Device for connecting splayed surface of steering frame swing bolster of lorry and vibration reducing abrasion plate

A technology for railway wagons and connection devices, which is applied in the direction of devices, bogies, and railway car body parts that move laterally between the chassis and the bogie, and can solve the problem of thermal damage to the bolster, potential safety hazards in vehicle operation, and wobble To avoid problems such as pillow damage, to avoid thermal damage defects, improve maintenance quality, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

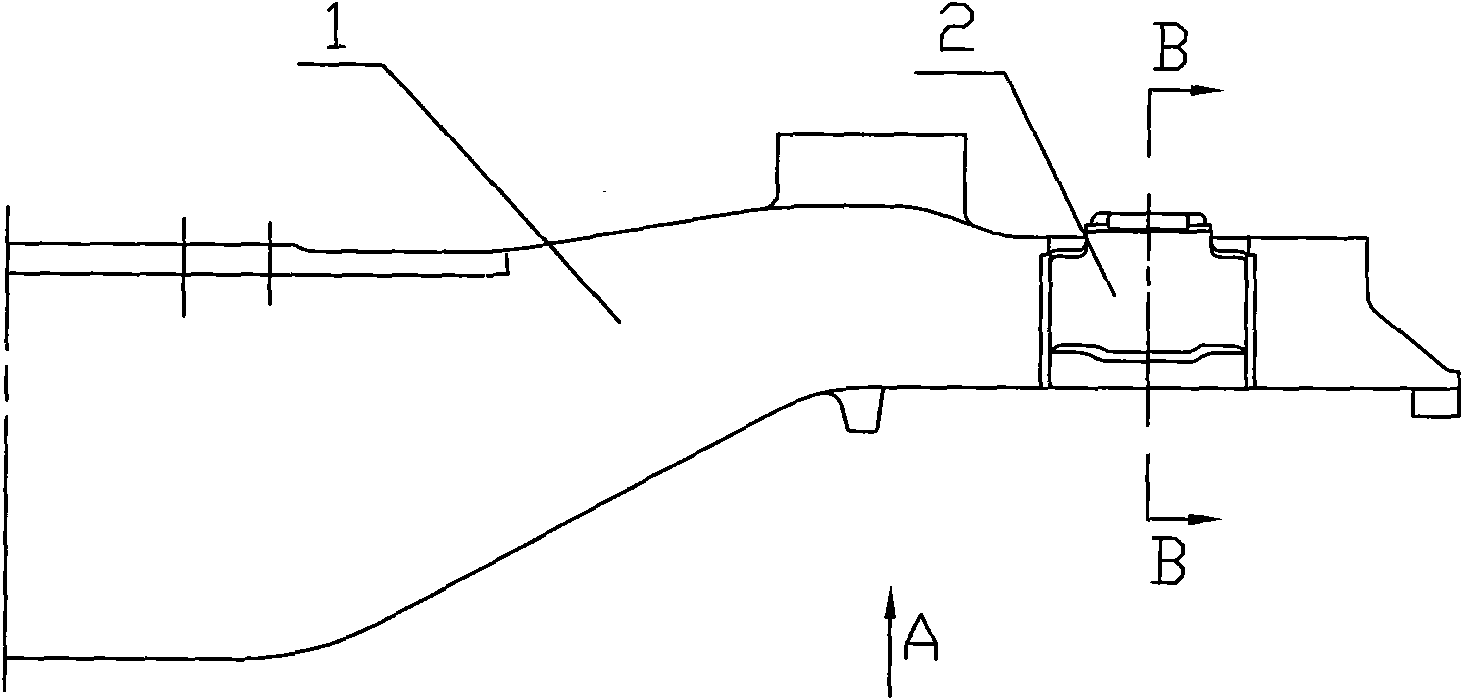

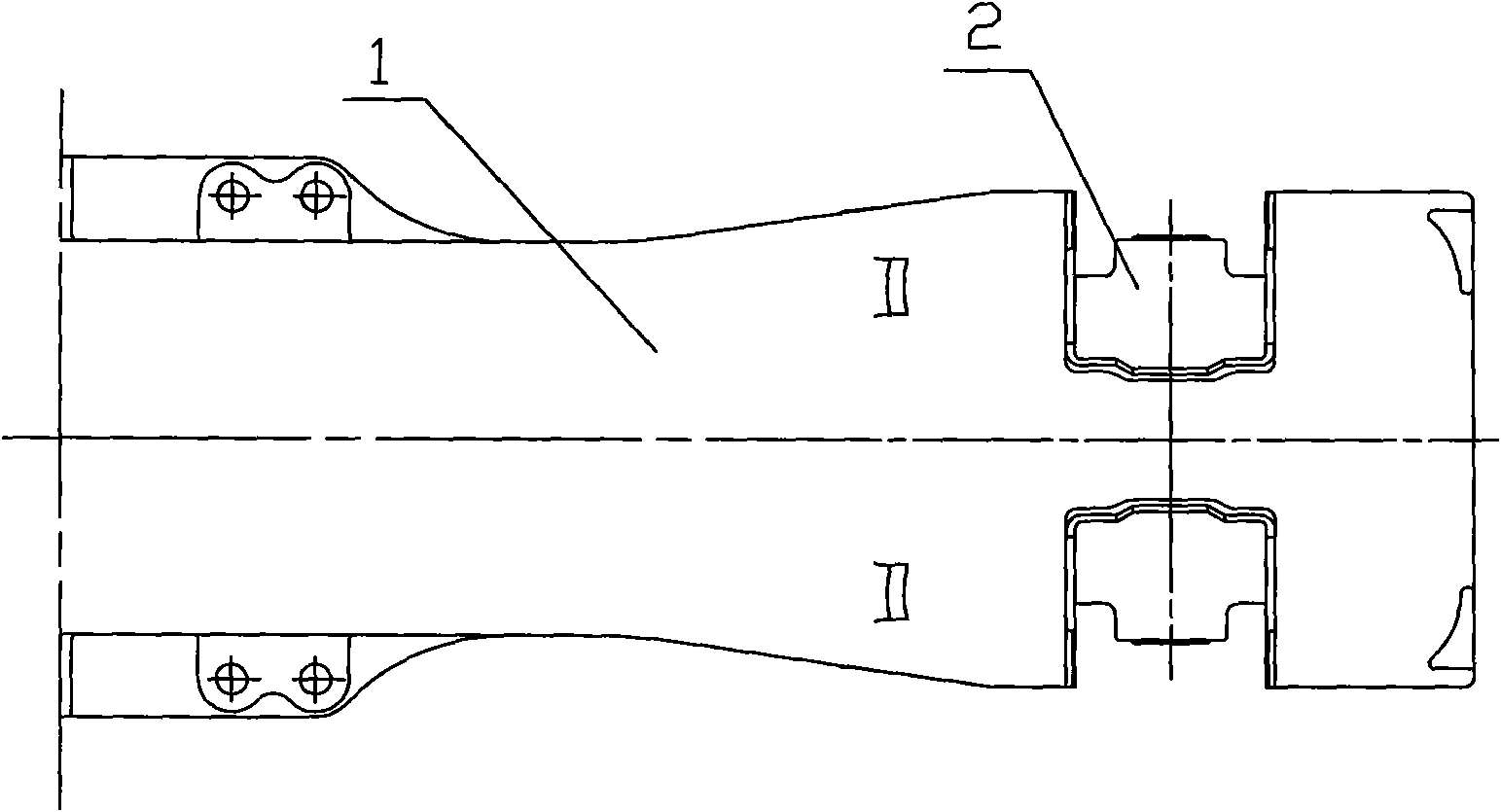

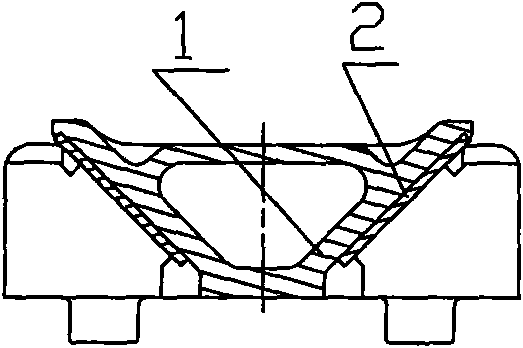

[0022] The connection device between the bolster bolster and the vibration-damping wear plate shown in the figure includes a bolster 1 and vibration-damping wear plates 2 installed on the splayed surfaces at both ends of the bolster 1 . The damping wear plate 2 is a metal profiled plate, and its shape and size match with the bolster 1 and the facades on both sides after it is installed in place. The vibration-absorbing wear plate 2 is composed of a central inclined panel 2a and two wing facade panels 2b, and the two wing facade panels 2b are symmetrically distributed in a U shape relative to the central inclined panel 2a. The vibration-absorbing wear plate 2 is in the state of no external force, and its two wing facade panels 2b are designed with an included angle θ in the direction perpendicular to the central inclined panel 2a. In this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com