Fast environmentally-friendly thermal treatment device for metal processing

A heat treatment device and metal processing technology, applied in heat treatment furnaces, heat treatment equipment, quenching devices, etc., can solve the problems of inability to collect and treat harmful gases, lack of exhaust gas treatment devices, environmental pollution, etc., to achieve safe and convenient use, pollution prevention, The effect of protecting the natural environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

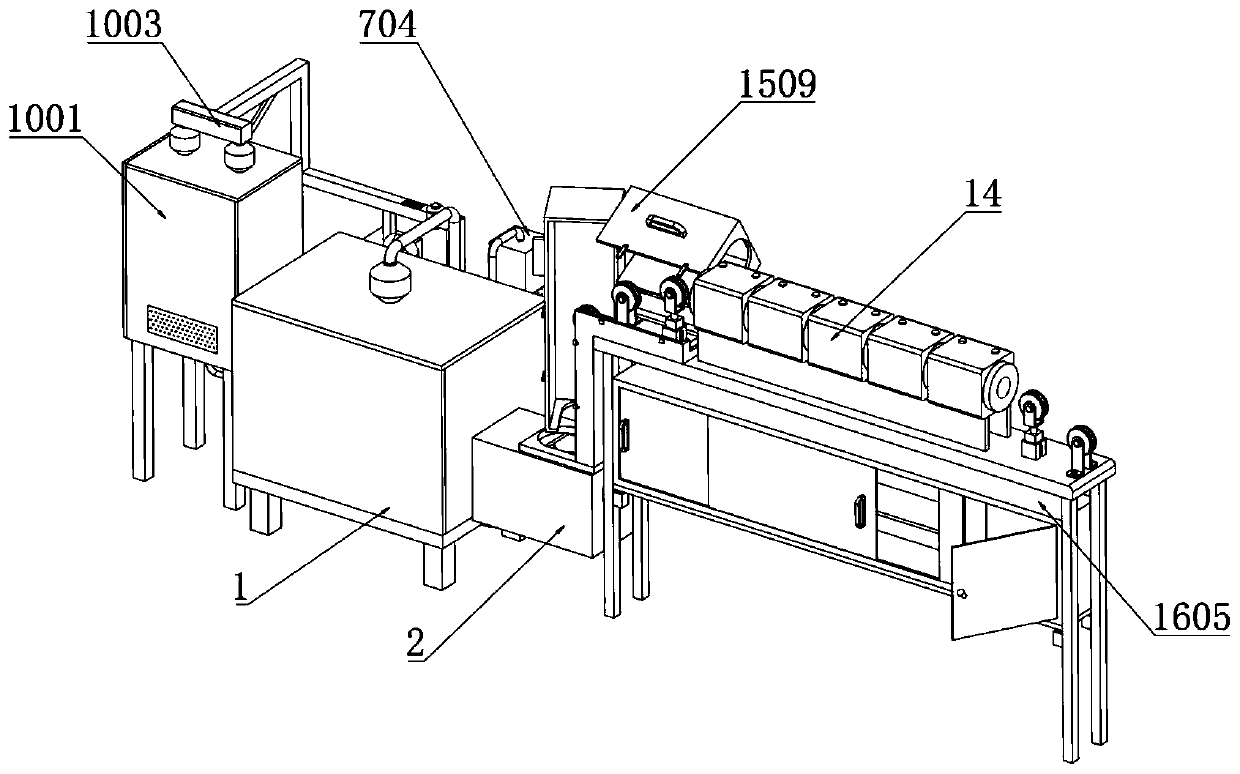

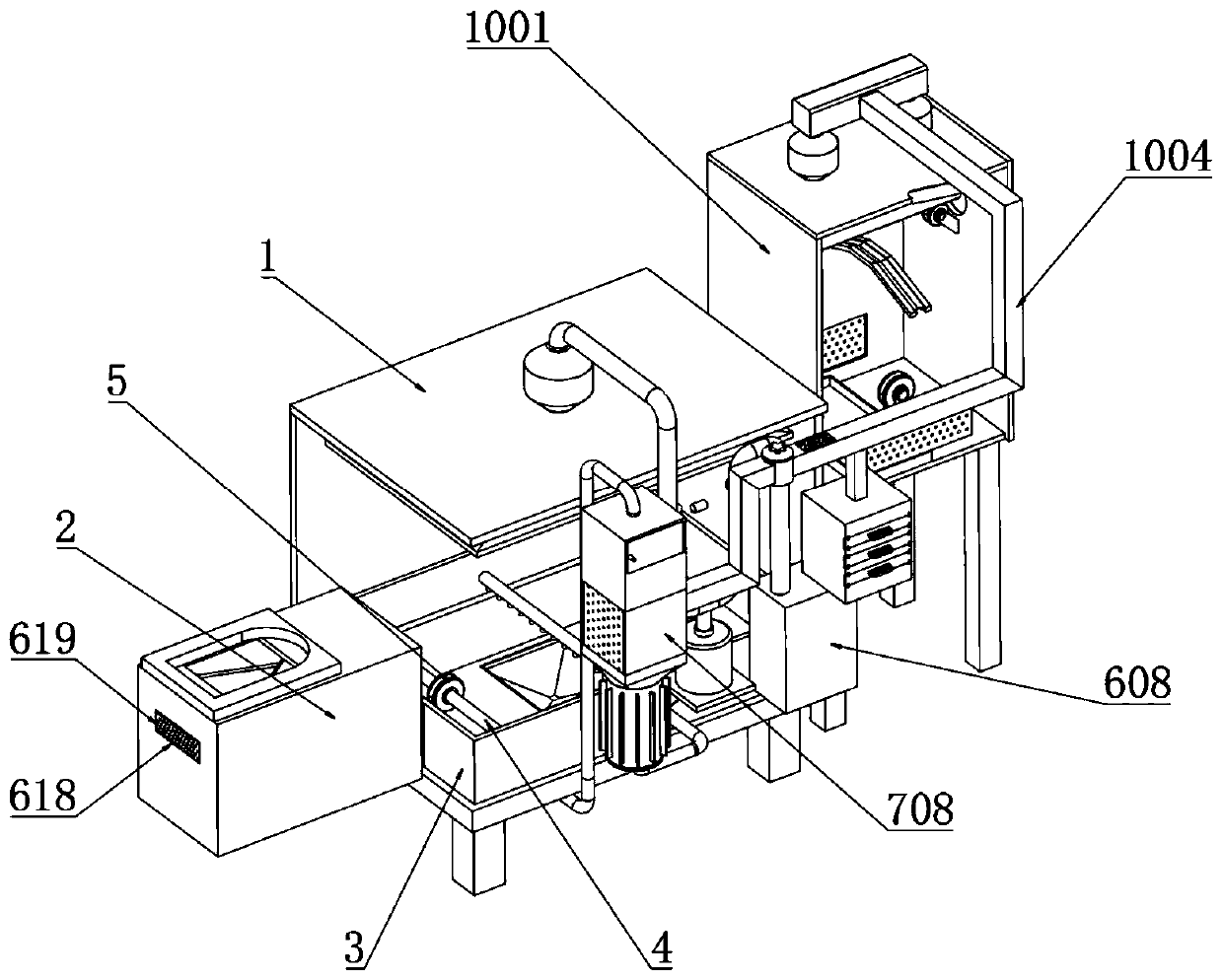

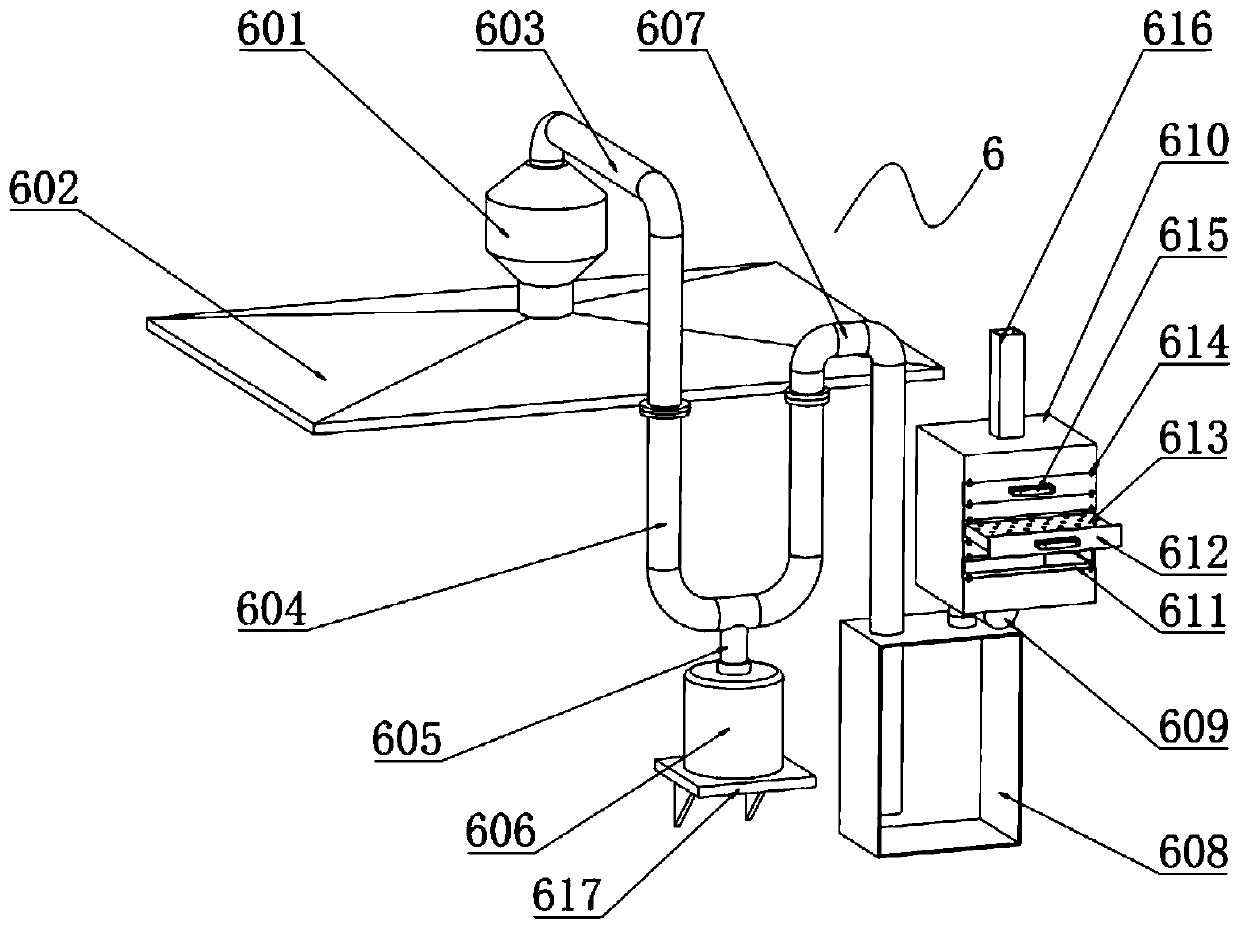

[0057] Example: such as Figure 1-4 As shown, the present invention provides a technical solution, a fast and environment-friendly heat treatment device for metal processing, including a heat treatment box 1, one end of the heat treatment box 1 is fixedly connected with a sealed side box 2, and a quenching tank 3 is placed at the bottom of the inner side of the heat treatment box 1, The inner side of the quenching tank 3 is symmetrically and fixedly connected with a support guide rod 4, the outer middle part of the support guide rod 4 is rotatably connected with a downward pressure guide wheel 5, and the middle part of the top end of the heat treatment box 1 is fixedly connected with an exhaust gas treatment mechanism 6;

[0058] The tail gas treatment mechanism 6 includes a collection fan 601, an upper collection bucket 602, an upper air pipe 603, a U-shaped pipe 604, a liquid return thin pipe 605, a collection bucket 606, a side air pipe 607, a scrubber box 608, a lower air p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com