Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69results about How to "Avoid surface abrasion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

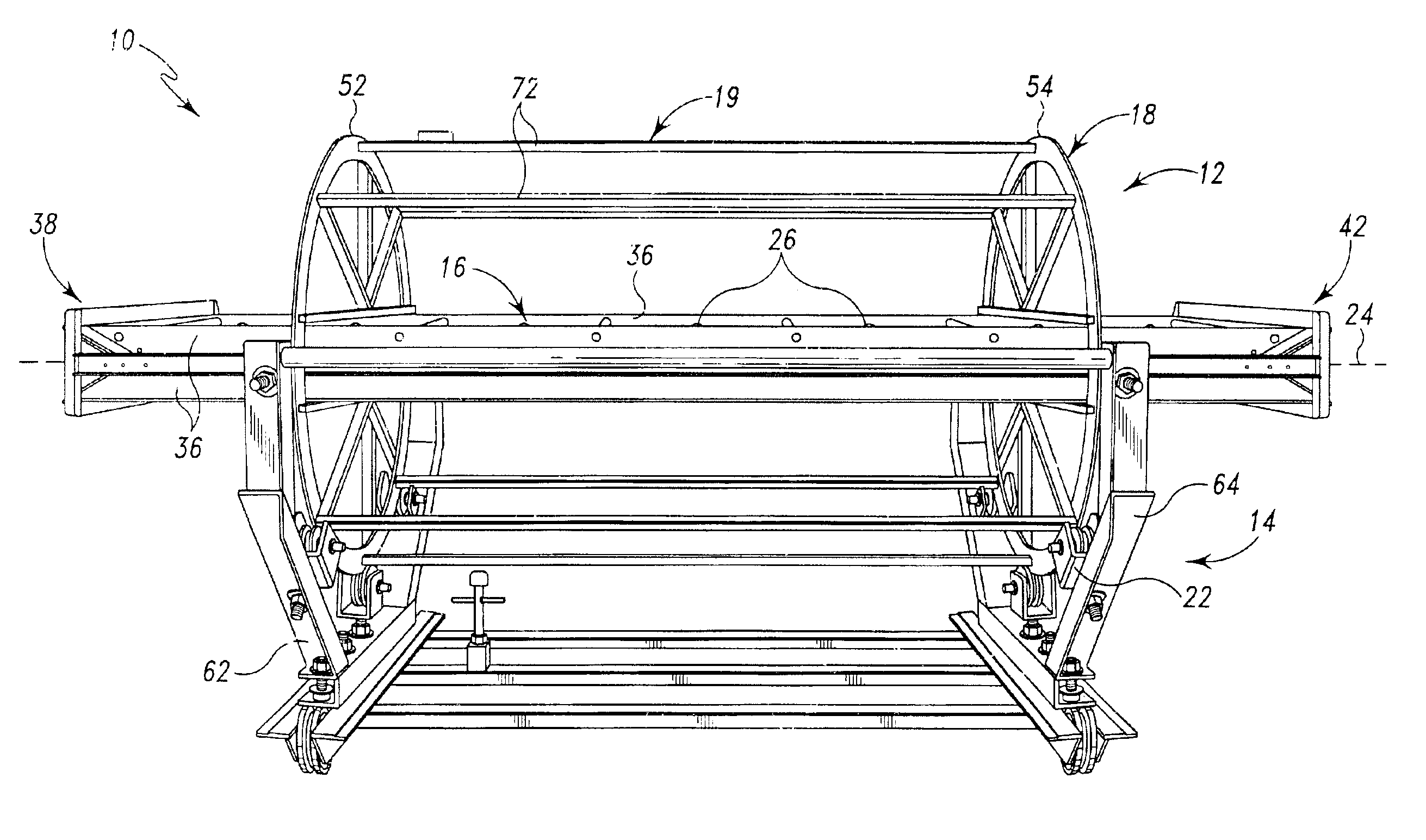

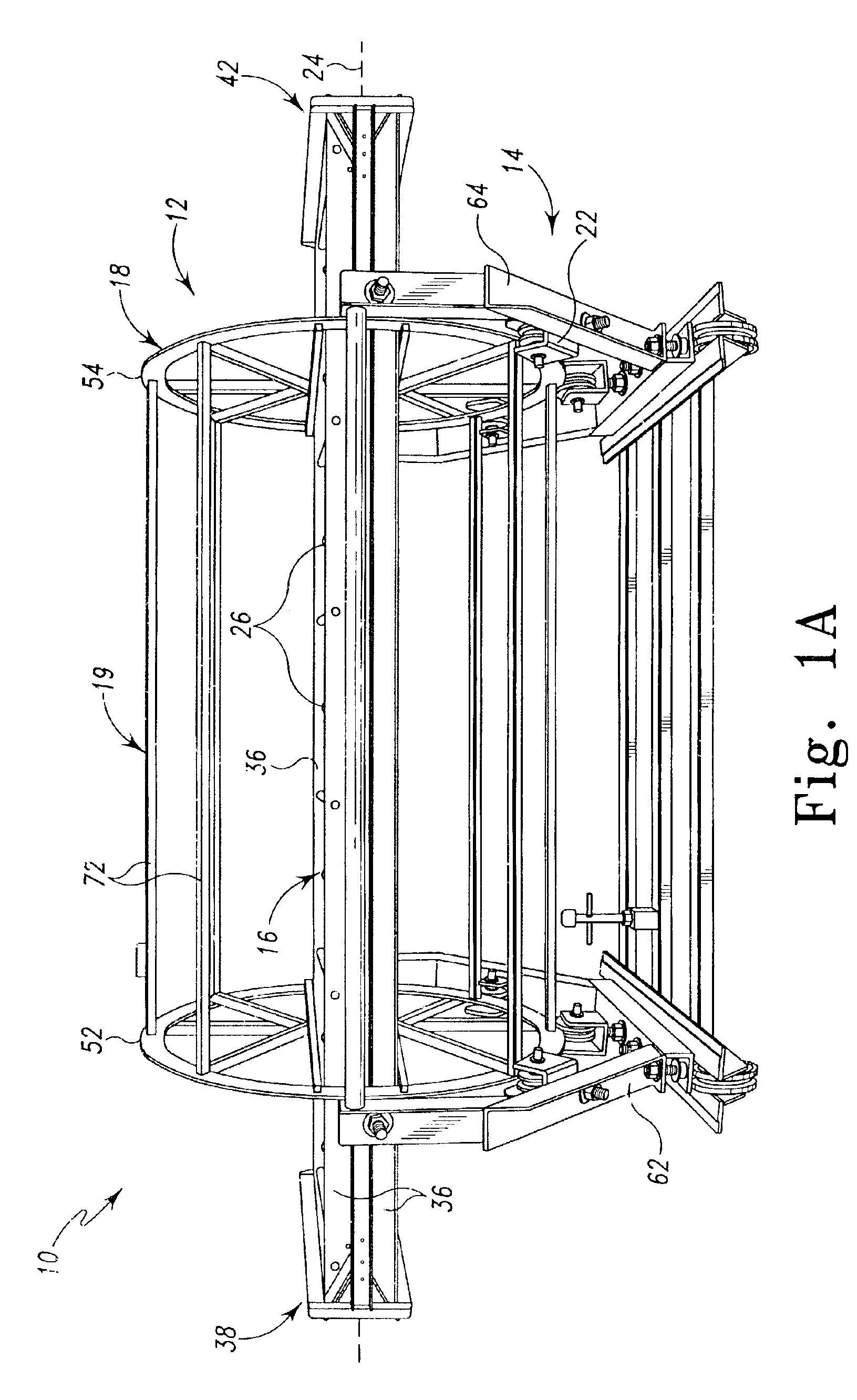

Panel turning apparatus

InactiveUS6860800B1Stop rotatingEasy to moveConveyorsMetal working apparatusEngineeringMechanical engineering

Owner:MAURER RONALD L

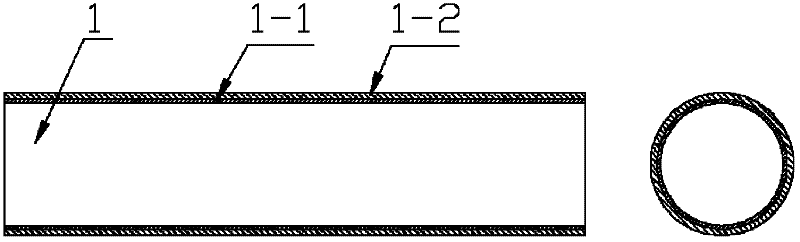

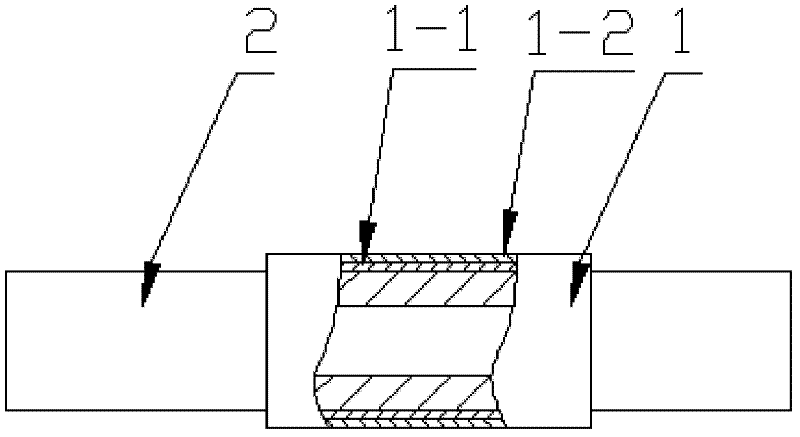

Rubber hose material and rubber hose using the same

ActiveUS20050067036A1High mechanical strengthKneading property can be improvedLayered productsFlexible pipesEngineeringEthylene propylene rubber

A rubber hose material for providing a rubber hose excellent in mechanical strength and with an intrinsic property (elongation) of rubber retained. The rubber hose material is formed by blending an ethylene-olefin resin (component (B)) as an organic filler into an ethylene-propylene rubber (component (A)).

Owner:SUMITOMO RIKO CO LTD

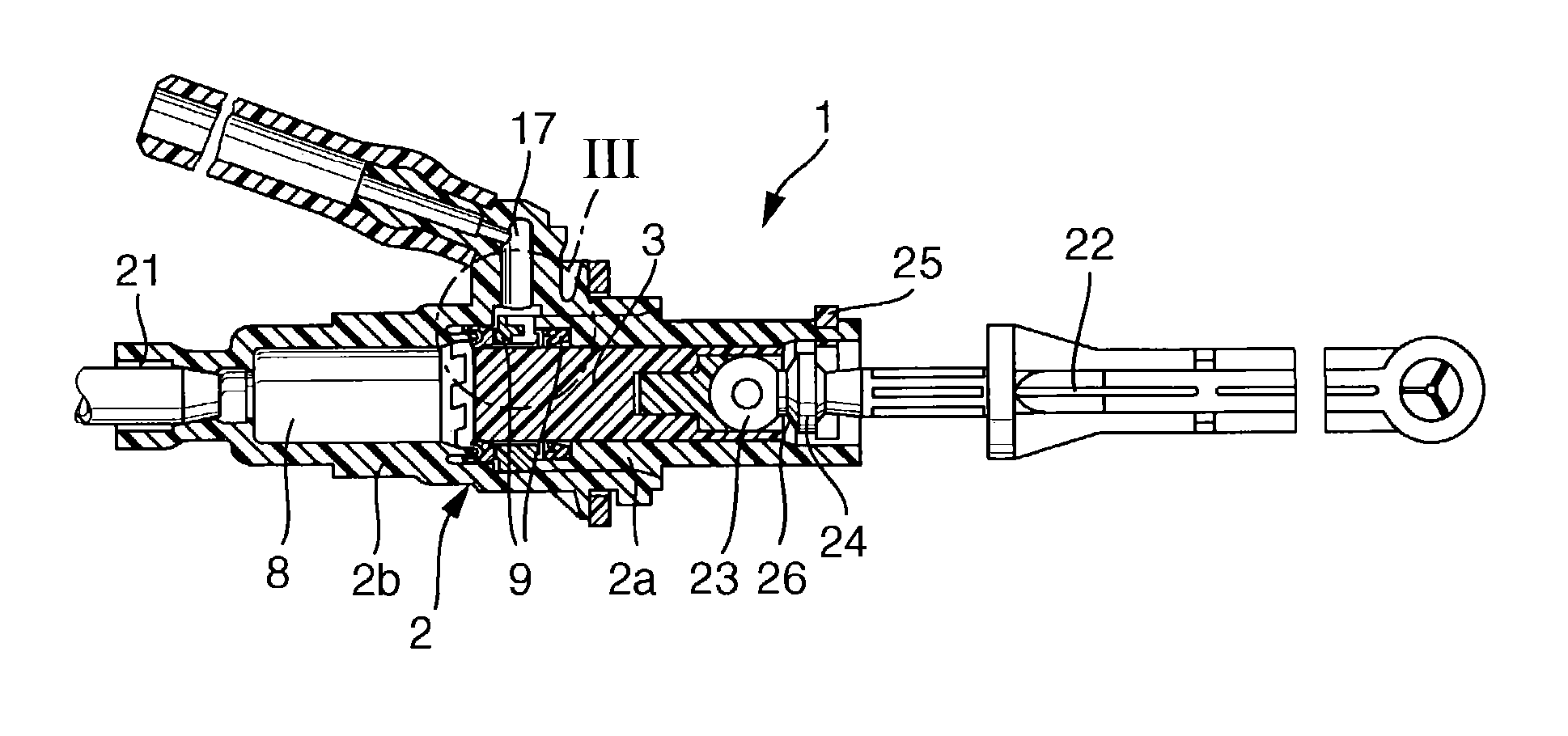

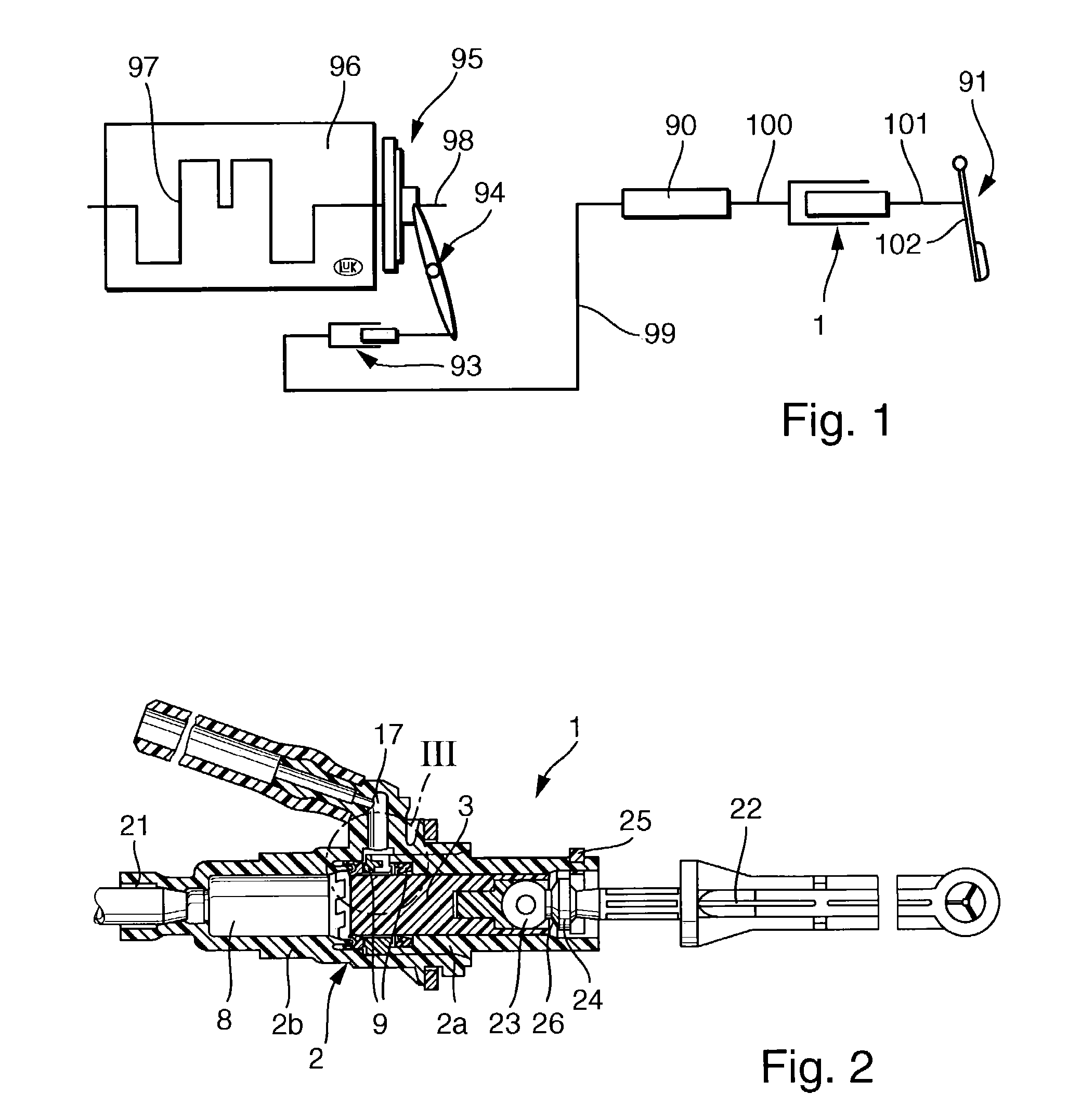

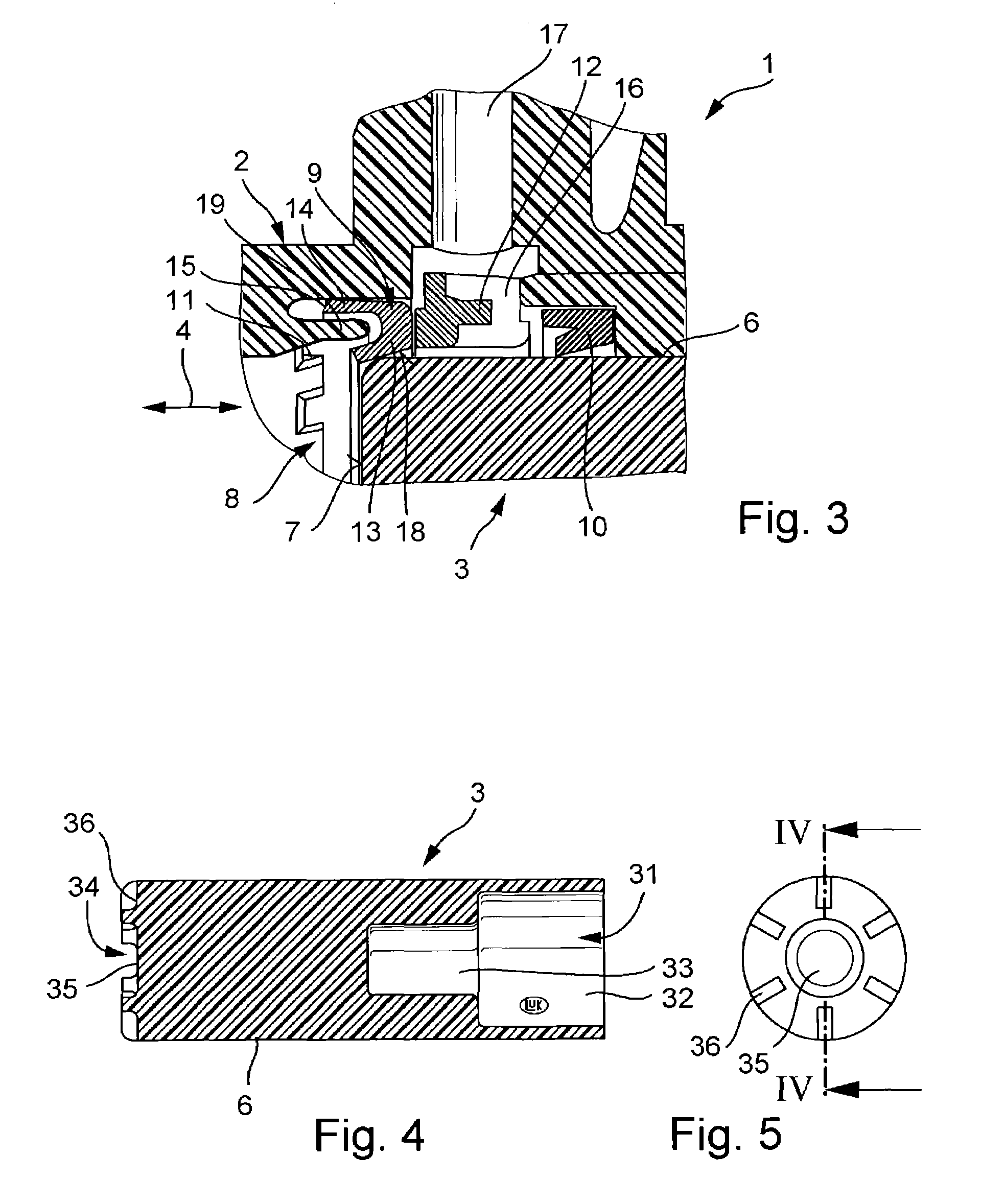

Hydraulic system for a motor vehicle

InactiveUS7059128B2Not easy to wearImprove wear resistancePiston ringsRotary clutchesMobile vehicleMaster cylinder

The piston in the master cylinder of a hydraulic system of the kind that is used particularly in motor vehicles is made of a duroplastic polymer material.

Owner:LUK LAMELLEN & KUPPLUNGSBAU BETEILIGUNGS KG

Sealing structure, fluid treatment unit, fluid treatment device and manual switching mechanism therefor

InactiveUS20130056402A1Easy to operateAvoid scratchesTreatment involving filtrationSolid sorbent liquid separationEngineeringScrew thread

A fluid treatment unit and a sealing structure which is preferably for the fluid treatment unit are provided. The sealing structure includes: a cylinder with an opening formed at one end thereof, the cylinder comprising an inner wall surface and an outer wall surface, and an outer thread being provided on the outer wall surface; a sealing cover which is capable of hermetically cooperating with the inner wall surface of the cylinder to seal the opening; a support cover which is capable of being connected with the cylinder by thread engagement; when the support cover and the cylinder are relatively rotated in order to achieve a threaded connection of the support cover and the cylinder, the support cover is capable of supporting the sealing cover and impelling it to move in parallel so as to allow the sealing cover to reach a position at which it seals the opening.

Owner:CHAU YIU CHAU

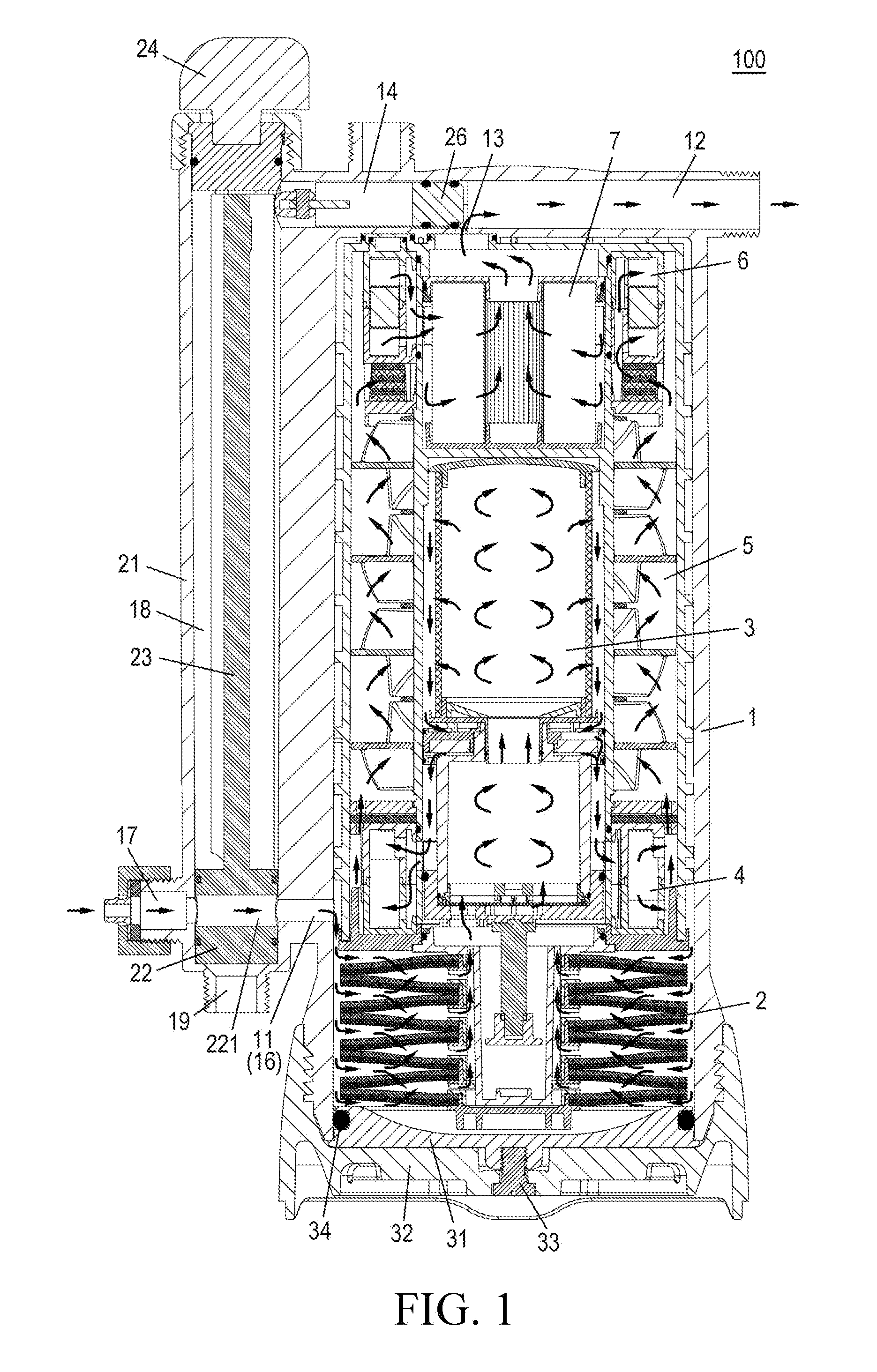

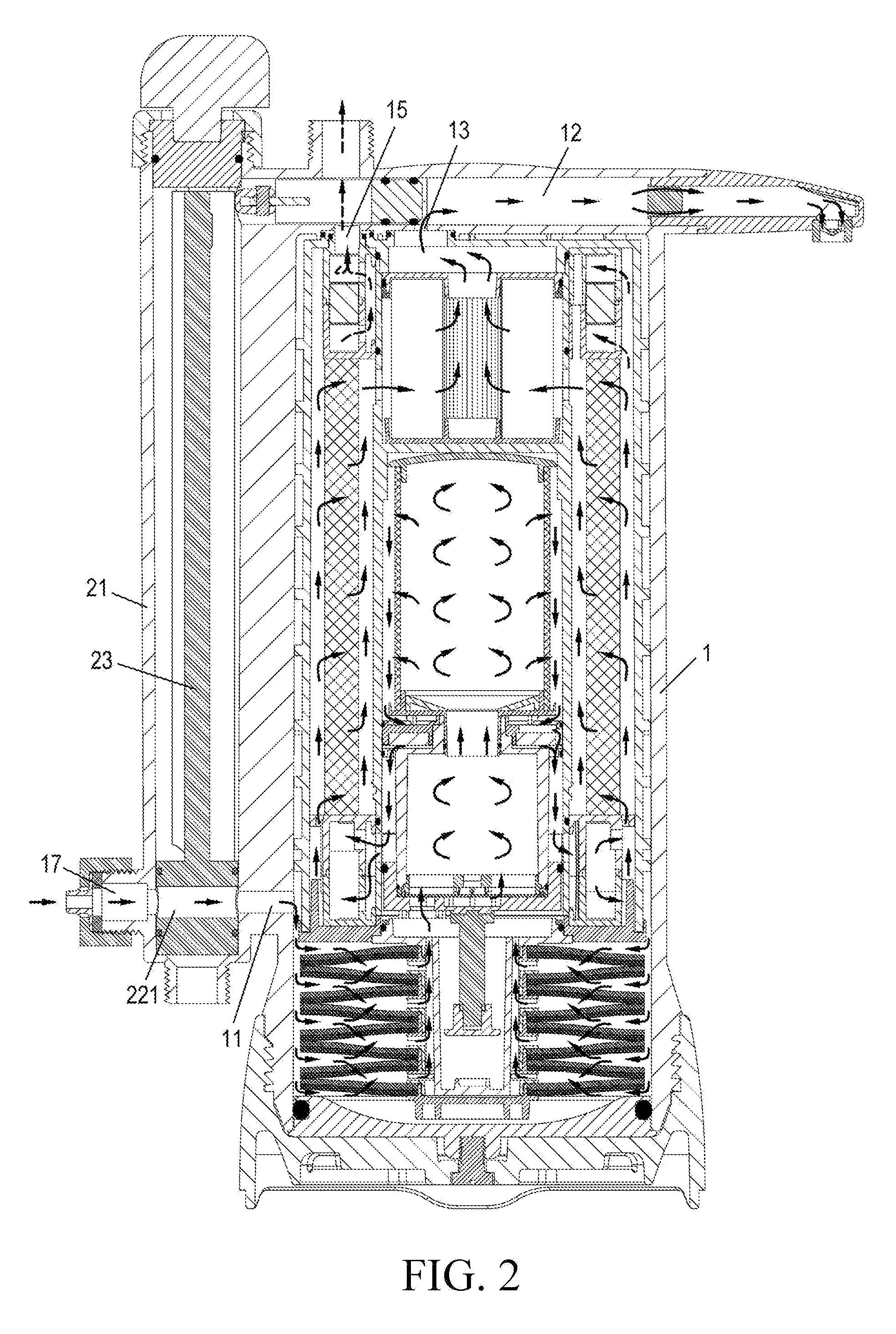

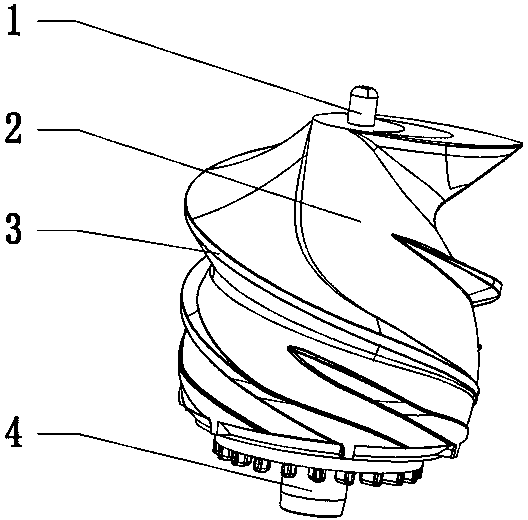

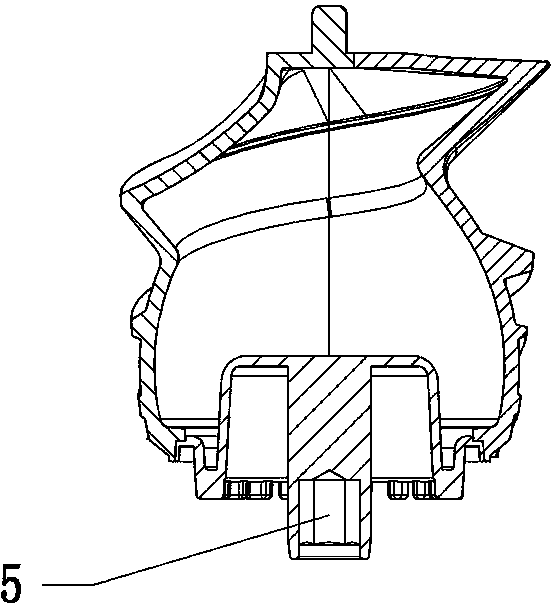

Household juicer screw and manufacturing method thereof

InactiveCN104305851AAvoid surface abrasionExtend your lifeStrainersThermal treatmentManufacturing engineering

The invention provides a household juicer screw and a manufacturing method thereof. The household juicer screw is completely made of metal. The manufacturing method includes casting screw parts by the metal, assembling the screw parts into a blank screw, eliminating residual welding stress in the blank screw by thermal treatment or aging treatment, cutting the blank screw until the blank screw conforms to the size requirement, finally polishing the operating surface and the welding seam of the screw to complete manufacture of the household juicer screw. The manufacturing method of the household juicer screw is simple, and the household juicer screw is long in service life and can replace widely used plastic screws in household juicers of the prior art.

Owner:佛山市顺德区客浦电器有限公司

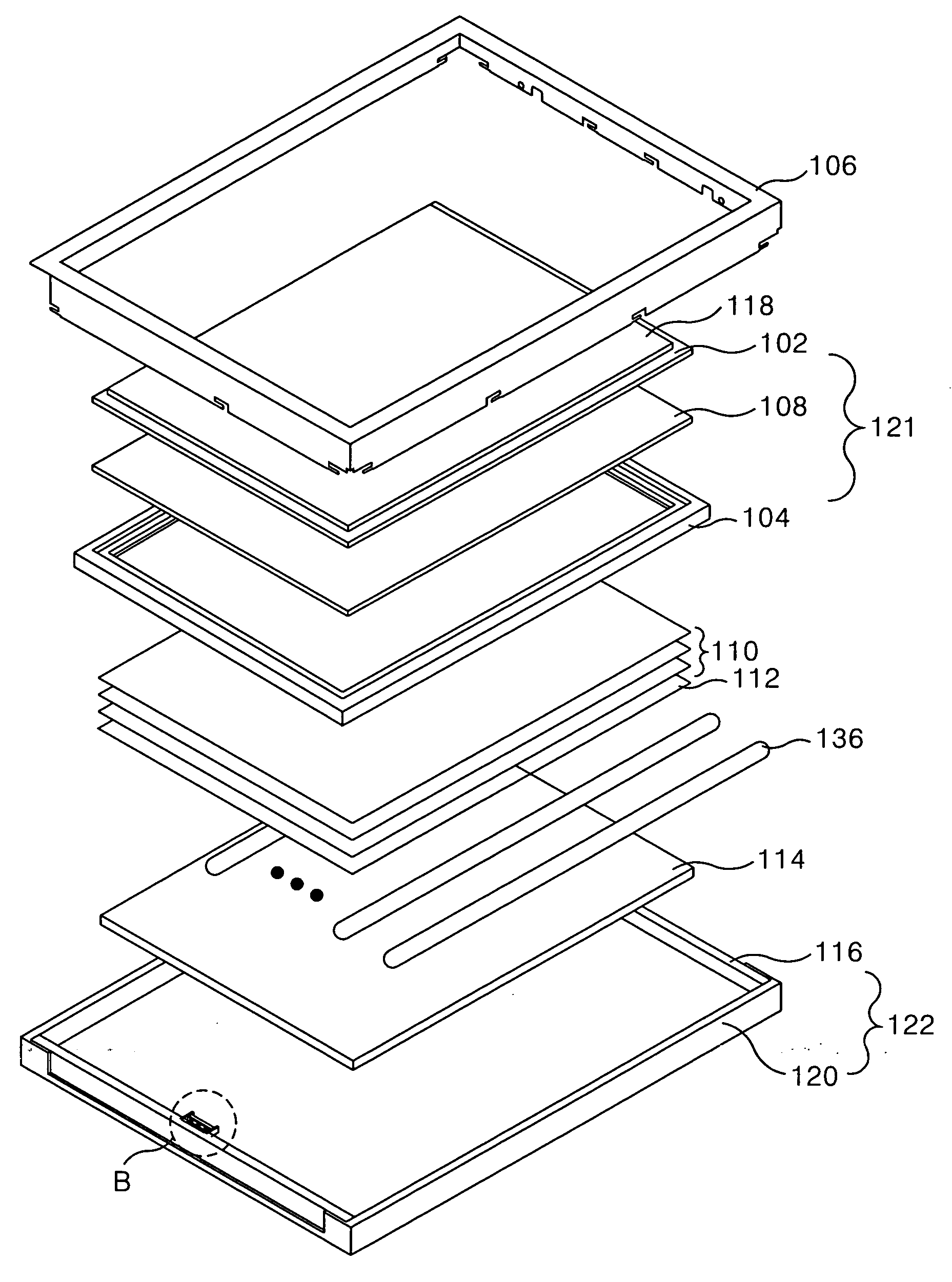

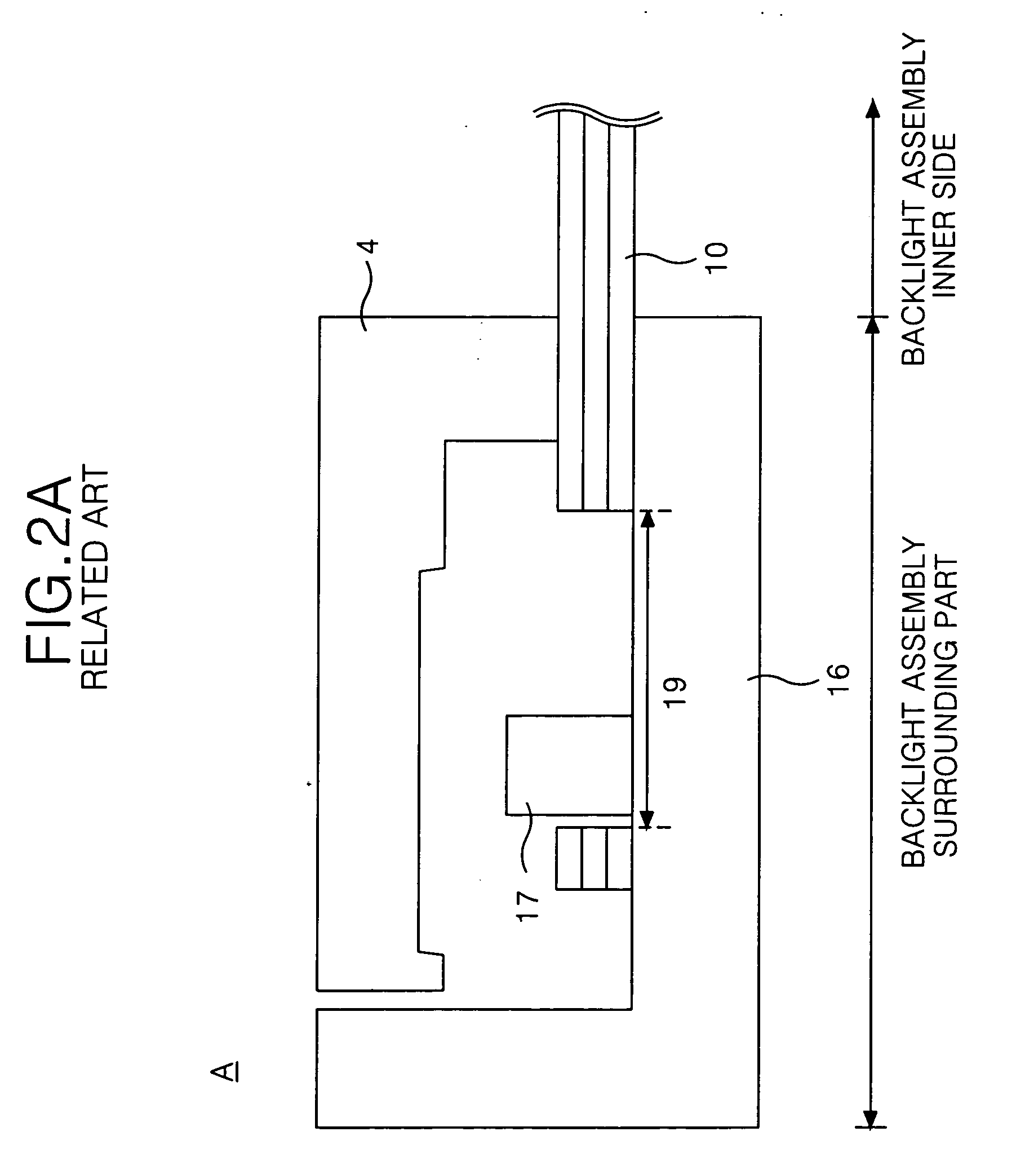

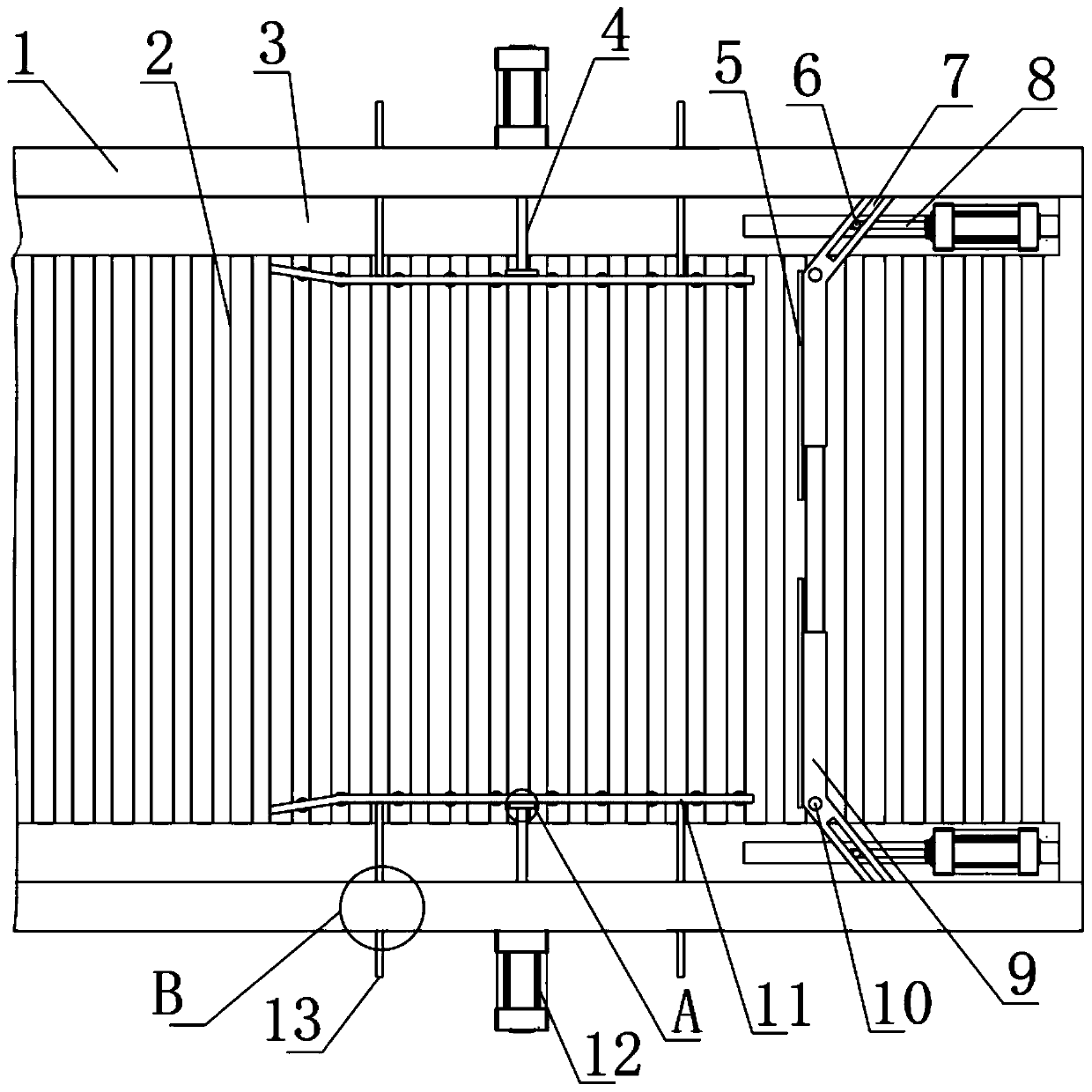

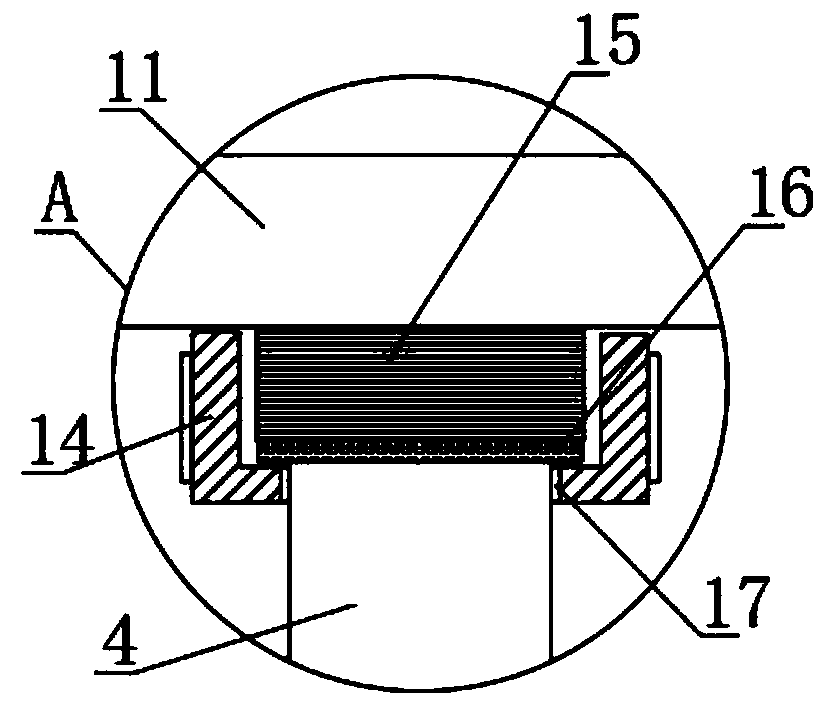

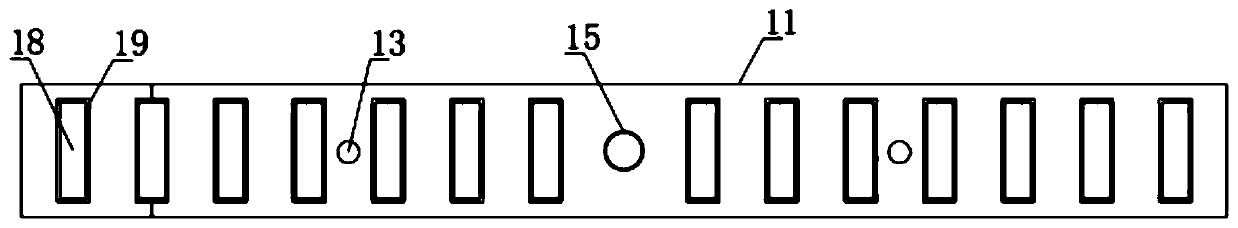

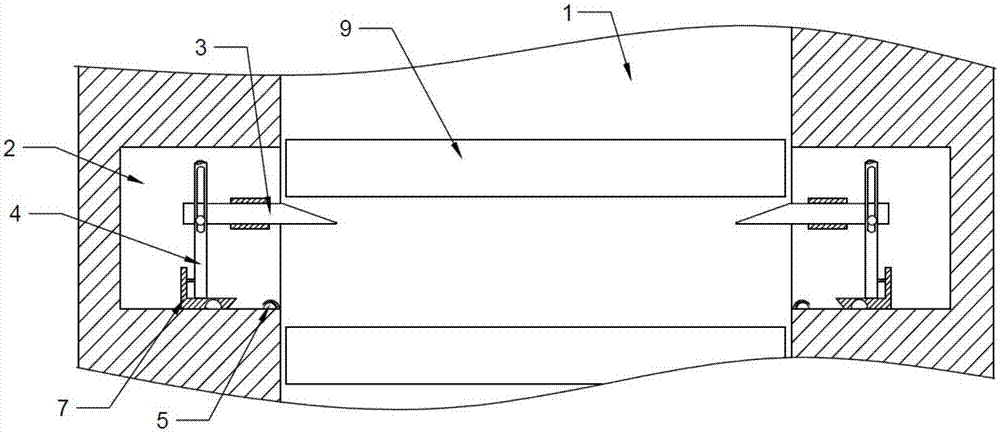

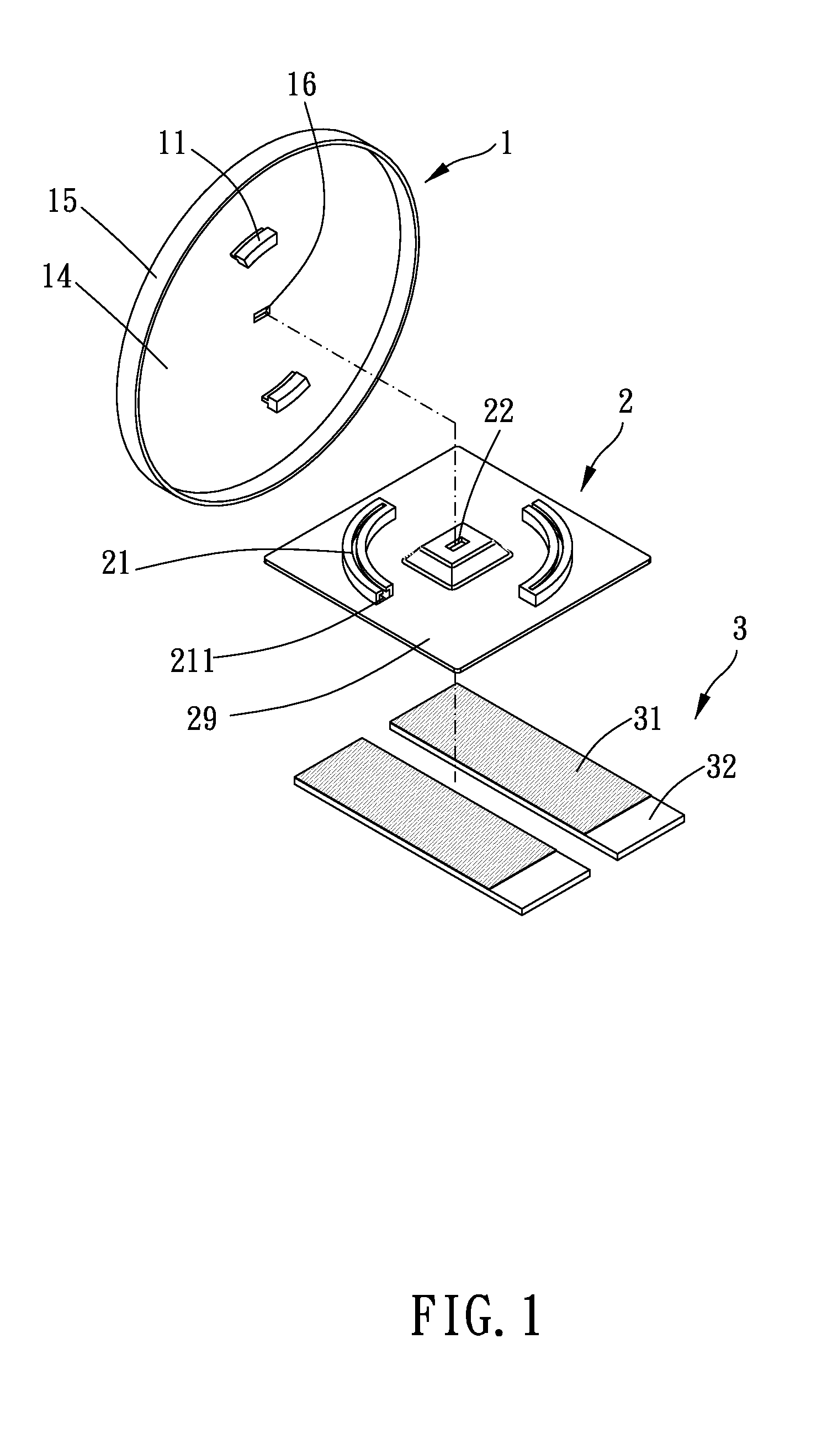

Backlight unit and liquid crystal display device using the same

ActiveUS20070002208A1Avoid surface abrasionPreventing of flat surfaceNon-linear opticsLiquid-crystal displayEngineering

A backlight unit that for preventing an optical sheet from moving freely and preventing deterioration of picture quality caused by deformation. The backlight unit of a liquid crystal display device includes a light source; a reflecting sheet disposed in a rear surface of the light source; an optical sheet to direct light emitted from the light source to travel in a direction towards a liquid crystal display panel; and a cover bottom assembly formed to house the light source, the reflection sheet and the optical sheet. The cover bottom assembly comprises support side bottoms formed at two short sides of the cover bottom assembly to dispose the optical sheet thereon, and the support side bottom includes a joining part to fix the optical sheet to the support side bottom using a movable body movable on a surface of the optical sheet.

Owner:LG DISPLAY CO LTD

Rubber hose material and rubber hose using the same

ActiveUS7055552B2High mechanical strengthImprove mechanical propertiesLayered productsFlexible pipesEngineeringEthylene propylene rubber

Owner:SUMITOMO RIKO CO LTD

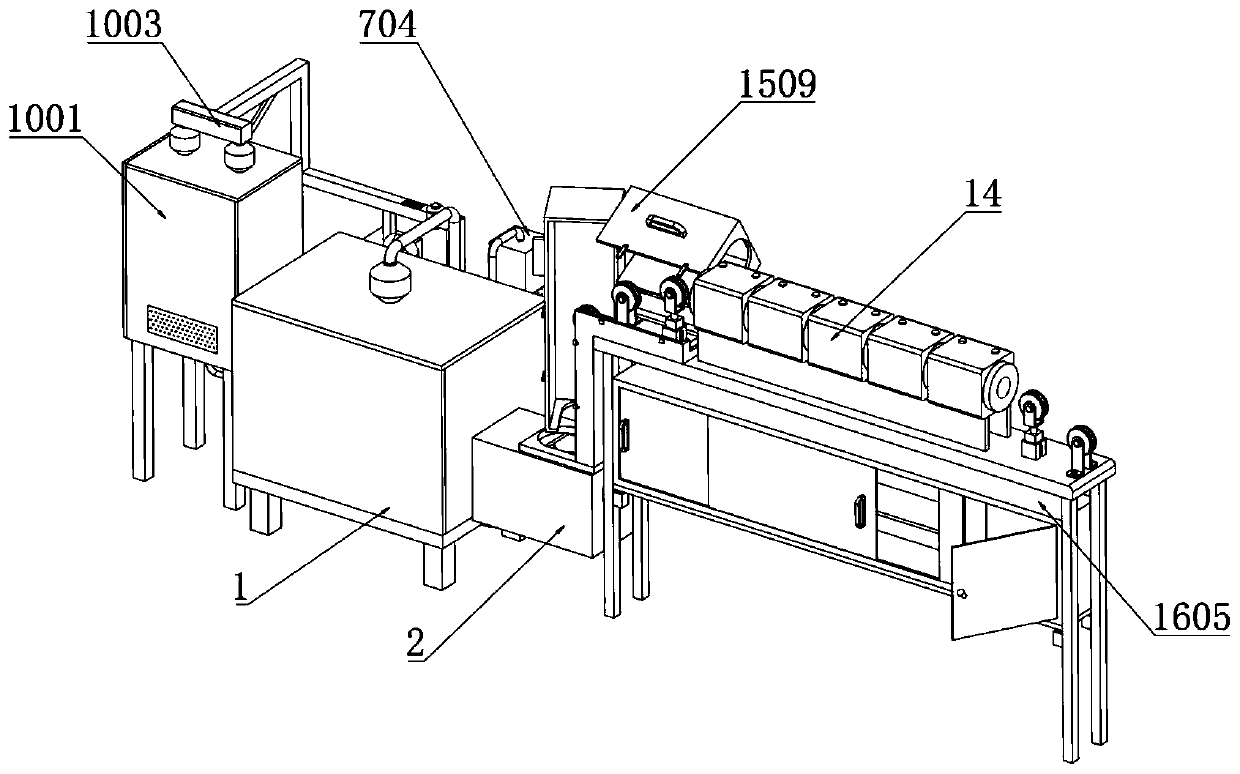

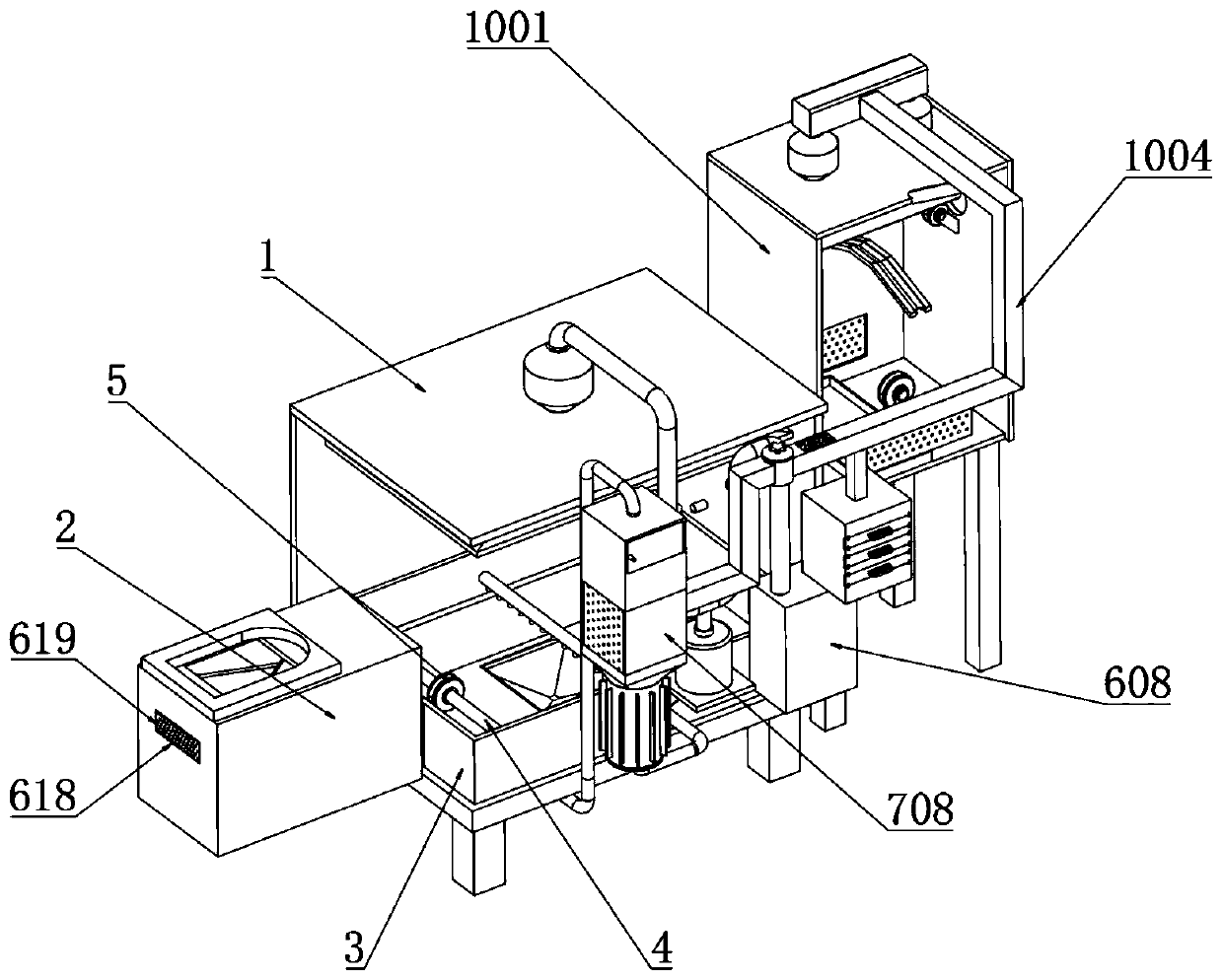

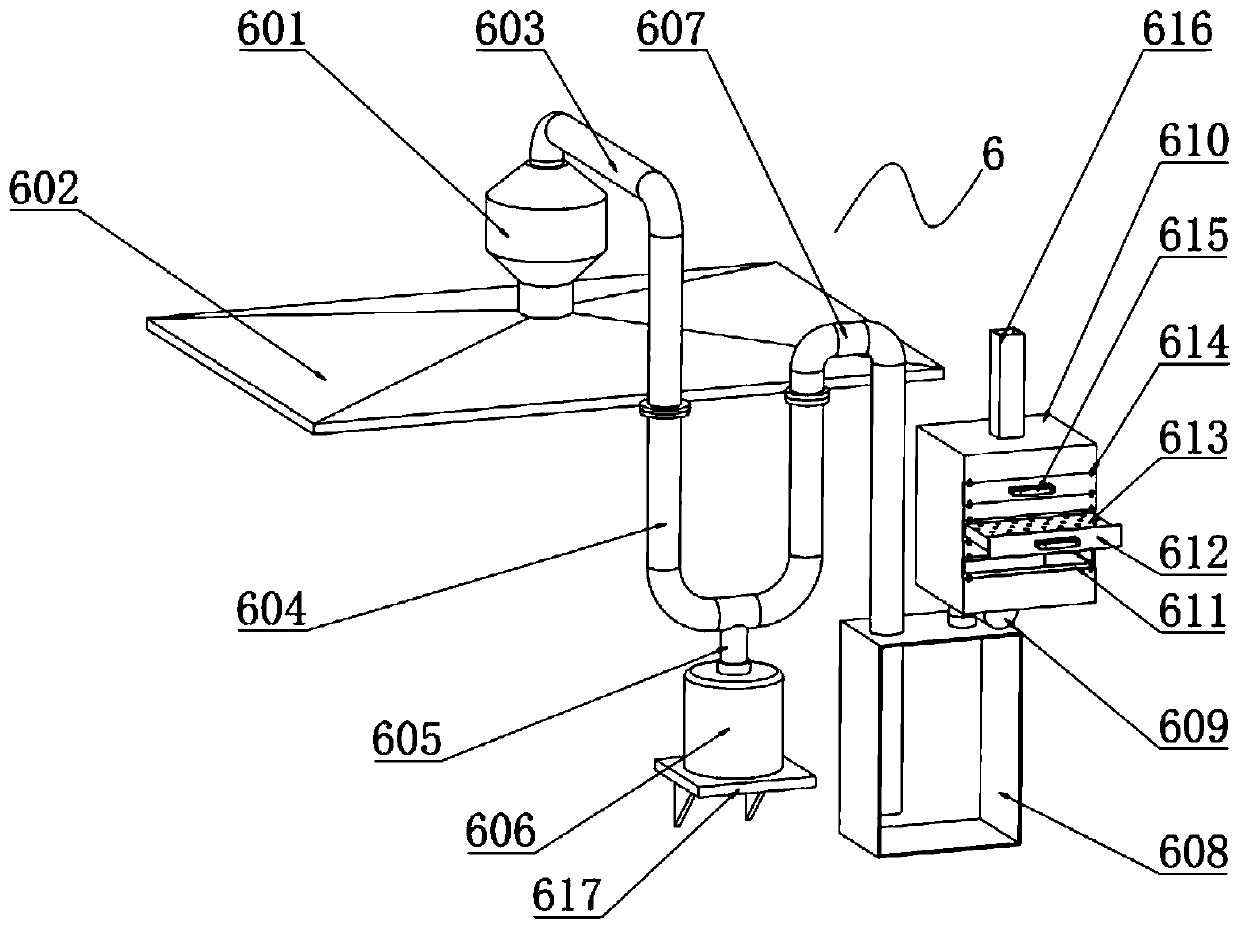

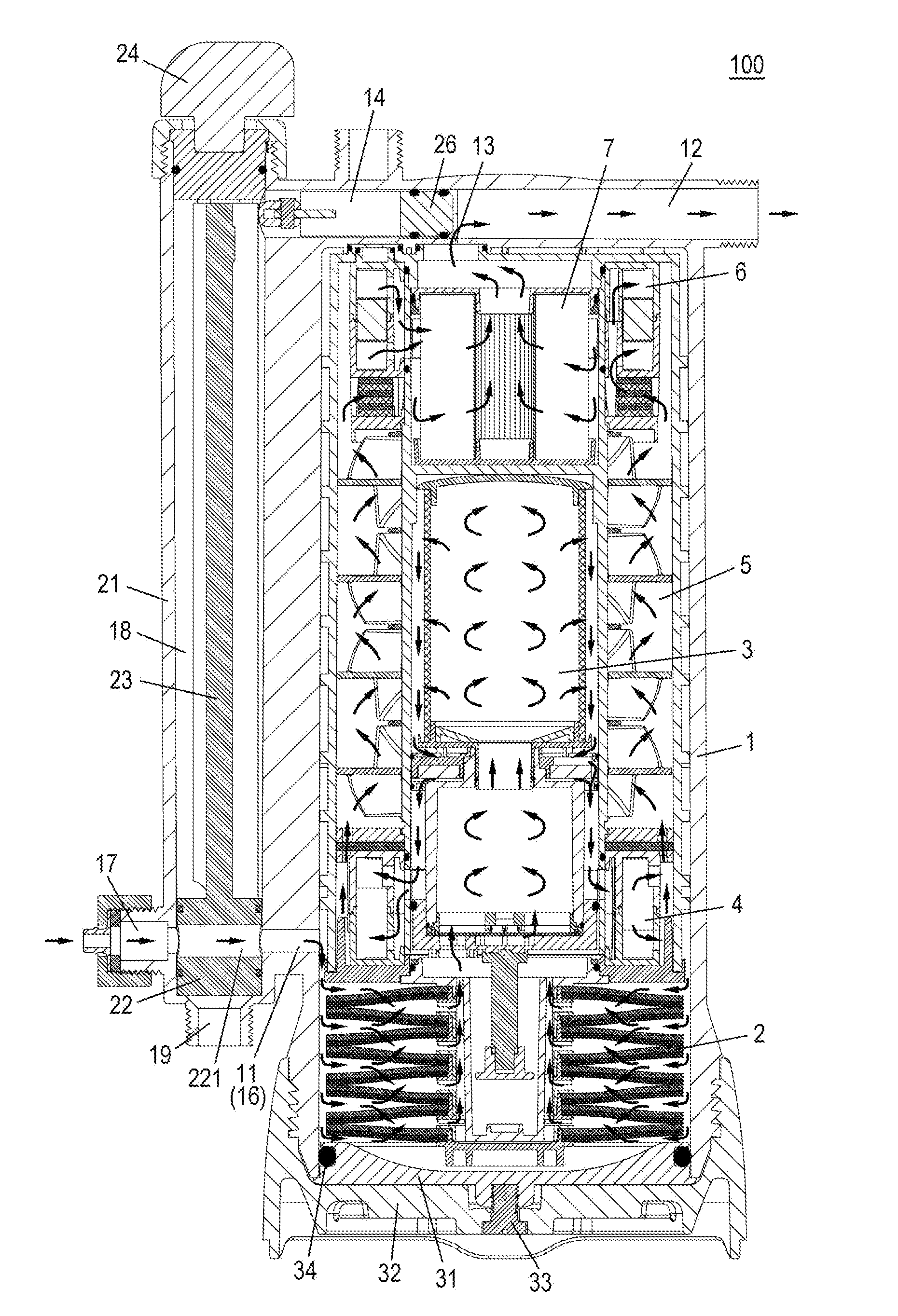

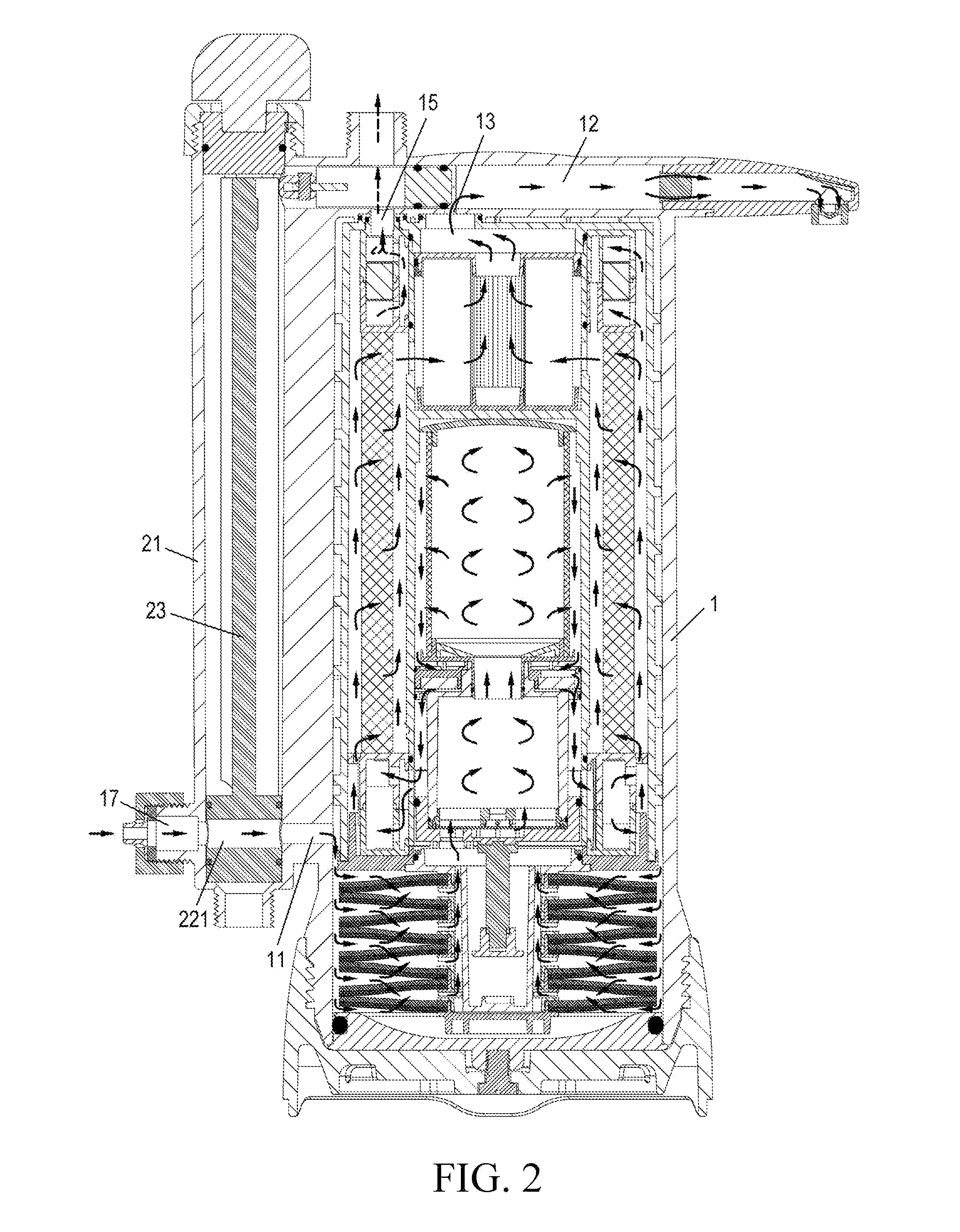

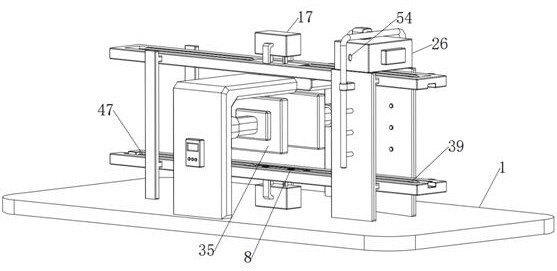

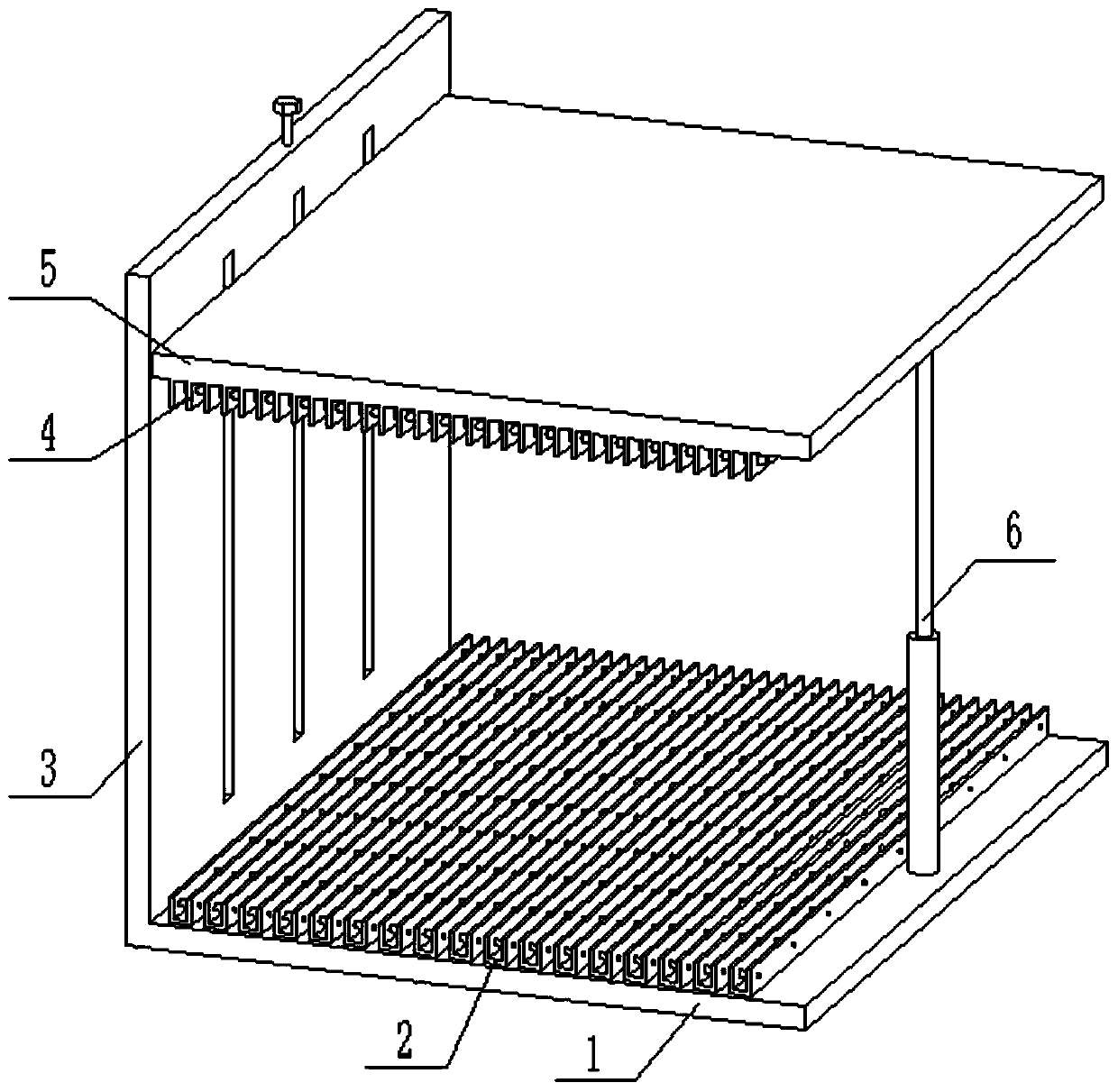

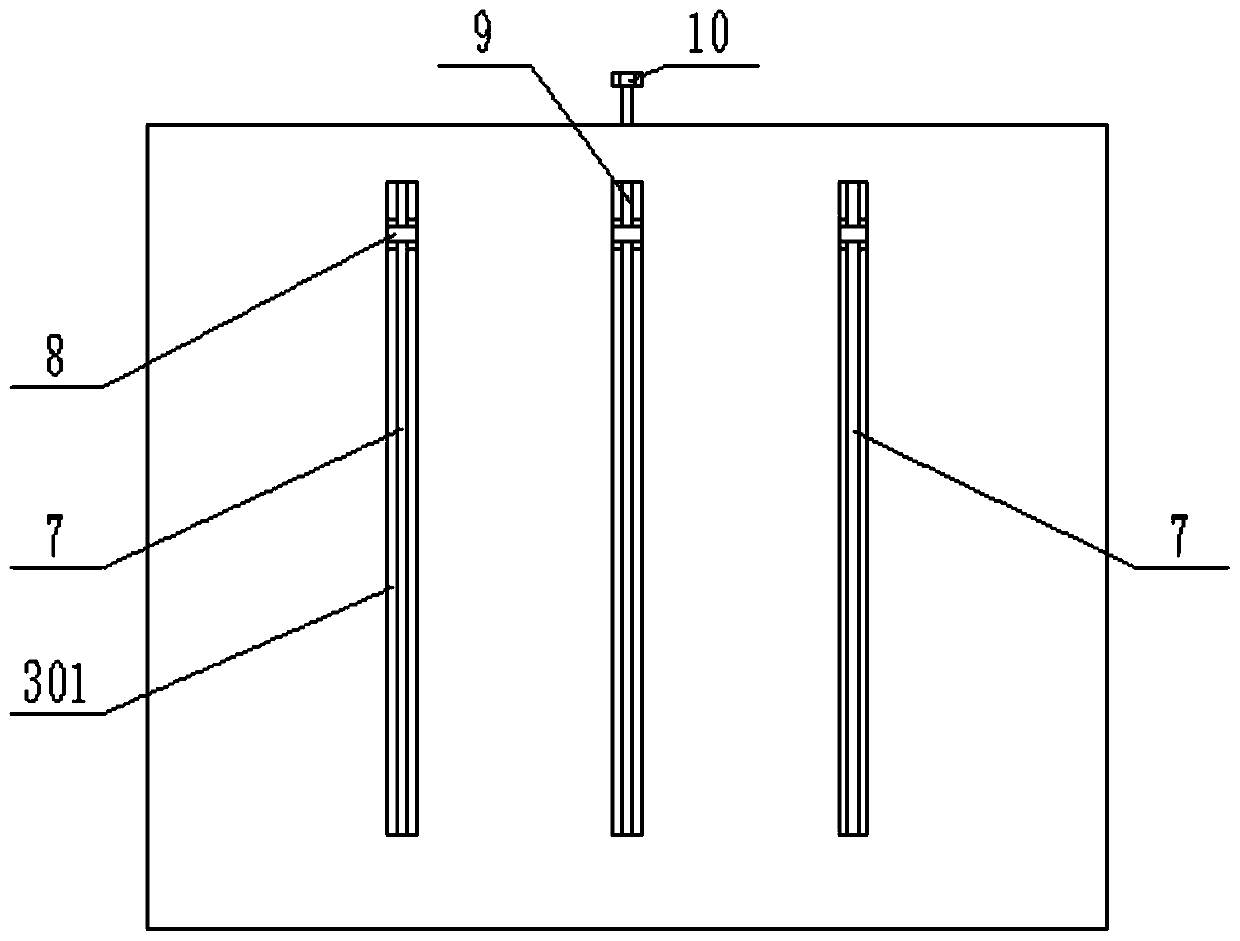

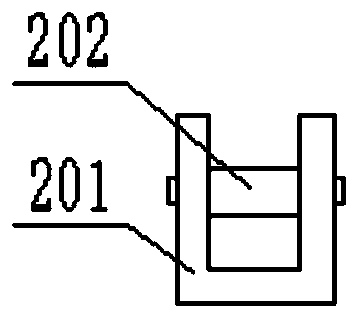

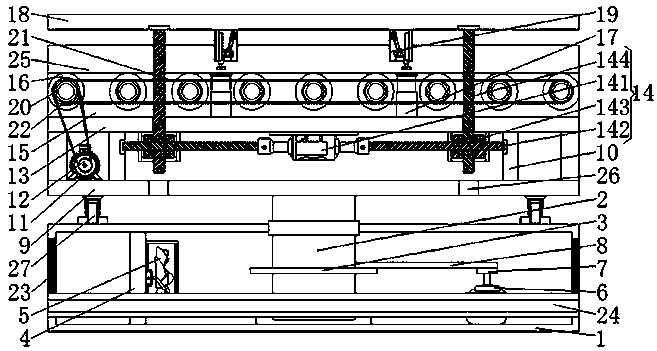

Fast environmentally-friendly thermal treatment device for metal processing

InactiveCN111304422AScientific and reasonable structureEasy to useDispersed particle filtrationDrying gas arrangementsExhaust gasThermal treatment

The invention discloses a fast environmentally-friendly thermal treatment device for metal processing. The fast environmentally-friendly thermal treatment device comprises a thermal treatment box, wherein a sealing side box is fixedly connected with one end of the thermal treatment box; a quenching tank is placed at the bottom of the inner side of the thermal treatment box; support guide rods aresymmetrically and fixedly connected with the inner side of the quenching tank; and a tail gas treatment mechanism is fixedly connected with the middle of the top end of the thermal treatment box. Thefast environmentally-friendly thermal treatment device transports exhaust gas into a gas washing box through a lateral gas guide pipe, the other part of harmful gas dissolved in water is dissolved andabsorbed by water in the gas washing box, the gas in the gas washing box is transported into an adsorption box through a lower gas guide pipe, and harmful components not dissolved in water and left in the gas are adsorbed by an activated carbon filter net, so that the using process of the thermal treatment device is optimized, harmful gas generated during the thermal treatment process is rapidlycollected and treated, harmful compositions contained in the harmful gas are effectively removed, the situation that the harmful gas is discharged into the atmosphere to pollute the atmosphere is prevented, and the natural environment is protected.

Owner:张周钦

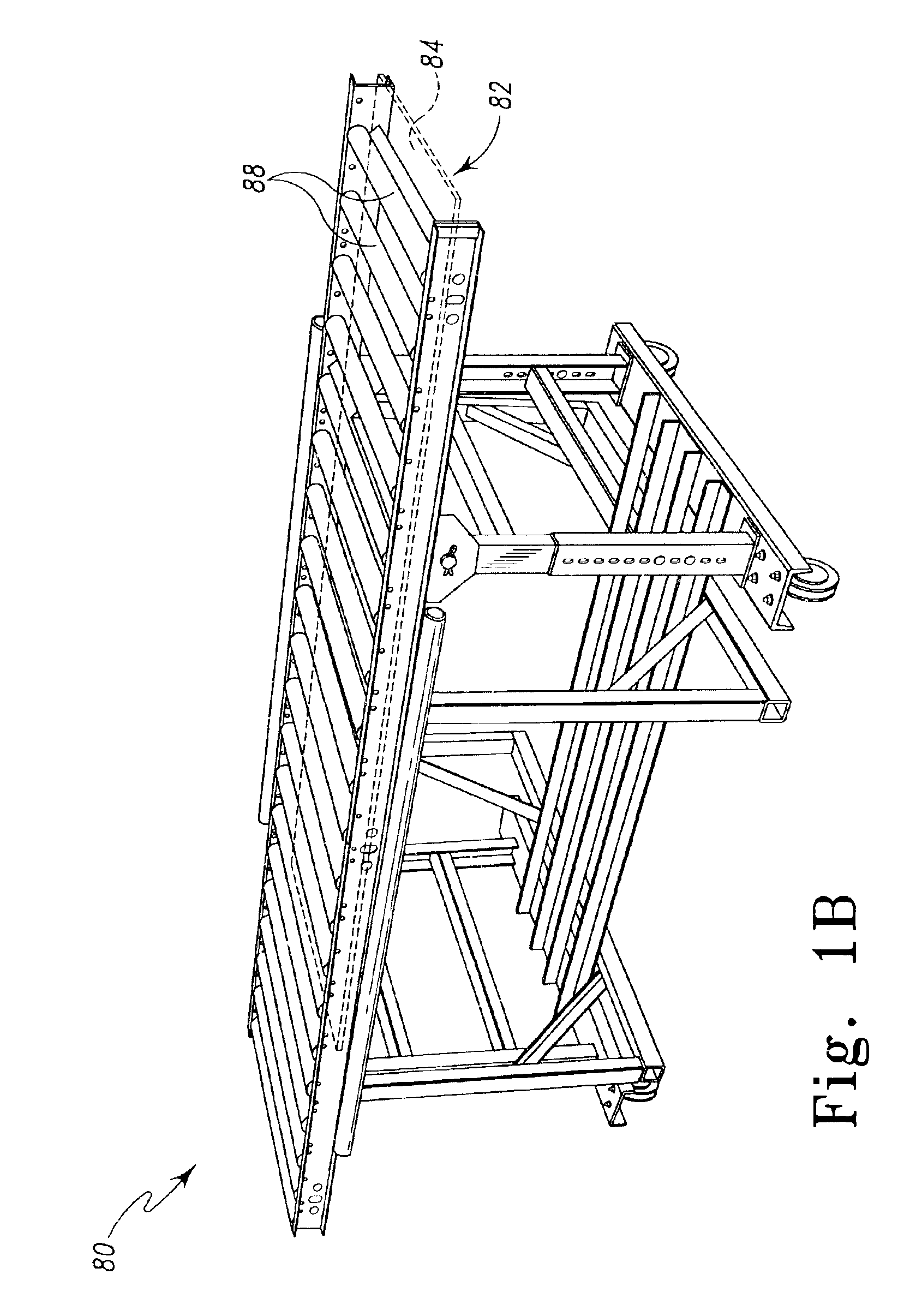

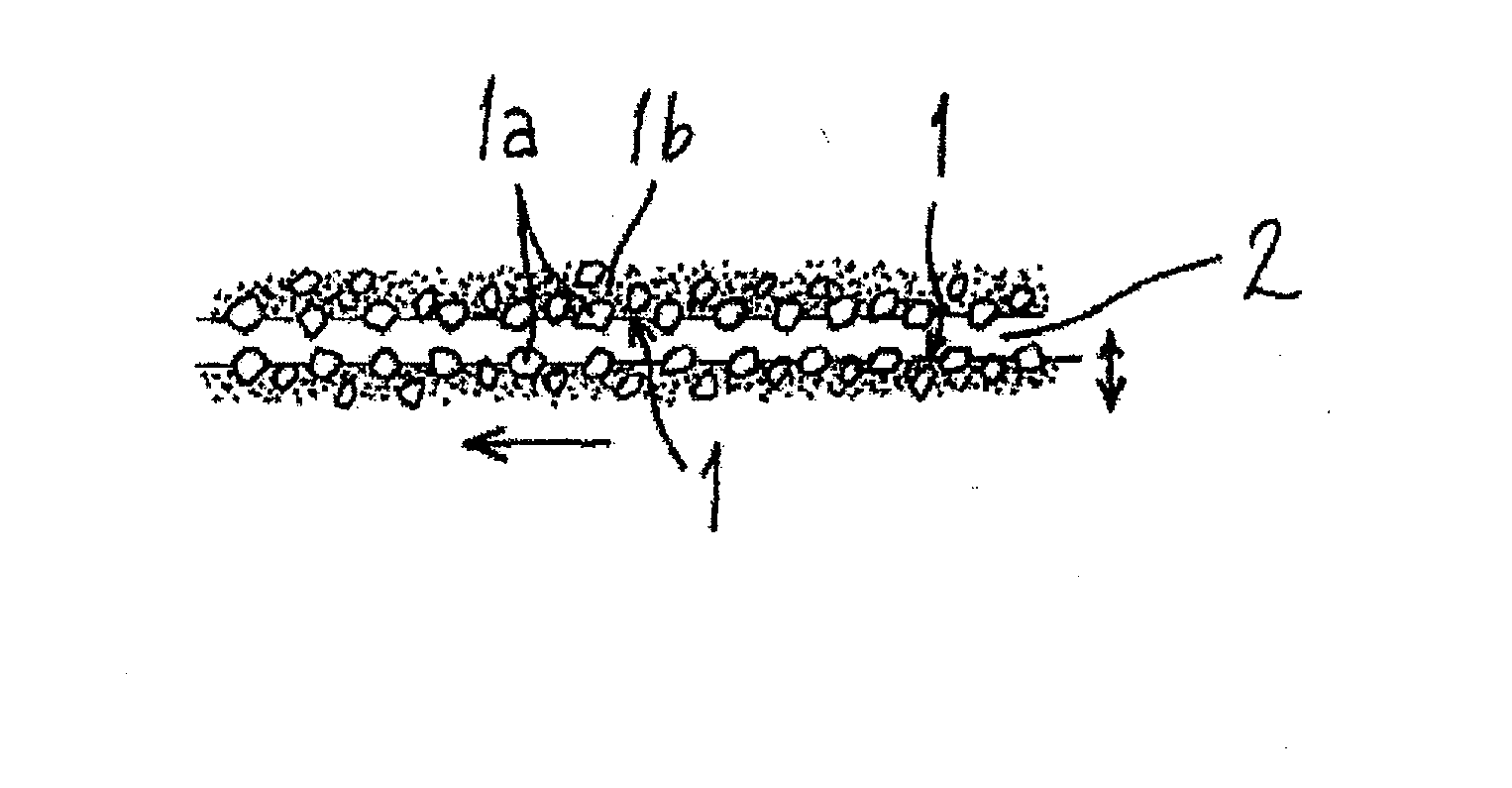

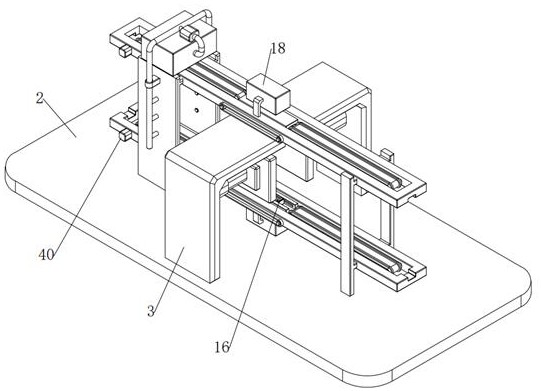

Method and apparatus for fibrillation of cellulose containing materials

InactiveUS20150057442A1Improve efficiencyAvoid surface abrasionReed/straw treatmentCork treatment detailsFiberCellulose

In a method for manufacturing fibril cellulose, cellulose based fibre raw material is processed mechanically in a refining gap for separating fibrils. The fibres to be refined are subjected to the action of a surface roughness Ra provided by grits elevated from a refining surface delimiting the refining gap, said surface roughness being lower than 3 μm, advantageously lower than 2 μm. The refining surface is formed by spraying grits and binder onto a substrate.

Owner:UPM-KYMMENE OYJ

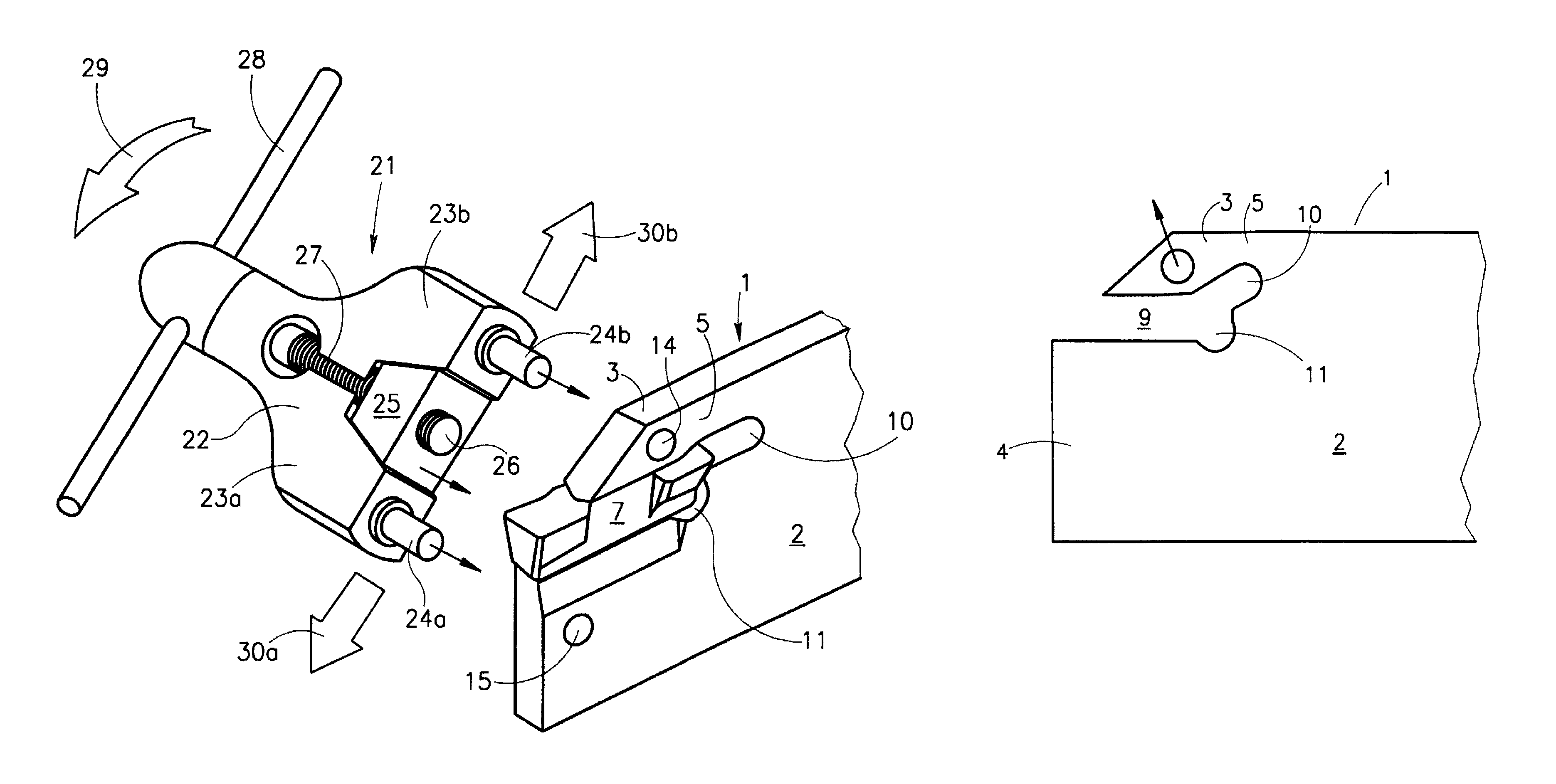

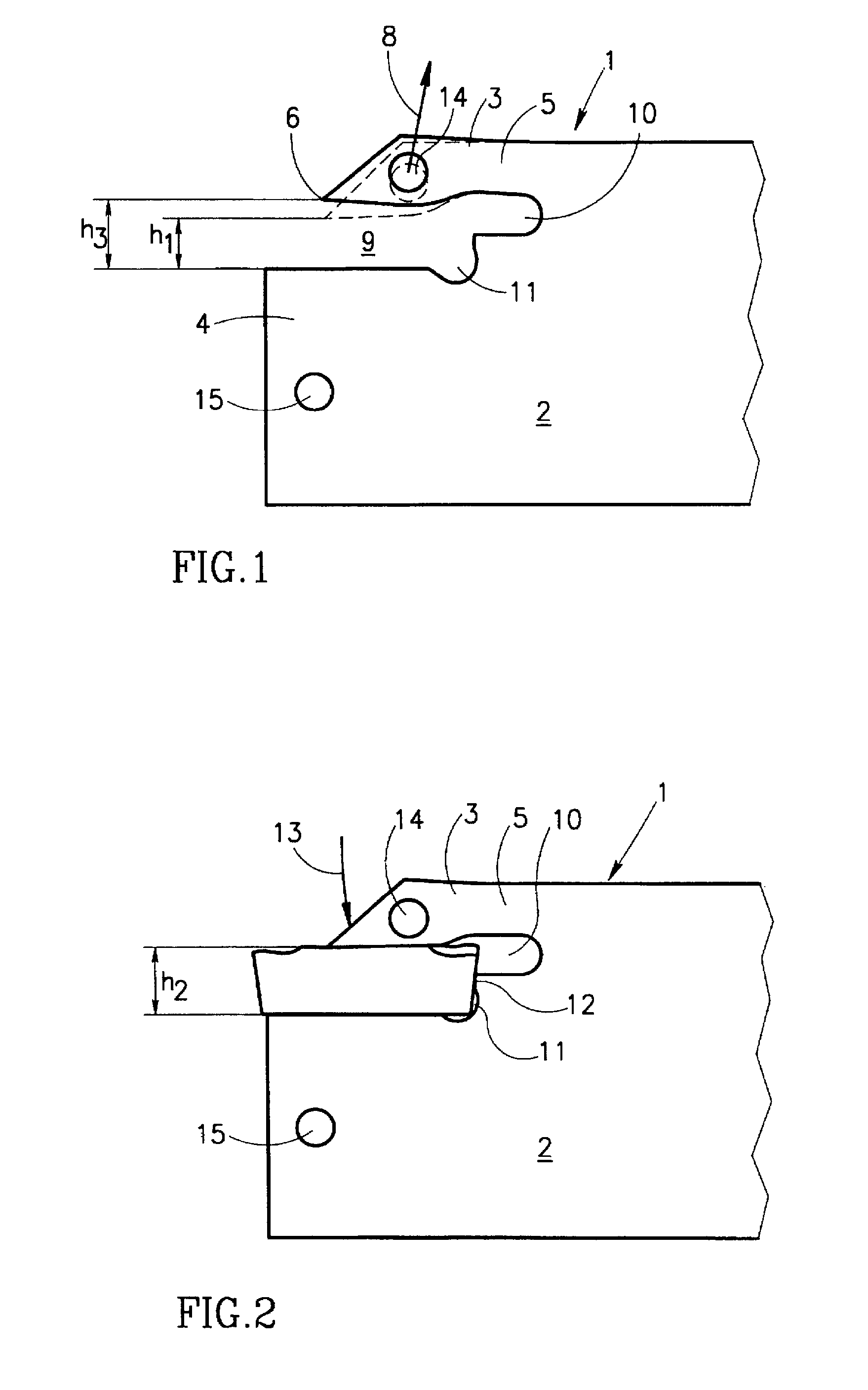

Clamping device for a cutting insert

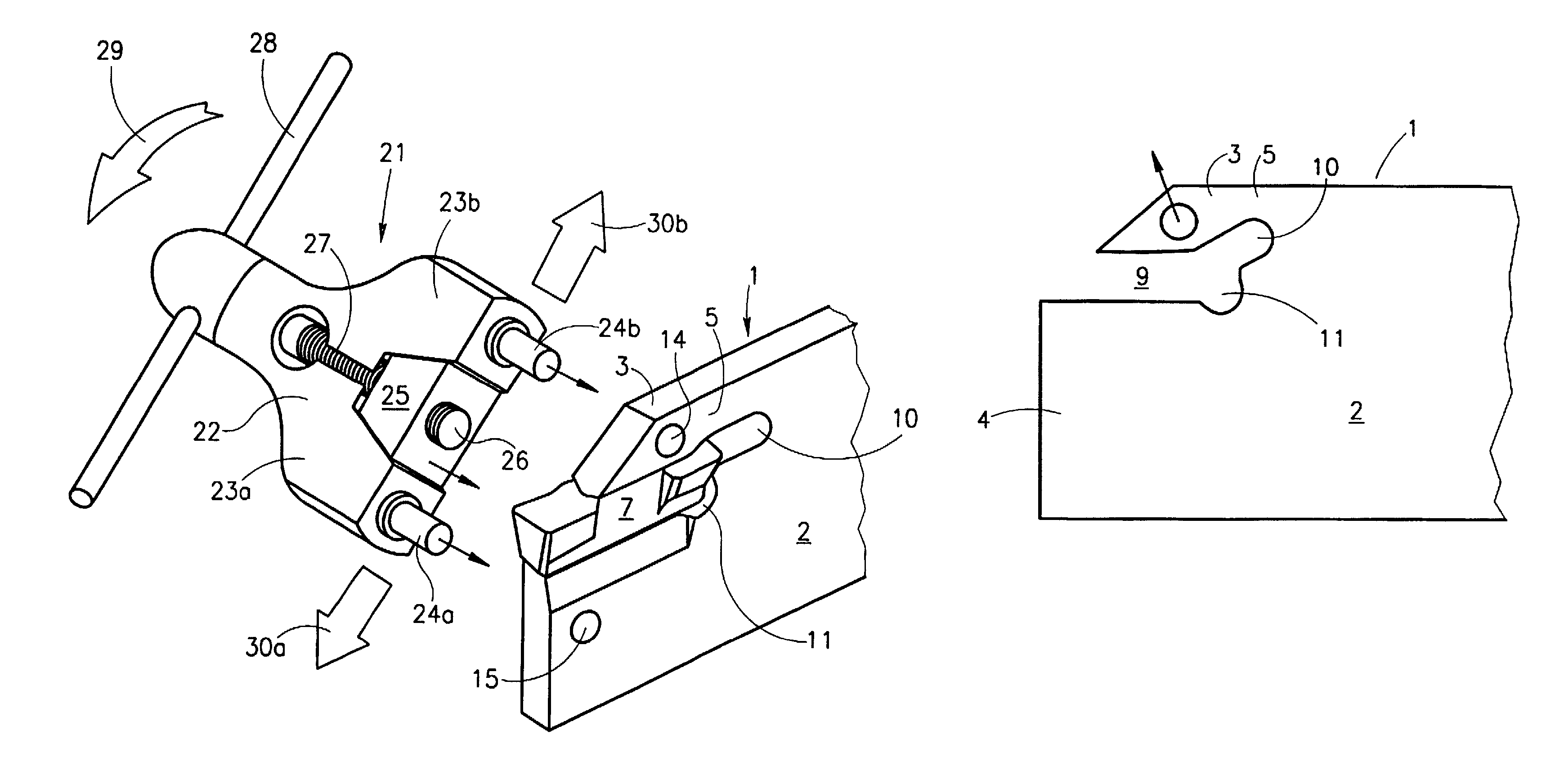

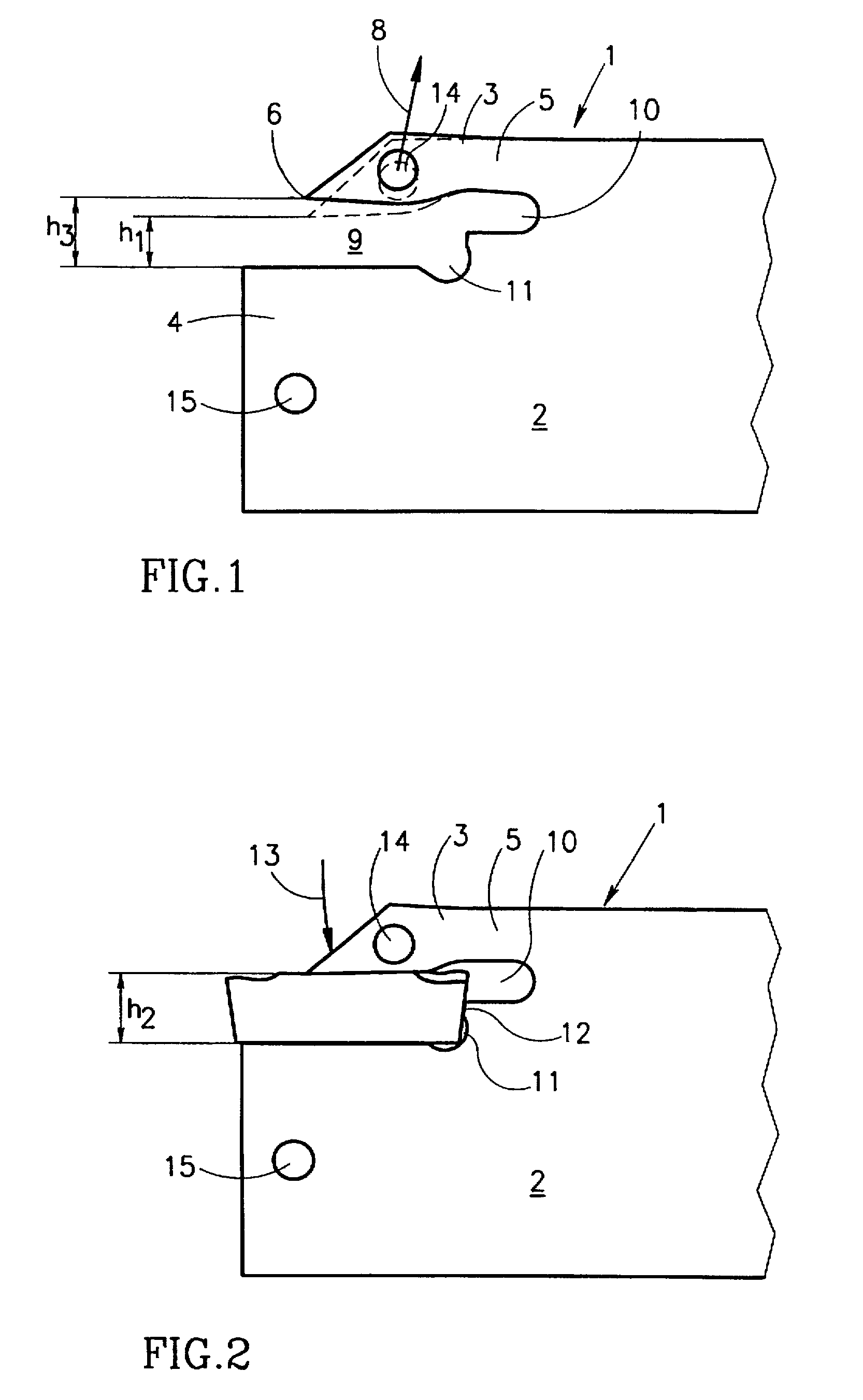

InactiveUSRE43718E1Avoid surface abrasionExtend your lifeLathesCutting insertsEngineeringSupport surface

A metal cutting tool assembly comprising a rigid holder blade, an insert receiving slot formed in a leading end of the holder blade and defined between a resiliently displaceable clamping jaw formed integrally with the holder blade and rigid base jaw forming part of the holder blade, spaced apart displacement and supporting surfaces respectively formed in or on the clamping jaw and the holder, and a slot opening key, a pair of spaced apart projecting prongs of the key with adapted to engage the surfaces. At least one of the prongs is displaceable with respect to the holder blade so as resiliently to displace the clamping jaw outwardly with respect to the base jaw into an opening position for insertion or removal of an insert.

Owner:ISCAR LTD

Straight rubber hose with hot melt adhesive sheath and preparation method for straight rubber hose

InactiveCN102510032AImprove adhesionImprove flexibilityElectrical apparatusPolymer sciencePolyolefin

The invention relates to a straight rubber hose with a hot melt adhesive sheath and a preparation method for the straight rubber hose. The hot melt adhesive sheath of which the inner wall is provided with an adhesive body is adhered on the straight rubber hose, and consists of two parts of structures, namely a semiflexible thermal contraction tube of which the inner layer is attached with an hot melt adhesive and a thermal contraction tube of which the outer layer is made of radiation crosslinking polyolefin. The preparation method for the straight rubber hose with the hot melt adhesive sheath comprises a step of contracting the hot melt adhesive sheath to the surface of a rubber hose body under a high temperature condition by high-temperature heating equipment, wherein the thermal contraction temperature ranges from 140 DEG C to 160 DEG C; the inner diameter of the hot melt adhesive sheath before thermal contraction is 2 to 10 millimeters more than the outer diameter of the rubber hose; and the thickness of the hot melt adhesive sheath ranges from 0.4 millimeters to 2.6 millimeters. A high-molecular material has a high anti-abrasion performance, so that a phenomenon of surface abrasion caused by friction between the rubber hose and other surrounding parts is avoided. The hot melt adhesive has high adhesiveness and high flexibility, so that the sheath is difficult to loose or shift from the hose body.

Owner:TIANJIN PENGYI GRP CO LTD

Clamping device for a cutting insert

InactiveUSRE43534E1Avoid surface abrasionExtend your lifeLathesCutting insertsEngineeringSupport surface

A metal cutting tool assembly comprising a rigid holder blade, an insert receiving slot formed in a leading end of the holder blade and defined between a resiliently displaceable clamping jaw formed integrally with the holder blade and rigid base jaw forming part of the holder blade, spaced apart displacement and supporting surfaces respectively formed in or on the clamping jaw and the holder, and a slot opening key, with a pair of spaced apart projecting prongs of the key adapted to engage the surfaces. At least one of the prongs is displaceable with respect to the holder blade so as resiliently to displace the clamping jaw outwardly with respect to the base jaw into an opening position for insertion or removal of an insert.

Owner:ISCAR LTD

Composite shaving board

InactiveCN104441101AReduced service lifeAvoid surface abrasionSynthetic resin layered productsWood veneer joiningEnvironmentally friendlyParaffin oils

The invention discloses a composite shaving board. The composite shaving board comprises a board body, wherein the board body comprises a shaving sandwich layer which is mainly formed by distributing a rough shaving layer and a fine shaving layer in a staggered mode, a metal net layer is arranged between the rough shaving layer and the fine shaving layer, meshes of the metal net layer are filled with metal powder, vermiculite anti-flaming layers which are connected through a polymer glue layer are arranged on the upper surface and the lower surface of the shaving sandwich layer respectively, and the periphery of the board body is wrapped in a paraffin layer. The composite shaving board is simple in structure, easy to manufacture, resistant to water and fire, capable of insulating heat and preserving heat, high in strength, high in torsional property, capable of preventing radiation, environmentally friendly, firm in structure, resistant to abrasion, attractive, durable and the like and can be widely applied to various fields and occasions.

Owner:GUILIN TECH ENTERPRISE DEV CENT

Sealing structure and fluid treatment unit

InactiveUS20160096750A1Reduce the overall heightAvoid surface abrasionSpecific water treatment objectivesTreatment involving filtrationStructural engineeringTreatment unit

A fluid treatment unit and a sealing structure which is preferably for the fluid treatment unit are provided. The sealing structure includes: a cylinder with an opening formed at one end thereof, the cylinder comprising an inner wall surface and an outer wall surface, and an outer thread being provided on the outer wall surface; a sealing cover which is capable of hermetically cooperating with the inner wall surface of the cylinder to seal the opening; a support cover which is capable of being connected with the cylinder by thread engagement; when the support cover and the cylinder are relatively rotated in order to achieve a threaded connection of the support cover and the cylinder, the support cover is capable of supporting the sealing cover and impelling it to move in parallel so as to allow the sealing cover to reach a position at which it seals the opening.

Owner:CHAU YIU CHAU

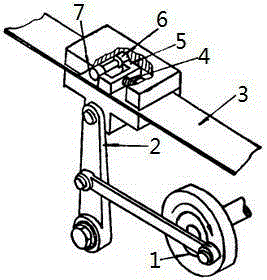

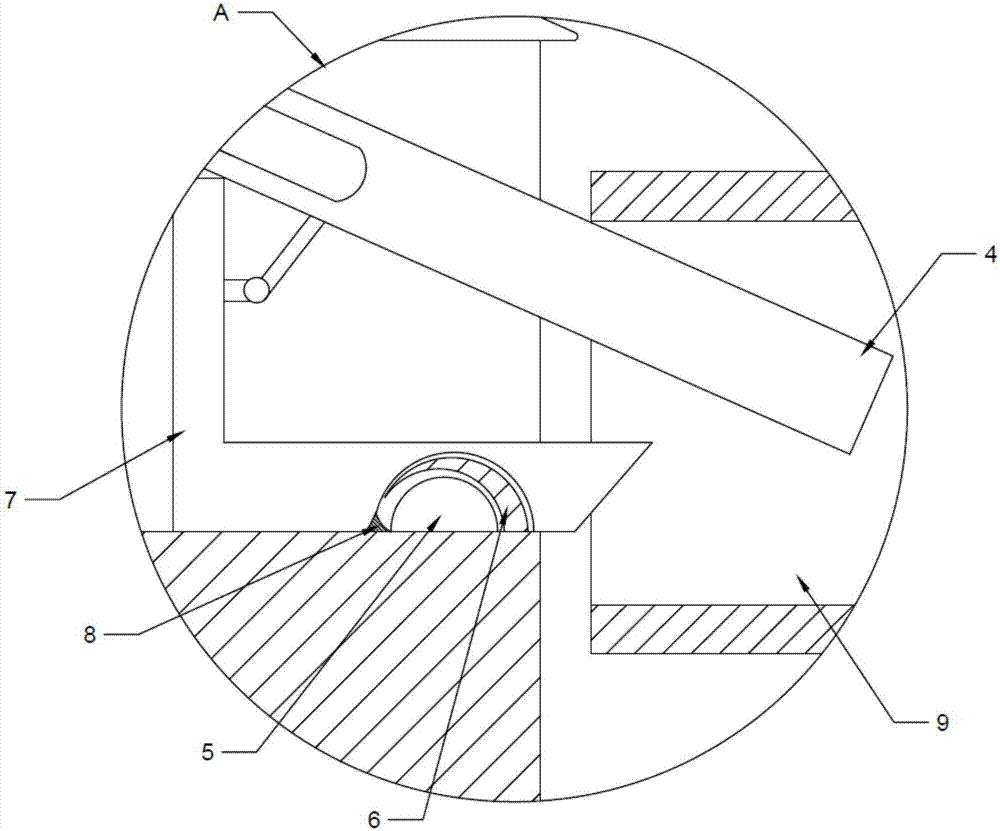

Belt conveying mechanism capable of pressing through slope

The invention discloses a belt conveying mechanism capable of pressing through a slope so as to solve the problem in processing and conveying of conveyor belts in the prior art that the conveyor belts are apt to be curled and deformed. The belt conveying mechanism capable of pressing through the slope comprises a conveying block, wherein a through hole for the belts to pass through is formed in the conveying belt, and the through hole is matched with the belts in shape; the conveying block is capable of reciprocating along the length direction of the belts driven by a crank-rocker mechanism; an accommodating cavity is arranged on the conveying block; the accommodating cavity is communicated with the through hole; a side wall, which is vertical to the conveying direction of the belts, of the accommodating cavity is a sloped wall; a pin roller which is vertical to the conveying direction of the belts is arranged in the accommodating cavity; and the sloped wall can be pressed against the pin roller so that the pin roller can press the belts tightly.

Owner:CHONGQING YANGDI ELECTROMECHANICAL

Placing rack for glass transport

InactiveCN108639755ARealize separate placementAvoid surface abrasionCharge manipulationConveyor partsEngineeringMechanical engineering

Owner:于骏浩

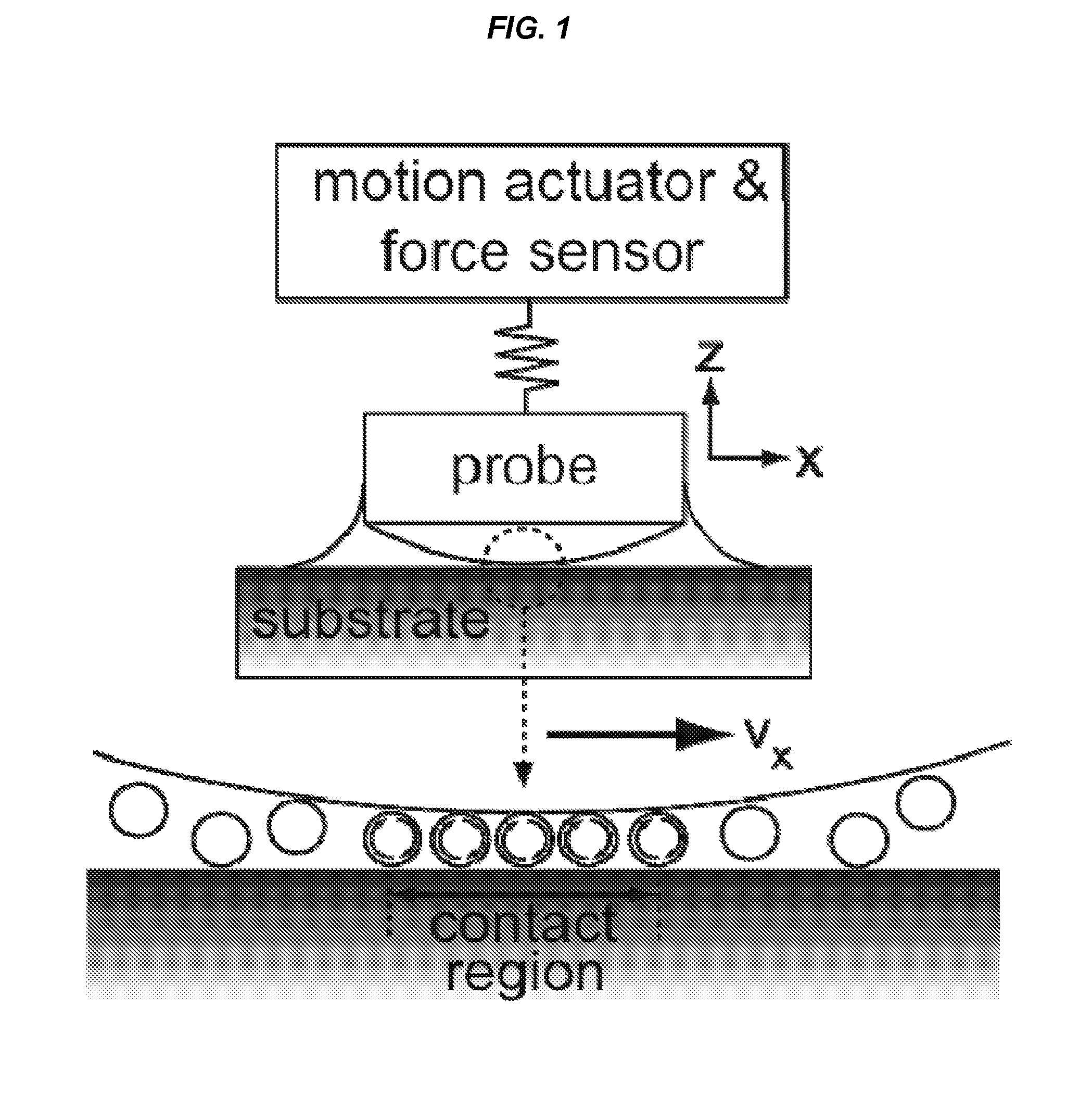

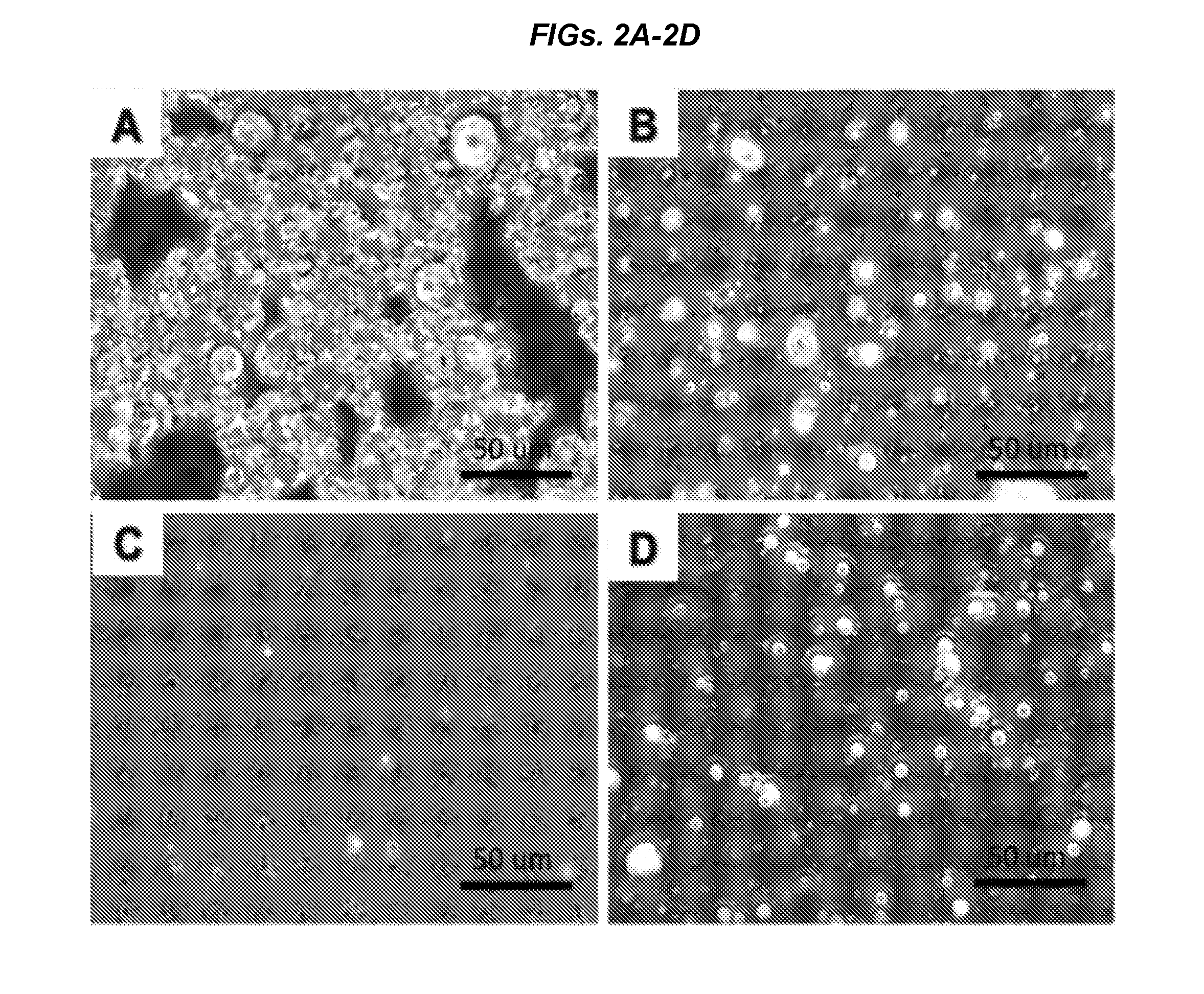

Silk microspheres and methods for surface lubrication

ActiveUS20150150993A1Avoid surface abrasionStable and robust material propertyPeptide/protein ingredientsGenetic material ingredientsMedicineMicrosphere

Provided herein relates to compositions and methods for lubrication of a surface. The surface amenable to the compositions and methods described herein can be a non-biological surface, a biological surface, or a combination thereof. In some embodiments, the composition comprising a phospholipid-coated silk microsphere can be used for lubrication of a surface. In some embodiments, the composition comprising a phospholipid-coated silk microsphere can be used for joint lubrication, e.g., for treatment of joint disorders such as arthritis.

Owner:THE ADMINISTRATORS OF THE TULANE EDUCATIONAL FUND +1

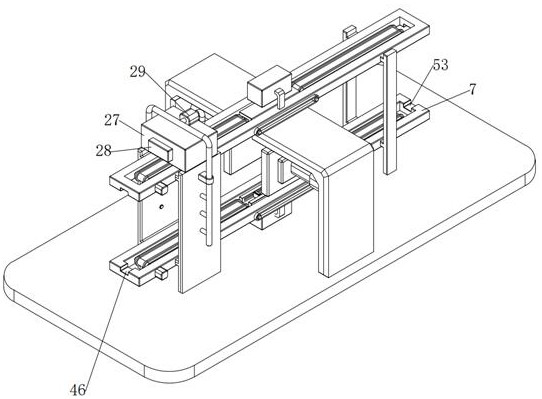

Self-adaptive pretreatment type automobile part stamping device and using method thereof

InactiveCN113953401AAchieve lossless clampingAvoid surface abrasionMetal-working feeding devicesStripping-off devicesMotor vehicle partStamping process

The invention discloses a self-adaptive pretreatment type automobile part stamping device and a using method thereof. The self-adaptive pretreatment type automobile part stamping device comprises a main body supporting mechanism, a magnetomotive type anti-skid stamping moving positioning mechanism, a gas expansion type non-damage fixed plate clamping mechanism, a static elimination type plate cleaning type stamping pretreatment mechanism, a plate double-face acting type stamping mechanism, a stamping plate vertical linkage type stamping feeding mechanism and a formed stamping part linkage type discharging conveying mechanism. The invention belongs to the technical field of automobile parts, and particularly relates to the self-adaptive pretreatment type automobile part stamping device and the using method thereof. According to the self-adaptive pretreatment type automobile part stamping device and the using method thereof, the stamping process is high in continuity, manual feeding and discharging from a stamping die are not needed, the labor cost is greatly reduced, the machining period is shortened, and the machining efficiency is effectively improved.

Owner:徐州清歌机械制造有限公司

Polymer wear-resistant PP composite material for eyeliner tube and preparation method thereof

The invention discloses a polymer wear-resistant PP composite material for an eyeliner tube. The polymer wear-resistant PP composite material comprises the following raw materials by weight: 65 to 85parts of polypropylene powder, 5 to 8 parts of silicone rubber, 0.5 to 1 part of tungsten carbide powder, 1 to 3 parts of nanometer toughened aluminum oxide, 0.5 to 0.8 part of an aluminum-based adhesive, 5 to 10 parts of sepiolite fiber, 5 to 10 parts of a compatibilizing and toughening agent, 1 to 3 parts of a lubricant and 0.1 to 0.7 part of an antioxidant. The invention relates to the technical field of polymer composite materials. The polymer wear-resistant PP composite material for the eyeliner tube and the preparation method thereof have the following advantages: improvement of the manufacturing materials of the eyeliner tube can be realized to increase the wear-resisting effect of the eyeliner tube; the wear resistance of the eyeliner tube can be greatly improved; the frequent situations of surface abrasion and edge peeling of the eyeliner tube after long-term use are avoided from occurrence; the glossiness and smoothness of the surface of the eyeliner tube are guaranteed; theinfluence on the appearance of the eyeliner tube is prevented; the purpose of prolonging the service life of the eyeliner tube is well achieved; and normal use of the eyeliner tube for people is guaranteed.

Owner:邵成杰

Artware packing piece production positioning device

InactiveCN110451227AAvoid surface frictionAvoid wear and tearConveyor partsEngineeringMechanical engineering

The invention discloses an artware packing piece production positioning device. The device comprises a frame; guide rails are symmetrically mounted and fixed on the inner surface of the frame; positioning plates are symmetrically placed in the frame; connecting mechanisms are arranged on the surfaces of the positioning plates; the connecting mechanisms comprise guide balance rods, connecting covers, thread projections, limiting blocks, movable holes, driven rollers and fixed holes; the driven rollers are rotated in the fixed holes, so that the surface friction force of packing pieces and the positioning plates is prevented, the wear of the packing pieces during positioning and conveying is prevented, and the product quality of the packing pieces is guaranteed; extension rods are driven toextend through cylinders, so that the two positioning plates automatically approach the middle, the automatic positioning and conveying of the packing pieces are realized, the positioning is acute, the efficiency is high, and the automatic production is conveniently achieved; the connecting covers and the thread projections are fixedly screwed through threads to achieve fixed connection between the positioning plates and the extension rods; and meanwhile, when the positioning plates are damaged, the disassembly, the maintenance and the replacement are convenient.

Owner:合肥格美塑业包装有限公司

Inner wall cleaning method for pipes

ActiveCN107876516AReduce surface tensionKeep pH neutralInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsCleaning methodsEngineering

The invention relates to the field of mechanical cleaning, in particular to an inner wall cleaning method for pipes. The method comprises the steps that the pipes to be cleaned are transversely put into a through hole in a cleaning table at the speed of 15-25 pieces per minute, when the pipes fall onto groove holes, positioning mechanisms and cleaning mechanisms are started, the positioning mechanisms extend into two end openings of each pipe to support the pipe, meanwhile the cleaning mechanisms extend into the two end openings of each pipe, and a cleaning solution obtained in the fourth stepis sprayed to the inner walls of the pipes under the high pressure for cleaning. By means of the scheme, the problem that the inner walls of the pipes are difficult to clean in the prior art is solved.

Owner:重庆创赢清洗有限公司

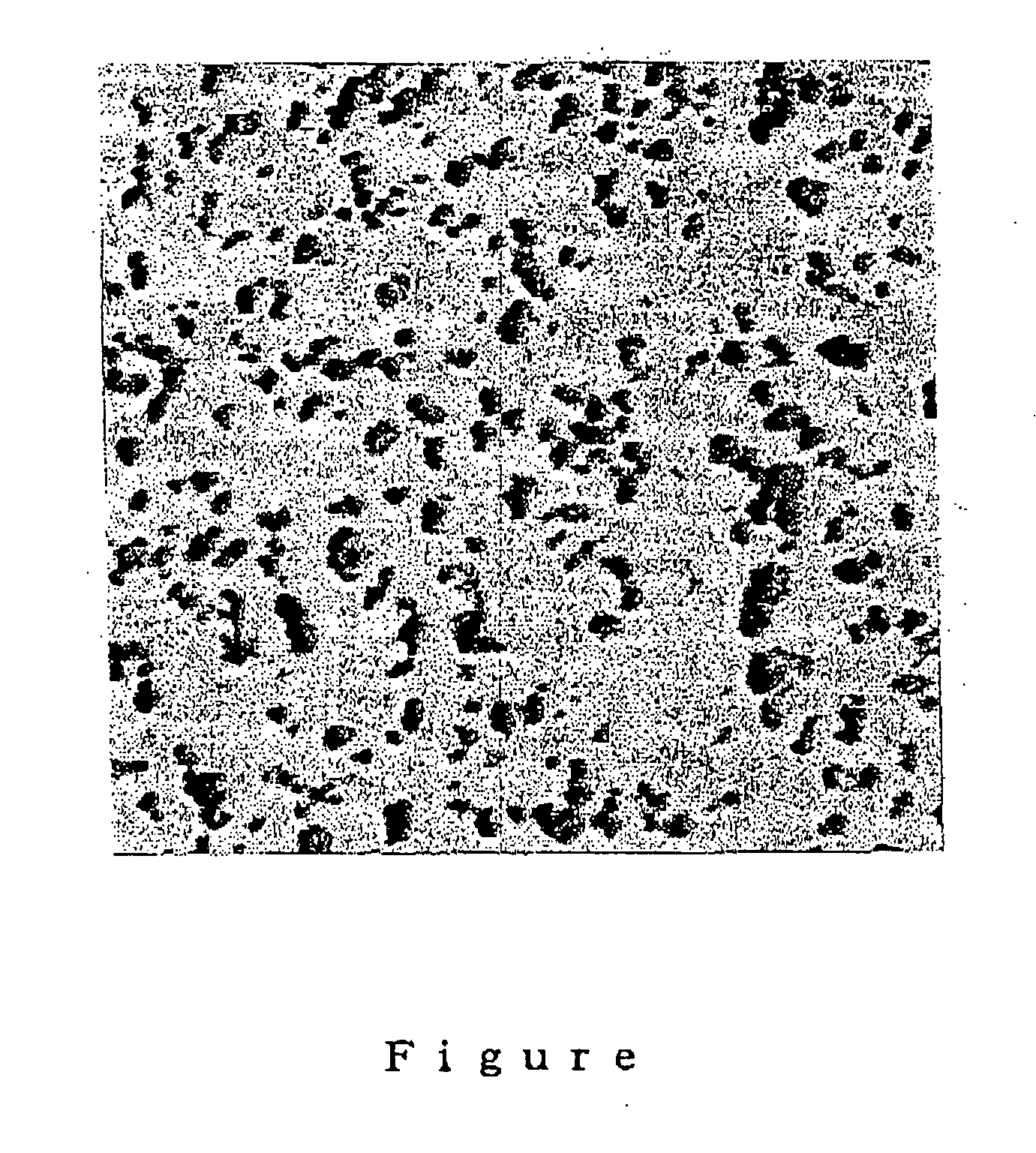

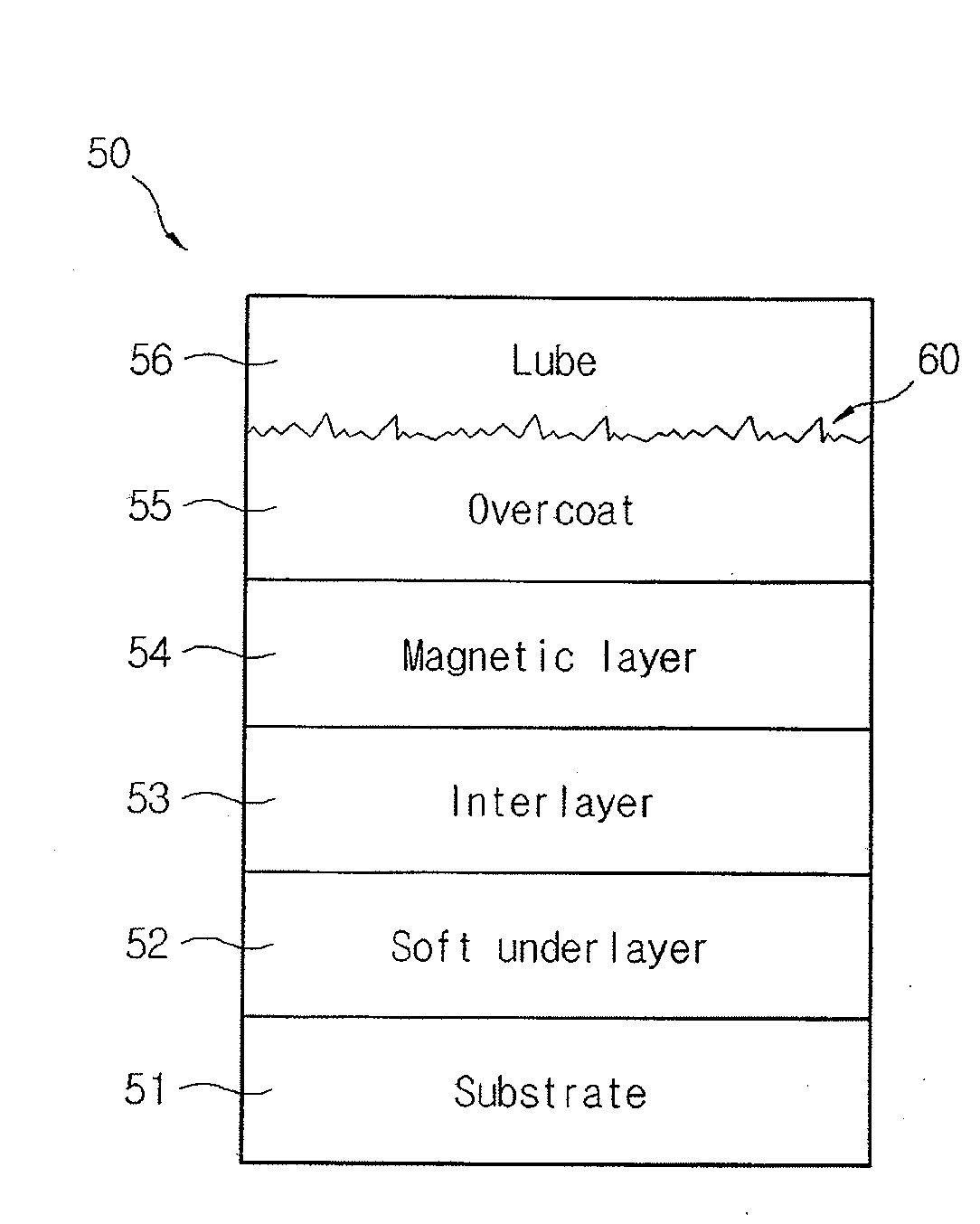

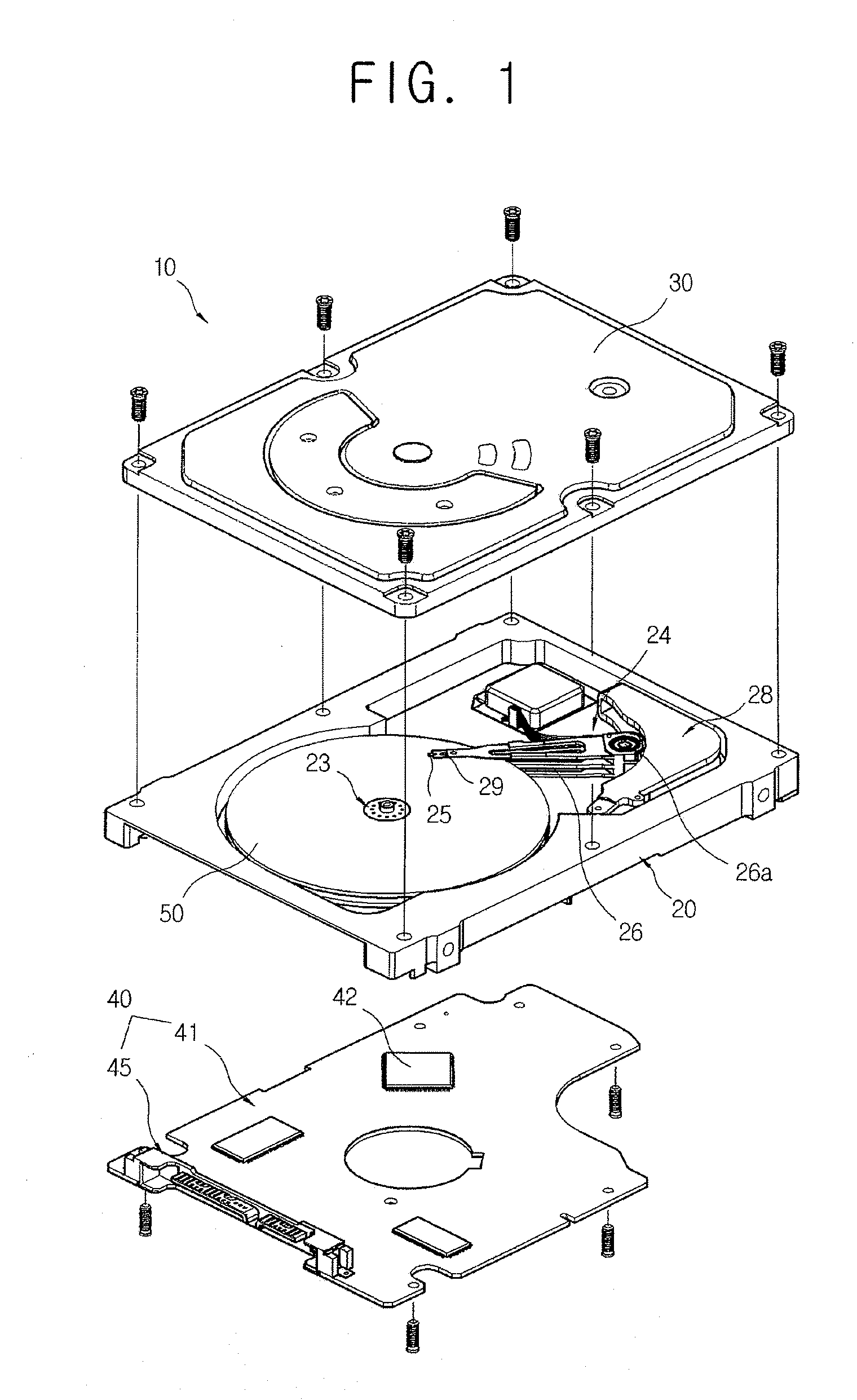

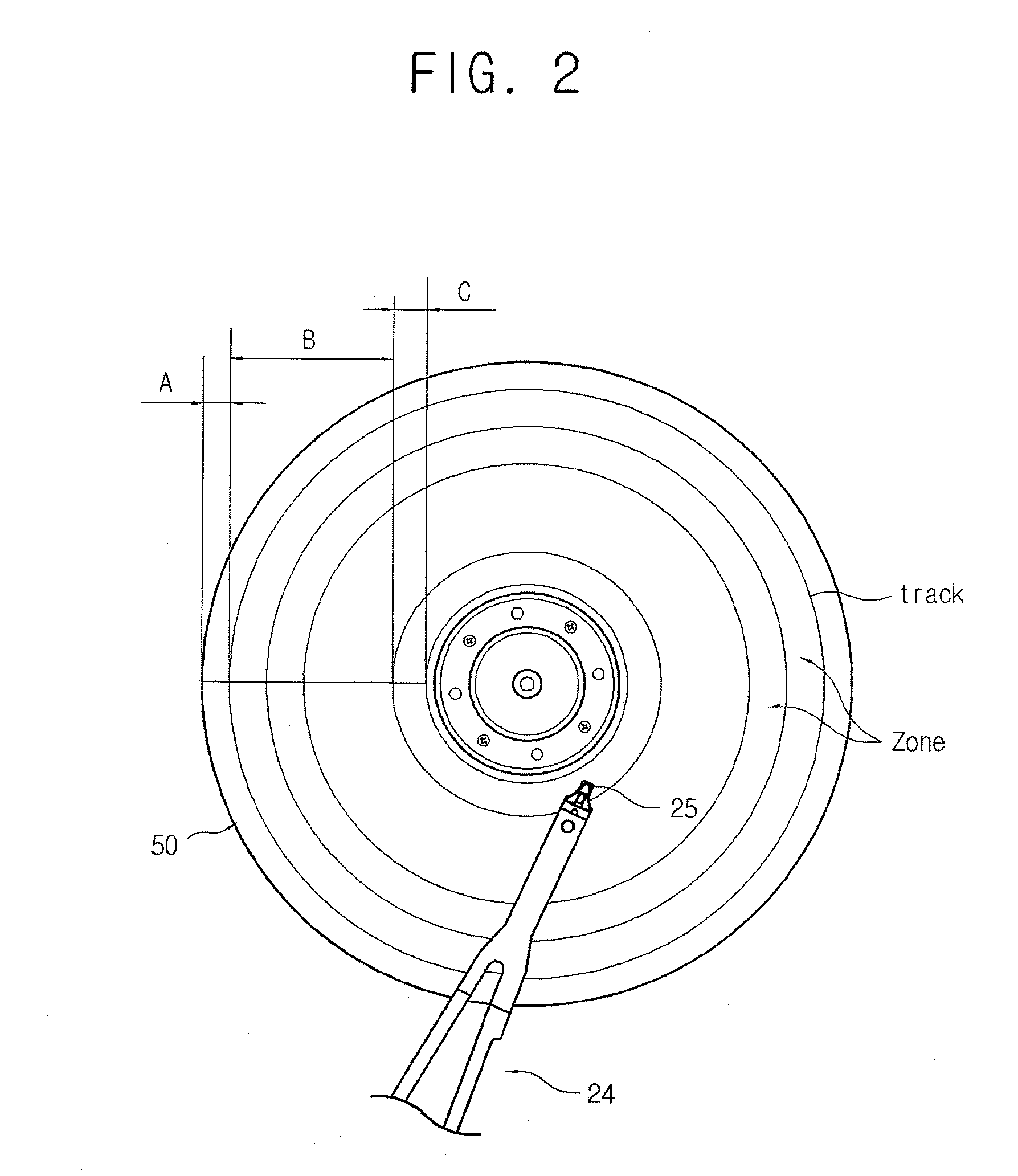

Magnetic recording media and hard disk drive apparatus having the same

InactiveUS20080187782A1Inhibit deteriorationSufficient surface roughnessProtective coatings for layersMagnetic materials for record carriersSurface roughnessMagnetic layer

A perpendicular magnetic recording medium includes a substrate forming a base, a magnetic layer deposited on a surface of the substrate in a direction along a thickness of the substrate, and an overcoat deposited on the magnetic layer in the direction along the thickness of the substrate to protect the magnetic layer, and having a texture formed partially indented from a surface and textured to have a predetermined surface roughness. The hard disk drive apparatus includes a magnetic head and the perpendicular magnetic recording medium where data is recorded and stored using the magnetic head.

Owner:SAMSUNG ELECTRONICS CO LTD

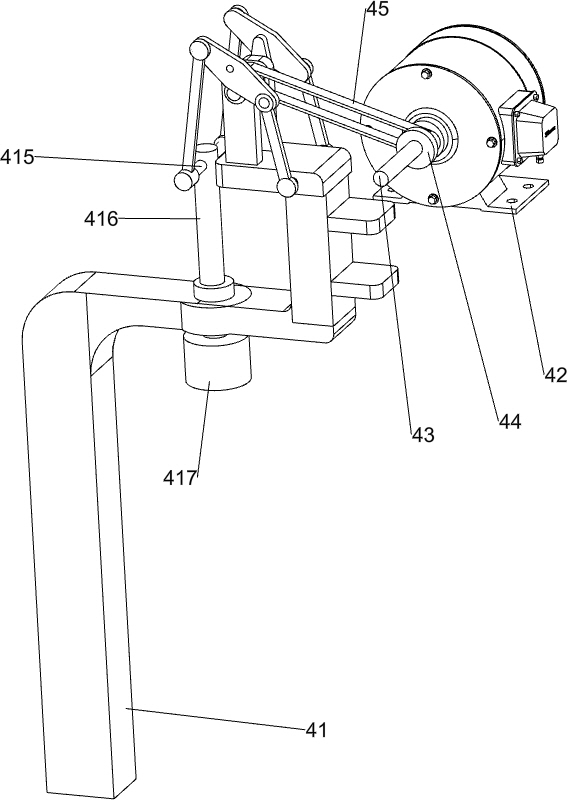

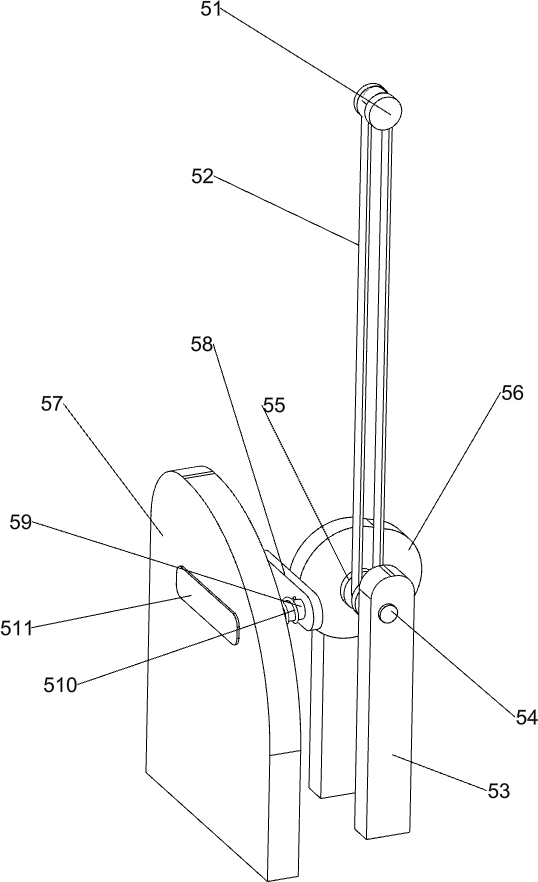

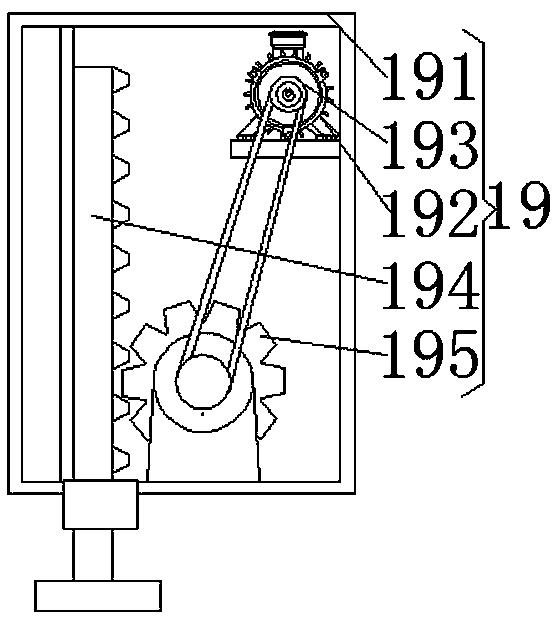

Tray steel pipe embedding machine

InactiveCN112025250AAvoid damageImprove work efficiencyMetal working apparatusRigid containersSteel tubePersonnel safety

The invention relates to an embedding machine, in particular to a tray steel pipe embedding machine. According to the tray steel pipe embedding machine, the technical problem to be solved is to provide the tray steel pipe embedding machine capable of accurately hammering a steel pipe into a tray, preventing an iron hammer from hammering the hands of people and the tray and protecting the safety ofoperators and the tray. In order to solve the technical problem, the invention provides the tray steel pipe embedding machine, and the tray steel pipe embedding machine comprises a base, a strut, a transmission mechanism and an embedding mechanism, wherein a first baffle plate is arranged at the top of the base; the strut is connected to the middle part of one side of the base; the transmission mechanism is mounted between the strut and the base; and the embedding mechanism is mounted on the transmission mechanism. Through cooperation of the transmission mechanism and the embedding mechanism,the steel pipe can be rapidly extruded into an embedding groove of the tray, so that the working efficiency is improved, people do not need to hammer the steel pipe with the iron hammer, and the trayis prevented from being damaged.

Owner:孙惠珍

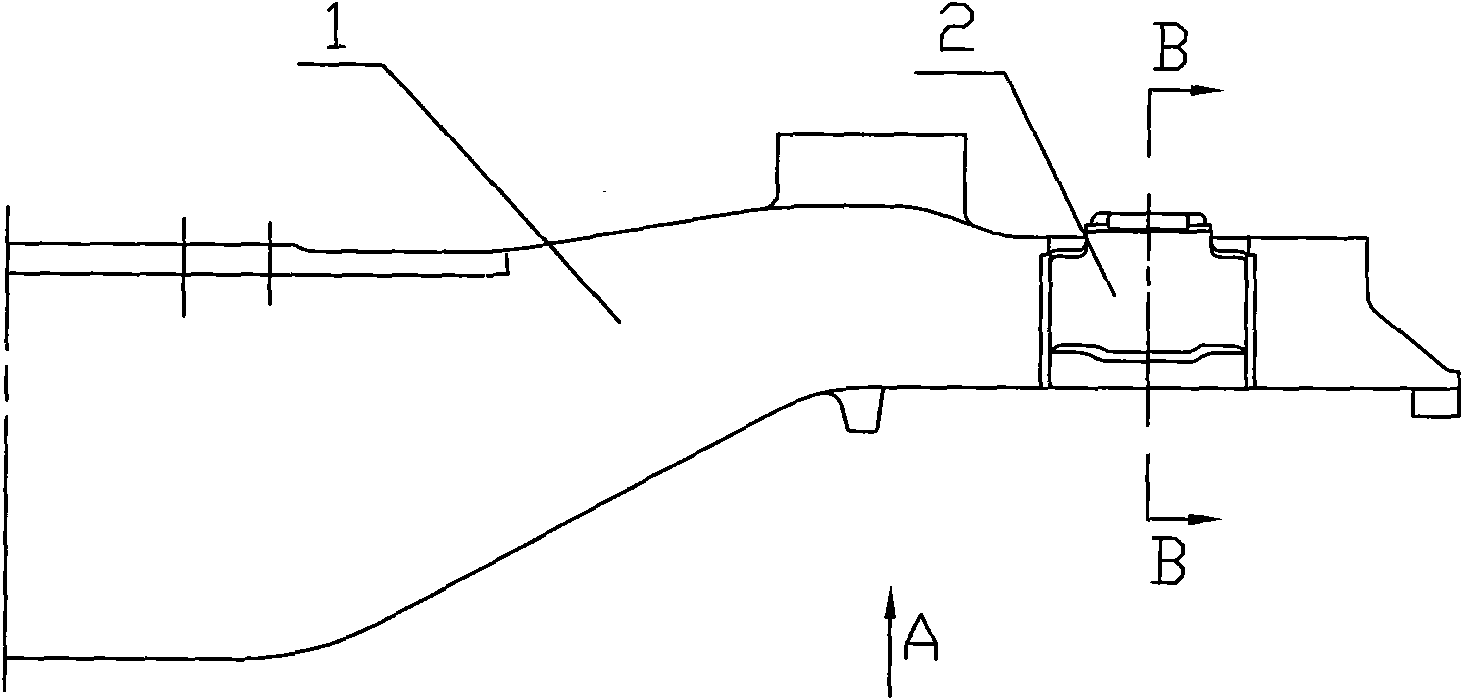

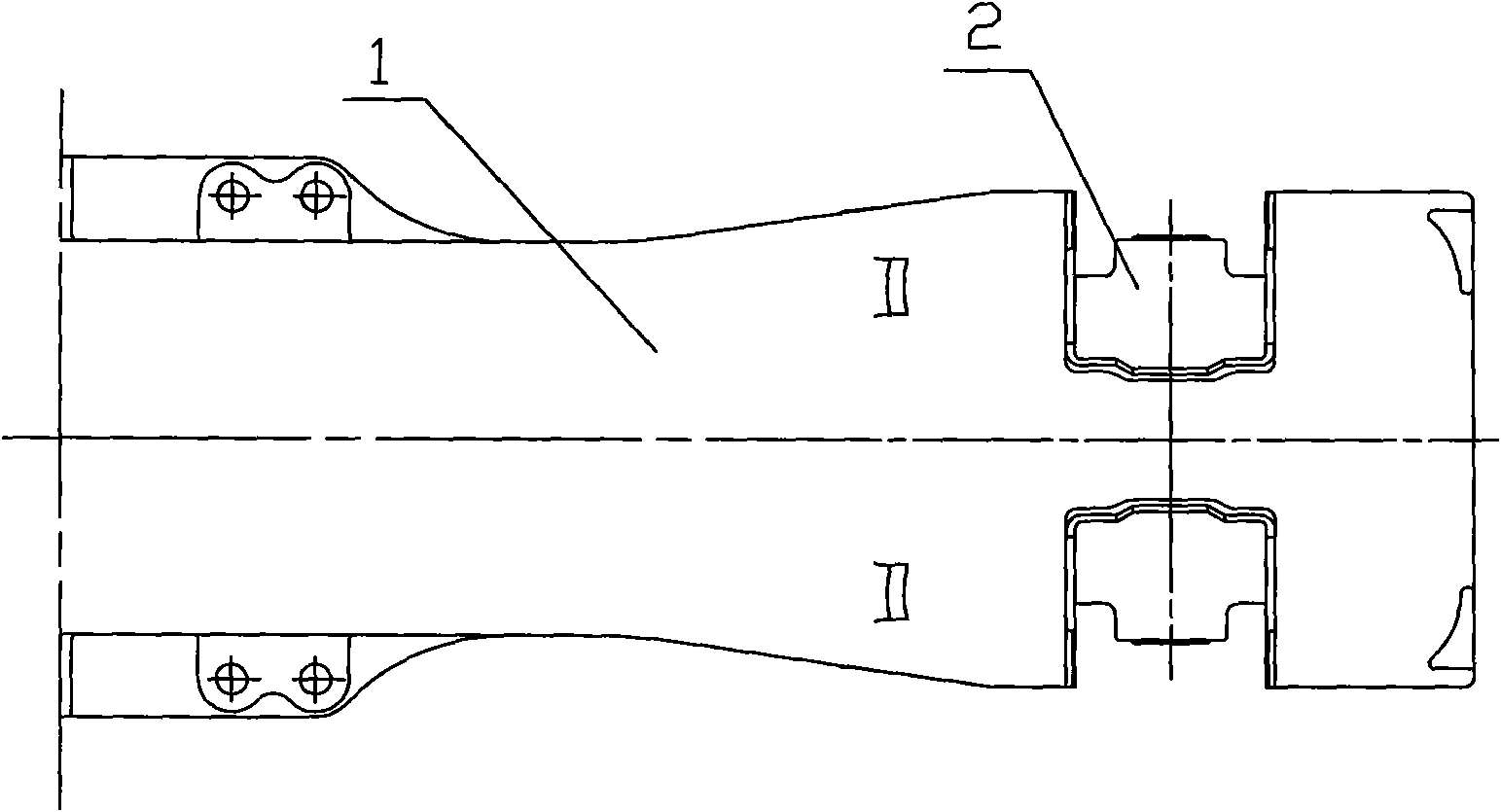

Device for connecting splayed surface of steering frame swing bolster of lorry and vibration reducing abrasion plate

InactiveCN101570195AExtended service lifeSimple structureBogiesBogie-underframe connectionsTruckWorking life

The invention discloses a device for connecting a splayed surface of a steering frame swing bolster of a lorry and a vibration reducing abrasion plate, and mainly solves the problem of heat damage of the swing bolster due to thermal cutting and welding when the prior abrasion plate is repaired and replaced and the problem of abrasion of the swing bolster caused by other moving components of a steering frame. The device comprises the swing bolster and vibration reducing abrasion plates which are arranged on splayed surfaces at two ends of the swing bolster, the vibration reducing abrasion plate consists of a central inclined plane plate and two-wing vertical face plates both of which have a U-shaped symmetrical distribution structure, the outer surface of the central inclined plane plate and the splayed surface of the swing bolster form a joint assembly relation, and the outer surfaces of the two-wing vertical face plates and two lateral vertical faces of the splayed surface of the swing bolster form a joint assembly relation. The device is simple in structure and convenient for assembly, not only can ensure zero abrasion of the splayed surface of the swing bolster, but also can ensure that the two lateral vertical faces of the splayed surface of the swing bolster are not damaged, meet the replacement repair requirement of welding-free cutting of the vibration reducing abrasion plate, improve the working life, repair work quality and work efficiency of the swing bolster components.

Owner:CRRC YANGTZE CO LTD

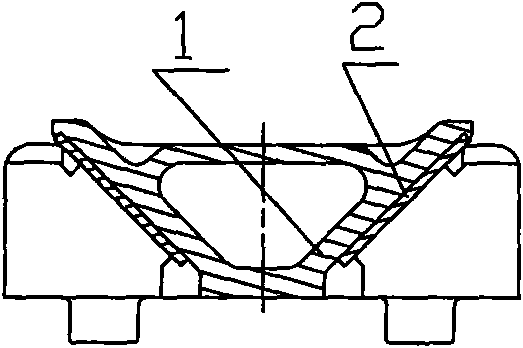

Side bending mold for back plate

InactiveCN104826933AAvoid surface abrasionGuaranteed bending qualityShaping toolsEjection devicesEngineeringMechanical engineering

Owner:昆山电子羽电业制品有限公司

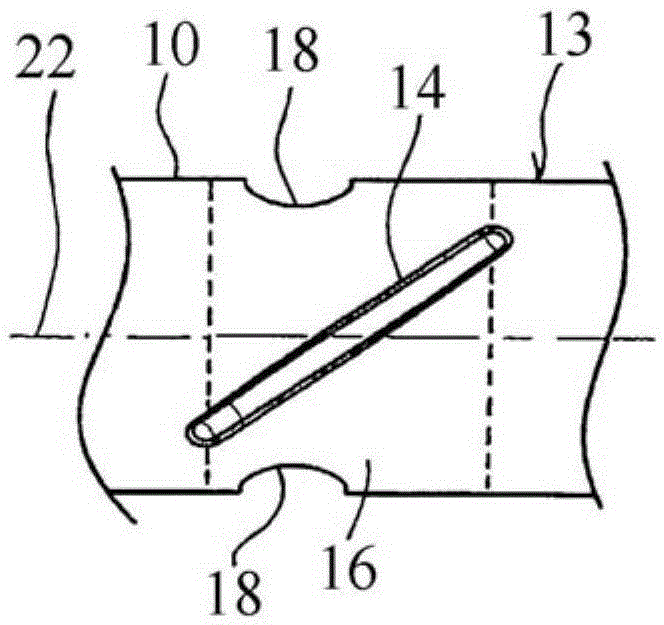

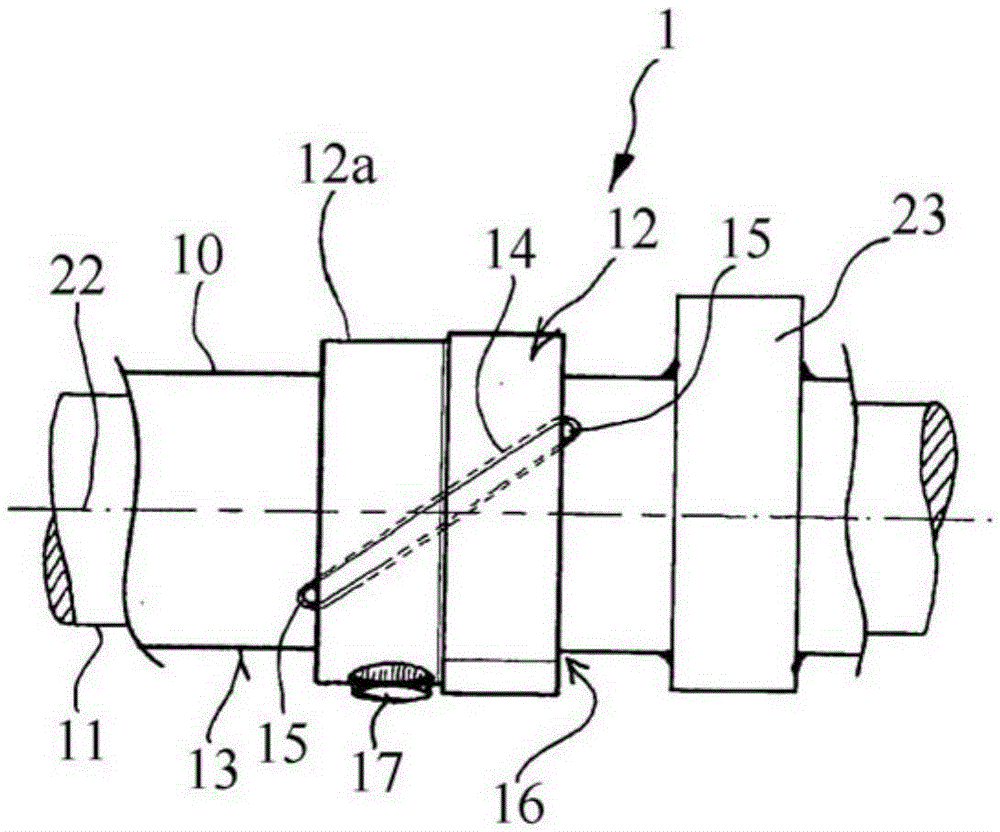

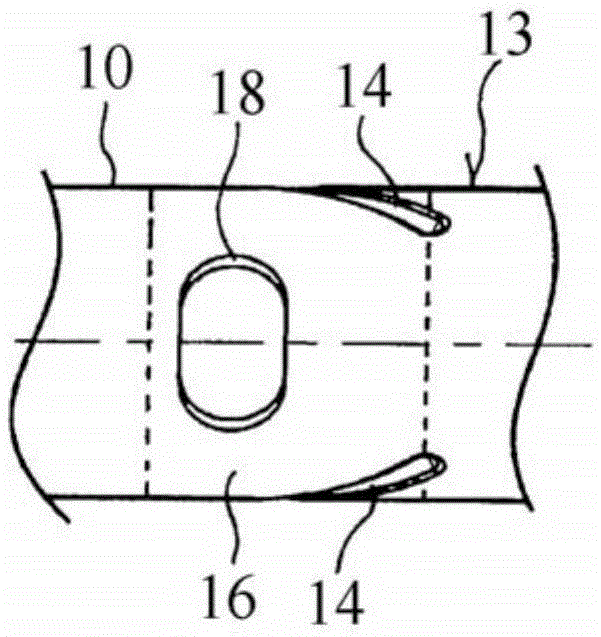

Adjustable camshaft

ActiveCN105339607AAvoid surface abrasionHelp to enterValve arrangementsMachines/enginesInternal combustion engineCam

The invention relates to an adjustable camshaft (1) for the valve train of an internal combustion engine, having an outer shaft (10) and an inner shaft (11) extending concentrically with the outer shaft (10) and rotatably accommodated therein, wherein on the outer surface (13) of the outer shaft (10), at least one cam member (12) is rotatably mounted while forming a slide bearing gap, wherein the cam member (12) is connected to the inner shaft (11) in a rotationally fixedly manner. According to the invention, in the outer surface (13) of the outer shaft (10), at least one oil routing groove (14) is introduced in a position and with an axial length such that the oil routing groove (14) is formed at least across the axial width of the slide bearing gap, and that on at least one side of the cam member (12), the oil routing groove is brought out from the slide bearing gap with a free groove portion (15).

Owner:THYSSENKRUPP PRESTA TECCENTER AG

Glass transport rack

InactiveCN108639755BRealize separate placementAvoid surface abrasionCharge manipulationConveyor partsEngineeringMechanical engineering

Owner:于骏浩

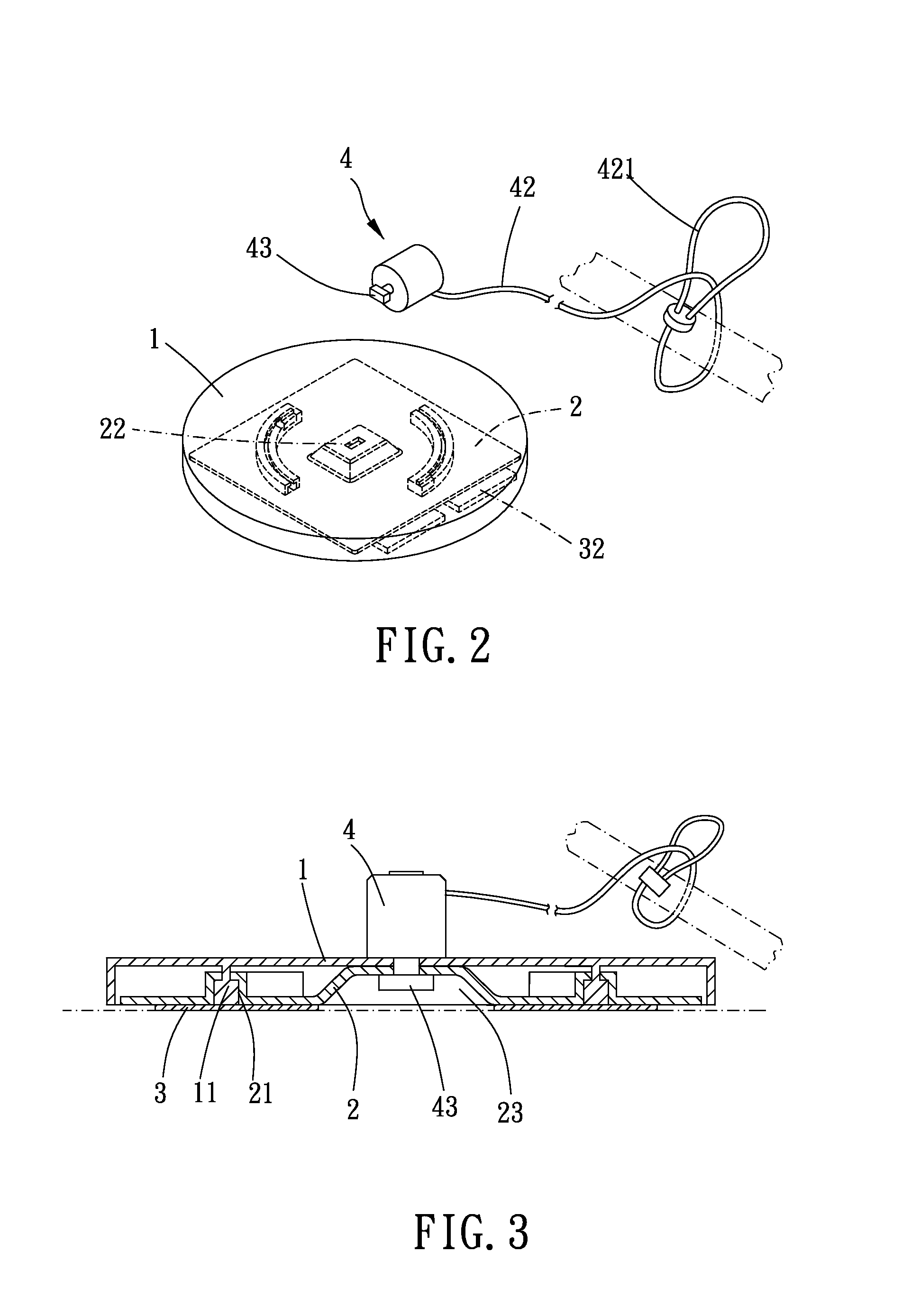

Antitheft device

InactiveUS20140239144A1Prevent surface abrasionAvoid surface abrasionLocks for portable objectsStands/trestlesEngineeringMechanical engineering

An antitheft device includes a cover, a base plate, and an adhesive element. The base plate is located in a receiving space of the cover and is adapted for a controlling element to connect thereto to release or lock the cover and the base plate. The base plate is able to be adhered onto an object to be secured by the adhesive element. The adhesive element is also located in the receiving space of the cover so that the adhesive element is prevented from being removed or broken easily.

Owner:LINTEX

Quenched-tempered heat treatment method for bearing sleeve machining

InactiveCN107385187AReduce temperature drop rateReduce temperature differenceFurnace typesHeat treatment furnacesQuenchingMachining process

The invention aims to provide a quenched-tempered heat treatment method for bearing sleeve machining. The heat treatment method comprises the steps that (1) pre-heating treatment is carried out, specifically, a bearing sleeve used in the machining process is made from 20CrMnTi steel, the rough-machined bearing sleeve is preheated to 350 DEG C, and heat preservation is carried out for 30 minutes at a constant temperature; (2) normalizing heating is carried out on the bearing sleeve, specifically, the bearing sleeve which is pre-heated in the step 1 is further subjected to secondary heating to reach 800 DEG C; (3) quenching and cooling treatment is carried out, specifically, cold water is firstly sprayed on the surface of the high-temperature bearing sleeve to carry out cold water cooling, when the temperature of the bearing sleeve is decreased to 530 DEG C, water spraying is stopped, and then the bearing sleeve is immersed into oil for secondary cooling and then is placed in air to be air-cooled to 120 DEG C; and (4) high-temperature tempering treatment is carried out. The method has the advantages that the temperature reduction speed in the quenching process can be decreased, the temperature difference between inside and outside of the bearing sleeve can be reduced, the surface fracture in the quenching process can be avoided, the quenching quality can be improved, and the hardness and the surface wear resistance of the bearing sleeve can be improved.

Owner:ANHUI BUERYUE BEARING

A transport steering device for semiconductor and pan-semiconductor substrates

PendingCN109037131AEffective fasteningAvoid surface abrasionSemiconductor/solid-state device manufacturingConveyor partsEngineeringSemiconductor

A transport steering device for semiconductor and pan-semiconductor substrates Including bottom box, A support plate is fixedly connecte with that top end of the rotating shaft, At that top two side of the support plate are fixedly connected with the transmission plate through the support frame, A lif device is fixedly connected with that middle position of the bottom of the transmission plate, Apartition plate is fixedly connected with the front face and the back face of the top of the transmission plate, a plurality of transmission rollers are arranged at the middle position of the side ofthe separator close to each other, An electric telescopic rod is fixedly connected with the top of the transmission plate between the transmission rollers, an end of the lifting device away from the transmission plate is rotatably connected with the lifting plate, and a fastening device is fixedly connected with the bottom of the lifting plate at a corresponding position of the electric telescopicrod. The invention relates to the technical field of semiconductors and pan-semiconductors. The device can effectively fasten the substrate, avoid surface abrasion in the transfer process, avoid collision, protect the substrate safety, and ensure the processing quality.

Owner:浙江雅市晶科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com