Tray steel pipe embedding machine

A technology of steel pipes and pallets, which is applied in the field of pallet steel pipe embedding machines, can solve problems such as hammers easily hitting people's hands, operator safety accidents, and hammers easily hitting pallets, etc., so as to avoid displacement, move smoothly, Avoid the effect of surface abrasion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

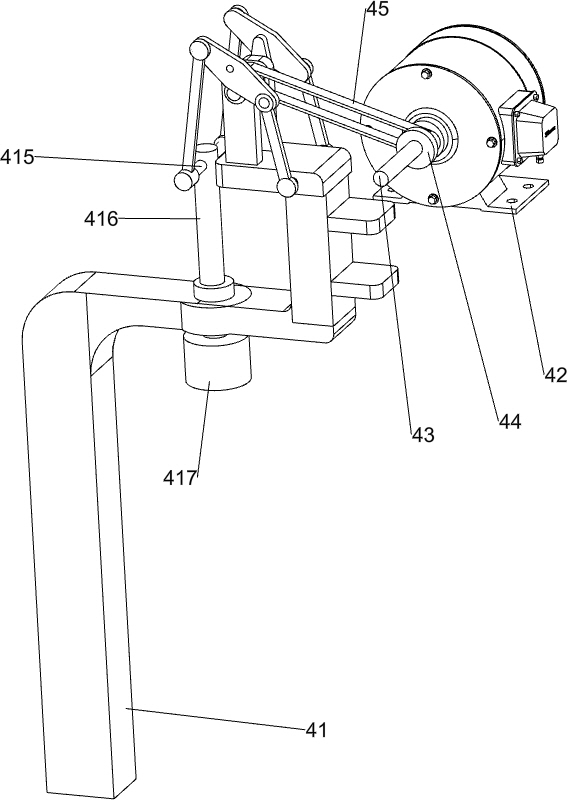

[0027] A pallet steel pipe embedding machine, such as Figure 1-5 As shown, it includes a base 1, a first baffle 2, a pillar 3, a transmission mechanism 4 and an embedded mechanism. The left front and right rear sides of the top of the base 1 are connected to the first baffle 2, and the middle part of the right side of the base 1 is connected to There is a pillar 3, a transmission mechanism 4 is installed between the pillar 3 and the base 1, and an embedded mechanism is installed on the transmission mechanism 4.

[0028] The transmission mechanism 4 includes a first support 41, a motor 42, a first transmission shaft 43, a first pulley 44, a first flat belt 45, a second transmission shaft 46 and a second pulley 47, and the left middle part of the base 1 is equipped with the first A bracket 41, the first bracket 41 is connected with the pillar 3, the top rear side of the pillar 3 is connected with a motor 42, the output shaft of the motor 42 is connected with a first transmissio...

Embodiment 2

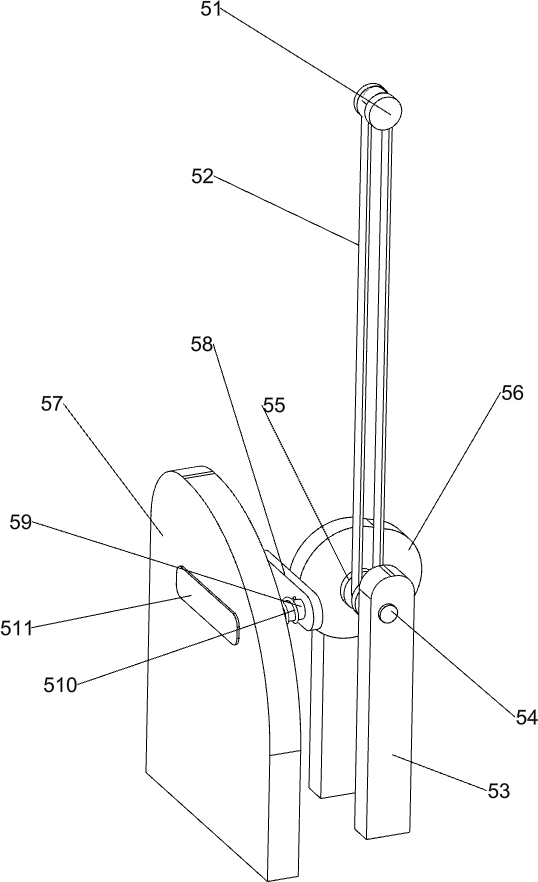

[0032] On the basis of Example 1, such as Figure 6 As shown, a clamping mechanism 5 is also included, and the clamping mechanism 5 includes a third pulley 51, a second flat belt 52, a second bracket 53, a third transmission shaft 54, a fourth pulley 55, a cam 56, a second gear Plate 57, transmission block 58, movable bar 59, spring 510 and pressure block 511, the front end of the first transmission shaft 43 is fixedly connected with the 3rd pulley 51, and the right side of base 1 top is equipped with the second support 53, and the second support 53 tops Rotationally connected with the third transmission shaft 54, the third transmission shaft 54 is fixedly connected with the fourth pulley 55, the second flat belt 52 is connected between the fourth pulley 55 and the third pulley 51, the third transmission shaft 54 The rear part is connected with a cam 56, and the right side of the base 1 is provided with a second baffle plate 57, the second baffle plate 57 is located between ...

Embodiment 3

[0035] On the basis of Example 2, such as Figure 7 As shown, also includes conveying mechanism 6, and conveying mechanism 6 comprises conveying plate 61, wheel connecting shaft 62 and transport wheel 63, has groove in the middle of base 1 top, is provided with conveying plate 61 slidingly in the groove, conveys The front and rear sides of the bottom of the plate 61 are rotatably connected with a wheel connecting shaft 62, and the left and right ends of the wheel connecting shaft 62 are connected with transport wheels 63, and the transport wheels 63 contact with the inner bottom of the groove.

[0036] Pallet is placed vertically on conveying plate 61, people pushes on conveying plate 61 and moves backward, can make moving conveying plate 61 move more smoothly by transport wheel 63, can also avoid the surface wear that pallet causes when moving on the base plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com