Household juicer screw and manufacturing method thereof

A juicer and screw technology, which is applied to the screw of a household juicer and its production field, can solve the problems of the household juicer losing the ability to extract juice, reducing the service life of the juicer, and the surface wear of the screw, and achieving wide application. and promotion, improve lifespan, and avoid the effect of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

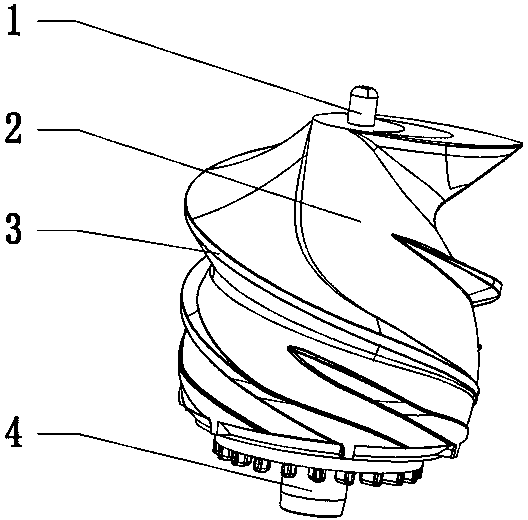

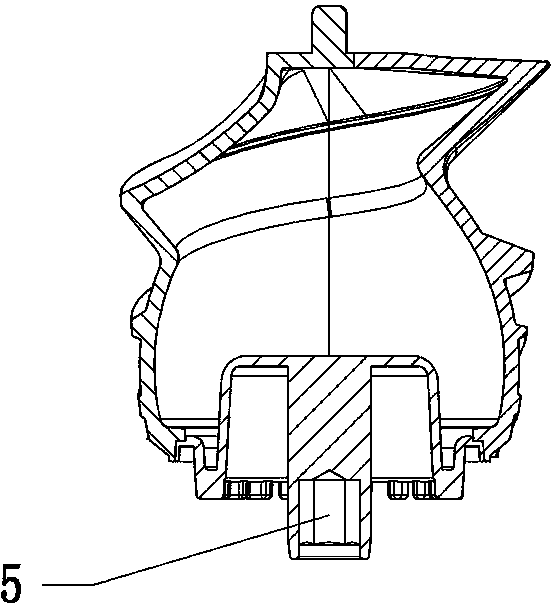

[0042] like figure 1 , figure 2 As shown, a household juice extractor screw includes an upper central shaft 1, an arc-shaped conical screw body 2, a screw thread 3 formed on the screw body 2, and a lower central shaft 4. The lower end of the lower central shaft 4 is provided with There is a shaft hole 5, which can be inserted into the transmission output shaft of the motor. When the motor rotates, the screw will also rotate; Avoid the shaking phenomenon of the household juicer screw caused by the different shafts of the upper and lower central axes when the screw of the household juice extractor rotates; the screw thread 3 formed on the screw body 2 has multiple threads, that is, multiple threads, and the number of threads of each thread The starting positions are different, but all terminate at the lower end of the screw body 2 .

[0043] The screw rod of this embodiment is completely made of acid and alkali-resistant food-grade stainless steel 304, so when using it to...

Embodiment 2

[0053] The manufacturing method of the above-mentioned domestic juice extractor screw also includes the following steps:

[0054] Step 1: Pouring the screw parts of the household juice extractor with metal materials: left part 6, right part 7 and lower part 8;

[0055] Step 2: Process and remove the burrs and sundries on the assembly surface of the screw parts;

[0056] Step 3: Assembling, bonding or riveting the screw parts into a rough screw;

[0057] Step 4: cutting and processing the relevant surface of the screw rough blank;

[0058] Step 5: Grinding the relevant surface of the screw rod after cutting, which is the finished screw rod of the household juice extractor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com