Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Avoid motor damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

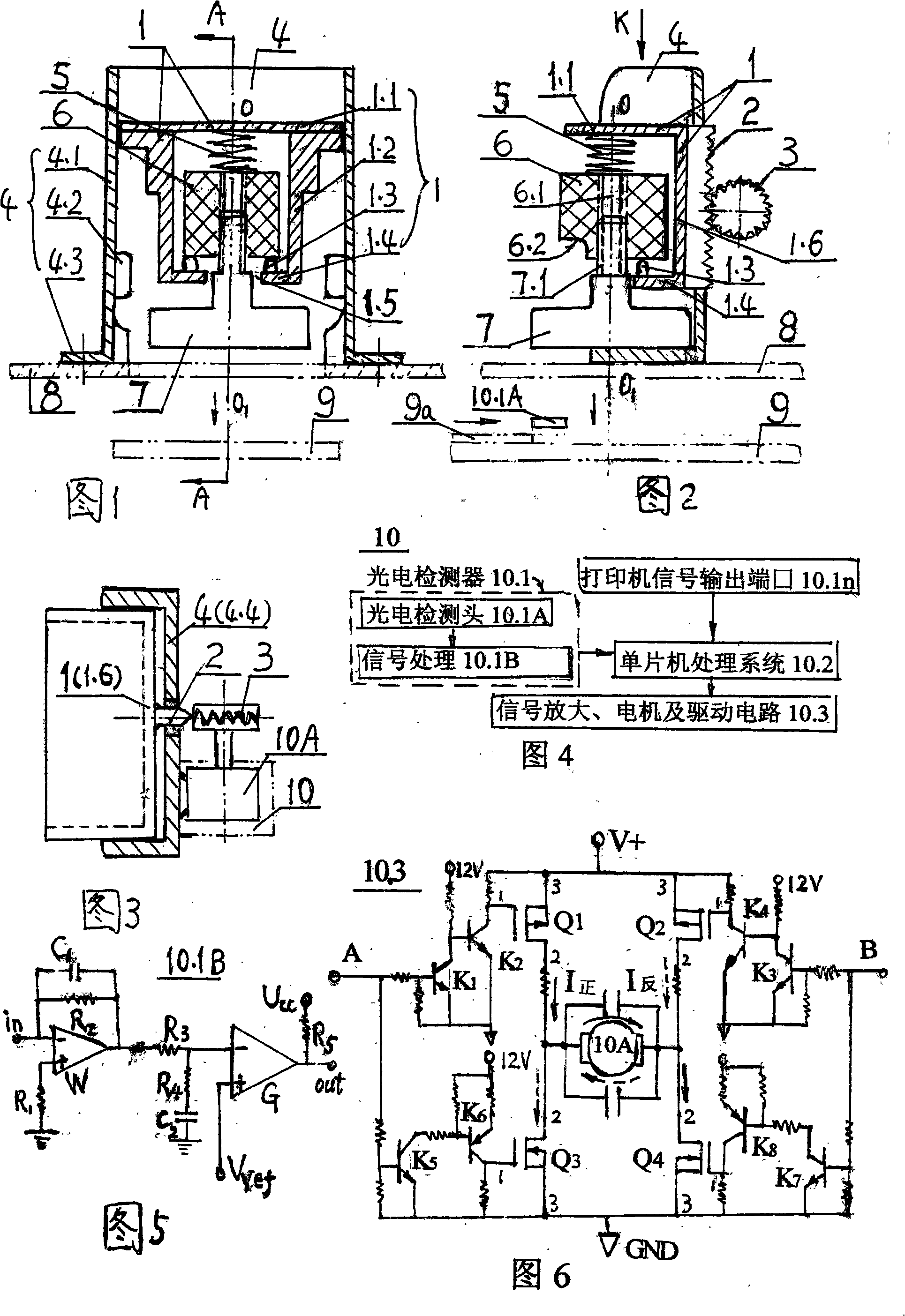

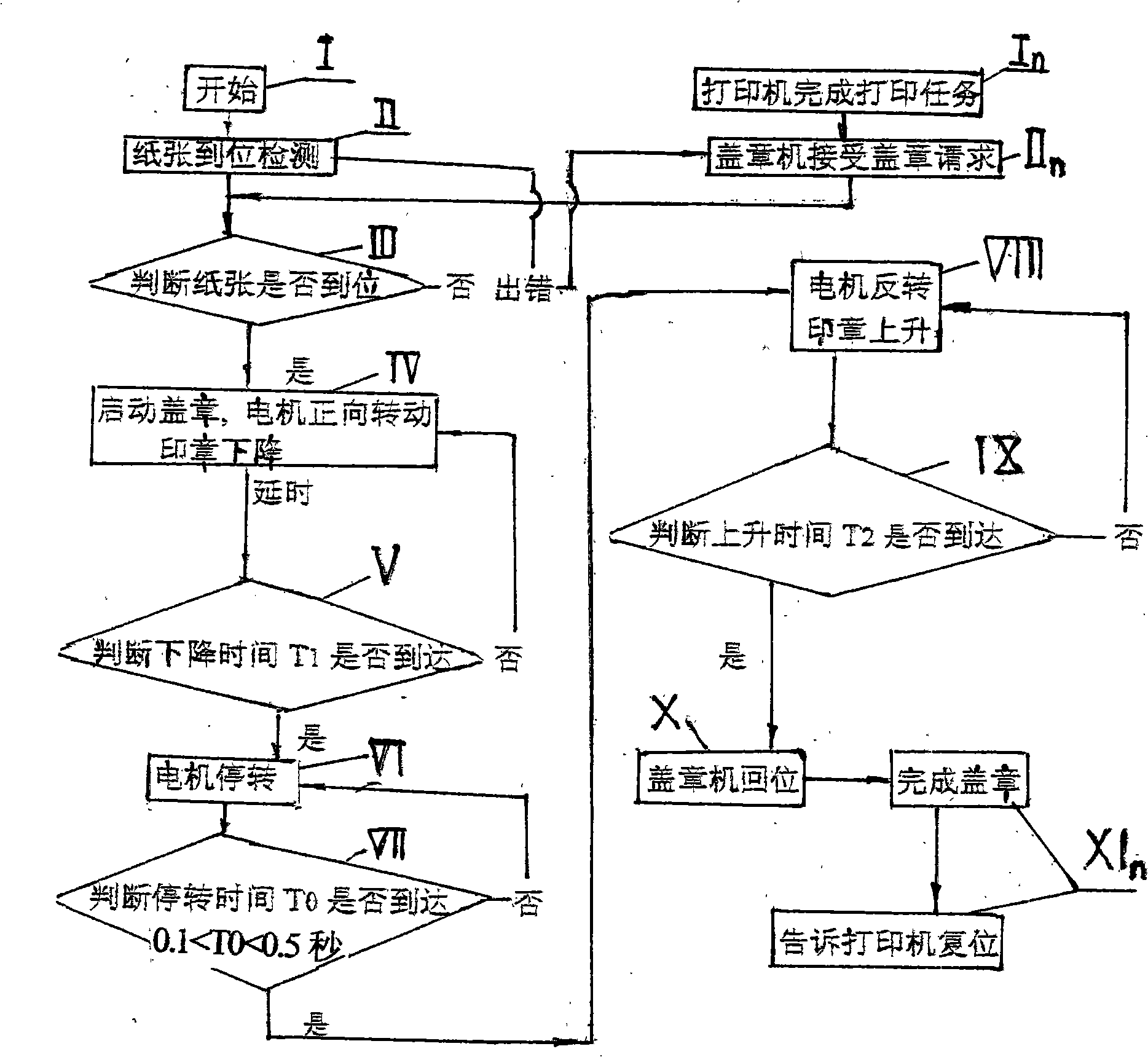

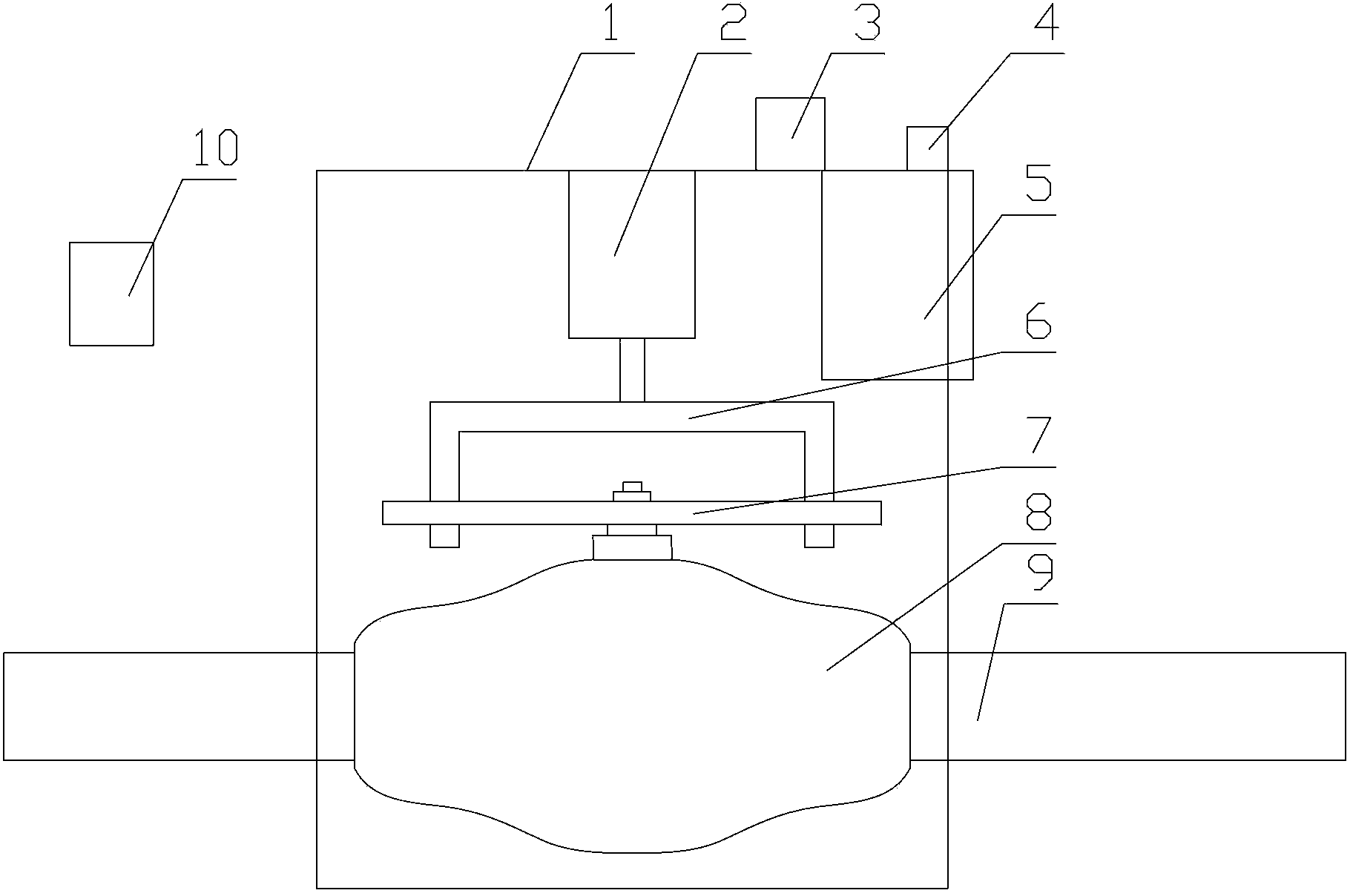

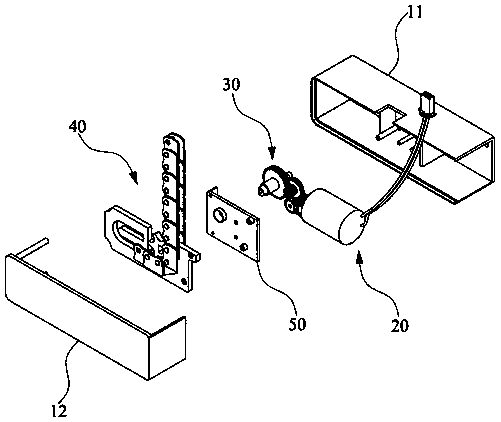

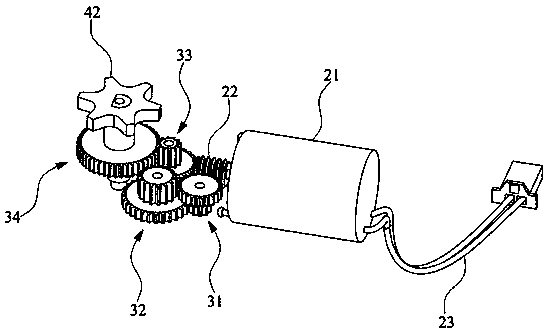

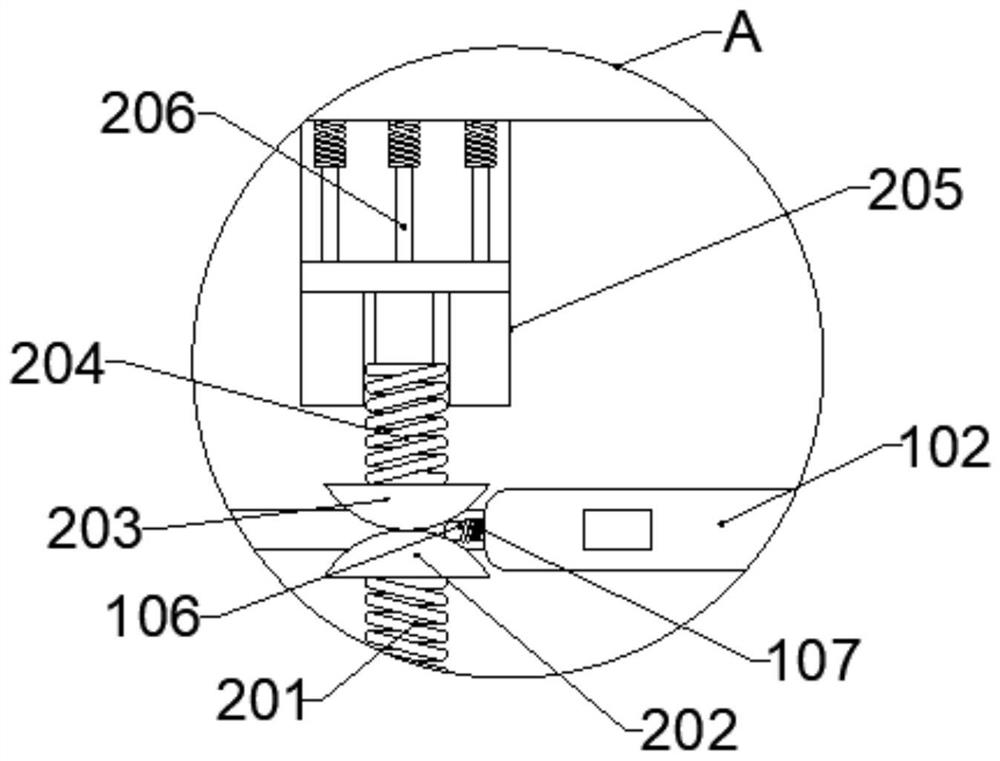

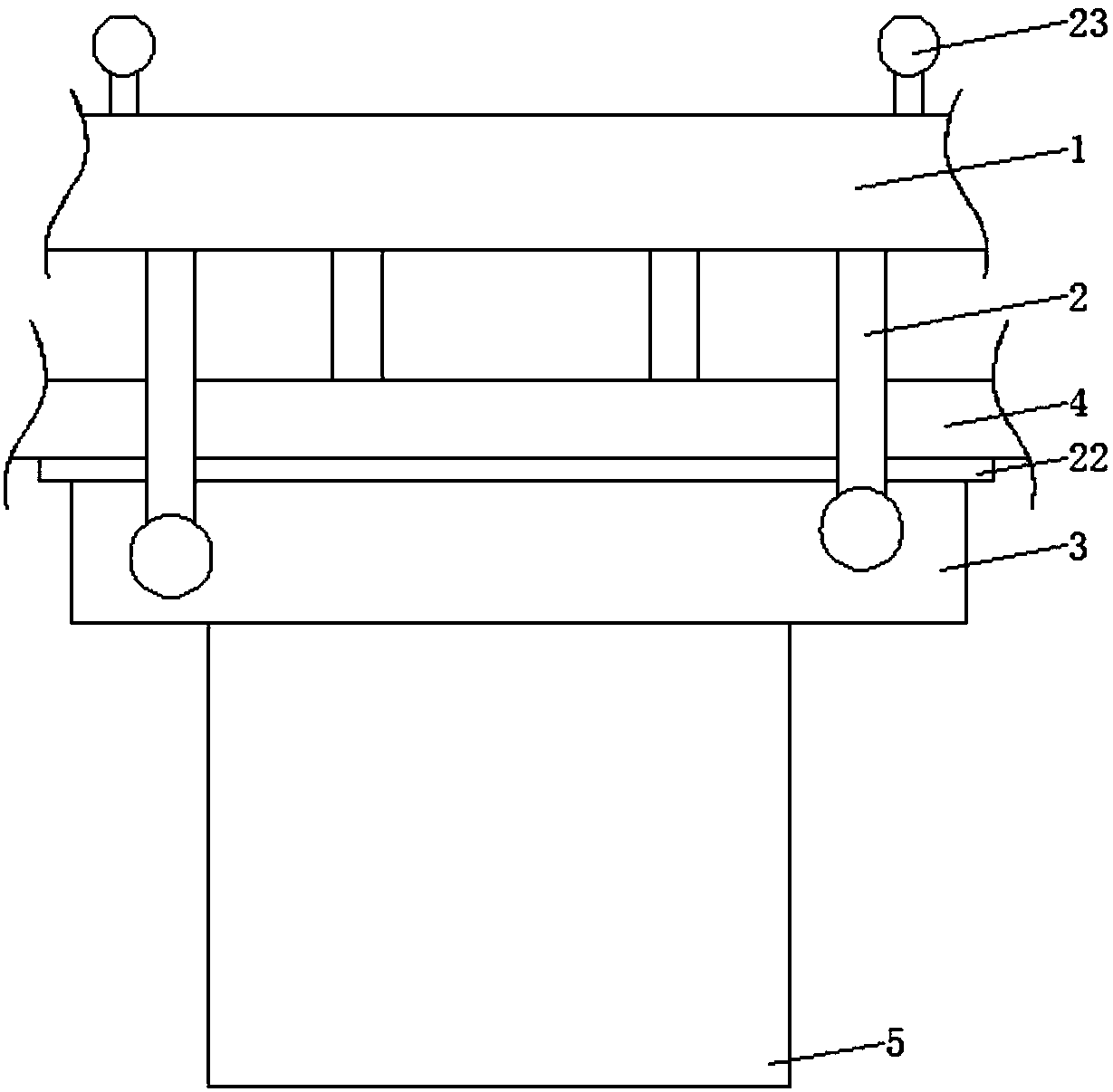

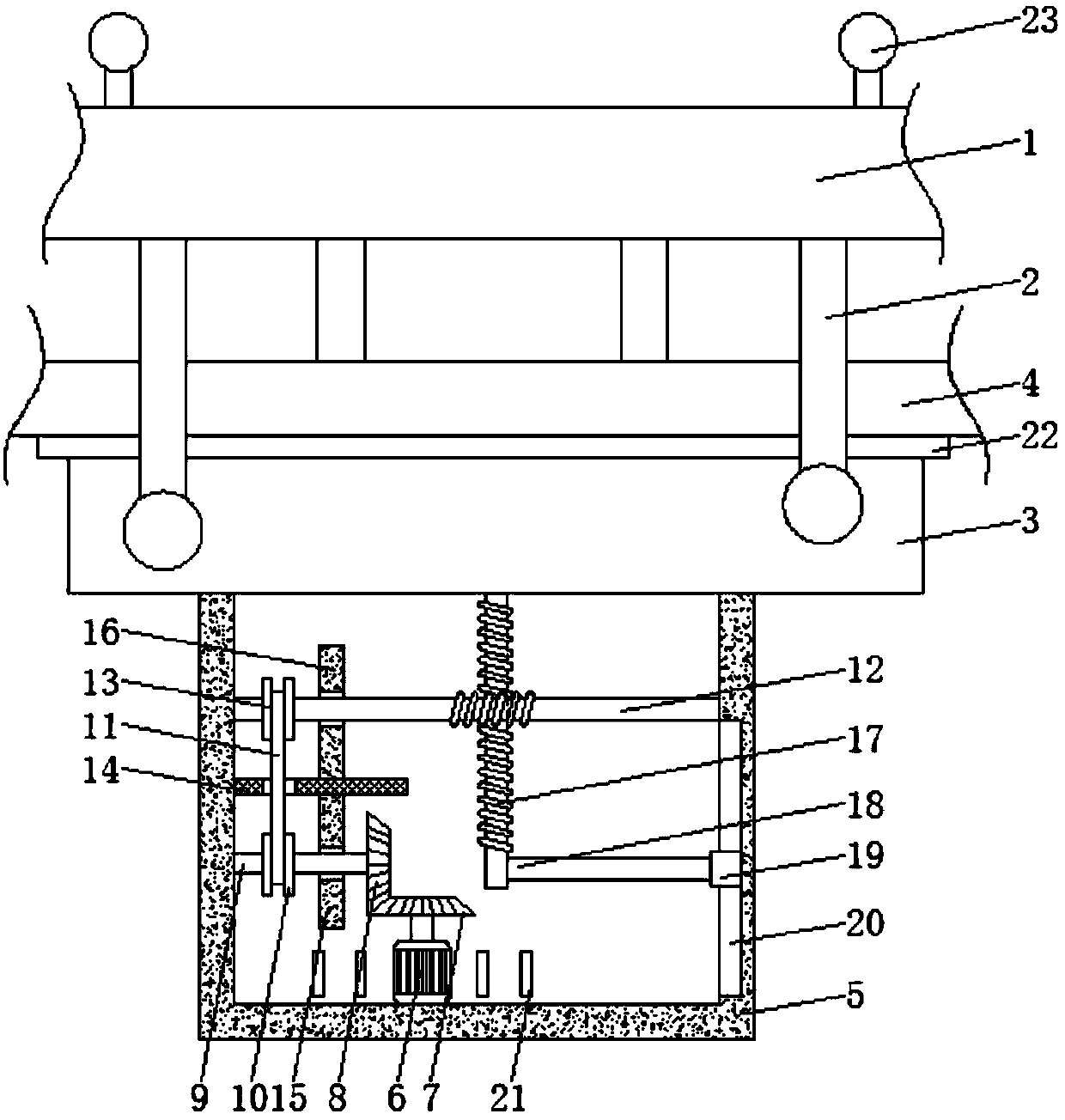

Automatic stamping machine and programmed control method

InactiveCN101337476AAvoid Motor Damage AccidentsAvoid motor damageStampingElectric machineryField-effect transistor

The invention relates to an automatic sealing machine and a program-controlled method. A transmission bracket driven through a gear rack and a motor is installed in an overall bracket, and a compression spring, a sealing handle and a stamp connected through a thread through-hole are installed in the transmission bracket. The sealing handle is pressed between the compression spring and a transmission bracket bottom board. The automatic sealing saves the manual trouble, is time-saving and labor-saving. The arrangement of the compression spring ensures that the descending process of the stamp becomes the optimal sealing process, avoids the damage to the motor, and provides a transient time from the stamp pressing to the stamp lifting. After the sealing handle is taken out, the stamp oil is very convenient to be refilled from the through-hole. A single-chip microcomputer is arranged and controlled through a program; a DC motor two-way drive circuit including a field effect pipe, the loss is low, the directional change is quick and the control is convenient. A photoelectric detector can be used for detecting whether the paper is in place, then the motor is controlled to rotate in the forward direction, the stamp descends; the motor is stopped; when the motor rotates in the reverse direction, the stamp ascends; the run-down time is controlled through the program, thereby the sealing is standard, and the effect is good. The automatic sealing machine can be separately used, and can also be matched with any program control system requiring automatic sealing, such as the printing, the separating and the feeding systems of an automatic paying and invoicing terminal.

Owner:四川道亨计算机软件有限责任公司

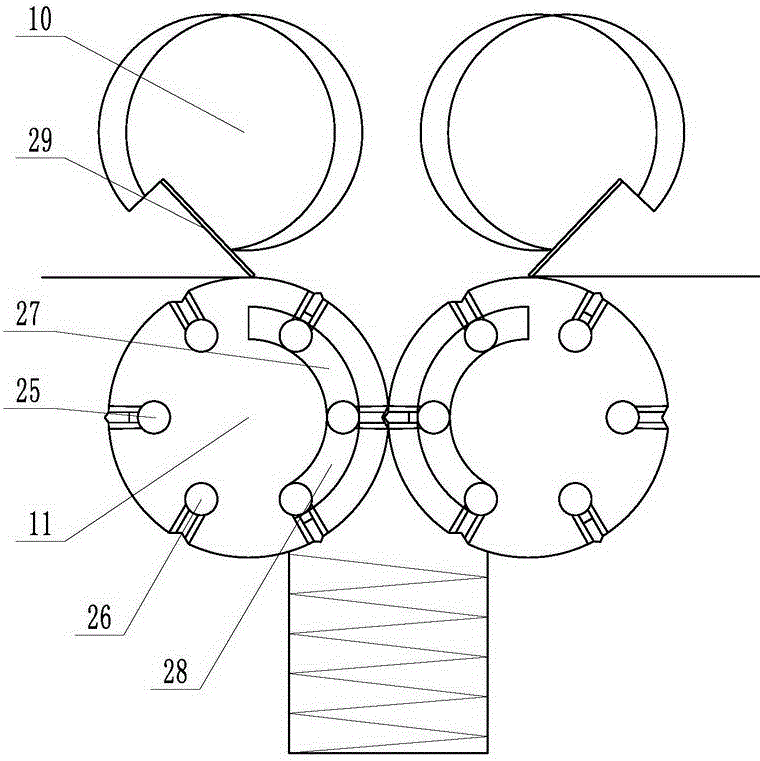

Cutting device for aerated block

InactiveCN108161132APrevent deviationLess effective in avoiding cuttingPositioning apparatusMaintainance and safety accessoriesThreaded pipeArchitectural engineering

The invention discloses a cutting device for an aerated block. The cutting device comprises a shell. A protective cover is fixedly connected to the bottom of the shell. A motor is fixedly connected tothe bottom of an inner cavity of the protective cover. An output shaft of the motor penetrates through the inner cavity of the shell and is fixedly connected with a first bevel gear. Second bevel gears are meshed with two sides of the first bevel gear. A rotating rod is fixedly connected to one side, far from the first bevel gear, of each second bevel gear. Through the arrangement of the protective cover, the motor, the first bevel gear, the second bevel gears, the rotating rods, fixing plates, bearings, first belt pulleys, belts, second belt pulleys, threaded rods, fixed blocks, threaded pipes, clamping plates, the aerated block, a cutting body and supporting legs, the aerated block is fixed in the process of cutting by the cutting device for the aerated block, and can be clamped, so that the problem that unstable cutting causes deviation and poor cutting effect and low cutting efficiency is solved, and convenience is brought to users.

Owner:吴燕梅

Valve pipe fitting polishing device

InactiveCN107855842AEasy to useReasonable height adjustmentRevolution surface grinding machinesGrinding work supportsPipe fittingThreaded pipe

The invention discloses a grinding device for valve pipe fittings, comprising a base, a motor is fixedly connected to the left side of the base, the output shaft of the motor penetrates into the inner cavity of the base and is fixedly connected with a first threaded rod, the first The surface of the threaded rod is provided with external threads, and the end of the first threaded rod away from the motor is movably connected with a bearing. The present invention sets the base, motor, threaded rod, bearing, threaded sleeve, movable rod, groove, sliding rod, sliding sleeve, first fixed block, movable rod, first fixed block, support plate, electric telescopic rod, threaded tube , threaded rod and splint can make the valve and pipe fitting grinding device convenient to use, and the height of the valve and pipe fitting grinding device can be adjusted reasonably according to the height of the user, and it has a clamping function to avoid dangerous situations caused by hand-held valve and pipe fittings. The safety of the device improves the working efficiency of the user.

Owner:叶侃

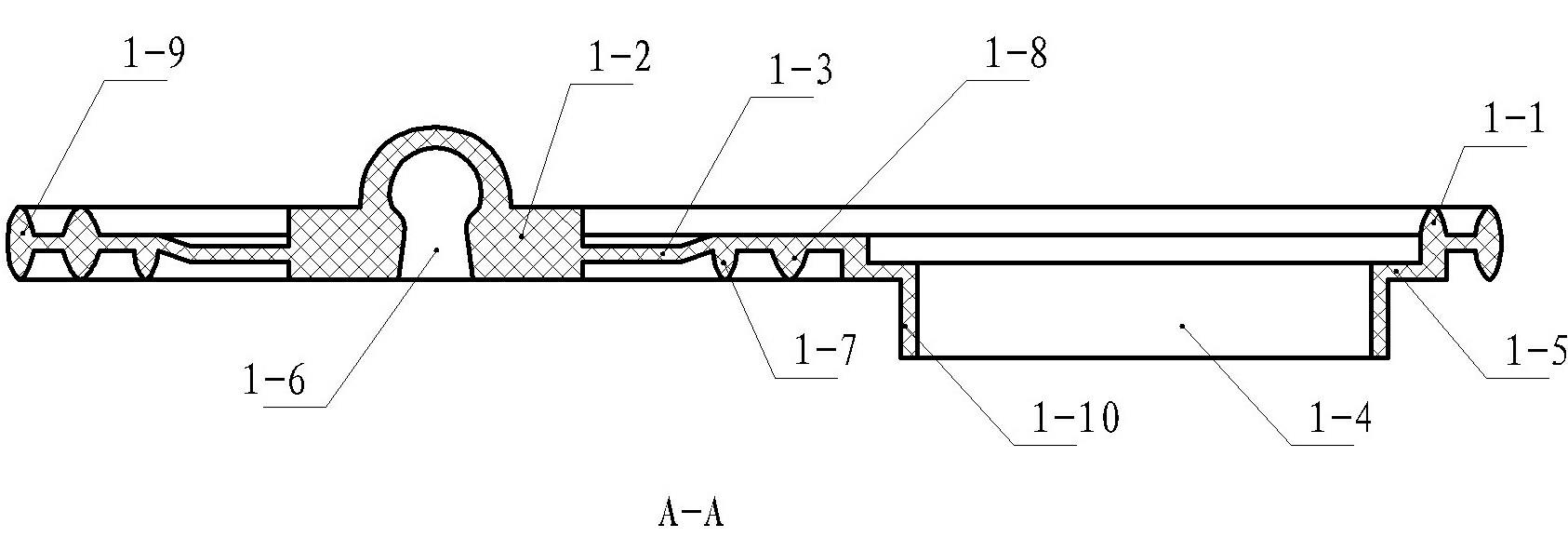

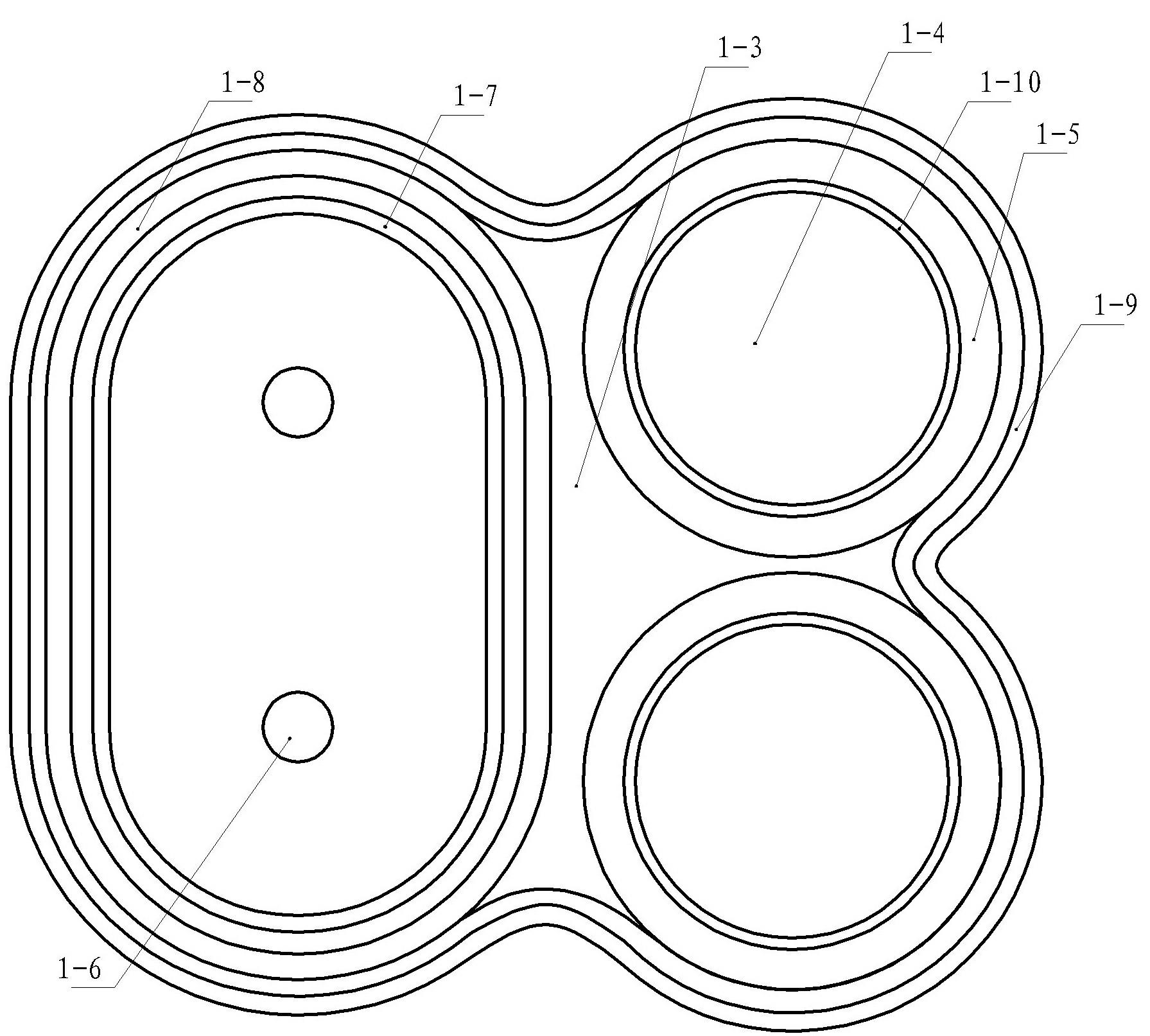

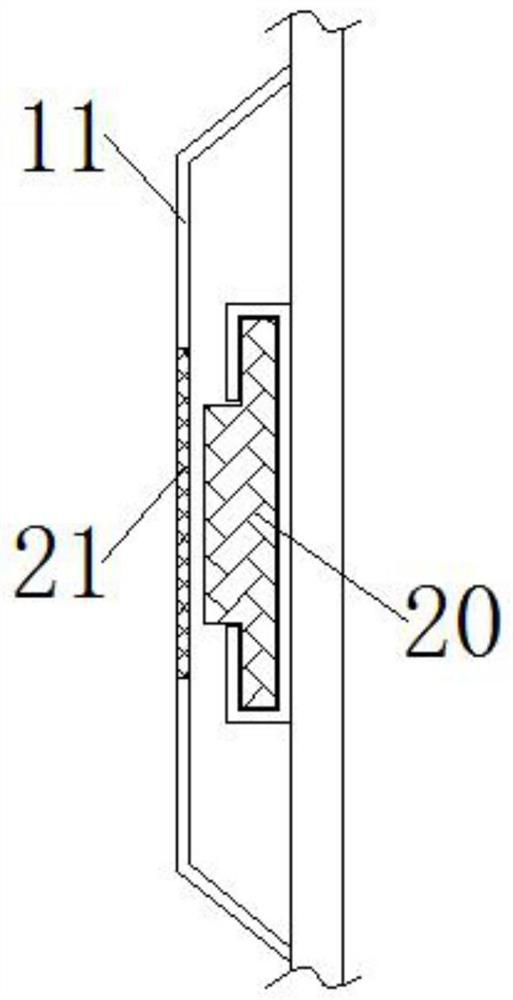

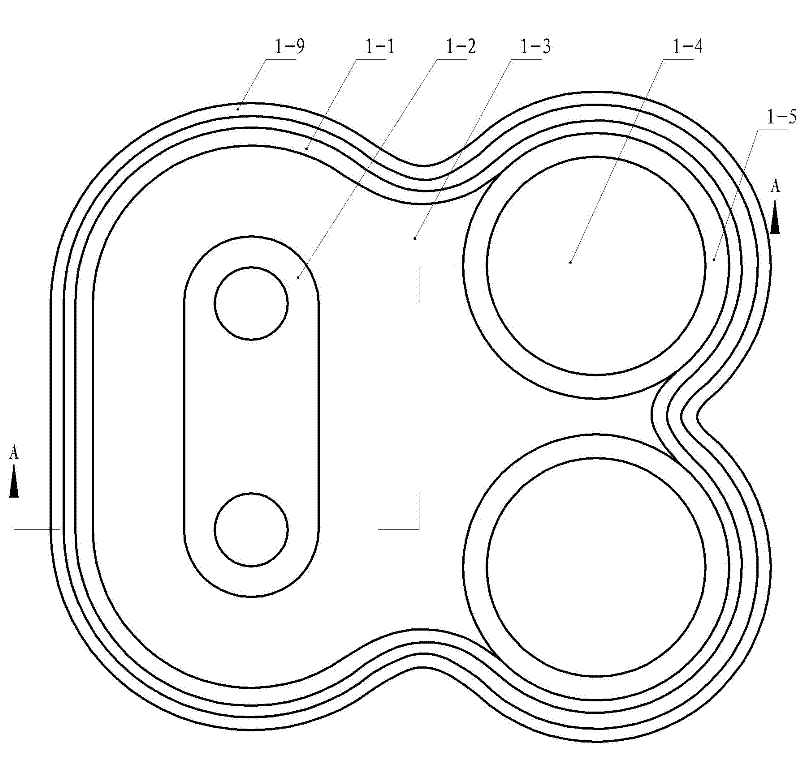

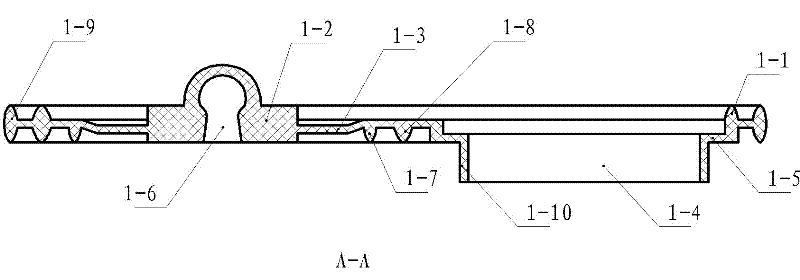

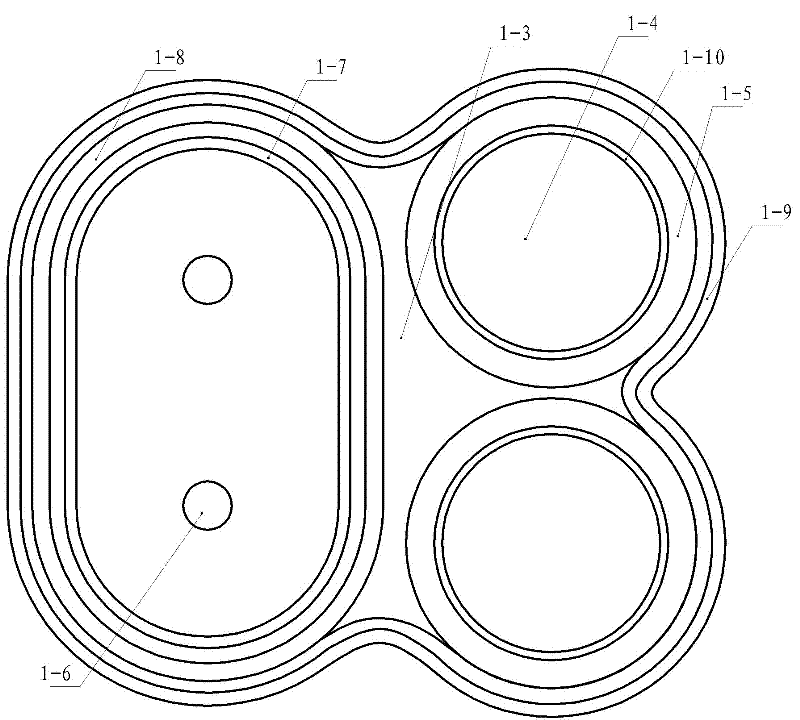

Diaphragm pump diaphragm with combined sealing structure and diaphragm pump

ActiveCN102094794AExtended service lifeHigh liftFlexible member pumpsPositive-displacement liquid enginesDiaphragm pumpWhole body

The invention discloses a diaphragm pump diaphragm with a combined sealing structure and a diaphragm pump. The diaphragm comprises an outer edge sealing ring and an inner diaphragm body, wherein the diaphragm body is provided with a vibrating clamping part and a valve seat installation hole; the vibrating clamping part is provided with a vibrator sealing ring; the vibrator sealing ring is arranged below the diaphragm; the outer edge sealing ring is arranged above the diaphragm; an outer edge additional sealing ring of which the appearance is matched with that of the diaphragm is arranged outside the outer edge sealing ring; the outer edge additional sealing ring is connected with the outer edge sealing ring to form a whole body; an additional sealing ring is arranged inside the vibrator sealing ring; the shape of the sealing ring is similar to that of the vibrator sealing ring; a protruding valve seat sealing sleeve is arranged on the lower side of the valve seat installation hole; and the pump cover and the pump body of the diaphragm pump are provided with installation structures which are matched with the outer edge additional sealing ring, the vibrator additional sealing ring and the valve seat sealing sleeve. Through the improvement, the problem of the sealing of the diaphragm of the diaphragm pump is radically solved, the lift of the diaphragm pump is improved, the service life of the diaphragm pump is prolonged and unnecessary maintenance and waste is reduced.

Owner:郑州绿帝农用机械有限公司

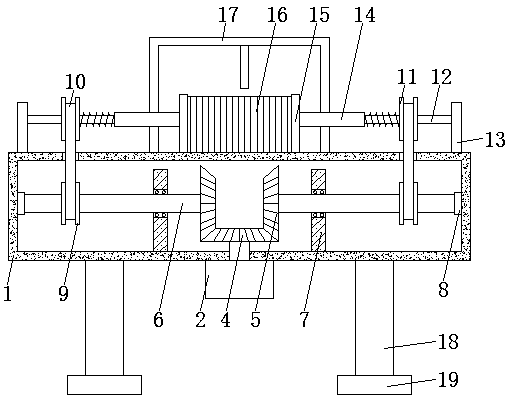

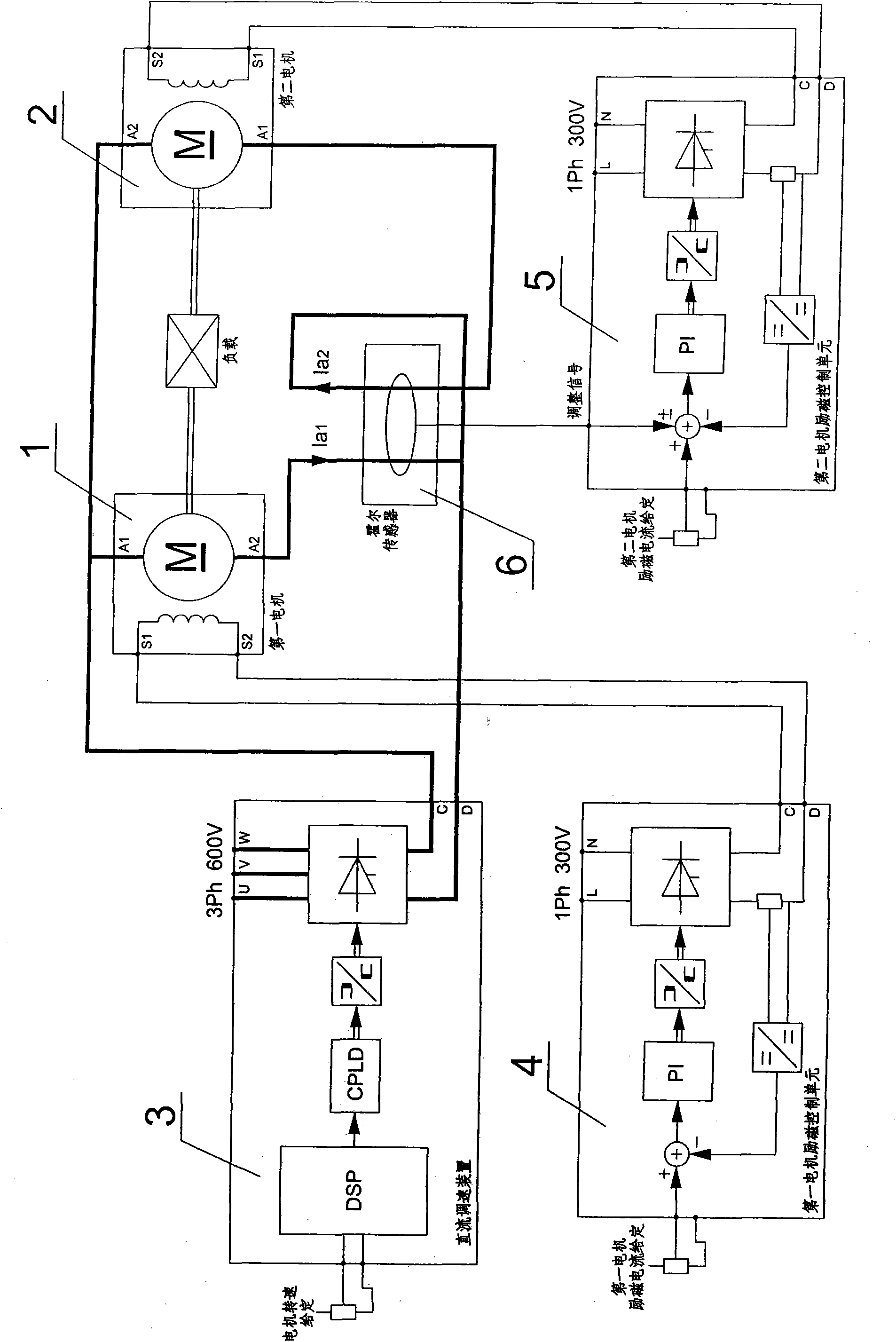

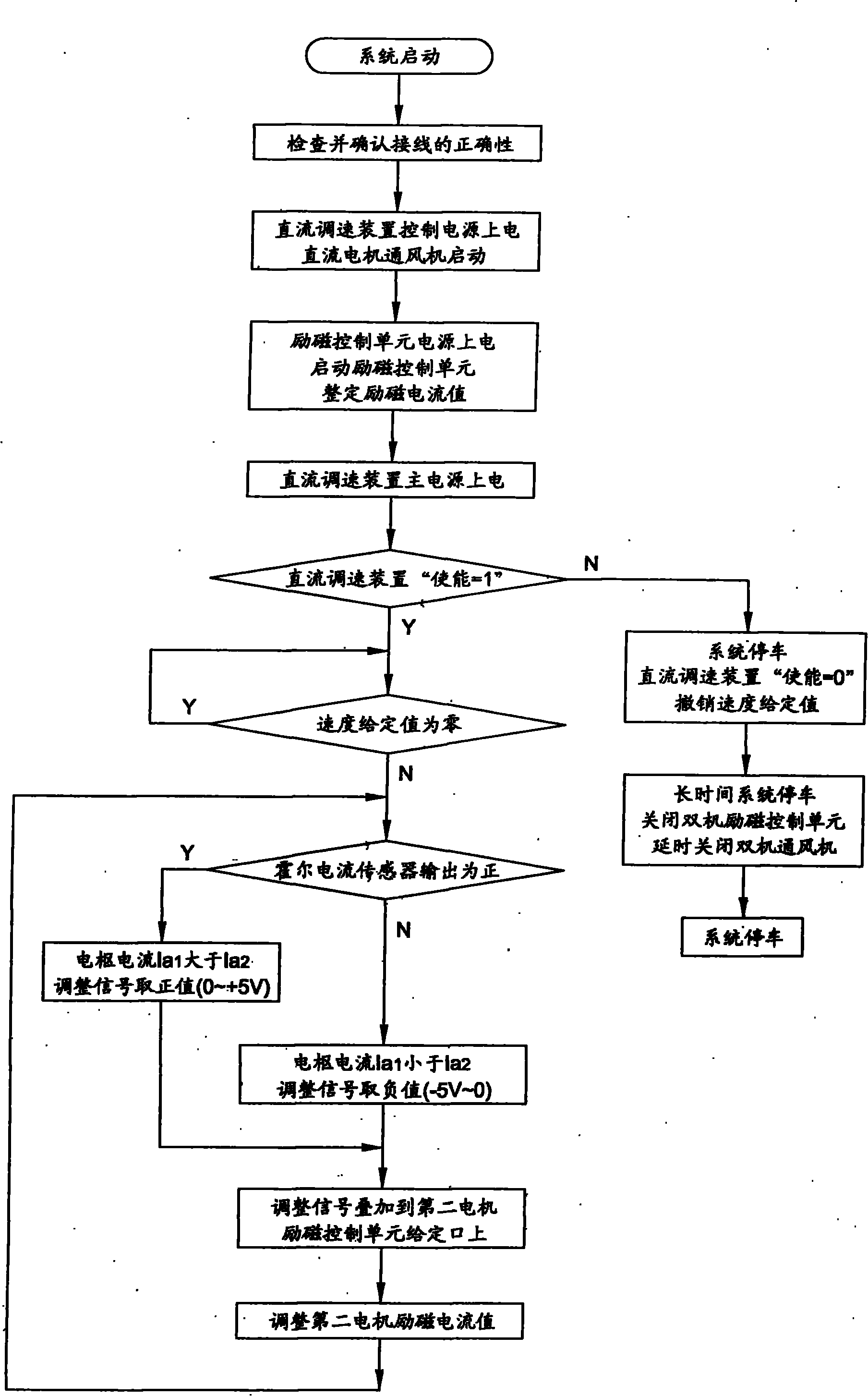

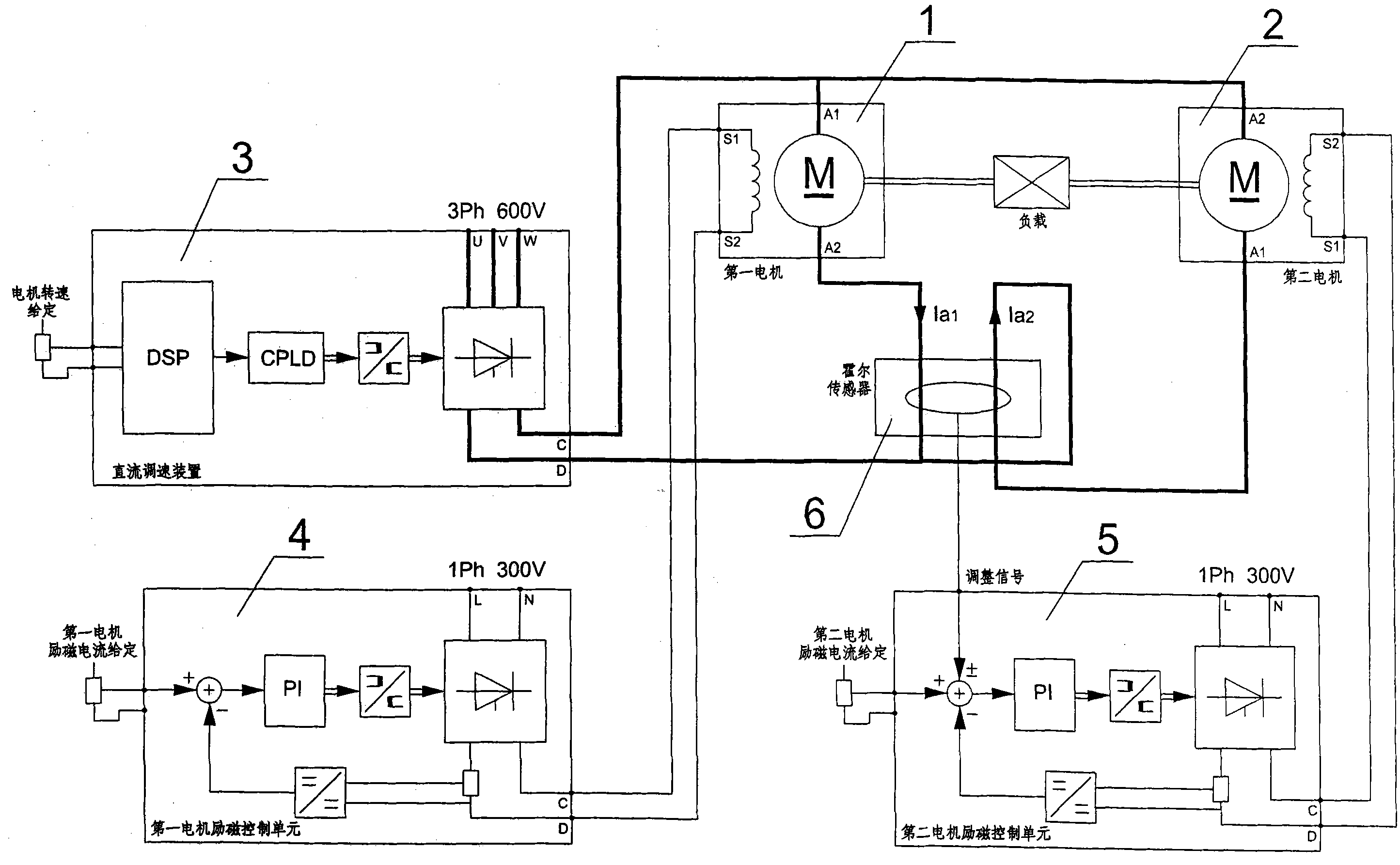

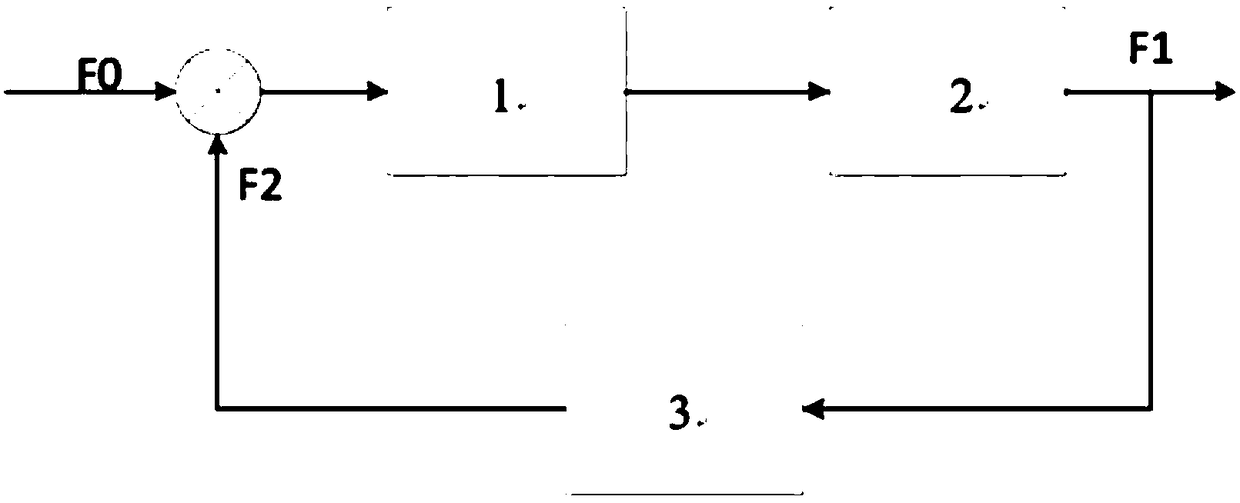

Load balancing control system coaxially operating with dual-direct-current (DC) separately excited machine and control method thereof

InactiveCN102158151AUniform loadAvoid motor damageMultiple dynamo-motor startersControl systemCurrent sensor

The invention provides a load balancing control system coaxially operating with a dual-direct-current (DC) separately excited machine and a control method thereof. The control system comprises a DC speed regulating device, excitation control units and a Hall current sensor; the control system detects the difference value between the armature current of a first motor and the armature current of a second motor by the Hall current sensor when the two motors are operated, and outputs a regulating signal corresponding to the difference value; the regulating signal is overlaid to a given mouth of the excitation control unit of the second motor so as to regulate the exciting current of the second motor, thus realizing automatic equalization of output power of the first and second motors; and if the armature current of the first motor is more than the armature current of the second motor, the regulating signal is a positive value, thus the exciting current of the second motor is increased; and conversely, the regulating signal is a negative value, thus the exciting current of the second motor is decreased.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

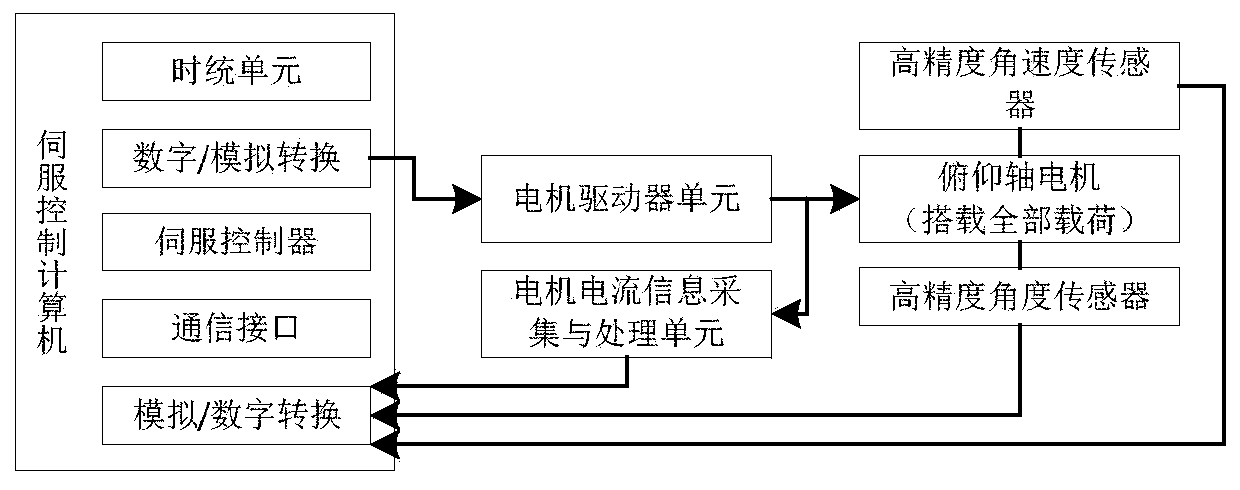

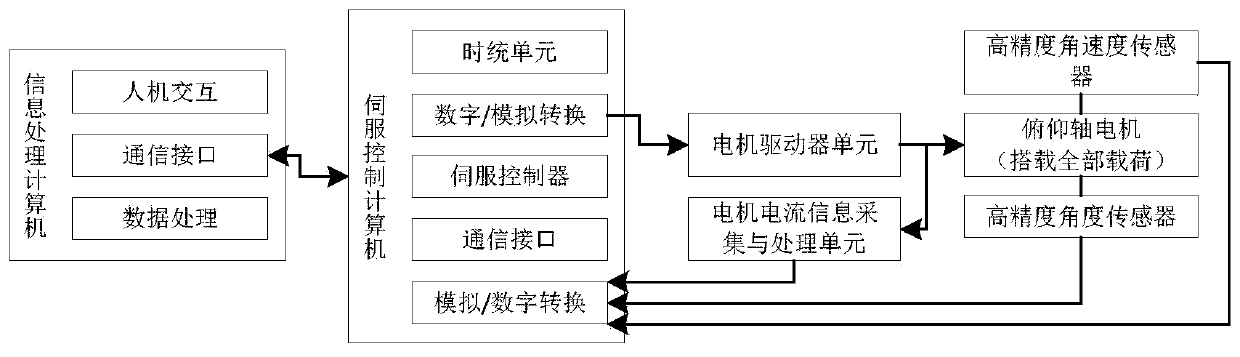

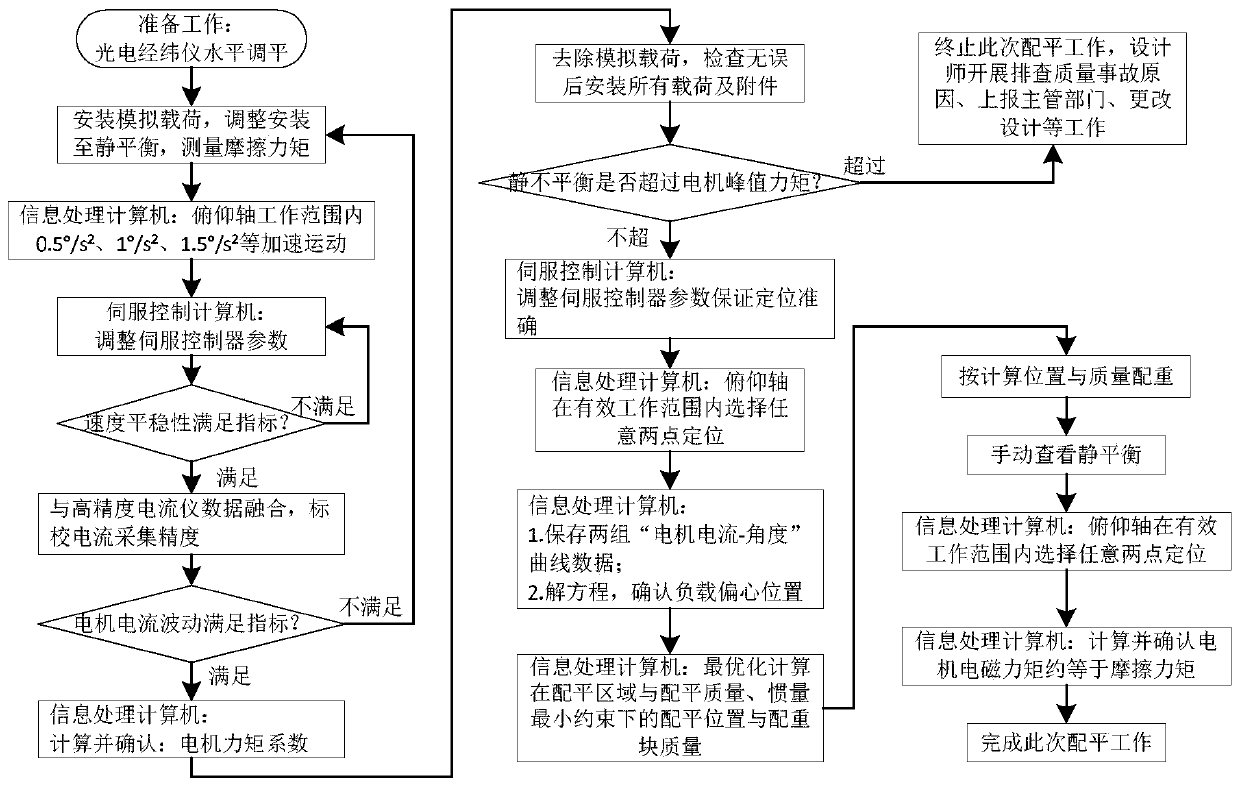

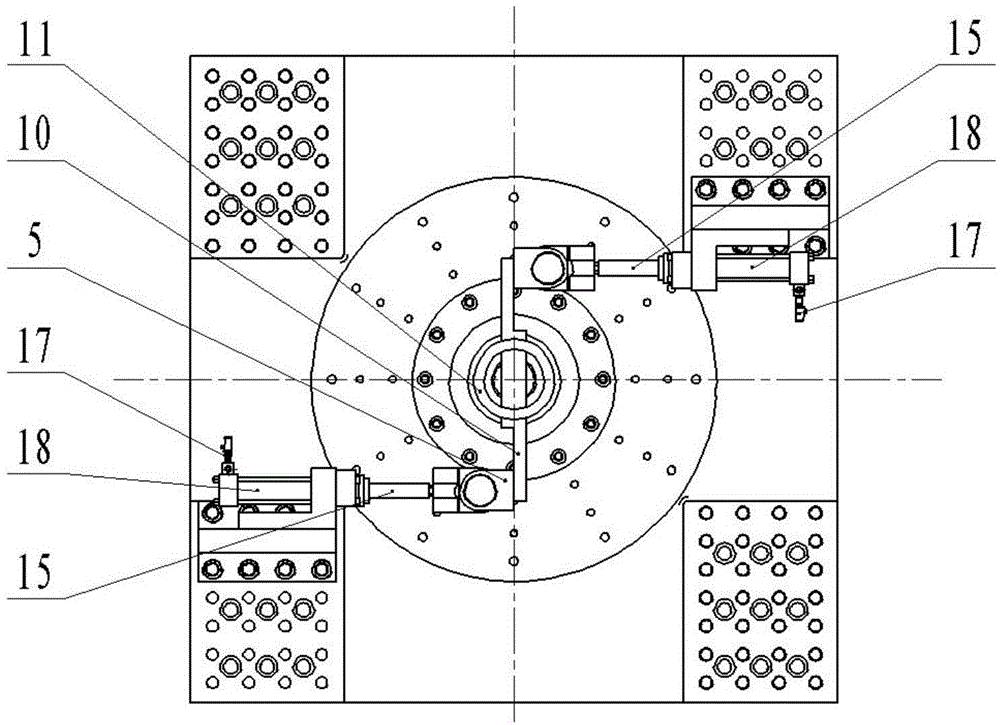

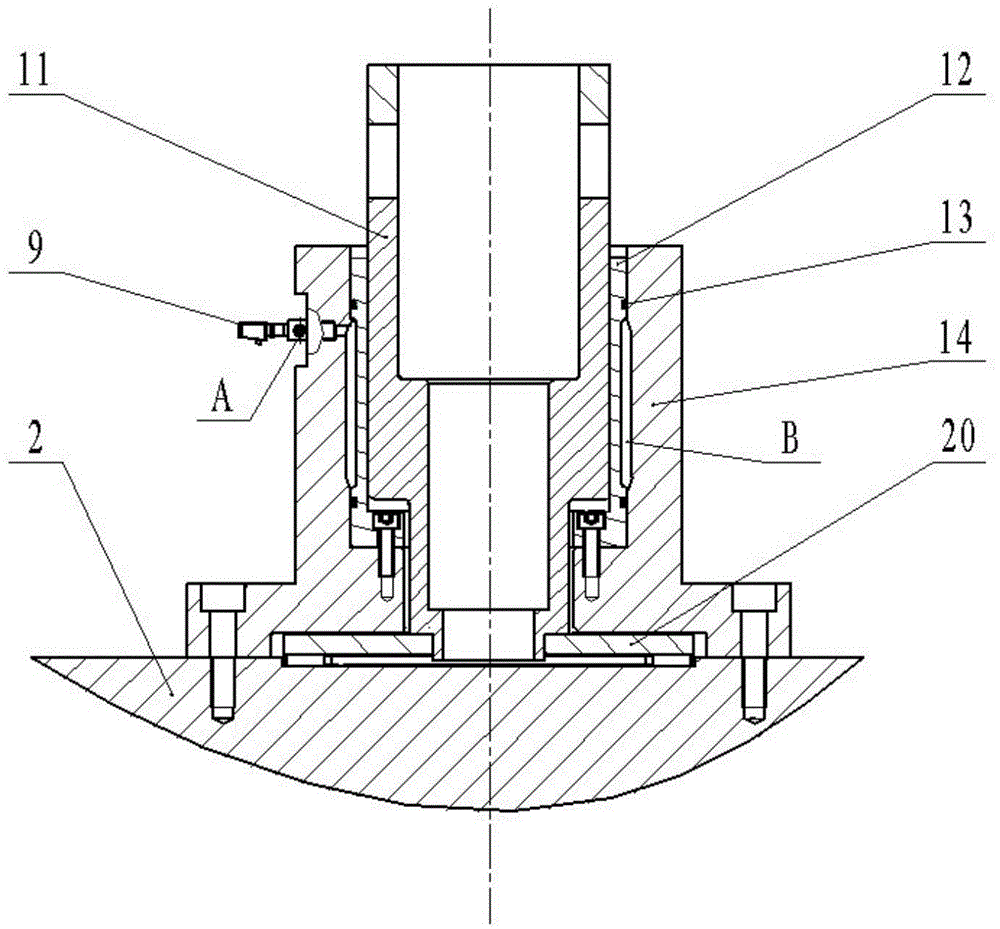

Precise static balance trimming method for pitch axis of large-size photoelectric theodolite

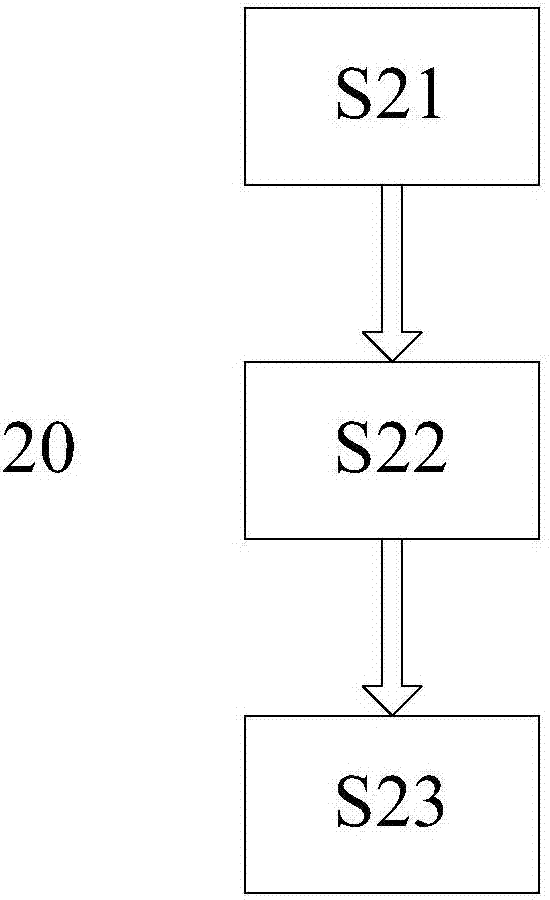

ActiveCN111238729AImprove calculation accuracyAvoid motor damageStatic/dynamic balance measurementPhysicsEngineering

In order to solve the technical problems that an existing manual trimming mode is time-consuming and difficult to guarantee trimming precision, and trimming realized by adopting three-dimensional modeling is difficult to meet practical requirements of real engineering, the invention provides a precise static balance trimming method for a pitch axis of a large-size photoelectric theodolite. The method comprises the following steps: 1) establishing a coordinate system; 2) horizontally leveling the photoelectric theodolite; 3) installing a simulation load on the pitch axis of the photoelectric theodolite, adjusting the installation position until the rotary motion of the pitch axis of the photoelectric theodolite reaches static balance, and measuring the friction torque Td of the shafting; 4)calculating a pitch axis motor torque coefficient KT; 5) measuring a real load eccentric position; 6) performing counterweight mass and position optimization calculation; 7) trimming; and (8) optimizing, rechecking and confirming counterweight mass and position.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

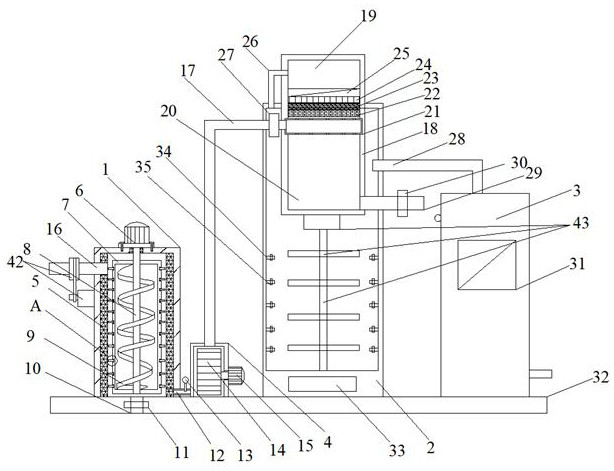

Layered sewage treatment equipment

InactiveCN112607919AFast deliveryReduce lossWater treatment parameter controlSpecific water treatment objectivesWater storage tankSludge

The present invention discloses layered sewage treatment equipment which comprises a pretreatment box, a purification box, a water storage tank, a lifting pump box, an isolation screen plate, a first motor, a knife rest, a dragon shaft, a spiral conveying blade, a water pressure sensor, an impeller, a second motor, a lifting pipe, a filter box, a controller, a base, an ozone generator and an arc-shaped scraper. The arc-shaped scraper is matched with the torsion spring so that the scraper head of the arc-shaped scraper can extend into meshes of the isolation screen plate, compared with a traditional scraper, the impurity scraping effect is improved, meanwhile, the loss of the arc-shaped scraper is reduced, and energy conservation and environmental protection are achieved by adopting a timed opening scraping mode; and the controller receives a water pressure signal of the water pressure sensor to adjust starting, stopping and the rotating speed of the second motor, the phenomenon that the motor is damaged due to idling is avoided, meanwhile, a good energy-saving effect is achieved, the sewage filtering efficiency is improved through the bottom-to-top filtering mode of sewage in the filtering box, meanwhile, sludge discharging is facilitated, design is reasonable, and the management cost is reduced.

Owner:曹芳芳

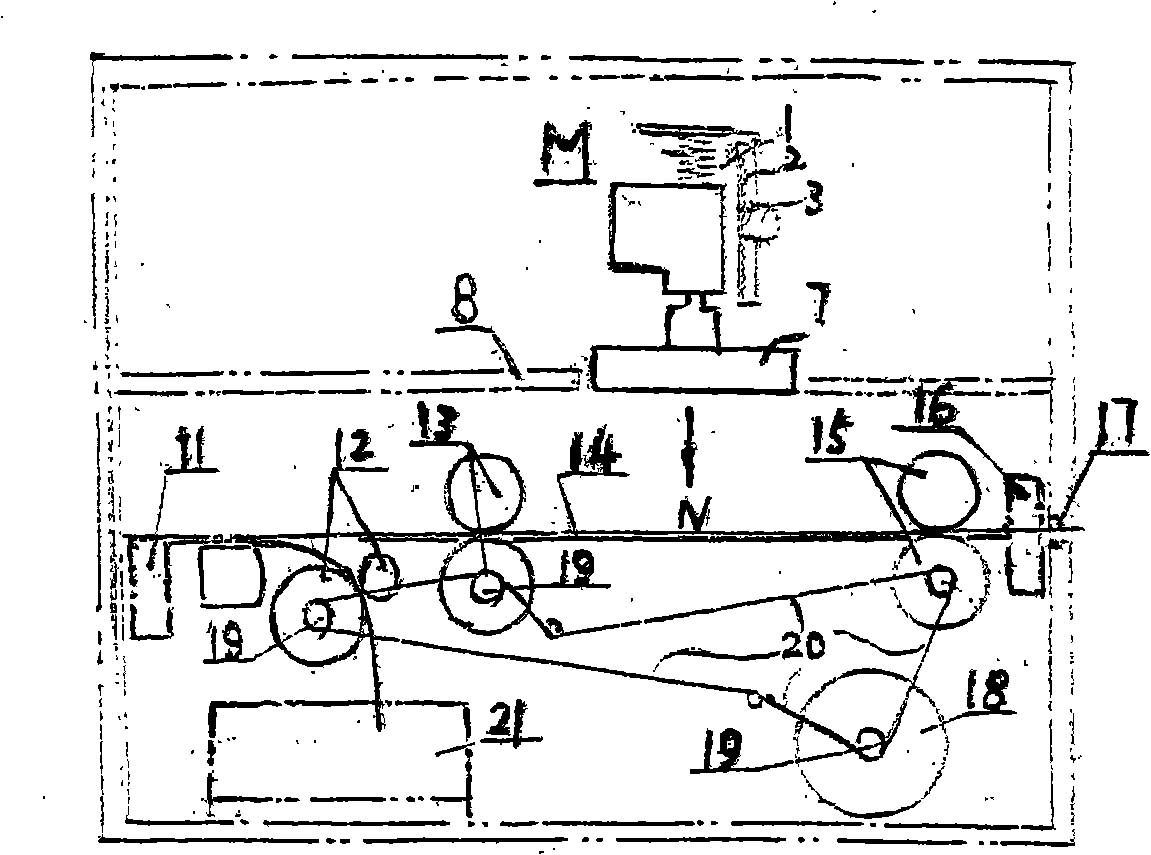

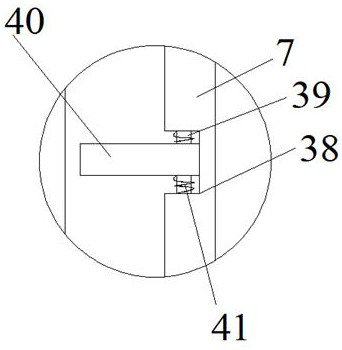

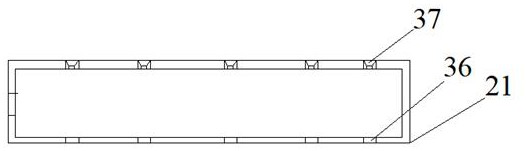

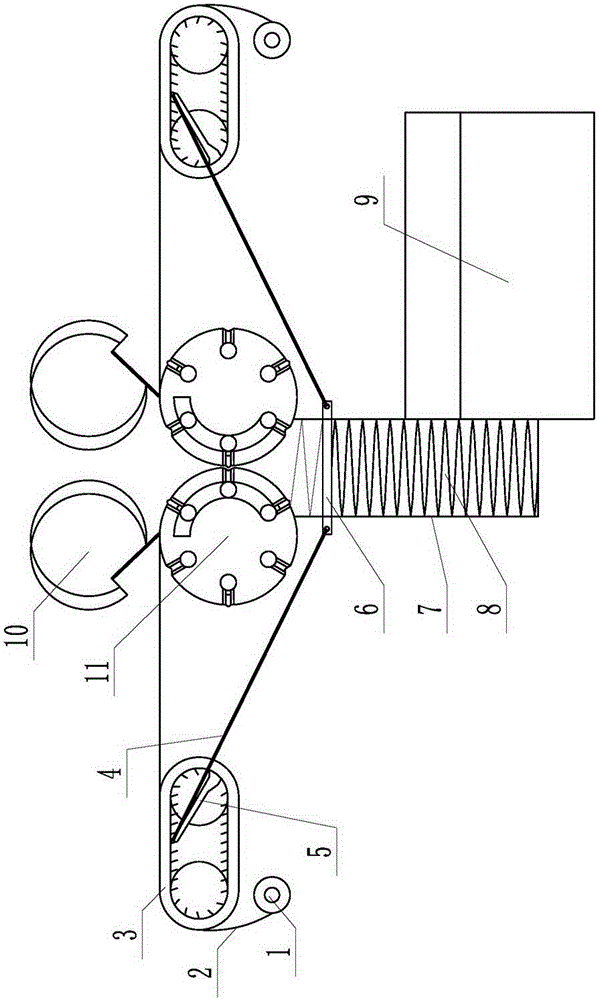

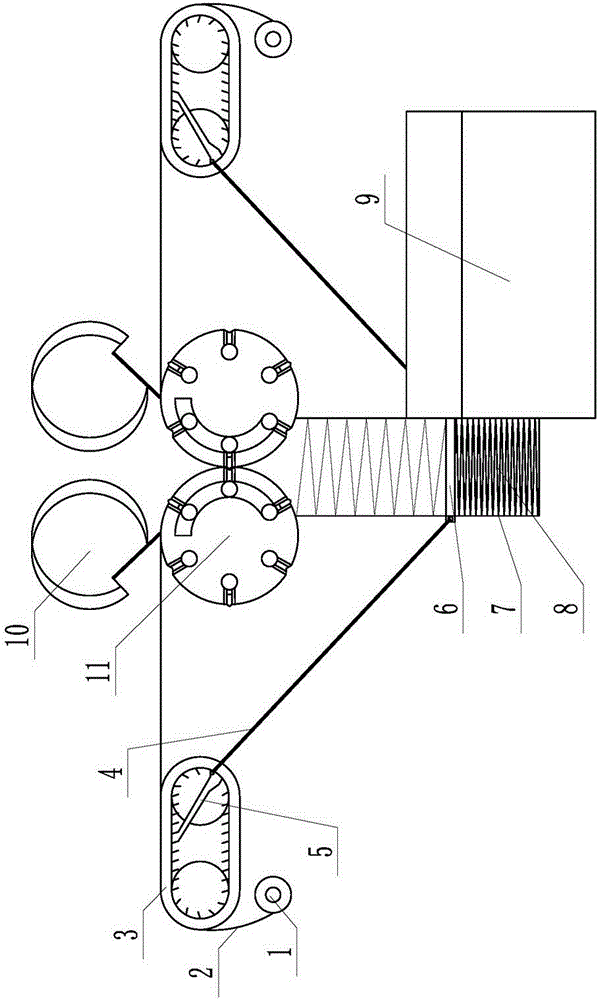

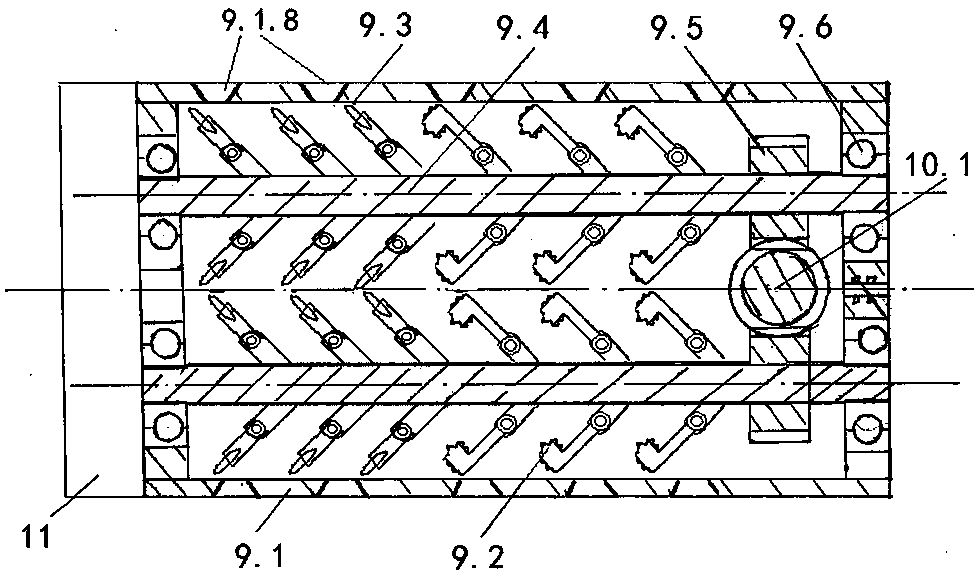

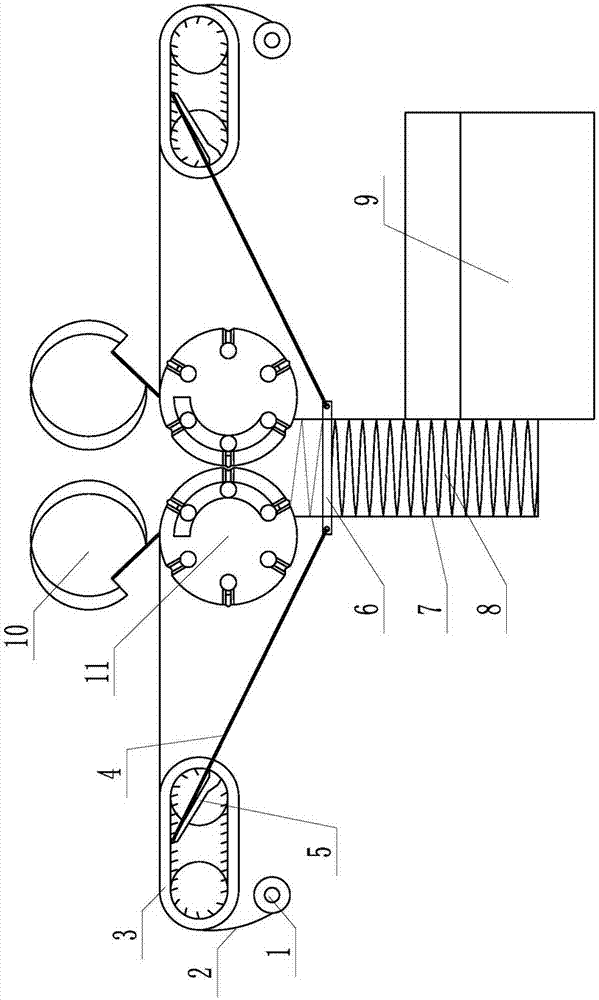

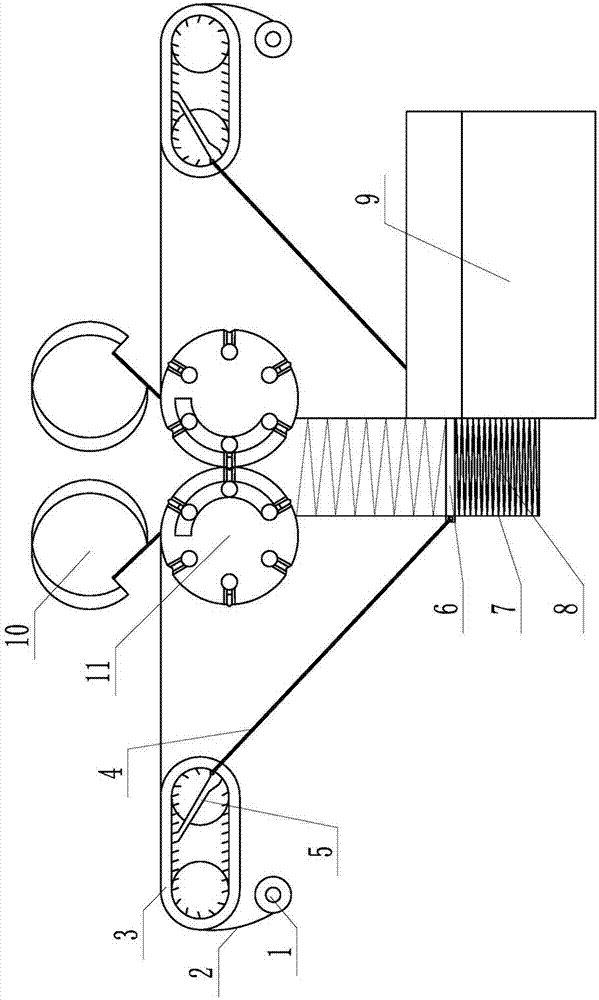

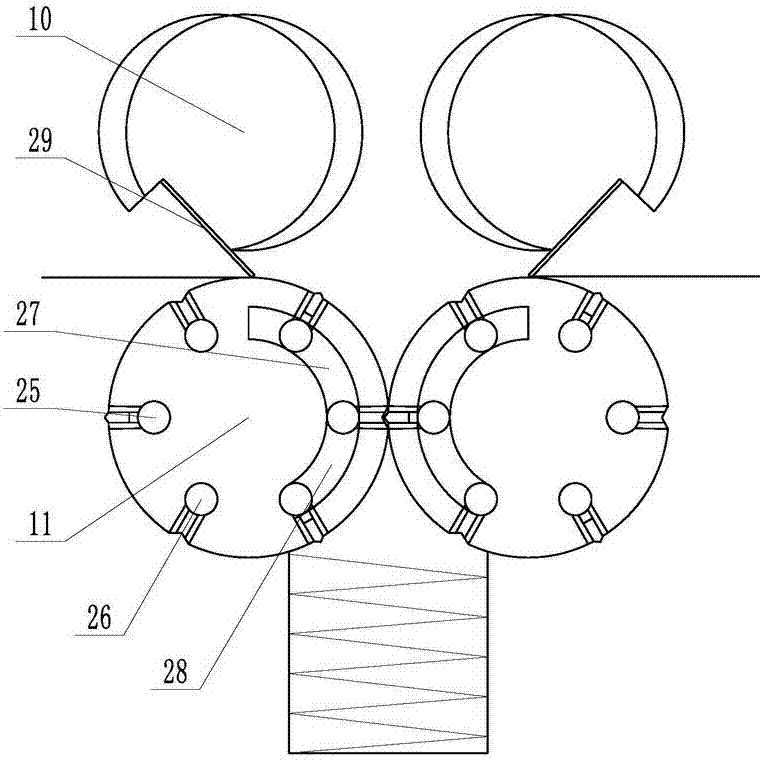

Tissue packaging machine for hygienic materials

ActiveCN106516232AReduce investmentReduce in quantityPaper article packagingFolding thin materialsProduction scheduleProduction line

The invention provides a tissue packaging machine for hygienic materials. By adoption of the tissue packaging machine for the hygienic materials, the problems that existing equipment cannot well integrate the tissue production process, negative influences are caused due to the fact that production is conducted through multiple procedures, tissues are scrapped due to secondary pollution, the cost is increased, the equipment is not provided with an overload protection device and consequentially is damaged, the service life of the equipment is shortened, and smooth proceeding of machining is affected are effectively solved. The tissue packaging machine for the hygienic materials comprises a tissue conveying mechanism, a folding mechanism and a packaging mechanism. Compared with the prior art, a folding production line and a packaging production line are combined, personnel investment and the number of procedures are reduced, the production process is simplified, and the tissue production schedule is accelerated; by adoption of a full-automatic production line, the probability of secondary pollution of the tissues in the transferring process can be lowered; and by additionally arranging the overload protection device on the packaging line, the situation that a motor and the equipment are damaged due to excessive stress in the operating process is avoided, the service life of the equipment is prolonged, the production speed is increased, the probability of time delay caused by halts is lowered, and the working efficiency is improved.

Owner:邯郸市洁雅卫生用品有限公司

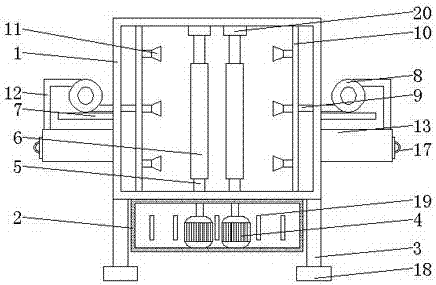

Mold polishing device

InactiveCN107962477AImprove work efficiencyImproved appearance quality and maintenance efficiencyGrinding carriagesGrinding machinesEngineeringAir blower

The invention discloses a mold polishing device. The device comprises a housing, wherein a first box body is fixedly connected to the bottom part of the housing; supporting legs are fixedly connectedto two sides of the bottom part of the housing and are positioned at two sides of the first box body; two motors are fixedly connected to the bottom part of an inner cavity of the first box body; output shafts of the motors pass through the housing and the first box body and extend into the inner cavity of the housing, and the output shafts of the motors are connected to polishing barrels; bearings are fixedly connected to the top part of the housing. According to the mold polishing device, supporting plates, air blowers, air inlet pipes, ventilating pipes, dust collecting ports, air outlet pipes, a second box body, a dust storing box, roller racks and rollers are arranged, so that the wastes produced by polishing can be timely removed and are prevented from flying everywhere to pollute surrounding environment, and the circumstance that a user inhales harmful wastes leading to influence on the body can be avoided; the working efficiency of the user is improved; and the mold apparent mass and the maintaining efficiency can be improved.

Owner:王腾蛟

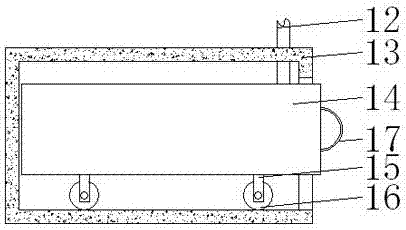

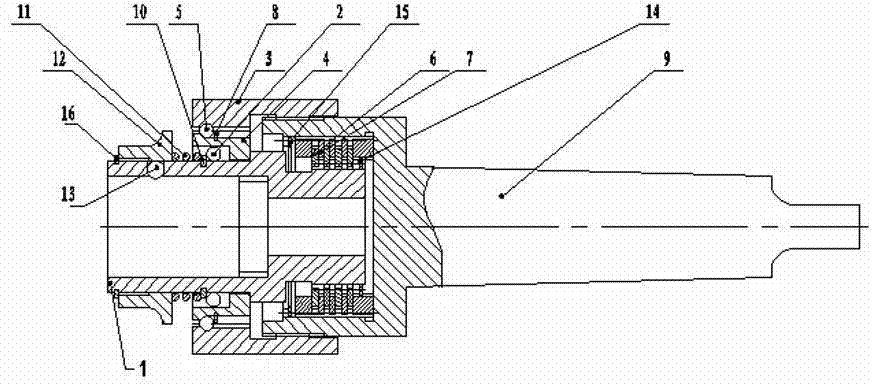

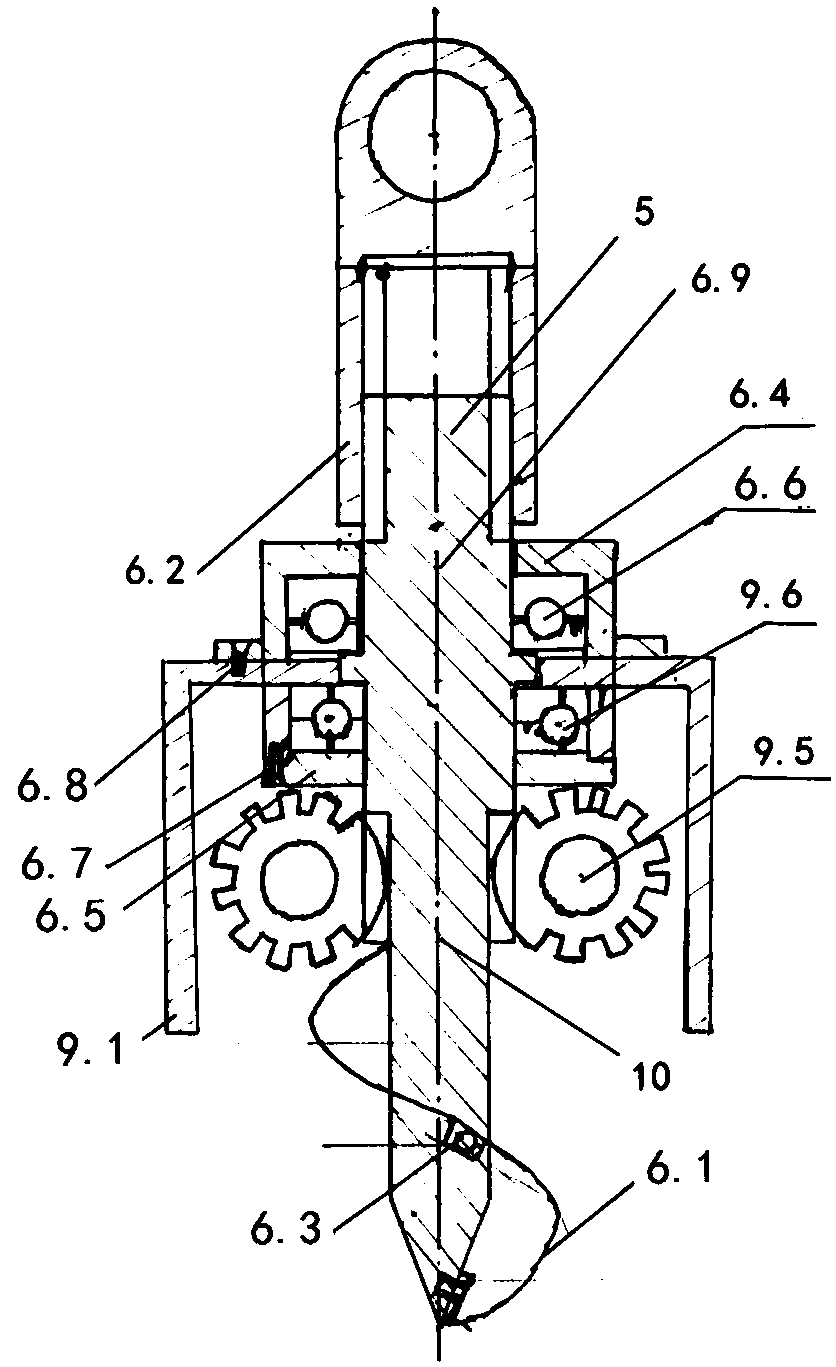

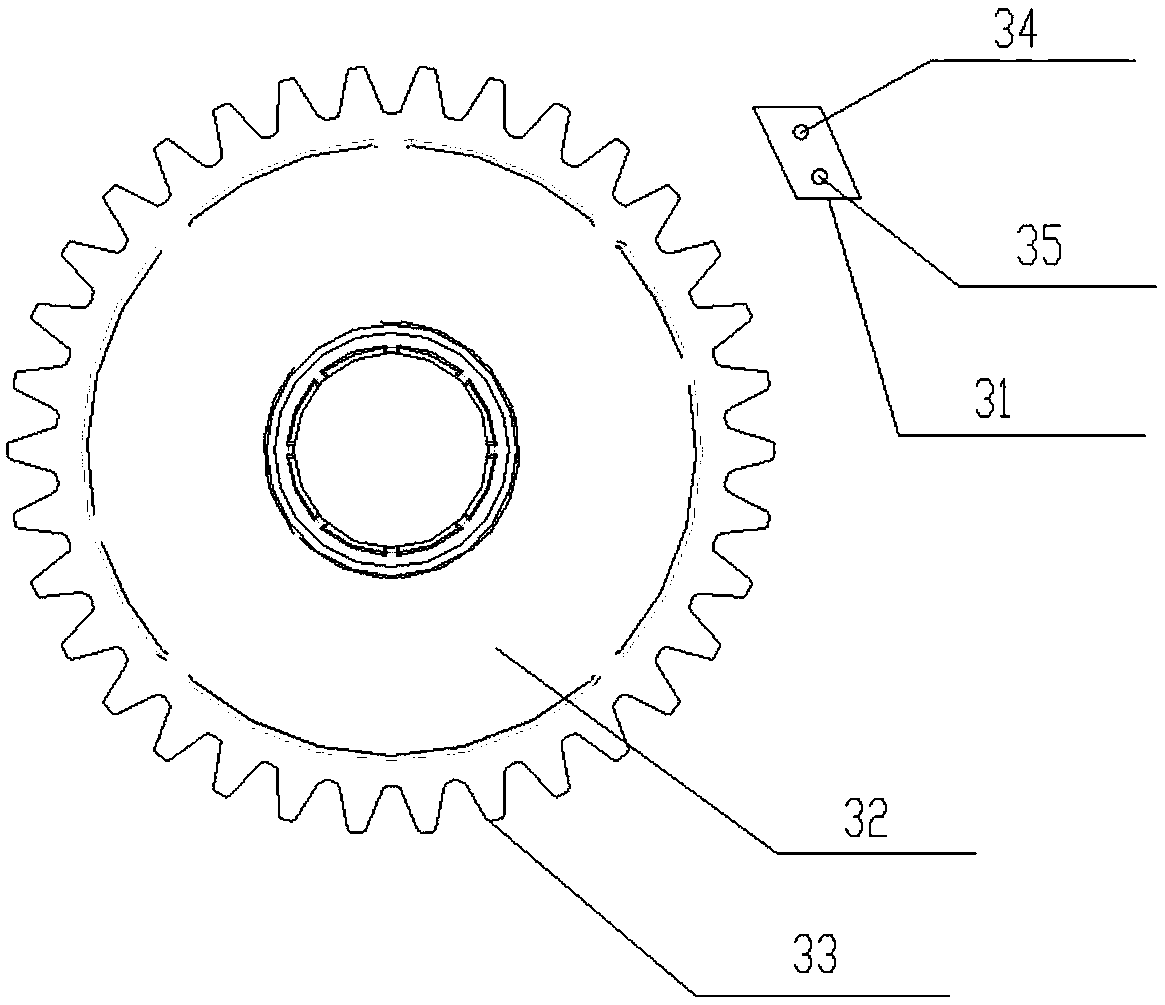

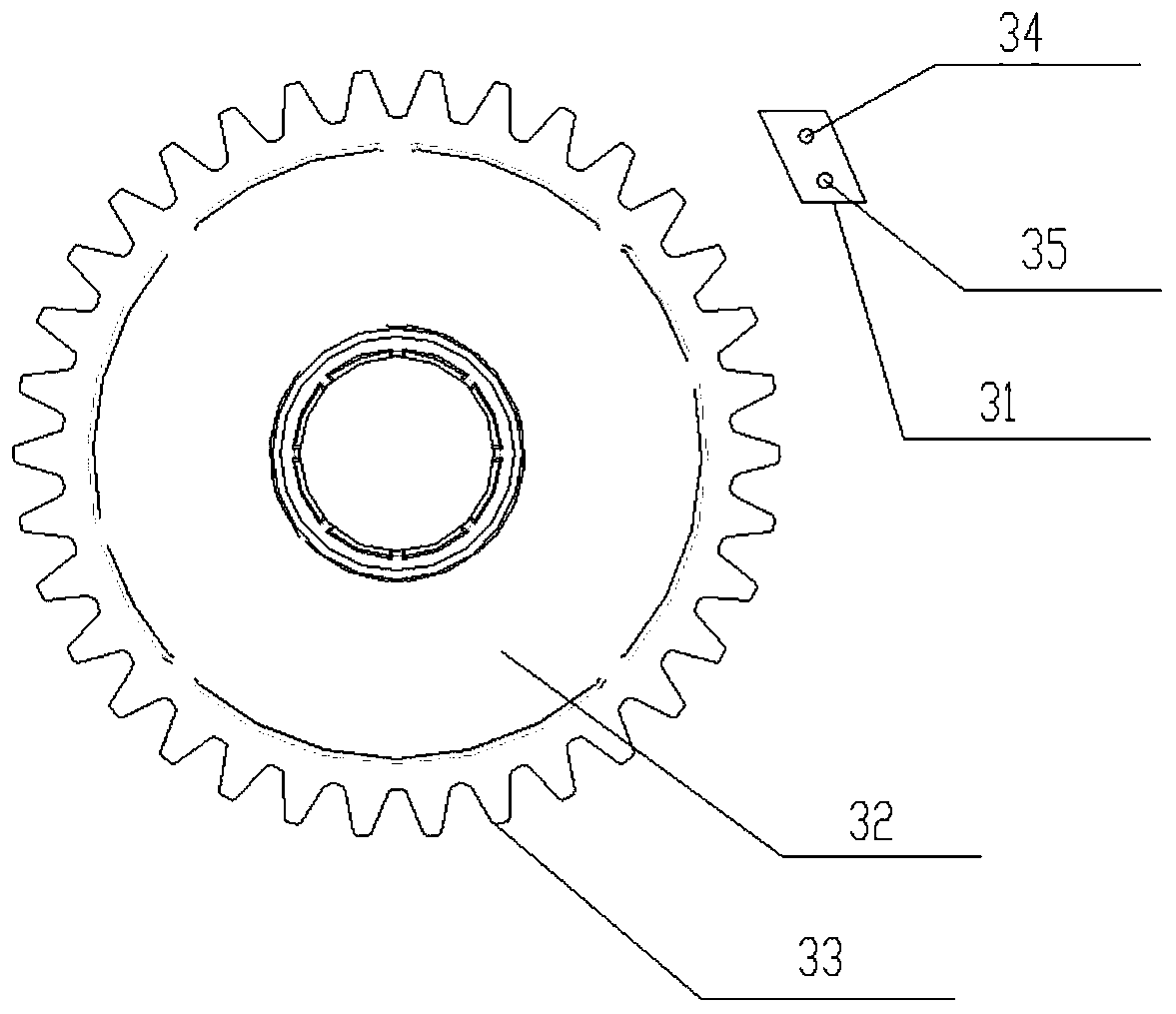

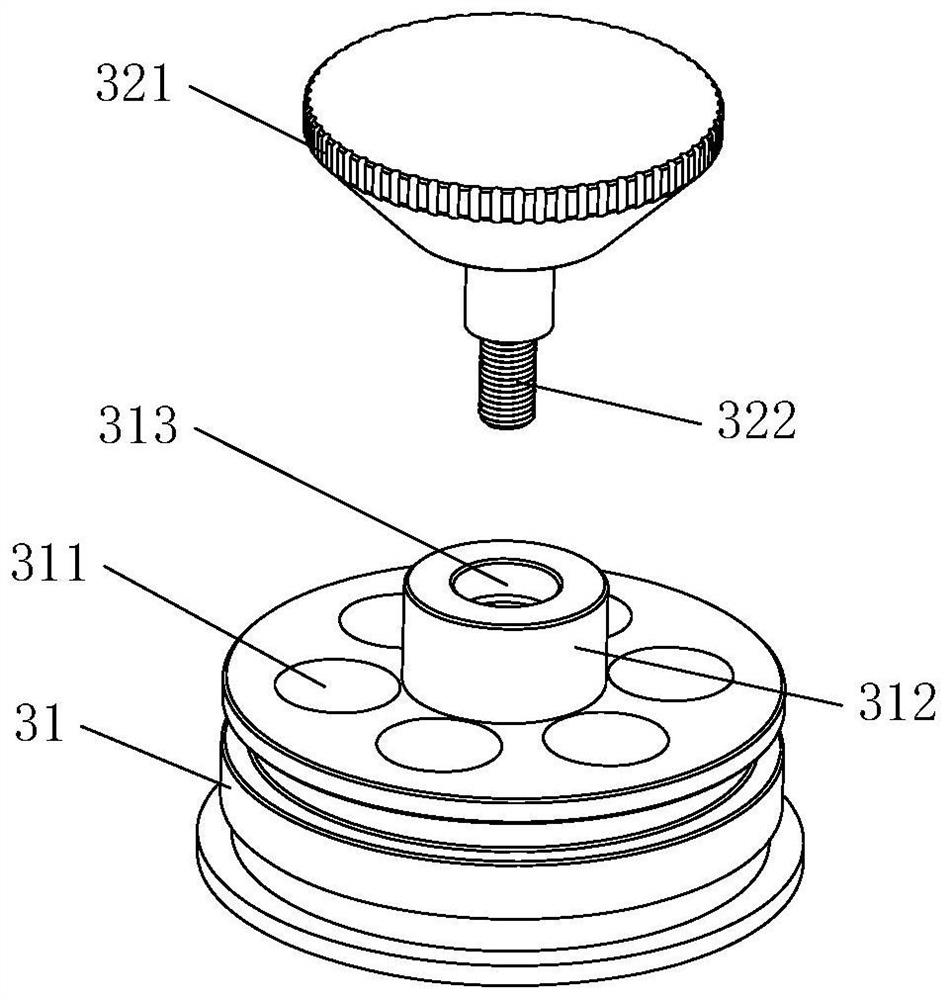

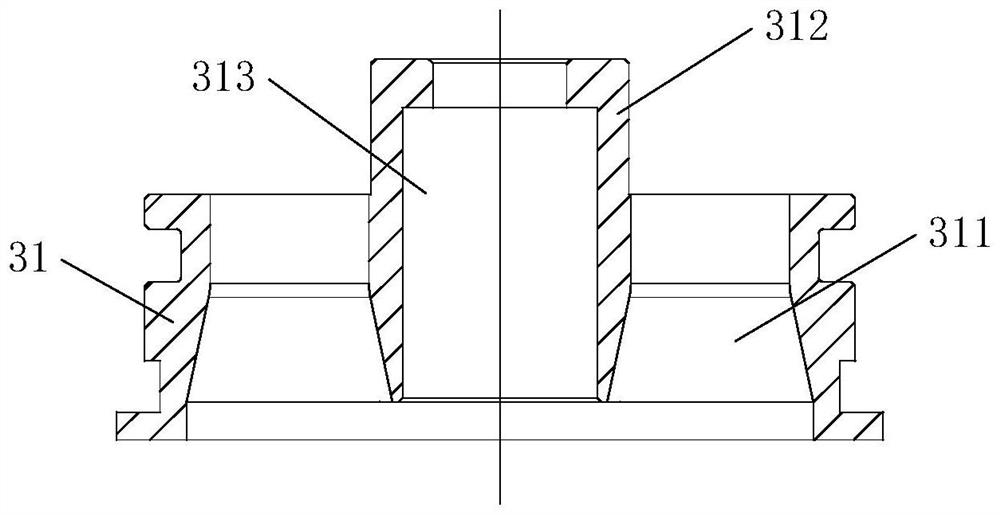

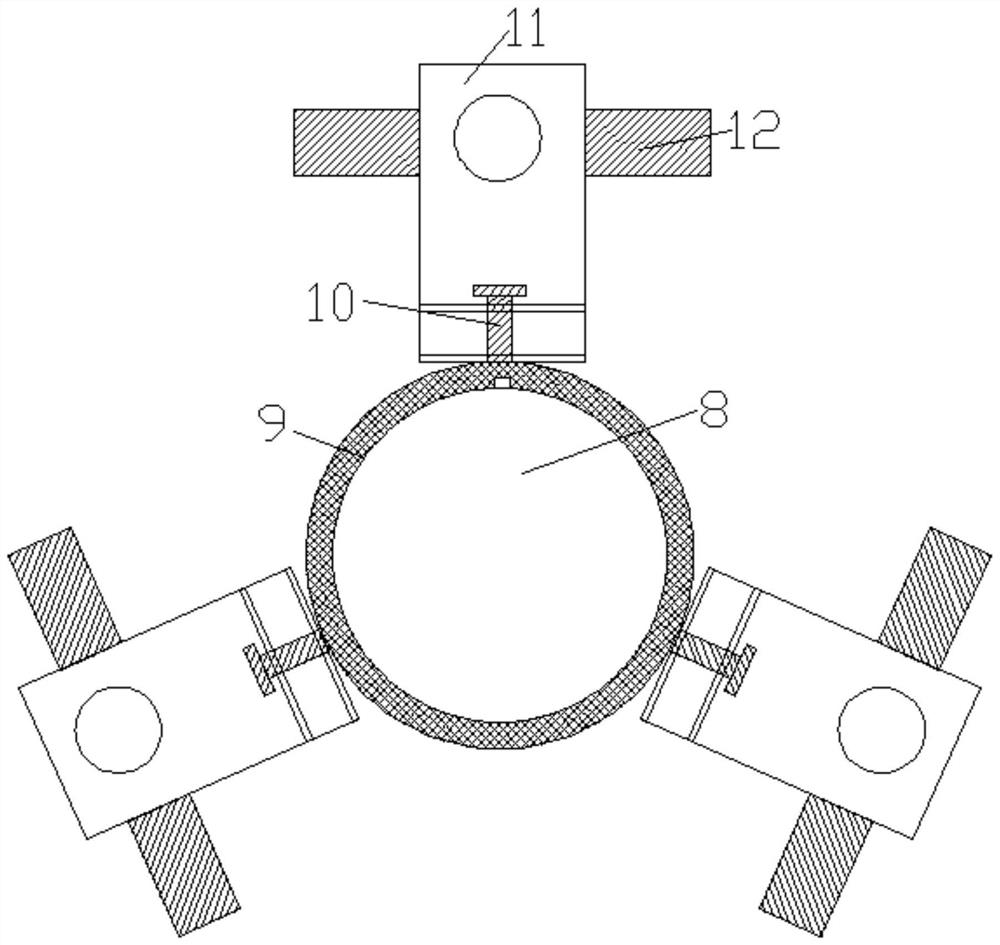

Low-rpm drilling fixture with safety protection function

ActiveCN103612132AIncrease or decrease friction torqueAvoid motor damagePositioning apparatusMetal-working holdersPower flowEngineering

The invention discloses a low-rpm drilling fixture with a safety protection function. The low-rpm drilling fixture with the safety protection function comprises an outer tooth shaft sleeve and an inner tooth shaft sleeve. The outer circumferential surface of the front end of the inner tooth shaft sleeve is connected with an adjusting nut. The front end of the outer tooth shaft sleeve is provided with a chuck. Outer teeth are arranged on the outer circumference of the rear end of the outer tooth shaft sleeve. The outer tooth shaft sleeve is sleeved with inner tooth friction plates. Inner teeth are arranged in the inner tooth shaft sleeve and are sleeved with outer tooth friction plates. The outer tooth friction plates and the inner tooth friction plates are located between a limiting end face of the outer tooth shaft sleeve and a limiting end face of the inner tooth shaft sleeve. When the outer tooth shaft sleeve and the inner tooth shaft sleeve squeeze each other, the outer tooth friction plates and the inner tooth friction plates are axially pressed tightly on the two limiting end faces. Through the structure, the inner tooth shaft sleeve is driven to press tightly or loosen the friction plates through the adjusting nut so that the friction moment between the outer tooth shaft sleeve and the inner tooth shaft sleeve can be increased or decreased, and the low-rpm drilling fixture can play roles in transmitting moment and carrying out overload safety protection. Consequently, current surges are completely avoided, and the phenomenon that a motor or a drill bit is damaged is prevented completely.

Owner:江苏索达重工有限公司

Motor driver verification device

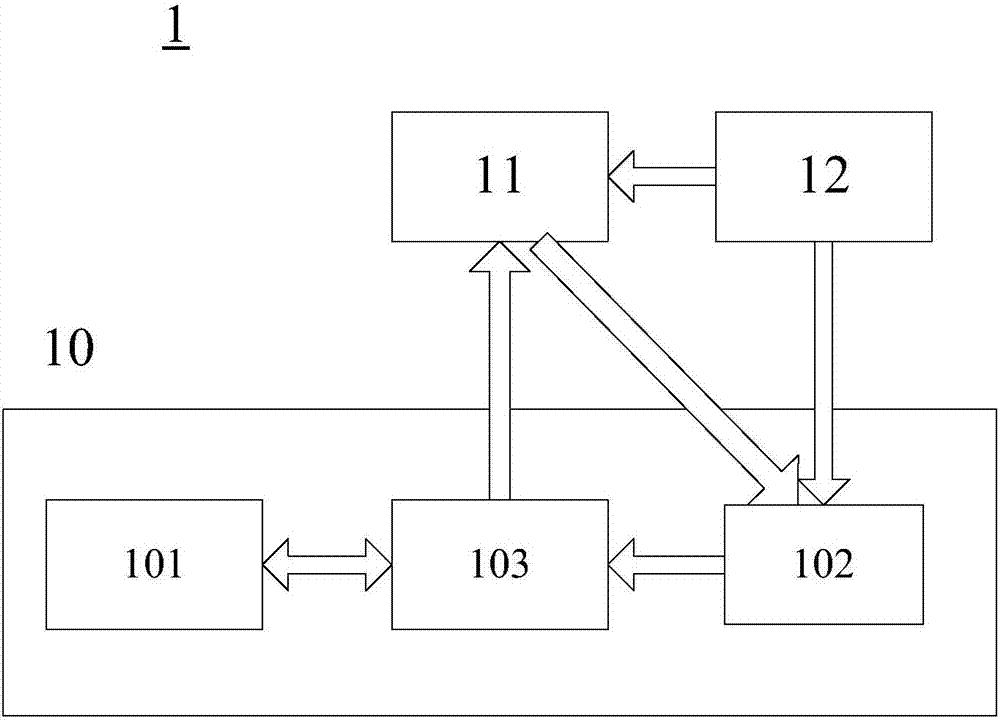

InactiveCN107091989AGuaranteed repair qualityAvoid motor damageProgramme controlComputer controlEmbedded systemElectric machinery

The invention provides a motor driver verification device, which comprises a human-computer interaction interface, a sensor unit and a processing unit, wherein the human-computer interaction interface is configured to receive a verification instruction of a user on the motor driver, and the verification instruction comprises a series of operation which needs to be executed by the motor driver and a motor driven by the motor driver; the sensor unit is configured to acquire information, and the information is related to the working states of the motor driver and the motor during a period of executing the series of operation; and the processing unit is configured to verify the performance of the motor driver based on the information acquired by the sensor unit.

Owner:INTEL PROD CHENGDU CO LTD +1

Automatic valve closing device for leakage of tap water pipeline

InactiveCN103821993AAvoid family and public wealth lossAvoid motor damageOperating means/releasing devices for valvesFluid-delivery valvesEngineeringControl switch

The invention discloses an automatic valve closing device for leakage of a tap water pipeline, and relates to an article of daily use, in particular to an alarm device for safety closing of a valve in case of tap water pipeline leakage. The automatic valve closing device comprises a fixed shell, a motor and a control circuit, and is characterized in that the fixed shell is mounted on the tap water pipeline, the motor is mounted inside the fixed shell, a shifting fork is mounted on a shaft of the moor, the front end of the shifting fork is inserted into a rotating switch of the valve, the control circuit is mounted on a sidewall of the fixed shell, a control switch on the control circuit is disposed outside the fixed shell, the control circuit is connected with an alarm lamp, a receiver and the motor via conducting wires to form a loop, the alarm lamp and the receiver are mounted outside the fixed shell, the control circuit is further connected with an external power source, a plurality of tap water pipeline flow detecting and signal projecting machines are disposed on various sections of the tap water pipeline, and an anti-rust coating layer coats an inner wall of the valve. The automatic valve closing device has the advantages of novel structure, simplicity in processing, low cost, convenience in use, safety, reliability and the like.

Owner:DALIAN EAGLE TEC

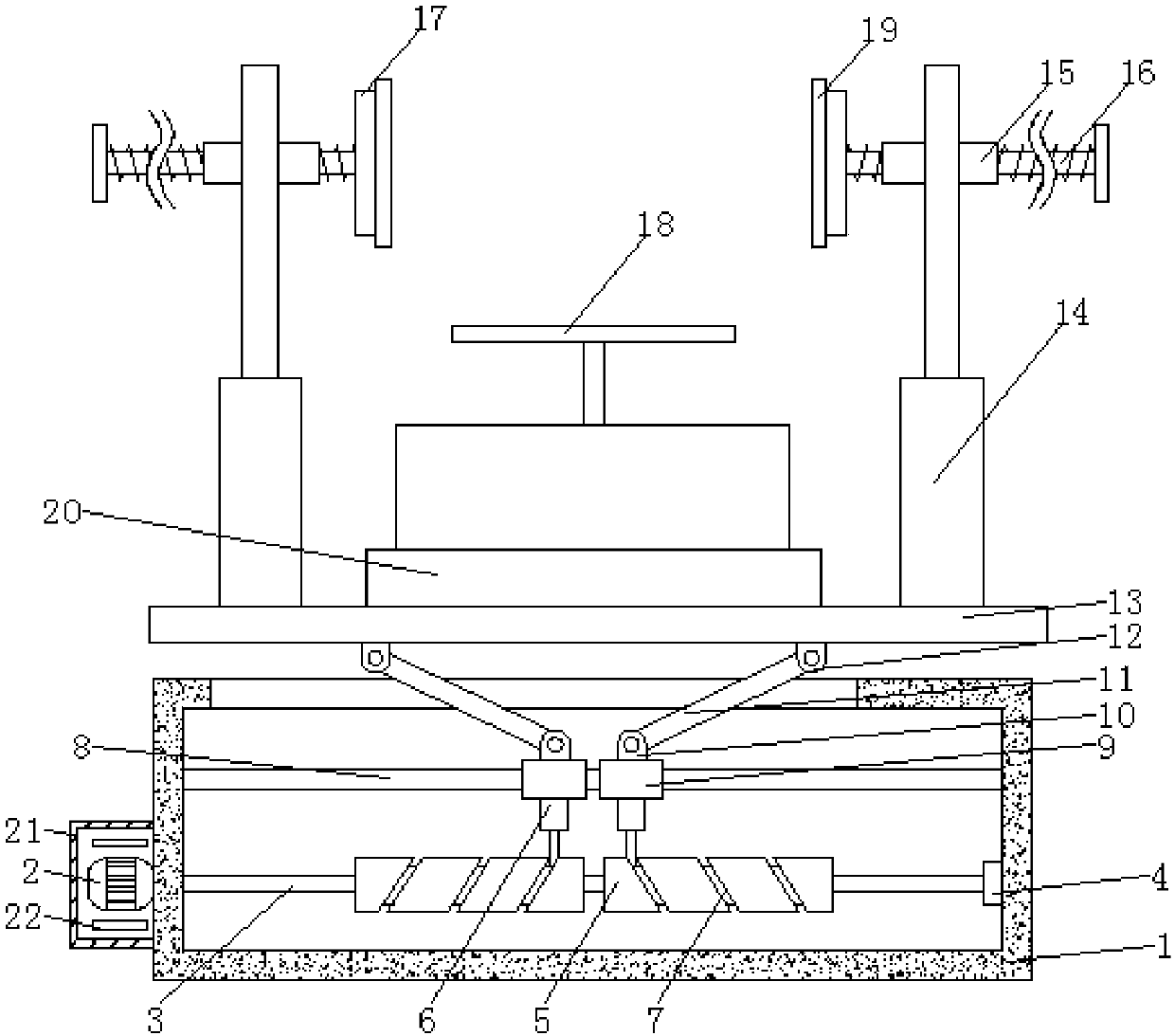

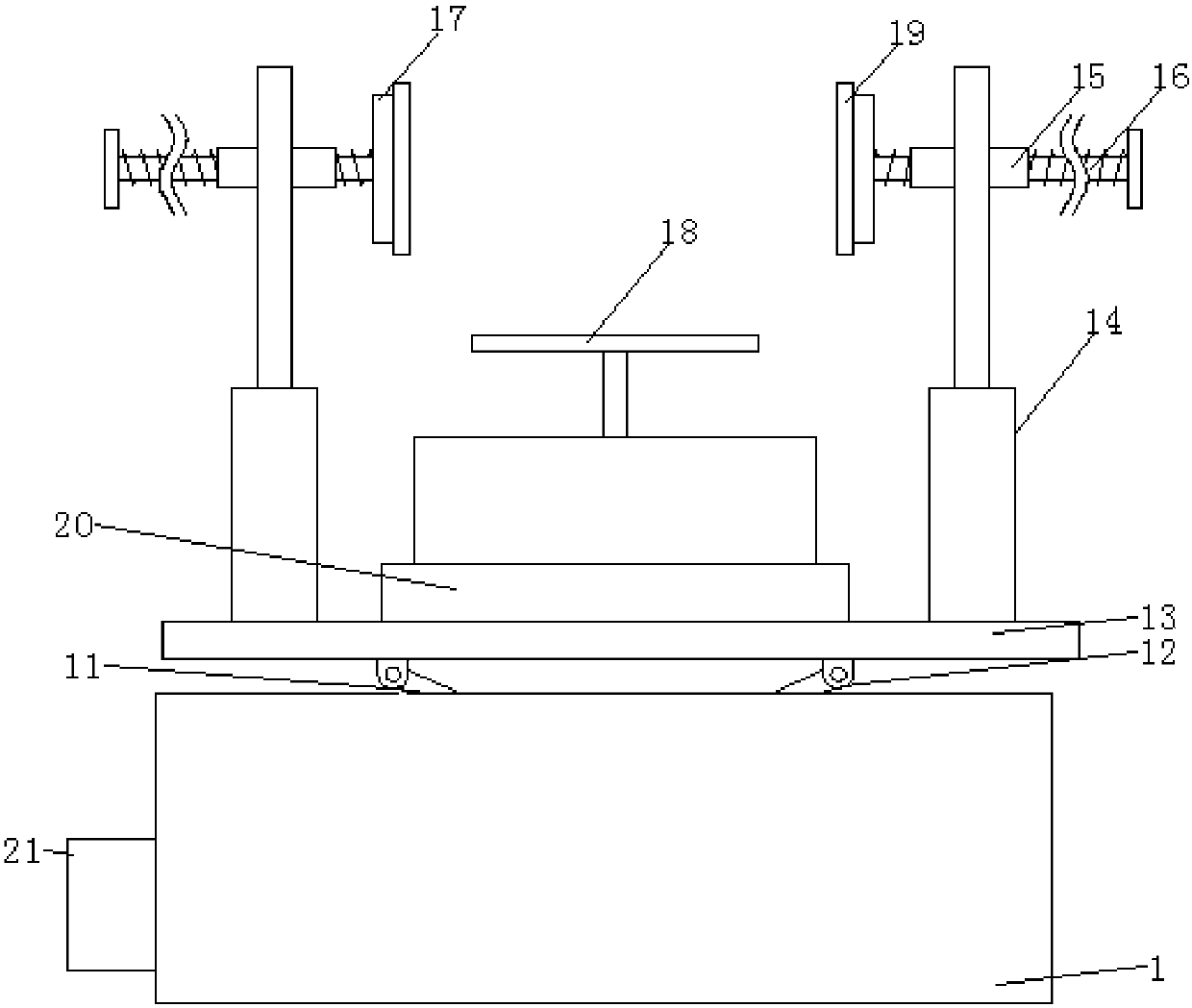

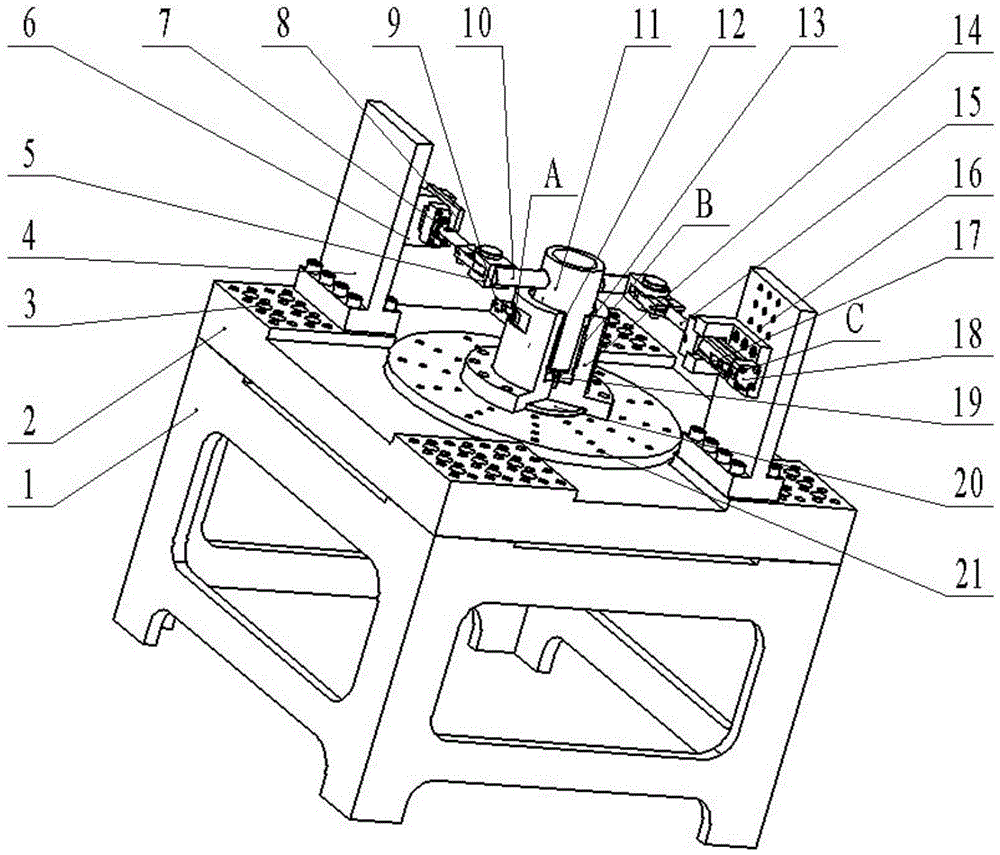

Dual-hydraulic cylinder driven hydraulic locking shaft sleeve performance testing platform

InactiveCN104677615AAvoid motor damageReduce energy consumptionMachine part testingHydraulic cylinderElectric machinery

The invention provides a dual-hydraulic cylinder driven hydraulic locking shaft sleeve performance testing platform, which mainly comprises a support, a mounting table, a hydraulic cylinder bracket and hydraulic cylinders. The platform has the main advantages that (1) twisting couple moment can be maximally provided, so that energy consumption is reduced, and the phenomenon of motor damage caused by excessively high power when a motor is used as a driver is avoided; (2) the distance between the axial lines of rods of the two hydraulic cylinders can be conveniently regulated, so that the requirements of different torque output can be flexibly met; (3) the heights of the hydraulic cylinders can be conveniently regulated, so that the performance testing requirements of hydraulic locking shaft sleeves with different lengths can be flexibly met; (4) the mounting requirements of hydraulic locking shaft sleeves with various sizes and hydraulic locking shaft sleeve seats can be met, and when the hydraulic locking shaft sleeves with different sizes are tested, only the hydraulic locking shaft sleeve seats and rotating shafts are required to be replaced, so that materials are saved, and simplicity in operation is ensured.

Owner:SHENYANG POLYTECHNIC UNIV

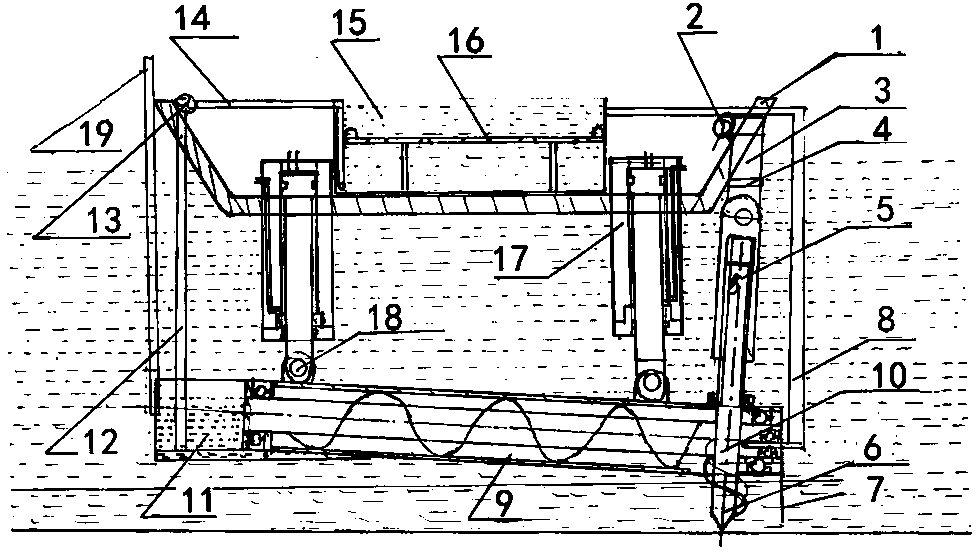

Using method for movable riverway sludge dredging device

The invention relates to a using method for a movable riverway sludge dredging device. According to the technical scheme, a movable hull and the sludge dredging device are included, a sludge agitator and a double-capacity mixer are used to fully mix the sludge at the bottom of a river with the river water to make the mixture into sewage, a suspending hammer at the front half part of the double-capacity mixer crushes the bulk material which is stirred out at the bottom of the river, and then a soft material such as a plastic bag or a rope is cut by a suspending slicing piece at the rear half part of the double-capacity mixer, so that the generated small-particle sewage is transported to a sewage storage tank in the form of fluid and then is pumped into the sludge treatment tank on the movable hull under the pumping action of a sewage pump for treatment, and the circulating water is sprayed to an inlet of the double-capacity mixer to drive the sludge into the double-capacity mixer to form a circulation. The using method has the beneficial effects that the riverway can be smoothly cleaned, the ecological impact on the riverway is very small, a lot of man-hours can be saved, and the serious influence on the use of the riverway and the traffic is unlikely; and in addition, compared to an existing dredging device, by the adoption of the using method, the efficiency is higher and the cleaning is thorough.

Owner:杨滨

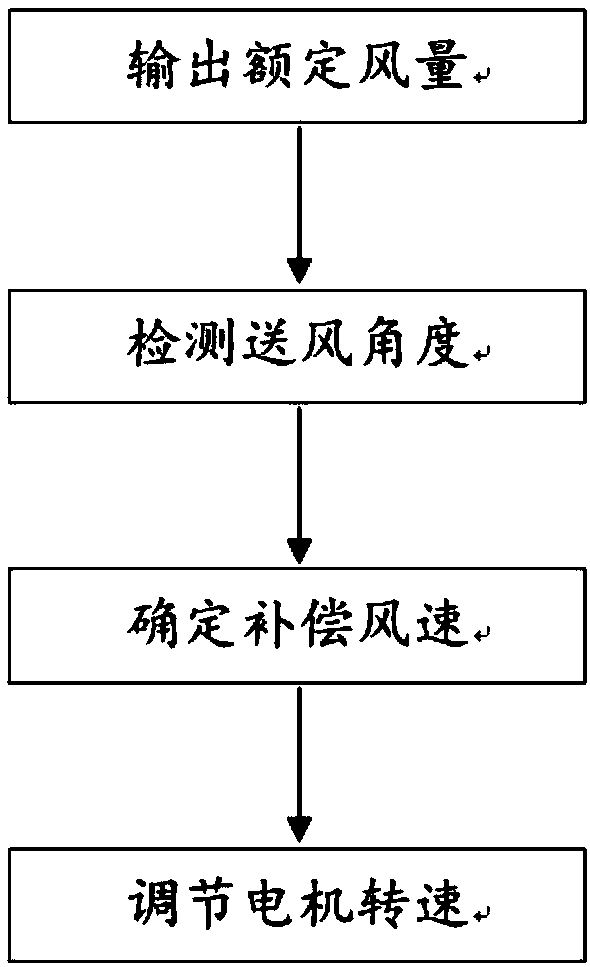

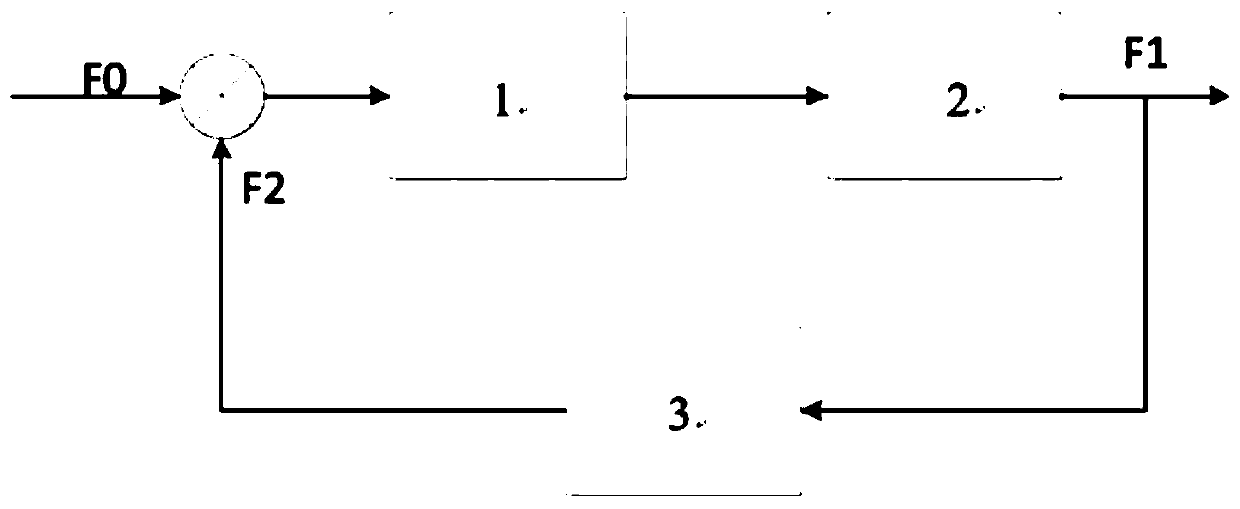

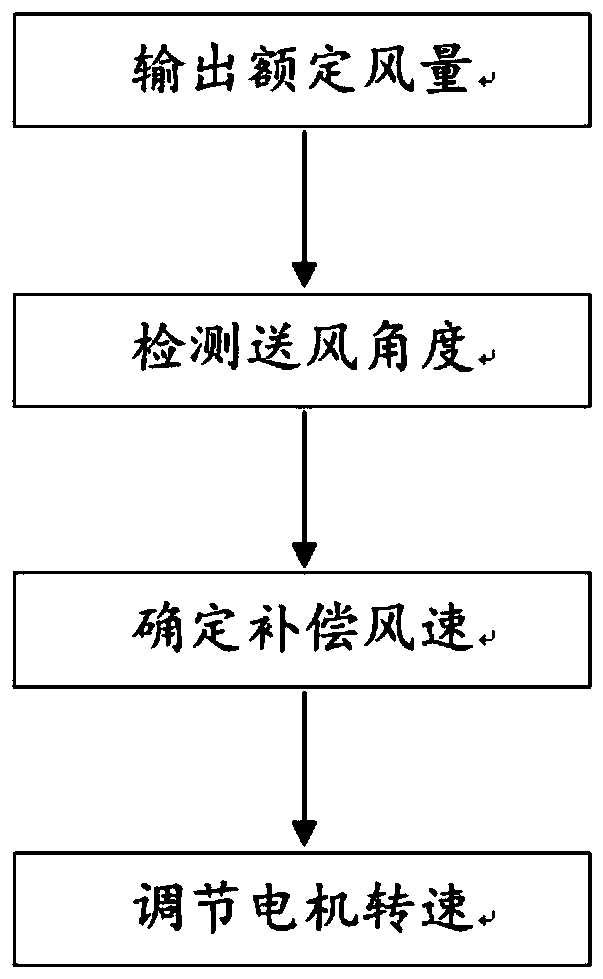

Control system for automatically adjusting motor rotating speed, household appliance and control method

ActiveCN108825544AImprove experienceStable air volumeEfficient regulation technologiesPump controlElectricityAuto regulation

The invention discloses a control system for automatically adjusting the motor rotating speed, a household appliance and a control method, and relates to the technical field of household appliances. The technical problem that the air outlet quantity of a household appliance in the prior art is instable is solved. The control system for automatically adjusting the motor rotating speed comprises a detecting device and a control device, the detecting device is connected with the control device, and the detecting device is used for detecting the size of an air inlet or the size of an air outlet inthe process that a motor drives the electric appliance to work; and the control device is electrically connected with the motor and can adjust the rotating speed of the motor according to a detectingresult of the detecting device so that the air outlet quantity can keep stable in the working process of the electric appliance. The control system can adjust the rotating speed of the motor based onthe size of the air inlet or air outlet, and therefore the air outlet quantity of the household appliance in the working process keeps stable.

Owner:GREE ELECTRIC APPLIANCES INC

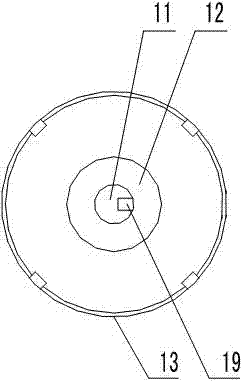

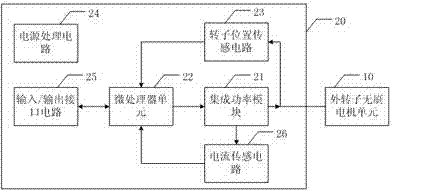

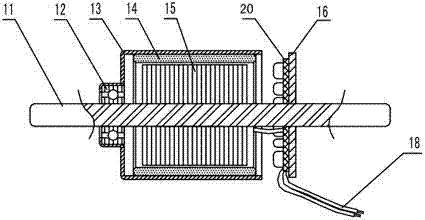

External-rotor brushless motor system

InactiveCN102223043AReduce functionAvoid frictionElectronic commutation motor controlAssociation with control/drive circuitsBrushless motorsElectric machine

The invention provides an external-rotor brushless motor system which comprises an external-rotor brushless motor unit and a driver. The external-rotor brushless motor unit comprises: a center shaft, housing, bearings, a permanent magnet, a stator armature, a rear cover, a fixed plate and a power line which is connected with the stator armature. The driver comprises: an integrated power module, a microprocessor unit, a rotor position sensing circuit, a power supply processing circuit, an input / output interface circuit and a current sensing circuit. When the external-rotor brushless motor provided in the invention is working, the center shaft is immovable and the housing is rotated. Machinery equipment is directly arranged on the housing, and rotation of the machinery equipment is driven by the rotation of the housing. In the prior art, the center shaft is regarded not only as a connection between the machinery equipment but also as an output of moment. The rotation can be affected when the machinery equipment is not concentric or there is an external force so that functions of the motor can be decreased. In the invention, the above situations can be avoided.

Owner:黎冬阳

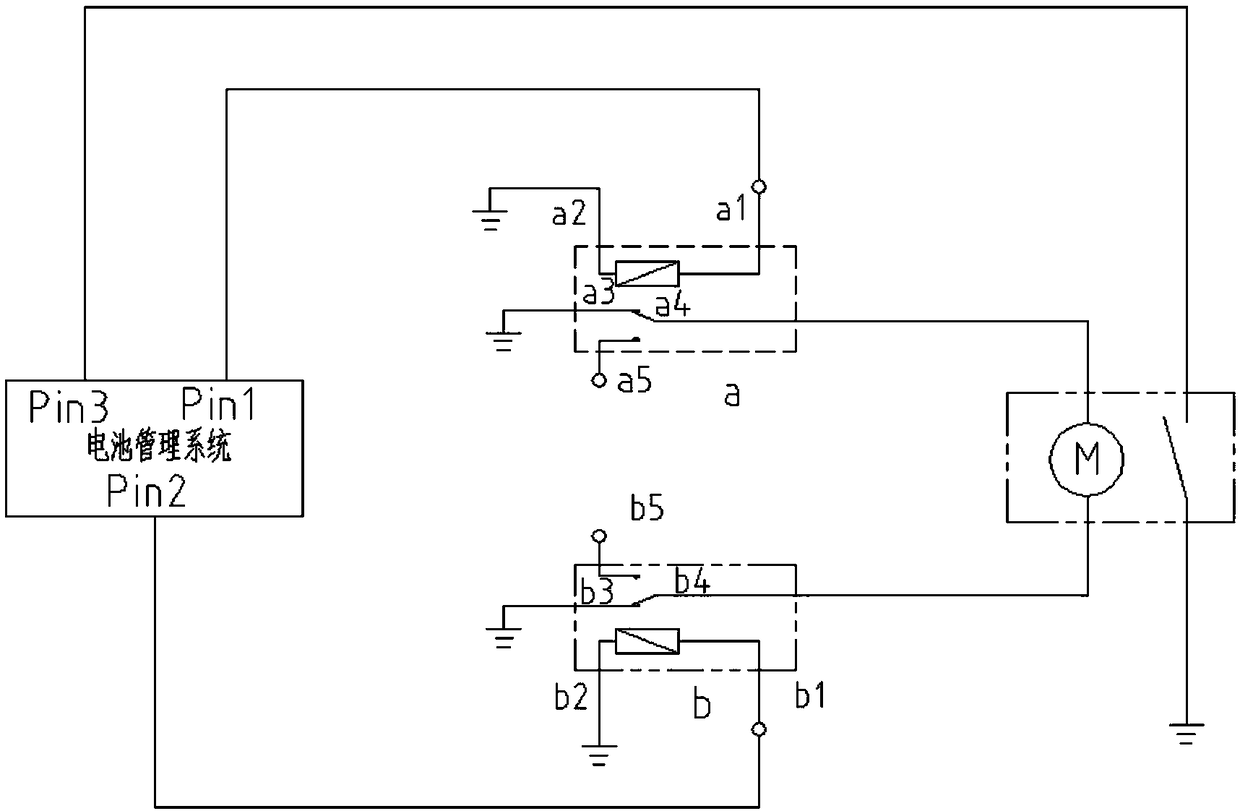

Charging gun locking device for charging equipment

InactiveCN108270123AEnsure personal safetyAvoid arcingVehicle connectorsCoupling device detailsControl circuitRotation control

The invention relates to a charging gun locking device for charging equipment, which comprises an electronic lock unit and a processing unit used for detecting the start and end of charging, wherein the electronic lock unit comprises a motor. The locking device further comprises a motor forward rotation control circuit used for locking a charging gun and a motor reverse rotation control circuit used for unlocking the charging gun. The processing unit is connected with the motor forward rotation control circuit and the motor reverse rotation control circuit. The charging gun locking device effectively avoids the occurrence of an arcing phenomenon caused by mistakenly pulling the charging gun in the charging process of the charging gun, and ensures the personal safety of the charging personnel.

Owner:ZHENGZHOU YUTONG BUS CO LTD

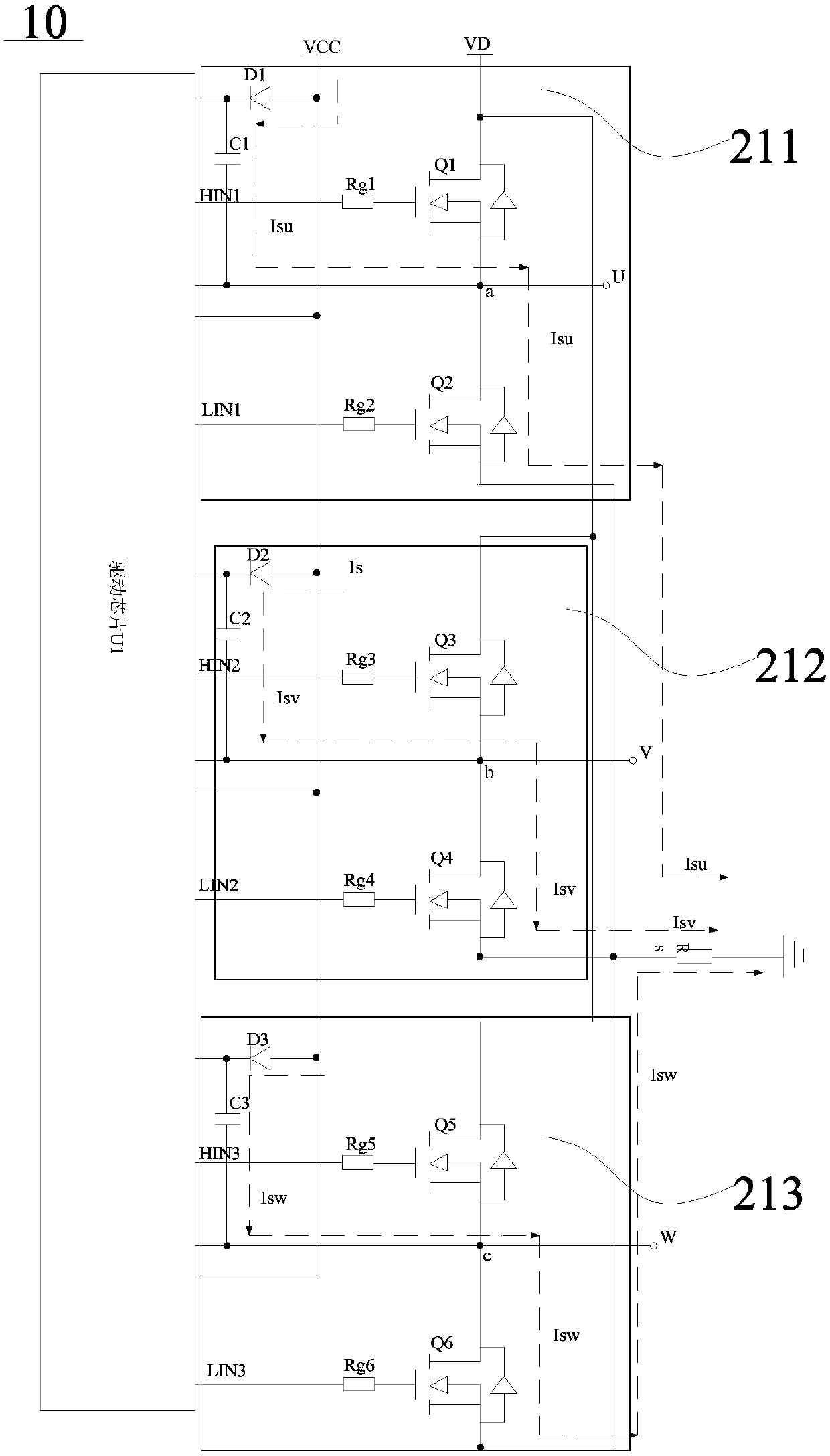

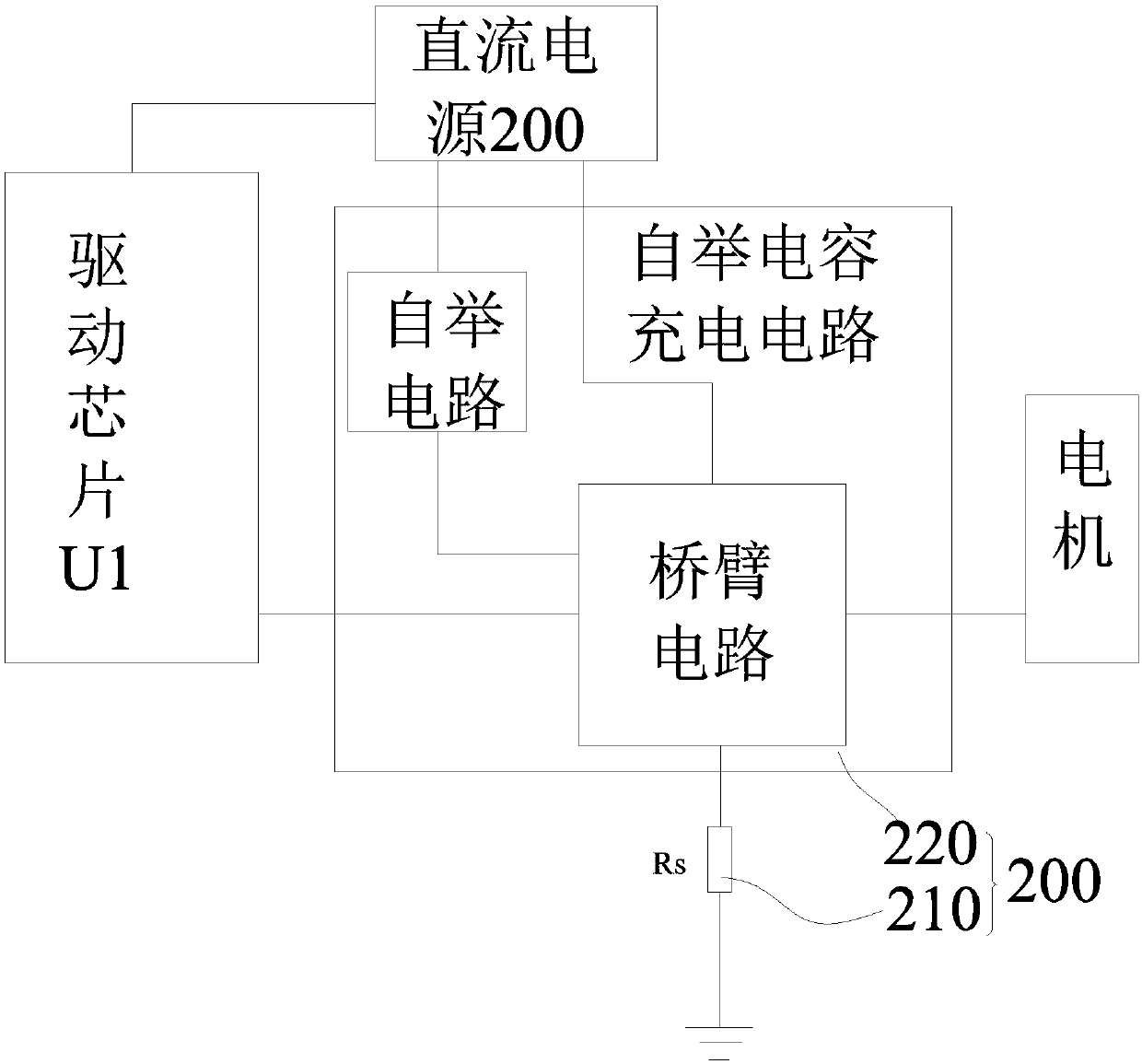

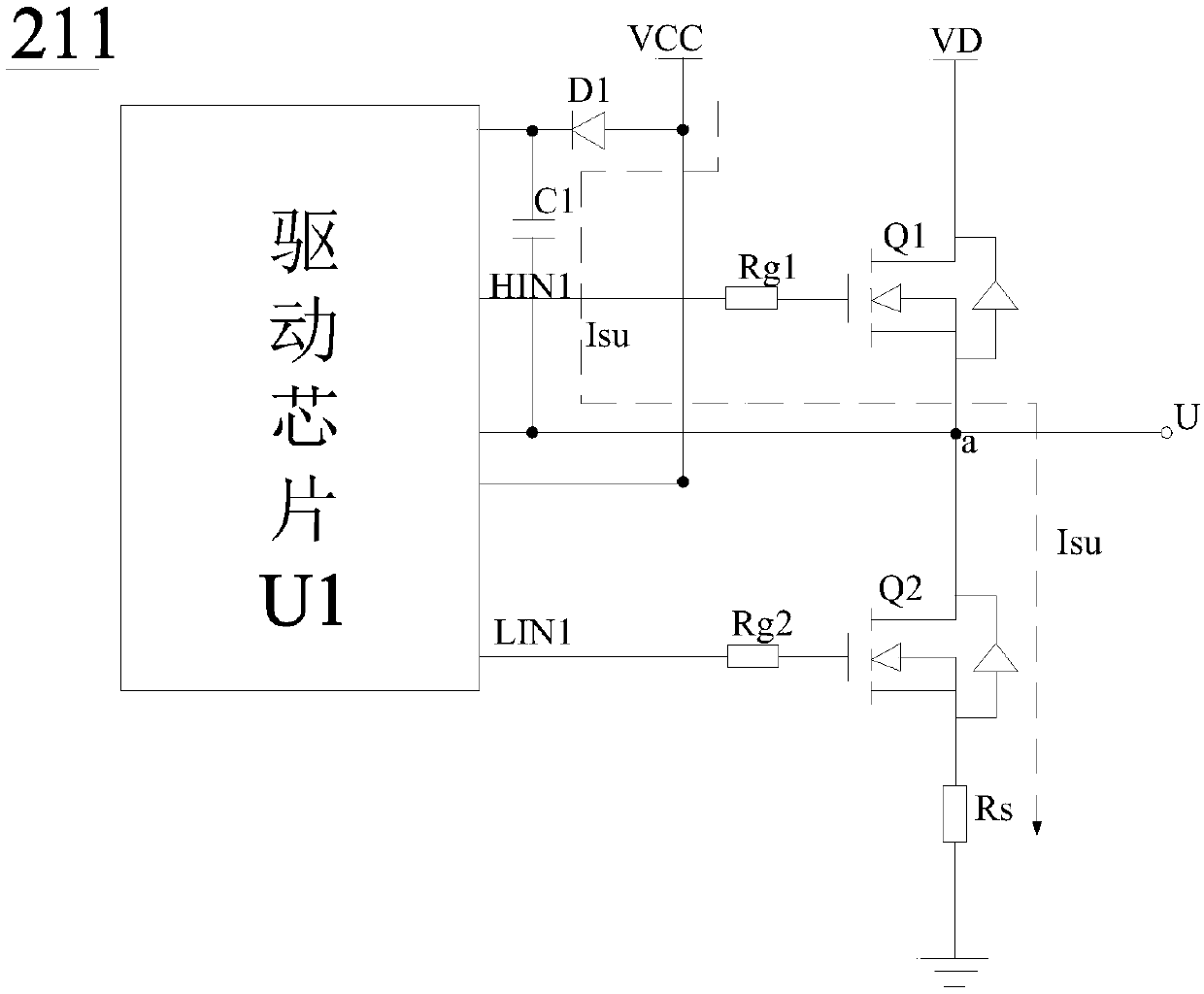

Bootstrap capacitor charging control device and control method for permanent-magnet synchronous motor

InactiveCN109546916AGuaranteed uptimeGuarantee working reliabilityAC motor controlElectric motor controlCapacitanceSynchronous motor

The invention relates to a bootstrap capacitor charging control device for a permanent-magnet synchronous motor, wherein the bootstrap capacitor charging control device is applied to a direct-currentmotor or a three-phase inverter power supply. The bootstrap capacitor charging control device comprises a direct-current power source and a three-phase bridge arm driving circuit. The three-phase bridge arm driving circuit includes U-phase, V-phase, and W-phase driving circuits connected in parallel and a current sampling circuit. A sampling resistor detects a bus current during the bootstrap capacitor charging process by each phase; a bus current for charging each phase is determined; the bus current for charging each phase is compared with a set current for starting each phase; first switchelements and second switch elements in the driving circuits are controlled to be in conduction one by one according to a U-phase, V-phase, and a W-phase sequence; and thus respective bootstrap capacitors are charged to drive the motor to work. According to the control device, the hardware resources are simplified; the working reliability of the bootstrap capacitor is guaranteed; the normal operation of the motor is ensured; and time wasting during the bootstrap capacitor charging process and motor damages caused by too heavy charging currents are avoided.

Owner:东莞市深鹏电子有限公司

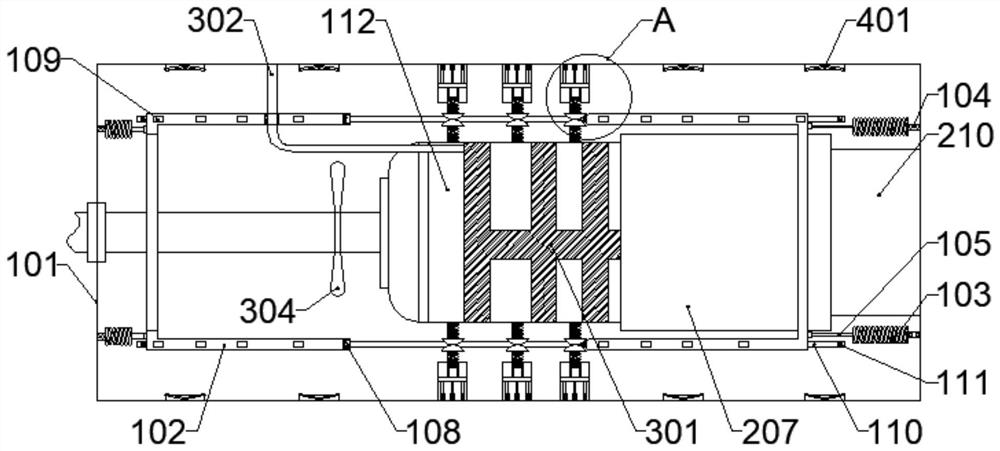

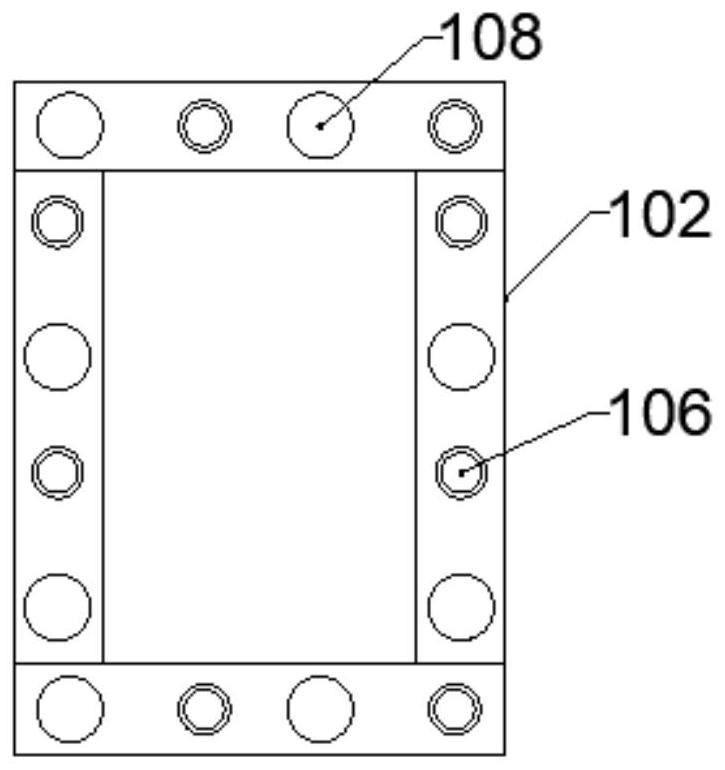

Automobile skylight opener

InactiveCN107795223AAvoid troubleAvoid the hassle of openingPower-operated mechanismPower supplyEngineeringSkylight

The application discloses an automobile sunroof opener, which comprises an outer casing, the outer casing includes a box body and a cover plate covering the box body; a driving mechanism built in the box body; a gear transmission mechanism driven by the driving mechanism; and connecting gears The transmission chain mechanism of the speed change mechanism, a support partition is set between the transmission chain mechanism and the gear transmission mechanism, and the chain of the transmission chain mechanism is exposed to the outer shell; wherein, the drive mechanism drives the gear transmission mechanism to drive the transmission chain mechanism, so that the chain is retracted Outer casing or release outer casing. The invention uses the chain of the transmission chain mechanism to open and close the sunroof of the car, so as to avoid the problem that the sunroof will only be lifted abruptly when it is stuck by foreign matter, and the sunroof is easily broken or the motor is damaged.

Owner:钟新国

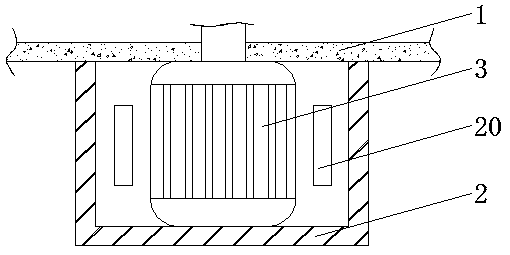

New energy automobile driving motor protection shell

ActiveCN113472135AAvoid motor damageIncrease flexibilityElectric machinesCooling/ventillation arrangementPhysicsMotor protection

The invention discloses a new energy automobile driving motor protection shell which comprises a shell mechanism, a damping mechanism, a heat dissipation mechanism and a waterproof mechanism, wherein the damping mechanism is located in the shell mechanism, the heat dissipation mechanism is located in the shell mechanism and on the outer wall of the shell mechanism, and the waterproof mechanism is located in the heat dissipation mechanism. When the protection shell is impacted, under the action of inertia, the inner shell is slidably connected to the outer surface of the motor in a sleeving mode, a second layer of protection is provided for the motor, meanwhile, during normal running, the inner shell slides back to the original position, the inner shell is slidably arranged, the flexibility of the device is improved, in the normal running process of the motor, the inner shell does not provide secondary protection for the motor, and heat dissipation of the motor and normal operation of the motor are facilitated. The device can provide double-layer protection for the motor, the outer shell protects the motor, the inner shell reduces impact force generated by collision, the motor is buffered, damage to the motor is prevented, and the device is suitable for various motors of different sizes.

Owner:LUOHE VOCATIONAL TECH COLLEGE

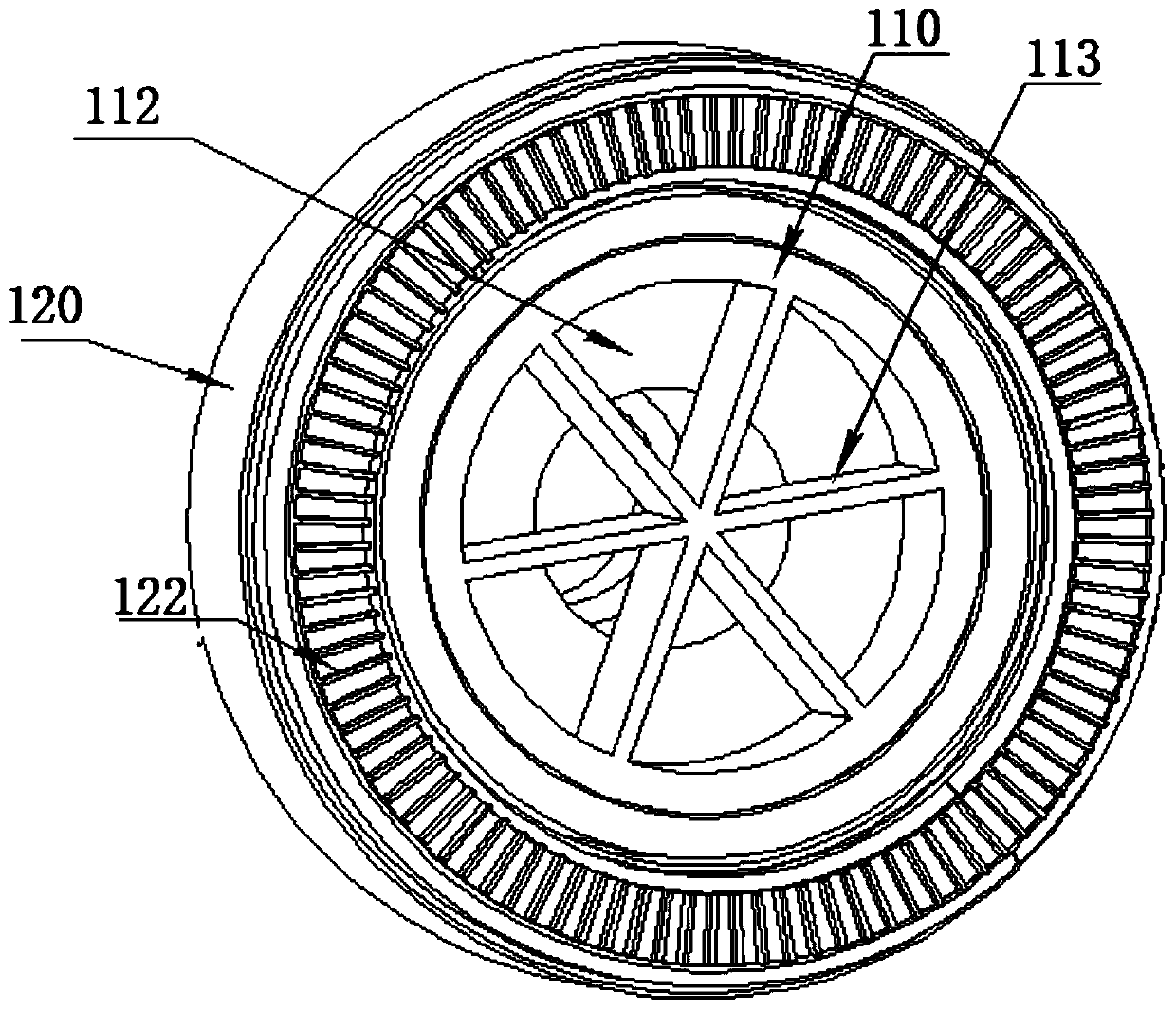

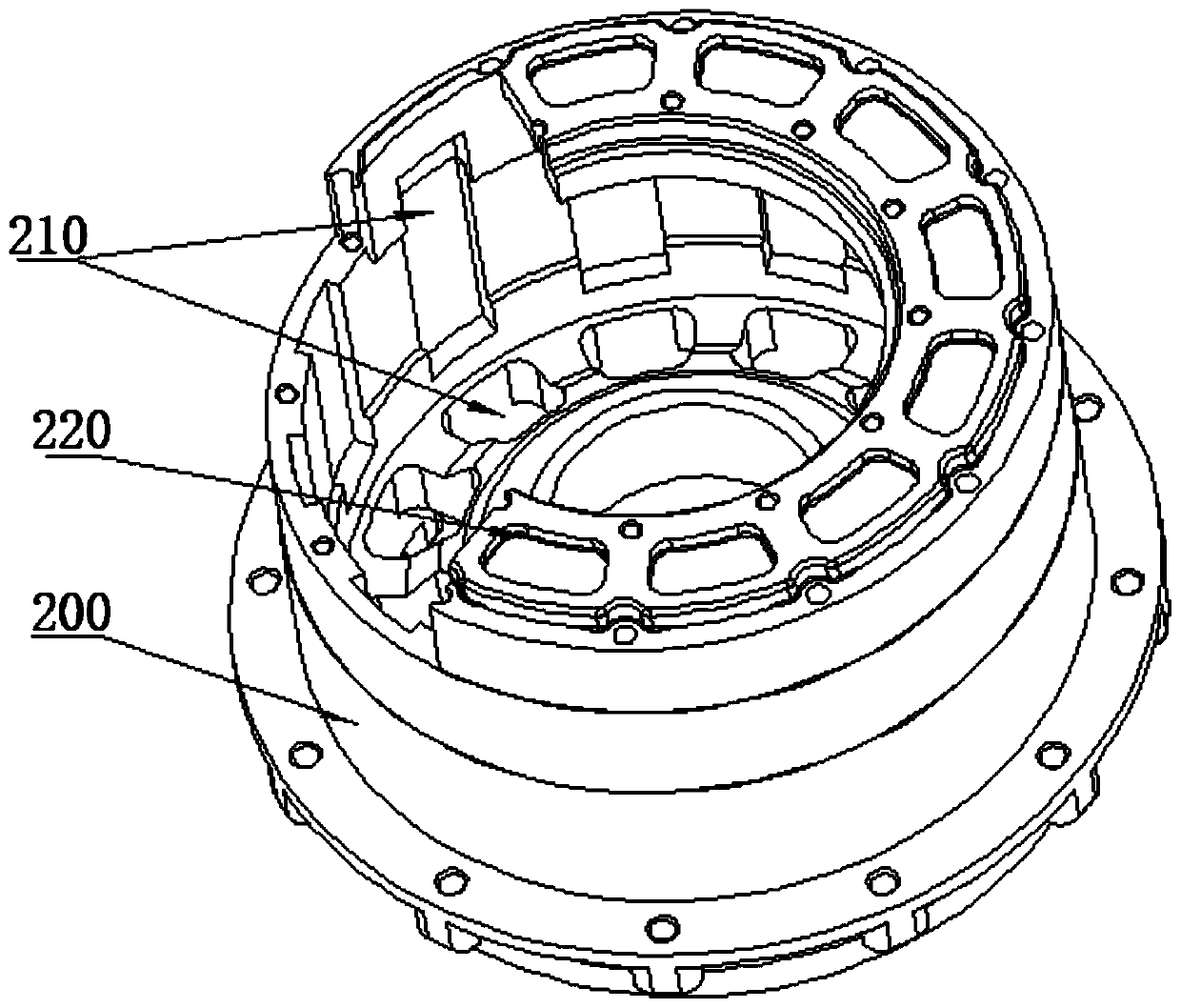

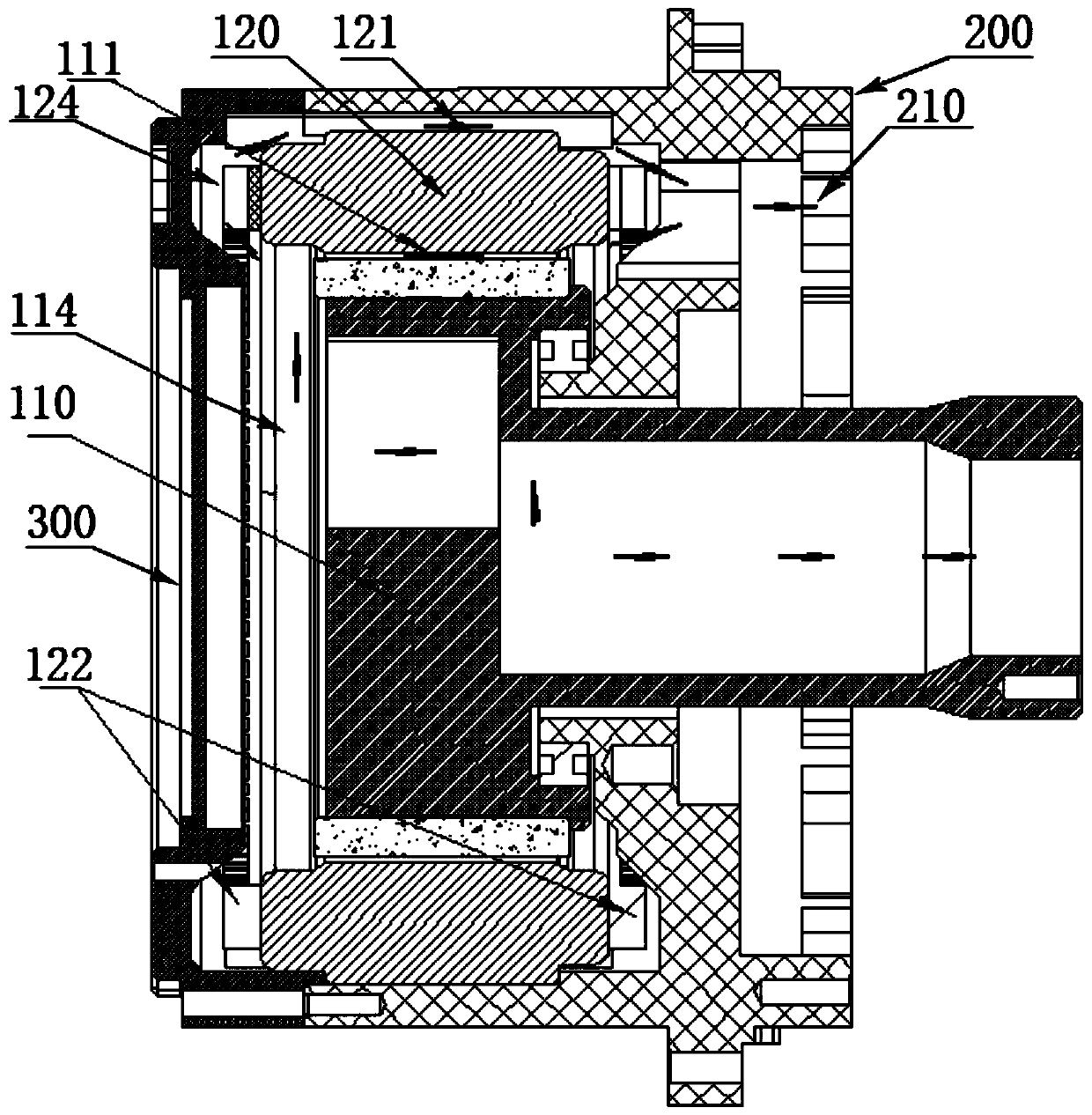

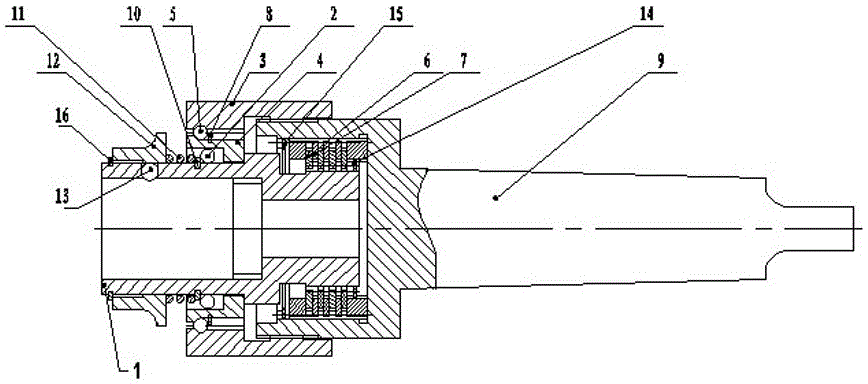

Robot power joint with turbulent flow heat dissipation structure and robot

InactiveCN111509912AImprove carrying capacityGuaranteed stabilityMagnetic circuit rotating partsJointsElectric machineryPhysics

The invention provides a robot power joint with a turbulent flow heat dissipation structure and a robot. The power joint comprises a motor, a joint shell and an end packaging part, the motor is installed in a hollow cavity formed by the joint shell, the end packaging part is located at the end of the motor, a first gap is formed between a rotor and a stator, and a first end gap is formed between afirst end of the rotor and the end packaging part; a plurality of axial airflow channels are formed in the middle of the rotor through spacers; a second gap is formed between the circumferential surface of the stator and the joint shell, a second end gap is formed between the first end of the stator and the end packaging part, and the first end of the stator and the first end of the rotor are thesame end of the motor; the axial airflow channels, the first end gap and the first gap form a communicated first air duct; an axial airflow air duct, the second end gap and the second gap form a communicated second air duct; one end, far away from the first end gap, of the joint shell is provided with a heat dissipation flow channel for communicating the first air duct and the second air duct with the outside.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

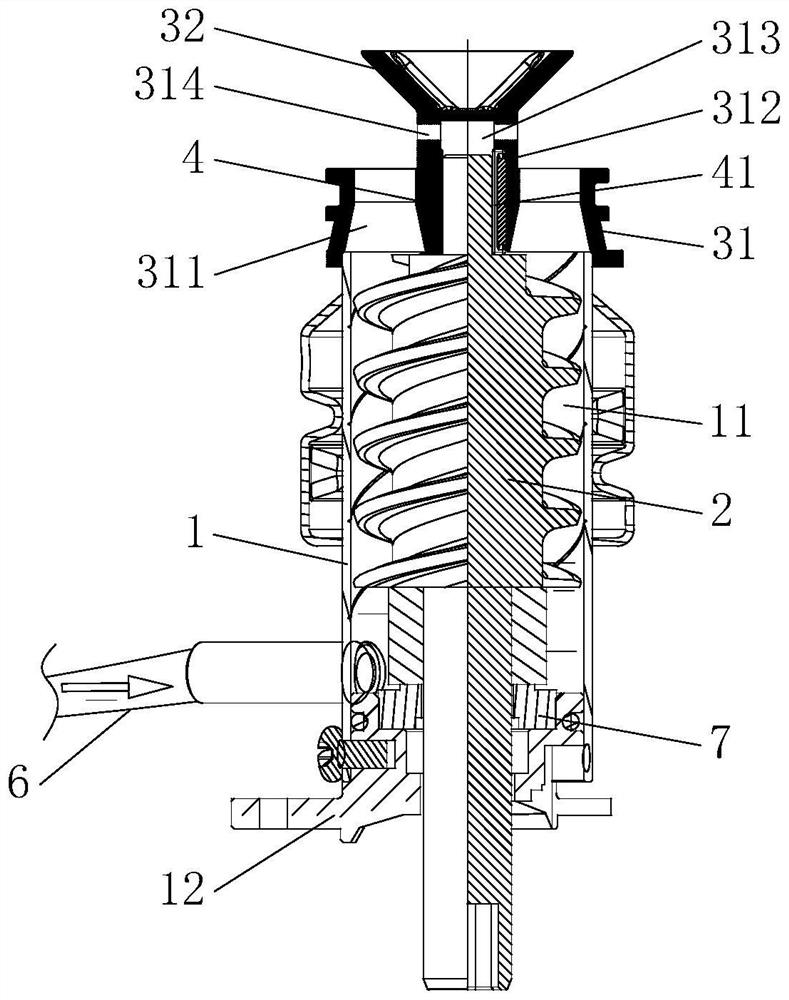

Portable plateau oxygen generator

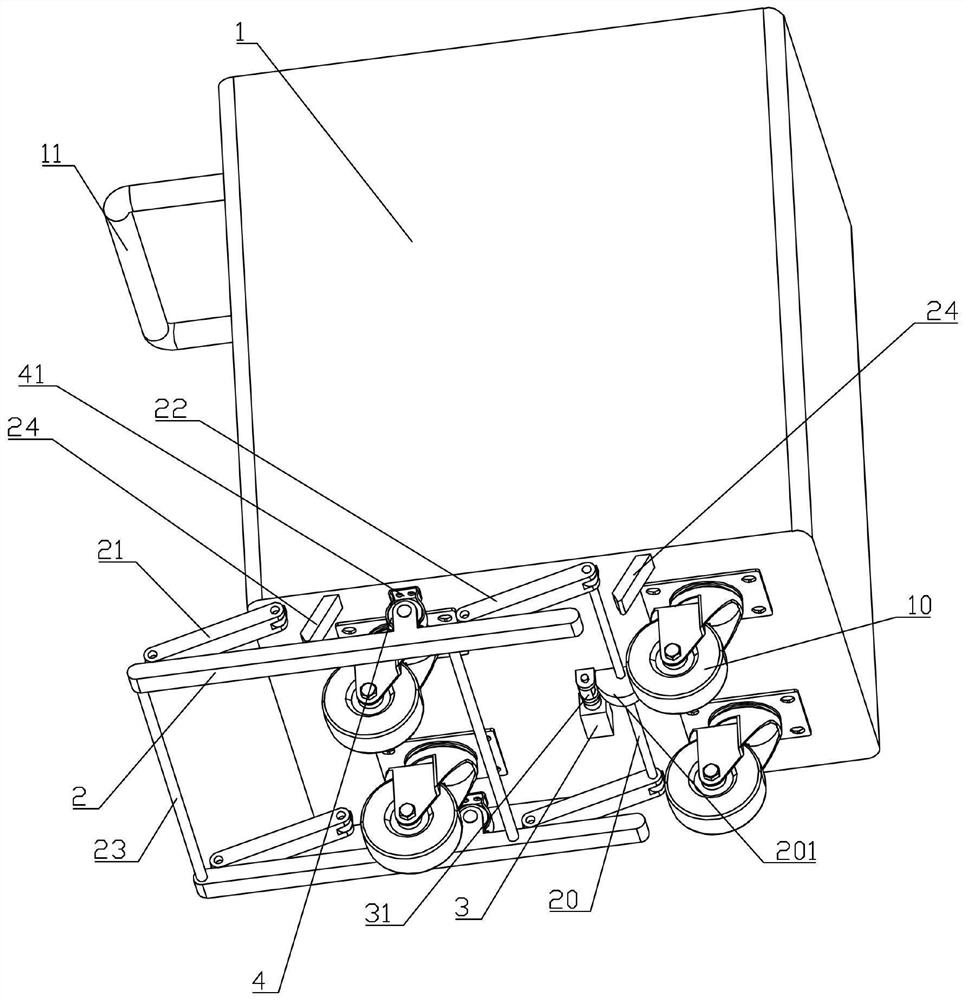

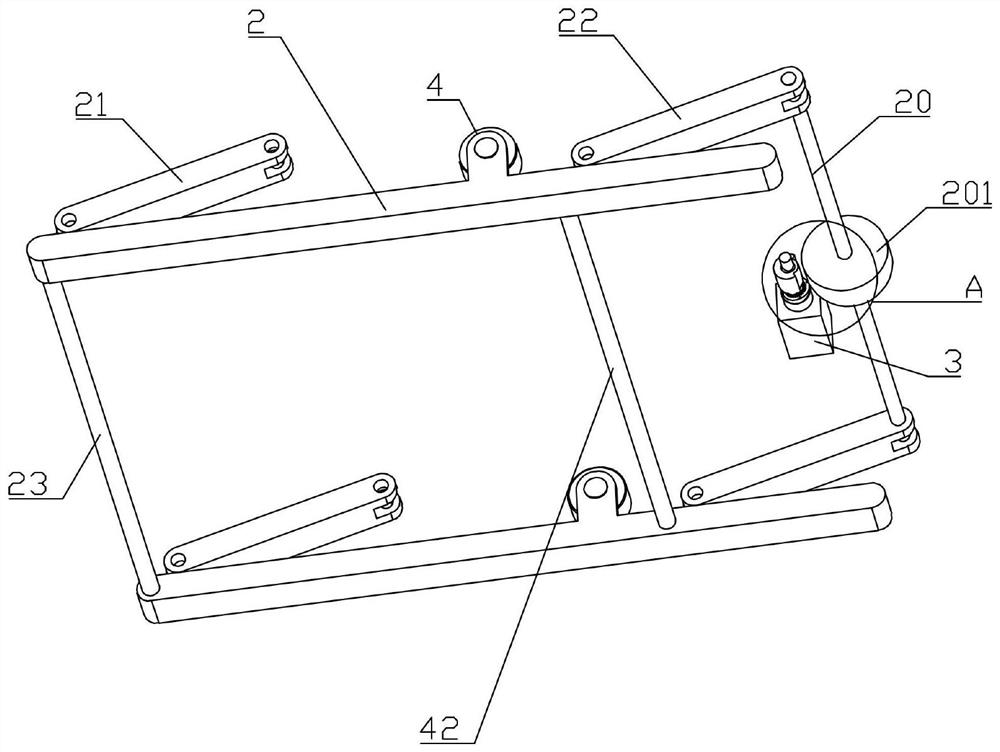

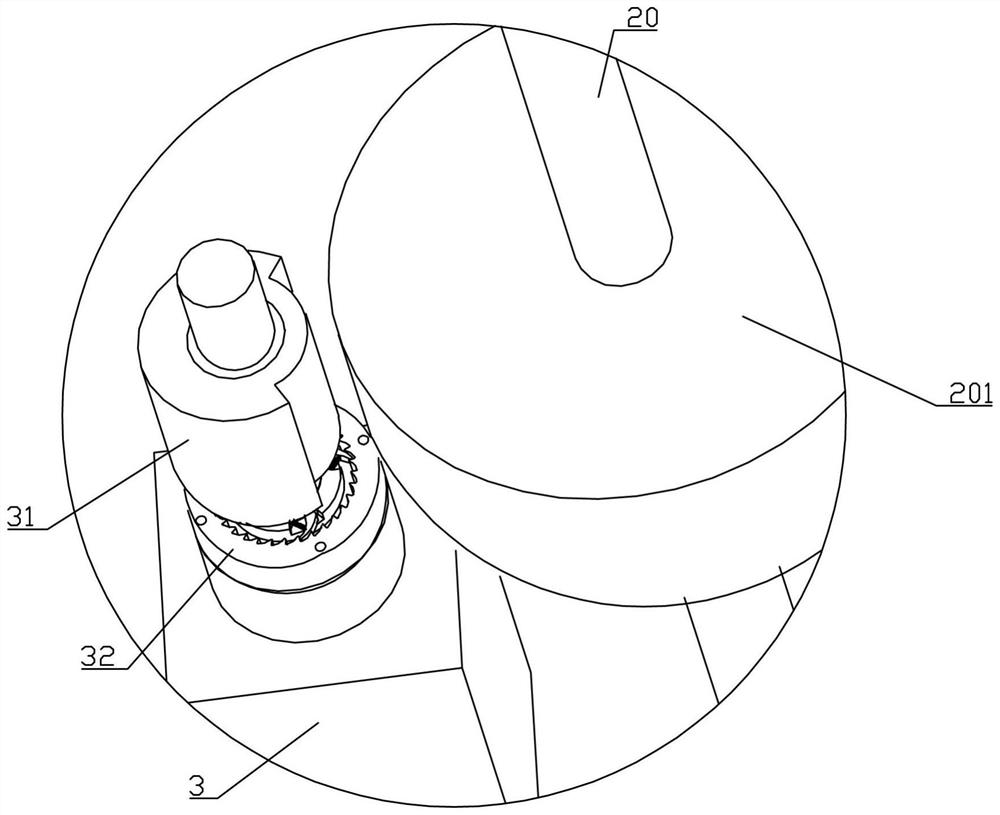

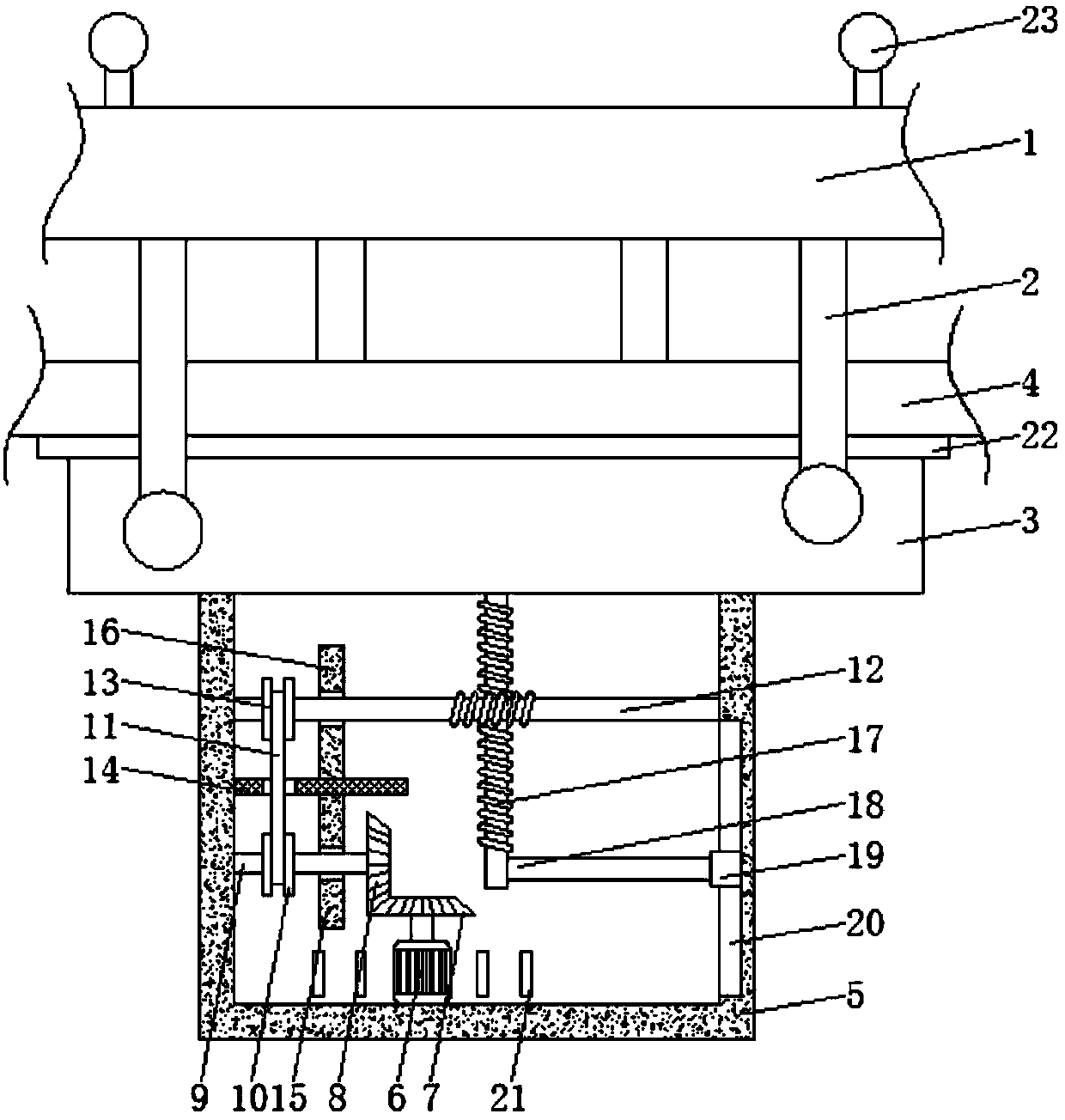

ActiveCN113912016AAvoid the problem of low lifespanEasy to useSpecific gas purification/separationOxygen preparationEngineeringScrew thread

The invention belongs to the technical field of oxygen generation equipment, and particularly relates to a portable plateau oxygen generator, which comprises a main body, wherein a supporting structure and a plurality of rollers are mounted on the lower end surface of the main body, a handrail is further mounted on the main body, the supporting structure comprises two horizontal rods, a front hinge rod and a rear hinge rod are hinged to the horizontal rods, the free ends of the front hinge rod and the rear hinge rod are hinged to the main body, foot bars are installed at the front ends of the two horizontal rods, clamping mechanisms are installed between the horizontal rods and the main body, and supporting rods are obliquely installed at the positions, corresponding to the front hinge rod and the rear hinge rod, of the lower end surface of the main body. According to the invention, an oxygen generator in a working state is supported through mutual cooperation of a horizontal rod, a front hinge rod and a rear hinge rod, and the oxygen generator in a moving state is supported through cooperation with rollers, so that the problem that the whole life of the oxygen generator is short due to thread damage caused by manufacturing of tight components such as a threaded guide sleeve, a screw rod and the like is solved.

Owner:杭州博大净化设备有限公司

Environmental carbon gold horizontal battery assembling line

PendingCN109980239AEasy to operateAvoid physical discomfortPrimary cell manufactureAssembling battery machinesGear wheelEngineering

The present invention discloses an environmental carbon gold horizontal battery assembling line. The environmental carbon gold horizontal battery assembling line comprises an assembling body, the bottom portion of the assembling body is fixedly connected with fourth fixed mounts, the bottom portions of the fixed mounts are fixedly connected with a base, the top portion of the base is provided witha conveyor belt, the bottom portion of the base is provided with a box body, and the top portion of the inner cavity of the box body is fixedly connected with a motor. Through arrangement of the motor, a first bevel gear, a second bevel gear, a rotation rod, a first tape reel, a belt, a turbine, a second belt disc, a panel, a first fixing block, a second fixing block and a screw, the height of the environmental carbon gold horizontal battery assembling line can be regulated to facilitate production operation by production workers and avoid generation of physical complaints of the production workers because the production workers stoop or stand for a long time so as to greatly improve the production efficiency, facilitate improvement of the product quality and bring huge economic benefitsfor enterprises or the individual.

Owner:GUANGZHOU ZHUOYUE POWER NEW ENERGY CO LTD

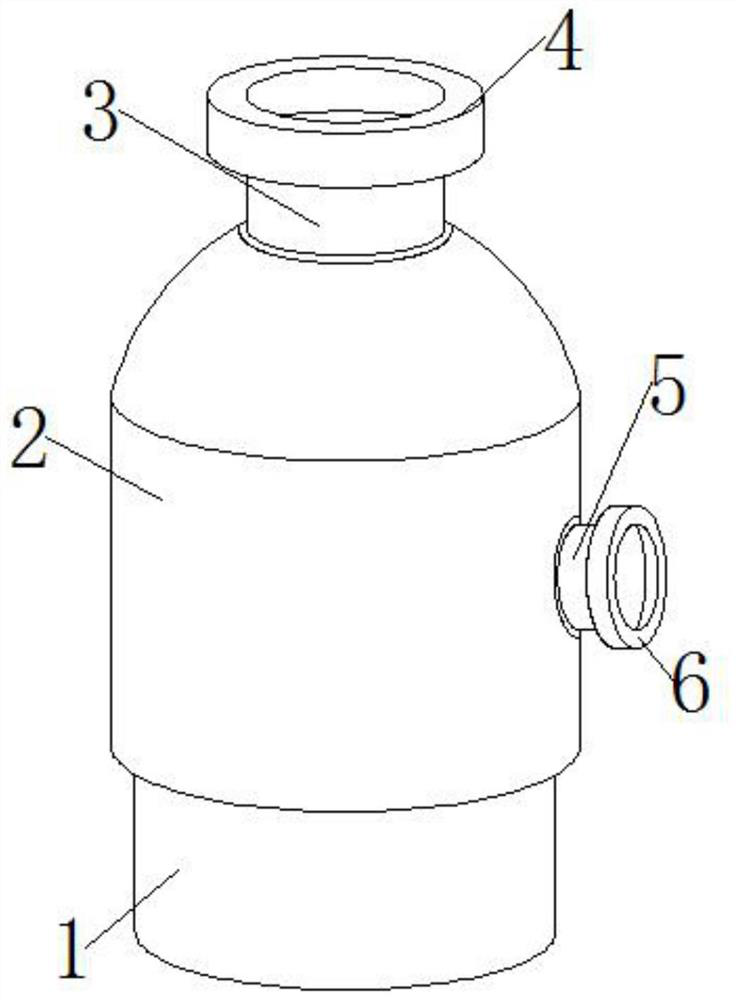

Self-adaptive control method and device for food waste disposer

InactiveCN112323924AAvoid motor damageProtect the motor from moistureDomestic plumbingElectric machineryRefuse Disposals

The invention discloses a self-adaptive control method and device for a food waste disposer, and relates to the field of food waste disposers. The self-adaptive control device comprises a machine body, the upper portion of the outer surface of the machine body is sleeved with a sound insulation cover, a water tank connector penetrates through the top of the machine body, a first flange plate is installed at the top end of the water tank connector, a sewer pipe connector penetrates through one side of the machine body, and a second flange plate is mounted at one end of the sewer pipe connector.Through the arrangement of a drying agent storage box and a heater, in the use process of the food waste disposer, a drying agent in the drying agent storage box in a fixed frame can continuously emit smell through a filter screen to dry the interior of the food waste disposer, a PLC board can control the heater to be turned on after the food waste disposer is dried, the food waste disposer is dried, so that a motor in the food waste disposer is prevented from being affected with damp, the device is safer and more durable, and damp damage to the food waste disposer is avoided.

Owner:江西奥菱普智能厨房科技有限公司

Paper towel packaging machine for hygienic materials

ActiveCN106516232BReduce investmentReduce in quantityPaper article packagingFolding thin materialsProduction scheduleProduction line

The invention provides a tissue packaging machine for hygienic materials. By adoption of the tissue packaging machine for the hygienic materials, the problems that existing equipment cannot well integrate the tissue production process, negative influences are caused due to the fact that production is conducted through multiple procedures, tissues are scrapped due to secondary pollution, the cost is increased, the equipment is not provided with an overload protection device and consequentially is damaged, the service life of the equipment is shortened, and smooth proceeding of machining is affected are effectively solved. The tissue packaging machine for the hygienic materials comprises a tissue conveying mechanism, a folding mechanism and a packaging mechanism. Compared with the prior art, a folding production line and a packaging production line are combined, personnel investment and the number of procedures are reduced, the production process is simplified, and the tissue production schedule is accelerated; by adoption of a full-automatic production line, the probability of secondary pollution of the tissues in the transferring process can be lowered; and by additionally arranging the overload protection device on the packaging line, the situation that a motor and the equipment are damaged due to excessive stress in the operating process is avoided, the service life of the equipment is prolonged, the production speed is increased, the probability of time delay caused by halts is lowered, and the working efficiency is improved.

Owner:邯郸市洁雅卫生用品有限公司

A control system, household appliance and control method for automatically adjusting motor speed

ActiveCN108825544BImprove experienceStable air volumeEfficient regulation technologiesPump controlMotor speedAir volume

The invention discloses a control system for automatically adjusting the motor rotating speed, a household appliance and a control method, and relates to the technical field of household appliances. The technical problem that the air outlet quantity of a household appliance in the prior art is instable is solved. The control system for automatically adjusting the motor rotating speed comprises a detecting device and a control device, the detecting device is connected with the control device, and the detecting device is used for detecting the size of an air inlet or the size of an air outlet inthe process that a motor drives the electric appliance to work; and the control device is electrically connected with the motor and can adjust the rotating speed of the motor according to a detectingresult of the detecting device so that the air outlet quantity can keep stable in the working process of the electric appliance. The control system can adjust the rotating speed of the motor based onthe size of the air inlet or air outlet, and therefore the air outlet quantity of the household appliance in the working process keeps stable.

Owner:GREE ELECTRIC APPLIANCES INC

Ice making module and ice maker

PendingCN114234509AGuaranteed continuous ice productionReduce in quantityLighting and heating apparatusIce productionElectric machineryEngineering

The embodiment of the invention provides an ice-making module and an ice maker, the ice-making module comprises an ice-making bucket, an ice scraping rod and an ice squeezer, the ice scraping rod is arranged in the ice-making bucket, the upper end of the ice scraping rod is connected with the ice squeezer through a shaft sleeve, the ice squeezer covers the upper end of the ice-making bucket, a gas channel is arranged on the ice squeezer, and the gas channel is communicated with the ice-making bucket. The air channel penetrates through the shaft sleeve and / or the ice scraping rod and is communicated with the ice making cavity of the ice making bucket, so that the air pressure in the ice making cavity of the ice making bucket is balanced with the external atmospheric pressure. By arranging the gas channel communicated with the ice-making cavity, the ice-making cavity can be communicated with the outside, the pressure in the ice-making cavity is kept consistent with the external atmospheric pressure, gas in the ice-making cavity is exhausted, pressure fluctuation of the ice-making cavity is eliminated, dynamic balance of the ice-making process is achieved, and the ice-making machine can continuously make ice for a long time; and the problem that the extruded ice in the ice making module is stuck to generate great abnormal noise and even damage the motor and the ice making module is solved.

Owner:CHUZHOU DONGLING ELECTRICAL APPLIANCE CO LTD

Diaphragm pump diaphragm with combined sealing structure and diaphragm pump

ActiveCN102094794BExtended service lifeHigh liftFlexible member pumpsPositive-displacement liquid enginesDiaphragm pumpWhole body

The invention discloses a diaphragm pump diaphragm with a combined sealing structure and a diaphragm pump. The diaphragm comprises an outer edge sealing ring and an inner diaphragm body, wherein the diaphragm body is provided with a vibrating clamping part and a valve seat installation hole; the vibrating clamping part is provided with a vibrator sealing ring; the vibrator sealing ring is arranged below the diaphragm; the outer edge sealing ring is arranged above the diaphragm; an outer edge additional sealing ring of which the appearance is matched with that of the diaphragm is arranged outside the outer edge sealing ring; the outer edge additional sealing ring is connected with the outer edge sealing ring to form a whole body; an additional sealing ring is arranged inside the vibrator sealing ring; the shape of the sealing ring is similar to that of the vibrator sealing ring; a protruding valve seat sealing sleeve is arranged on the lower side of the valve seat installation hole; and the pump cover and the pump body of the diaphragm pump are provided with installation structures which are matched with the outer edge additional sealing ring, the vibrator additional sealing ring and the valve seat sealing sleeve. Through the improvement, the problem of the sealing of the diaphragm of the diaphragm pump is radically solved, the lift of the diaphragm pump is improved, the service life of the diaphragm pump is prolonged and unnecessary maintenance and waste is reduced.

Owner:郑州绿帝农用机械有限公司

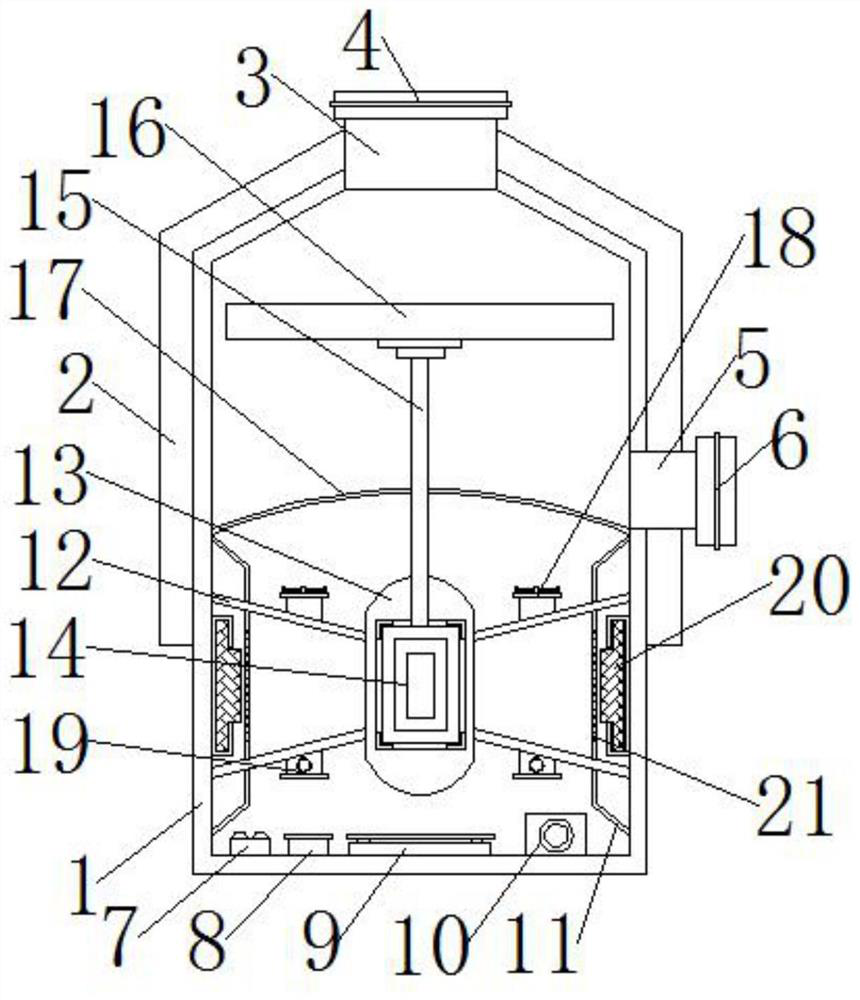

Raw material stirring device for chemical production

InactiveCN112675733AImprove sealing performanceAvoid motor damageRotary stirring mixersMixer accessoriesElectric machineryDrive motor

The invention discloses a raw material stirring device for chemical production. The raw material stirring device comprises a shell and a shell cover, wherein a stirring cavity and a closed cavity are formed in the shell; the stirring cavity and the closed cavity are separated through a partition plate; a stirring device is arranged in the stirring cavity; the stirring device comprises a driving motor, a rotating shaft and a stirring rod; a feeding port, a feeding pipe and a cleaning device are arranged at the top of the shell cover; the cleaning device comprises a hydraulic pump, a telescopic rod, a cleaning brush and a water tank; the cleaning brush comprises a fixed plate and bristles fixed to the fixed plate; limiting grooves are formed in the inner walls of the two sides of the stirring cavity; limiting rods are fixedly installed in the limiting grooves; a discharging port is formed in one side of the shell; and a control device is arranged on one side of the shell. According to the invention, the used shell is rapidly and efficiently cleaned through the cleaning device, and raw materials in the shell are stirred and mixed through the stirring device, so stirring efficiency is improved, and great convenience is brought to a user.

Owner:HEBEI CHEM & PHARMA COLLEGE

Low speed safety protection drilling jig

ActiveCN103612132BIncrease or decrease friction torqueAvoid motor damagePositioning apparatusMetal-working holdersLow speedEngineering

The invention discloses a low-rpm drilling fixture with a safety protection function. The low-rpm drilling fixture with the safety protection function comprises an outer tooth shaft sleeve and an inner tooth shaft sleeve. The outer circumferential surface of the front end of the inner tooth shaft sleeve is connected with an adjusting nut. The front end of the outer tooth shaft sleeve is provided with a chuck. Outer teeth are arranged on the outer circumference of the rear end of the outer tooth shaft sleeve. The outer tooth shaft sleeve is sleeved with inner tooth friction plates. Inner teeth are arranged in the inner tooth shaft sleeve and are sleeved with outer tooth friction plates. The outer tooth friction plates and the inner tooth friction plates are located between a limiting end face of the outer tooth shaft sleeve and a limiting end face of the inner tooth shaft sleeve. When the outer tooth shaft sleeve and the inner tooth shaft sleeve squeeze each other, the outer tooth friction plates and the inner tooth friction plates are axially pressed tightly on the two limiting end faces. Through the structure, the inner tooth shaft sleeve is driven to press tightly or loosen the friction plates through the adjusting nut so that the friction moment between the outer tooth shaft sleeve and the inner tooth shaft sleeve can be increased or decreased, and the low-rpm drilling fixture can play roles in transmitting moment and carrying out overload safety protection. Consequently, current surges are completely avoided, and the phenomenon that a motor or a drill bit is damaged is prevented completely.

Owner:江苏索达重工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com