Core part coating reinforced metal plate edge trimming device provided with security and protection device

A metal plate and metal plate technology, applied in the direction of grinding drive devices, metal processing equipment, grinding machine tool parts, etc., can solve the problem that the quality cannot be standardized and unified, the machine tool cannot be completely trimmed, and it is not suitable for mass production, etc. problems, to achieve the effect of wide processing range, firm braking and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

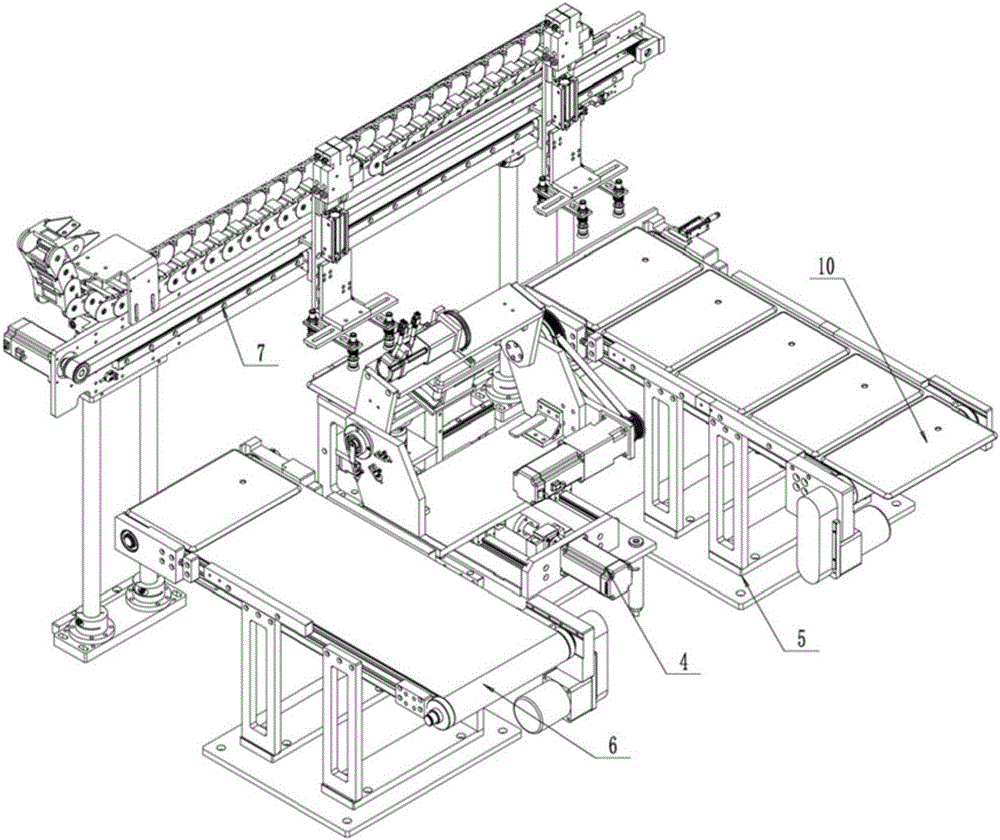

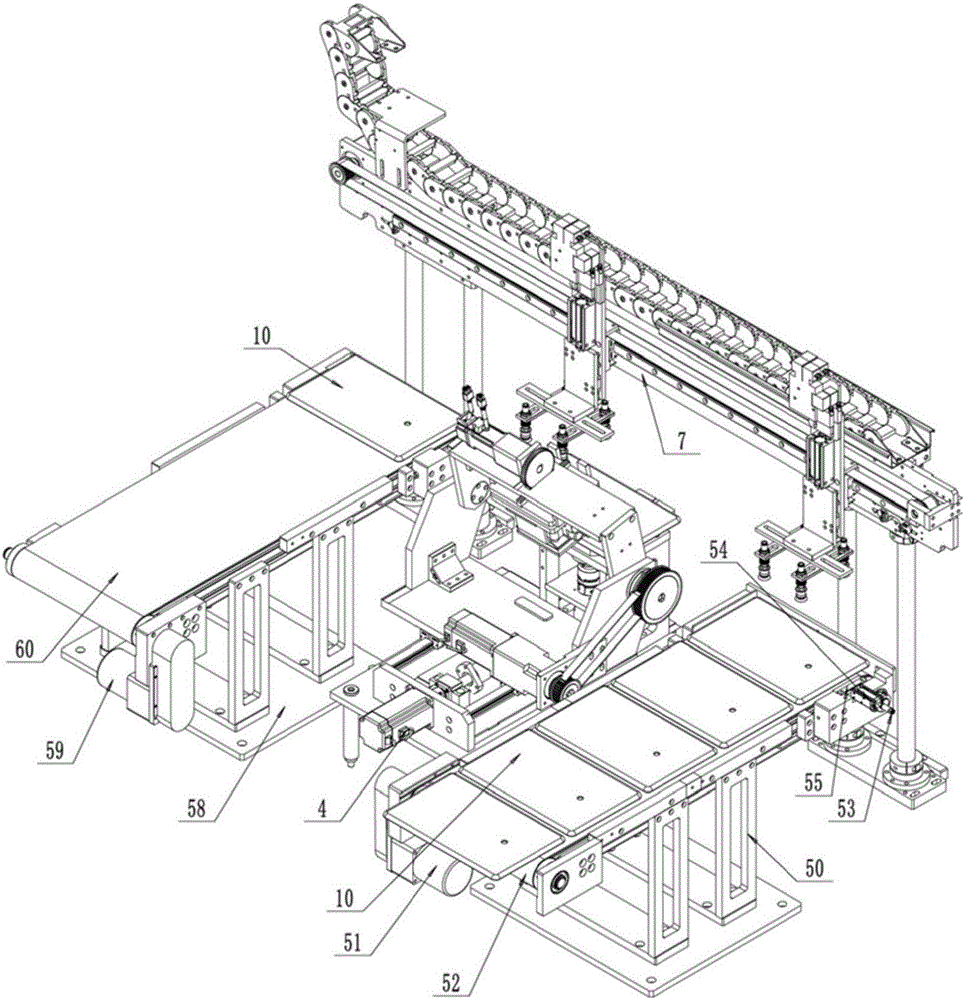

[0046] refer to Figure 1-13 , specifically as Figure 1-3 As shown in the figure, the core component coating strengthening and the metal plate trimming device with the security device of the present invention includes a frame assembly 2, a core component coating strengthening processing device 3 arranged on the frame assembly 2, and a processing device for the outer cover. The transparent protective cover body 1 on the device 3; the processing device 3 includes a core component coating strengthening trimming center 4, a feeding device 5, a feeding device 6 and a manipulator device 7; the opening and closing door of the transparent protective cover body 1 is arranged in the repairing On the front side of the side center 4, a channel is provided between the opening and closing door and the upper end of the frame assembly 2 to pass through the metal plate 10 to be processed. The channel corresponds to the beginning of the feeding device 5 and the end of the feeding device 6 resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com