Adjustable camshaft

A camshaft, adjustable technology, applied in the direction of valve device, machine/engine, mechanical equipment, etc., can solve problems such as high cost and disadvantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

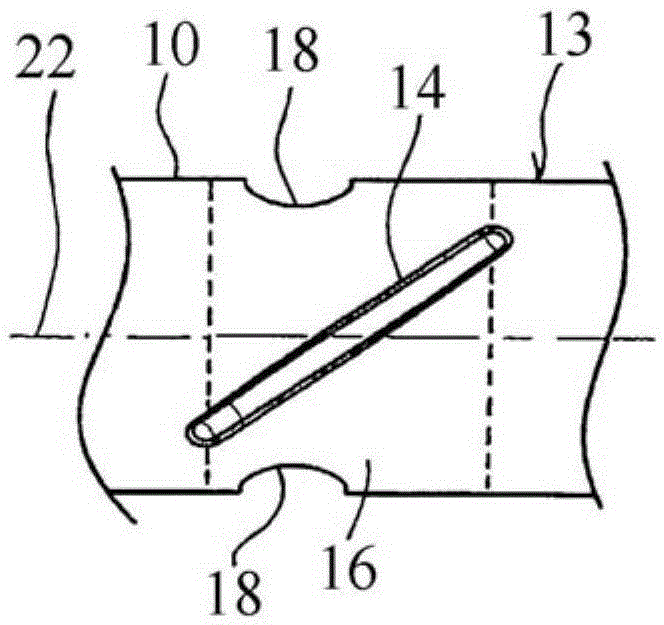

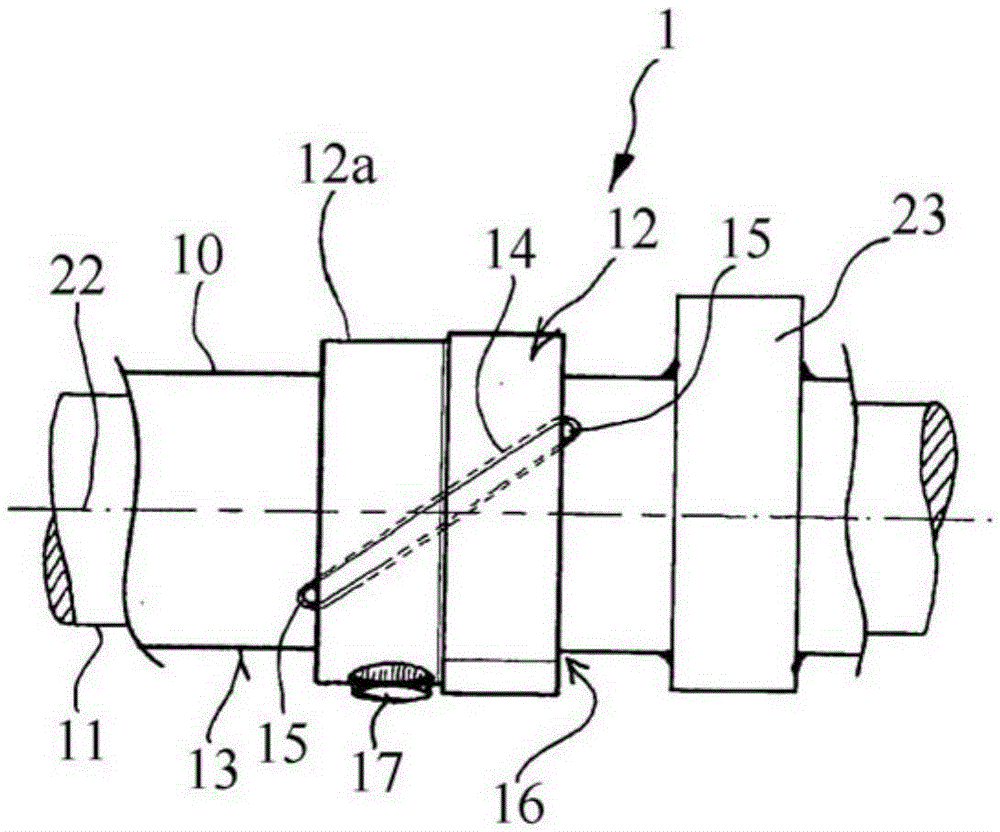

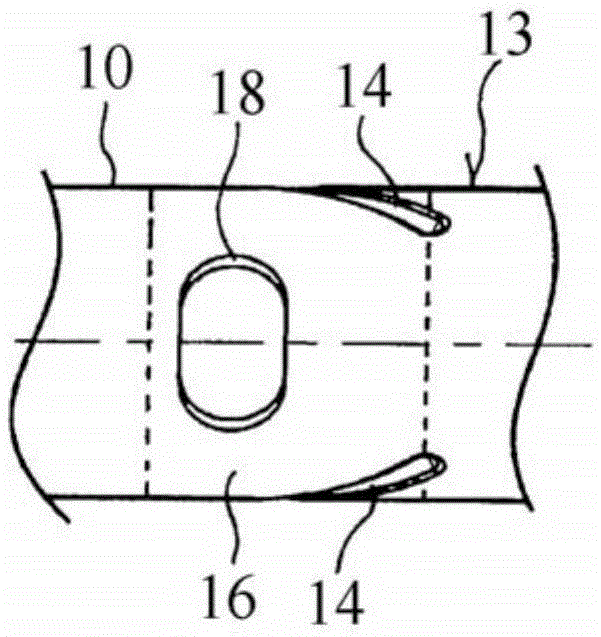

[0050] figure 1 and figure 2 A first exemplary embodiment of an adjustable camshaft 1 is shown, figure 1 shows the details of the outer axis 10, while figure 2 shows the basis for figure 1 Detail of the outer shaft 10 of the camshaft 1. The outer shaft 10 is formed in the form of a hollow shaft, through which the inner shaft 11 extends and is rotatable independently of the outer shaft 10 about a common camshaft axis 22 . Here, the inner shaft 11 is rotatably supported in the outer shaft 10 . The cam element 23 is rigidly mounted on the outer shaft 10, and the cam element 23 may for example be welded to the outer shaft 10 or fixed on the enlarged diameter by press fitting. Therefore, the cam member 23 rotates in phase with the outer shaft 10 .

[0051] In the region of the joint 16 a further cam element 12 is mounted rotatably on the outer surface 13 of the outer shaft 10 so as to form a slide bearing play. The cam element 12 includes a cam flange 12a, and the cam elem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com