Osmanthus tea processing process

A processing technology and technology of sweet-scented osmanthus tea, applied in the directions of tea spice, tea treatment before extraction, etc., can solve the problems of reducing the quality of sweet-scented sweet-scented tea and different quality of sweet-scented sweet-scented tea.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below by means of specific embodiments:

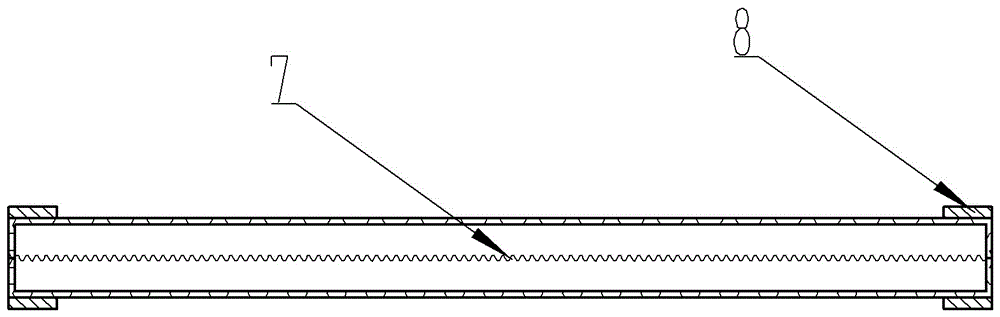

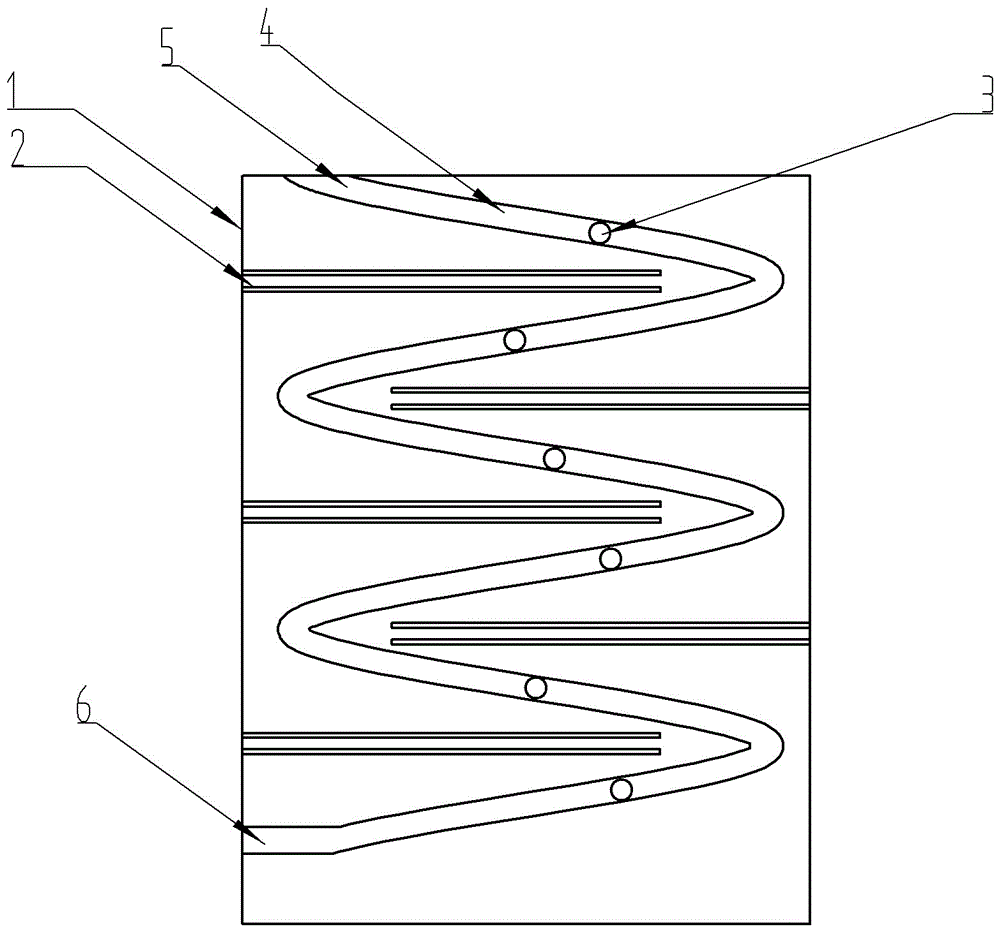

[0026] The reference signs in the drawings of the description include: box body 1, bamboo mat pair 2, heating cylinder 3, slide rail 4, inlet 5, outlet 6, heating wire 7, insulating rubber layer 8.

[0027] The sweet-scented osmanthus tea processing technique used in the present embodiment comprises the step of using magnolia and osmanthus to scent together, and the step of scenting comprises:

[0028] Lay a layer of tea embryos on a clean bamboo mat, and osmanthus flowers on another bamboo mat. Two bamboo mats form a pair of bamboo mats. The distance between the two bamboo mats is 5-7 cm, and the tea embryo is on top of the osmanthus flowers;

[0029] In a box, a pair of multi-layer bamboo mats is placed, and the distance between each layer of bamboo mats is 20-30 cm. An S-shaped slide rail that runs through the entire box from top to bottom is arranged in the box. The S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com