Flake molding compound for manufacturing manhole cover and preparation method of flake molding compound

A technology of sheet molding compound and manhole cover, which is applied in the field of sheet molding compound, can solve the problems of unsatisfactory mechanical strength, poor material interface bonding, and difference in thermal expansion coefficient, etc., and achieve light weight, stable process and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In the process of making the manhole cover, the material sheet molding compound used is very important, and its intermediate core material is composed of glass fiber cloth impregnated with resin paste, the content of glass fiber cloth is 20-40 parts, and the resin paste includes the following materials :

[0029] 19-23 parts of unsaturated resin; 6-8 parts of low shrinkage agent; 1.4-1.6 parts of styrene; 0.5-1.5 parts of curing agent; 1.5-1.7 parts of zinc stearate; 0.3 parts; 40-50 parts of heavy calcium carbonate 800-1000 mesh.

[0030] Preferably, the resin paste is made of the following materials: 21 parts of unsaturated resin; 7 parts of low shrinkage agent; 1.5 parts of styrene; 1 part of curing agent; 1.6 parts of zinc stearate; 0.02 parts of benzoquinone; 0.25 parts of pigment paste part; 45 parts of heavy calcium carbonate 800-1000 order, and wherein heavy calcium carbonate is waste material, and the present invention turns waste into wealth, has stronger env...

Embodiment 2

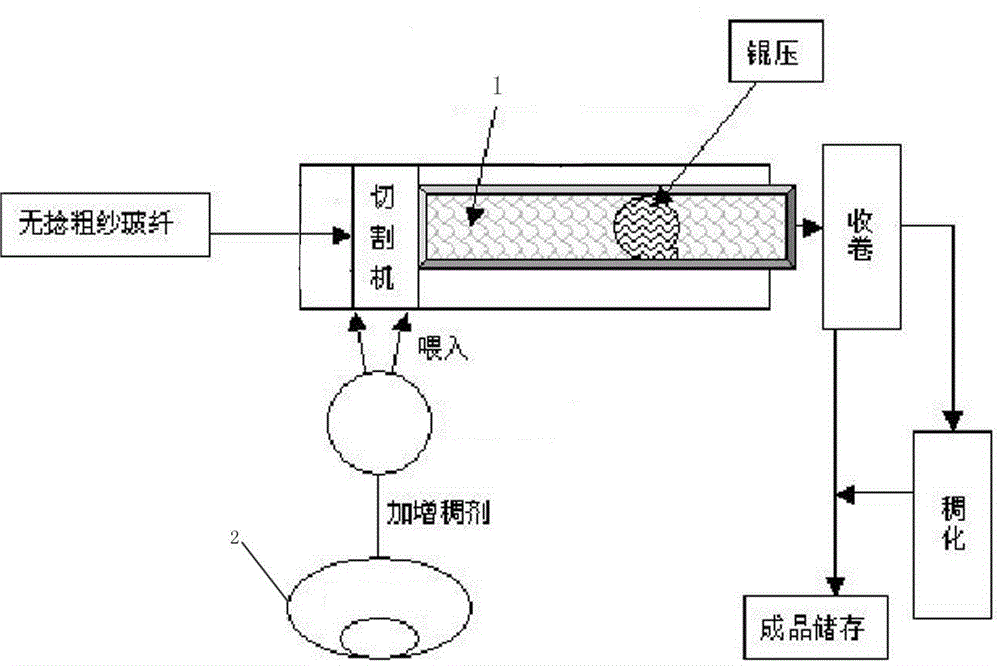

[0034] Such as figure 1 As shown, the technological process of sheet molding compound (SMC) production mainly includes resin paste preparation, pasting operation, infiltration, thickening and other processes. Combined with the preparation method of resin paste, the preparation process of sheet molding compound (SMC) is as follows:

[0035] 1) 19-23 parts of unsaturated resin, 6-8 parts of low shrinkage agent, 1.4-1.6 parts of styrene, 0.5-1.5 parts of curing agent, 1.5-1.7 parts of zinc stearate, 0.01-0.03 parts of benzoquinone, Put 0.2-0.3 parts of the pigment paste into the batching kettle 2, stir for 30-60 minutes and add a thickener, the thickener is 40-50 parts of heavy calcium carbonate 800-1000 mesh;

[0036] 2) After stirring for 60-120 minutes, add magnesium oxide and stir quickly for 20-30 seconds to make a resin paste; the SMC product equipment is equipped with a trough, and the resin paste is immediately poured into the trough; there are 2 sets of film rolls on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com