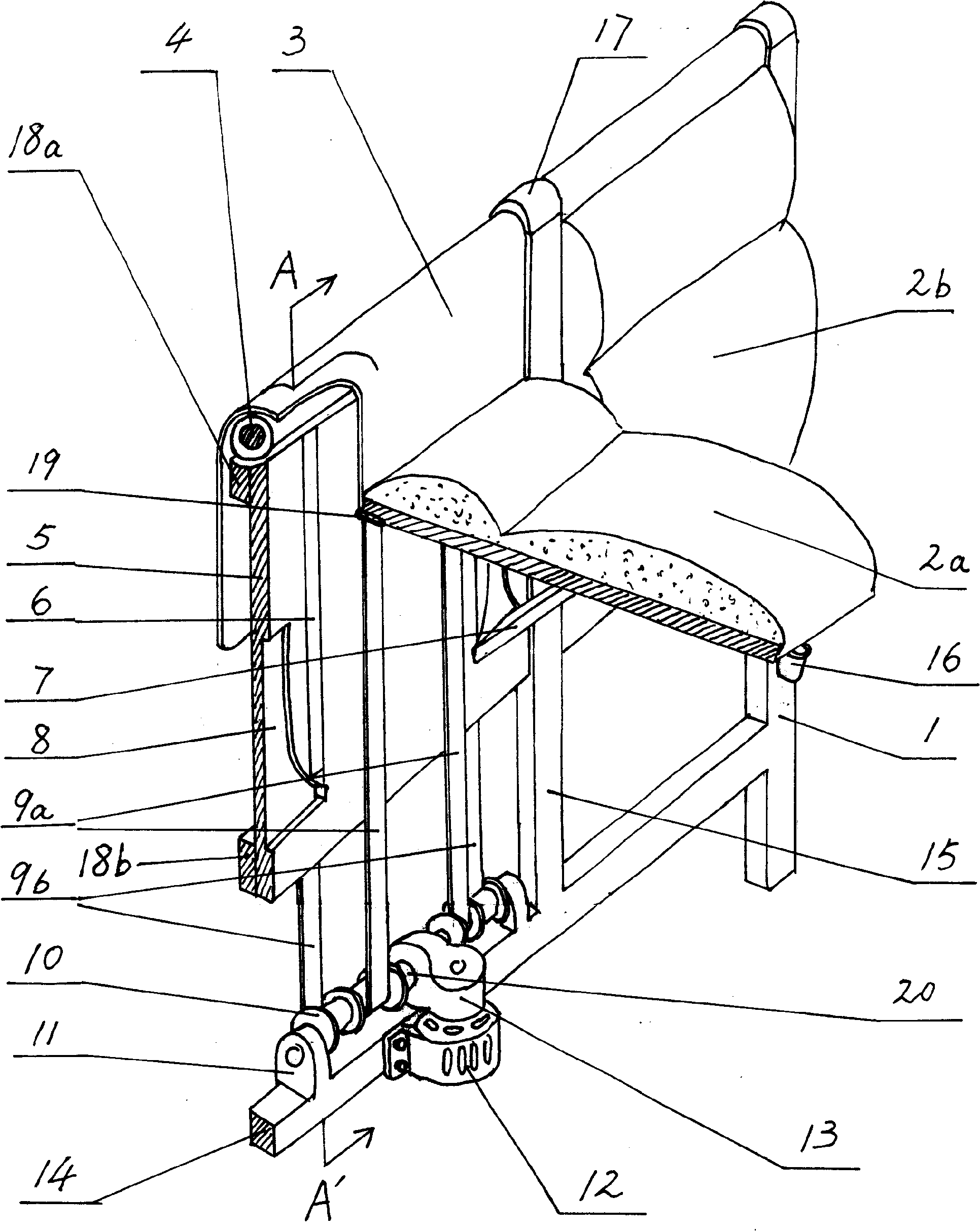

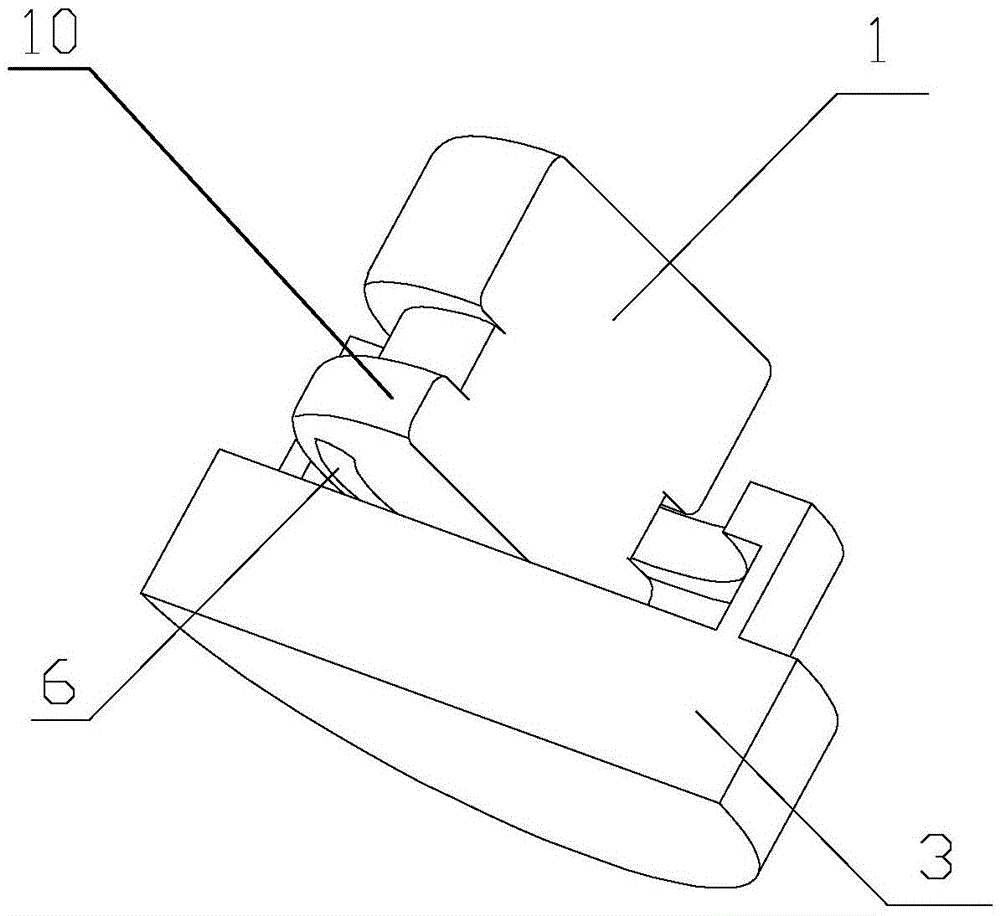

Movable backrest and drive mechanism thereof

The invention relates to an adjustable backrest and a dynamic mechanism thereof, which is the adjustable backrest that one or more than one adjustable backrest that can adjust the inclination by the electric way are arranged on the original backrest of a bed or a recliner; the top end of the backrest is pulled by a traction loop tensioned on the original backrest; the traction loop can be driven to lead the top end of the adjustable backrest to move upwardly and downwardly; the aim of adjusting the inclination of the adjustable backrest can be reached by the function of an adjustable support. The latest research abroad indicates that the semi-reclining position that keeps the leg and the spine to be about 135 degrees is the ideal sitting position which is beneficial to the health of the spine; the system can be adjusted to the posture conveniently. The use of the system can not only bring the convenience and comfort to the leisure life of people, but also bring health to the spines of users. The system can be used in the household life and can be widely used in high-grade places of beaches, shower, leisure, holidays, hotels, restaurants, and the like, or special places of hospitals or nursing houses, etc.

Owner:王名勇

Preparing method of case leather

ActiveCN104445039ABeautiful styleImprove visual effectsLeather clicking/perforating/clickingLeather surface mechanical treatmentTouch SensesColloid

The invention discloses a preparing method of case leather. The method comprises the steps that a. cow leather is selected, and the cow leather comprises a corium layer and a subcutaneous tissue layer; b. a sheet-shaped subcutaneous tissue layer is evenly cut on the subcutaneous tissue layer of the cow leather, and the cut sheet-shaped subcutaneous tissue layer is kept on the inner side of the cow leather; c. a needed embossment pattern is engraved on the cut sheet-shaped subcutaneous tissue layer, and the subcutaneous tissue layer on the outer periphery of the embossment pattern is removed; d. the cow leather with the embossment pattern engraved is placed in a three-dimensional forming mould, the embossment pattern part is pressed to the corium layer of the cow leather, and accordingly a protruding pattern structure consistent with the embossment pattern is formed on the outer surface of the corium layer of the cow leather; e. antiseptic treatment is carried out; f. colloid injection is carried out; and g. metal decorating piece embedding is carried out. Through the process design, according to the preparing method of the case leather, the case leather which is attractive in style, good in visual effect and obvious in touch sense can be produced.

Owner:GUANGZHOU TIANYIFANG LEATHER CO LTD

Random wax dyeing technology

The invention discloses a random wax dyeing technology, which comprises steps of pretreating cloth, starching, bleaching, mercerizing, waxing, printing and dyeing and de-waxing, wherein the waxing process is random wax liquid sprinkling. The random wax dyeing technology has the advantages of high reliability, convenient printing and dyeing, and simple process, the product has the advantages of bright color, beautiful pattern, good finished product quality, and low price, and the method has wide market prospect in printing and dyeing market.

Owner:TAICANG HONGYING PRINTING

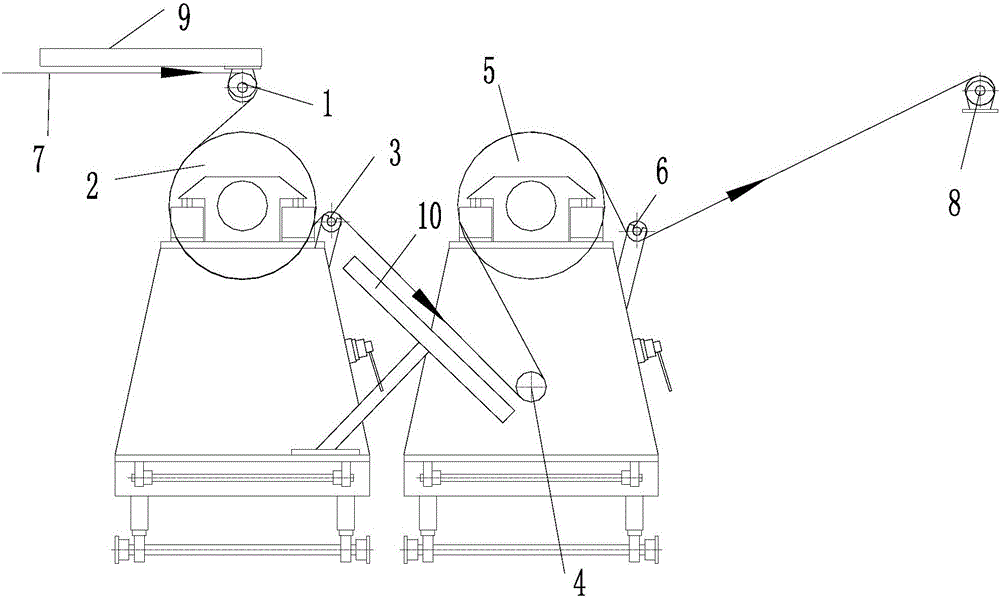

Method for making grain on double sides by suction for artificial leather production and double-side grain suction-making equipment

The invention provides a method for making grain on double sides by suction for artificial leather production. The method is characterized in that the artificial leather wound on a first suction roll and a second suction roll in sequence moves forwards sequentially through the first suction roll and the second suction roll under traction action; one side surface of the artificial leather fits the first suction roll and then grain is made by suction on the side surface of the artificial leather by the first suction roll; the other side surface of the artificial leather fits the second suction roll and then grain is made by suction on the other side surface of the artificial leather by the second suction roll. By the method for making grain on double sides by suction, double-side grain is made during the single manufacturing process, processing procedures are simplified, production efficiency is increased, production cost is lowered, and labor intensity of operation workers is reduced. The invention further provides double-side grain suction-making equipment for artificial leather production; by the double-side grain suction-making equipment, making of double-side grain can be completed during the single manufacturing process, processing procedures are simplified, production efficiency is increased, production cost is lowered, and labor intensity of operation workers is reduced.

Owner:FOSHAN SANSHUI HUIXINGLONG PLASTIC CO LTD

Manufacture method for fan blades

ActiveCN102490232ALow costPromote environmental protectionWood working apparatusPolyvinyl chloridePulp and paper industry

The invention discloses a manufacture method for fan blades, which is characterized by including the following steps: enabling plates to be made into shapes of fan blades, and carving predetermined patterns on the fan blades; grinding the fan blades in step A and enabling surfaces of the fan blades to be smooth, and then removing dust; evenly coating edges of the fan blades in step B with white glue; coating the surfaces of the fan blades with a layer of white glue after the white glue in step C is dried and becomes transparent; removing particles of light sands after the glue in step D is dried and removing dust; installing the fan blades in step E on a template machine for polyvinyl chloride (PVC) absorption, and deflashing after absorption. The manufacture method for fan blades aims at overcoming defects in the prior art and can lower production cost and manufacture fan blades which are varied in style and attractive and environment-friendly.

Owner:中山乡源木业有限公司

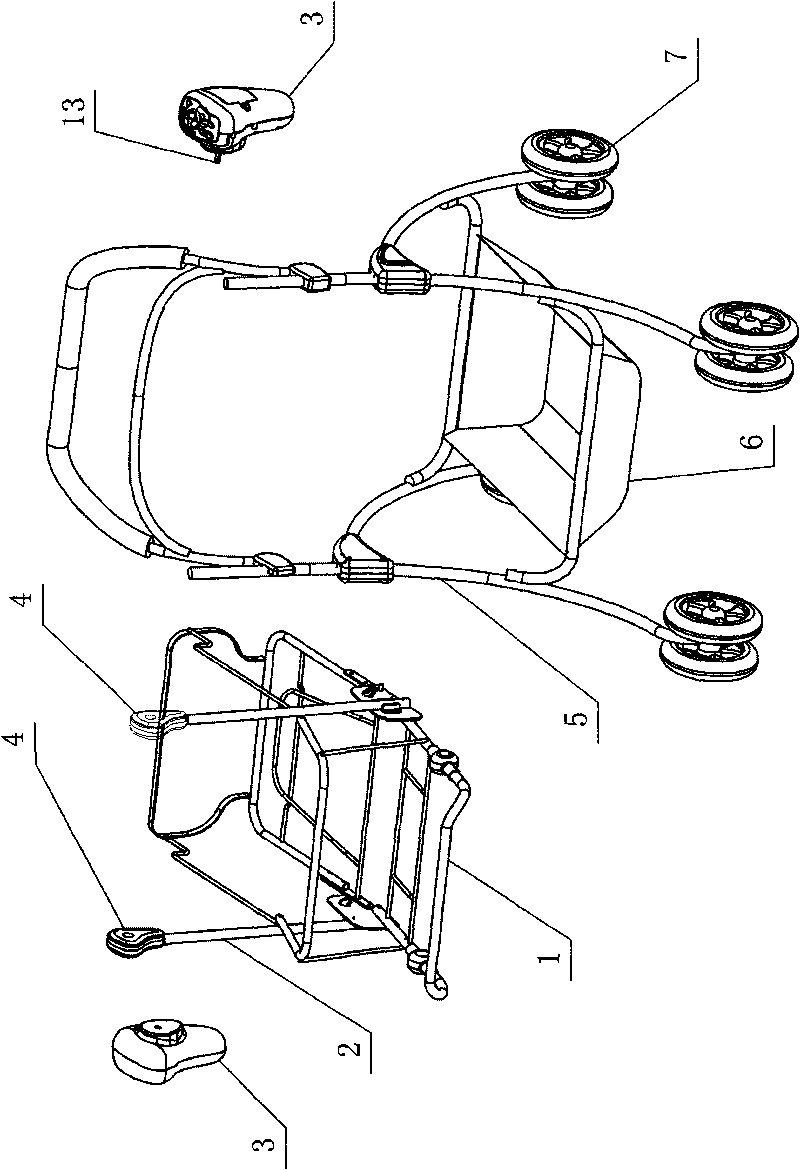

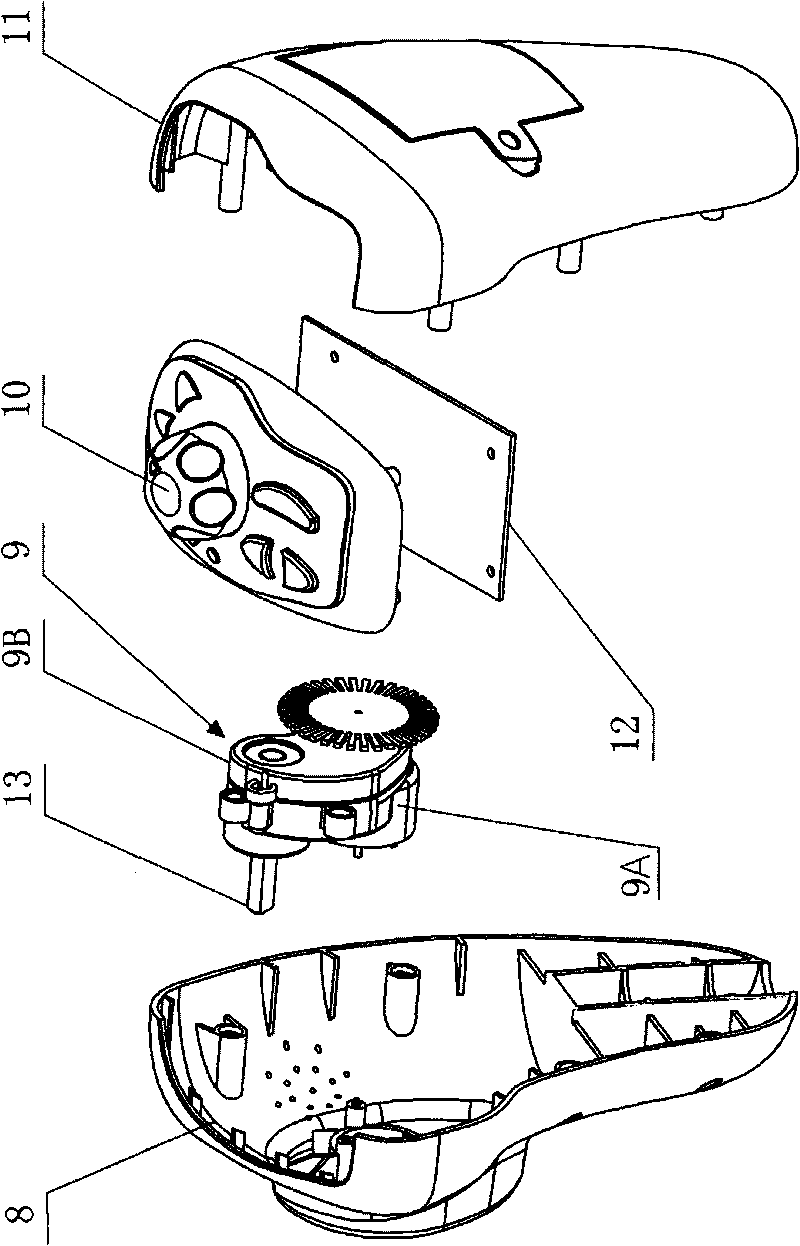

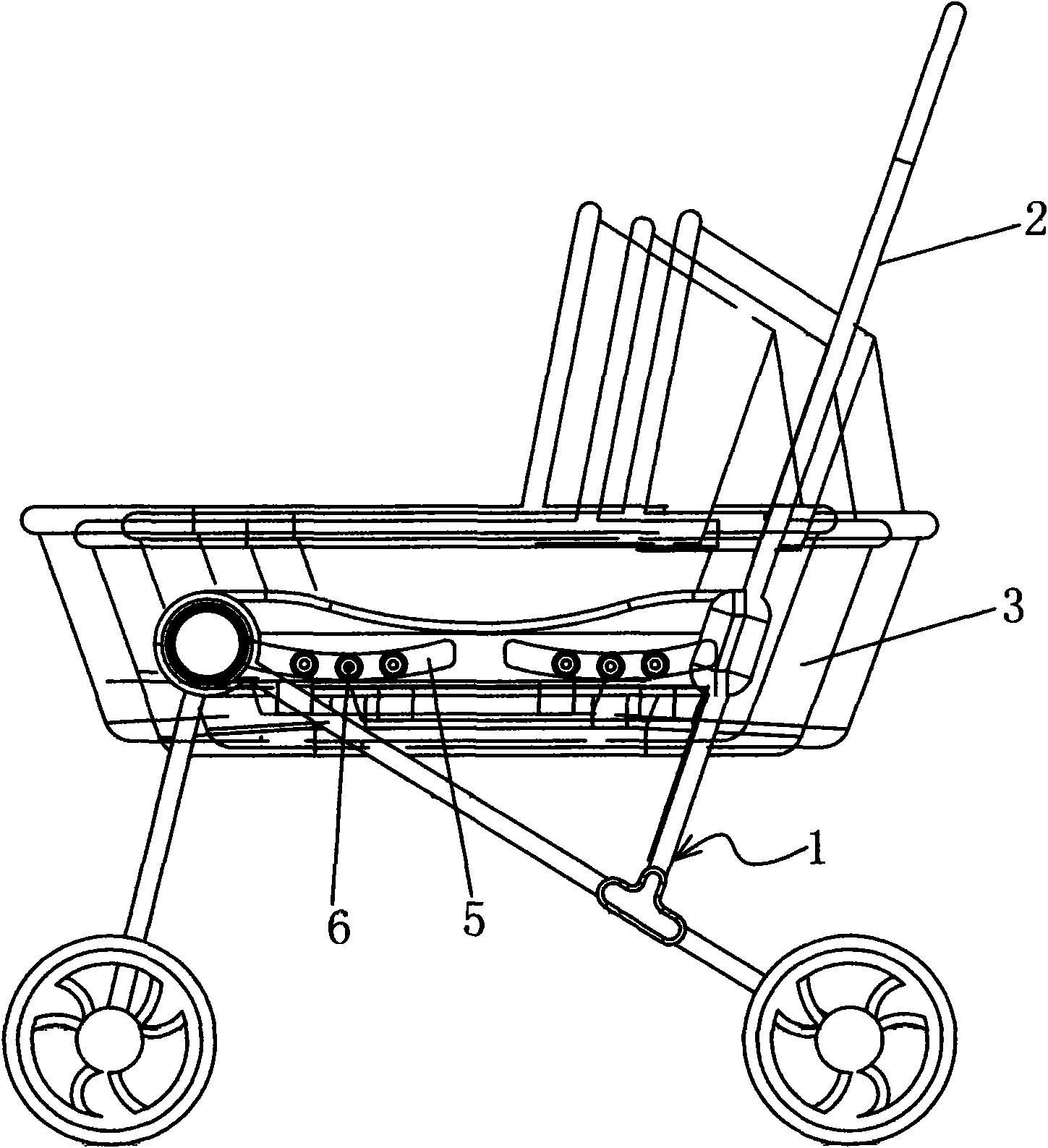

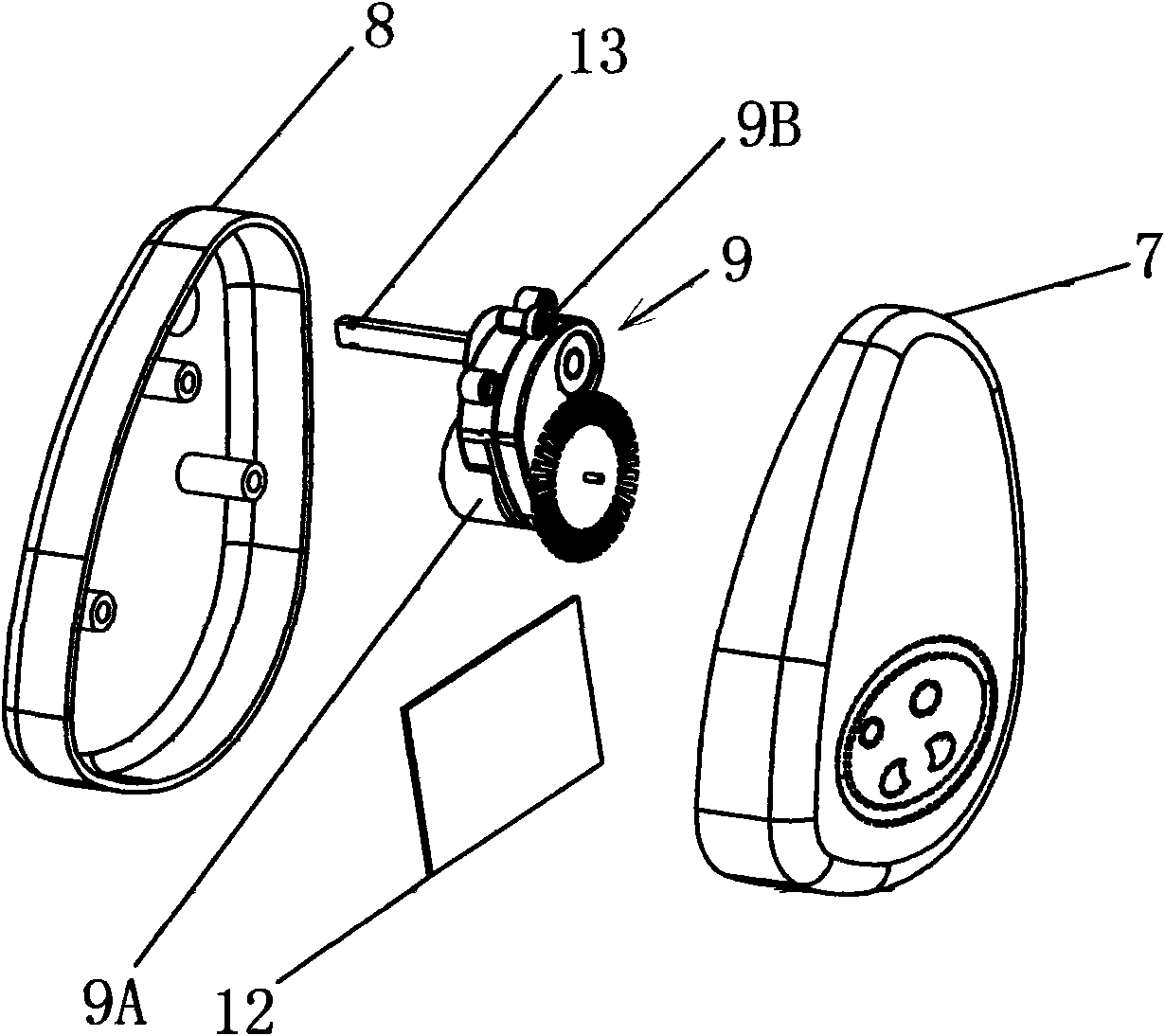

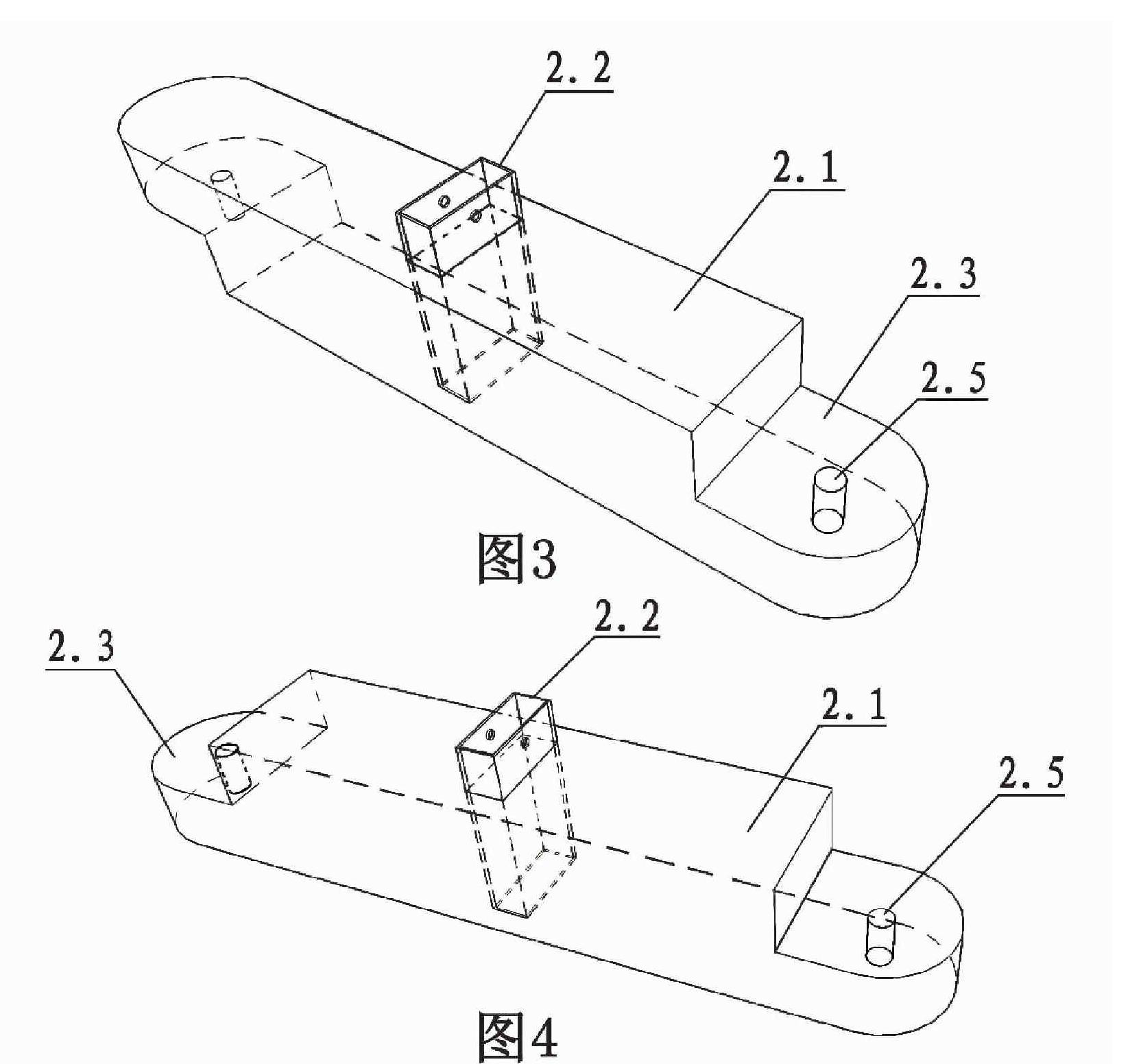

Baby carrier with gliding seat and manufacturing method and using method thereof

InactiveCN102039923APut to sleepAct as a cradleCarriage/perambulator accessoriesCarriage/perambulator with multiple axesVehicle frameElectric machinery

The invention provides a baby carrier with a gliding seat, and relates to a handcart for carrying and placating a child. The baby carrier comprises a frame (1) with running wheels (7) and a seat (3) arranged on the frame (1). The baby carrier is characterized in that: a lower slide rail seat (4) is arranged on the frame (1), the lower slide rail seat (4) is transversely placed on the frame (1), and the lower slide rail seat (4) is provided with a lower slide rail (5); and pulleys (6) capable of gliding front and back along the lower slide rail (5) are arranged at the corresponding positions of the lower slide rail seat (4) respectively and enable the seat (3) to glide to and fro relative to the frame (1). The baby carrier has the advantages that: when the baby cries, a handle is pulled to and fro by hand, or the pulleys are driven by using a motor, and the pulleys glide along the glide rail; and because the middle of the glide rail is low and the two ends of the glide rail are high, the seat glides to and fro relative to the frame to play a role of a cradle, and the baby can be quickly put to sleep through the baby carrier.

Owner:ZHONGSAN CITY TOGYINBABY CO LTD

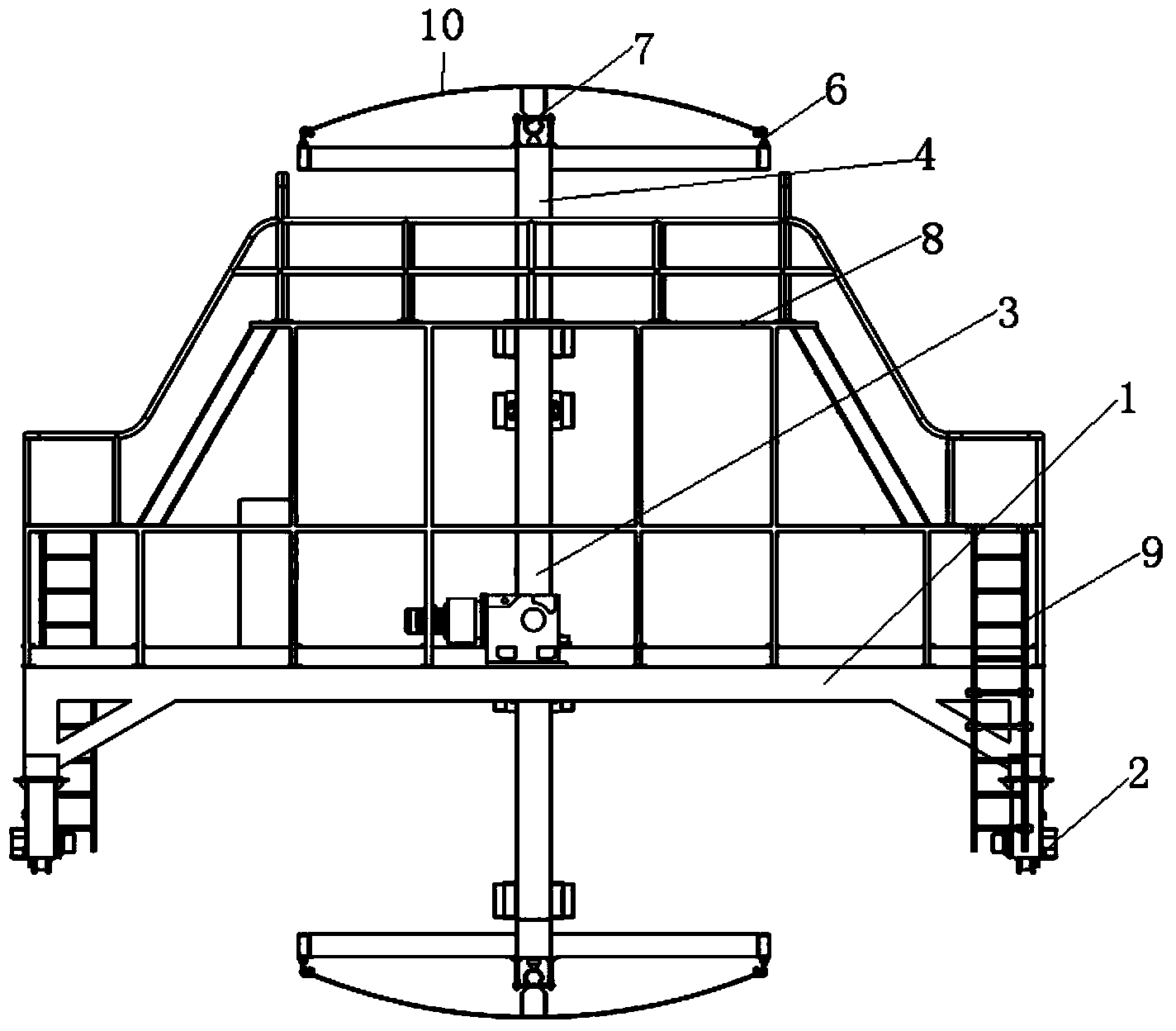

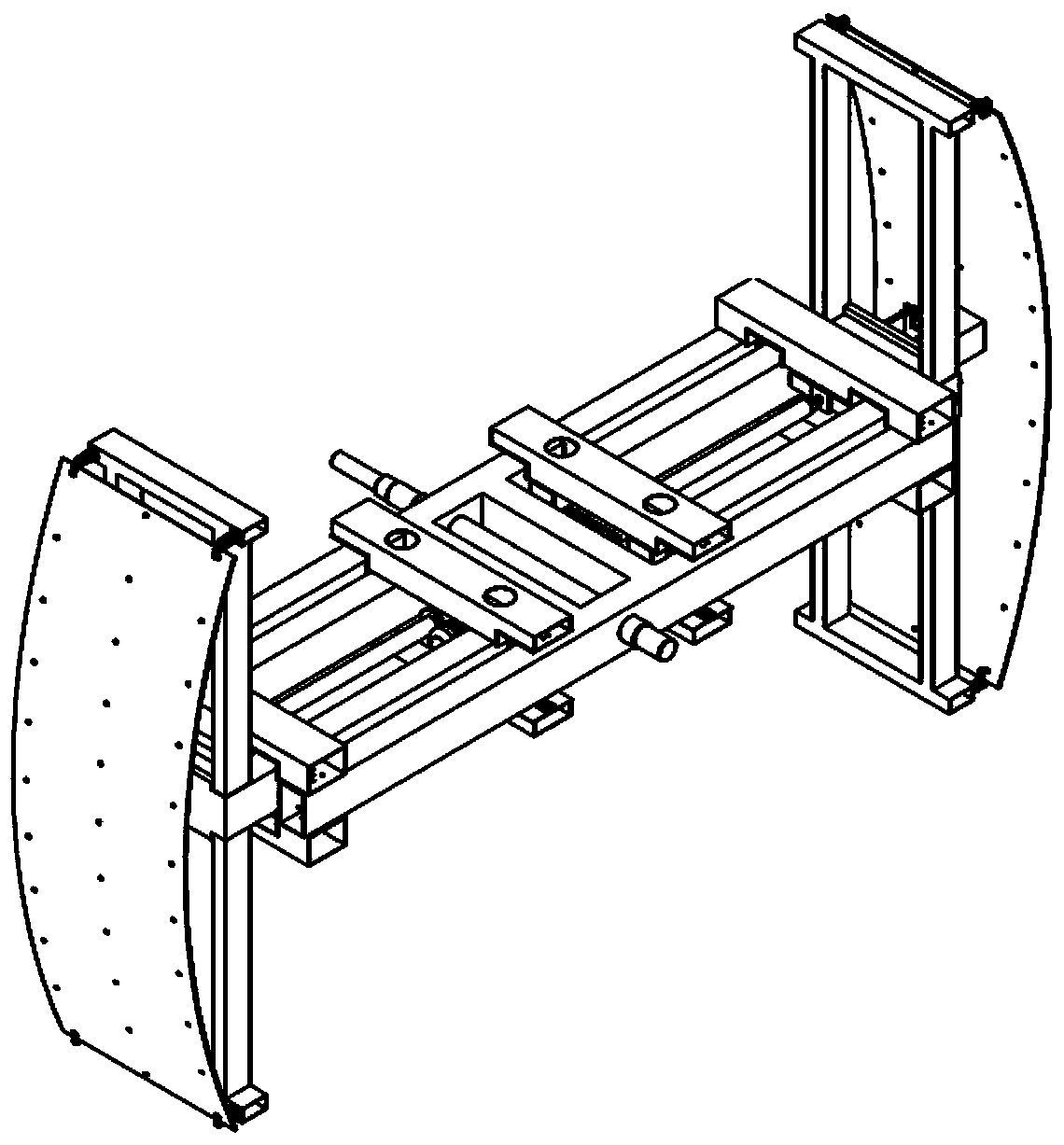

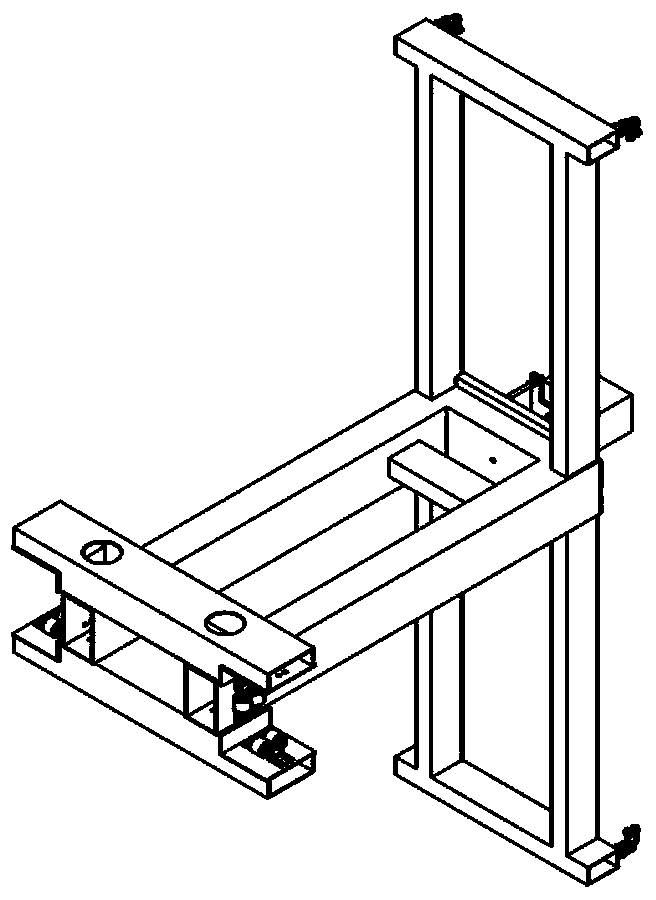

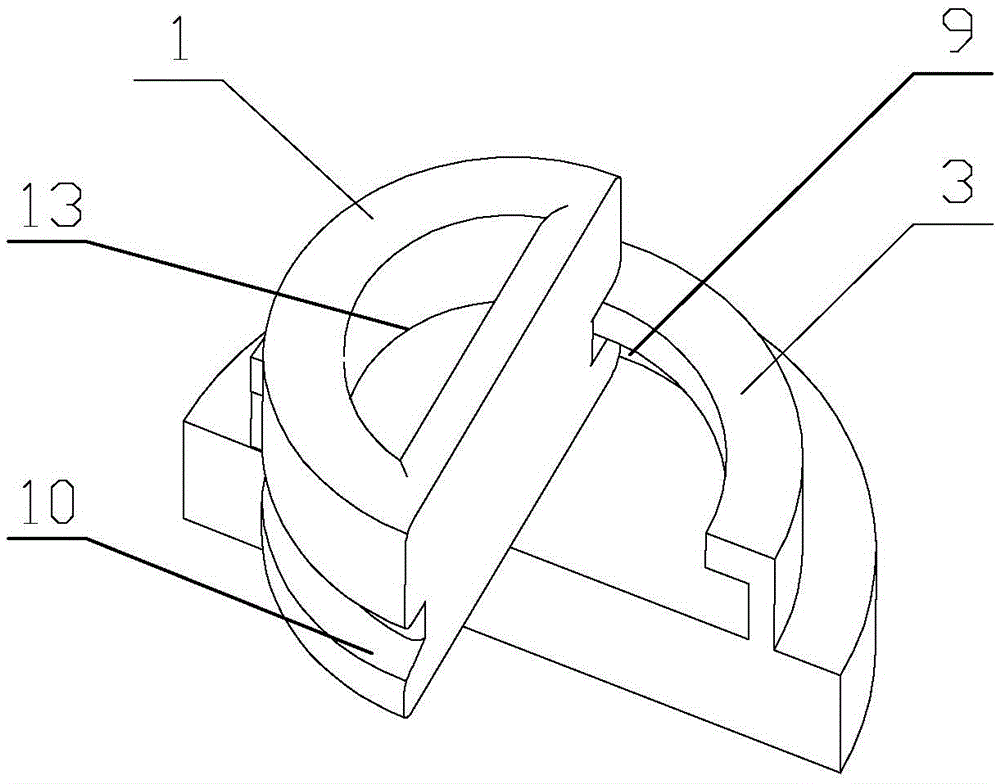

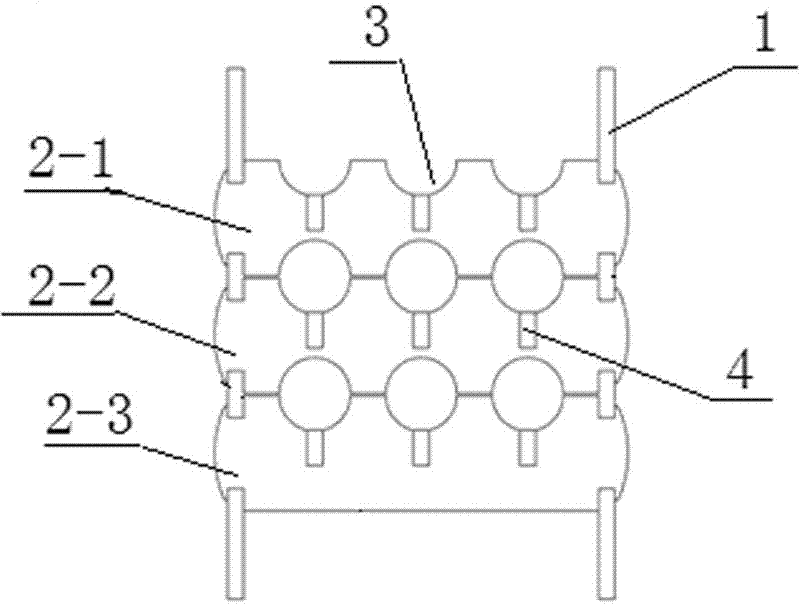

Metro circular-arc-shaped section reinforcing construction apparatus

ActiveCN104265304ARealization of section reinforcementSimple structureUnderground chambersTunnel liningBuilding construction

The invention discloses a metro circular-arc-shaped section reinforcing construction apparatus. The metro circular-arc-shaped section reinforcing construction apparatus comprises a main structure; traveling systems are arranged on the two sides of the lower part of the main structure; a rotating system is arranged in the middle part of the main structure; telescopic systems are arranged on the two ends of the rotating system, respectively; a gripping system and an adjustment system are arranged on the outer ends of the telescopic systems; a working platform is arranged on the upper part of the main structure. The metro circular-arc-shaped section reinforcing construction apparatus is capable of realizing section reinforcements before and after the operation of the metro, and is simple in structure, attractive in appearance and convenient for construction without temporary support and rail.

Owner:CHINA RAILWAY FIFTH SURVEY & DESIGN INST GRP +1

Method for preparing composite resin manhole cover through cooperation between non-metal powder of waste circuit boards and polyester resin

InactiveCN108821645ASimple manufacturing processShorten the production cycleArtificial islandsSolid waste managementResin-Based CompositePrinted circuit board

The invention discloses a method for preparing a composite resin manhole cover through cooperation between non-metal powder of waste circuit boards and polyester resin. According to the invention, non-metal materials of waste printed circuit boards are used as a main raw material for preparation of the manhole cover; the non-metal materials are rich in glass fibers and thermosetting resin, and arereasonably treated and then compounded with unsaturated polyester resin for preparation of the composite resin manhole cover; the unsaturated polyester resin has low viscosity, conducts good infiltration action on the glass fibers in the non-metal powder of waste printed circuit boards, and is rapid in pressure curing; so a prepared cured compound has sufficient toughness and does not crack. Thepreparation method for the manhole cover in the invention is simple and rapid in process, short in production cycle and high in efficiency; since industrial waste is used as a main raw material, production cost is reduced, and environmental protection and energy conservation are facilitated; and the prepared manhole cover is high in bearing capacity, has the characteristics of tight fitting, wearresistance, corrosion resistance, light structure, beautiful appearance, light weight and easy installation, and has been applied in related projects.

Owner:安徽大来机械制造有限公司

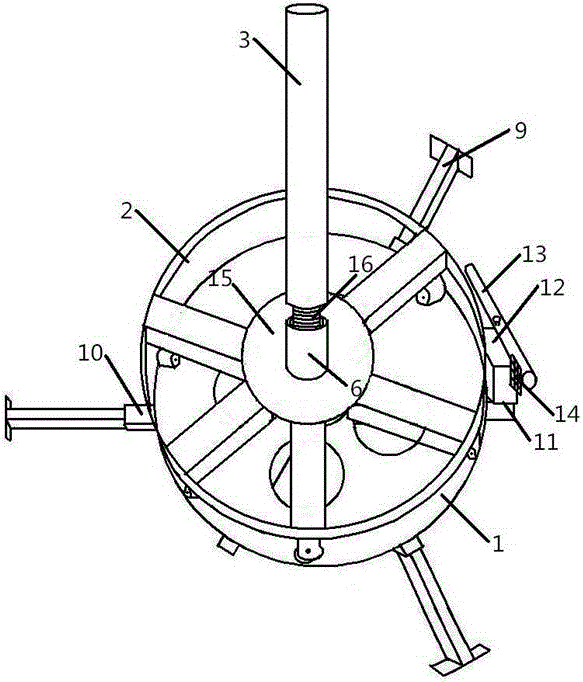

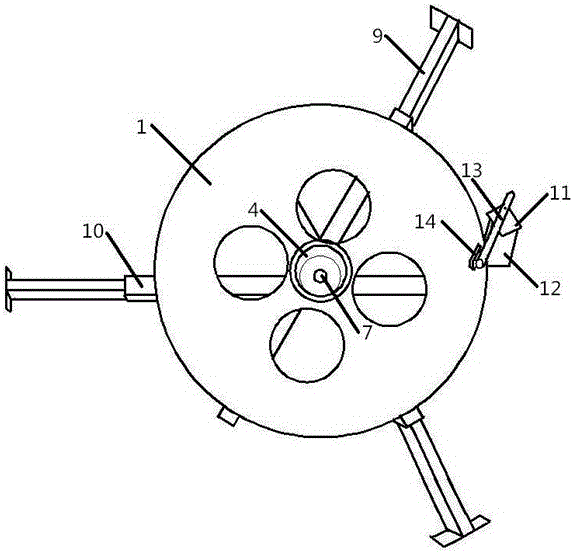

Combined vertical cable pay-off rack

ActiveCN105947776AEasy to transportEasy to install and disassembleFilament handlingEngineeringStructural engineering

The invention relates to a combined vertical cable pay-off rack comprising a base, a runner and a vertical shaft. The combined vertical cable pay-off rack is characterized in that a circular groove is formed in the center of the base; a conical bearing is arranged in the center of the bottom of the runner; the diameter of an outer ring of the conical bearing is equal to that of the circular groove; the height of the conical bearing is equal to the depth of the circular groove; rollers are uniformly distributed along the circumference of the outer edge of the bottom of the runner; a vertical cylinder is arranged in the center of the upper part of the runner; and the vertical shaft is rotatably connected together with the vertical cylinder. The combined vertical cable pay-off rack is simple in structure, convenient to mount and transport as well as take up and pay off, good in stability and very long in service life.

Owner:STATE GRID CORP OF CHINA +1

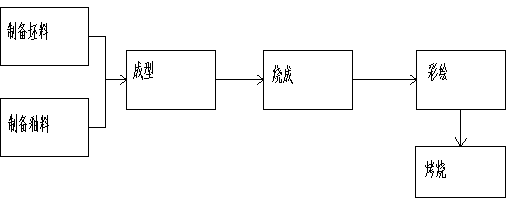

Blue and white color porcelain preparation method

The present invention discloses a blue and white color porcelain preparation method, wherein the blue and white color porcelain is prepared by carrying out billet material preparing, molding, firing, colored drawing and other processing processes. The preparation method sequentially comprises: preparing a billet material and a glaze material, carrying out rolling pressing molding on a rolled and pressed mud cake in a gypsum mold, placing the mold billet into a chain type drying agent or baking chamber to dry, drying the green billet after separating the mold and the billet, taking out the green billet after achieving a certain strength, finishing the billet, loading the qualified green billet into a kiln car boron plate or gate bowl, carrying biscuit firing in a biscuit firing kiln tunnel, burning by using natural gas, carrying out biscuit finishing and polishing water washing after discharging out from the kiln, drying, carrying out glaze spraying on the biscuit porcelain in a manual or automatic glaze applying production line manner, drying, loading into a glaze firing tunnel kiln to carry out glaze firing, carrying out manual applique, colored drawing and gold inlaying on the qualified white porcelain, drying, placing into a natural gas open-flame burning roller channel decorating kiln to fire, and discharging out from the kiln to obtain the color porcelain. The blue and white color porcelain preparation method has the following advantages that: the industrial production efficiency is increased, the product appearance is beautiful, the duration time, the degree and the temperature of heating can be well controlled, the finished product quality is increased and the like.

Owner:ANHUI QINGHUAFANG FINE BONE PORCELAIN

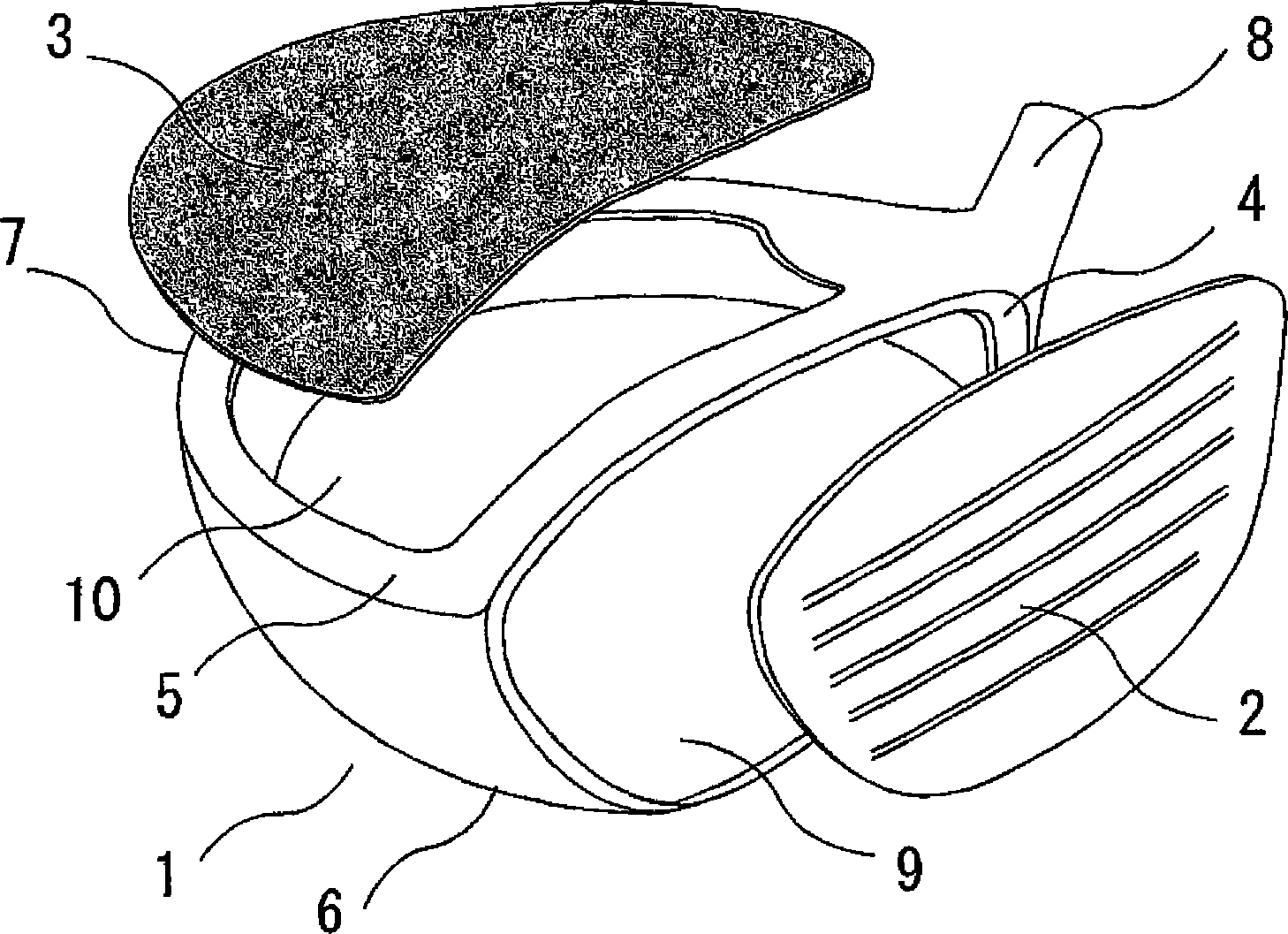

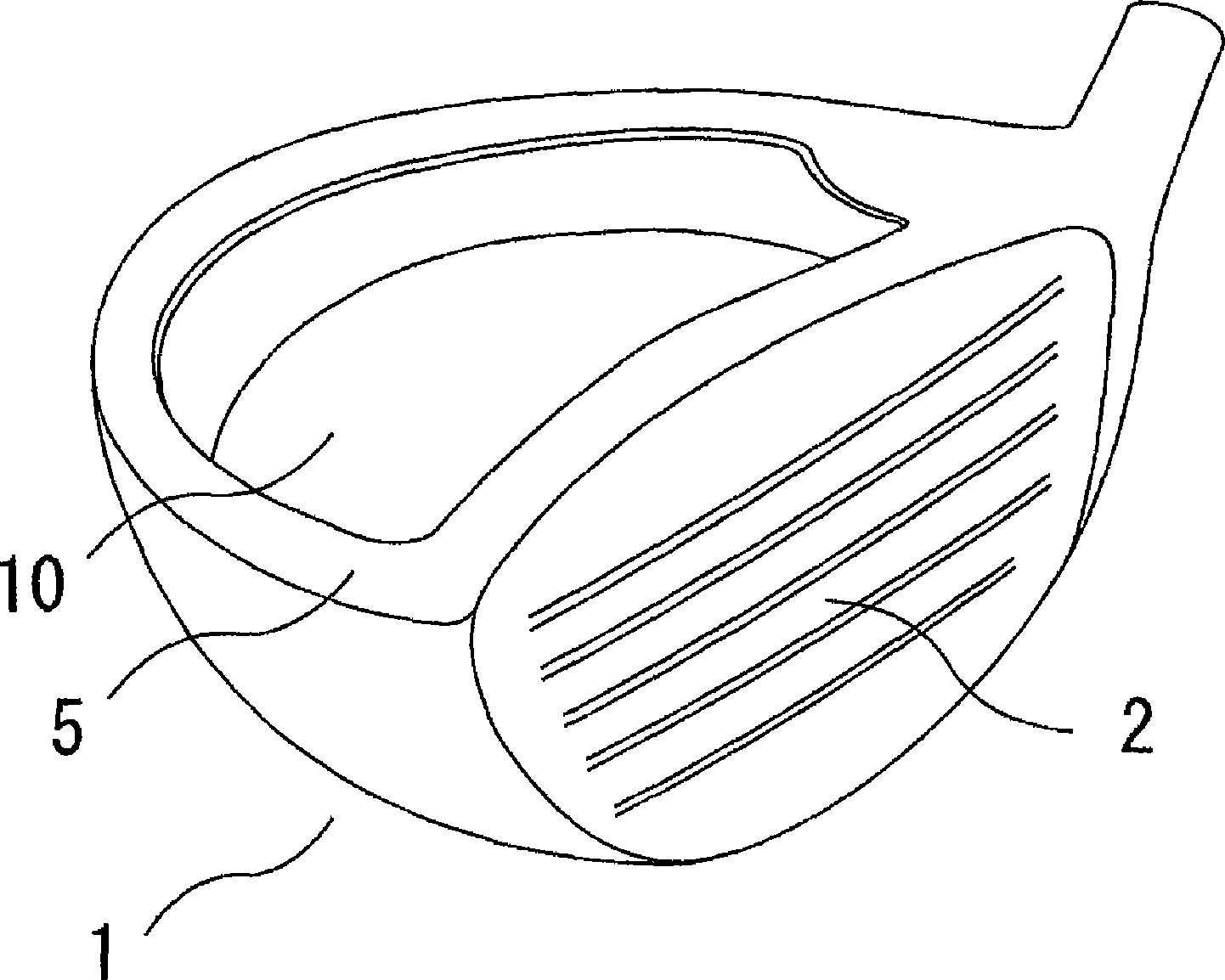

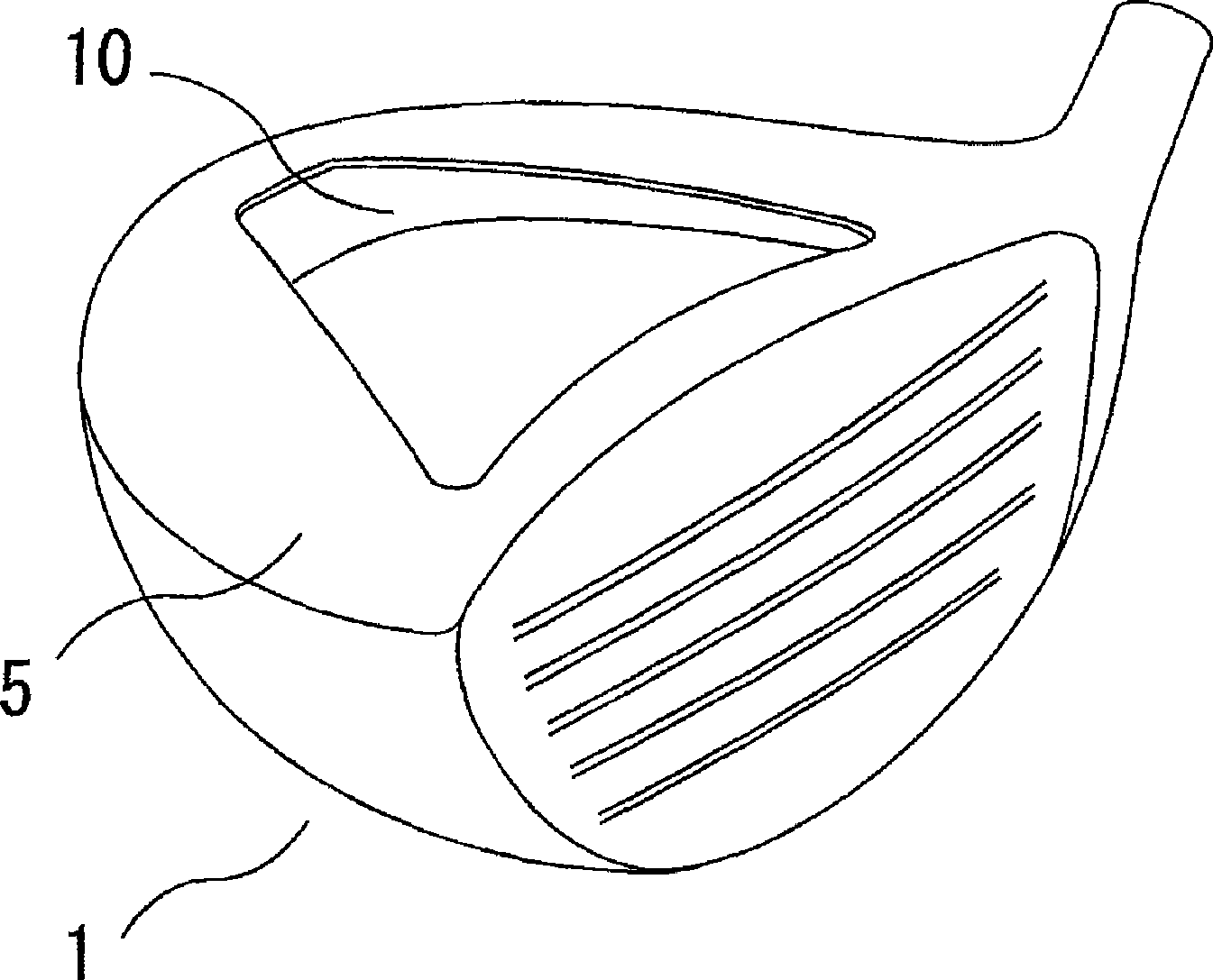

Method of manufacturing golf club head

A method of manufacturing a golf club head without losing treatment effect by applying peening treatment to the face and the inner surfaces around the face of the wood or iron golf club head formed in hollow structure with a metal material. In the wood or iron golf head formed in the hollow structure, reforming treatment is applied to the face and, as required, to areas around the face by utilizing an opening formed in a head body of a metal material, and the opening is closed with a cover member by using a method with which the treatment effect is not lost. Thus, a golf club with high functional performance which could not be achieved before can be easily provided at low cost.

Owner:MARUMAN & CO LTD

Waterborne colorful rock slice paint added with rice husk silicon nitride based porous ceramic powder

InactiveCN106854409AHigh elongation at breakImprove water resistanceMulticolor effect coatingsWeather resistanceHusk

The invention discloses a waterborne colorful rock slice paint added with rice husk silicon nitride based porous ceramic powder. Rice husks are carbonized and then sintered with silicon nitride to obtain porous ceramic powder, the porous ceramic powder is added in paint preparation to enhance the mechanical strength and wear resistance of a coating film, and at the same time porous ceramic has small pore size, high porosity and good sound absorption effect. The colorful rock slice paint imitates the granite pattern, has the advantages of elegant appearance, excellent weather resistance, long service life, and good noise adsorption effect, can be used in walls of cinemas, theaters, subways and the like, the construction is convenient, and the use effect is excellent.

Owner:安徽省阜阳闽安建材有限公司

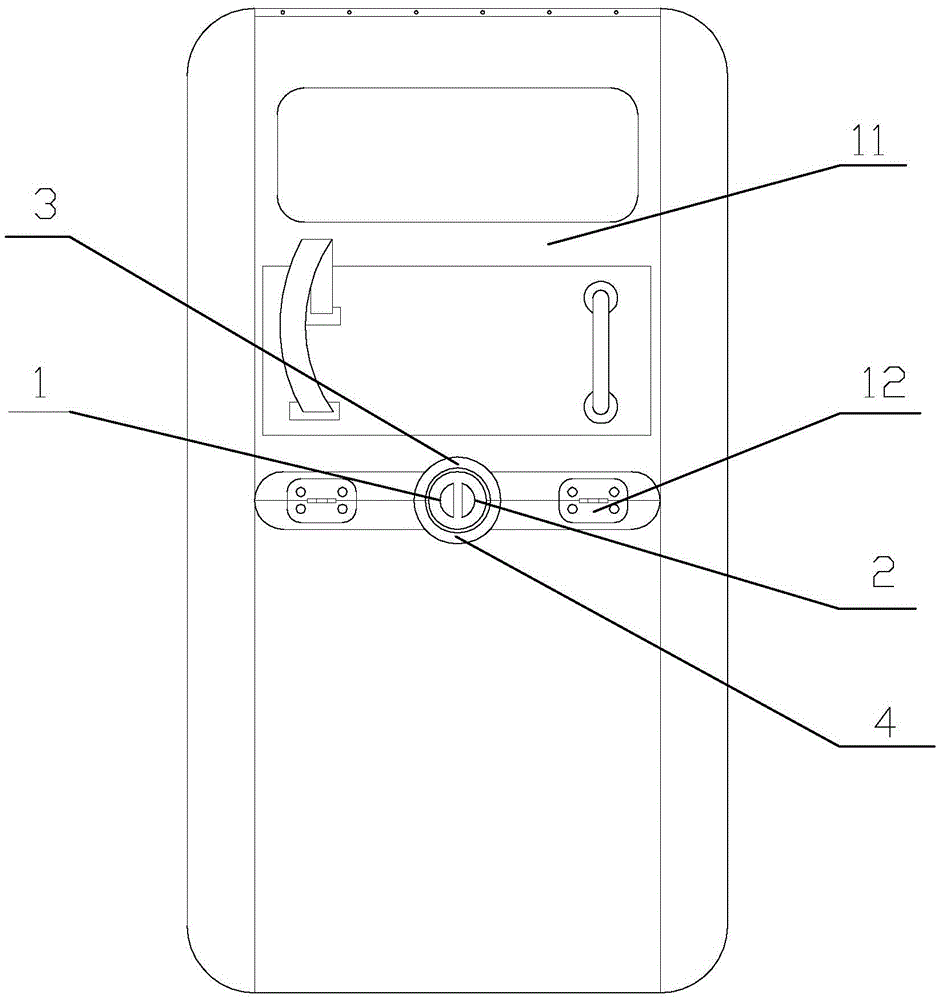

Folding mechanism of shield

Owner:JIANGSU WUWEI POLICE EQUIP MFG

Specky fabric and manufacturing method thereof

ActiveCN103397549AFull of infinite beautyBeautiful styleFibre treatmentTextile decorationEngineeringHot-melt adhesive

The invention provides a specky fabric which is fashionable and comfortable, and a manufacturing method thereof, aiming at the disadvantages that a fabric in the prior art cannot meet the requirements of consumers on fashionability, comfort and functionality. According to the fabric provided by the invention, a point-shaped membrane is compounded on one surface of the fabric by a hot melt adhesive; speckles are arranged on the other surface of the fabric and are formed by penetration of the point-shaped membrane. The specky fabric is obtained by the following posttreatment: in a coating process, a rubber roller provided with a point-shaped adhesive discharging hole is used for carrying out coating and compounding on a hot melt adhesive penetration point; the coating amount of the membrane is 12g / m-14g / m and a rubber roller gap is 0.1mm-0.2mm; a compound roller gap is 0.1mm+ / -0.05mm; the speckles on one surface of the fabric are formed by adhesive liquid penetration points on the other surface of the fabric; the speckles are natural in shape and have the characteristics of being fashionable and comfortable.

Owner:ZHEJIANG TAIHUA NEW MATERIAL

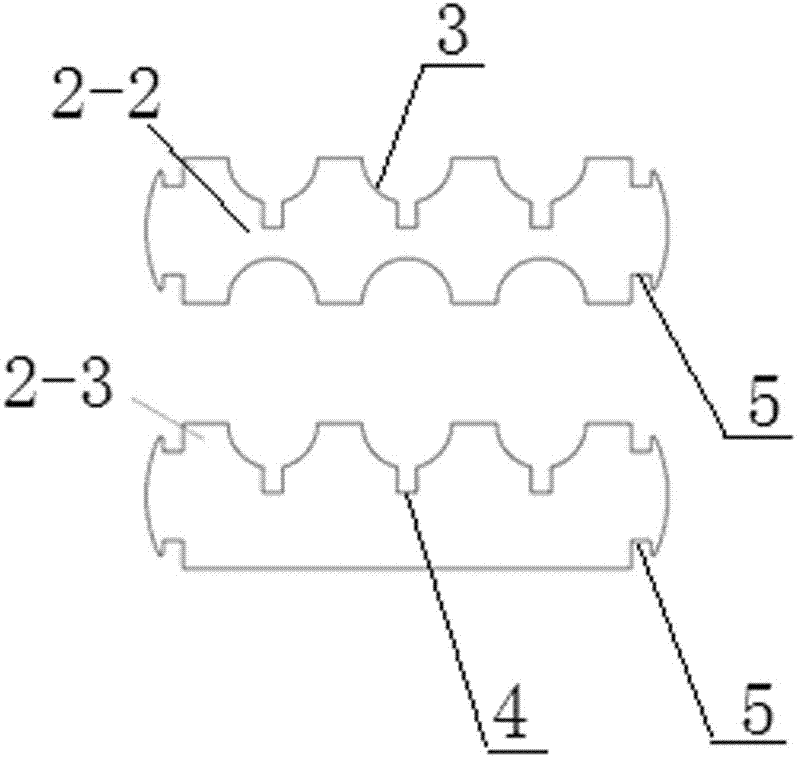

Latch connection type spliced red wine rack

InactiveCN102389211AMeet short-term demand for saffron wineReduce production linksBottle cupboardsAdhesive glueStructural engineering

The invention relates to a latch connection type spliced red wine rack, which comprises two supporting side plates and front and back wine storage plates; the front and back wine storage plates are formed in a manner that two to five spliced assemblies are spliced together; each spliced assembly is provided with two to four semicircular grooves; a latch clamping groove is disposed under each semicircular groove; latch clamps are arranged at the both ends of each spliced assembly; latch clamp grooves are arranged at the both sides of each of two supporting side plates; and the latch grooves ofthe spliced assemblies of the two supporting side plates and the front and back wine storage plates are mutually clamped, fixed and assembled by the latch clamps. The rack is automatic to assemble, convenient, fast and small in packaging volume, and can save packaging, storing and transporting space; and the rack realizes environment protection and energy saving without adhesive connection of nails and glues; moreover, the rack has beautiful style and not only can meet demand of storing red wine for a short time in most of families but also has decorative effect.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

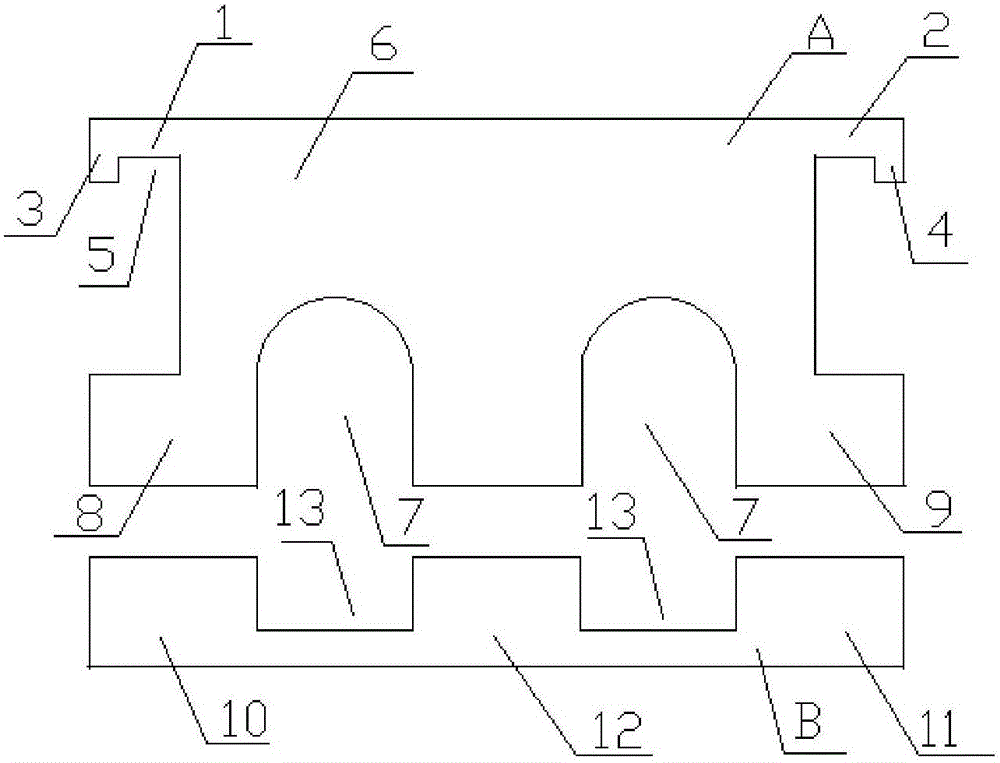

A combined door and window of a lock structure

ActiveCN106761254BBeautiful styleAchieving common standardizationStrutsWallsButt jointEconomic benefits

The invention belongs to the technical field of house building and relates to a combined type house component with a lock catch structure, in particular to a combined type house door window with the lock catch structure. The combined type house door window with the lock catch structure can be assembled into a main body frame of a combined type house and used for persistent or temporary housing building occasions. A main body structure comprises an upper component and a lower component, and the upper component and the lower component are combined in a vertical butt-joint mode to form the combined type house door. The upper component and the lower component are each of an integrated plate-shaped structure poured through concrete, and the thickness of the upper component is the same with that of the lower component. Steel bars are contained in the upper component and the lower component, the upper component comprises a first transverse rod, a second transverse rod, a first vertical pillar, a second vertical pillar, locking holes, a first wall body, first holes, a first connecting pillar and a second connecting pillar, and the lower component comprises a third connecting pillar, a fourth connecting pillar, a second wall body and second holes. The combined type house door window with the lock catch structure is simple in overall structure, the building speed is quick, high in dismounting and replacing performance, low in comprehensive manufacturing cost, high in seismic performance and long in service life and has good economic benefits and application prospects.

Owner:杨阳

Solar energy tree cap and production method thereof

InactiveCN101416600BSuitable for needsEasy to install on siteElectric circuit arrangementsLighting elementsEngineeringLighting system

The invention relates to a solar energy tree cap and making method thereof. The solar energy tree cap comprises a skeleton structure supported around a plant and an enclosure shade. Wherein the skeleton structure is formed by connecting a pedestal, supporting rods in the middle and a chuck at the top from the downside to the upside; the pedestal is formed by splicing at least three preformed components end to end around the root part of the plant; rod shoes which are opened with holes connected with the supporting rods are connected on the preformed components; the chuck on which solar energydecorative lighting system is fixed is above the plant, with the bottom connected with pins in intervals and the top connected with lifting lugs; the supporting rods are distributed along lateral faces of the plant, with the bottom connected with the rod shoes of the pedestal, the top connected with the pins of the chuck and the middle part connected with hanging components which are connected with the enclosure shade enclosing and connected on the supporting rods. The invention integrates using function and decorative function, can not only prevent wind and preserve temperature for rare trees in the winter and provide parks and scenic spots with effective tools to prevent wind and preserve temperature for rare trees in the winter, but also add ornamentation for landscape environment.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

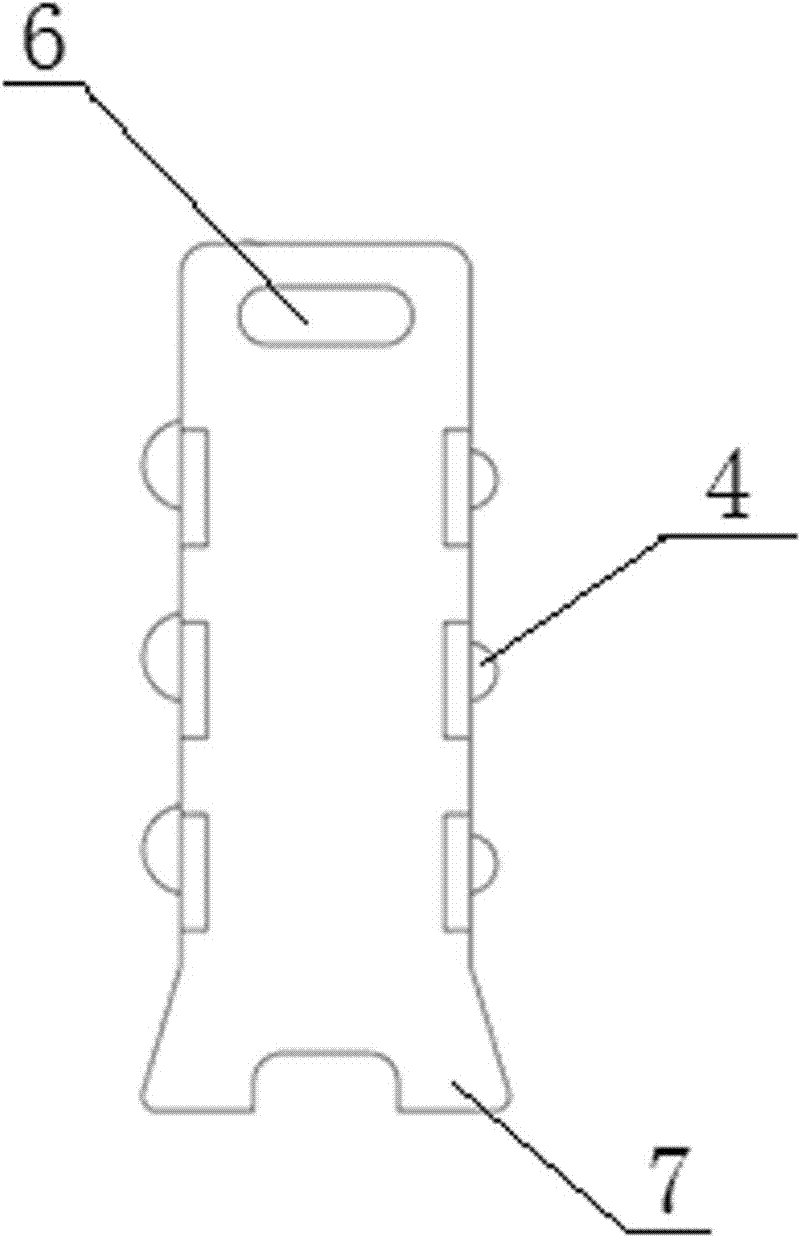

Combined type house door window with lock catch structure

ActiveCN106761254ABeautiful styleAchieving common standardizationStrutsWallsButt jointEconomic benefits

The invention belongs to the technical field of house building and relates to a combined type house component with a lock catch structure, in particular to a combined type house door window with the lock catch structure. The combined type house door window with the lock catch structure can be assembled into a main body frame of a combined type house and used for persistent or temporary housing building occasions. A main body structure comprises an upper component and a lower component, and the upper component and the lower component are combined in a vertical butt-joint mode to form the combined type house door. The upper component and the lower component are each of an integrated plate-shaped structure poured through concrete, and the thickness of the upper component is the same with that of the lower component. Steel bars are contained in the upper component and the lower component, the upper component comprises a first transverse rod, a second transverse rod, a first vertical pillar, a second vertical pillar, locking holes, a first wall body, first holes, a first connecting pillar and a second connecting pillar, and the lower component comprises a third connecting pillar, a fourth connecting pillar, a second wall body and second holes. The combined type house door window with the lock catch structure is simple in overall structure, the building speed is quick, high in dismounting and replacing performance, low in comprehensive manufacturing cost, high in seismic performance and long in service life and has good economic benefits and application prospects.

Owner:杨阳

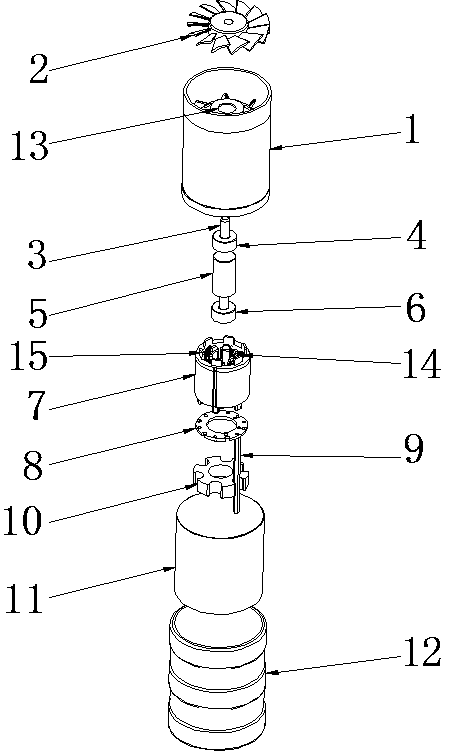

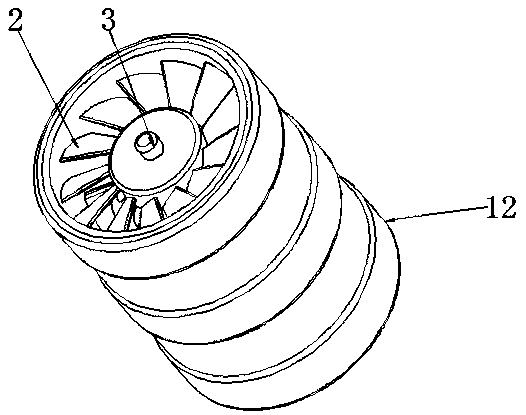

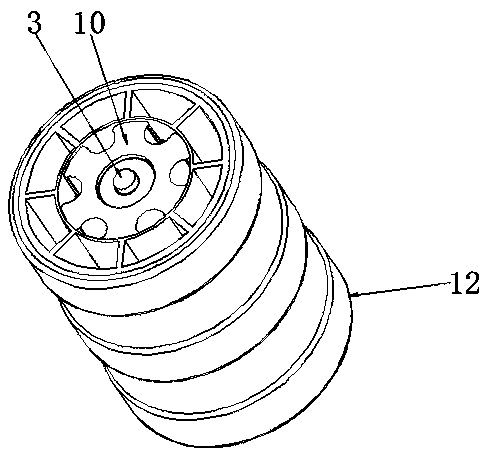

Small motor with double air ducts for cooling and resisting magnetic field

PendingCN110943567AStable jobReduce damageCooling/ventillation arrangementSupports/enclosures/casingsElectric machineryMotor shaft

The invention discloses a small motor with double air ducts for cooling and resisting a magnetic field. Aluminum alloy air duct, the top of an inner cavity of the aluminum alloy air duct is rotationally connected with aluminum alloy high-speed fan blades. A motor shaft center is rotatably connected to an inner cavity of the aluminum alloy air duct, a first high-speed ball bearing is movably connected to the top end of the motor shaft center and located below the aluminum alloy high-speed fan blades, and the top end of the motor shaft center is rotatably connected with the inner surface of thefirst high-speed ball bearing. The invention discloses a small motor with double air ducts for cooling and resisting a magnetic field. The aluminum alloy high-speed fan blades and the aluminum alloy air duct are arranged; the aluminum alloy high-speed fan blades rotate to suck outside air into the aluminum alloy air ducts for cooling through negative pressure siphoning, the double air ducts are matched with negative pressure siphoning of the aluminum alloy high-speed fan blades, so that the temperature rising speed of the motor is greatly reduced when the inner cavity of the small motor works,and the small motor works more stably through the arrangement of the shell shielding magnetic sleeve and the shockproof silica gel sleeve.

Owner:江苏阿萨普智能科技有限公司

A speckled fabric and method of making the same

ActiveCN103397549BFull of infinite beautyBeautiful styleFibre treatmentTextile decorationState of artEngineering

The invention provides a specky fabric which is fashionable and comfortable, and a manufacturing method thereof, aiming at the disadvantages that a fabric in the prior art cannot meet the requirements of consumers on fashionability, comfort and functionality. According to the fabric provided by the invention, a point-shaped membrane is compounded on one surface of the fabric by a hot melt adhesive; speckles are arranged on the other surface of the fabric and are formed by penetration of the point-shaped membrane. The specky fabric is obtained by the following posttreatment: in a coating process, a rubber roller provided with a point-shaped adhesive discharging hole is used for carrying out coating and compounding on a hot melt adhesive penetration point; the coating amount of the membrane is 12g / m-14g / m and a rubber roller gap is 0.1mm-0.2mm; a compound roller gap is 0.1mm+ / -0.05mm; the speckles on one surface of the fabric are formed by adhesive liquid penetration points on the other surface of the fabric; the speckles are natural in shape and have the characteristics of being fashionable and comfortable.

Owner:ZHEJIANG TAIHUA NEW MATERIAL

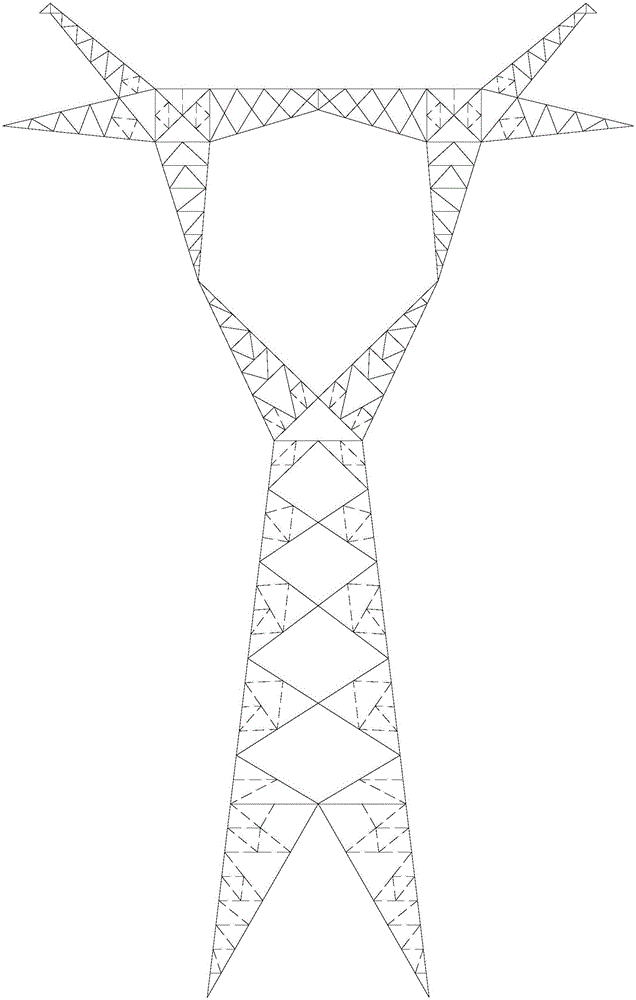

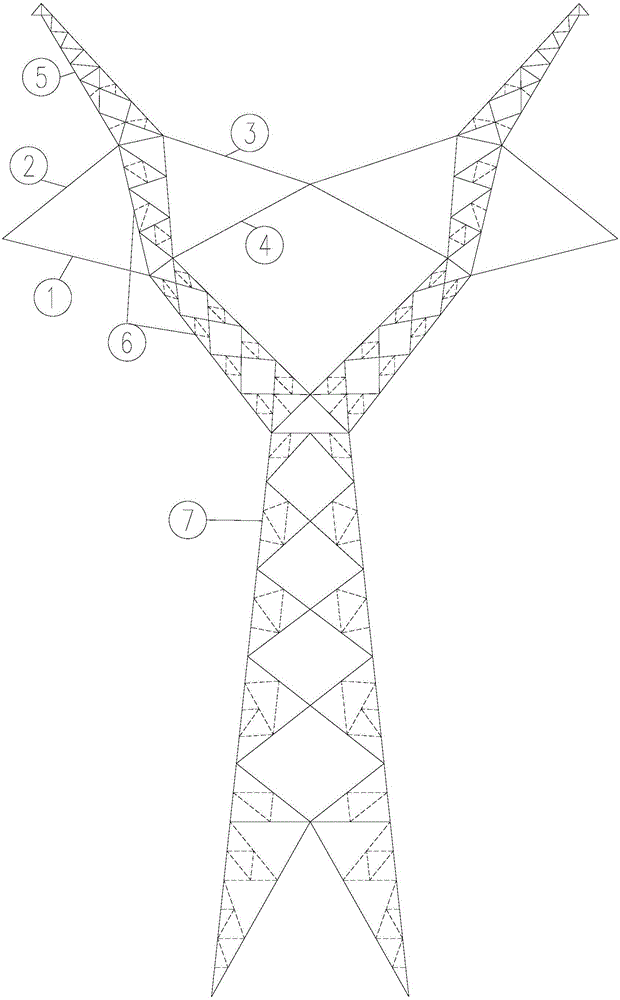

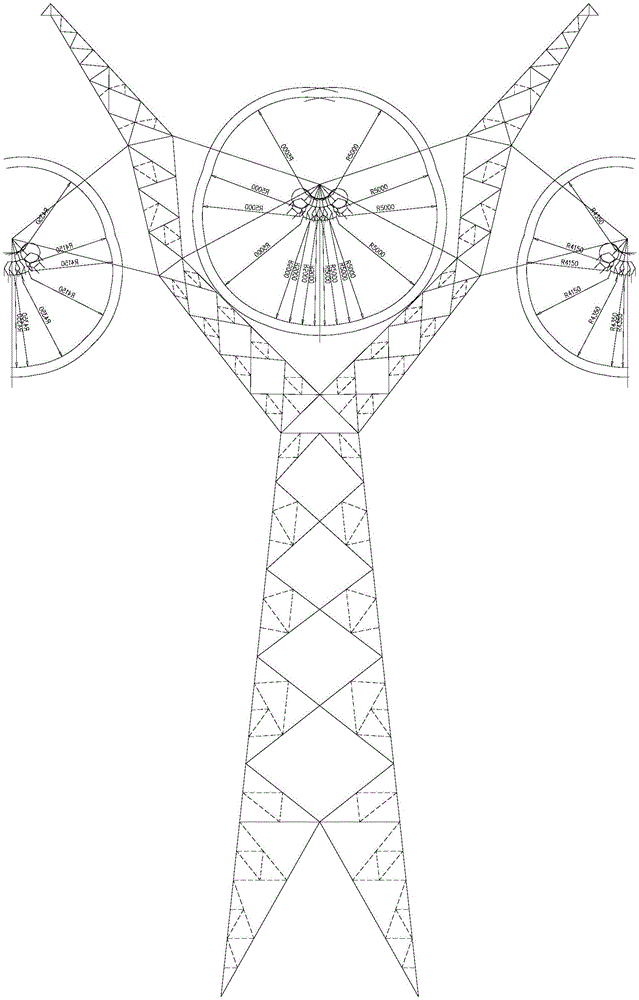

750 kV wine glass composite cross arm tower

The invention discloses a 750 kV wine glass composite cross arm tower. The 750 kV wine glass composite cross arm tower comprises two sets of side phase composite material cross arms, one set of middle phase composite material cross arms, one set of steel structure tower windows, two sets of steel structure ground wire supports and one set of steel structure tower bodies. The bottoms of the tower windows are fixed to the tops of the steel structure tower bodies. The two sets of side phase composite material cross arms are arranged on the two sides of the middles of the tower windows. The two sets of steel structure ground wire supports are arranged on the two sides of the tops of the tower windows. The middle phase composite material cross arms are arranged in the tower windows. The steel structure ground wire supports are connected with ground wires and angle steel of the tower windows. The angle steel of the tower windows are connected with tower body steel structures, ground connection downward leading is achieved, and the thunder prevention purpose is achieved. The purpose of tower head insulation is achieved by ensuring the effect that all the distances from wire hanging points to any metal piece meet the requirement of the insulation distance. All components form a space truss system so as to transmit loads. The creep distance of the cross arms is increased through umbrella skirts on the surfaces of the composite material components. Electric field distribution is improved through a grading and shielding ring.

Owner:NORTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com