Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

125results about How to "Avoid shunting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

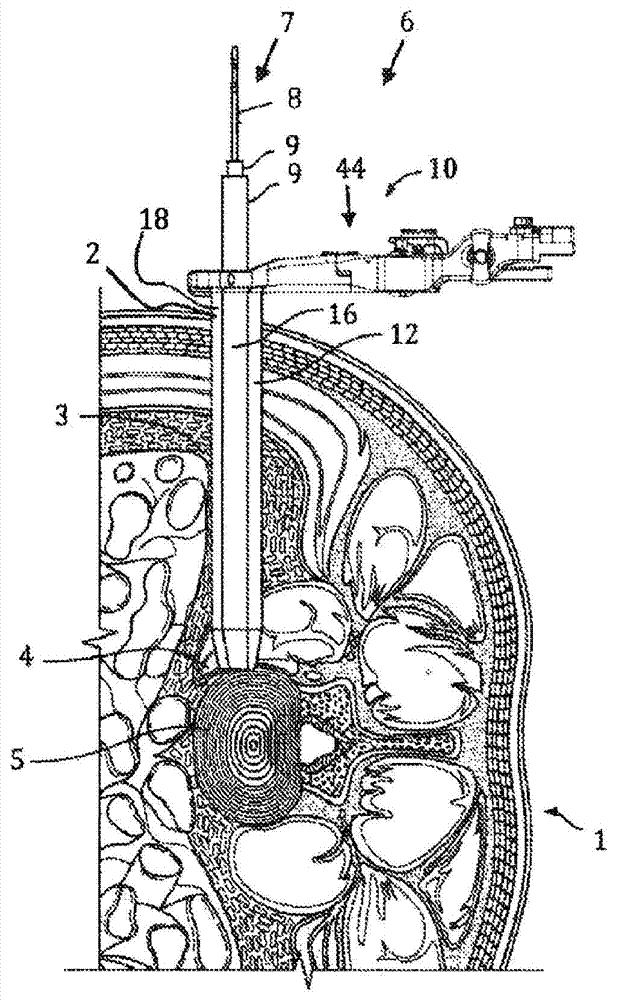

Implantable artificial partition and methods of use

InactiveUS7160312B2Reduce the cross-sectional areaReduce probabilitySuture equipmentsHeart valvesMedicineGastro intestinal

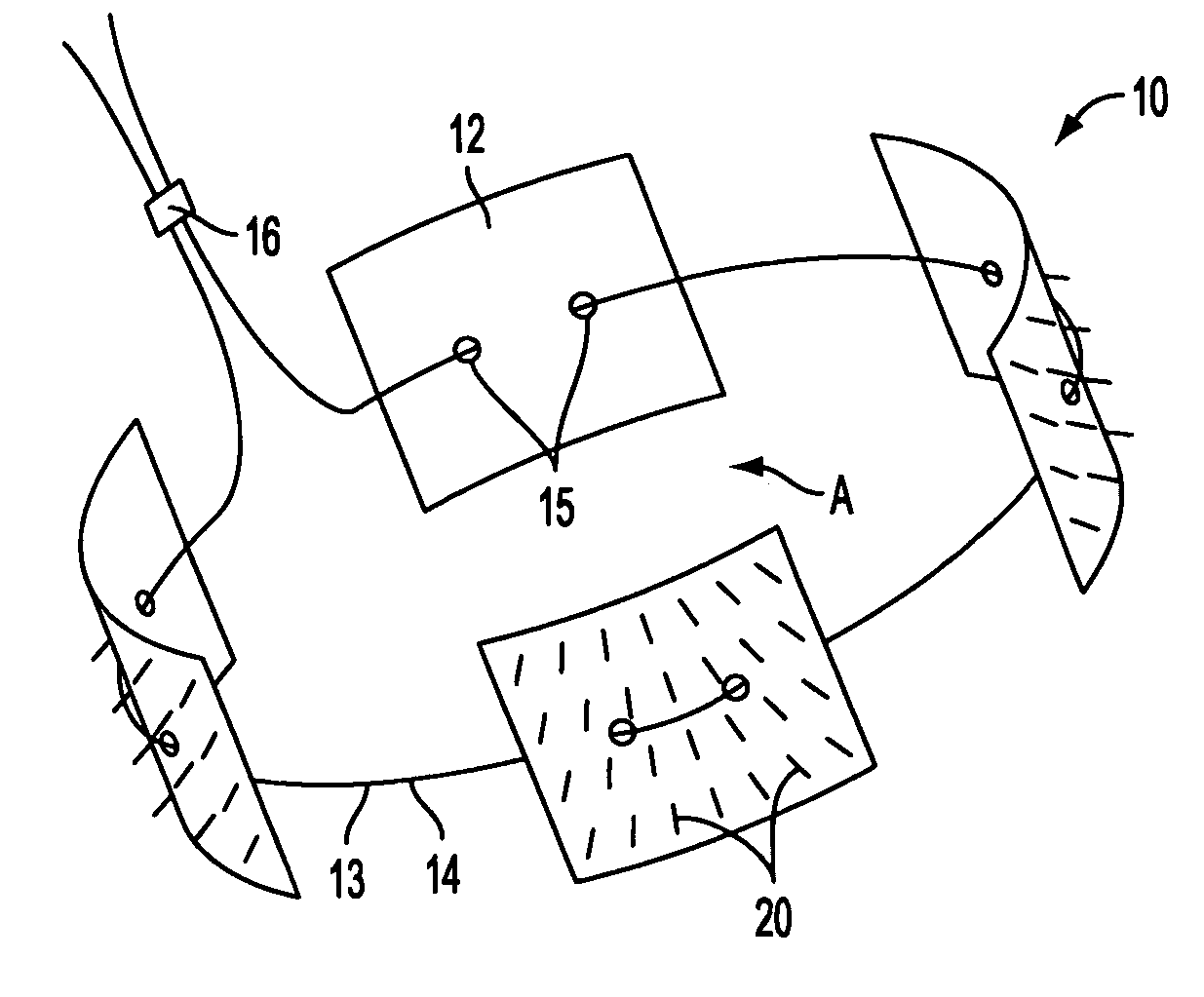

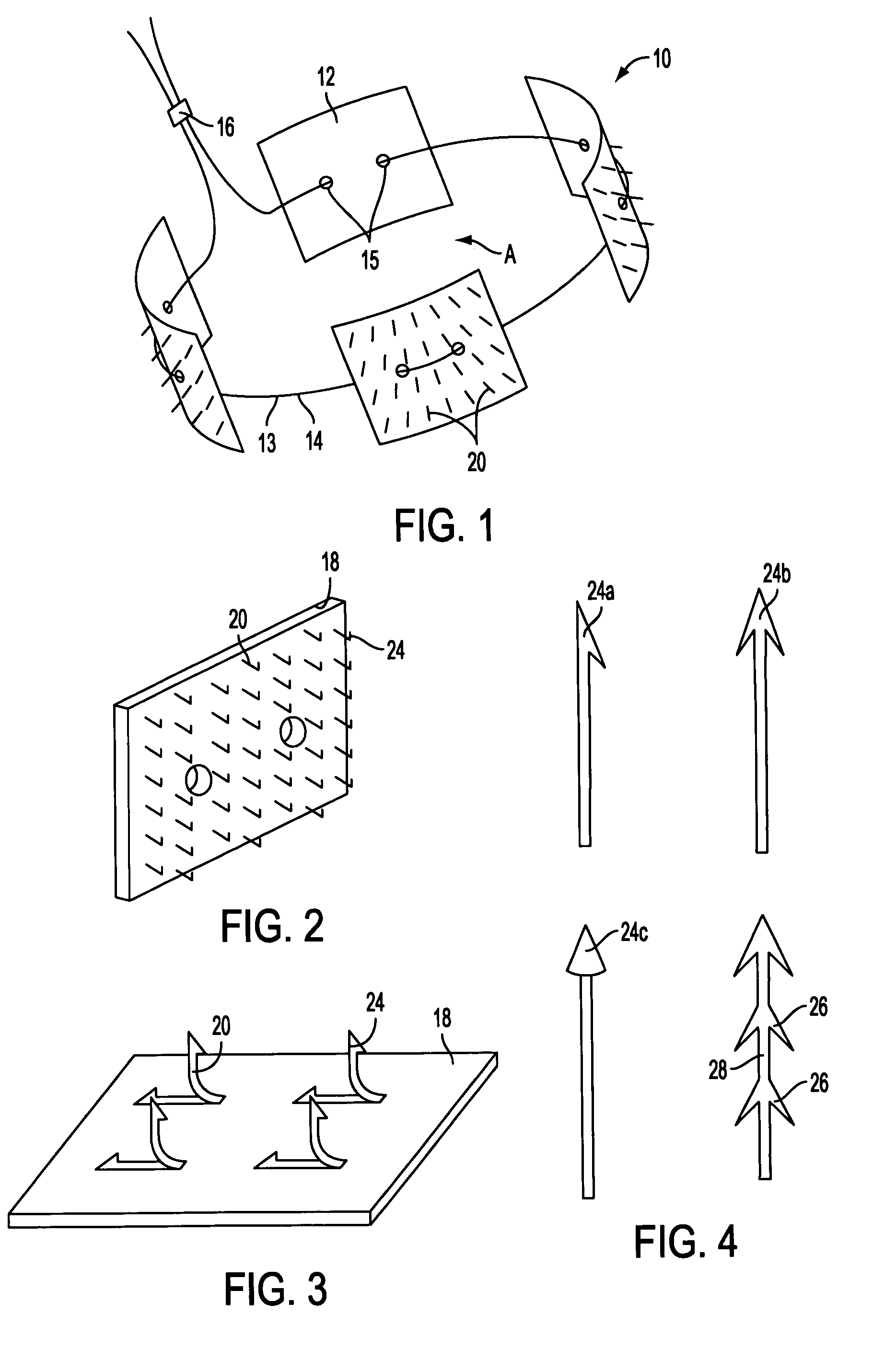

Apparatus and methods are provided for partitioning a gastro-intestinal lumen by intraluminally reducing a local cross-sectional area thereof. The apparatus comprises a plurality of anchors adapted for intraluminal penetration into a wall of the gastro-intestinal lumen to prevent migration or dislodgement of the apparatus, and a partition, which may include a drawstring or a toroidal balloon, coupled to the plurality of anchors to provide a local reduction in the cross-sectional area of the gastro-intestinal lumen.

Owner:USGI MEDICAL

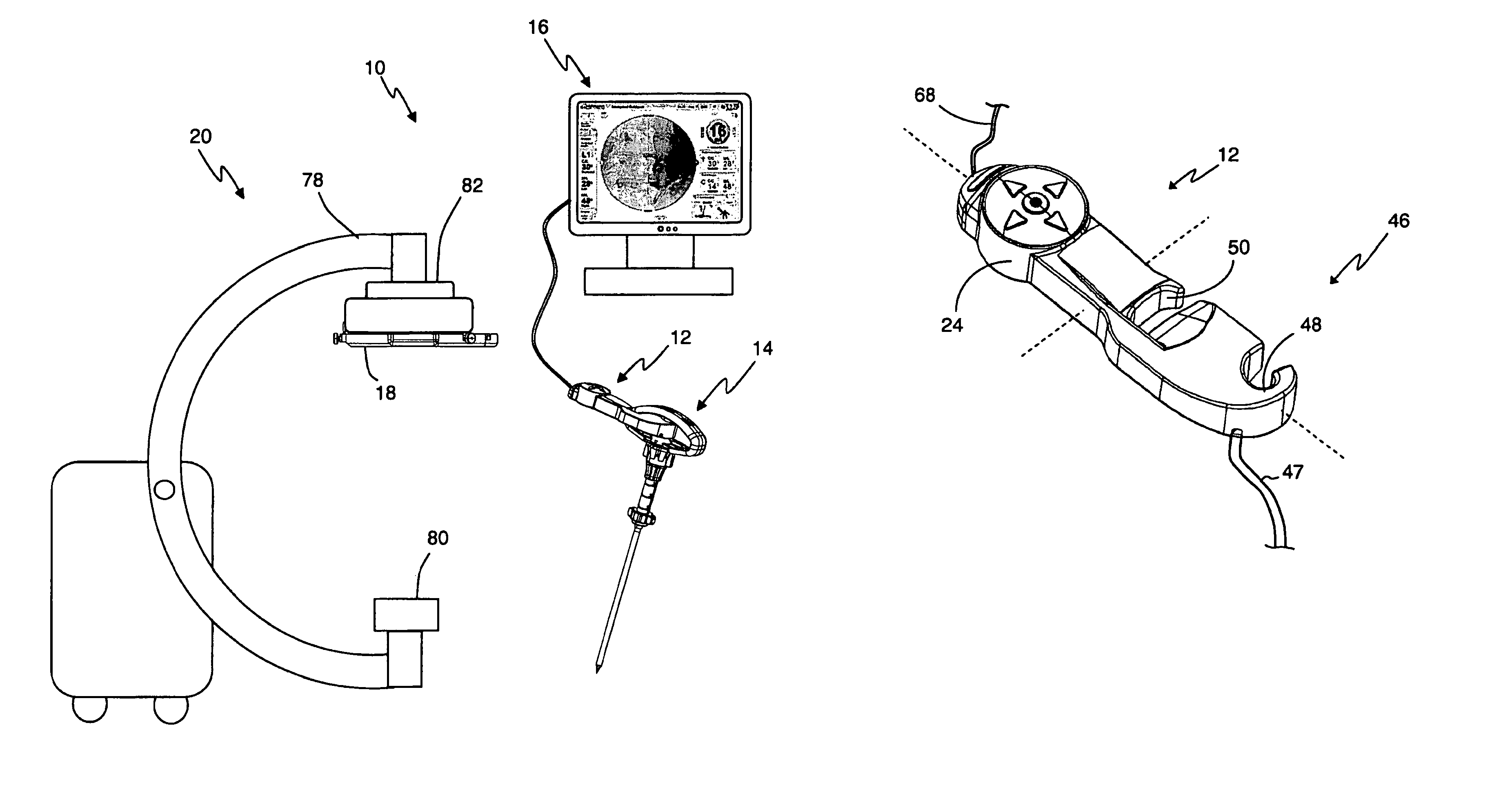

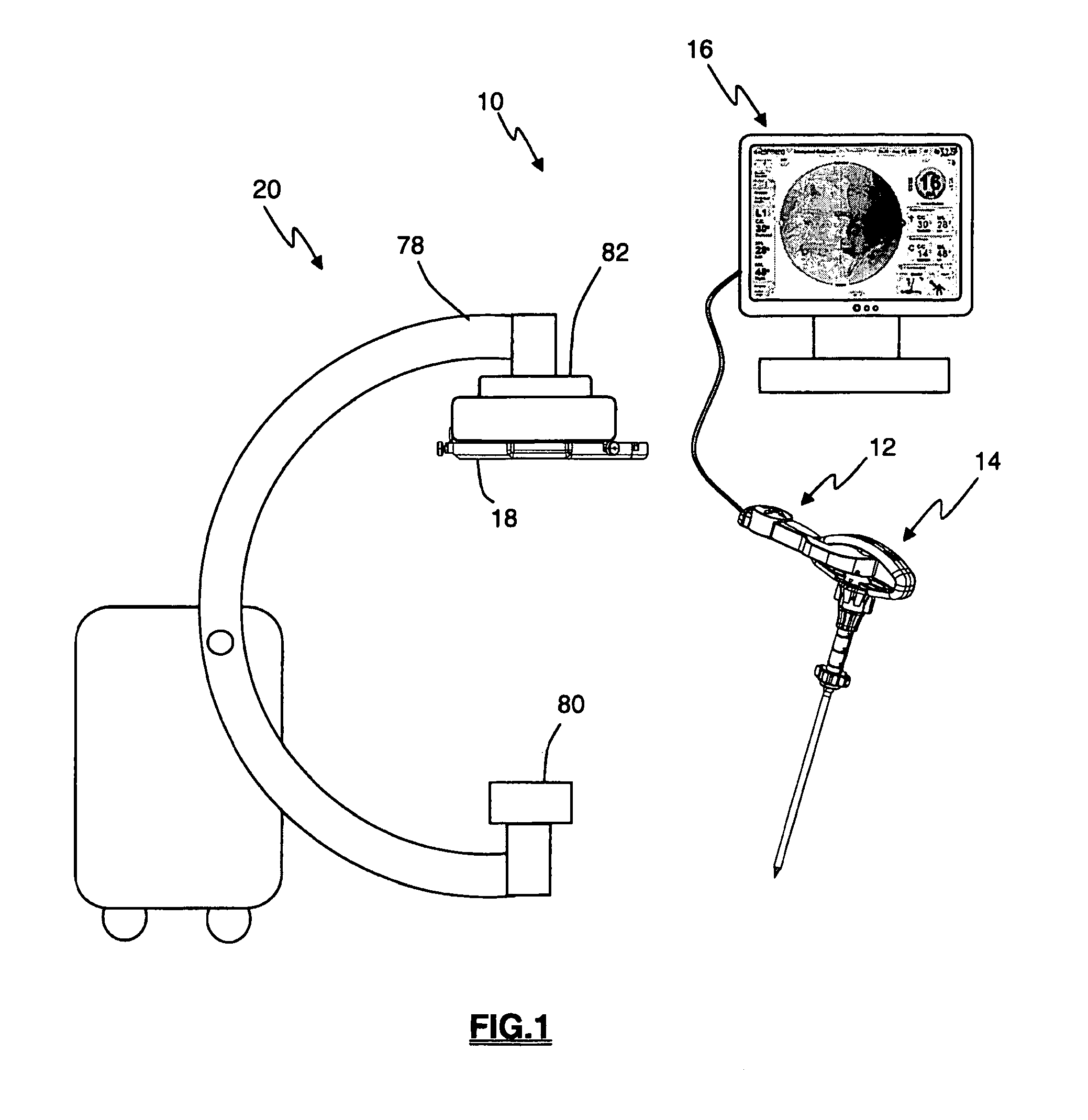

Surgical trajectory monitoring system and related methods

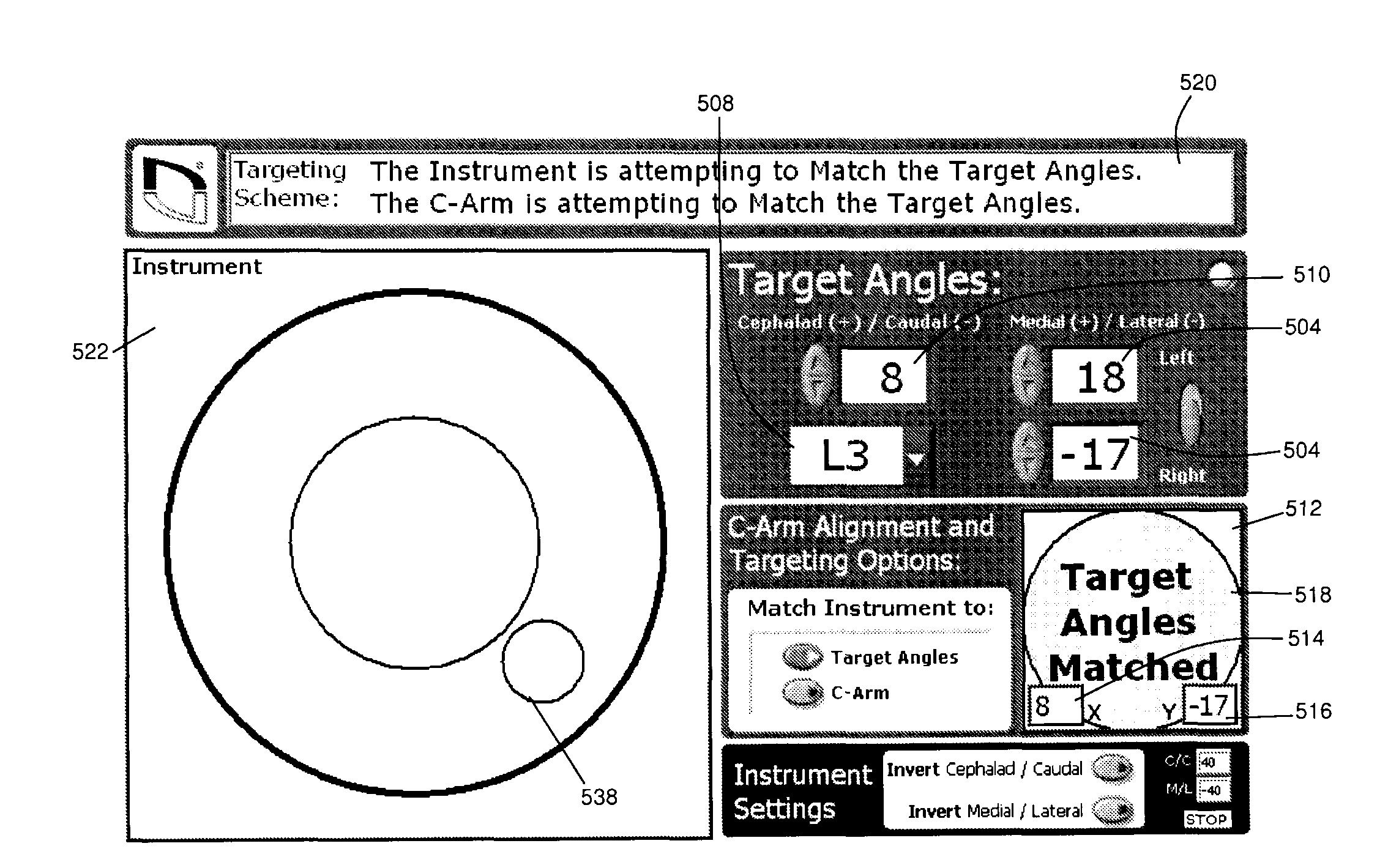

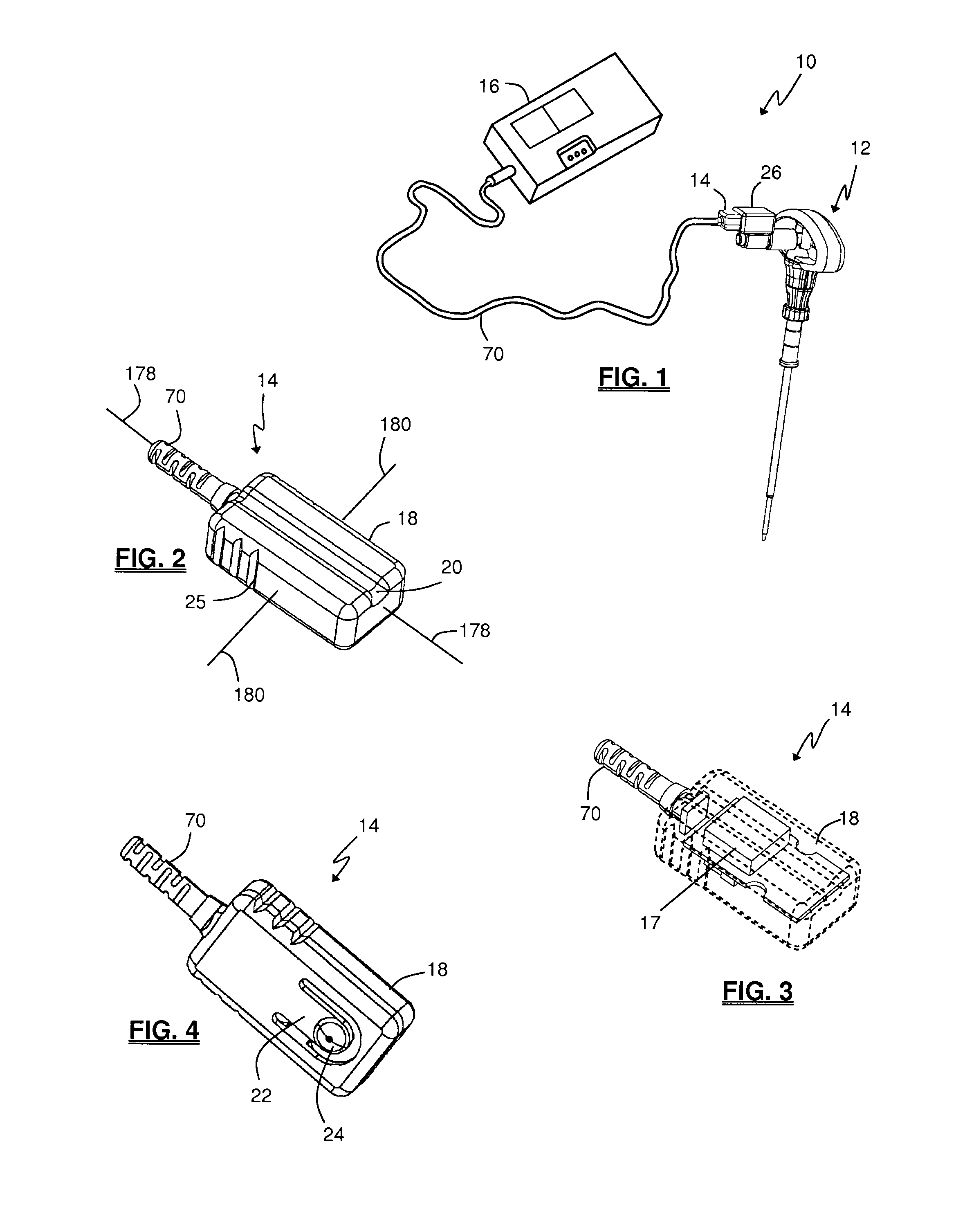

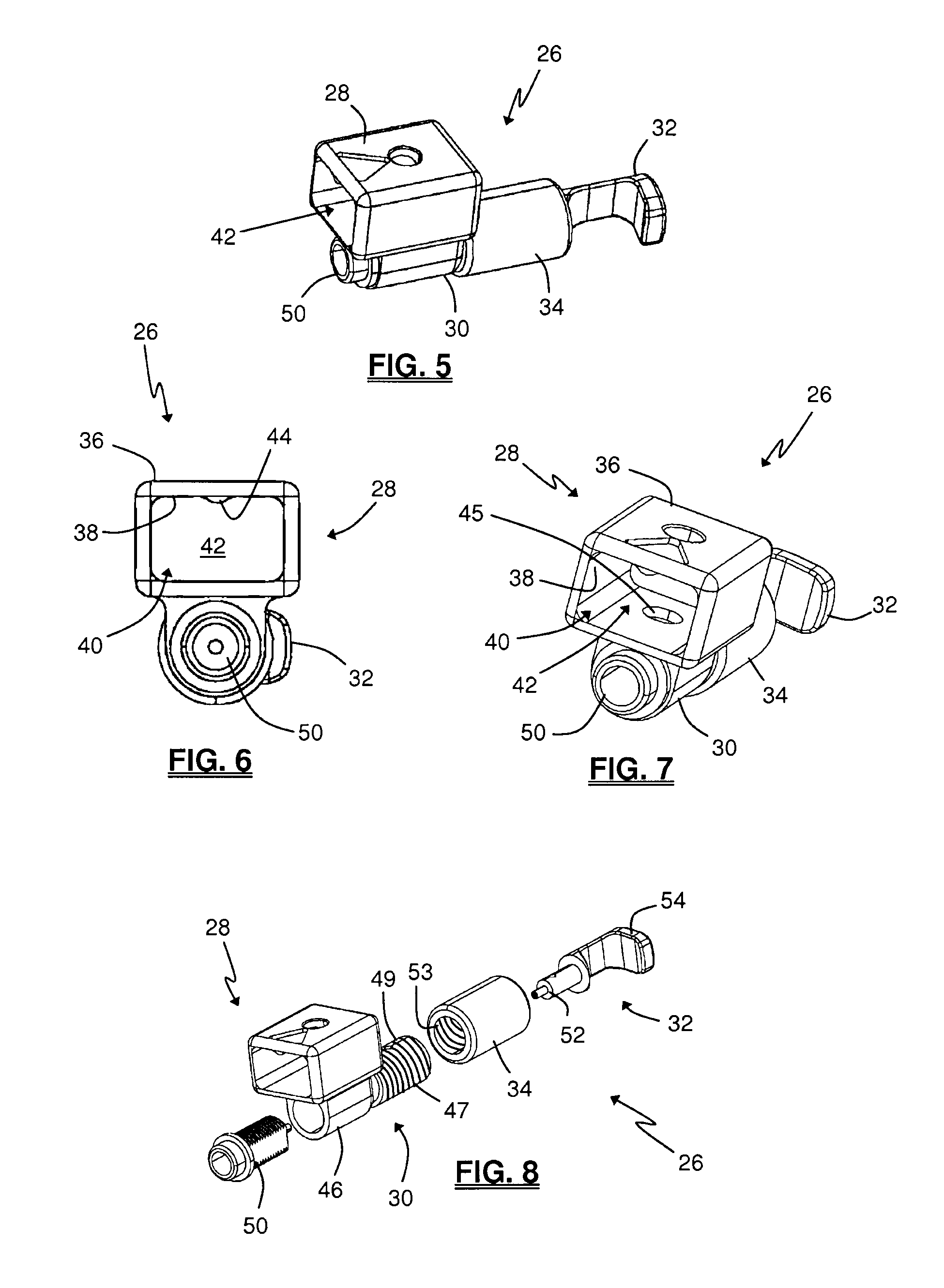

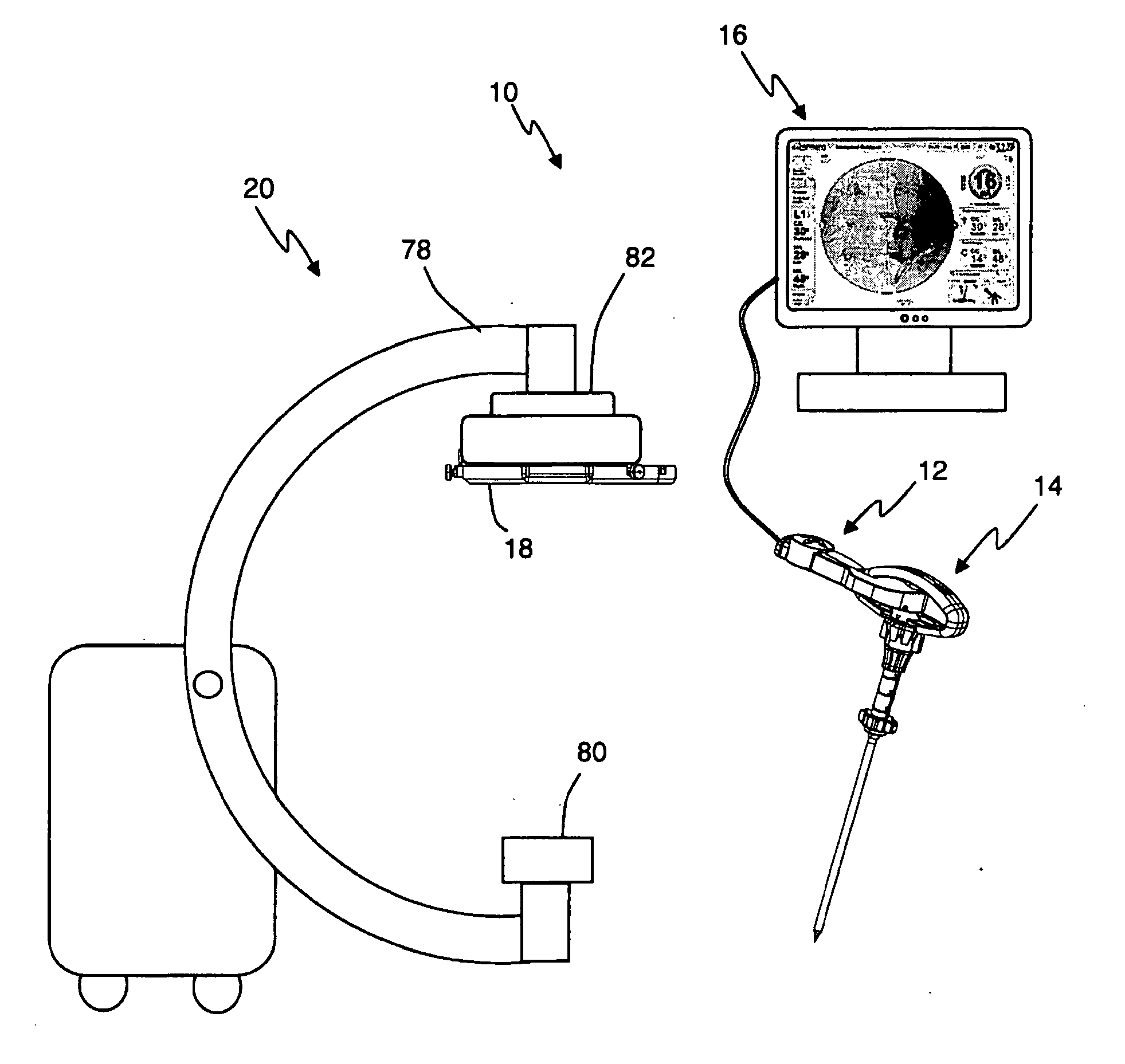

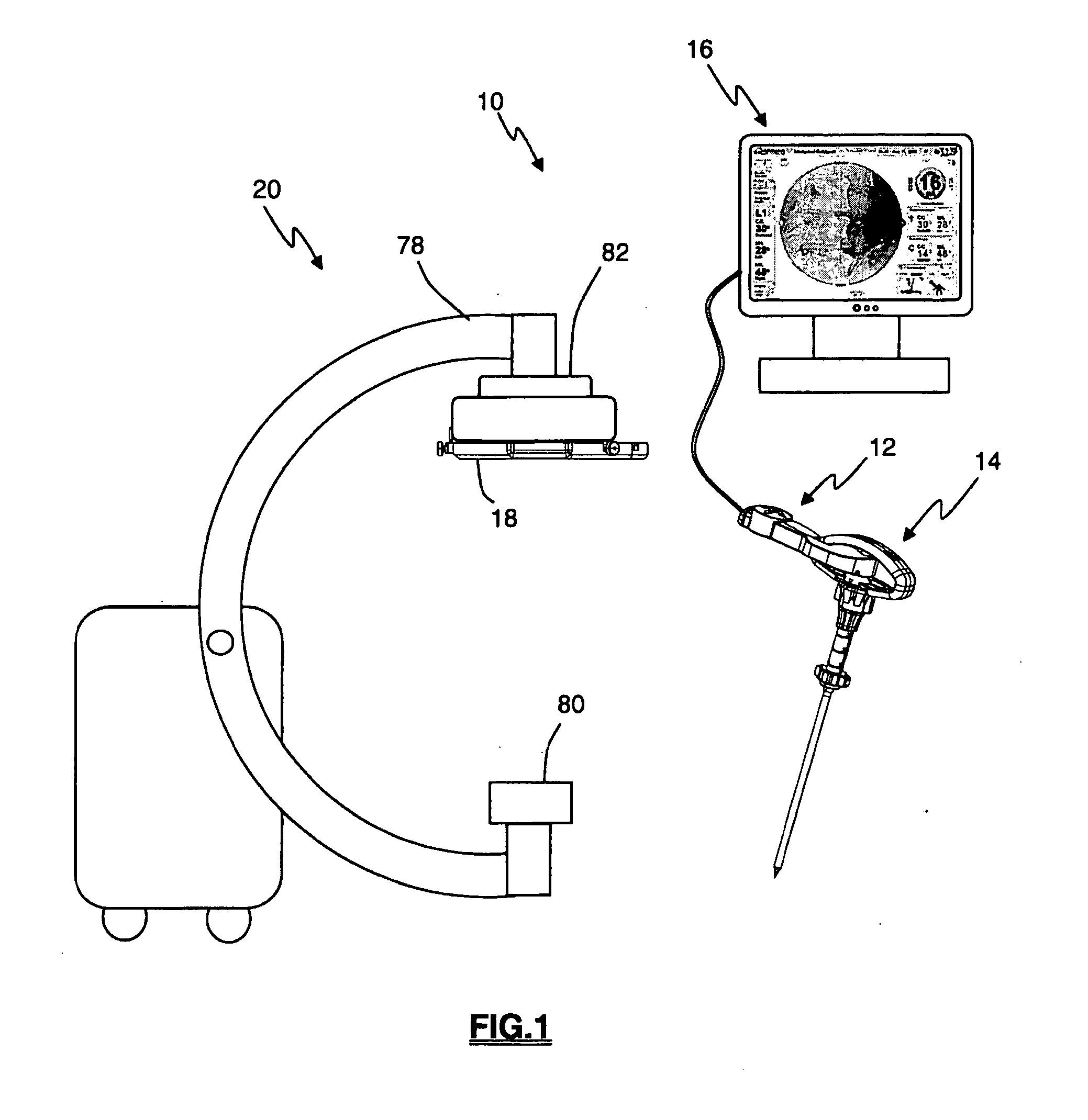

ActiveUS8442621B2Facilitates safe reproducible useAvoid shuntingInternal osteosythesisSurgical needlesTranspedicular fixationMonitoring system

Owner:NUVASIVE +1

Surgical Trajectory Monitoring System and Related Methods

ActiveUS20100312103A1Improve securityFacilitates reproducible useSpinal electrodesSurgical navigation systemsTranspedicular fixationMonitoring system

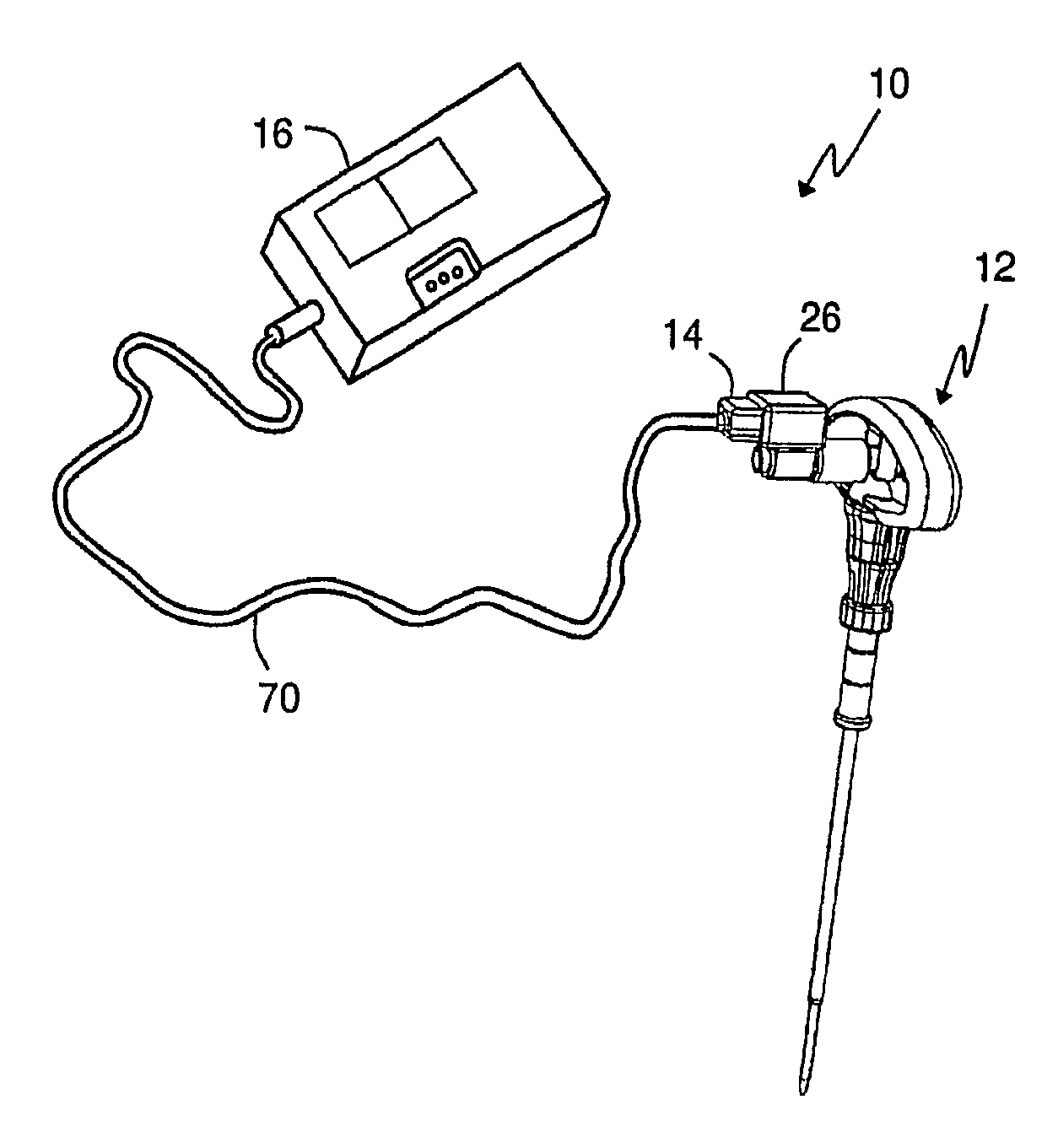

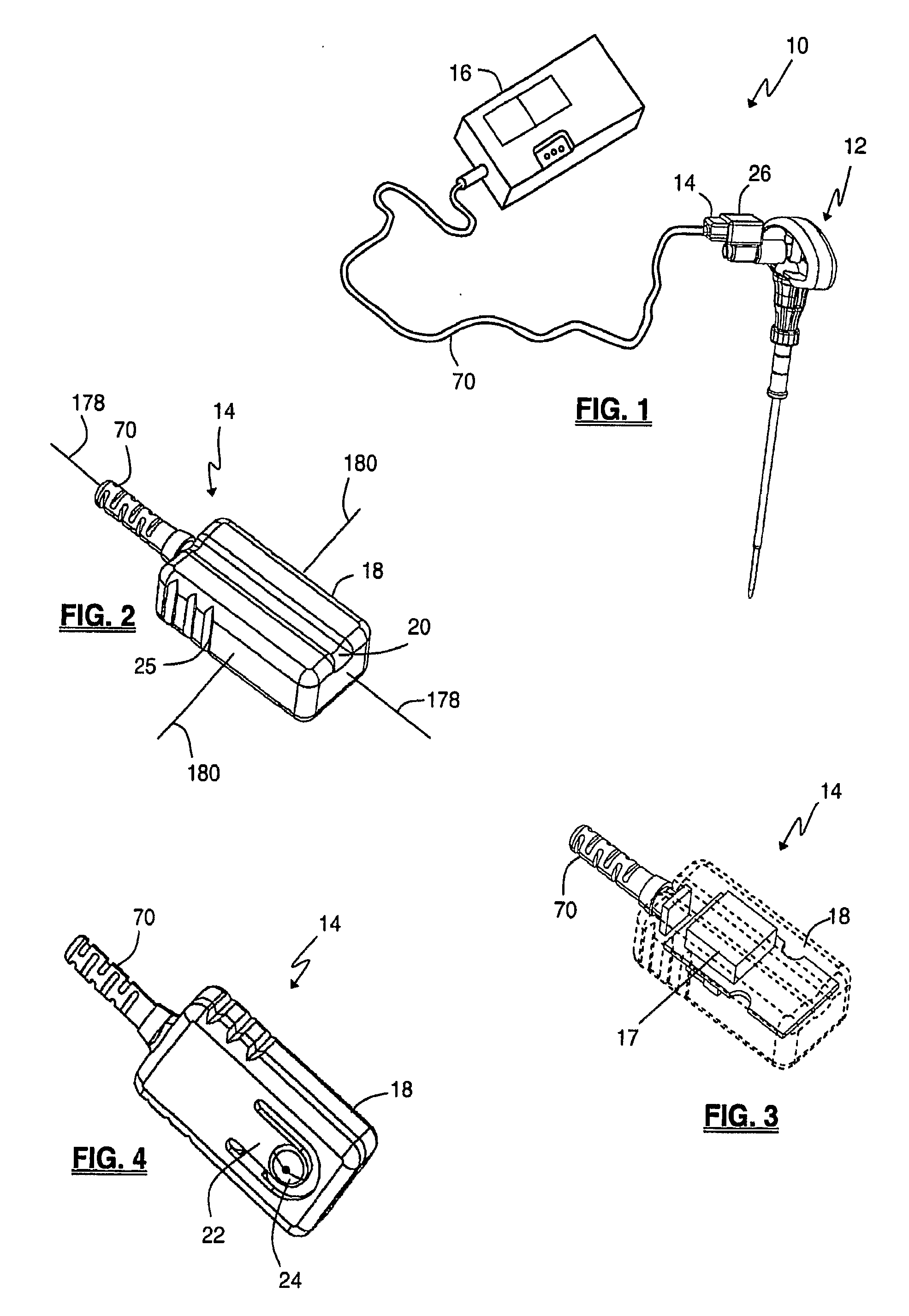

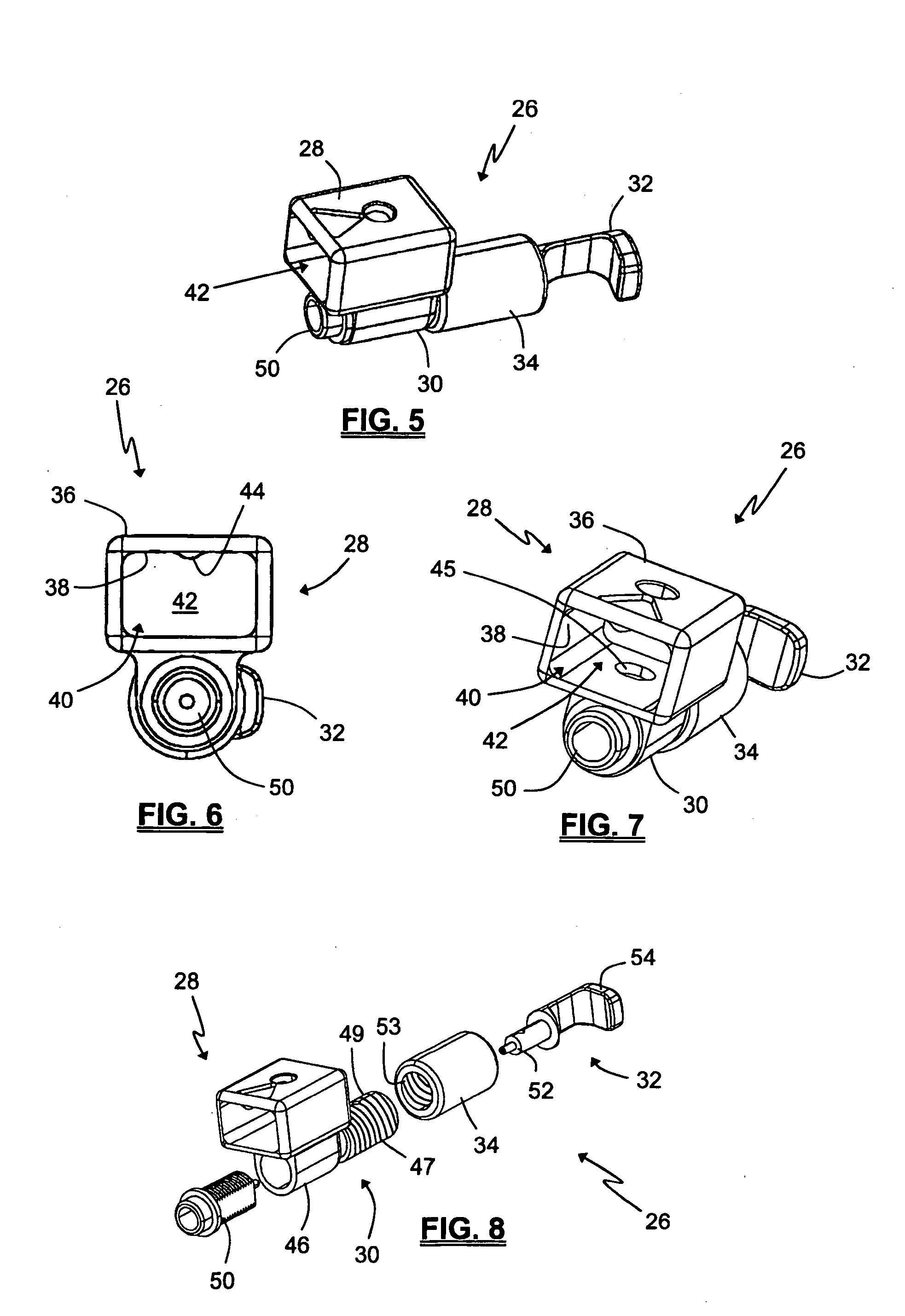

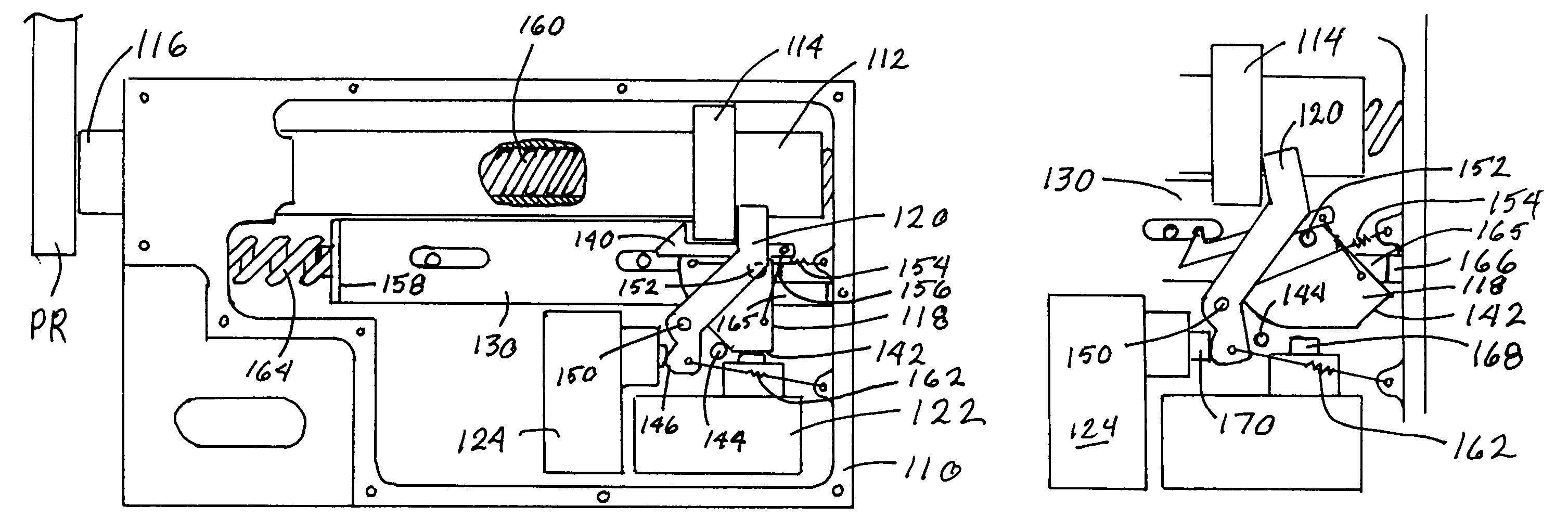

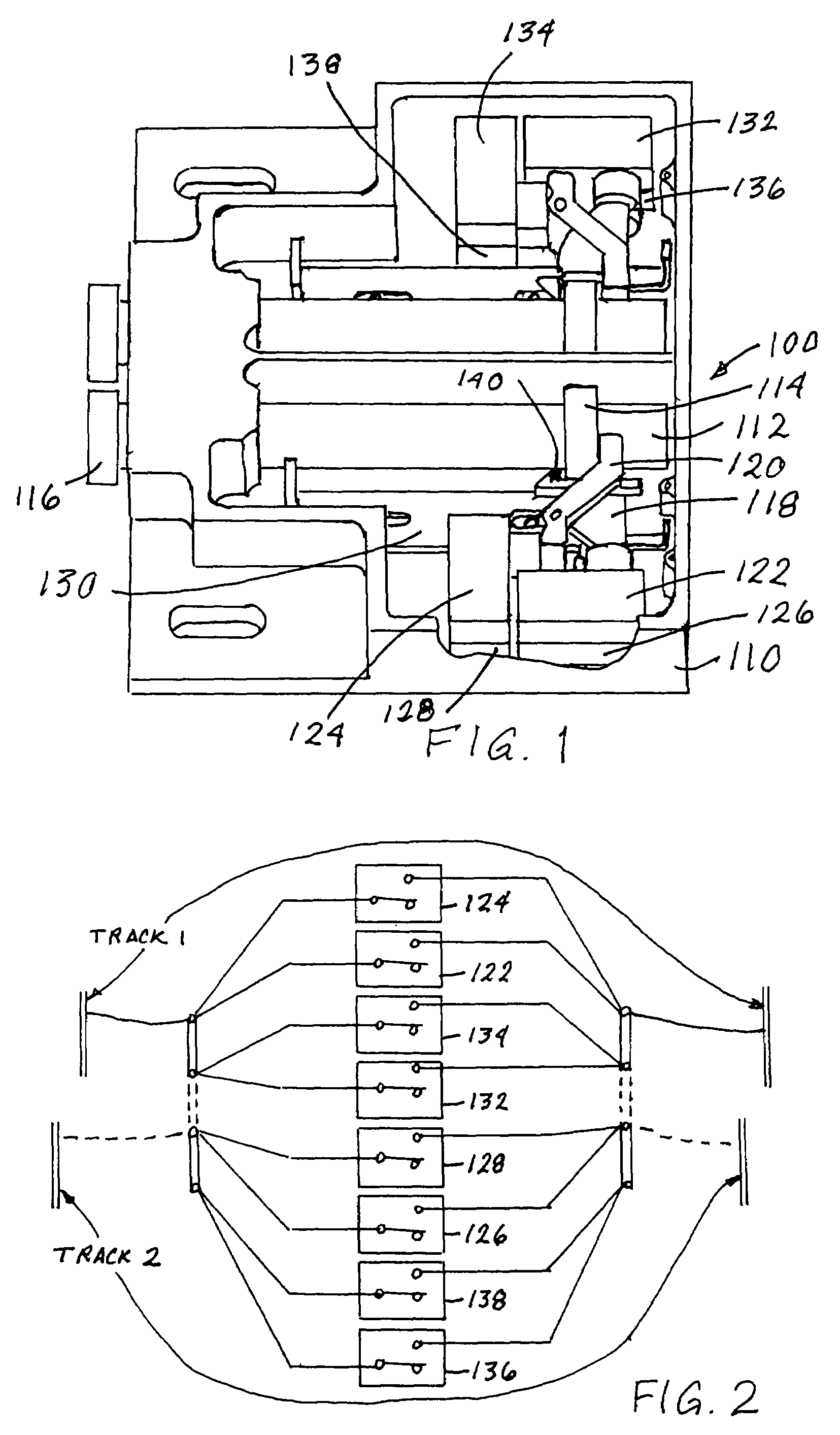

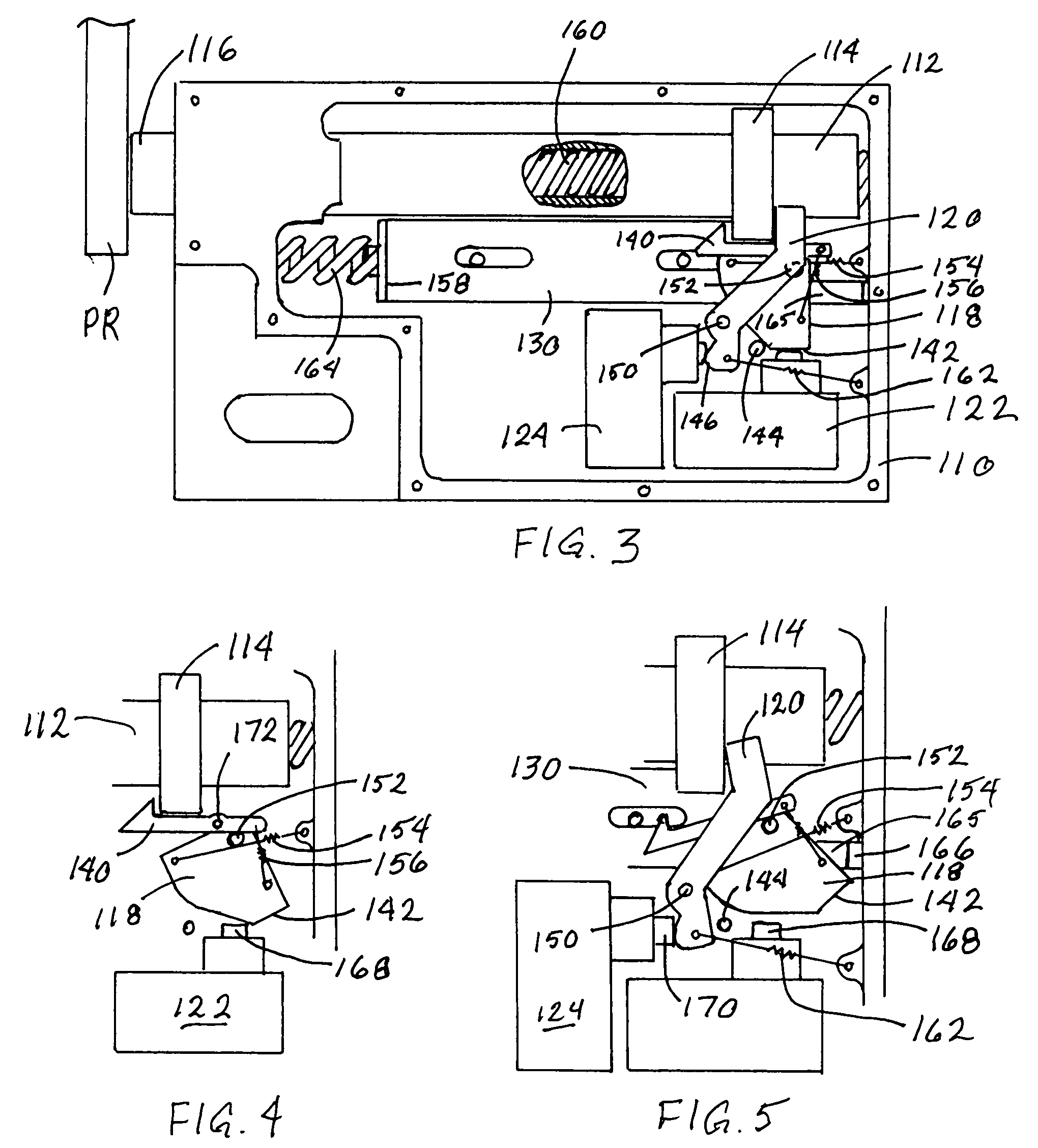

The present invention relates to a system and methods generally aimed at monitoring the trajectory of surgical instruments and especially for monitoring the trajectory of surgical instrument used during pedicle fixation to ensure the proper placement of pedicle screws.

Owner:NUVASIVE

Surgical Trajectory Monitoring System and Related Methods

ActiveUS20100036384A1Improve securityFacilitates reproducible useInternal osteosythesisSurgical needlesTranspedicular fixationMonitoring system

Systems and methods for determining a desired trajectory and / or monitoring the trajectory of surgical instruments and / or implants in any number of surgical procedures, such as (but not limited to) spinal surgery, including (but not limited to) ensuring proper placement of pedicle screws during pedicle fixation procedures and ensuring proper trajectory during the establishment of an operative corridor to a spinal target site.

Owner:NUVASIVE +1

Neurophysiological apparatus and procedures

ActiveUS20090138050A1Simple technologyAvoid nerve damageElectrotherapyInternal osteosythesisMedicineElectrical impulse

Neurophysiological instruments and techniques are improved through various enhancements. Stimulation of an instrument is possible while it is advancing into the spine or elsewhere, alerting the surgeon to the first sign the instrument or device (screw) may be too near a nerve. A directional probe helps surgeons determine the location of the hole in the pedicle. Electrically insulating sleeves prevent shunting into the soft tissues. According to a different improvement, the same probe to be used to stimulate different devices, such as screws and wires. Electrical impulses may be recorded from non-muscle regions of the body, including the spine and other portions of the central nervous system as opposed to just the extremities.

Owner:NUVASIVE

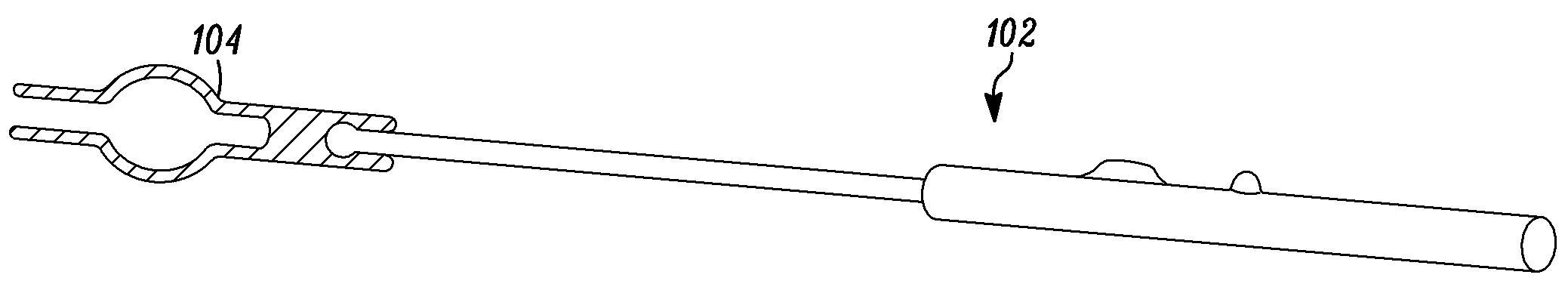

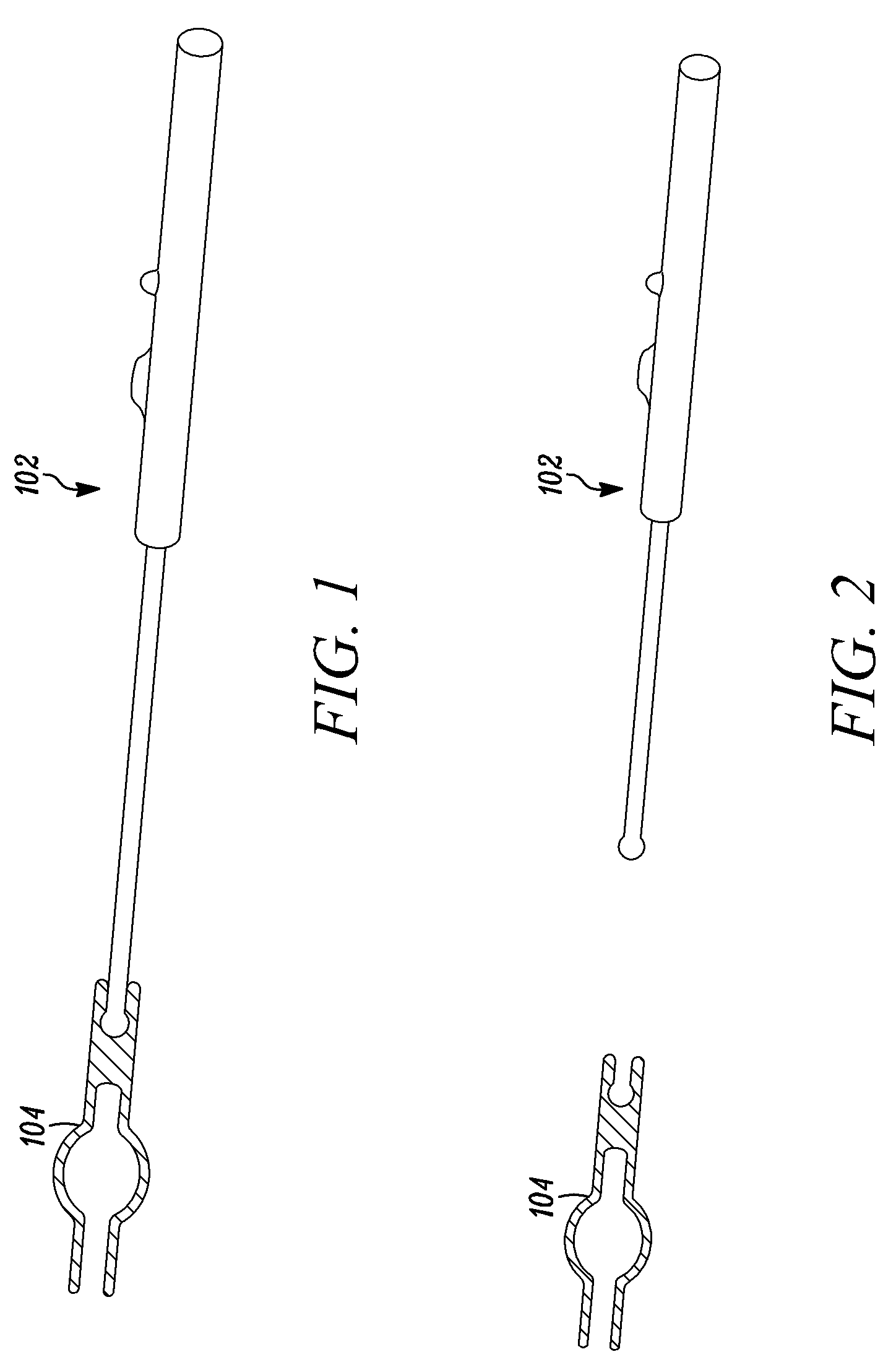

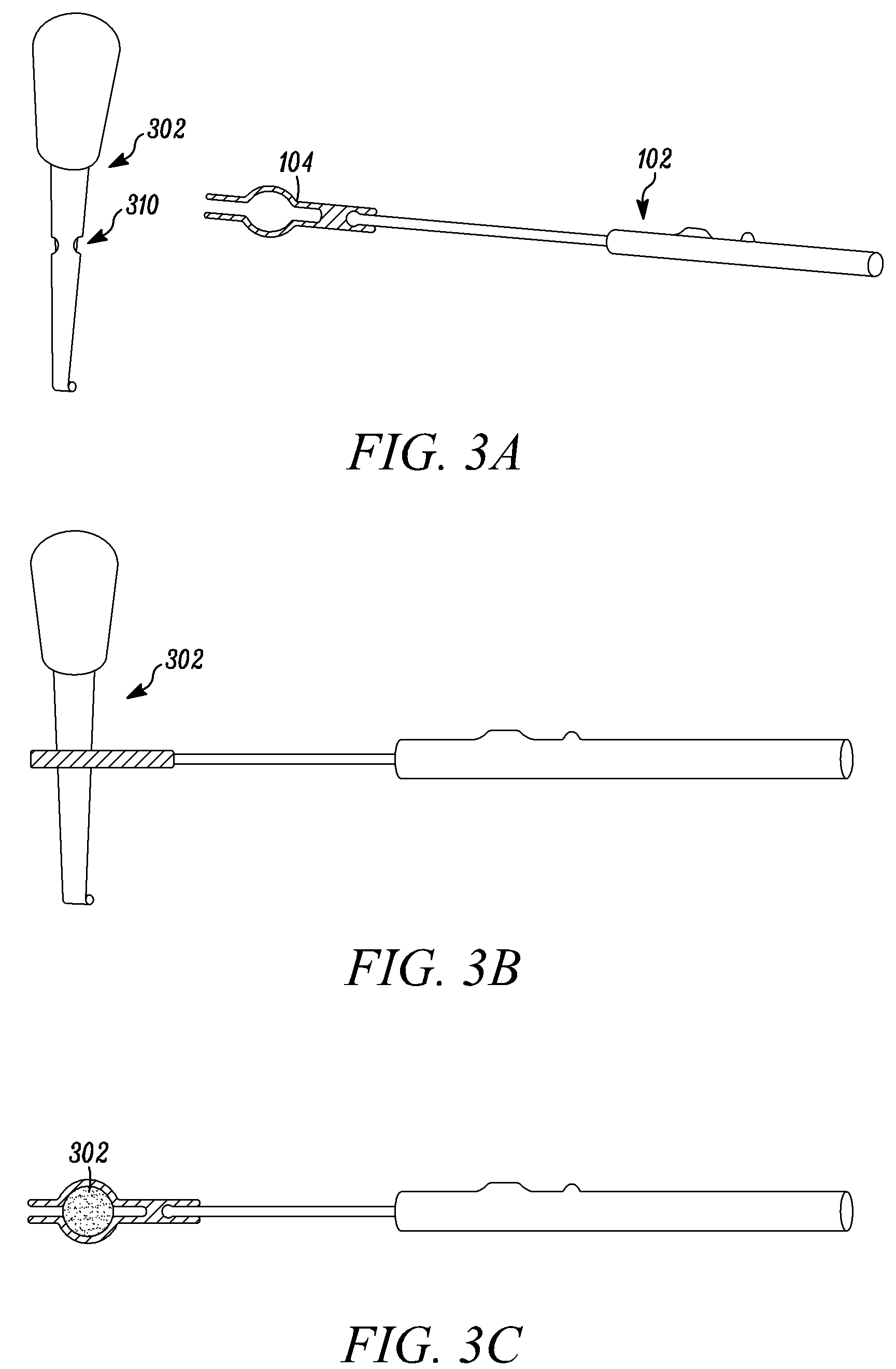

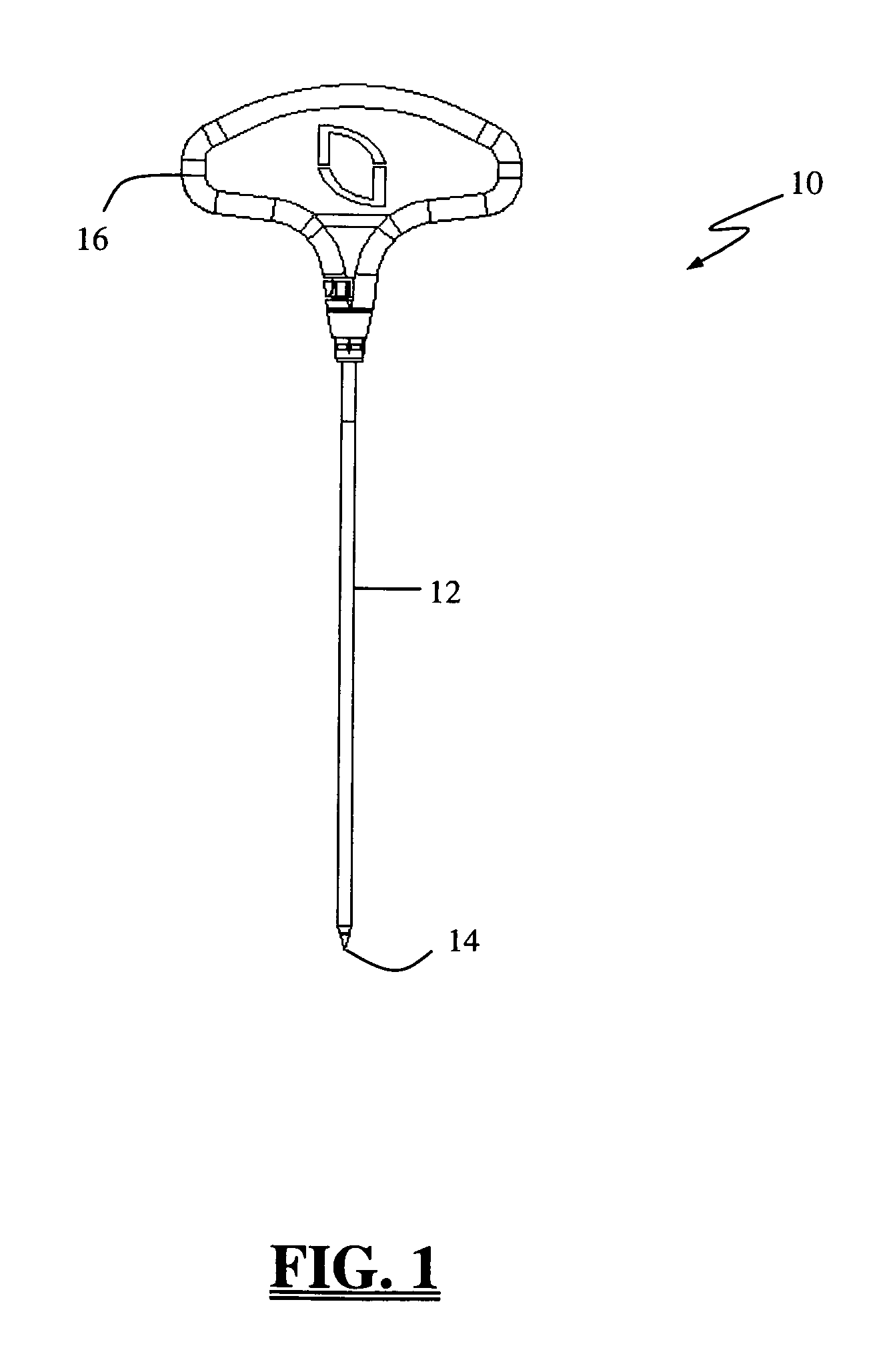

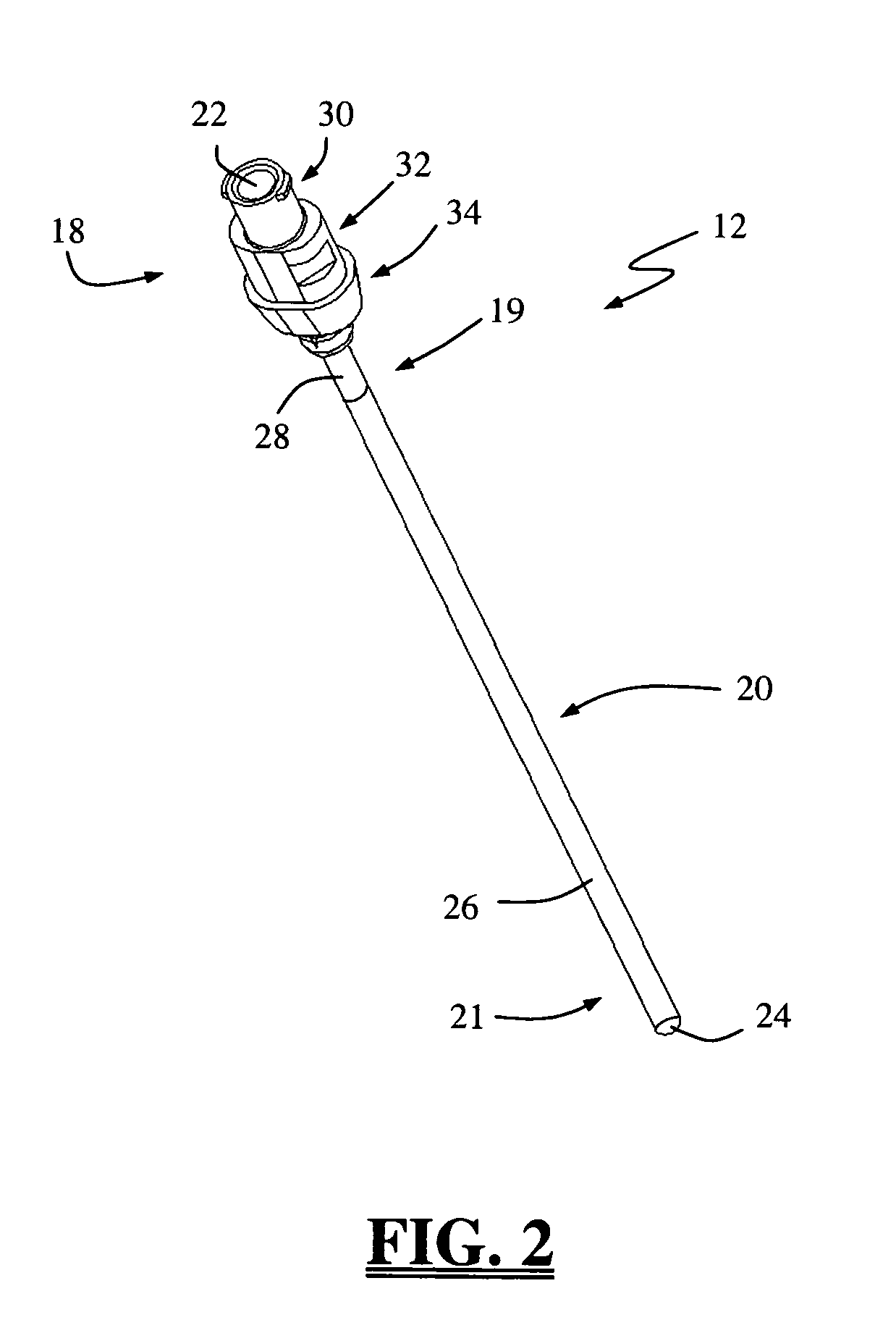

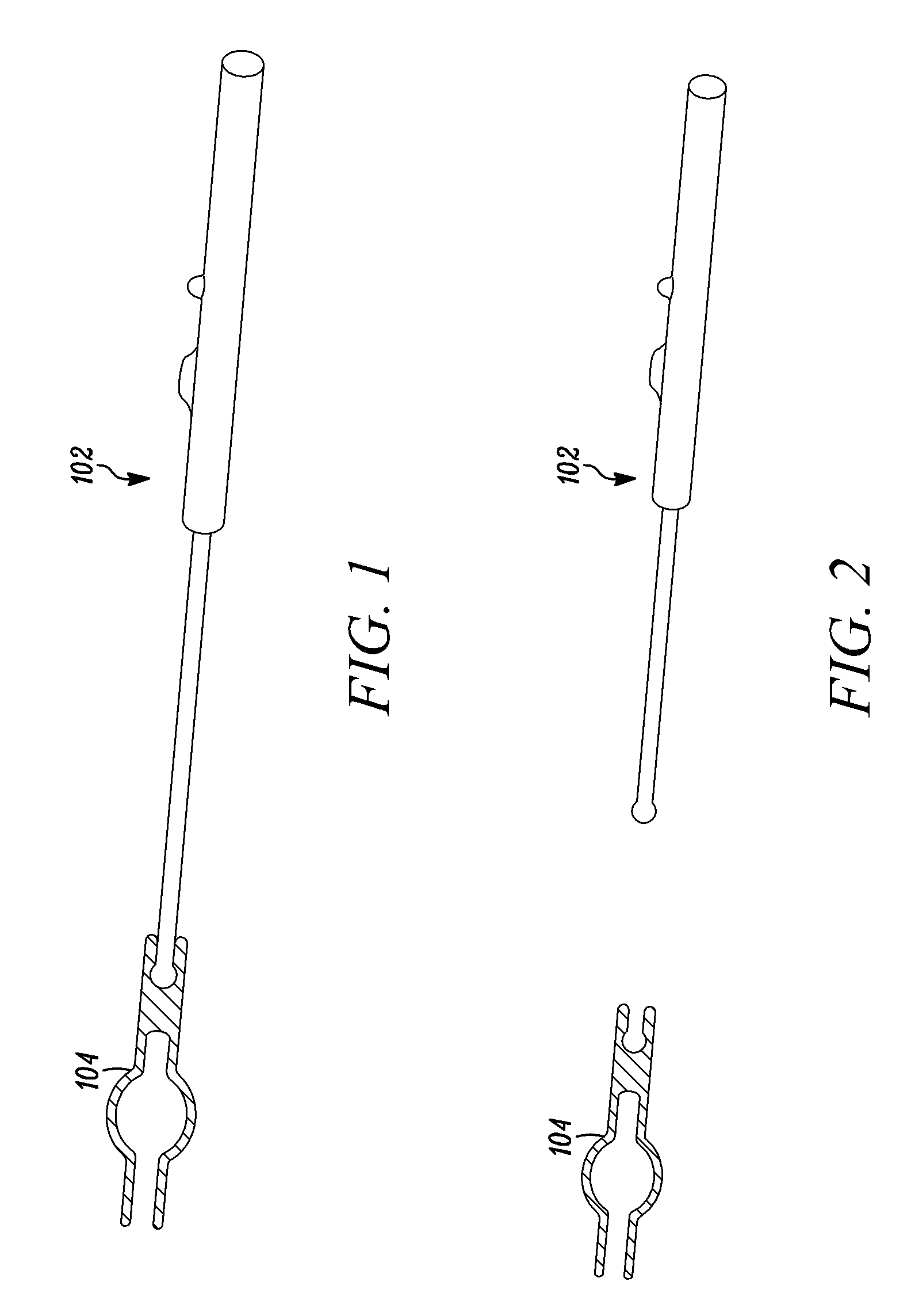

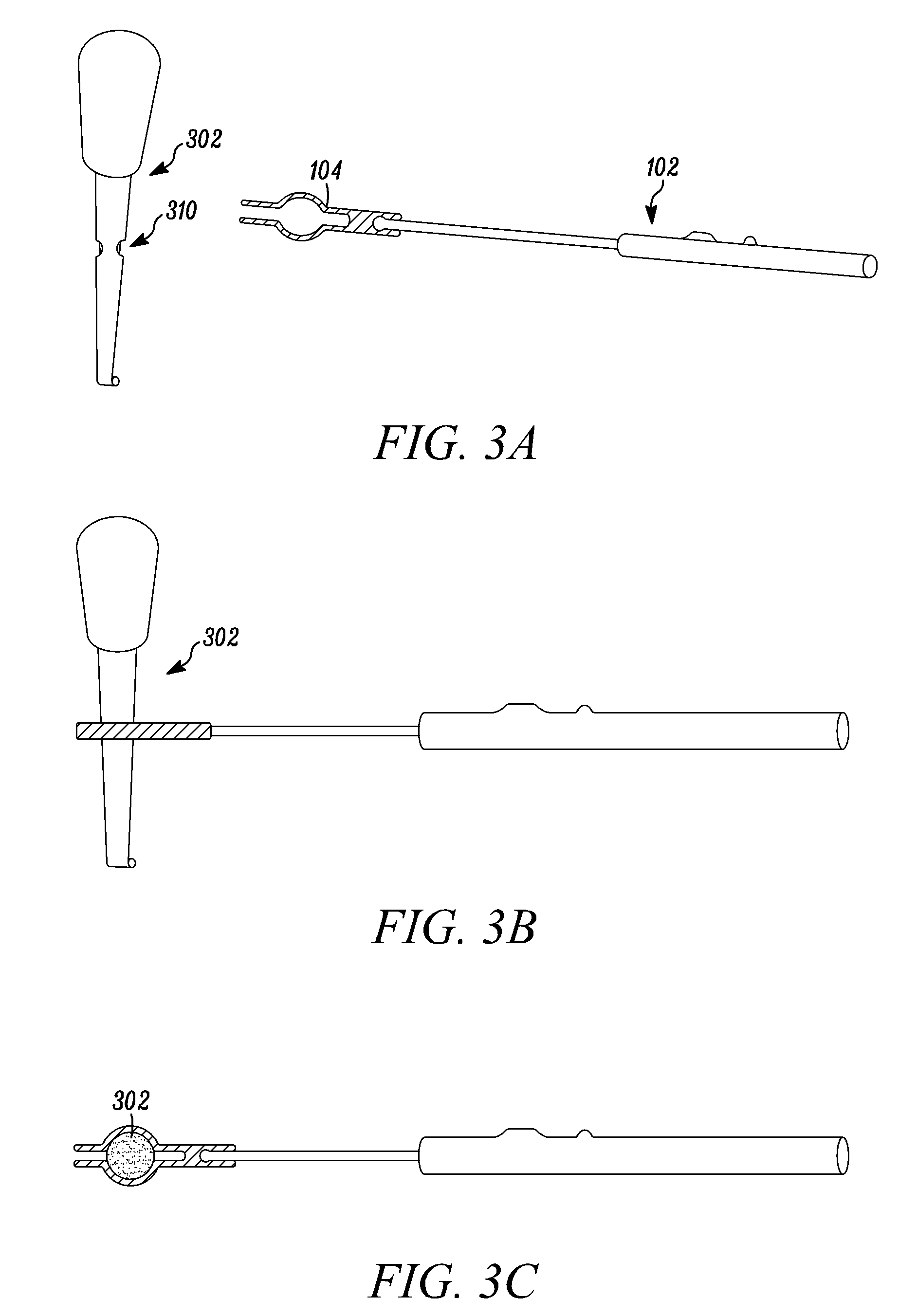

Insulated pedicle access system and related methods

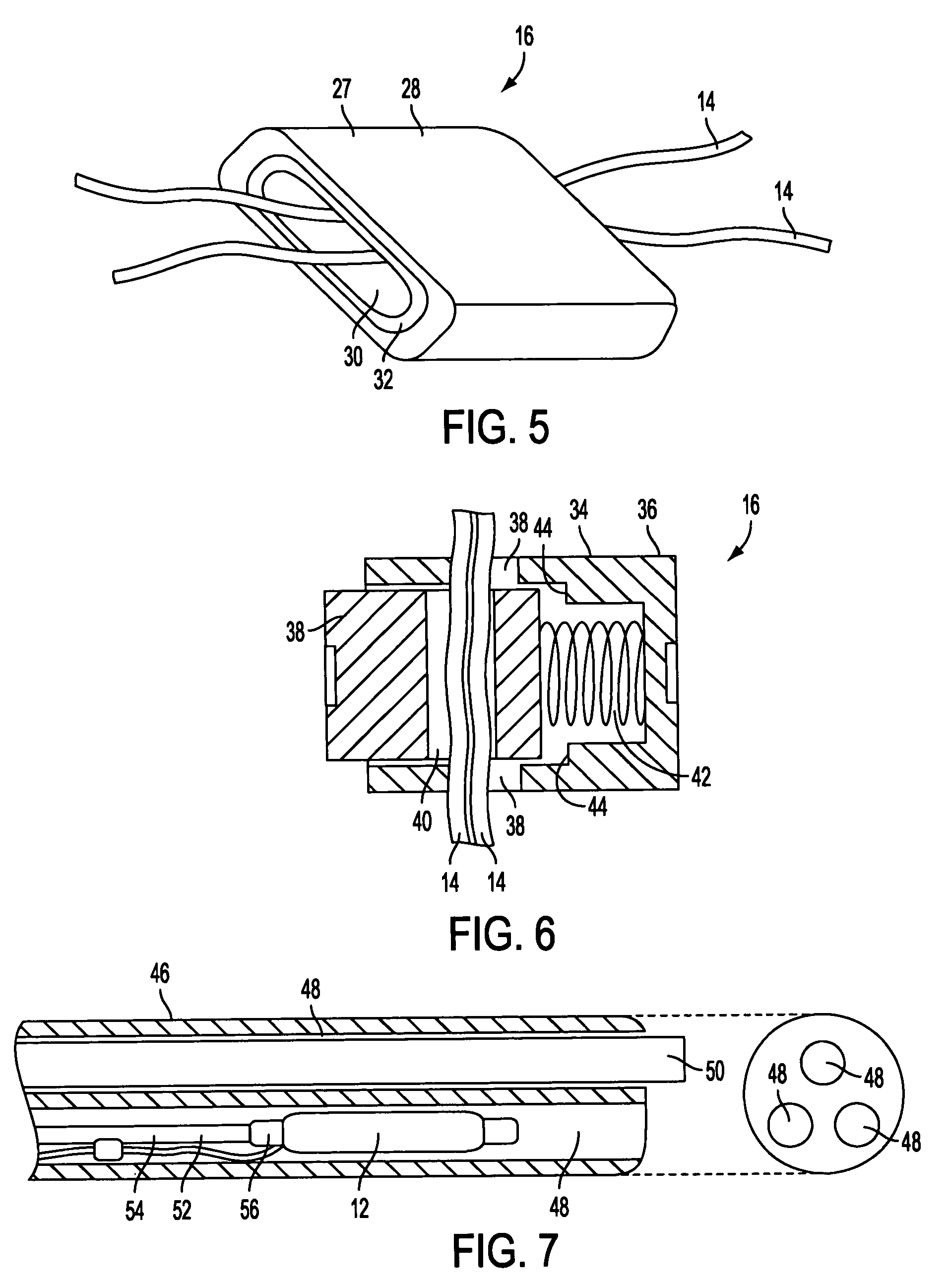

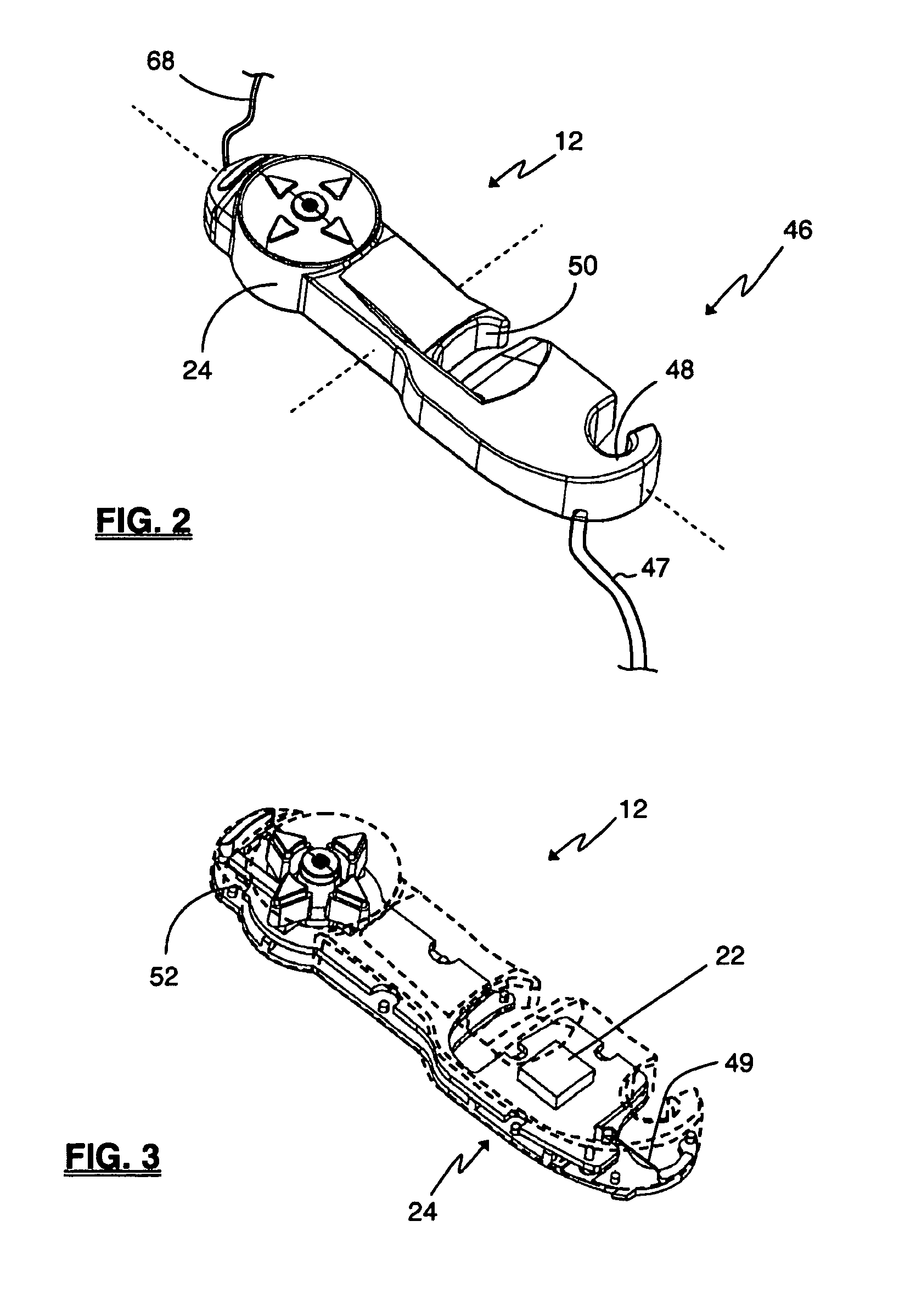

ActiveUS7942826B1Easy to operateFacilitate easy movement and positioningSpinal electrodesElectromyographyIntegrity assessmentPilot hole

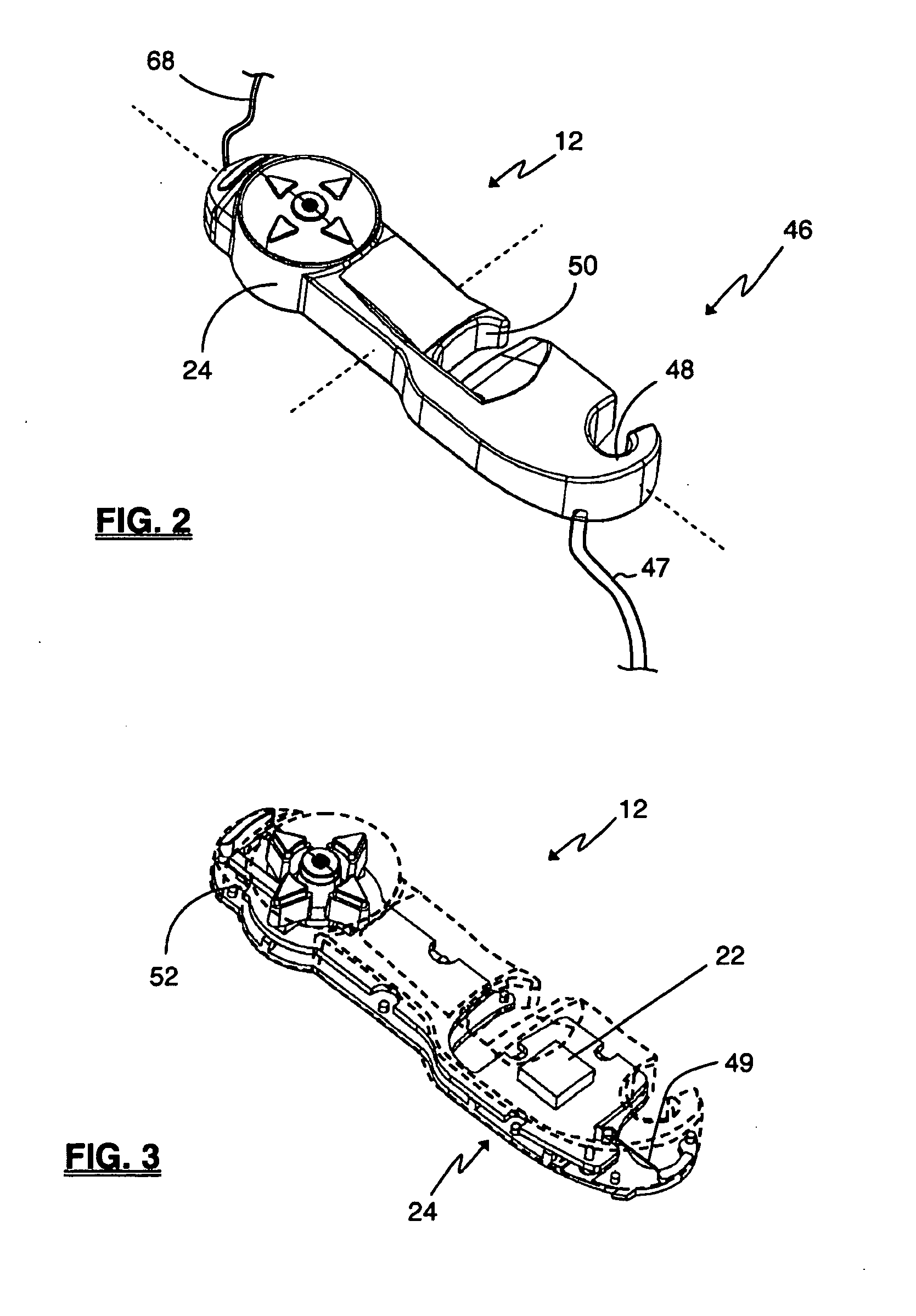

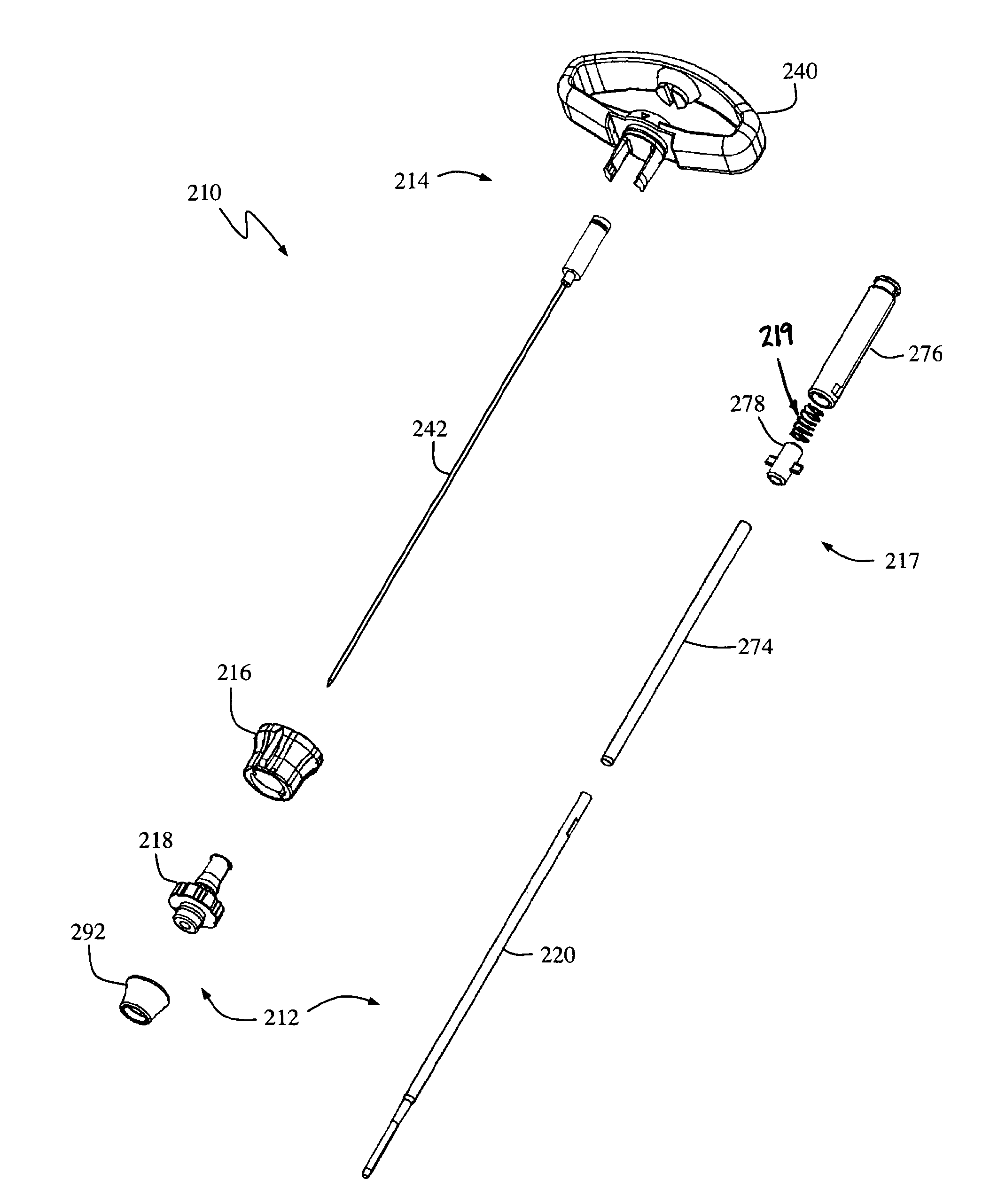

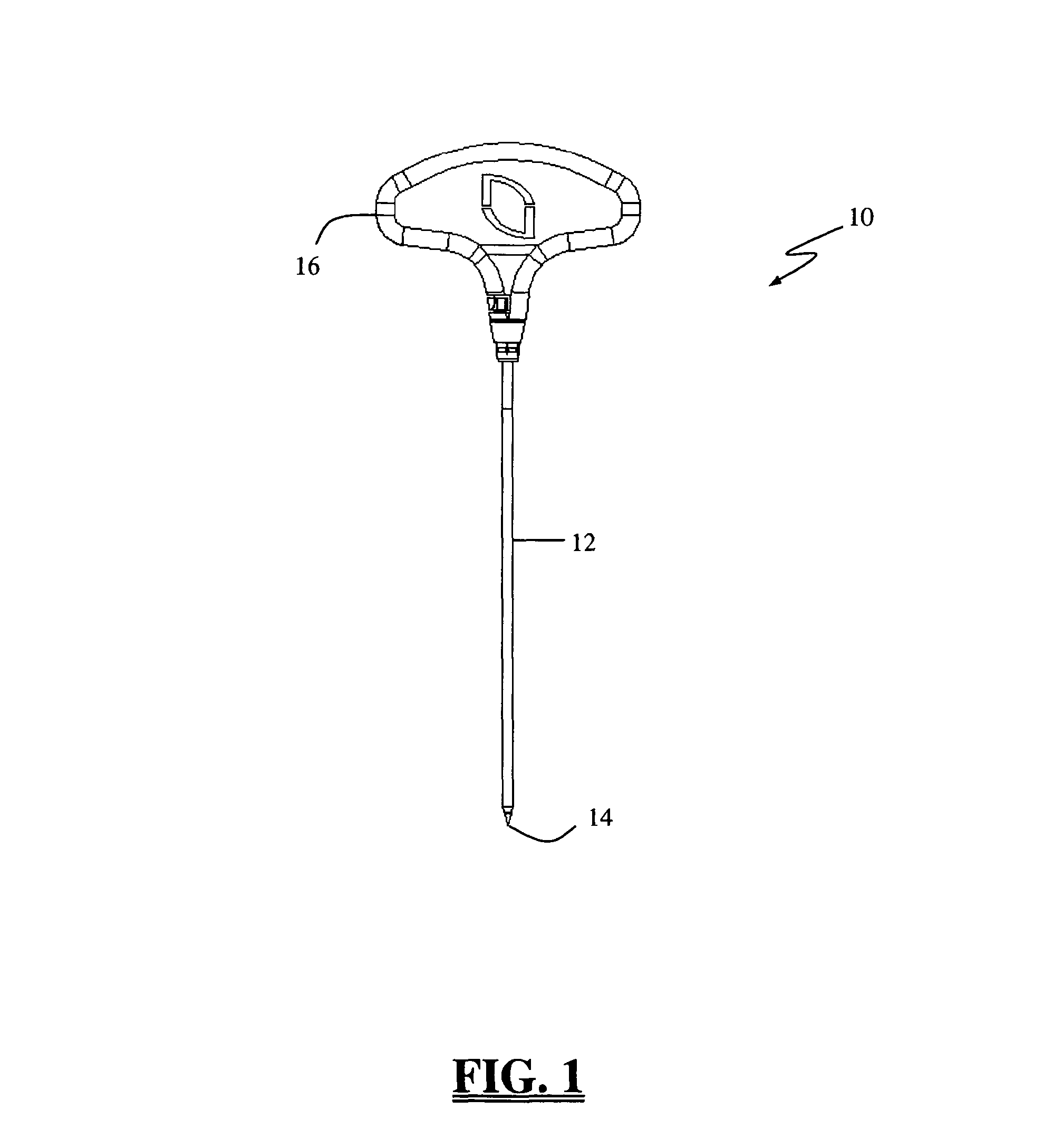

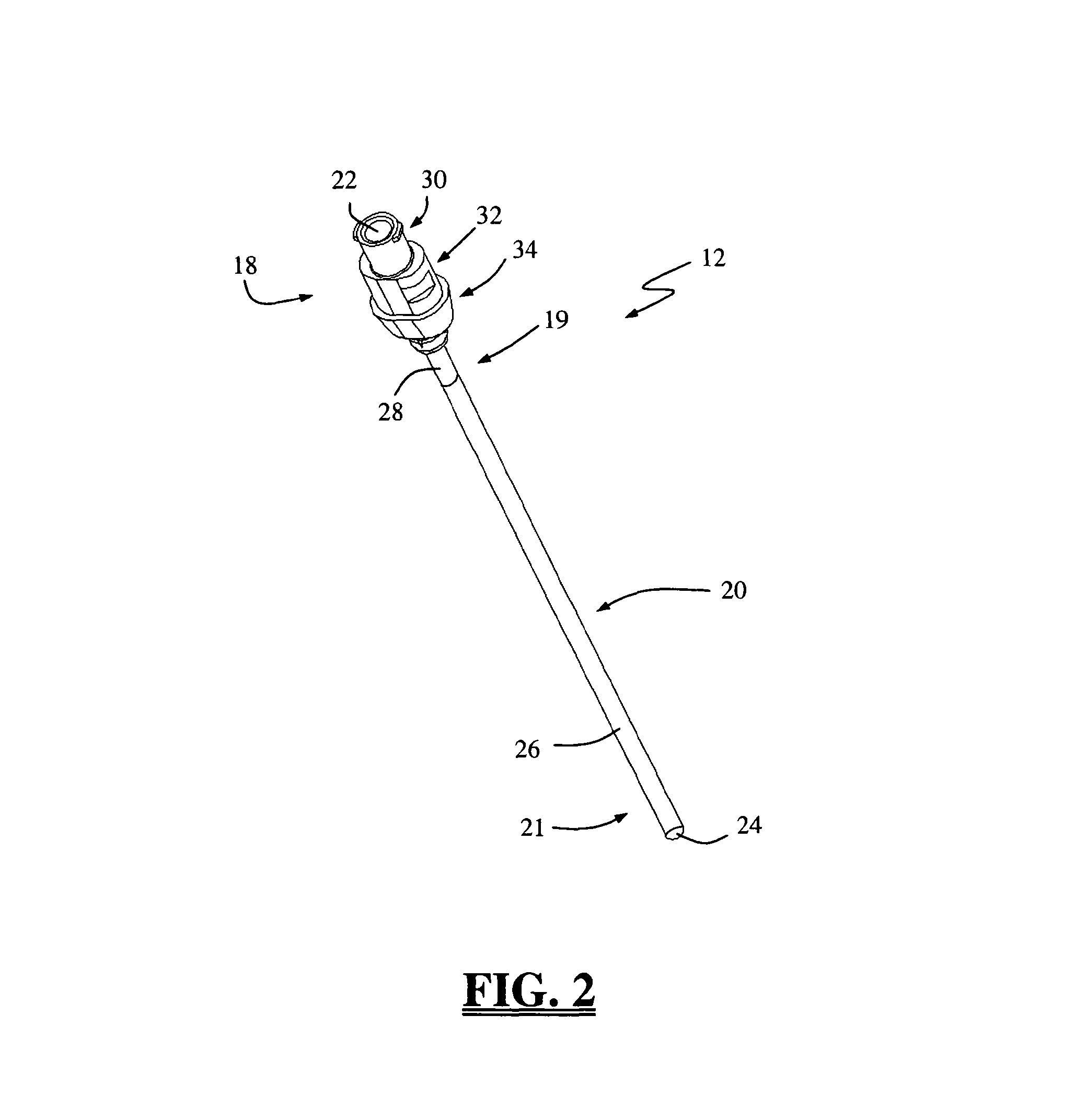

A pedicle access system including a cannula, a stylet, and a removable T-handle. The pedicle access system may be used to percutaneously approach the pedicle, initiate pilot hole formation, and conduct a stimulation signal to the target site for the purposes of performing a pedicle integrity assessment during the pilot hole formation. To do this, the cannula and stylet are locked in combination and inserted through an operating corridor to the pedicle target site, using the T-handle to facilitate easy movement and positioning of the cannula / stylet combination. A stimulation signal may be applied during pilot hole formation to conduct the pedicle integrity assessment. In a significant aspect, the T-handle may be detached from the cannula / stylet combination to facilitate the use of various surgical tools as necessary.

Owner:NUVASIVE

Monitoring trajectory of surgical instrument during the placement of a pedicle screw

ActiveUS9119572B2Facilitates safe reproducible usePrecise alignmentSpinal electrodesSurgical navigation systemsTranspedicular fixationEngineering

The present invention relates to a system and methods generally aimed at monitoring the trajectory of surgical instruments and especially for monitoring the trajectory of surgical instrument used during pedicle fixation to ensure the proper placement of pedicle screws.

Owner:NUVASIVE

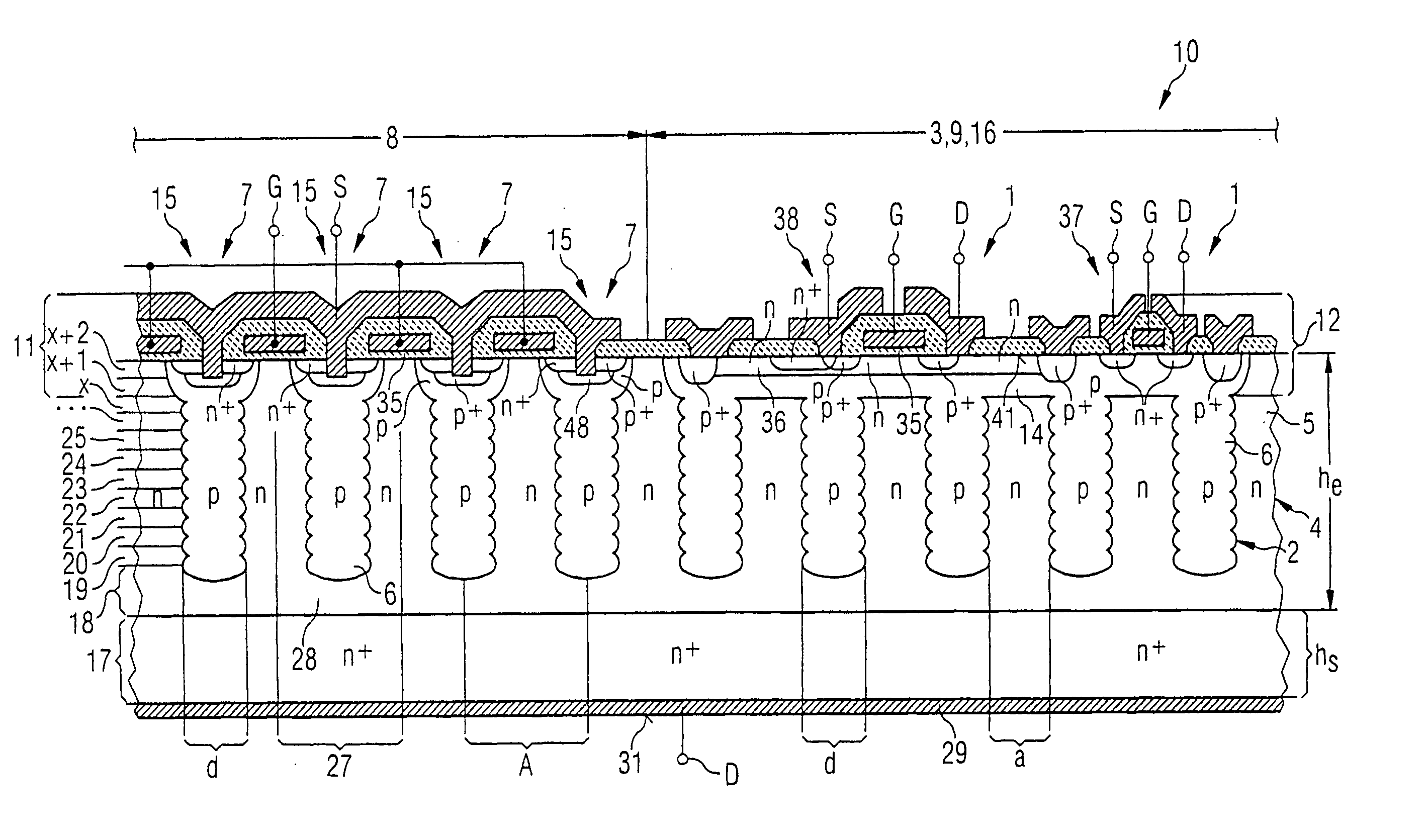

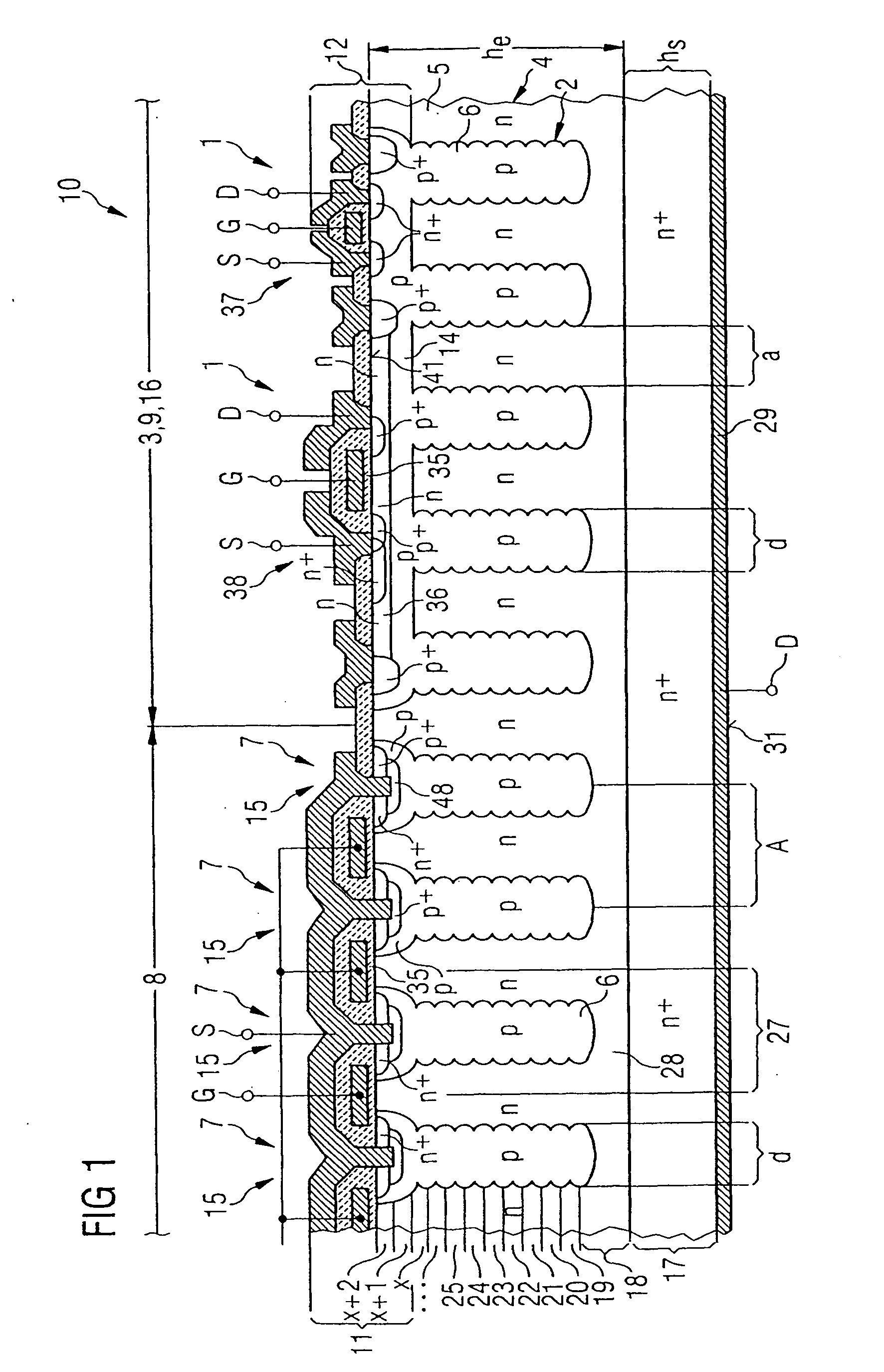

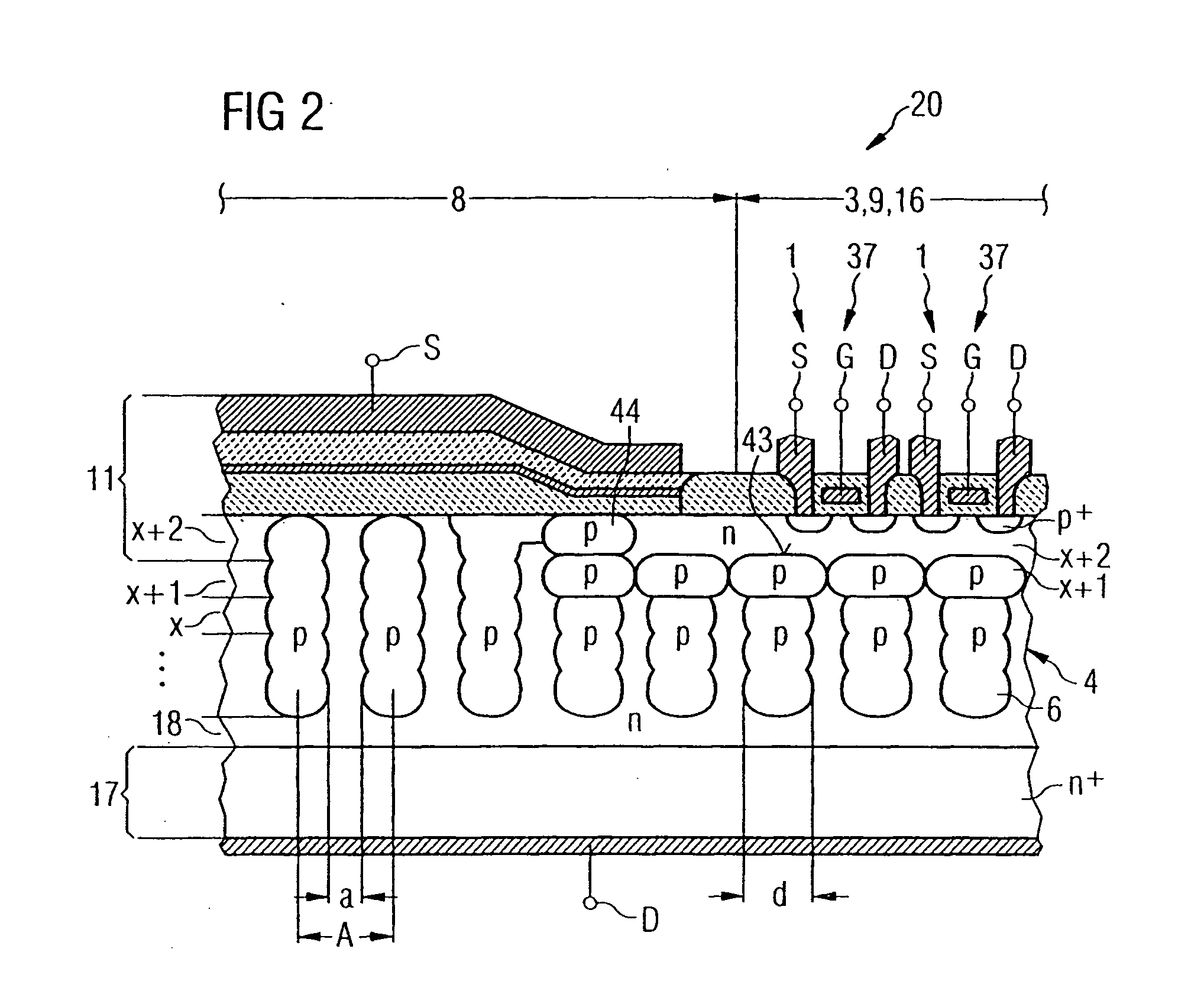

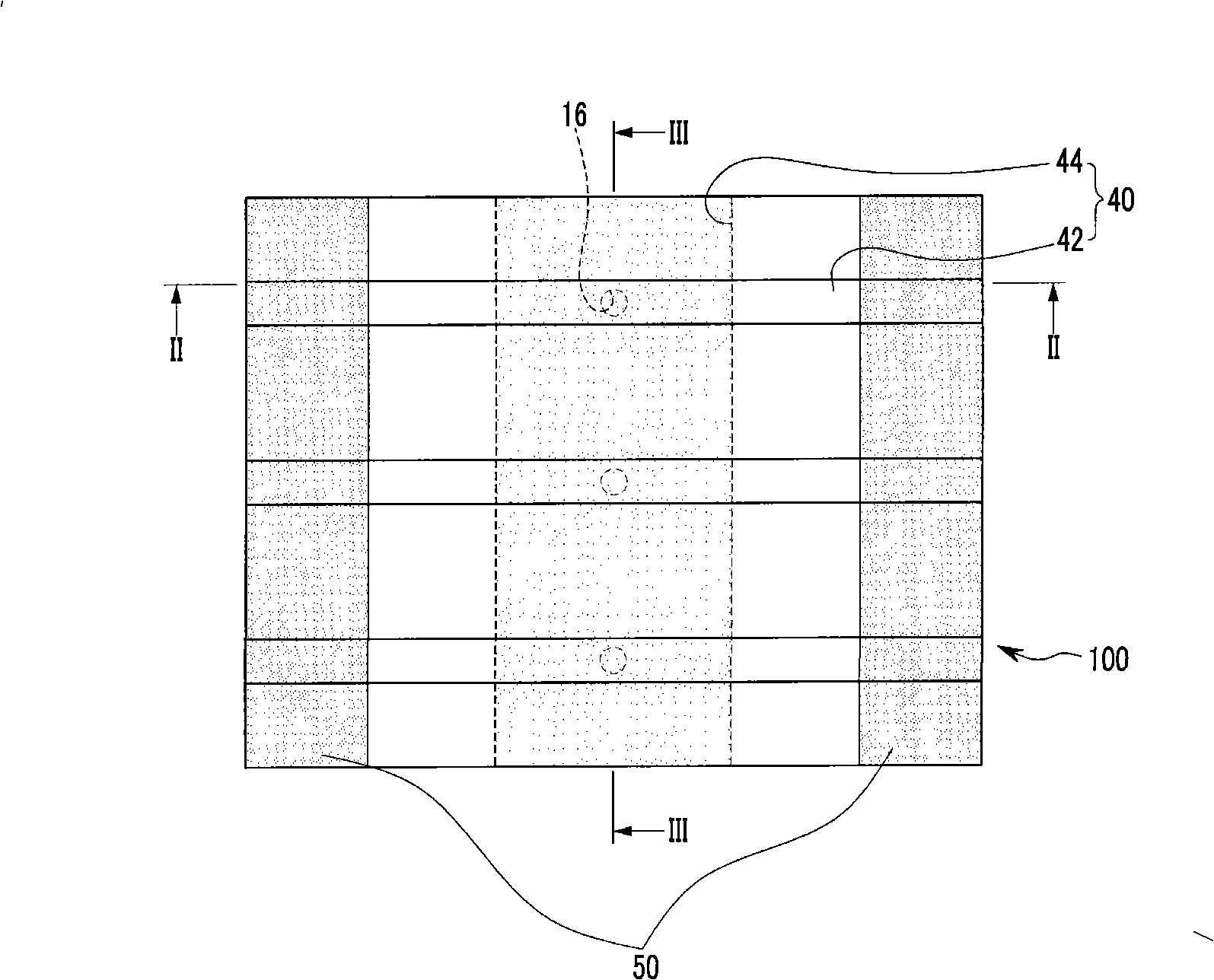

Semiconductor power device with charge compensation structure and monolithic integrated circuit, and method for fabricating it

ActiveUS20050045922A1Avoid shuntingImprove isolationTransistorSolid-state devicesSemiconductor chipEngineering

The invention relates to a semiconductor power device with charge compensation structure and monolithic integrated circuit, and method for fabricating it. In the case of this semiconductor power device, zones (6) in charge compensation cells (27) that are arranged vertically and doped complementarily to the semiconductor chip volume (5) are arranged in the entire chip volume, the complementarily doped zones (6) extending right into surface regions (11) of the semiconductor power elements (7) and not projecting into surface regions (12) of semiconductor surface elements (1).

Owner:INFINEON TECH AG

Insulated pedicle access system and related methods

ActiveUS8784330B1Easy to operateFacilitate easy movement and positioningSpinal electrodesInternal osteosythesisIntegrity assessmentPilot hole

A pedicle access system including a cannula, a stylet, and a removable T-handle. The pedicle access system may be used to percutaneously approach the pedicle, initiate pilot hole formation, and conduct a stimulation signal to the target site for the purposes of performing a pedicle integrity assessment during the pilot hole formation. To do this, the cannula and stylet are locked in combination and inserted through an operating corridor to the pedicle target site, using the T-handle to facilitate easy movement and positioning of the cannula / stylet combination. A stimulation signal may be applied during pilot hole formation to conduct the pedicle integrity assessment. In a significant aspect, the T-handle may be detached from the cannula / stylet combination to facilitate the use of various surgical tools as necessary.

Owner:NUVASIVE

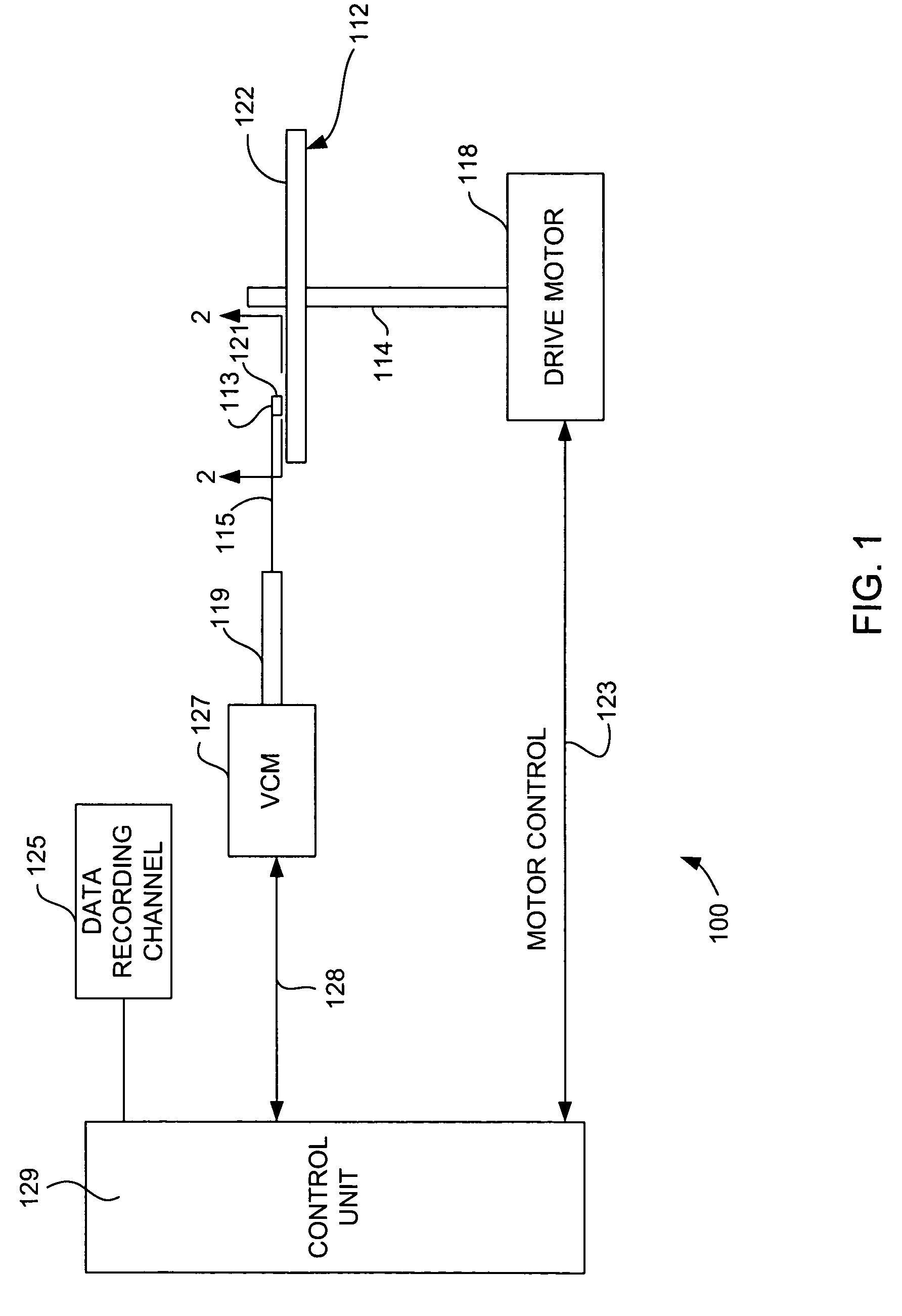

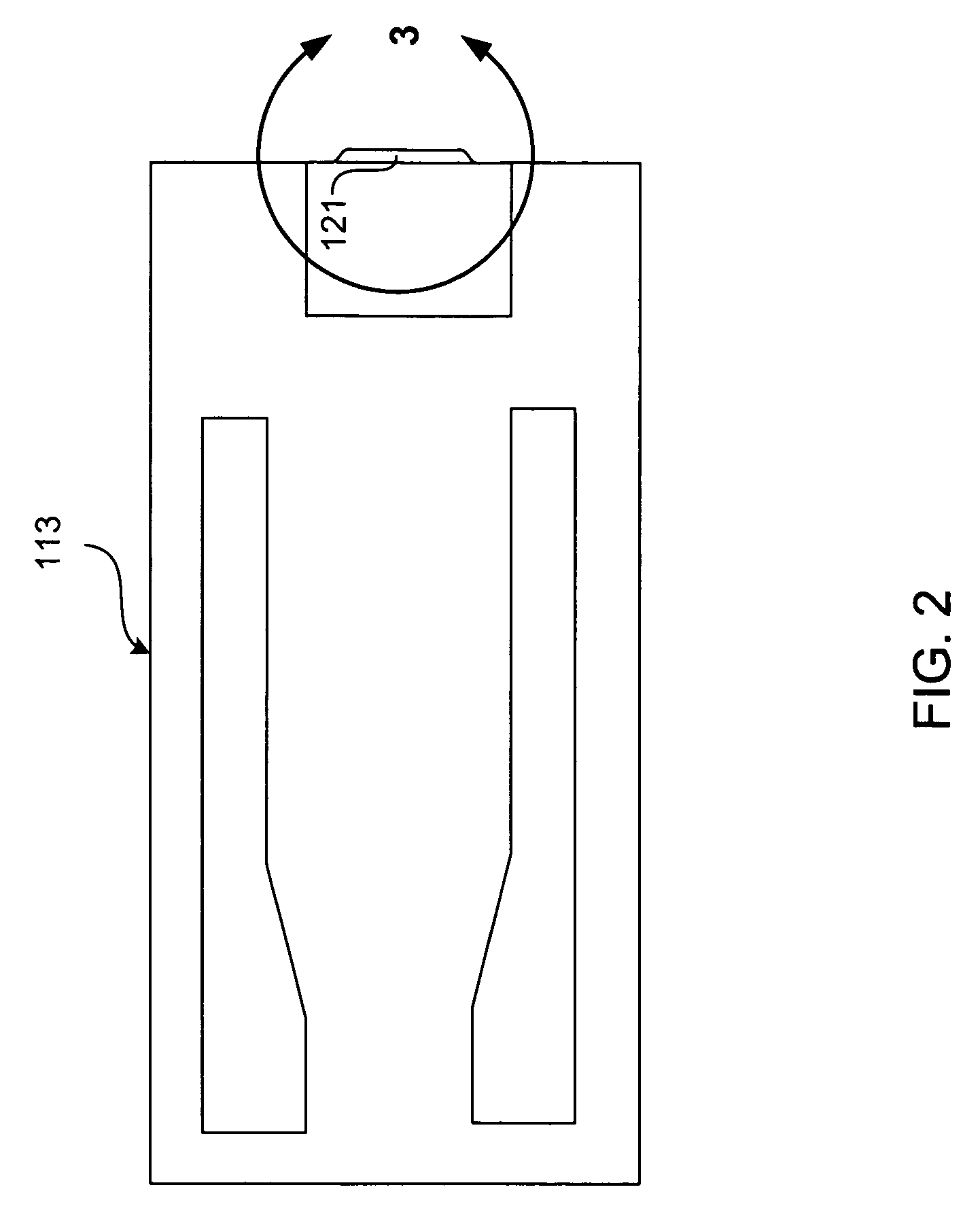

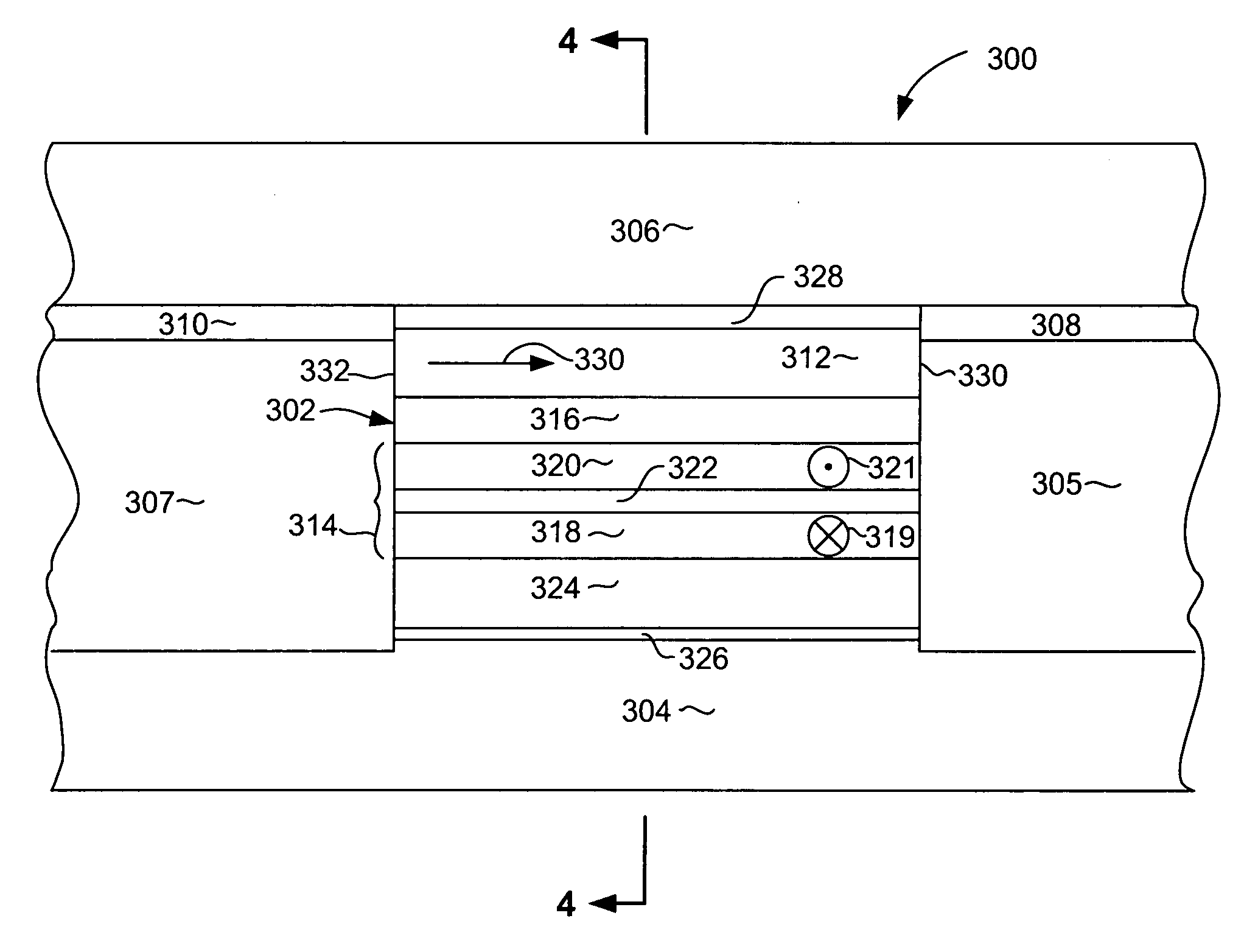

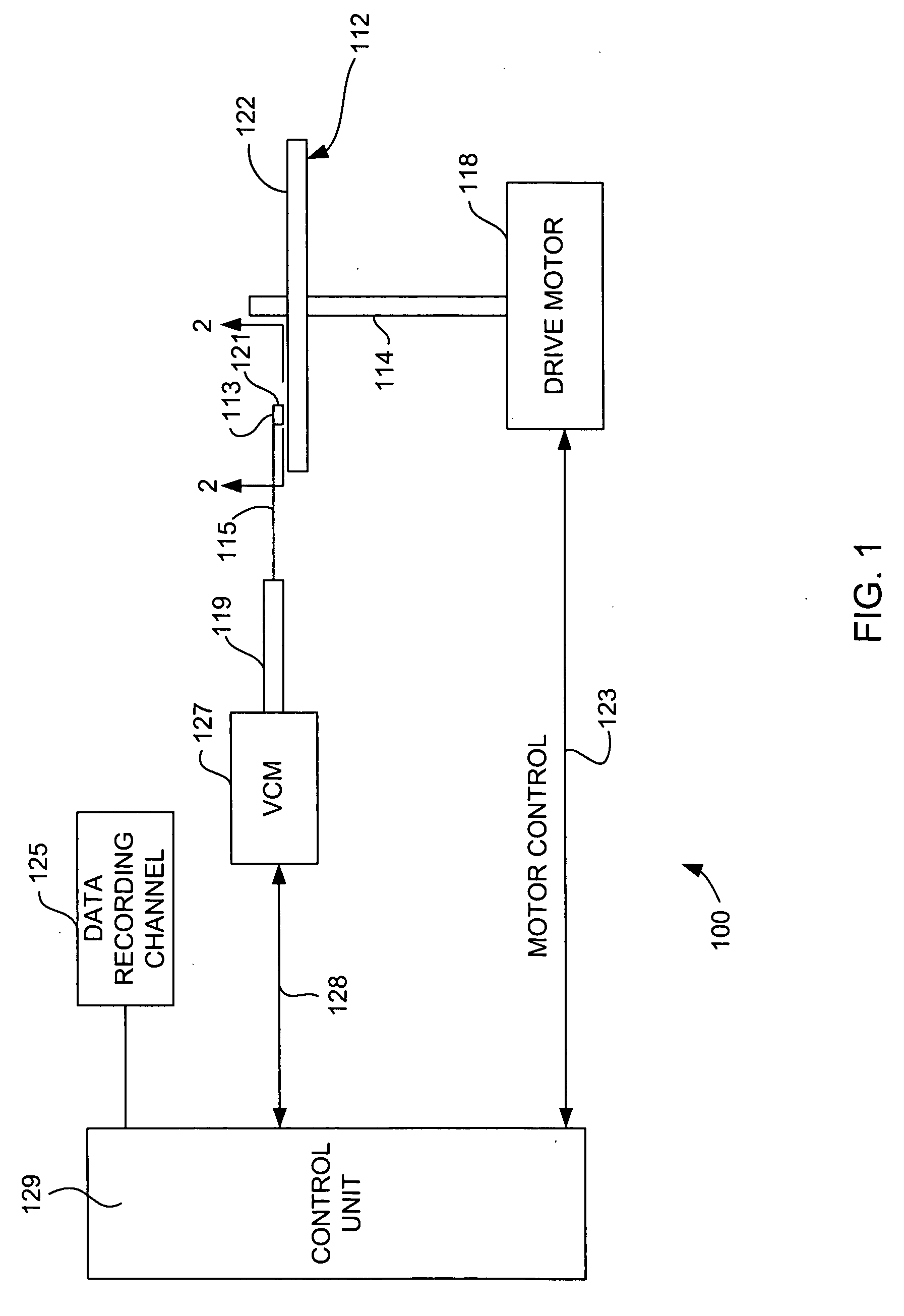

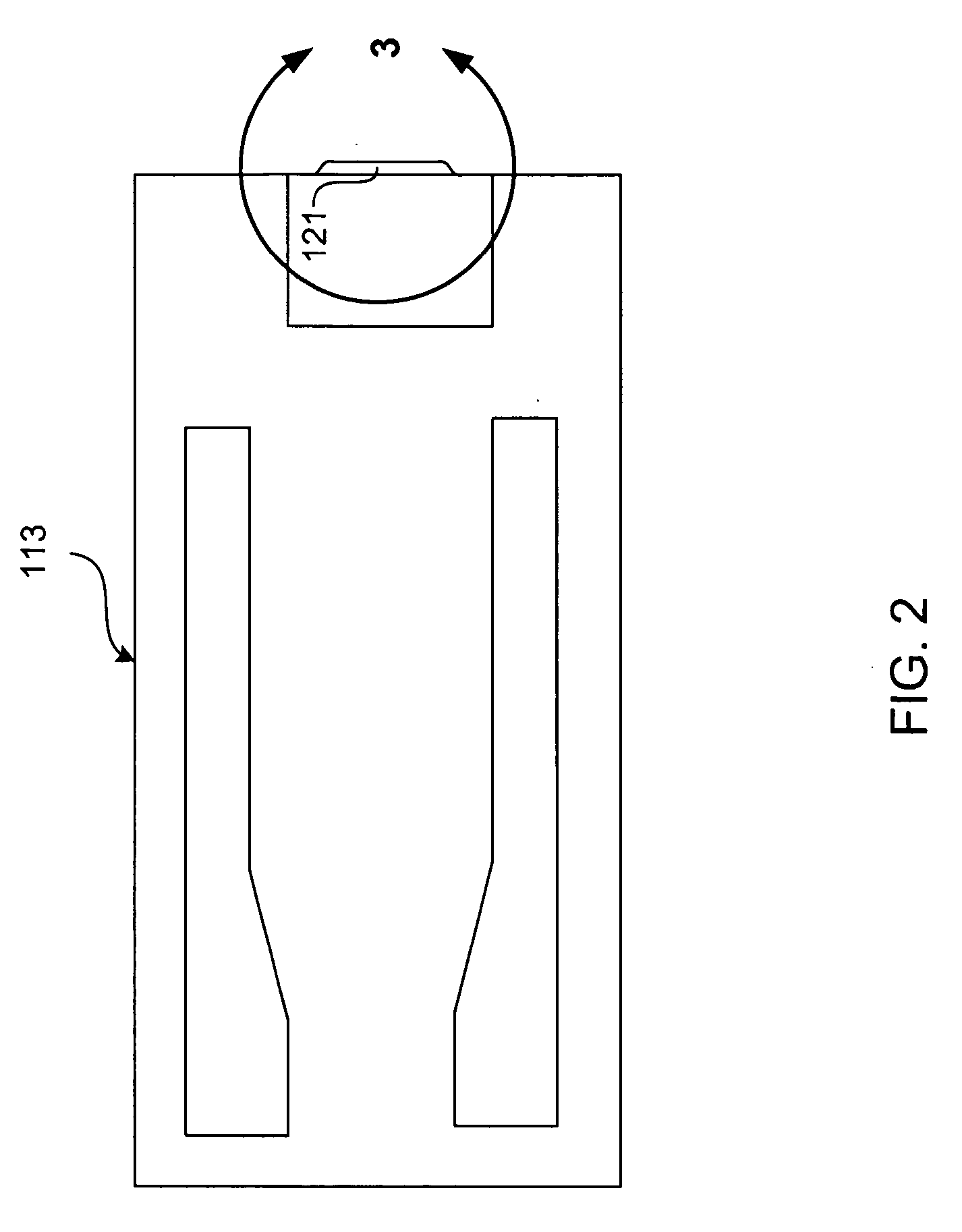

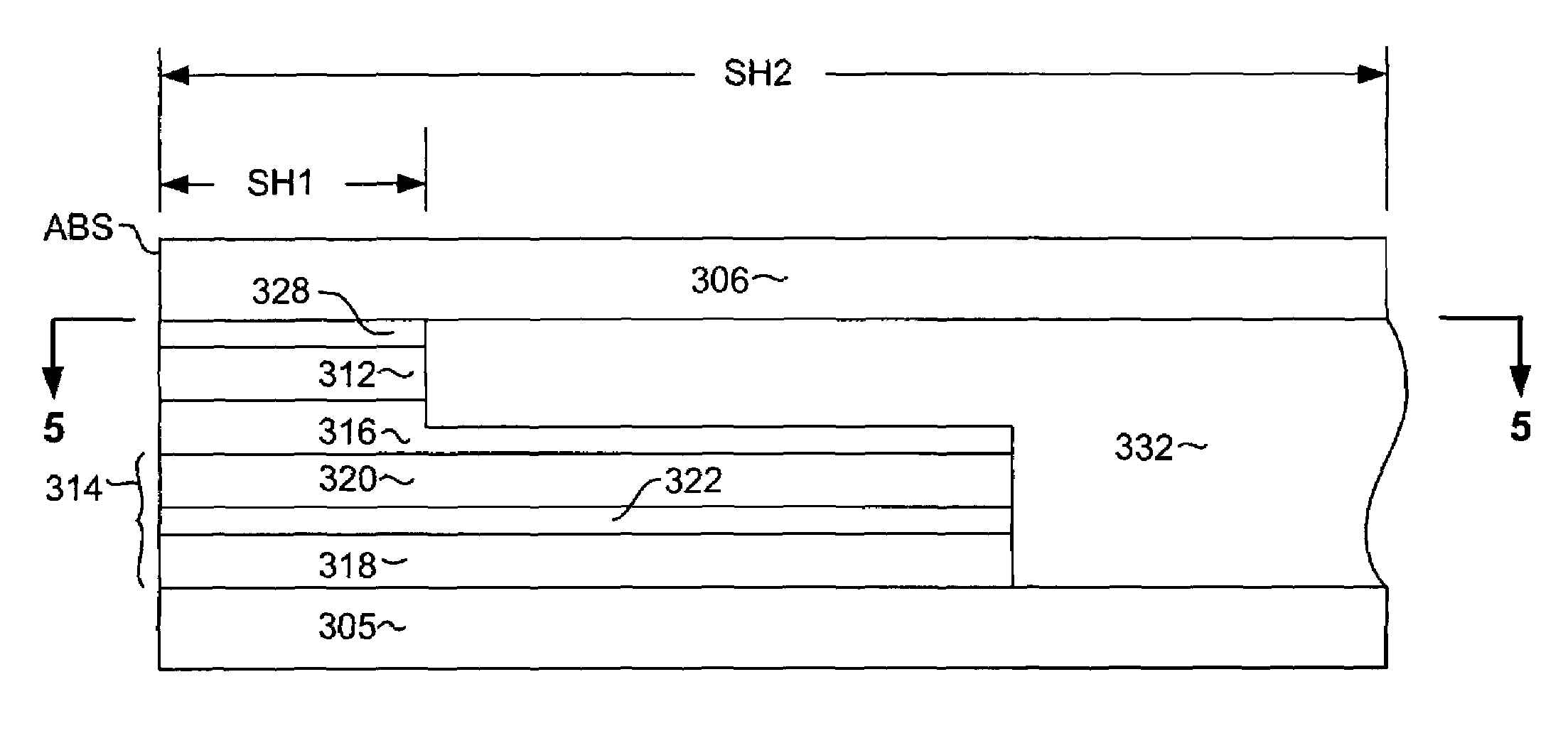

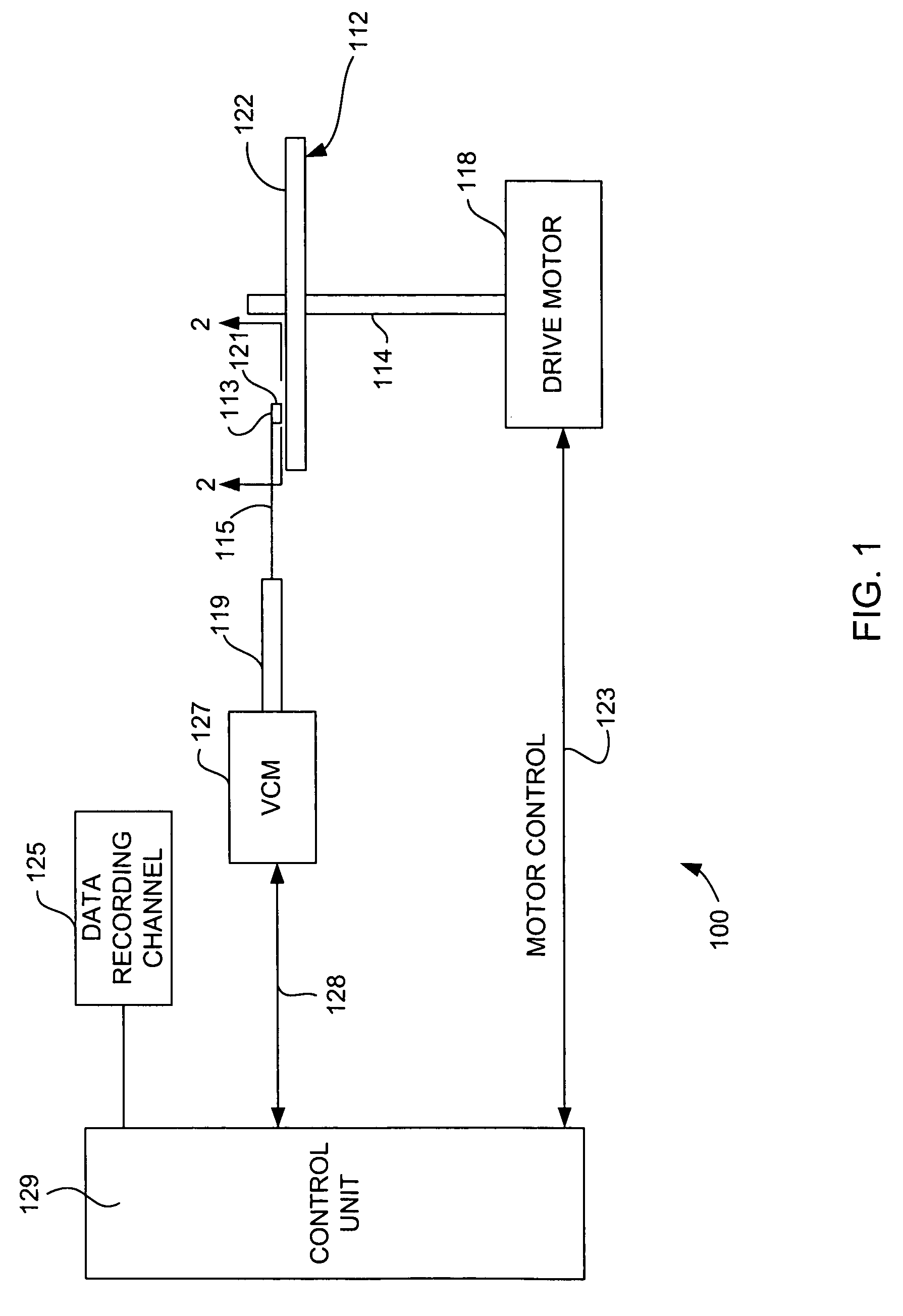

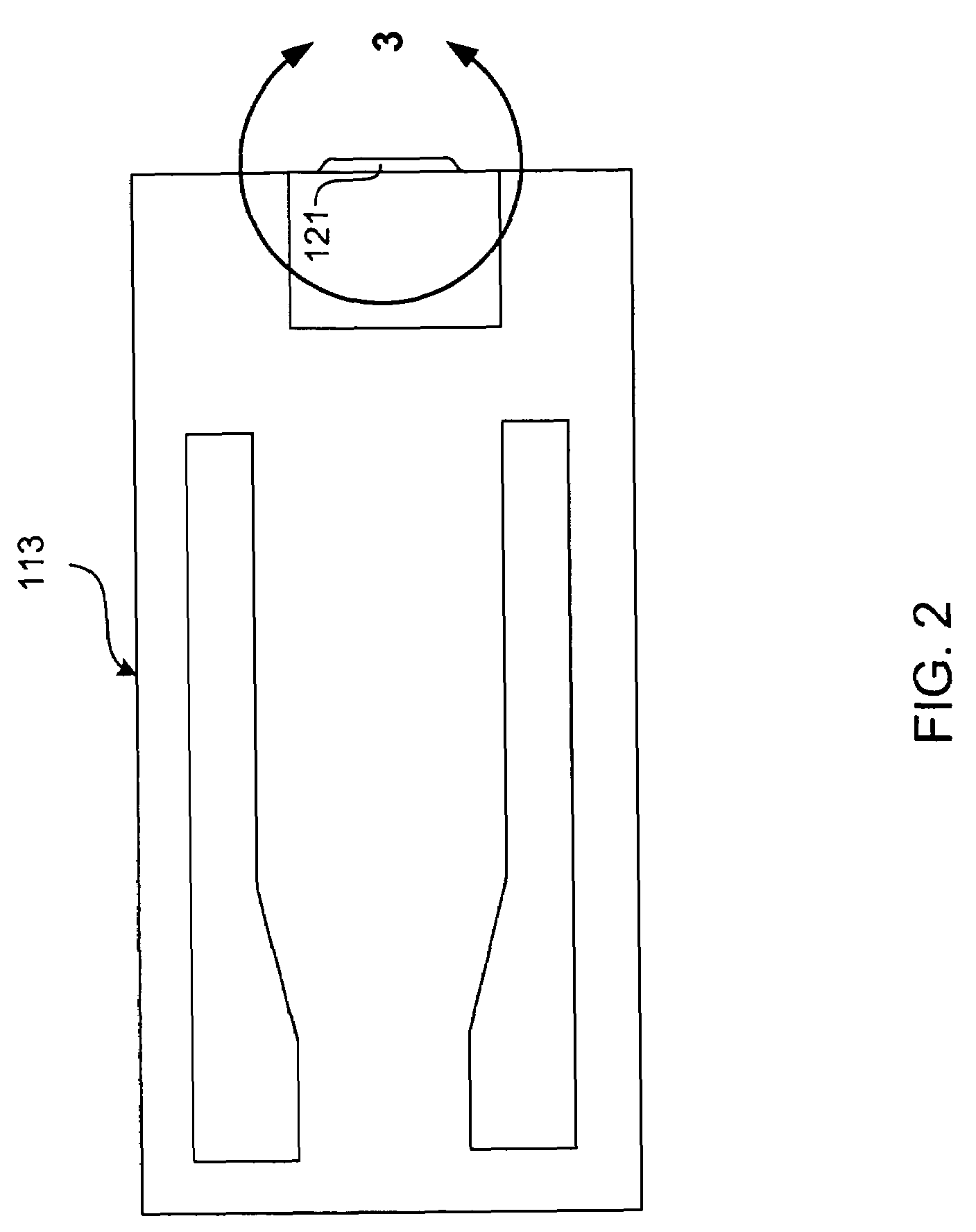

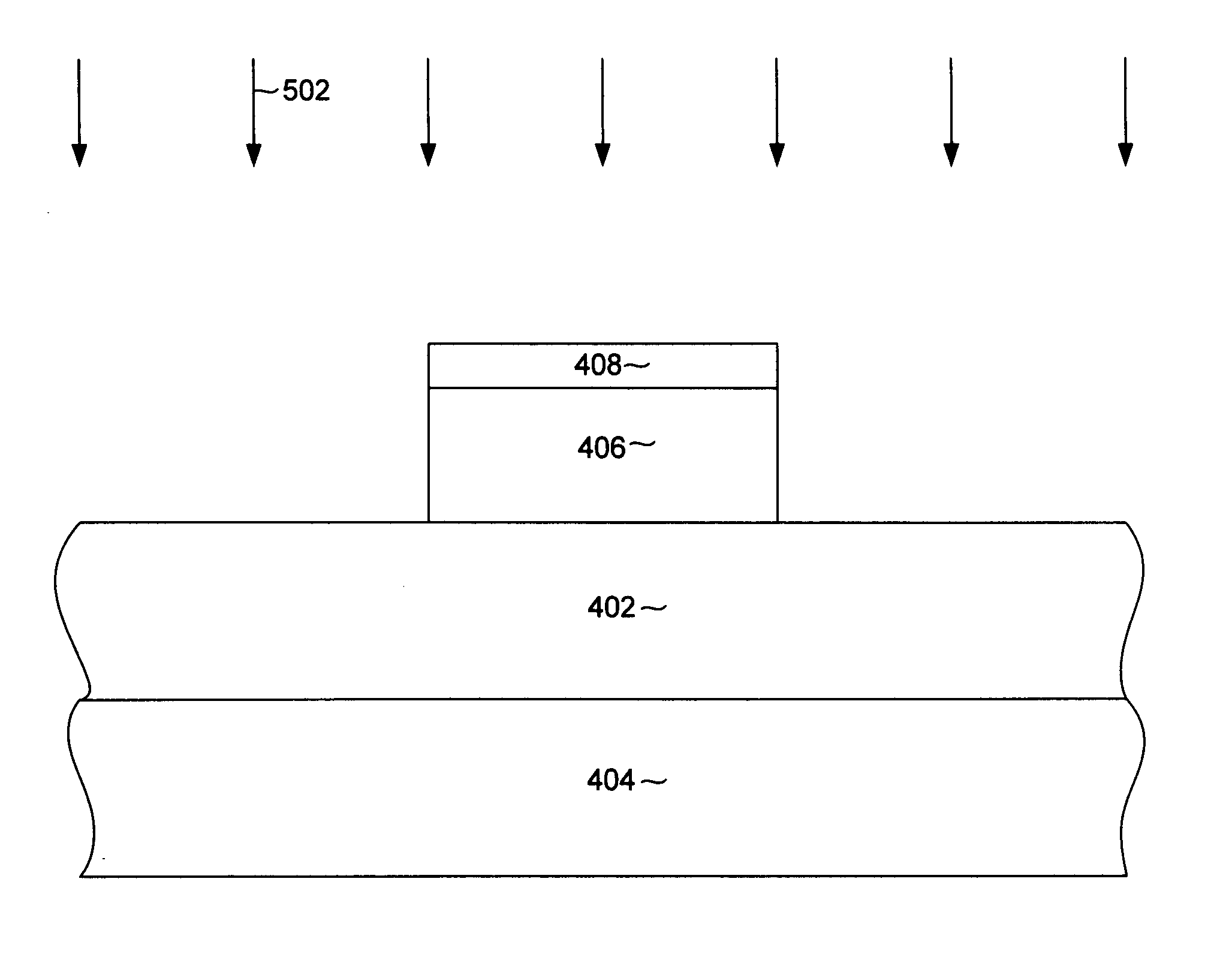

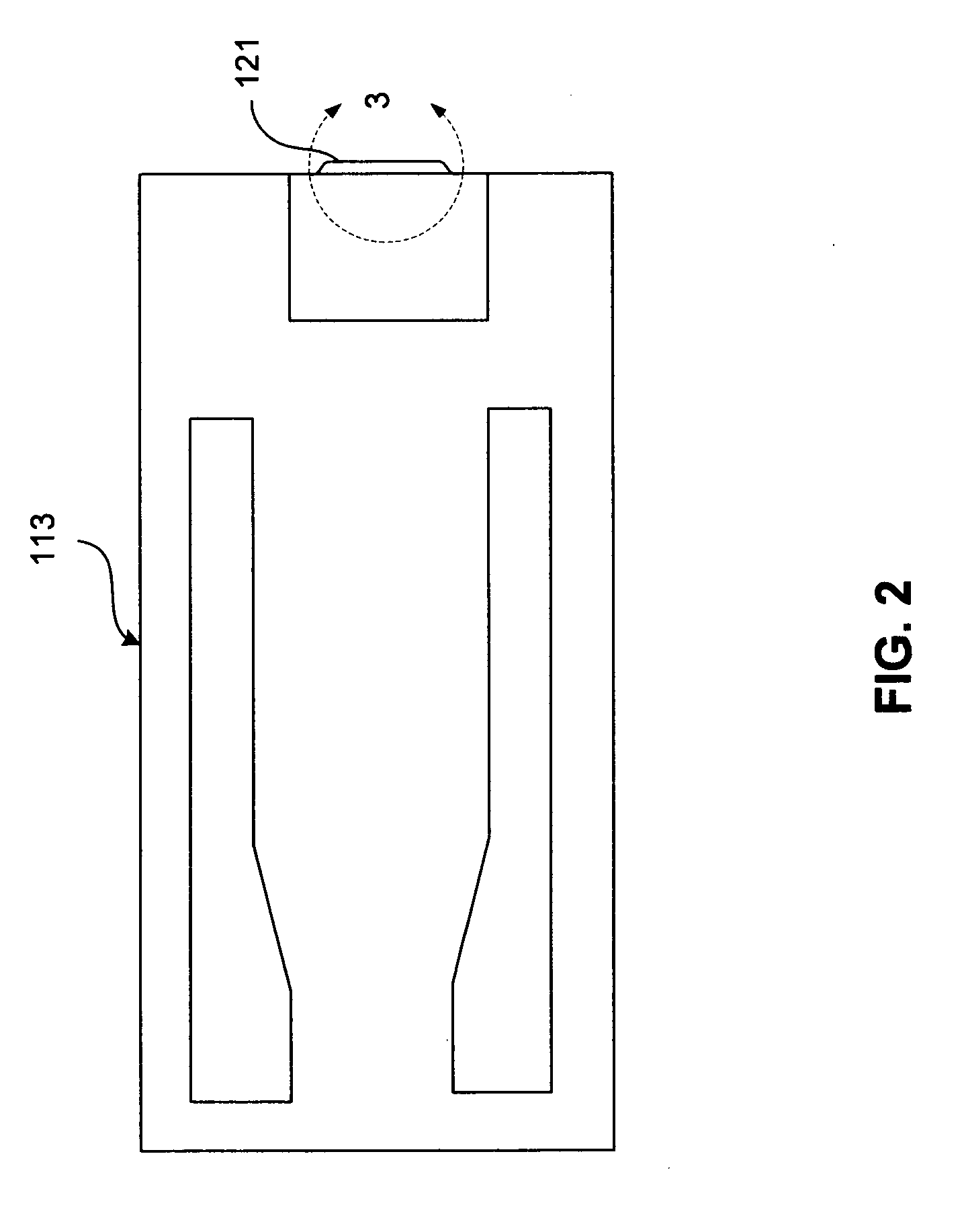

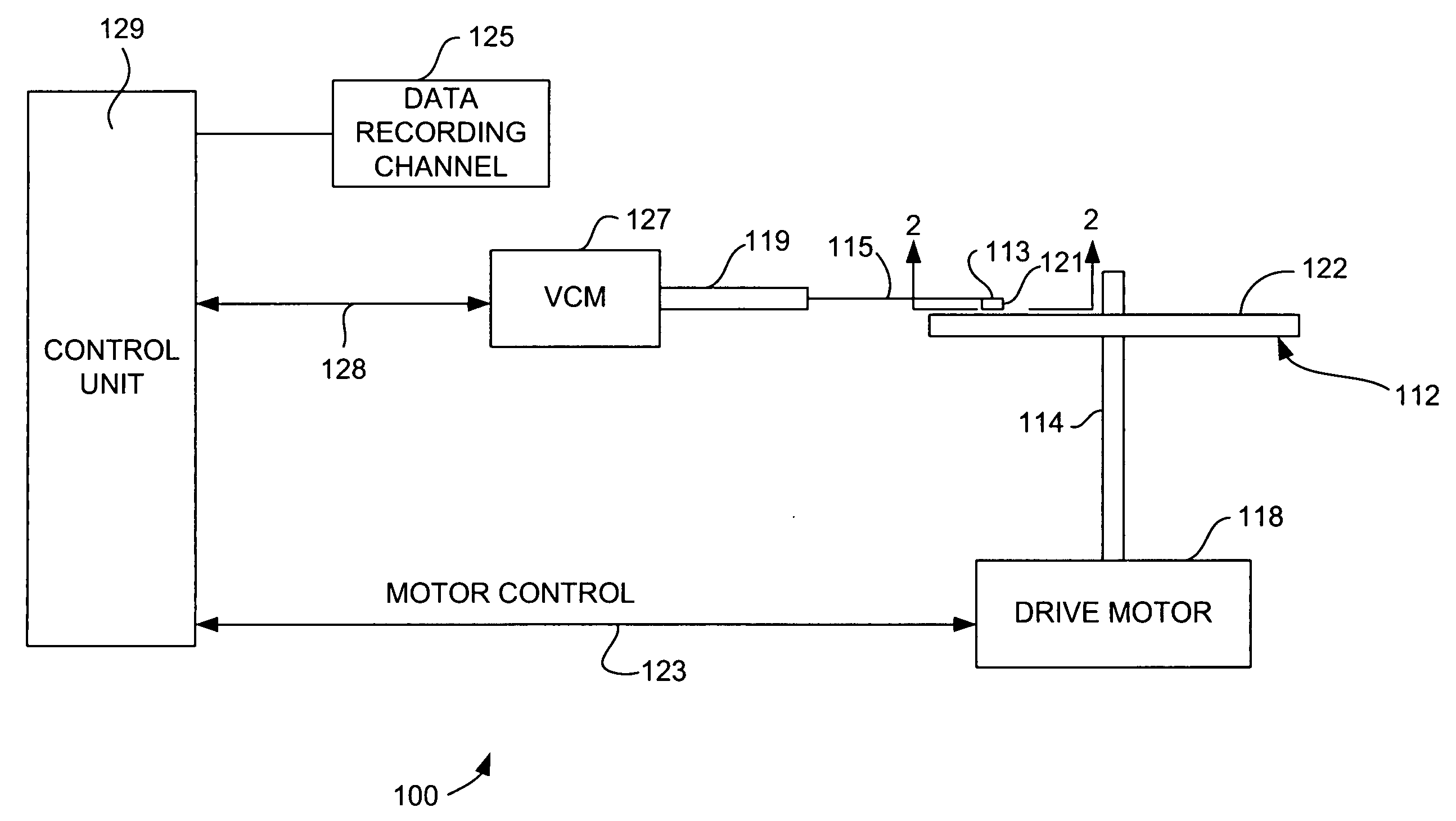

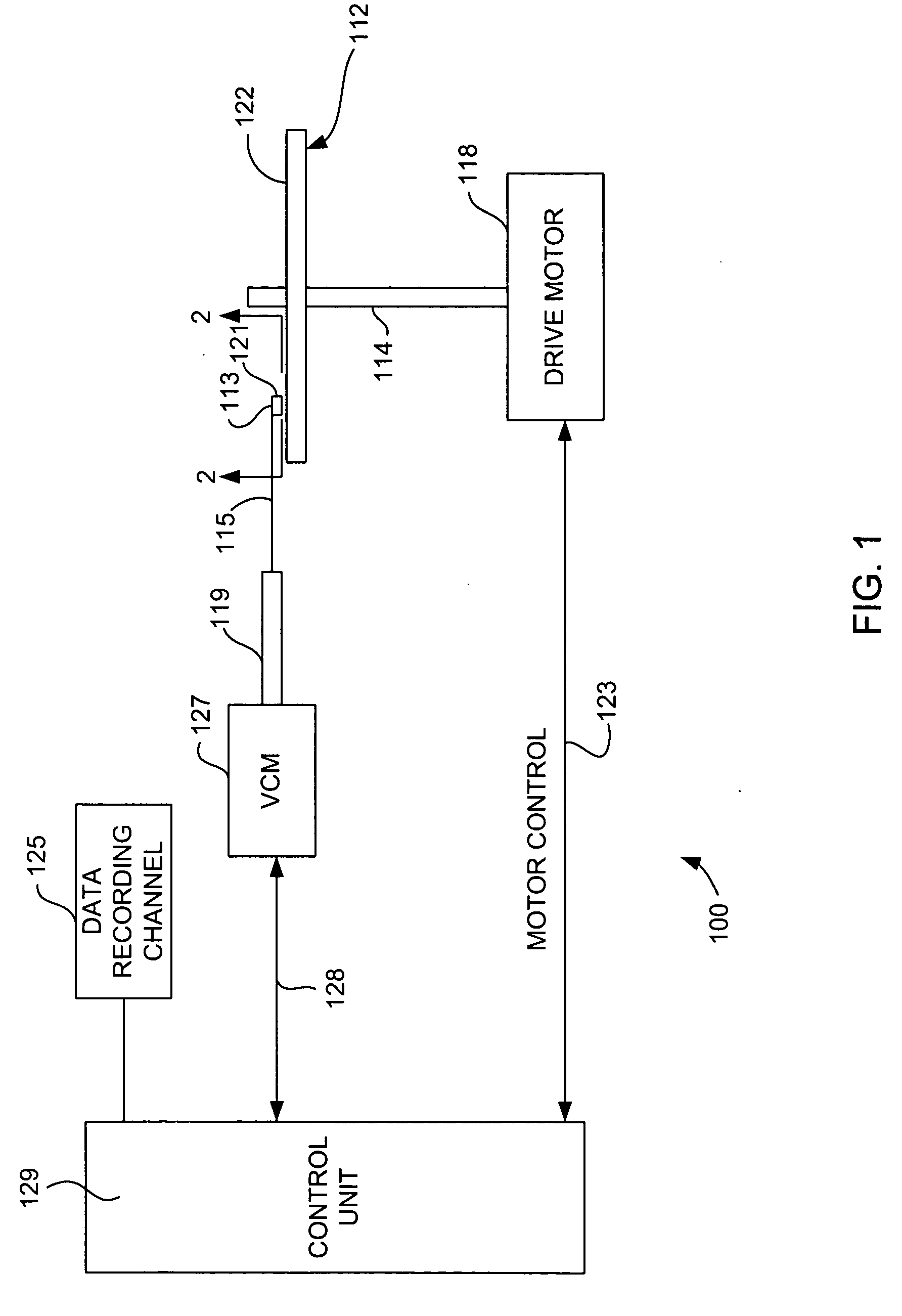

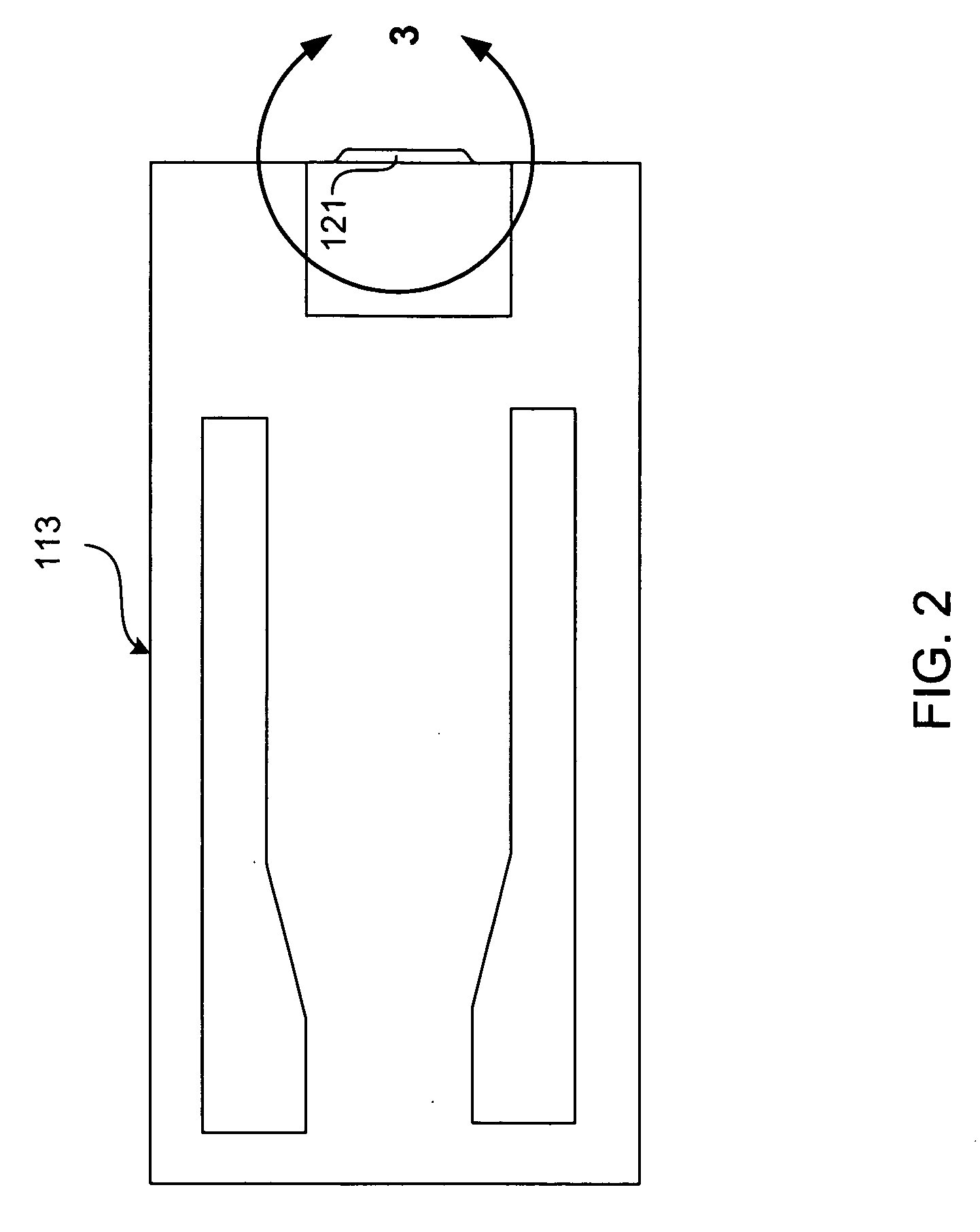

Magnetoresistive sensor having a shape enhanced pinned layer

InactiveUS7369371B2Good body shapeAvoid shuntingNanomagnetismMagnetic measurementsEngineeringInduced anisotropy

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

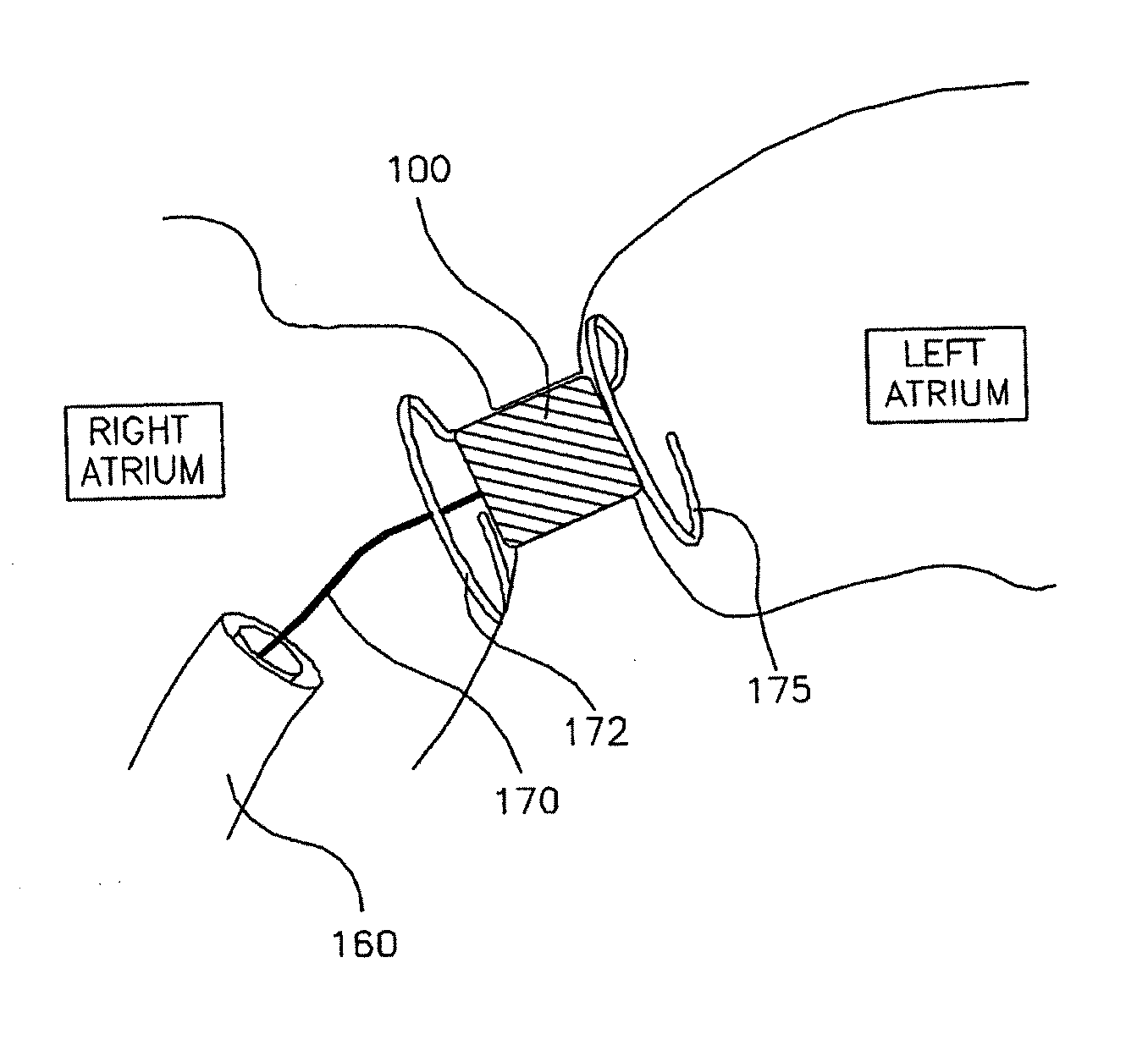

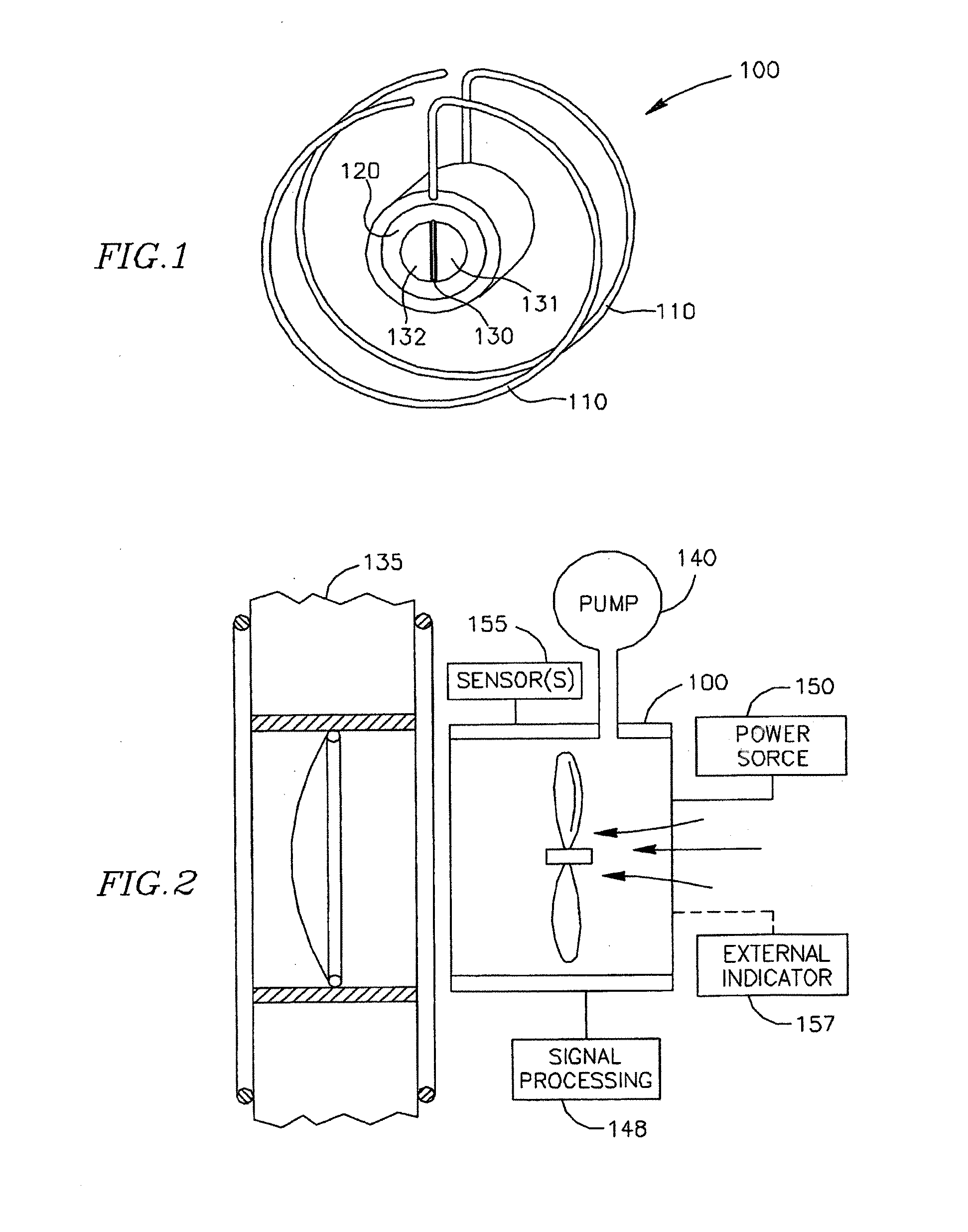

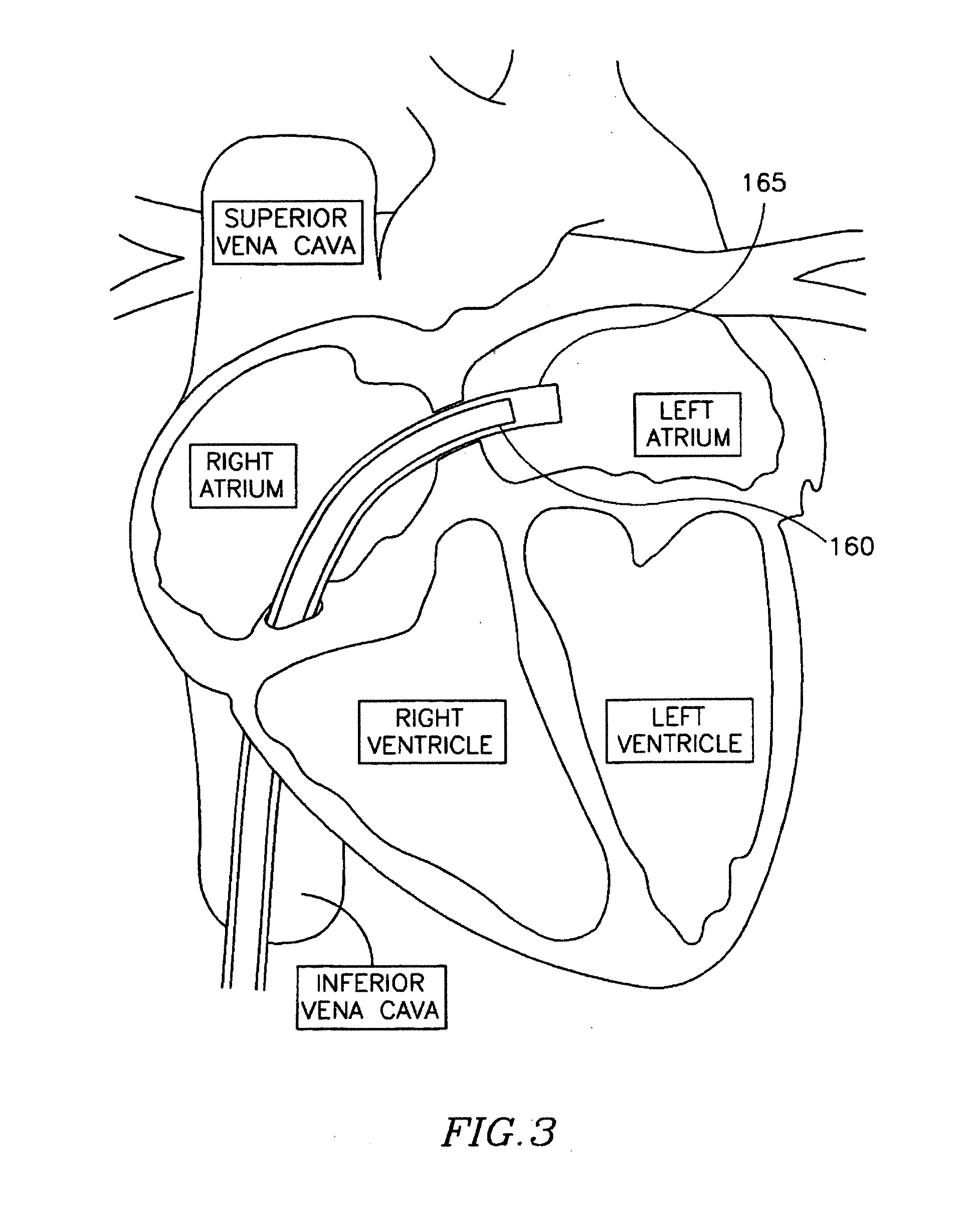

Methods and apparatus for reducing localized circulatory system pressure

InactiveUS20110218477A1Reduces increased diastolic pressurePreventing further deteriorationHeart valvesWound drainsSystoleElectrical battery

The present invention is thus directed to methods and apparatus for decreasing pressure in a first portion of a vessel of the cardiac structure of a patient by implanting a shunt communicating with an area outside said first portion, whereby a volume of blood sufficient to reduce pressure in said first portion is released. Preferably, the first portion comprises the left ventricle and the pressure reduced is the end diastolic pressure, which is accomplished by having the shunt communicate with the left ventricle so a small volume of blood is released from the left ventricle to reduce the end diastolic pressure. Most preferably, the shunt selectively permits flow when a pressure differential between the left ventricle and another chamber of a heart above a threshold pressure, whereby shunting is prevented during left ventricular systole, or, alternatively, selectively permits flow when a pressure differential between the left ventricle and another chamber of a heart is between a lower threshold and a higher threshold, whereby shunting is again prevented during left ventricular systole. In certain embodiments a semi-passive check-valve is controlled and actuated by an external signal, either using a signal generated by an intra-corporeal electrical battery or an externally coupled energy source. In certain embodiments, the shunt has a pump with an input connected to the left ventricle, or other portion with excessive pressure, and an output connected to a volume of lower pressure. The preferred method of implanting the shunt to effect the present invention is by deploying a tubular element having two ends and a tissue affixation element disposed at each of said ends via a catheter, preferably, the fixation element is a shape retaining metallic material that returns to its original shape as part of the retention aspect of its function. In preferred embodiments of the apparatus, the tubular element is comprised of a biologically inert non-metallic material.

Owner:WAVE LTD V

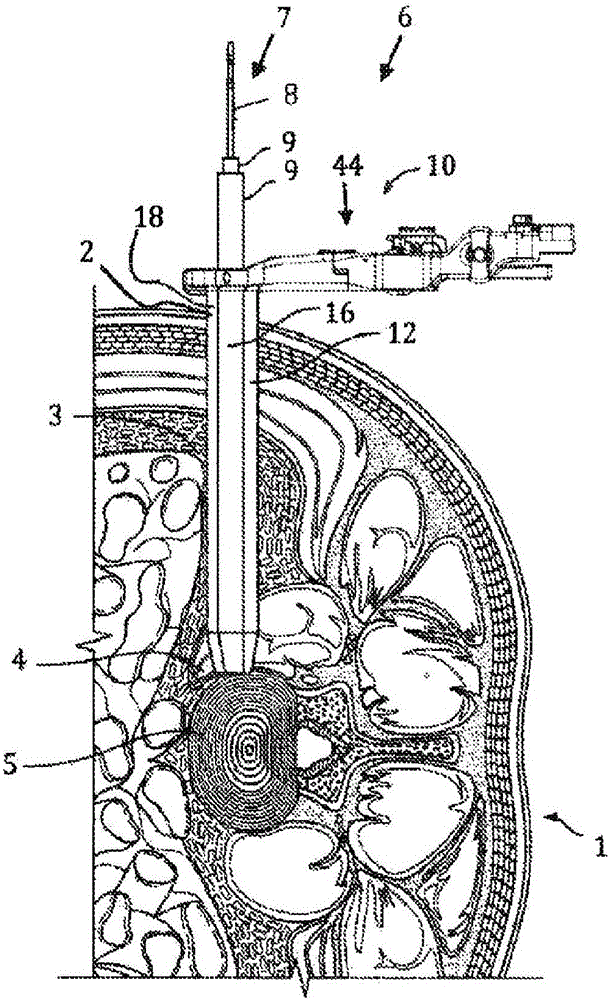

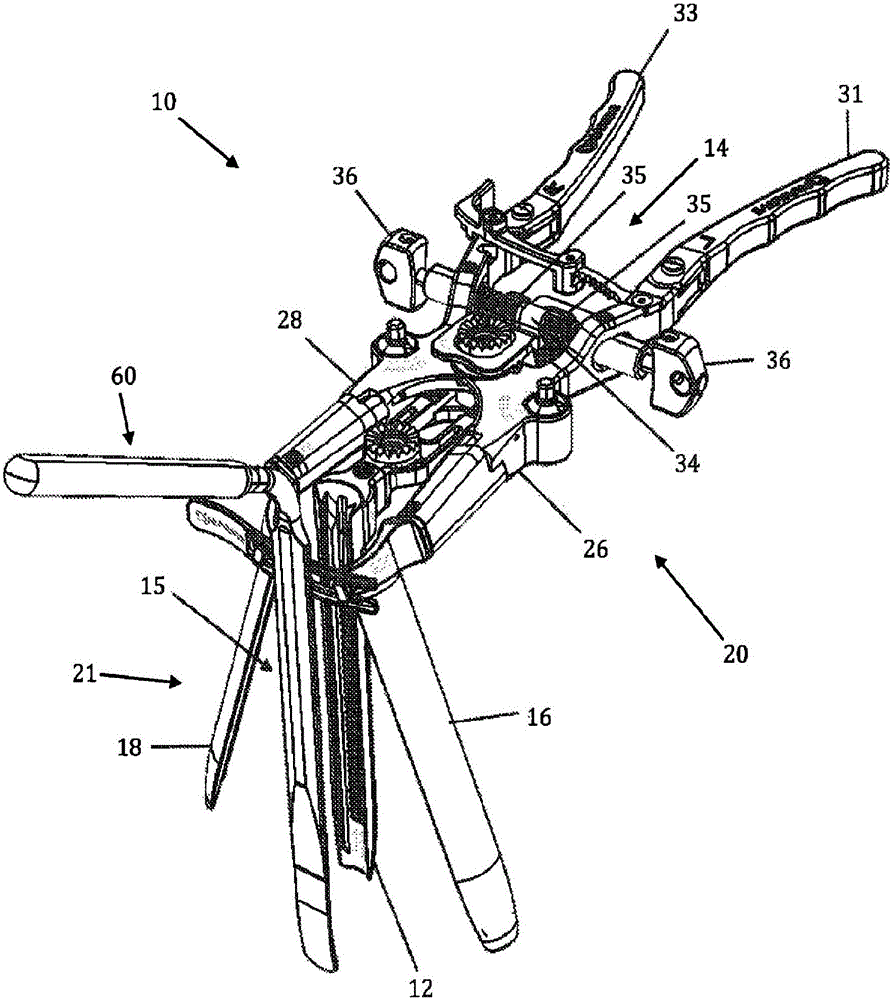

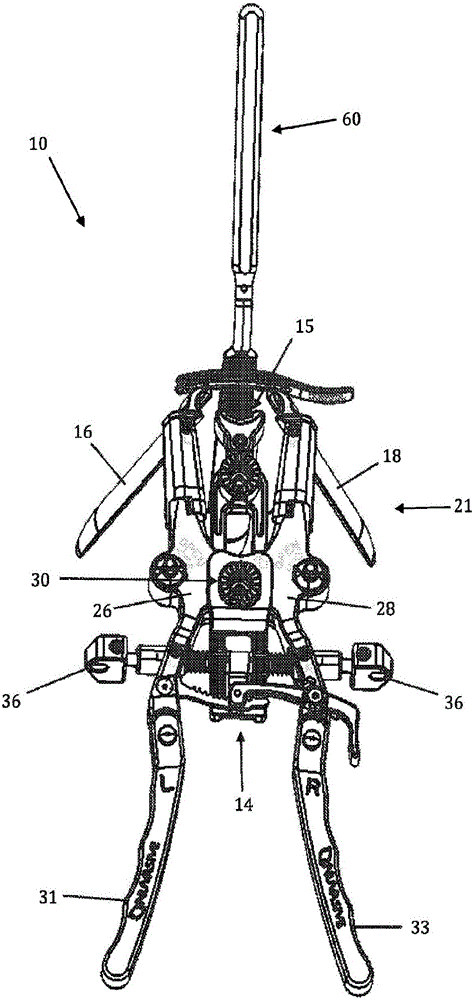

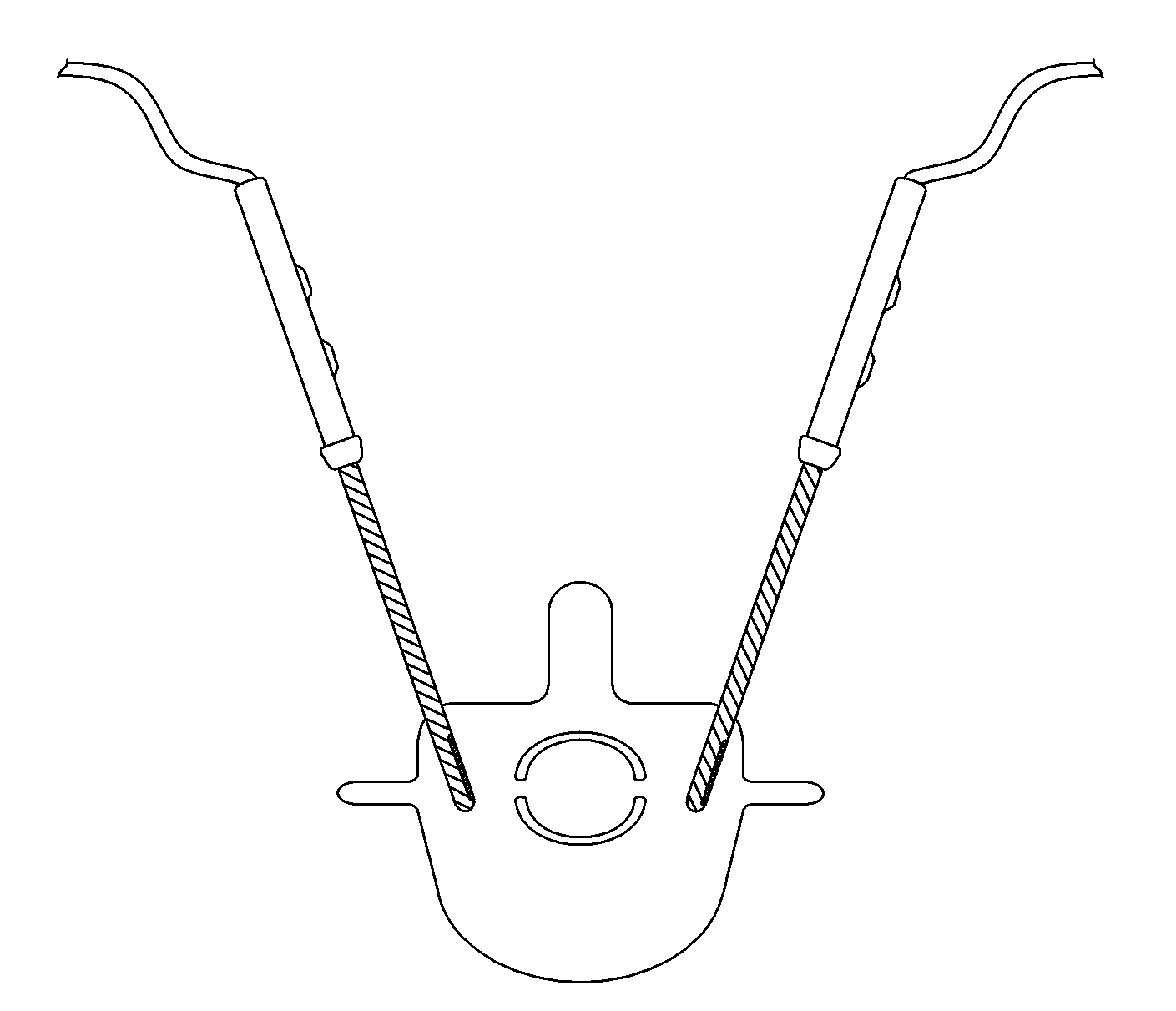

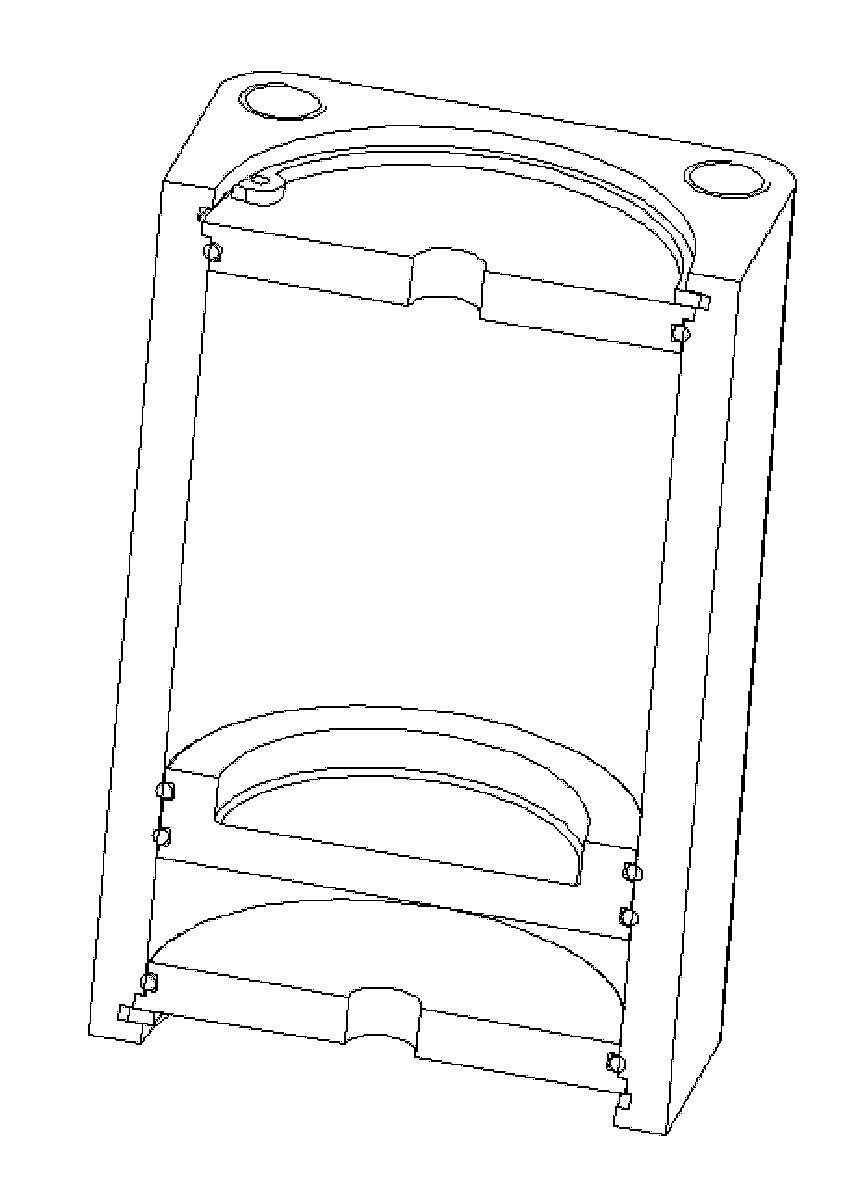

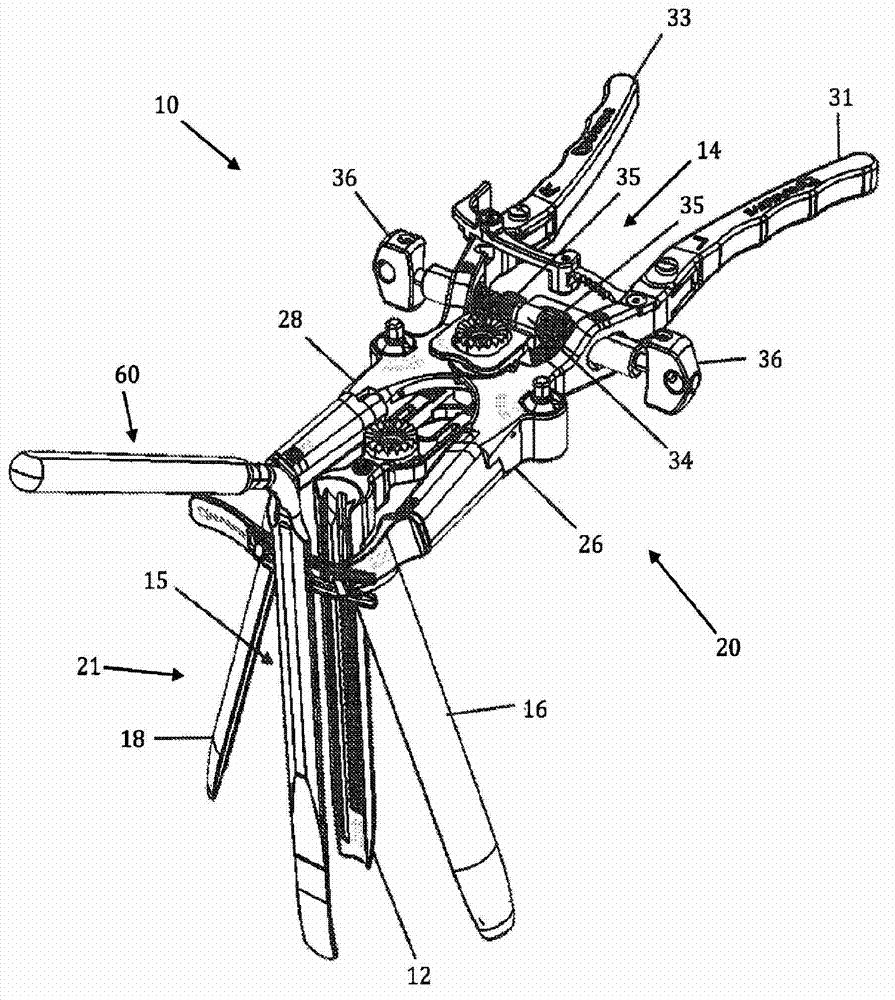

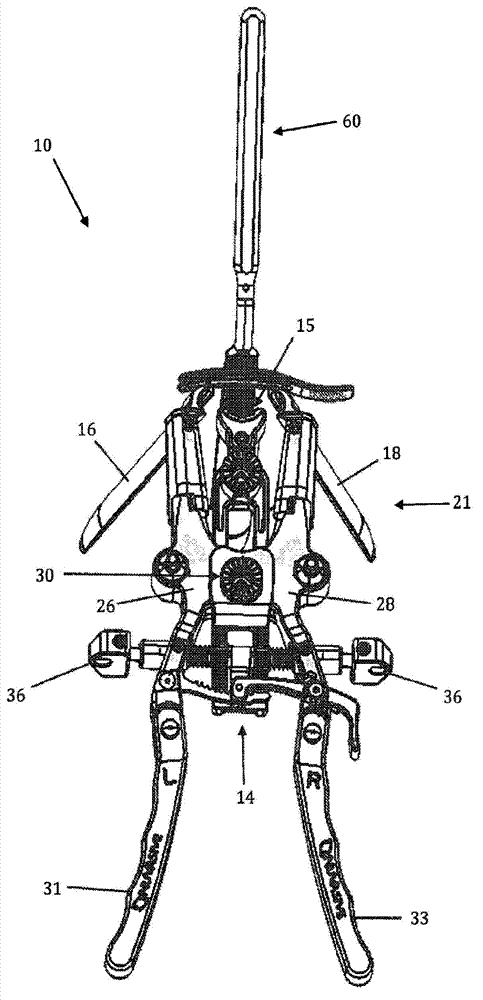

Retractor assembly

The invention relates to a retractor assembly for forming a surgical access to a spinal surgical target site comprising a retractor body and a plurality of retractor blades extending perpendicular to the retractor body. The retractor body is operable to separate the plurality of retractor blades relative to one another to retract the tissue away from the interior of the retractor blades and retracts the interior of the tissue which is far away from the retractor blades when the retractor blades are separated, thereby forming a surgical access. The retractor assembly also comprises a supplemental retractor blade assembly can be attached to two of the plurality of retractor blades and includes a crossbar connector and an elongated supplemental retractor blade. The crossbar connector extends from a first end to a second end and includes an elongate slot. The elongate slot is open at the first end and is configured to slidably receive elements of the two retractor blades to attach the cross-bar connector in a slidable manner to the two retractor blades. The crossbar connector further includes a back surface configured to engage the supplemental retractor blade.

Owner:纽文思公司

Method of manufacturing a magnetoresistive sensor having a shape enhanced pinned layer

InactiveUS20070035891A1Eliminate needAvoid shuntingNanomagnetismMagnetic measurementsEngineeringInduced anisotropy

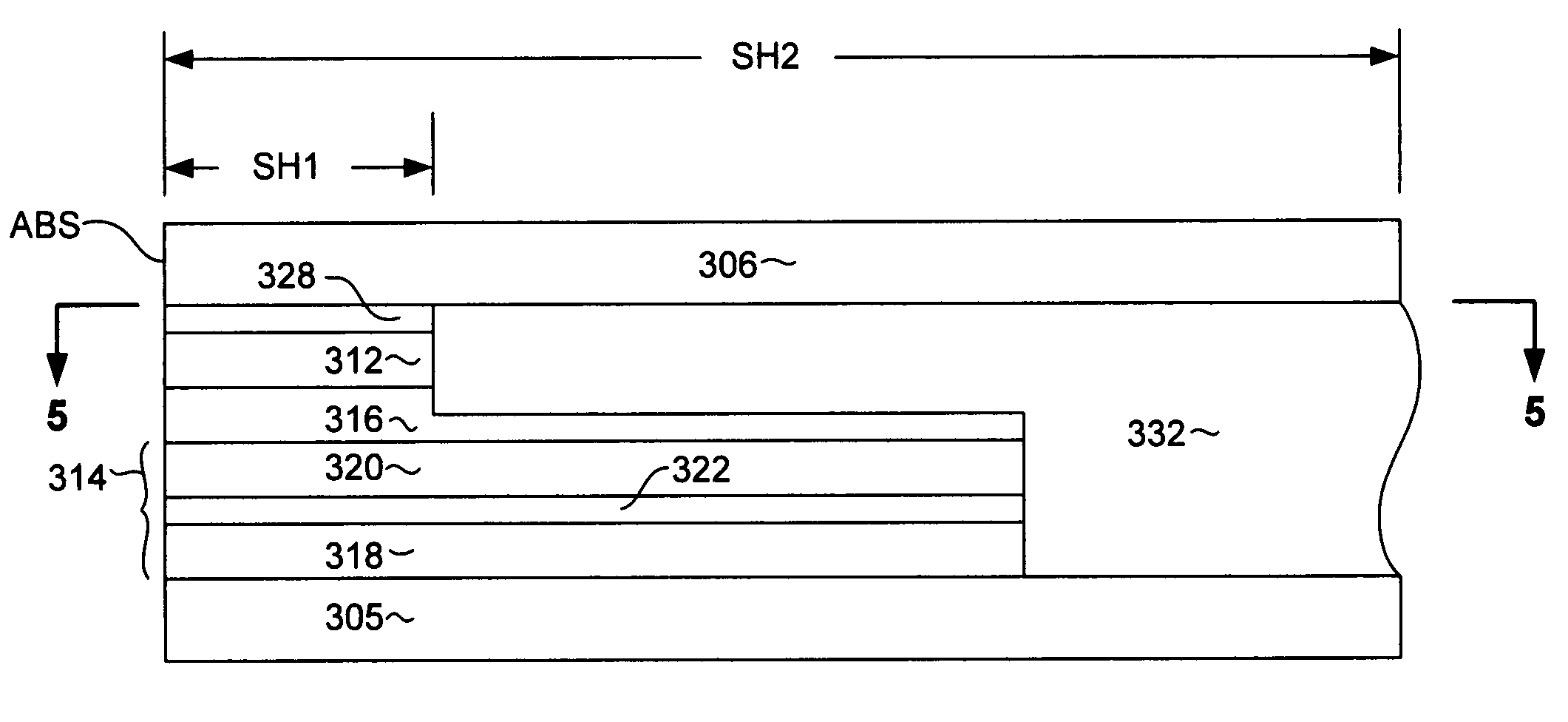

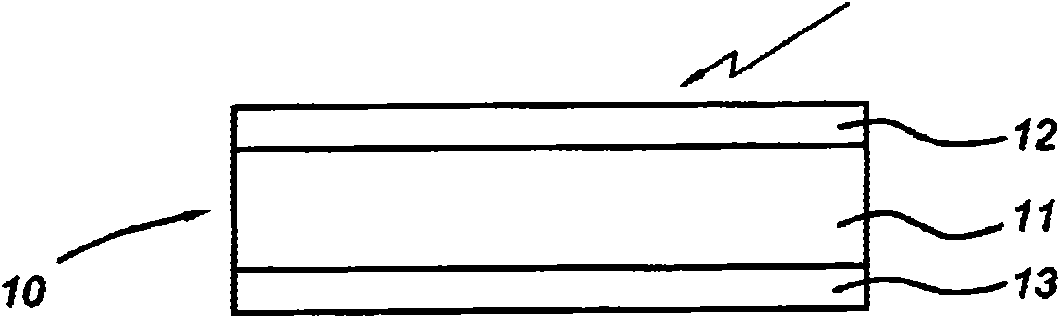

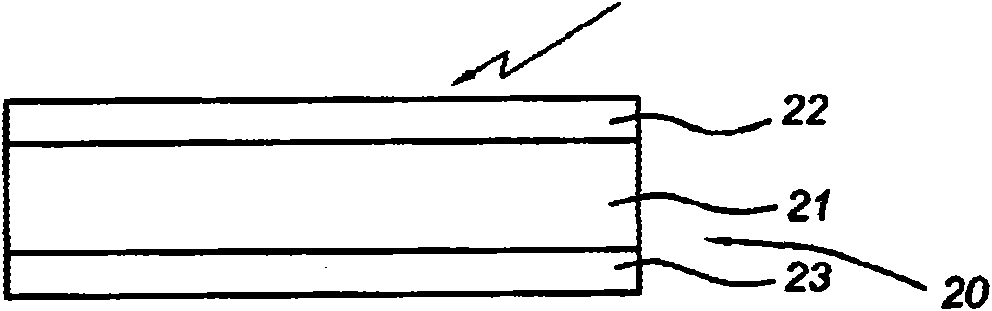

A magnetoresistive sensor having a pinned layer that extends beyond the stripe height defined by the free layer of the sensor. The extended pinned layer has a strong shape induced anisotropy that maintains pinning of the pinned layer moment. The extended portion of the pinned layer has sides beyond the stripe height that are perfectly aligned with the sides of the sensor within the stripe height. This perfect alignment is made possible by a manufacturing method that uses a mask structure for more than one manufacturing phase, eliminating the need for multiple mask alignments.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Magnetoresistive sensor having a shape enhanced pinned layer

InactiveUS7420787B2Eliminate needAvoid shuntingNanomagnetismMagnetic measurementsEngineeringInduced anisotropy

A magnetoresistive sensor having a pinned layer that extends beyond the stripe height defined by the free layer of the sensor. The extended pinned layer has a strong shape induced anisotropy that maintains pinning of the pinned layer moment. The extended portion of the pinned layer has sides beyond the stripe height that are perfectly aligned with the sides of the sensor within the stripe height. This perfect alignment is made possible by a manufacturing method that uses a mask structure for more than one manufacturing phase, eliminating the need for multiple mask alignments.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Neurophysiological apparatus and procedures

ActiveUS9131947B2Simple technologyAvoid nerve damageElectrotherapyInternal osteosythesisElectrical impulseNeurophysiology

Neurophysiological instruments and techniques are improved through various enhancements. Stimulation of an instrument is possible while it is advancing into the spine or elsewhere, alerting the surgeon to the first sign the instrument or device (screw) may be too near a nerve. A directional probe helps surgeons determine the location of the hole in the pedicle. Electrically insulating sleeves prevent shunting into the soft tissues. According to a different improvement, the same probe to be used to stimulate different devices, such as screws and wires. Electrical impulses may be recorded from non-muscle regions of the body, including the spine and other portions of the central nervous system as opposed to just the extremities.

Owner:NUVASIVE

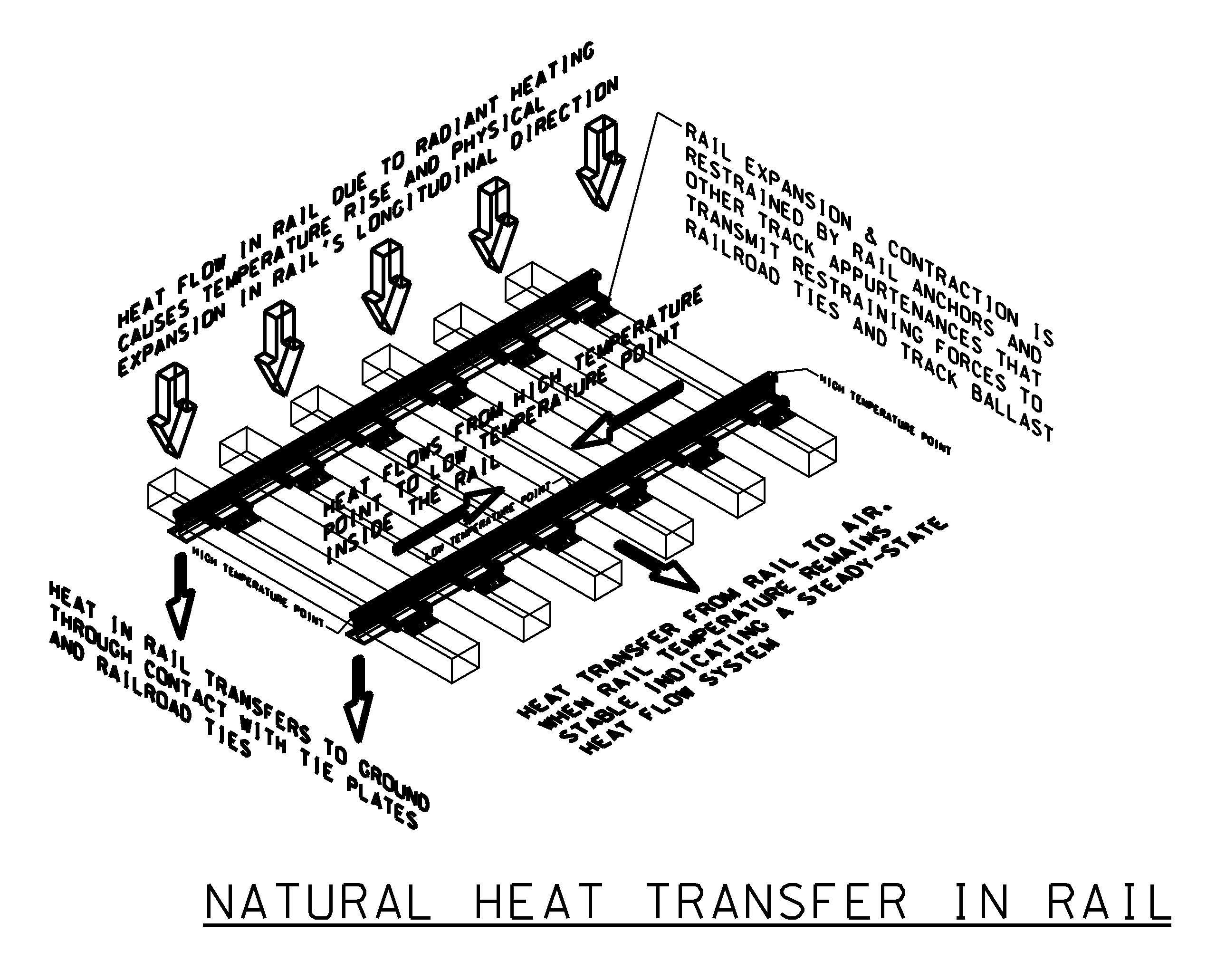

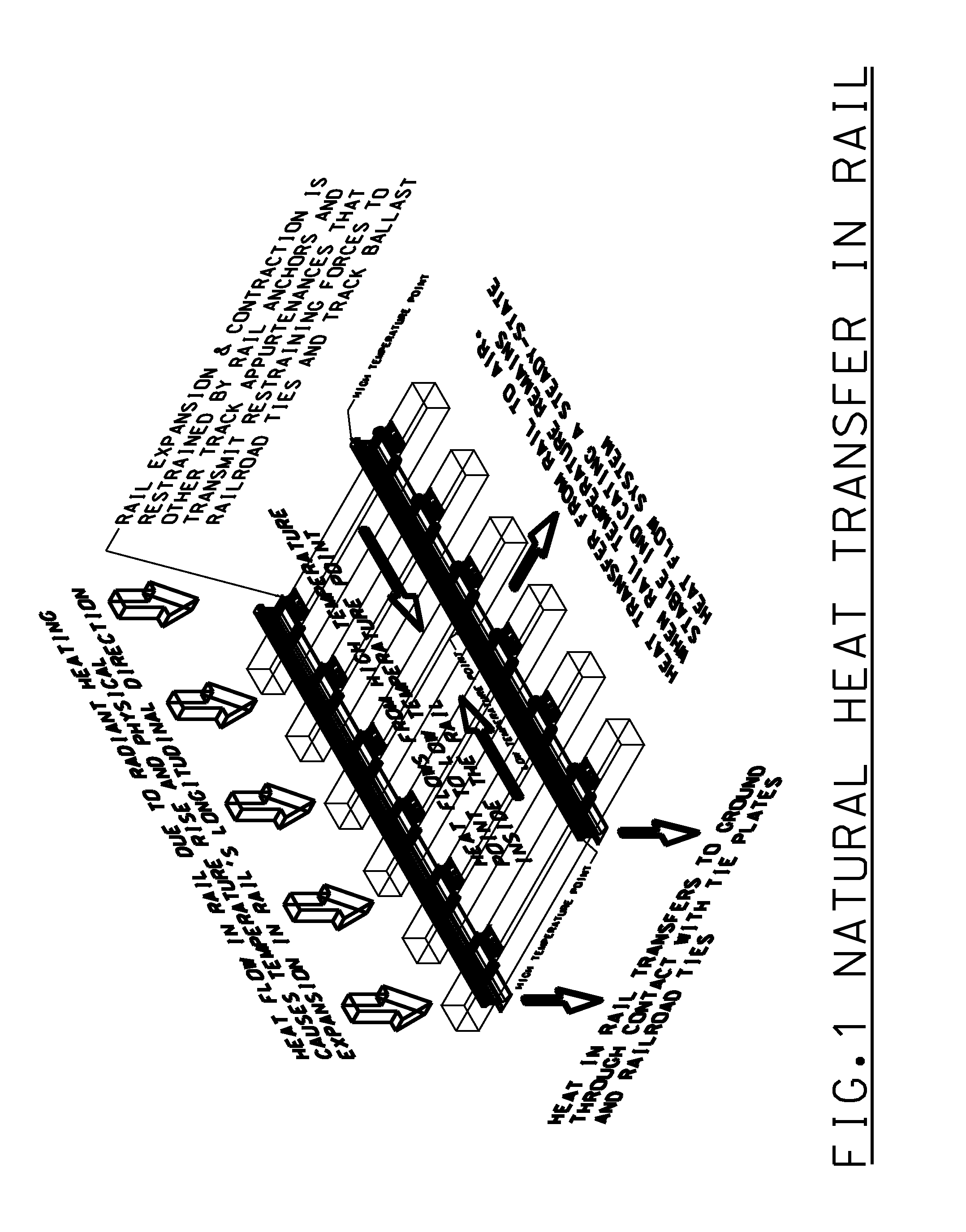

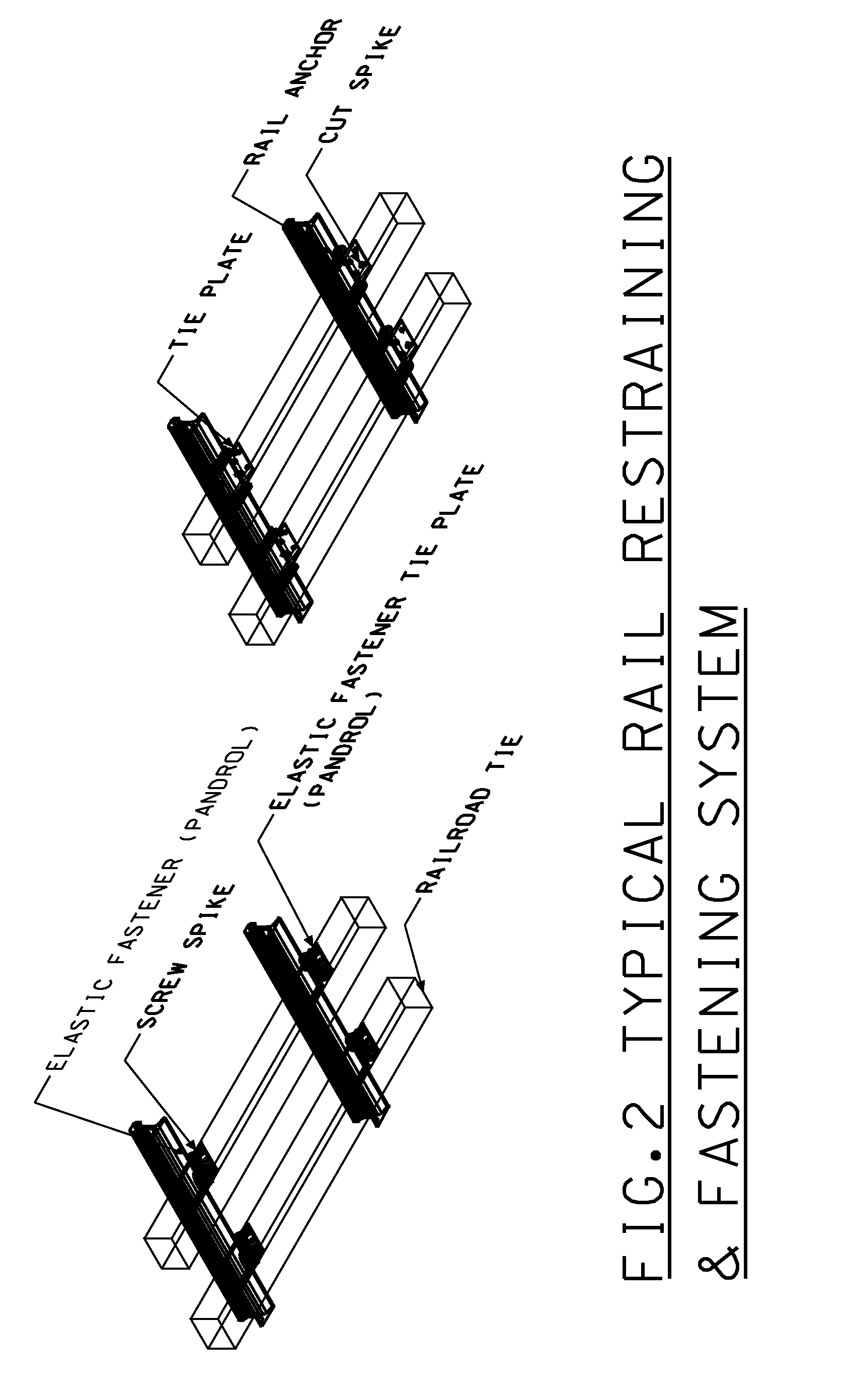

Geothermal Rail Cooling and Heating System

InactiveUS20140033755A1Ensure effective applicationReduce heatRail switchesGeothermal energy generationCooling effectEngineering

A Geothermal Rail Cooling and Heating System is a reversible system process that accelerates heat transfer between the steel rail used in railway track and the adjacent earth. It is comprised of the Rail Heat Exchangers specially shaped to fit tightly inside the rail web, a refrigerant cycling on its physical condensing and evaporative characteristics, a mechanical and power supply system, and an underground tubing loop system for heat dissipation or absorption. When the railroad track undergoes a range of temperature changes that results in rapid rail expansion, it may cause track buckling or sun kink. Upon detection of such occurrence, the system responds with cooling effect to slow down expansion, and simultaneously reduce the risk of track failure. By switching the direction of refrigerant flow utilizing the system built-in reversing valve, the function is alternated for the evaporator and condenser to enable heating instead of cooling.

Owner:WONG ROBERT HON SING

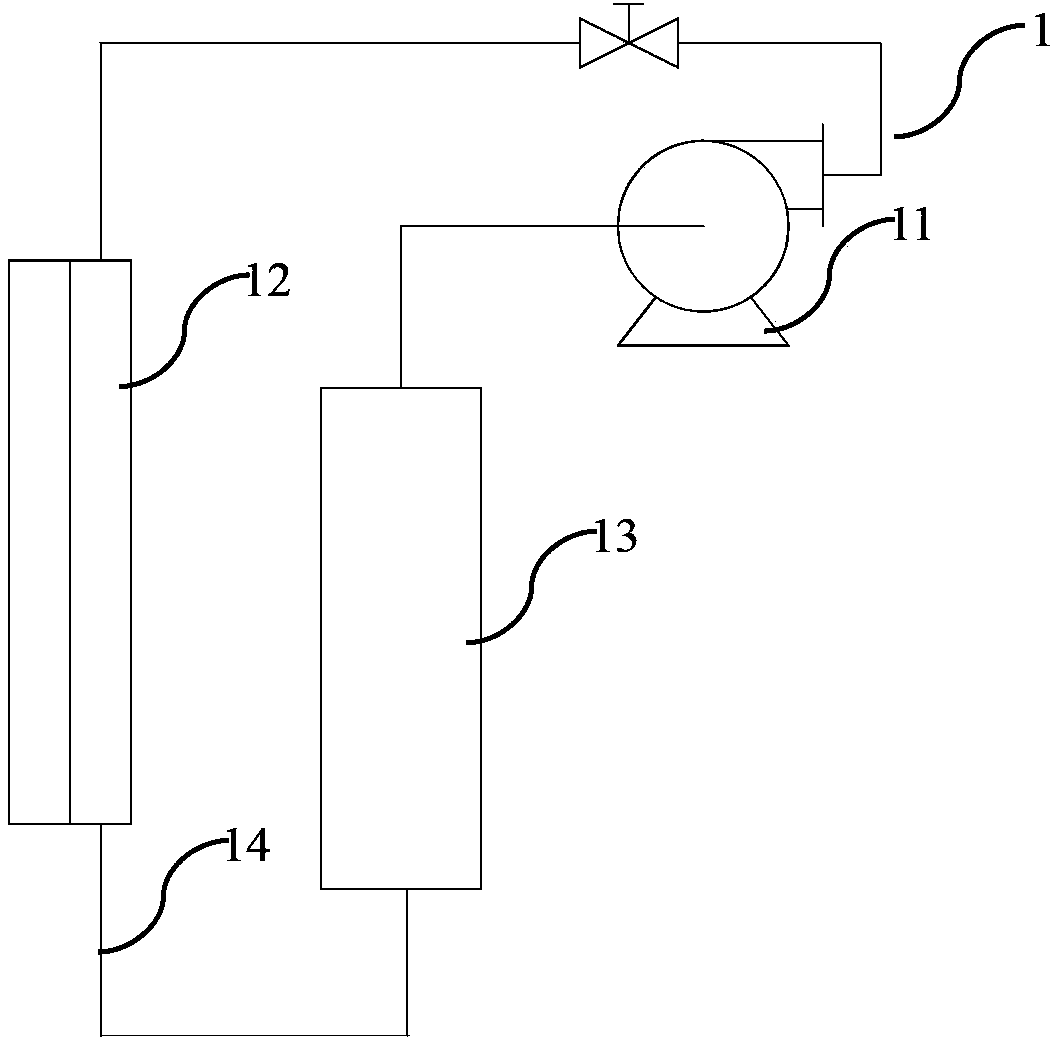

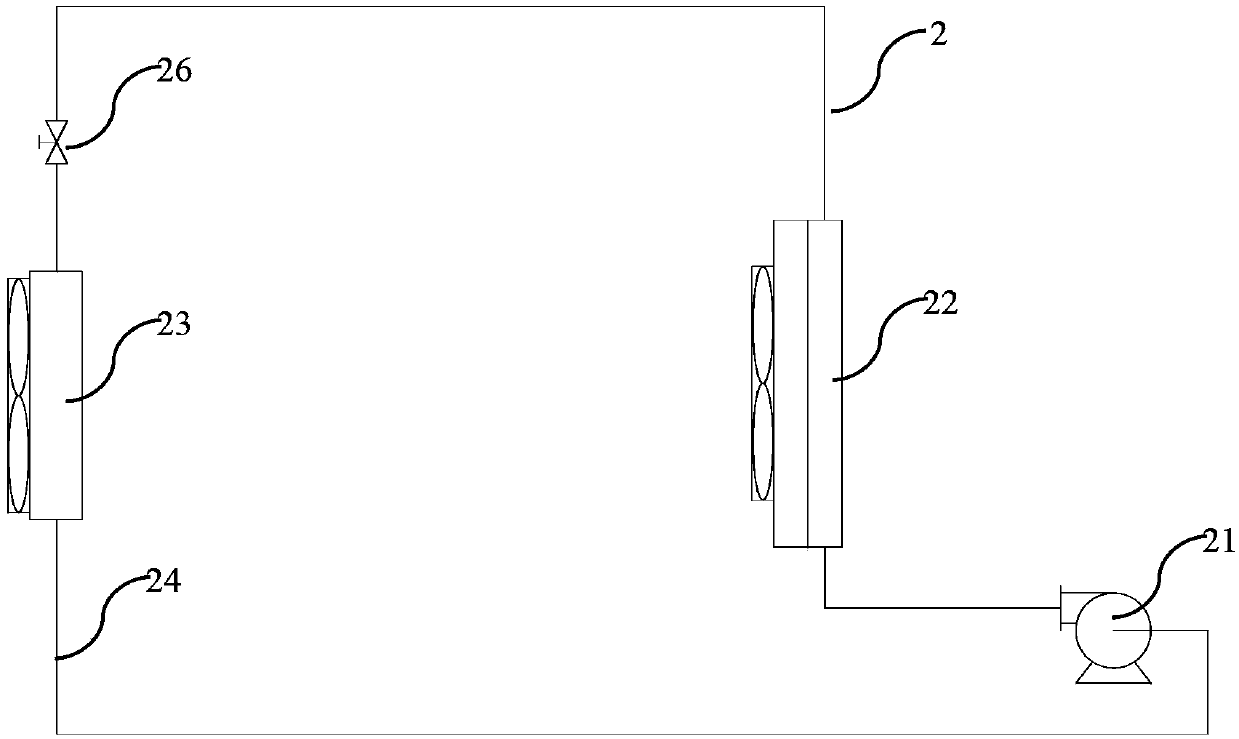

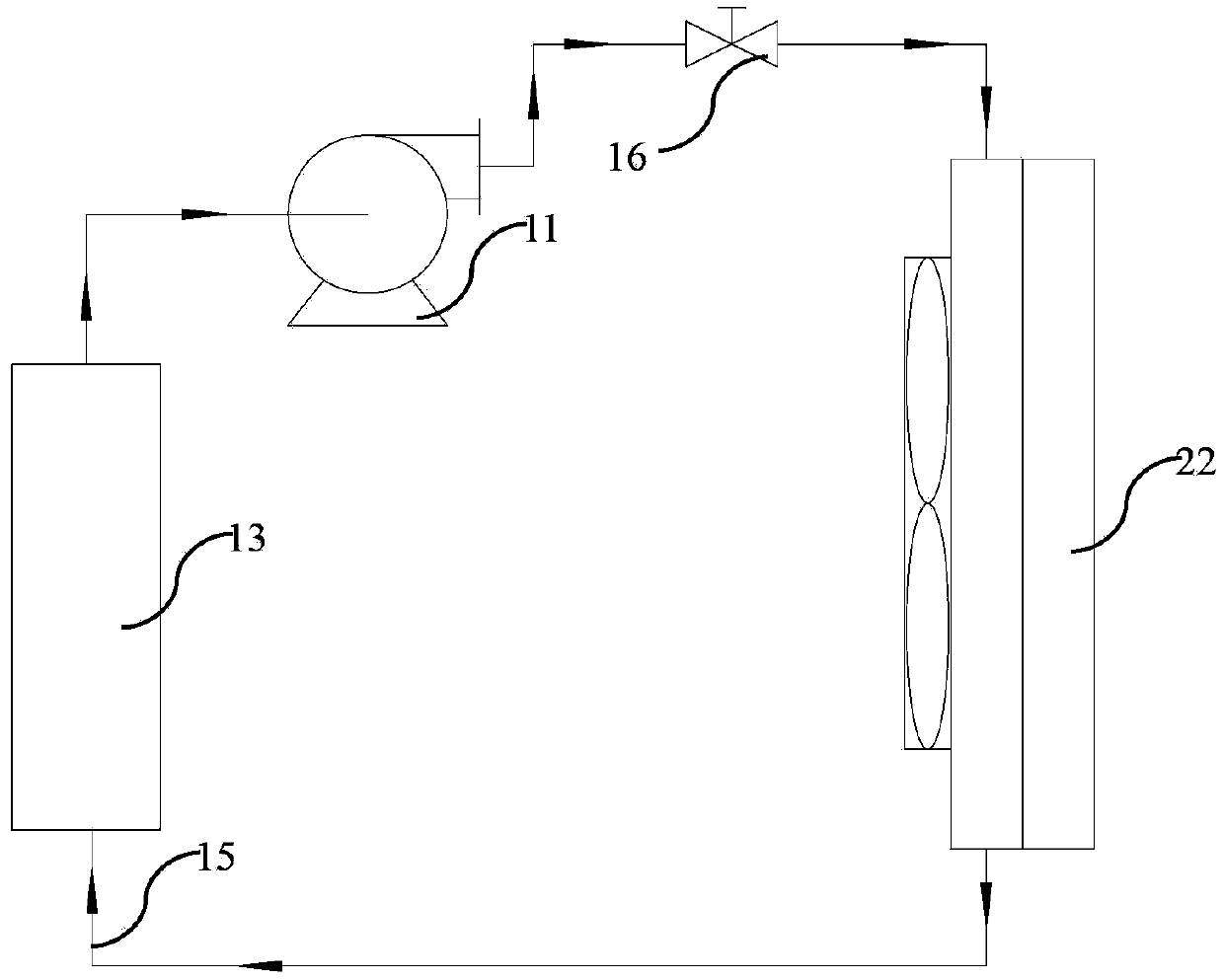

Vehicle-mounted battery pack heat management system

ActiveCN103996889AIncrease energy densityImprove heat transfer efficiencySecondary cellsBatteriesHeat managementThermal management system

The invention provides a vehicle-mounted battery pack heat management system which comprises a battery heat exchange system and an air-conditioner heat exchange system, wherein the battery heat exchange system comprises a circulating pump, a heat exchanger and a battery pack; the battery pack, the circulating pump and the heat exchanger are connected through a circulating pipeline containing a heat exchange liquid inside; a switch valve is arranged between the circulating pump and the heat exchanger; and the air-conditioner heat exchange system comprises a compressor, a radiator A and a radiator B which are connected through a circulating pipeline containing an air conditioner cooling medium inside. The vehicle-mounted battery pack heat management system is formed only by modifying an original air conditioner system, so that the vehicle-mounted battery pack heat management system is simple in structure and convenient to implement; and when the heating capacity of the battery pack is not strong, the vehicle-mounted battery pack heat management system can satisfy the radiation demand of the battery pack only by utilizing the original components in the air conditioner, thereby lowering the energy consumption and protecting the environment.

Owner:MICROVAST

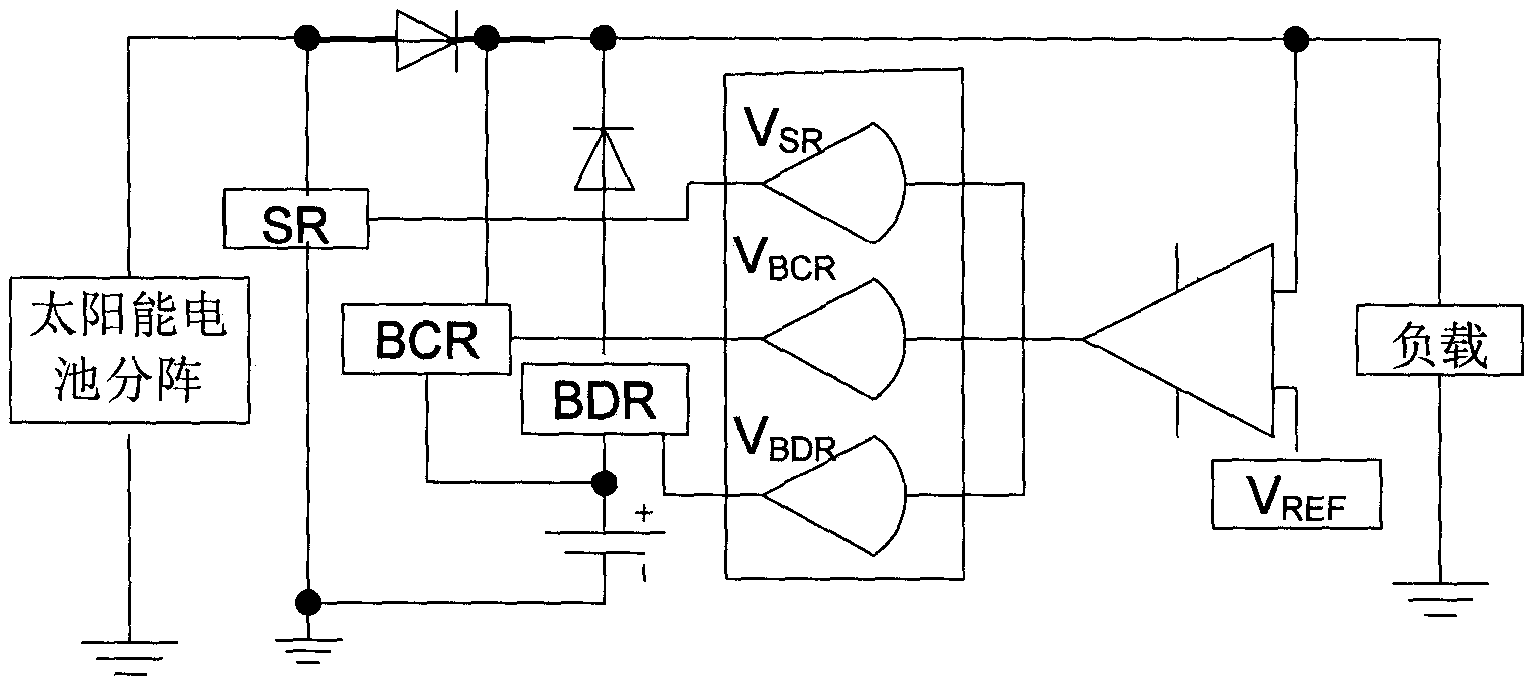

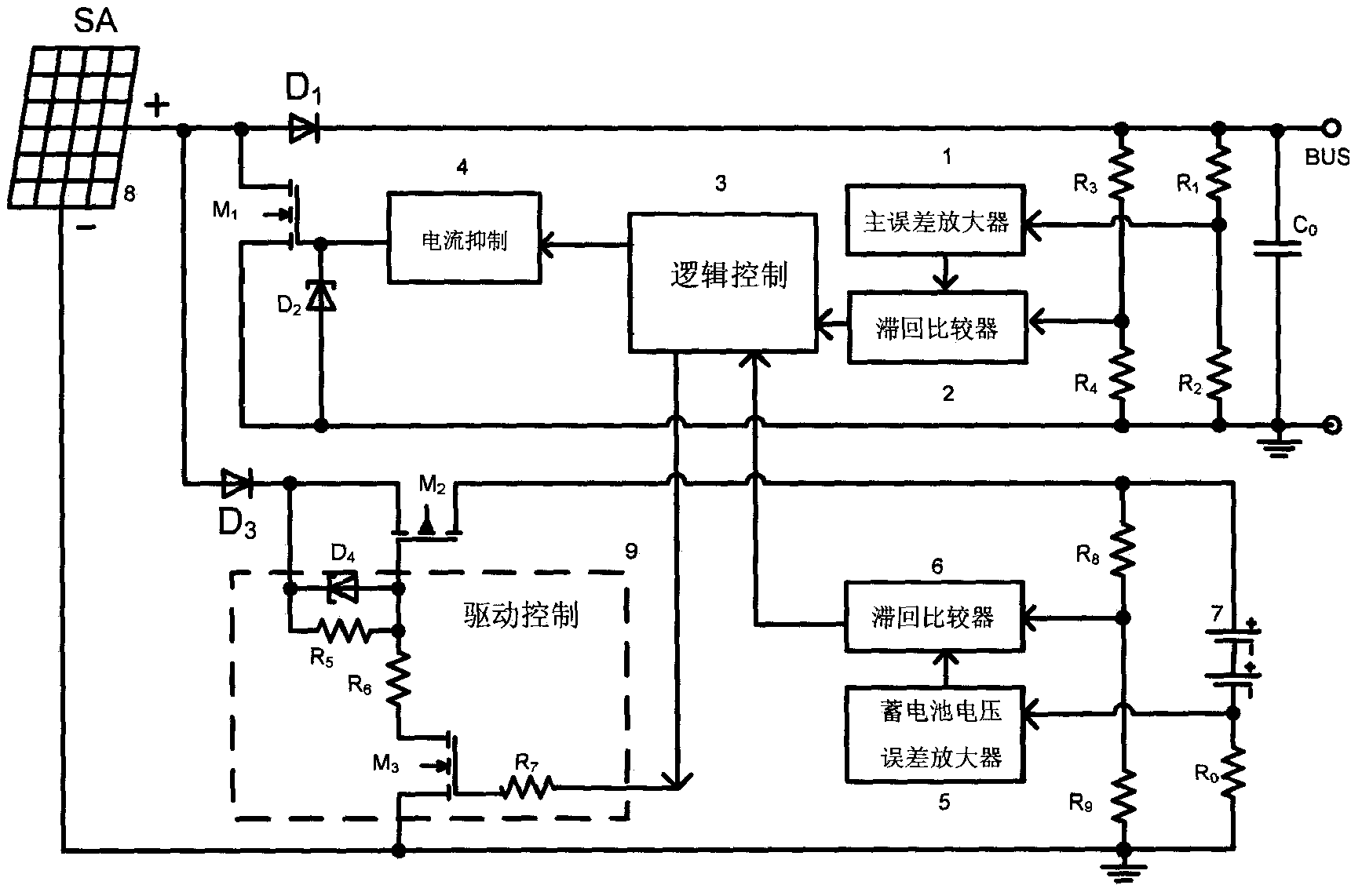

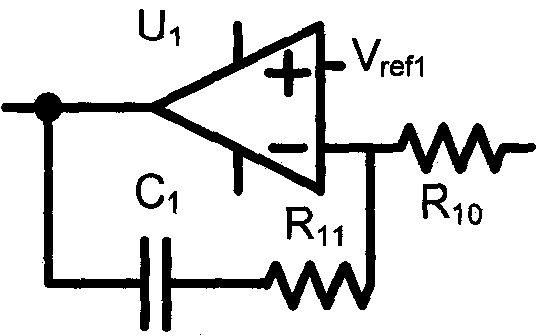

A shunt regulator for solar cell array

ActiveCN106134502BImprove reliabilityImprove applicabilityApparatus without intermediate ac conversionEngineeringSolar cell

A shunt regulator for solar cell arrays, including a power MOS tube M1 for splitting solar cell arrays, a power MOS tube M2 for charging batteries with solar cell arrays, and a main error amplifier for adjusting bus voltage , the battery error amplifier used to regulate the battery charging current. The output of the main error amplifier enters the logic control after passing through the hysteresis comparator to generate shunt drive pulses to control the opening and closing of the power MOS transistor M1, so as to control the constant bus voltage. The output of the battery error amplifier enters the logic control after passing through the hysteresis comparator, generates driving pulses and passes through the drive control unit to control the opening and closing of the power MOS transistor M2, so as to control the size of the battery charging current. The invention adopts the power MOS tube M2 to replace the traditional charging regulator, which saves the volume and weight of the power controller, and is not only suitable for low-orbit spacecraft requiring frequent charging, but also for high-orbit regular charging spacecraft.

Owner:BEIJING SATELLITE MFG FACTORY

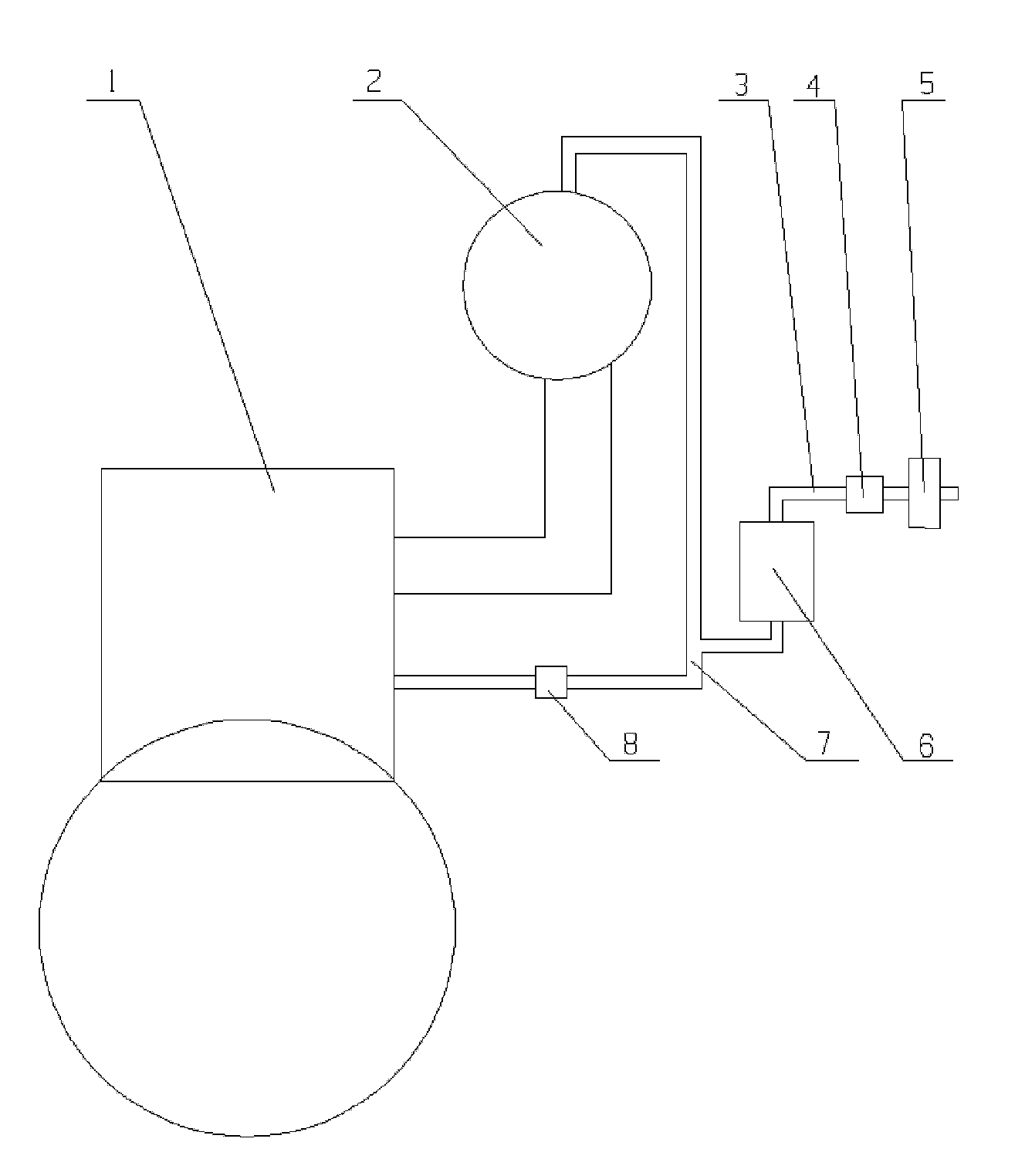

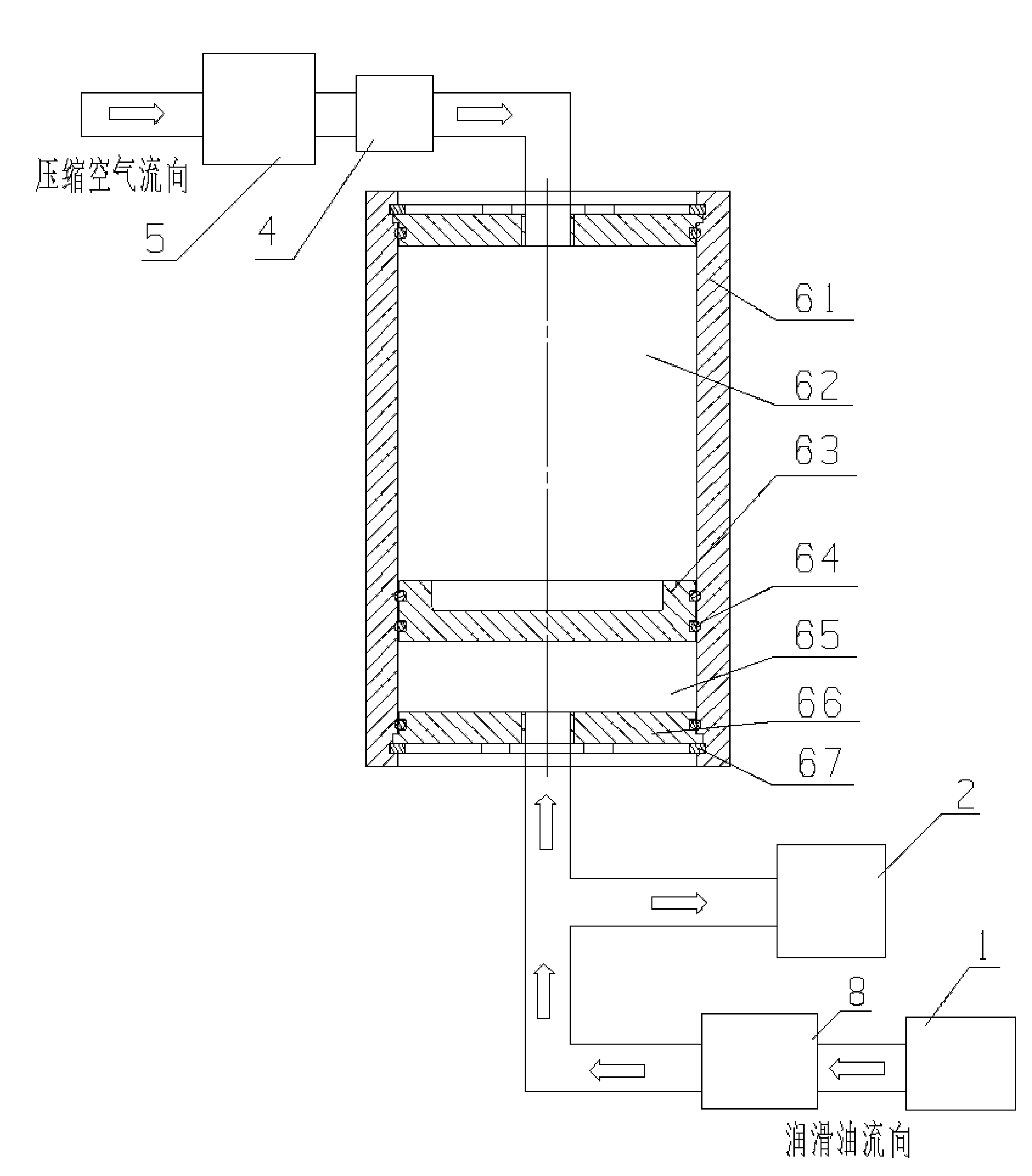

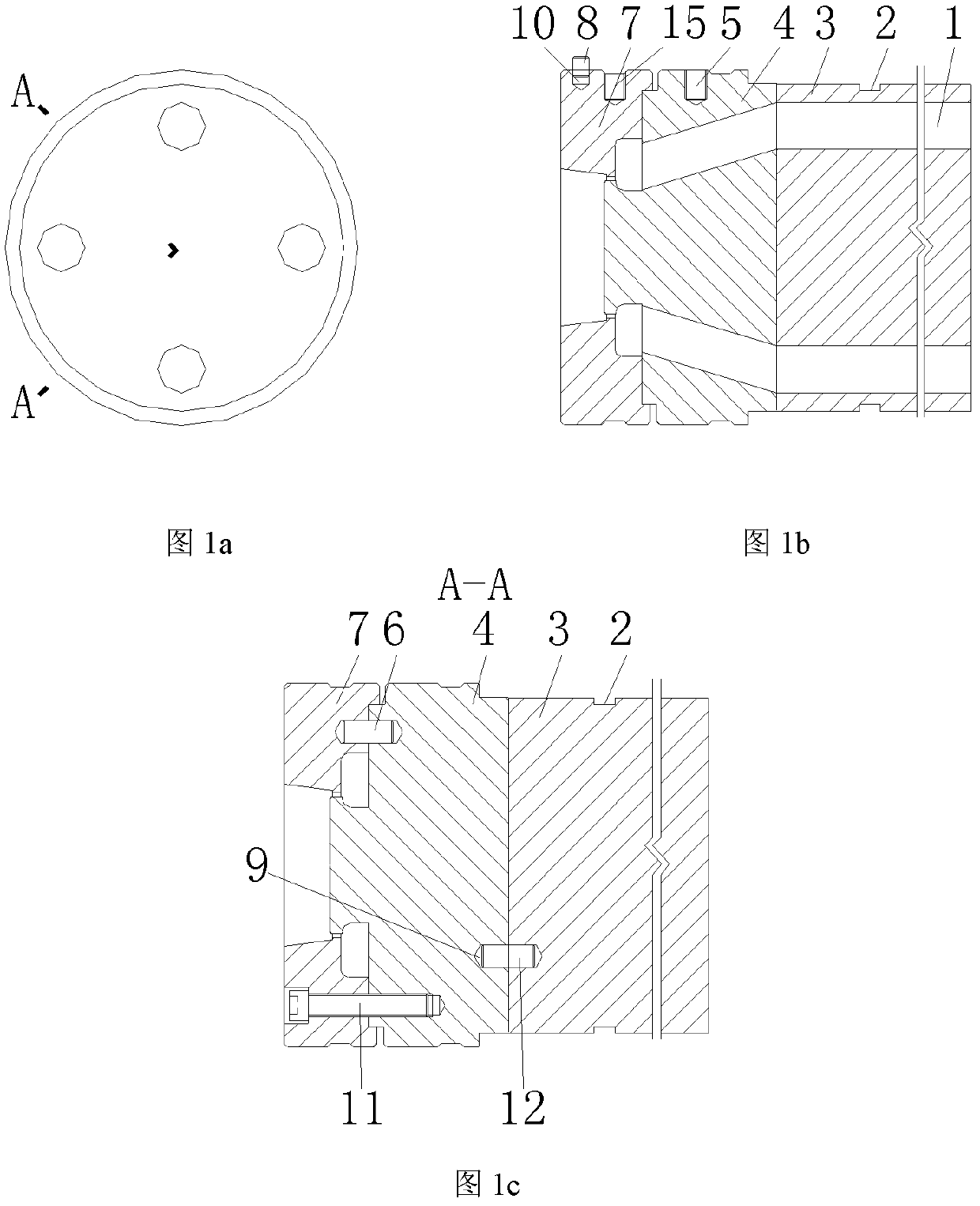

Fuel cut-off protection device for turbocharger

ActiveCN103184928AMeet frequent start and stopMeet the working conditions of unplanned downtimeMachines/enginesEngine componentsTurbochargerPetroleum engineering

The invention discloses a fuel cut-off protection device for a turbocharger. The fuel cut-off protection device comprises a three-way oil tube, wherein the first branch of the three-way oil tube is connected with the turbocharger; the second branch of the three-way oil tube is connected with a lubricating oil circuit of an engine; the third branch of the three-way oil tube is connected with the fuel cut-off protection device of the turbocharger; a one-way valve which is conducted from the engine to the three-way oil tube along a single direction is arranged in the first branch; and the fuel cut-off protection device is used for storing lubricating oil during normal running of the engine, and inputting the stored lubricating oil into the turbocharger when the engine stops running. The fuel cut-off protection device for the turbocharger can be used for storing lubricating oil during running of the engine, and can be used for inputting the stored lubricating oil into the turbocharger when the engine stops running to cool and lubricate, so that energy can be saved; and the fuel cut-off protection device for the turbocharger is suitable for the situations of frequent start and stop and halt and unexpected halt of the engine.

Owner:GUANGXI YUCHAI MASCH CO LTD

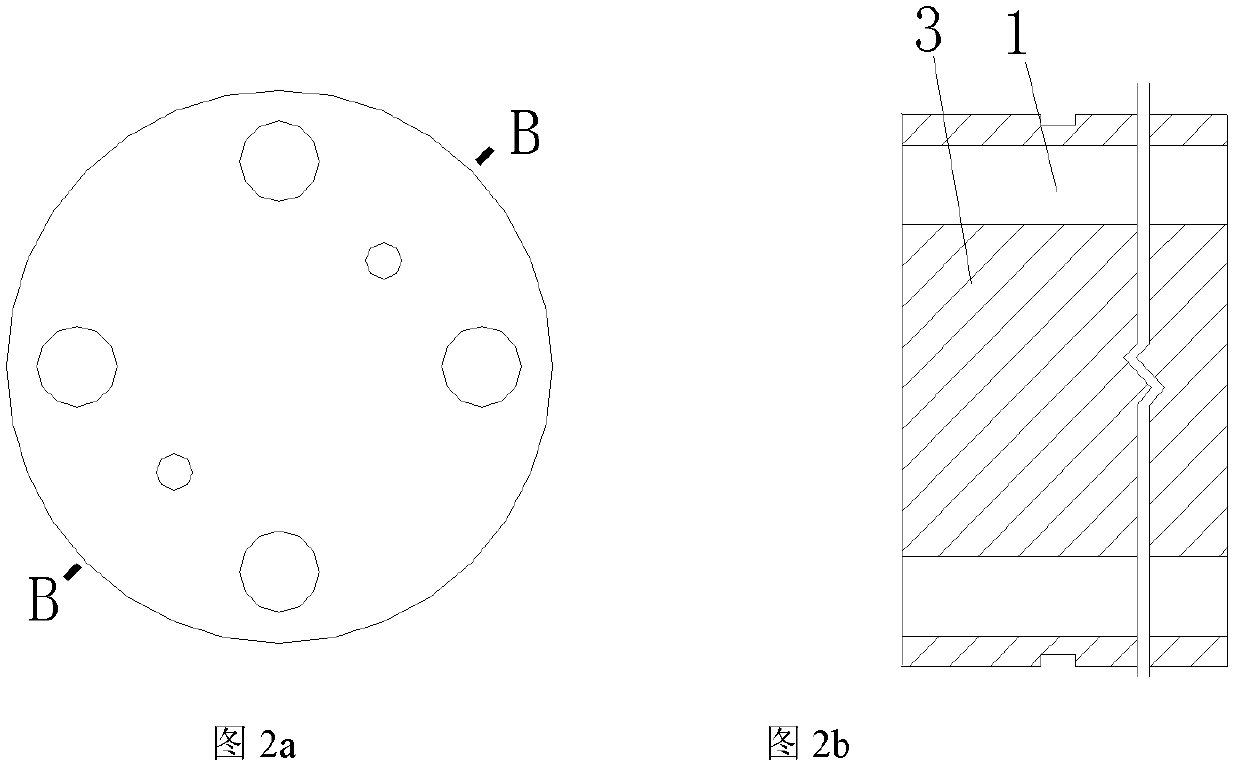

Method of manufacturing crystalline silicon solar cells using co diffusion of boron and phosphorus

ActiveCN101919070AReduce overflowImprove qualityFinal product manufacturePhotovoltaic energy generationCrystalline siliconCo diffusion

The present invention provides a method of manufacturing a crystalline silicon solar cell, subsequently comprising: providing a crystalline silicon substrate having a first side and a second side opposite the first side; pre-diffusing Phosphorus into a first side of the substrate to render a Phosphorus diffused layer having an initial depth; blocking the first side of the substrate; - exposing a second side of the substrate to a Boron diffusion source; heating the substrate for a certain period of time and to a certain temperature so as to diffuse Boron into the second side of the substrate and to simultaneously diffuse the Phosphorus further into the substrate.

Owner:NEDERLANDSE ORG VOOR TOEGEPAST-NATUURWETENSCHAPPELIJK ONDERZOEK (TNO)

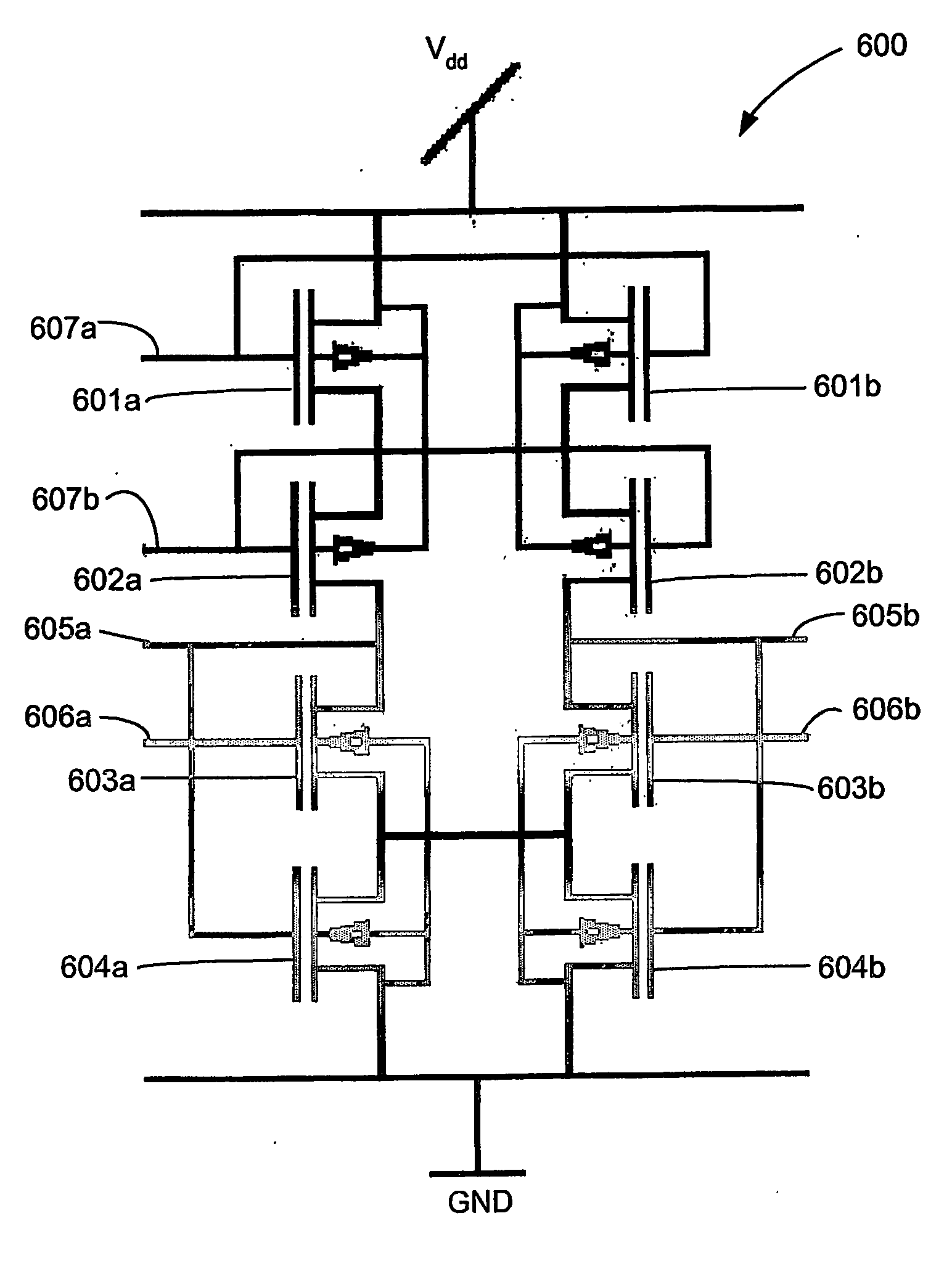

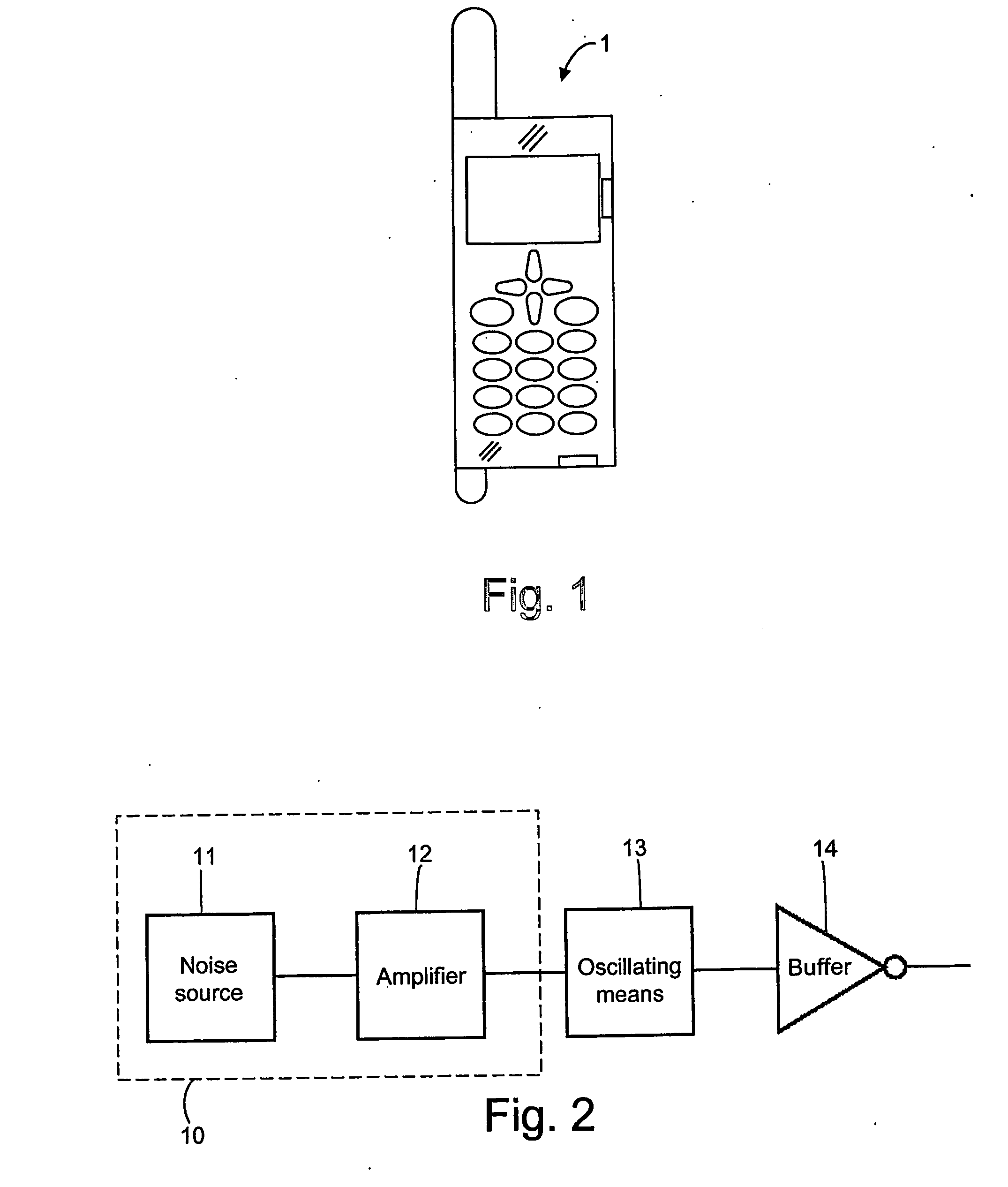

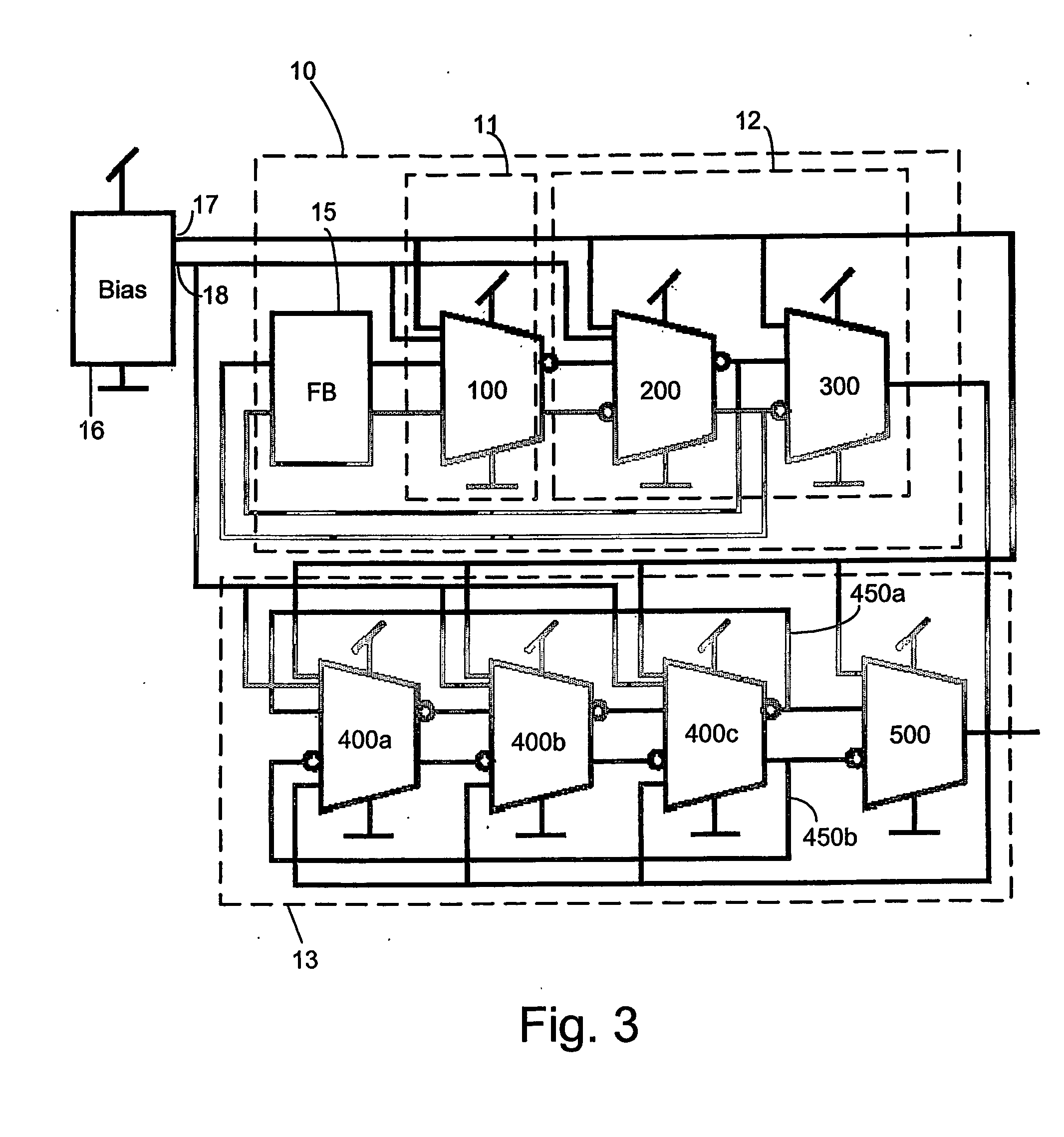

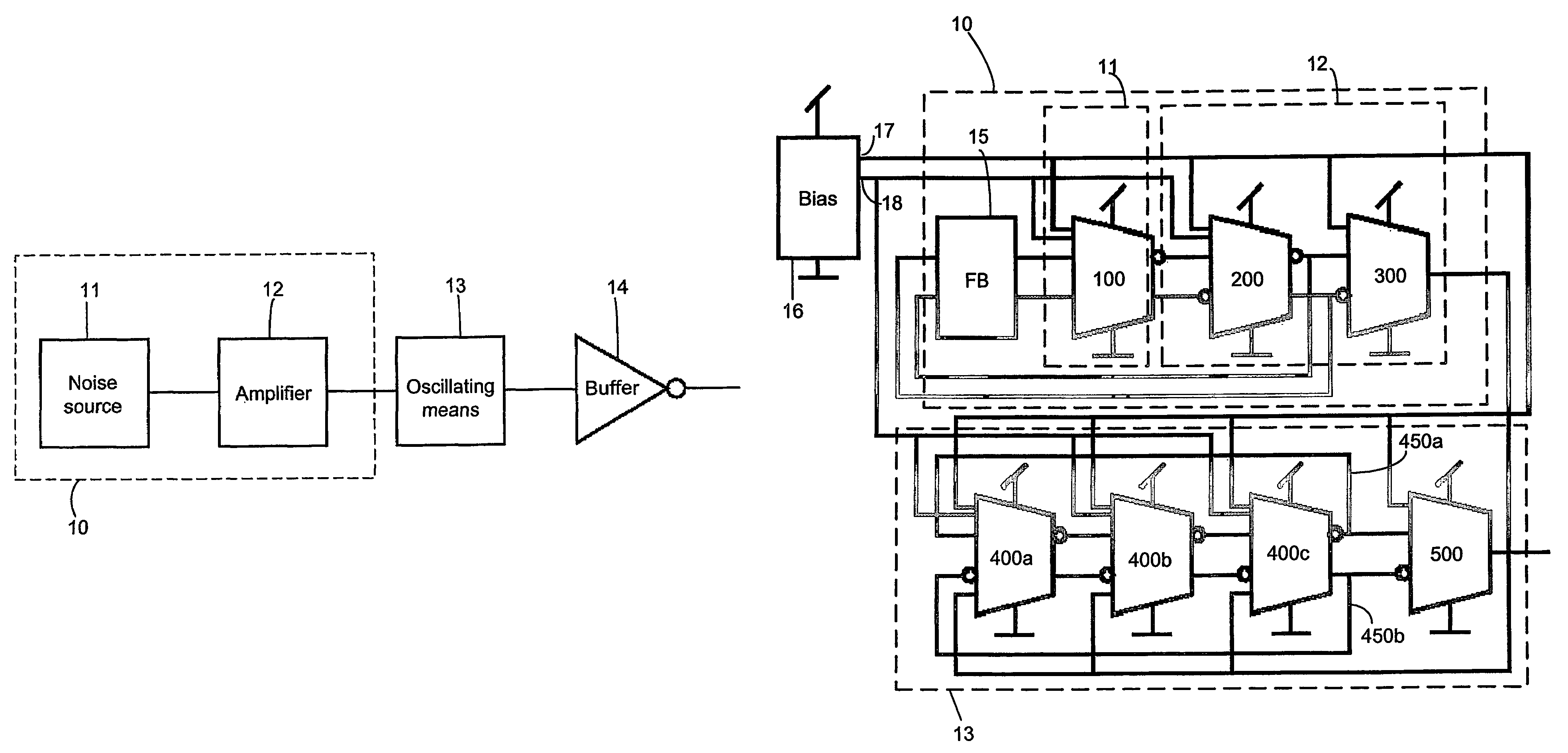

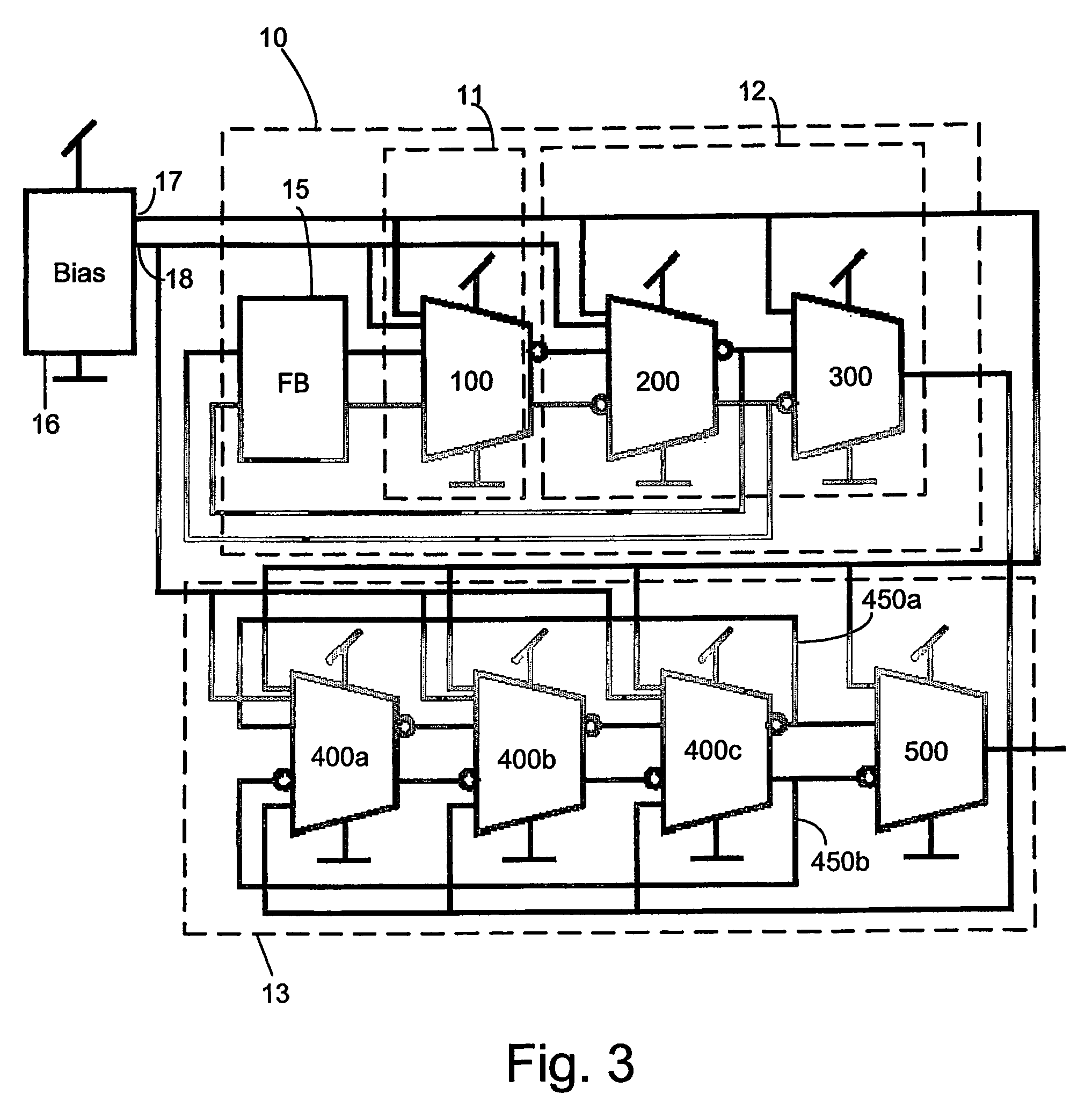

Noise generator

ActiveUS20060186957A1Raise the ratioAvoid shuntingRandom number generatorsAmplifier combinationsAudio power amplifierInterference ratio

A device for generating a noise signal, which may be used for generating a truly random sequence (10) of bits is disclosed. The device comprises a noise source (11), and an amplifier (12) connected to the noise source (11). The device according noise source according to the invention is protected from interfering signals to provide high noise-interference ratio. Further, the present invention relates to an integrated circuit and an electronic apparatus comprising the device for generating a noise signal according to the invention.

Owner:OPTIS WIRELESS TECH LLC

Noise generator

ActiveUS7511586B2Raise the ratioAvoid shuntingRandom number generatorsAmplifier combinationsAudio power amplifierInterference ratio

A device for generating a noise signal, which may be used for generating a truly random sequence (10) of bits is disclosed. The device comprises a noise source (11), and an amplifier (12) connected to the noise source (11). The device according noise source according to the invention is protected from interfering signals to provide high noise-interference ratio. Further, the present invention relates to an integrated circuit and an electronic apparatus comprising the device for generating a noise signal according to the invention.

Owner:OPTIS WIRELESS TECH LLC

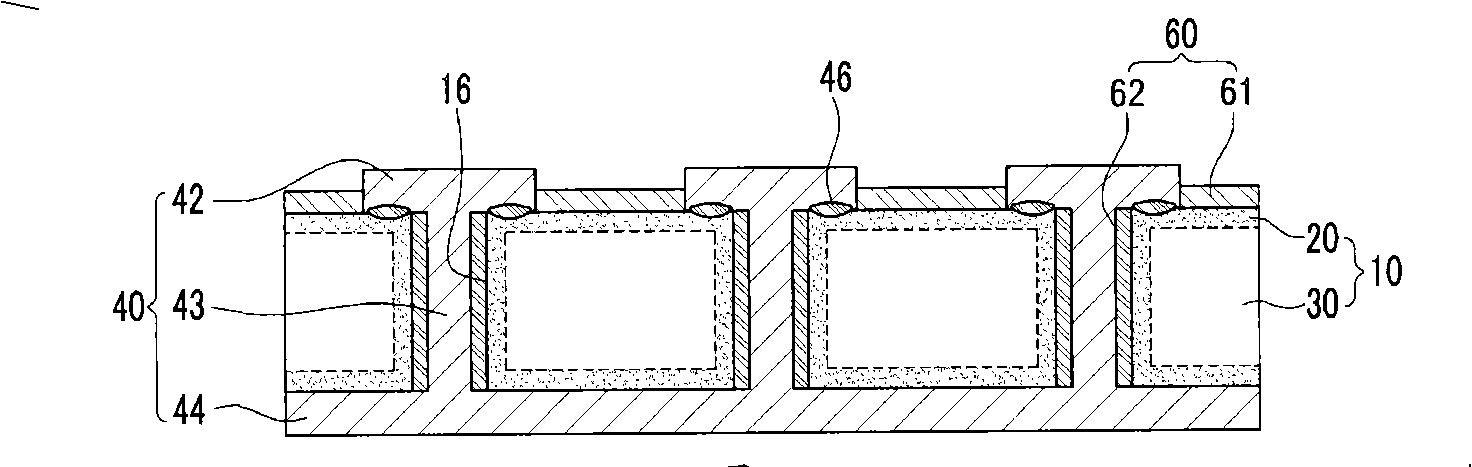

Solar cell and method for manufacturing the same

InactiveCN101494249AFirmly connectedShunt resistance minimizedPhotovoltaic energy generationSemiconductor devicesEngineeringSolar cell

Owner:SAMSUNG SDI CO LTD

Mould for multi-blank equal-channel angular welding extruded molded pipe

InactiveCN102601147AAvoid shuntingAvoid dead zoneExtrusion diesExtrusion containersButt jointEngineering

The invention relates to a mould for a multi-blank equal-channel angular welding extruded molded pipe. An end face of one end of a convex mould is connected with one end face of a liner of an extruding cylinder; the end face of the other end of the convex mould is connected with one end face of a concave mould; during a connecting process, an outlet of each metal flowing channel in the liner of the extruding cylinder is butt-jointed with an inlet of each metal flowing channel on the end face of the matching end of the convex mould; a sized rod at the center of the end face of the matching end of the convex mould and the concave mould is embedded into a welding chamber at the center of the concave mould; and a clearance between the sized rod and the concave mould is as thick as the wall of the formed pipe. According to a method of changing a split-flow mould into the multi-blank entering welding chamber, the blanks are independent from each other, are subjected to equal-channel angular deformation before alloy enters the welding chamber and are welded and extruded after the alloy enters the welding chamber; the alloy split-flow process is efficiently avoided; and the extrusion force is concentrated on equal-channel angular refined grains and welding process, the welding quality is better and the grain size of the products is smaller, so that the better extruded products are obtained.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Dual angle milling for current perpendicular to plane (CPP) magnetoresistive sensor definition

InactiveUS20050269288A1Avoid damageReduce bias voltageNanomagnetismElectrical transducersIon beamAtomic physics

A method for constructing a magnetoresistive sensor which eliminates all redeposited material (redep) from the sides of the sensor. The method involves forming a mask over a plurality of sensor layers, and then performing an ion mill at an angle that is nearly normal to the surface of the sensor layers. A second (glancing) ion mill is then performed at a larger angle with respect to the normal. The first ion mill may be 0-30 degrees with respect to normal, whereas the second ion mill can be 50-89 degrees with respect to normal. The first ion mill is performed with a larger bias voltage than the second ion mill. The higher bias voltage of the first ion mill provides a well collimated ion beam to form straight vertical side walls. The lower bias voltage of the second ion mill prevent damage to the sensor layers during the removal of redep from the sides of the sensor.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Magnetoresistive sensor having a shape enhanced pinned layer

InactiveUS20070035887A1Good body shapeInhibit currentNanomagnetismMagnetic measurementsEngineeringInduced anisotropy

A magnetoresistive sensor having a pinned layer that extends beyond the stripe height defined by the free layer of the sensor. The extended pinned layer has a strong shape induced anisotropy that maintains pinning of the pinned layer moment. The extended portion of the pinned layer has sides beyond the stripe height that are perfectly aligned with the sides of the sensor within the stripe height. This perfect alignment is made possible by a manufacturing method that uses a mask structure for more than one manufacturing phase, eliminating the need for multiple mask alignments.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

High quality, high yield and efficient cultivation technique for outcrop watermelons

InactiveCN106717925AAvoid damageAvoid interferenceBioloigcal waste fertilisersWaste based fuelOutcropEconomic benefits

The invention discloses a high quality, high yield and efficient cultivation technique for outcrop watermelons. The technique specially includes variety selection, seed treatment, nutritive-soil preparation, seeding, seedling management, transplanting engraftment and field management. With the technique, problems that the watermelons are late on the market, serious in pest and disease damage and low in yield and benefit in an existing traditional open cultivation mode of the watermelons are solved, the watermelons come into the market 1 month ahead of time, economic benefit is increased, and the technique is suitable for open cultivation of the watermelons for melon farmers in Eastern Shandong.

Owner:重庆珞优农业科技有限公司

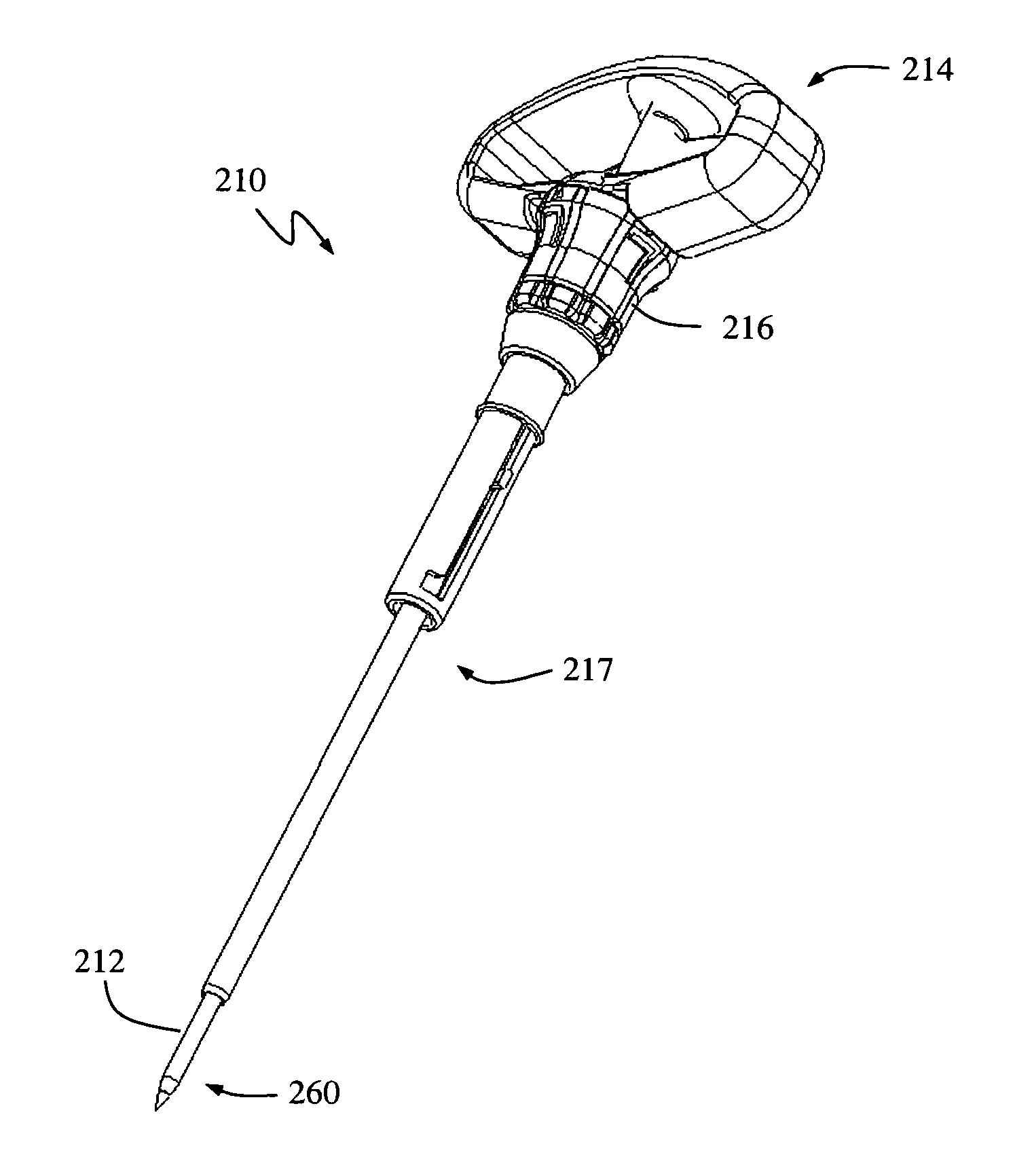

Surgical access system and related methods

ActiveCN103167825AAvoid shuntingSpinal electrodesDiagnostic recording/measuringRetractor bladeSurgical access

A surgical access system comprising a tissue dilation assembly and a tissue retraction assembly, both of which may be equipped with one or more electrodes for use in detecting the existence of (and optionally the distance and / or direction to) neural structures. A retractor assembly for creating an operative corridor to a spinal surgical target site is disclosed, comprising: a retractor body and a plurality retractor blades extending generally perpendicularly to the retractor body, the retractor body being operable to separate the at plurality of retractor blades relative to each; and a supplemental retractor blade assembly attachable to at least two of the plurality of retractor blades, the supplemental retractor blade assembly comprising an elongated supplemental retractor blade and a crossbar connector, the crossbar connector configured to be attached to said at least two retractor blades while engaging the supplemental retractor blade.

Owner:纽文思公司

Osmanthus tea processing process

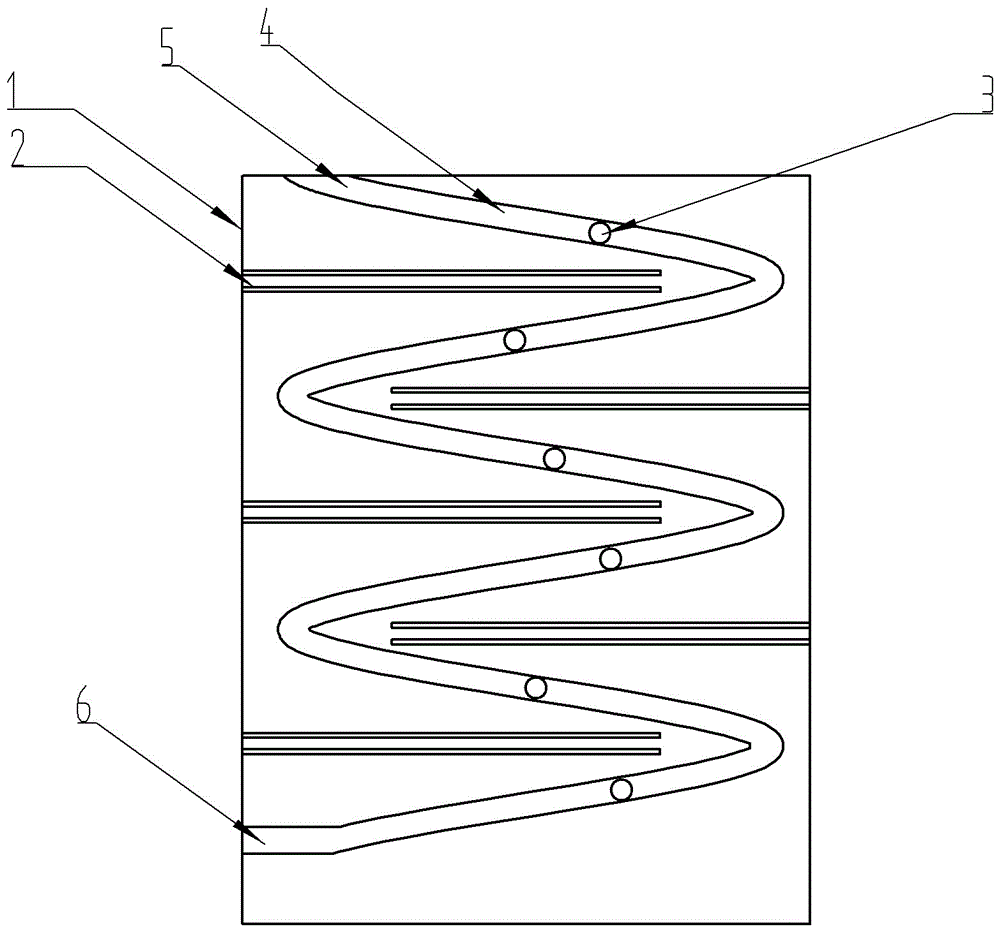

ActiveCN106490230AAchieve energy saving effectResulting in different qualityPre-extraction tea treatmentTea flavoringEngineeringOsmanthus

The invention discloses an osmanthus tea processing process which includes the step of scenting magnolia flowers and osmanthus together. The scenting step includes the steps: laying a layer of unsifted tea on a clean bamboo mat, laying the osmanthus on another bamboo mat, forming a bamboo mat pair by the two bamboo mats and positioning the unsifted tea above the osmanthus; placing a plurality of bamboo mat pairs in a box and arranging an S-shaped sliding rail penetrating the whole box from top to bottom between every two bamboo mat pairs in the box; placing the magnolia flowers into a hollow cylinder with a shell with uniform pores; enabling one cylinder to enter the rail from the upper portion every 10-20 seconds in the whole scenting step until finishing scenting. The S-shaped sliding rail is positioned between the bamboo mat pairs in a zigzag manner, the vertical distance between bent points of each bent portion is equal to that between bent points of another bent portion, and the bent points are vertically parallel and level. Unified quality of osmanthus tea is ensured.

Owner:GUIZHOU YANGCHUNBAIXUE TEA IND

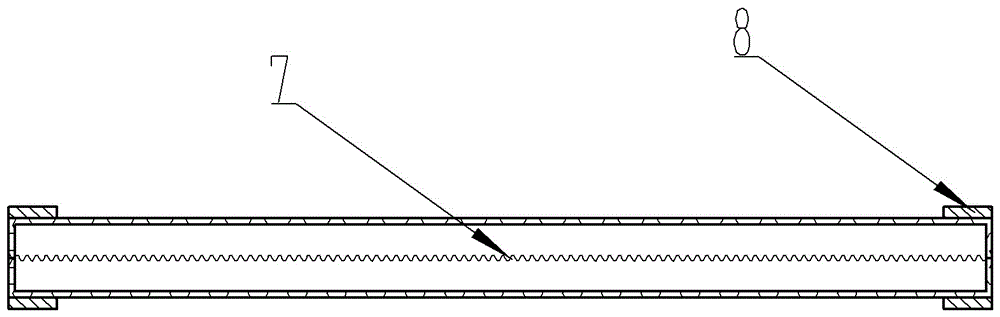

Non-powered trailed switch detector for railroad track switching equipment

InactiveUS7147189B2Avoid shuntingReduce cost and complexityPoint operation from vehicleVehicle route interaction devicesOrbitTrack circuit

An apparatus is provided for sensing movement of a point rail away from a stock rail by a selected distance, by closing a switch to shunt a track circuit, with means for resetting the apparatus to open the switch only after manual resetting of the point rail.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com