Self-adaptive pretreatment type automobile part stamping device and using method thereof

A technology of auto parts and stamping devices, which is applied in the field of auto parts, can solve the problems of reducing labor costs, unguaranteed stamping effects, damage, etc., and achieve the effect of avoiding surface wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solution in the embodiment of the solution will be clearly and completely described below in conjunction with the accompanying drawings in the embodiment of the solution. Obviously, the described embodiment is only a part of the embodiment of the solution, not all embodiments; based on The embodiments in this solution, and all other embodiments obtained by persons of ordinary skill in the art without creative efforts, all belong to the scope of protection of this solution.

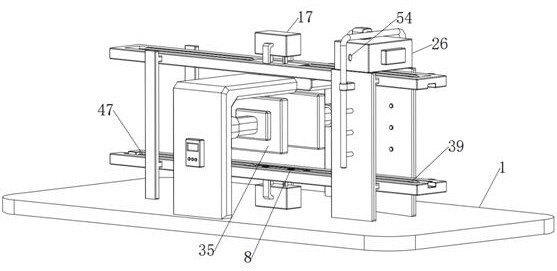

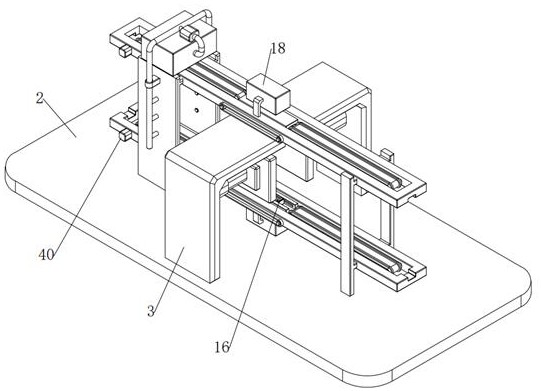

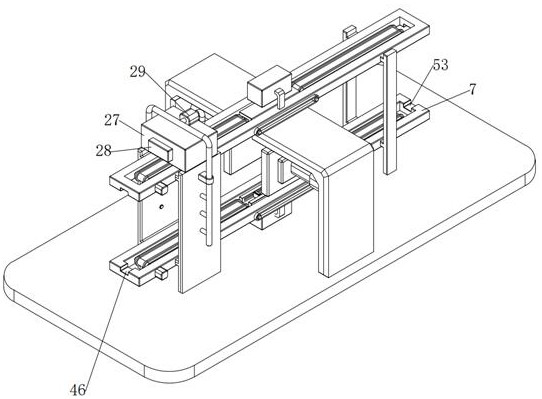

[0038] Such as Figure 1-Figure 3 As shown, an adaptive pretreatment auto parts stamping device proposed in this scheme includes a main body support mechanism 1, a magnetic power type anti-slip stamping mobile positioning mechanism 8, a gas expansion type non-damage fixed plate clamping mechanism 17, Static elimination type plate cleaning type stamping pretreatment mechanism 26, plate double-sided action type stamping mechanism 35, stamping plate vertical linkage type stamping feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com